turn CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 261 of 659

BRAKES 5-28

Fig.

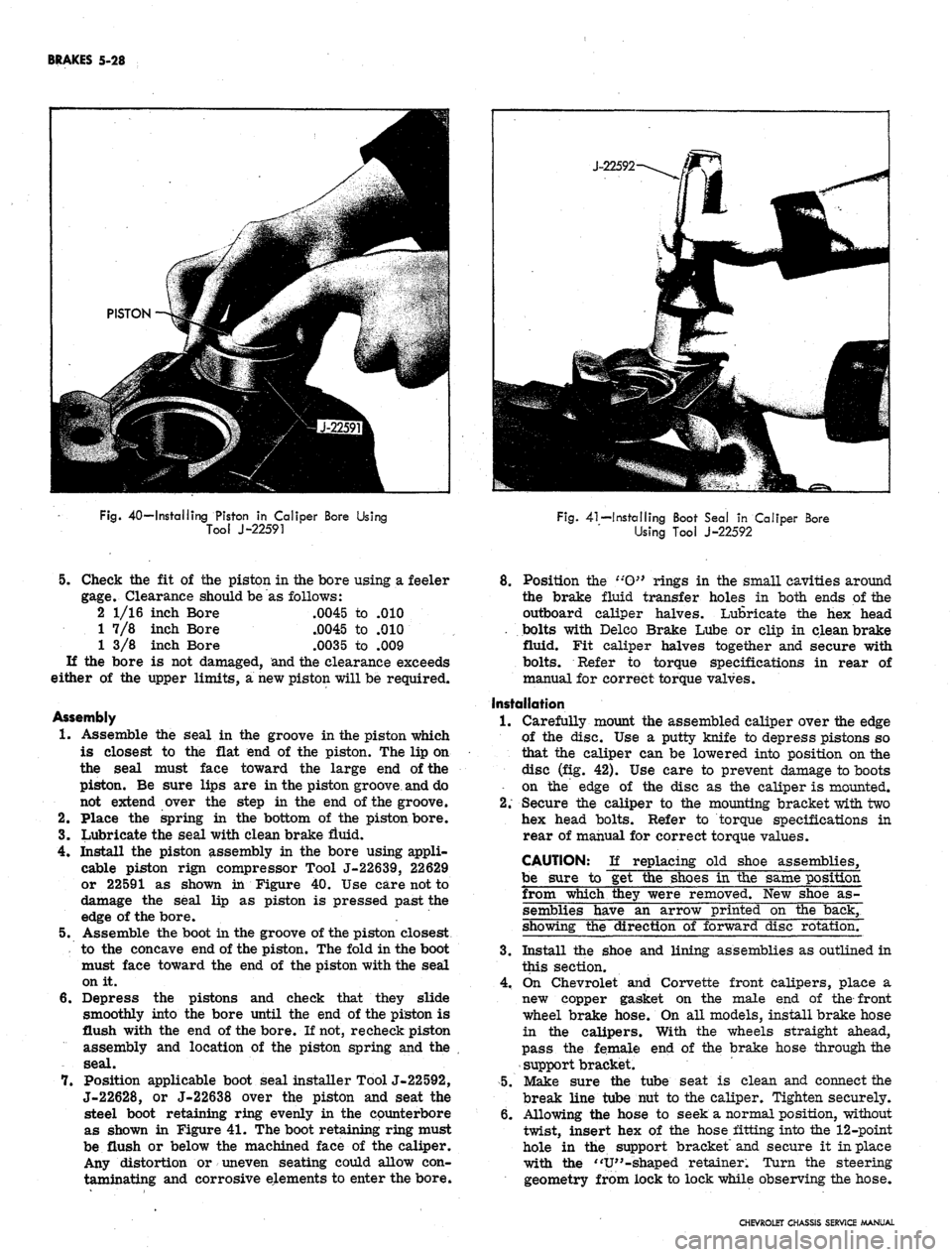

40—Installing Piston in Caliper Bore Using

Tool J-22591

Fig.

41—Installing Boot Seal in Caliper Bore

Using Tool J-22592

5.

Check the fit of the piston in the bore using a feeler

gage.

Clearance should be as follows:

2 1/16 inch Bore .0045 to .010

1 7/8 inch Bore .0045 to .010

1 3/8 inch Bore .0035 to .009

If the bore is not damaged, and the clearance exceeds

either of the upper limits, a new piston will be required.

Assembly

1.

Assemble the seal in the groove in the piston which

is closest to the flat end of the piston. The lip on

the seal must face toward the large end of the

piston. Be sure lips are in the piston groove and do

not extend over the step in the end of the groove.

2.

Place the spring in the bottom of the piston bore.

3.

Lubricate the seal with dean brake fluid.

4.

Install the piston assembly in the bore using appli-

cable piston rign compressor Tool J-22639, 22629

or 22591 as shown in Figure 40. Use care not to

damage the seal lip as piston is pressed past the

edge of the bore. .

5.

Assemble the boot in the groove of the piston closest

to the concave end of the piston. The fold in the boot

must face toward the end of the piston with the seal

on it.

6. Depress the pistons and check that they slide

smoothly into the bore until the end of the piston is

flush with the end of the bore. If not, re check piston

assembly and location of the piston spring and the

seal.

7.

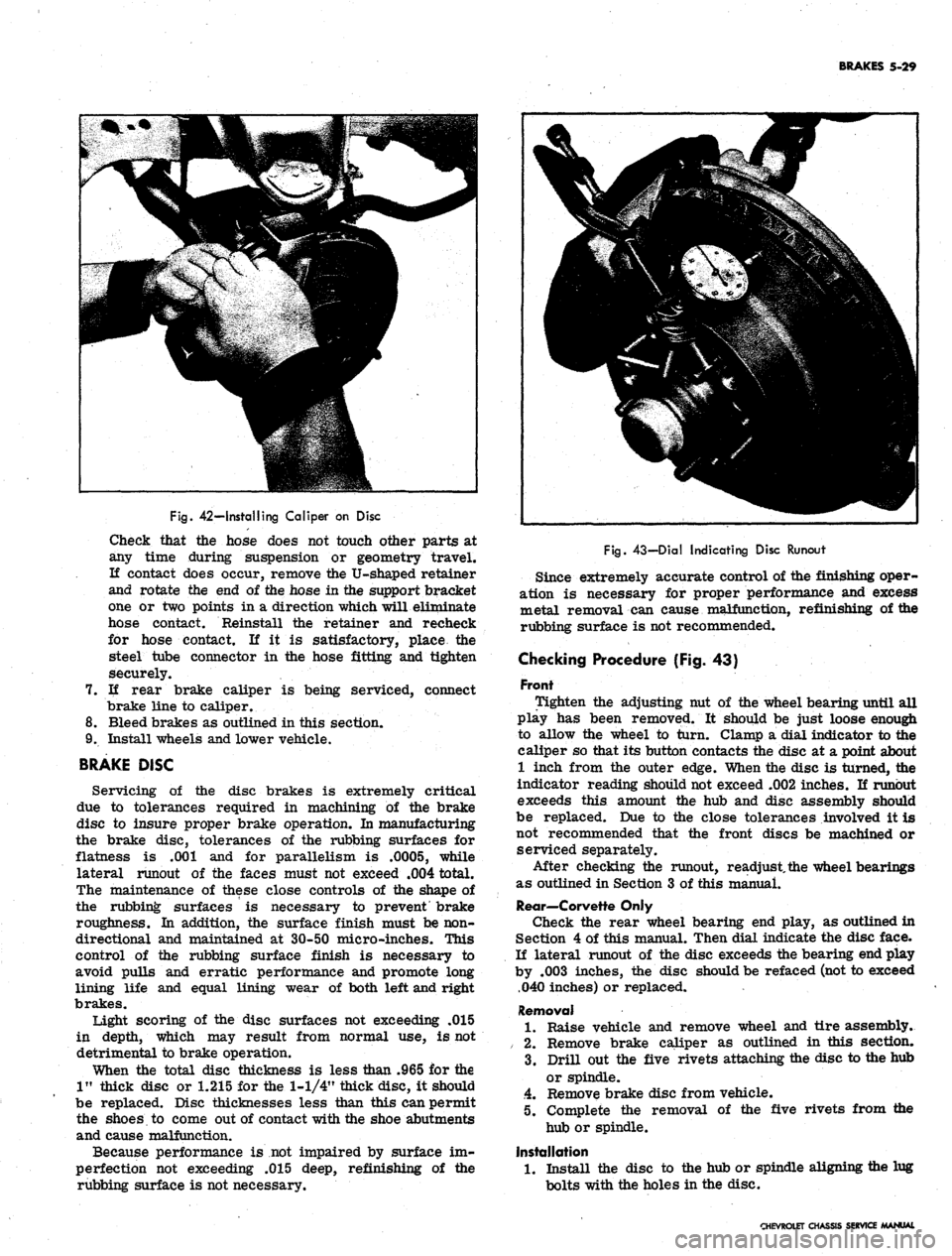

Position applicable boot seal installer Tool J-22592,

J-22628, or J-22638 over the piston and seat the

steel boot retaining ring evenly in the counterbore

as shown in Figure 41. The boot retaining ring must

be flush or below the machined face of the caliper.

Any distortion or uneven seating could allow con-

taminating and corrosive elements to enter the bore.

8. Position the t:O}> rings in the small cavities around

the brake fluid transfer holes in both ends of the

outboard caliper halves. Lubricate the hex head

. bolts with Delco Brake Lube or clip in clean brake

fluid. Fit caliper halves together and secure with

bolts.

Refer to torque specifications in rear of

manual for correct torque valves.

Installation

1.

Carefully mount the assembled caliper over the edge

of the disc. Use a putty knife to depress pistons so

that the caliper can be lowered into position on the

disc (fig. 42). Use care to prevent damage to boots

• on the edge of the disc as the caliper is mounted.

2.

Secure the caliper to the mounting bracket with two

hex head bolts. Refer to torque specifications in

rear of manual for correct torque values.

CAUTION: If replacing old shoe assemblies,

be sure to get the shoes in the same position

from which they were removed. New shoe as-

semblies have an arrow printed on the back,

showing the direction of forward disc rotation.

3.

Install the shoe and lining assemblies as outlined in

this section.

4.

On Chevrolet and Corvette front calipers, place a

new copper gasket on the male end of the front

wheel brake hose. On all models, install brake hose

in the calipers. With the wheels straight ahead,

pass the female end of the brake hose through the

support bracket.

5.

Make sure the tube seat is clean and connect the

break line tube nut to the caliper. Tighten securely.

6. Allowing the hose to seek a normal position, without

twist, insert hex of the hose fitting into the 12-point

hole in the support bracket and secure it in place

with the "V"-shaped retainer. Turn the steering

geometry from lock to lock while observing the hose.

CHEVROLET CHASSIS SERVICE MANUAL

Page 262 of 659

BRAKES 5-29

Fig.

42—Installing Caliper on Disc

Check that the hose does not touch other parts at

any time during suspension or geometry travel.

If contact does occur, remove the U-shaped retainer

and rotate the end of the hose in the support bracket

one or two points in a direction which will eliminate

hose contact. Reinstall the retainer and recheck

for hose contact. If it is satisfactory, place the

steel tube connector in the hose fitting and tighten

securely.

If rear brake caliper is being serviced, connect

brake line to caliper.

Bleed brakes as outlined in this section.

Install wheels and lower vehicle.

BRAKE DISC

Servicing of the disc brakes is extremely critical

due to tolerances required in machining of the brake

disc to insure proper brake operation. In manufacturing

the brake disc, tolerances of the rubbing surfaces for

flatness is .001 and for parallelism is .0005, while

lateral runout of the faces must not exceed .004 total.

The maintenance of these close controls of the shape of

the rubbing surfaces is necessary to prevent brake

roughness. In addition, the surface finish must be non-

directional and maintained at 30-50 micro-inches. This

control of the rubbing surface finish is necessary to

avoid pulls and erratic performance and promote long

lining life and equal lining wear of both left and right

brakes.

tight scoring of the disc surfaces not exceeding .015

in depth, which may result from normal use, is not

detrimental to brake operation.

When the total disc thickness is less than .965 for the

1"

thick disc or 1.215 for the 1-1/4" thick disc, it should

be replaced. Disc thicknesses less than this can permit

the shoes to come out of contact with the shoe abutments

and cause malfunction.

Because performance is not impaired by surface im-

perfection not exceeding .015 deep, refinishing of the

rubbing surface is not necessary.

Fig.

43—Dial Indicating Disc Runout

Since extremely accurate control of the finishing oper-

ation is necessary for proper performance and excess

metal removal can cause malfunction, refinishing of the

rubbing surface is not recommended.

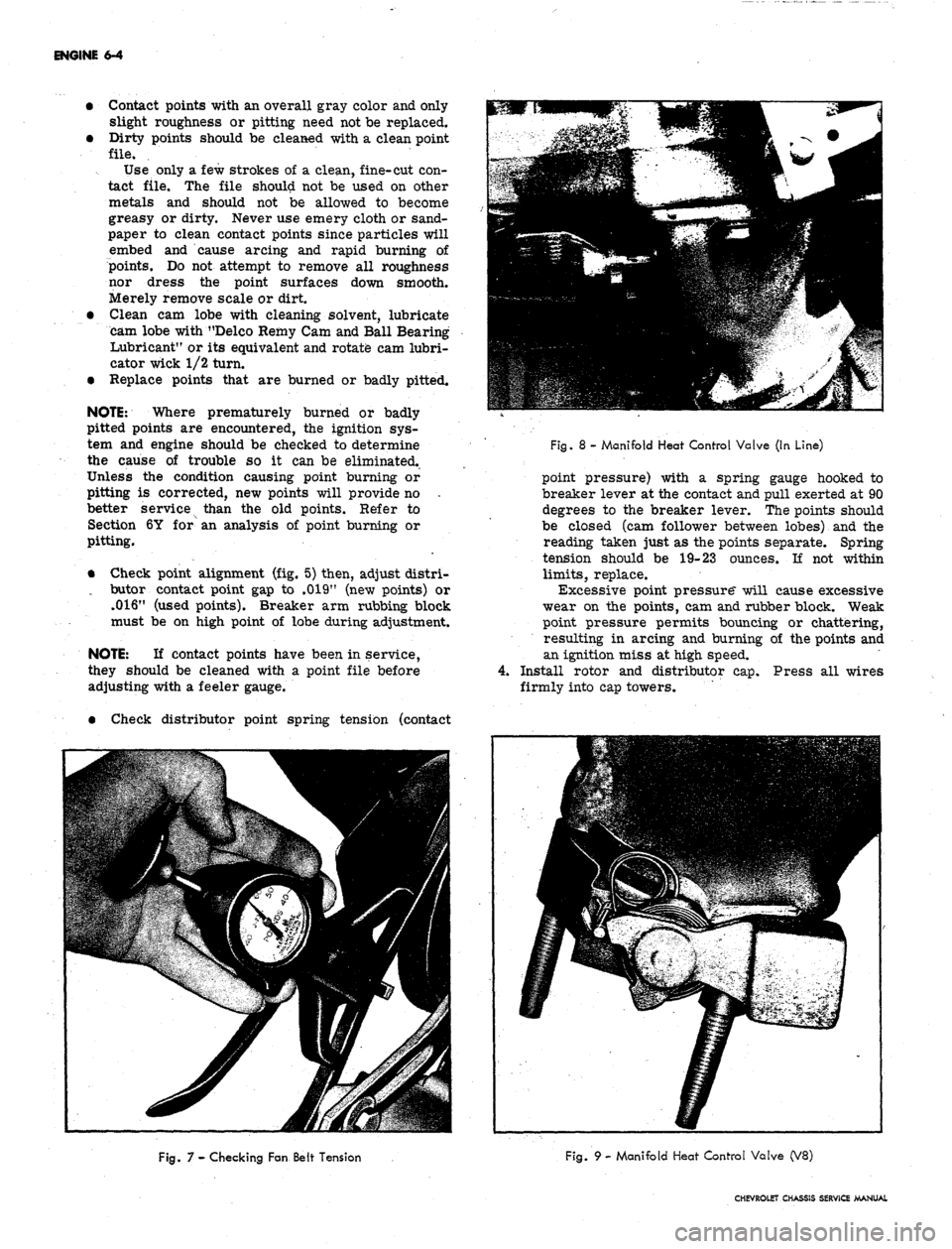

Checking Procedure (Fig. 43)

Front

Tighten the adjusting nut of the wheel bearing until all

play has been removed. It should be just loose enough

to allow the wheel to turn. Clamp a dial indicator to the

caliper so that its button contacts the disc at a point about

1 inch from the outer edge. When the disc is turned, the

indicator reading should not exceed .002 inches. If runout

exceeds this amount the hub and disc assembly should

be replaced. Due to the close tolerances involved it is

not recommended that the front discs be machined or

serviced separately.

After checking the runout, readjust, the wheel bearings

as outlined in Section 3 of this manual.

Rear—Corvette Only

Check the rear wheel bearing end play, as outlined in

Section 4 of this manual. Then dial indicate the disc face.

If lateral runout of the disc exceeds the bearing end play

by .003 inches, the disc should be refaced (not to exceed

.040 inches) or replaced.

Removal

1.

Raise vehicle and remove wheel and tire assembly.

/ 2. Remove brake caliper as outlined in this section.

3.

Drill out the five rivets attaching the disc to the hub

or spindle.

4.

Remove brake disc from vehicle.

5. Complete the removal of the five rivets from the

hub or spindle.

Installation

1.

Install the disc to the hub or spindle aligning the lug

bolts with the holes in the disc.

CHEVROLET CHASSIS SERVICE MANUAL

Page 268 of 659

ENGINE

6-3

(ROUND) Y~~fll^H

CENTRIFUGAL

A ^k

ADVANCE--jflgKpl

MECHANISM

UB|

CAM

KSK^2

LUBRICATOR

VlSMi

REPLACEMENT

^BK

-^ADJUST

SQUARELY

AND

JUST

TOUCHING

LOBE

OF

CAM

/ROTOR

HBB

__

I^BH^F

?

(SOUARE)

^K^ I /—

CAM

jKft^J / LUBRICATOR

H^T^

CAUTION!

QV NEVER

OIL

•L-^

CAM LUBRICATOR-

REPLACE

WICK

WHEN

NECESSARY

LATERAL

MISALIGNMENT

PROPER

LATERAL ALIGNMENT

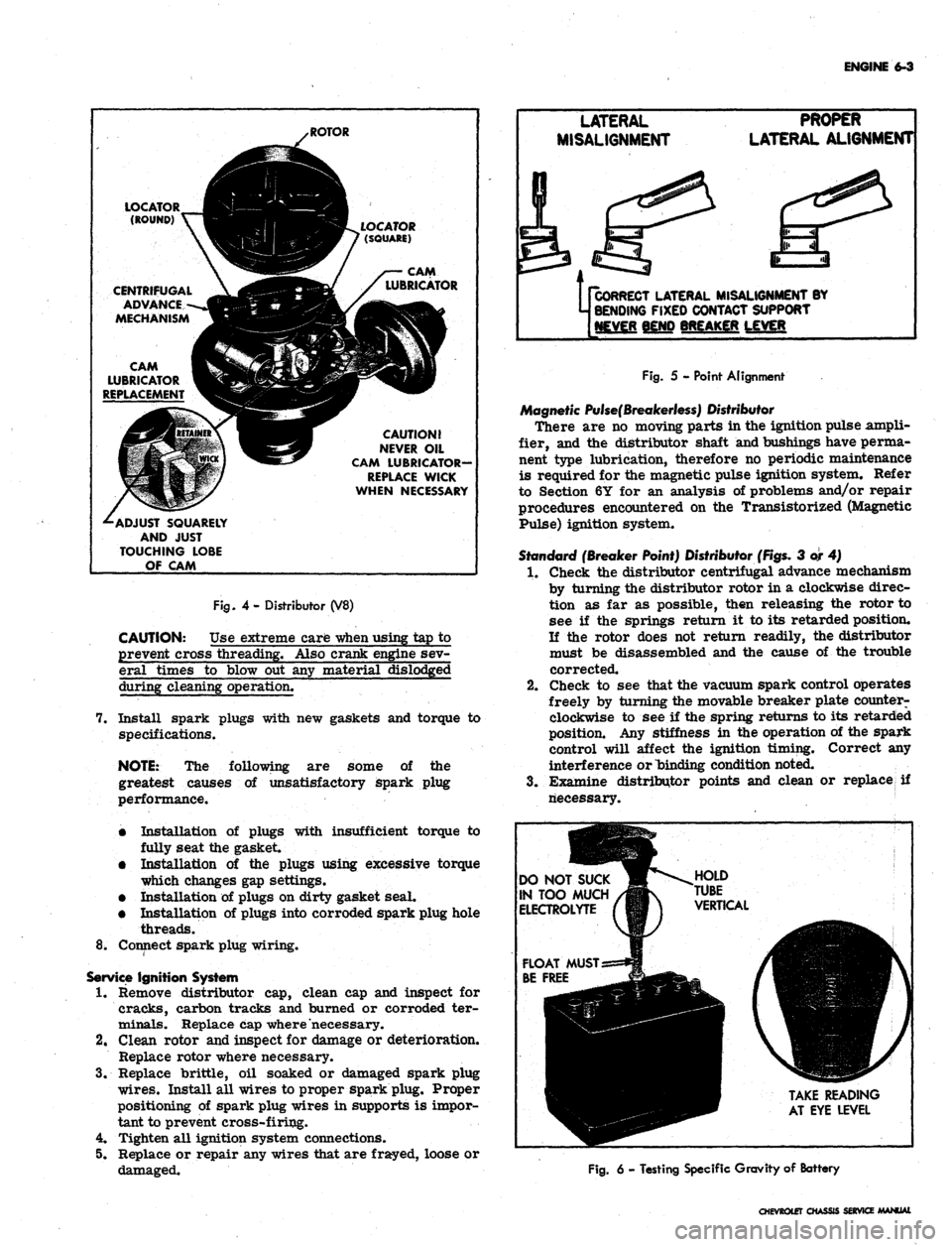

Fig.

4- Distributor (V8)

CAUTION: Use extreme care

-when

using tap to

prevent cross threading. Also crank engine sev-

eral times to blow out any material dislodged

during cleaning operation.

7. Install spark plugs with new gaskets and torque to

specifications.

NOTE:

The following are some of the

greatest causes of unsatisfactory spark plug

performance.

•

Installation of plugs with insufficient torque to

fully seat the gasket.

•

Installation of the plugs using excessive torque

which changes gap settings.

•

Installation of plugs on dirty gasket seal.

•

Installation of plugs into corroded spark plug hole

threads.

8^ Connect spark plug wiring.

Service

Ignition System

1.

Remove distributor cap, clean cap and inspect for

cracks, carbon tracks and burned or corroded ter-

minals. Replace cap where necessary.

2.

Clean rotor and inspect for damage or deterioration.

Replace rotor where necessary.

3.

Replace brittle, oil soaked or damaged spark plug

wires.

Install all wires to proper spark plug. Proper

positioning of spark plug wires in supports is impor-

tant to prevent cross-firing.

4.

Tighten all ignition system connections.

5. Replace or repair any wires that are frayed, loose or

damaged.

Us

CORRECT

LATERAL MISALIGNMENT BY

j BENDING

FIXED CONTACT SUPPORT

[NEVER

BEND BREAKER LEVER

Fig.

5 - Point Alignment

Magnetic

Pulse(Breakerless)

Distributor

There are no moving parts in the ignition pulse ampli-

fier, and the distributor shaft and bushings have perma-

nent type lubrication, therefore no periodic maintenance

is required for the magnetic pulse ignition system. Refer

to Section 6Y for an analysis of problems and/or repair

procedures encountered on the Transistorized (Magnetic

Pulse) ignition system.

Standard

(Breaker Point) Distributor

(Figs.

3 or 4)

1.

Check the distributor centrifugal advance mechanism

by turning the distributor rotor in a clockwise direc-

tion as far as possible, then releasing the rotor to

see if the springs return it to its retarded position.

If the rotor does not return readily, the distributor

must be disassembled and the cause of the trouble

corrected.

2.

Check to see that the vacuum spark control operates

freely by turning the movable breaker plate counter-

clockwise to see if the spring returns to its retarded

position. Any stiffness in the operation of the spark

control will affect the ignition timing. Correct any

interference or binding condition noted.

3.

Examine distributor points and clean or replace if

riecessary.

DO

NOT SUCK

IN

TOO MUCH

ELECTROLYTE

TAKE

READING

AT

EYE LEVEL

Fig.

6 - Testing Specific Gravity of Battery

CHEVROtET

CHASSIS SERVICE MANUAL

Page 269 of 659

ENGINE 6-4

• Contact points with an overall gray color and only

slight roughness or pitting need not be replaced.

• Dirty points should be cleaned with a clean point

file.

Use only a few strokes of a clean, fine-cut con-

tact file. The file should not be used on other

metals and should not be allowed to become

greasy or dirty. Never use emery cloth or sand-

paper to clean contact points since particles will

embed and cause arcing and rapid burning of

points. Do not attempt to remove all roughness

nor dress the point surfaces down smooth.

Merely remove scale or dirt.

• Clean cam lobe with cleaning solvent, lubricate

cam lobe with "Delco Remy Cam and Ball Bearing

Lubricant" or its equivalent and rotate cam lubri-

cator wick 1/2 turn.

• Replace points that are burned or badly pitted.

NOTE: Where prematurely burned or badly

pitted points are encountered, the ignition sys-

tem and engine should be checked to determine

the cause of trouble so it can be eliminated.

Unless the condition causing point burning or

pitting is corrected, new points will provide no .

better service than the old points. Refer to

Section 6Y for an analysis of point burning or

pitting.

• Check point alignment (fig. 5) then, adjust distri-

. butor contact point gap to .019" (new points) or

.016"

(used points). Breaker arm rubbing block

must be on high point of lobe during adjustment.

NOTE: If contact points have been in service,

they should be cleaned with a point file before

adjusting with a feeler gauge.

• Check distributor point spring tension (contact

Fig. 8 - Manifold Heat Control Valve (In Line)

point pressure) with a spring gauge hooked to

breaker lever at the contact and pull exerted at 90

degrees to the breaker lever. The points should

be closed (cam follower between lobes) and the

reading taken just as the points separate. Spring

tension should be 19-23 ounces. If not within

limits,

replace.

Excessive point pressure" will cause excessive

wear on the points, cam and rubber block. Weak

point pressure permits bouncing or chattering,

resulting in arcing and burning of the points and

an ignition miss at high speed.

4.

Install rotor and distributor cap. Press all wires

firmly into cap towers.

Fig. 7 - Checking Fan Belt Tension

Fig. 9 - Manifold Heat Control Valve (V8)

CHEVROLET CHASSIS SERVICE MANUAL

Page 272 of 659

ENGINE 6-7

Tune Up should be checked whenever the Air Injection

Reactor System seems to be malfunctioning. Particular

care should be taken in checking items that affect fuel-air

ratio such as the crankcase ventilation system, the car-

buretor and the carburetor air cleaner. Carburetors and

distributors for engines with the Air Injection Reactor

System are designed, particularly, for these engines;

therefore, they must not be interchanged with or replaced

by a carburetor or distributor designed for an engine

without the Air Injection Reactor System.

Choke Adjustment (Fig. 11)

With Remote Choke

1.

Remove air cleaner and check to see that choke

valve and rod move freely.

2.

Disconnect choke r*od at choke lever.

Check choke adjustment as follows:

On all except 275 hp 327 cu. in. engines, hold

choke valve closed and pull rod up against stop. The

top of choke rod end should be 1/2 - 1 rod diameter

4.

5.

above top of hole in choke valve lever.

On 275 hp 327 cu. in. engines, hold choke valve

closed and push rod down against stop on thermostat

bracket. The top of the choke rod should be 1/2 - 1

rod diameter below the top of the hole in the choke

lever.

If necessary, adjust rod length by bending rod at off-

set. (Bend must be such that rod enters choke lever

hole freely and squarely.)

Connect rod at choke lever and install air cleaner.

3.

With Manual

Choke

1.

Remove air cleaner.

2.

Push hand choke knob in to within 1/8" of instrument

panel.

3.

Loosen choke cable at carburetor bracket and adjust

cable through the clip until the choke valve is wide

open.

4.

Tighten cable clamp at carburetor bracket and check

operation of choke valve to ensure full closed and

wide open positions.

INSTRUMENT CHECK-OUT

Instrument Hook Up

Connect vacuum gauge, dwell meter, tachometer and

timing light as recommended by the manufacturer of the

equipment being used.

Check and Adjust Dwell

1.

Start engine then ch^ck ignition dwell.

.2.

If dwell is not within specifications, adjust dwell as

follows:

V8 ENGINES

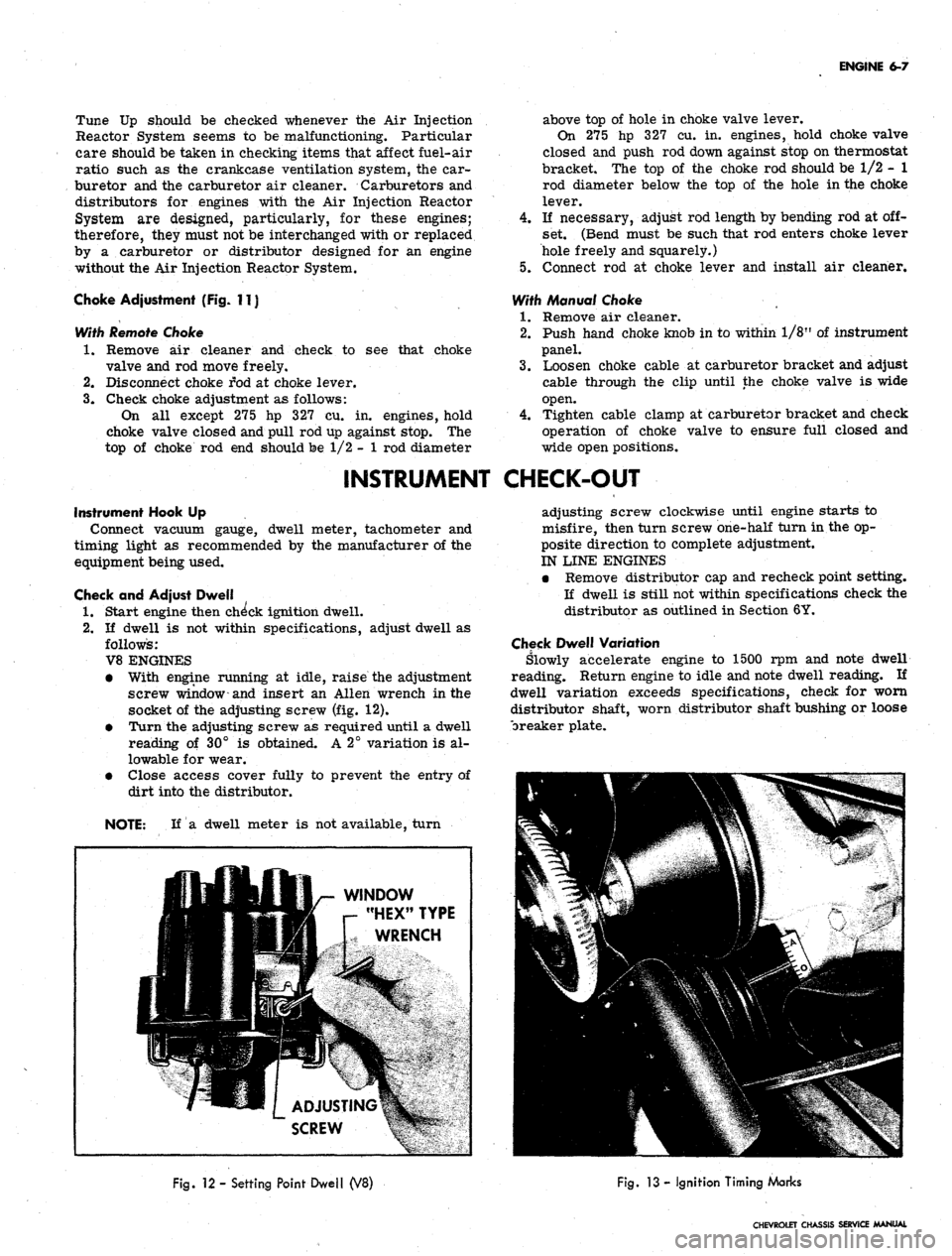

• With engine running at idle, raise the adjustment

screw window-and insert an Allen wrench in the

socket of the adjusting screw (fig. 12).

• Turn the adjusting screw as required until a dwell

reading of 30° is obtained. A 2° variation is al-

lowable for wear.

• Close access cover fully to prevent the entry of

dirt into the distributor.

NOTE: If a dwell meter is not available, turn

adjusting screw clockwise until engine starts to

misfire, then turn screw one-half turn in the op-

posite direction to complete adjustment.

IN LINE ENGINES

• Remove distributor cap and recheck point setting.

If dwell is still not within specifications check the

distributor as outlined in Section 6Y.

Check Dwell Variation

Slowly accelerate engine to 1500 rpm and note dwell

reading. Return engine to idle and note dwell reading. If

dwell variation exceeds specifications, check for worn

distributor shaft, worn distributor shaft bushing or loose

breaker plate.

WINDOW

"HEX" TYPE

WRENCH

Fig.

12 - Setting Point Dwell (V8)

Fig.

13 - Ignition Timing Marks

CHEVROLET CHASSIS SERVICE MANUAL

Page 273 of 659

ENGINE

6-8

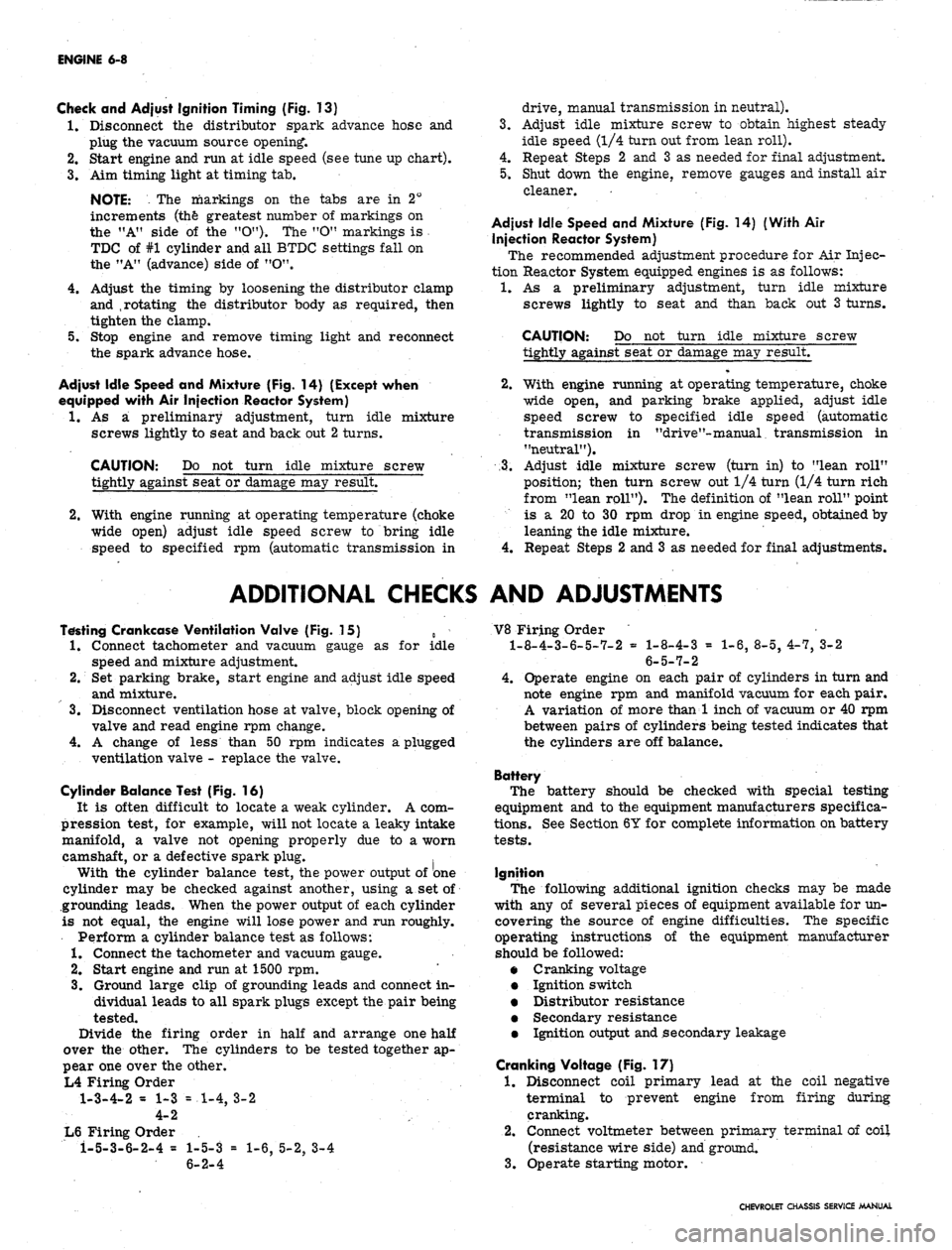

Check

and

Adjust Ignition Timing

(Fig. 13)

1.

Disconnect

the

distributor spark advance hose

and

plug

the

vacuum source opening.

2.

Start engine

and run at

idle speed

(see

tune

up

chart).

3.

Aim

timing light

at

timing

tab.

NOTE:

- The

markings

on the

tabs

are in 2°

increments

(the

greatest number

of

markings

on

the

"A"

side

of the "O"). the "O"

markings

is

TDC

of

#1 cylinder

and all

BTDC settings fall

on

the

"A"

(advance) side

of "O".

4.

Adjust

the

timing

by

loosening

the

distributor clamp

and

,

rotating

the

distributor body

as

required, then

tighten

the

clamp.

5.

Stop engine

and

remove timing light

and

reconnect

the spark advance hose.

Adjust Idle Speed

and

Mixture

(Fig. 14)

(Except when

equipped with

Air

Injection Reactor System)

1.

As a

preliminary adjustment, turn idle mixture

screws lightly

to

seat

and

back

out 2

turns.

CAUTION:

Do not

turn idle mixture screw

tightly against seat

or

damage

may

result.

2.

With engine running

at

operating temperature (choke

wide open) adjust idle speed screw

to

bring idle

speed

to

specified

rpm

(automatic transmission

in

drive, manual transmission

in

neutral).

3.

Adjust idle mixture screw

to

obtain highest steady

idle speed

(1/4

turn

out

from lean roll).

4.

Repeat Steps

2 and 3 as

needed

for

final adjustment.

5.

Shut down

the

engine, remove gauges

and

install

air

cleaner.

Adjust Idle Speed

and

Mixture

(Fig. 14)

(With

Air

Injection Reactor System)

The recommended adjustment procedure

for Air

Injec-

tion Reactor System equipped engines

is as

follows:

1.

As a

preliminary adjustment, turn idle mixture

screws lightly

to

seat

and

than back

out 3

turns.

CAUTION:

Do not

turn idle mixture screw

tightly against seat

or

damage

may

result.

2.

With engine running

at

operating temperature, choke

wide open,

and

parking brake applied, adjust idle

specified idle speed (automatic

"drive"-manual transmission

in

to

in

screw

transmission

"neutral").

;3.

Adjust idle mixture screw (turn

in) to

"lean roll"

position; then turn screw

out 1/4

turn

(1/4

turn rich

from "lean roll").

The

definition

of

"lean roll" point

is

a 20 to 30 rpm

drop

in

engine speed, obtained

by

leaning

the

idle mixture.

4.

Repeat Steps

2 and 3 as

needed

for

final adjustments.

ADDITIONAL CHECKS

AND

ADJUSTMENTS

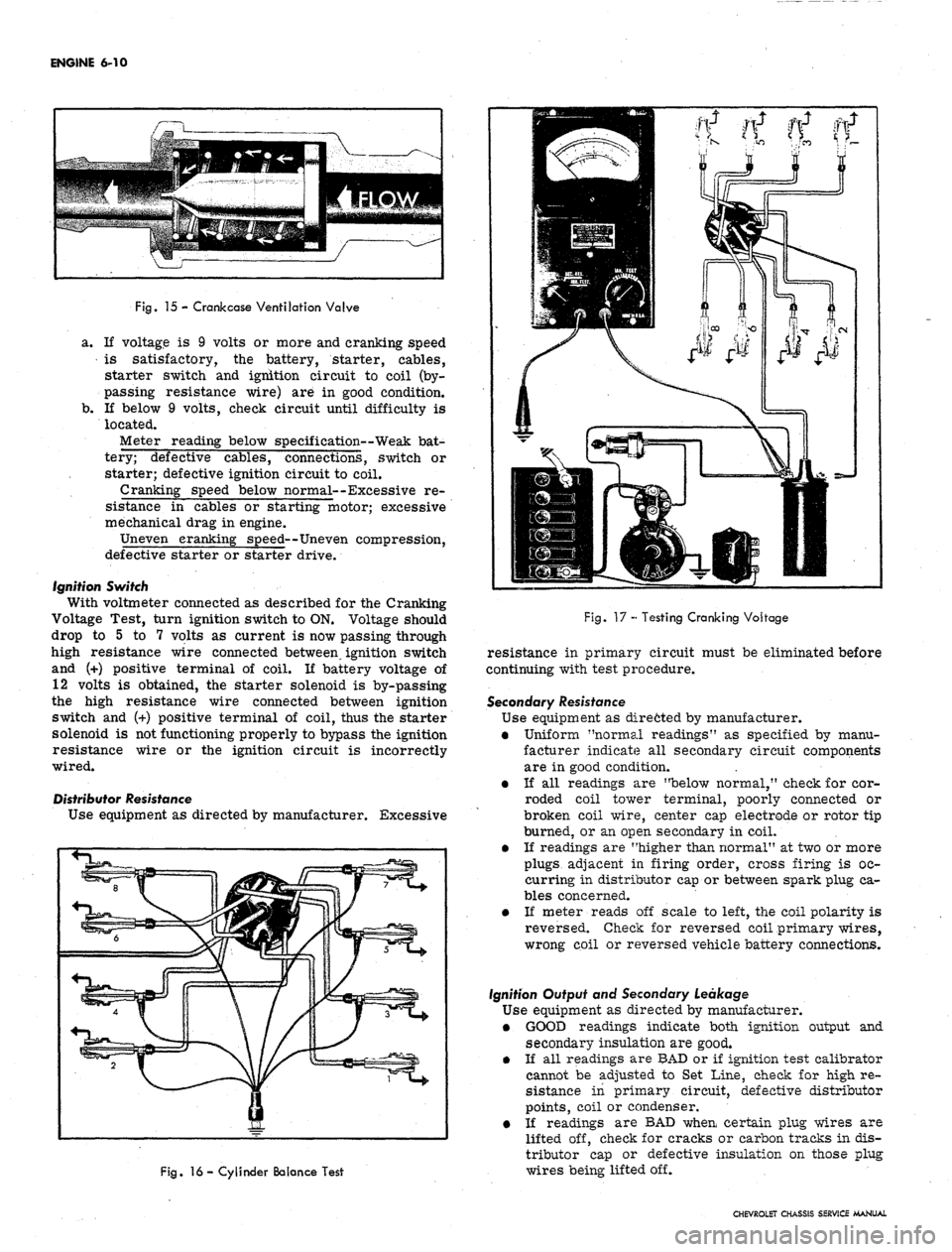

Testing Crankcase Ventilation Valve

(Fig. 15) 0

1.

Connect tachometer

and

vacuum gauge

as for

idle

speed

and

mixture adjustment.

2.

Set

parking brake, start engine

and

adjust idle speed

and mixture.

3.

Disconnect ventilation hose

at

valve, block opening

of

valve

and

read engine

rpm

change.

4.

A

change

of

less than

50 rpm

indicates

a

plugged

ventilation valve

-

replace

the

valve.

Cylinder Balance Test

(Fig. 16)

It

is

often difficult

to

locate

a

weak cylinder.

A com-

pression test,

for

example, will

not

locate

a

leaky intake

manifold,

a

valve

not

opening properly

due to a

worn

camshaft,

or a

defective spark plug.

With

the

cylinder balance test,

the

power output

of one

cylinder

may be

checked against another, using

a set of

grounding leads. When

the

power output

of

each cylinder

is

not

equal,

the

engine will lose power

and run

roughly.

Perform

a

cylinder balance test

as

follows:

1.

Connect

the

tachometer

and

vacuum gauge.

2.

Start engine

and run at 1500 rpm.

3.

Ground large clip

of

grounding leads

and

connect

in-

dividual leads

to all

spark plugs except

the

pair being

tested.

Divide

the

firing order

in

half

and

arrange

one

half

over

the

other.

The

cylinders

to be

tested together

ap-

pear

one

over

the

other.

L4 Firing Order

V8 Firing Order

1-8-4-3-6-5-7-2

1-6, 8-5, 4-7, 3-2

1-3-4-2

= 1-3

4-2

L6 Firing Order

1-5-3-6-2-4

=

=

1-4. 3-2

1-5-3

6-2-4

1-6, 5-2, 3-4

1-8-4-3

6-5-7-2

4.

Operate engine

on

each pair

of

cylinders

in

turn

and

note engine

rpm and

manifold vacuum

for

each pair.

A variation

of

more than

1

inch

of

vacuum

or 40 rpm

between pairs

of

cylinders being tested indicates that

the cylinders

are off

balance.

Battery

The battery should

be

checked with special testing

equipment

and to the

equipment manufacturers specifica-

tions.

See

Section 6Y

for

complete information

on

battery

tests.

Ignition

The following additional ignition checks

may be

made

with

any of

several pieces

of

equipment available

for un-

covering

the

source

of

engine difficulties.

The

specific

operating instructions

of the

equipment manufacturer

should

be

followed:

Cranking voltage

Ignition switch

Distributor resistance

Secondary resistance

Ignition output

and

secondary leakage

Cranking Voltage

(Fig. 17)

1.

Disconnect coil primary lead

at the

coil negative

terminal

to

prevent engine from firing during

cranking.

2.

Connect voltmeter between primary terminal

of coi|

(resistance wire side)

and

ground.

3.

Operate starting motor.

CHEVROLET CHASSIS SERVICE MANUAL

Page 275 of 659

ENGINE 6-10

Fig.

15 - Crank case Ventilation Valve

a. If voltage is 9 volts or more and cranking speed

is satisfactory, the battery, starter, cables,

starter switch and ignition circuit to coil (by-

passing resistance wire) are in good condition.

b.

If below 9 volts, check circuit until difficulty is

located.

Meter reading below specification—Weak bat-

tery; defective cables, connections, switch or

starter; defective ignition circuit to coil.

Cranking speed below normal--Excessive re-

sistance in cables or starting motor; excessive

mechanical drag in engine.

Uneven cranking speed—Uneven compression,

defective starter or starter drive.

Ignition Switch

With voltmeter connected as described for the Cranking

Voltage Test, turn ignition switch to ON. Voltage should

drop to 5 to 7 volts as current is now passing through

high resistance wire connected between ignition switch

and (+) positive terminal of coil. If battery voltage of

12 volts is obtained, the starter solenoid is by-passing

the high resistance wire connected between ignition

switch and (+) positive terminal of coil, thus the starter

solenoid is not functioning properly to bypass the ignition

resistance wire or the ignition circuit is incorrectly

wired.

Distributor Resistance

Use equipment as directed by manufacturer.

Excessive

(t n ti ft

Fig.

16 - Cylinder Balance Test

Fig.

17 - Testing Cranking Voltage

resistance in primary circuit must be eliminated before

continuing with test procedure.

Secondary Resistance

Use equipment as dire6ted by manufacturer.

• Uniform "normal readings" as specified by manu-

facturer indicate all secondary circuit components

are in good condition.

• If all readings are "below normal," check for cor-

roded coil tower terminal, poorly connected or

broken coil wire, center cap electrode or rotor tip

burned, or an open secondary in coil.

• If readings are "higher than normal" at two or more

plugs adjacent in firing order, cross firing is oc-

curring in distributor cap or between spark plug ca-

bles concerned.

• If meter reads off scale to left, the coil polarity is

reversed. Check for reversed coil primary wires,

wrong coil or reversed vehicle battery connections.

Ignition Output and Secondary Leakage

Use equipment as directed by manufacturer.

• GOOD readings indicate both ignition output and

secondary insulation are good.

• If all readings are BAD or if ignition test calibrator

cannot be adjusted to Set Line, check for high re-

sistance in primary circuit, defective distributor

points, coil or condenser.

e If readings are BAD when certain plug wires are

lifted off, check for cracks or carbon tracks in dis-

tributor cap or defective insulation on those plug

wires being lifted off.

CHEVROLET CHASSIS SERVICE MANUAL

Page 276 of 659

ENGINE 6-11

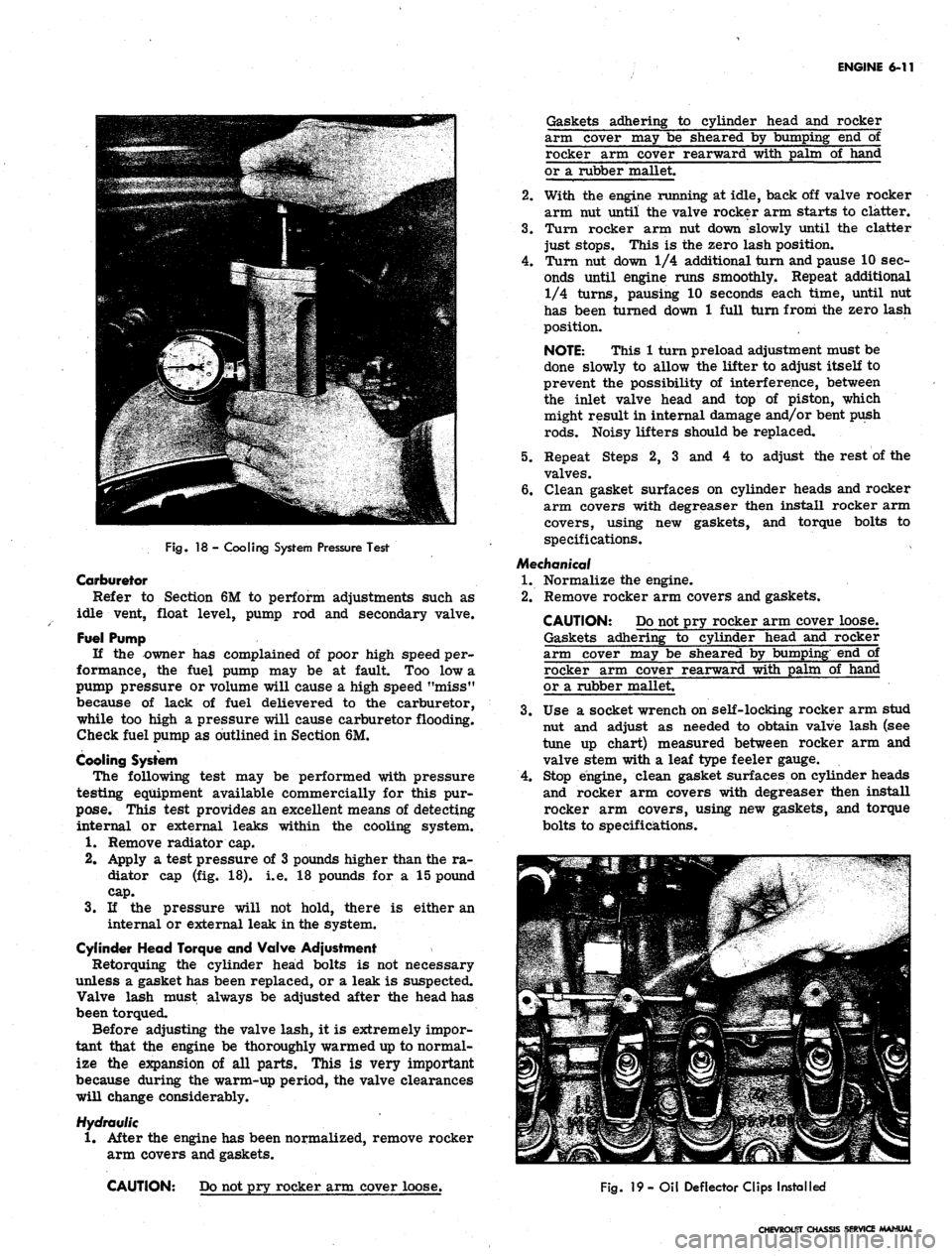

Fig.

18 - Cooling System Pressure Test

Carburetor

Refer to Section 6M to perform adjustments such as

idle vent, float level, pump rod and secondary valve.

Fuel Pump

If the owner has complained of poor high speed per-

formance, the fuel pump may be at fault. Too low a

pump pressure or volume will cause a high speed "miss"

because of lack of fuel delievered to the carburetor,

while too high a pressure will cause carburetor flooding.

Check fuel pump as outlined in Section 6M.

Cooling System

The following test may be performed with pressure

testing equipment available commercially for this pur-

pose.

This test provides an excellent means of detecting

internal or external leaks within the cooling system.

1.

Remove radiator cap.

2.

Apply a test pressure of 3 pounds higher than the ra-

diator cap (fig. 18). i.e. 18 pounds for a 15 pound

cap.

3.

If the pressure will not hold, there is either an

internal or external leak in the system.

Cylinder Head Torque and Valve Adjustment

Retorquing the cylinder head bolts is not necessary

unless a gasket has been replaced, or a leak is suspected.

Valve lash must always be adjusted after the head has

been torqued.

Before adjusting the valve lash, it is extremely impor-

tant that the engine be thoroughly warmed up to normal-

ize the expansion of all parts. This is very important

because during the warm-up period, the valve clearances

will change considerably.

Hydraulic

1.

After the engine has been normalized, remove rocker

arm covers and gaskets.

CAUTION: Do not pry rocker arm cover loose.

Gaskets adhering to cylinder head and rocker

arm cover may be sheared by bumping end of

rocker arm cover rearward with palm of hand

or a rubber mallet.

2.

With the engine running at idle, back off valve rocker

arm nut until the valve rocker arm starts to clatter.

3.

Turn rocker arm nut down slowly until the clatter

just stops. This is the zero lash position.

4.

Turn nut down 1/4 additional turn and pause 10 sec-

onds until engine runs smoothly* Repeat additional

1/4 turns, pausing 10 seconds each time, until nut

has been turned down 1 full turn from the zero lash

position.

NOTE: This 1 turn preload adjustment must be

done slowly to allow the lifter to adjust itself to

prevent the possibility of interference, between

the inlet valve head and top of piston, which

might result in internal damage and/or bent push

rods.

Noisy lifters should be replaced.

5.

Repeat Steps 2, 3 and 4 to adjust the rest of the

valves.

6. Clean gasket surfaces on cylinder heads and rocker

arm covers with degreaser then install rocker arm

covers, using new gaskets, and torque bolts to

specifications.

Mechanical

1.

Normalize the engine.

2.

Remove rocker arm covers and gaskets.

CAUTION: Do not pry rocker arm cover loose.

Gaskets adhering to cylinder head and rocker

arm cover may be sheared by bumping end of

rocker arm cover rearward with palm of hand

or a rubber mallet.

3.

Use a socket wrench on self-locking rocker arm stud

nut and adjust as needed to obtain valve lash (see

tune up chart) measured between rocker arm and

valve stem with a leaf type feeler gauge.

4.

Stop engine, clean gasket surfaces on cylinder heads

and rocker arm covers with degreaser then install

rocker arm covers, using new gaskets, and torque

bolts to specifications.

Fig.

19

- Oil Deflector Clips Installed

CHEVROLET CHASSIS SERVICE MANUAL

Page 278 of 659

ENGINE 6-13

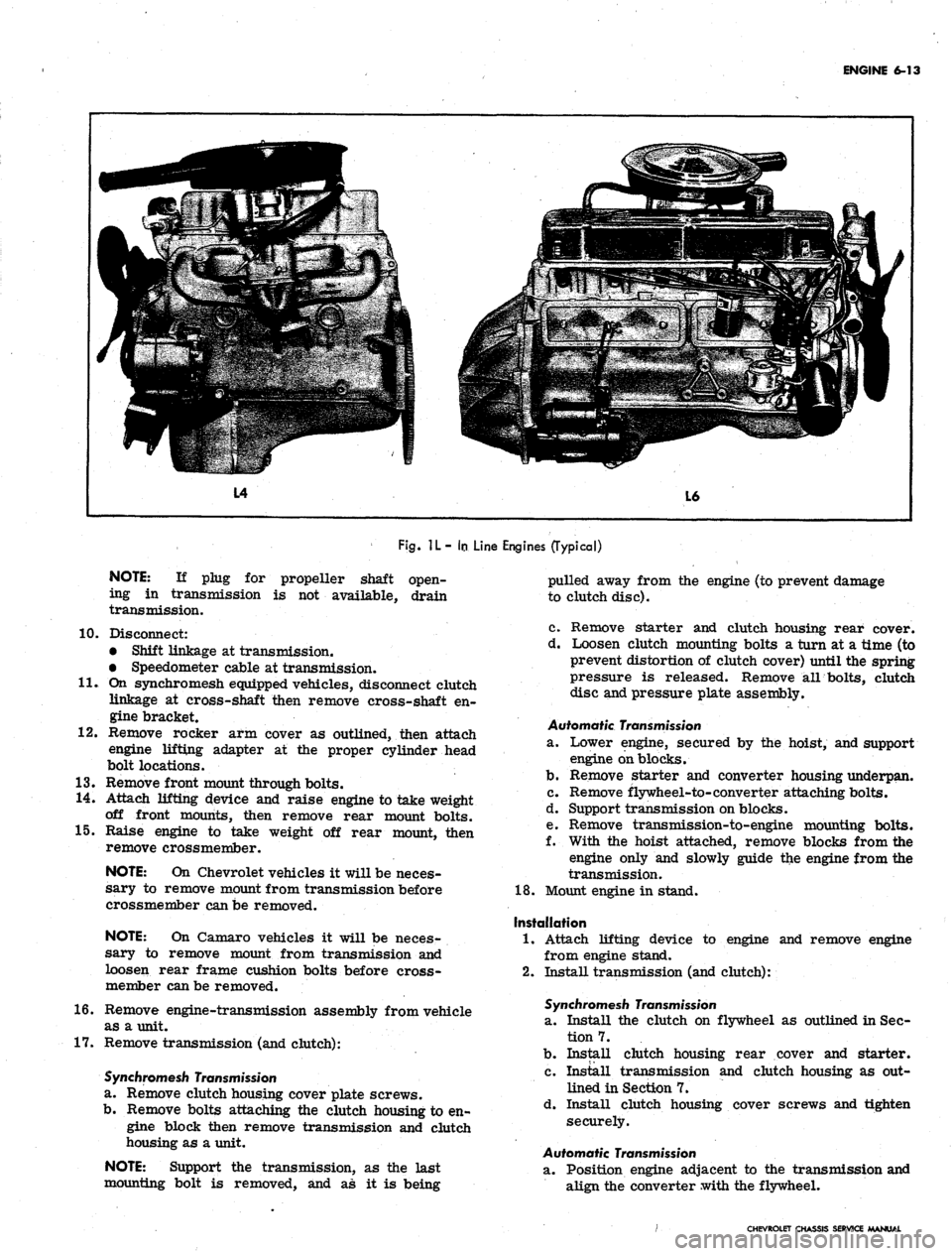

Fig.

1L- In

Line Engines (Typical)

NOTE:

If plug for propeller shaft open-

ing in transmission is not available, drain

transmission.

10.

11.

12.

Disconnect:

• Shift linkage at transmission.

• Speedometer cable at transmission.

On synchromesh equipped vehicles, disconnect clutch

linkage at cross-shaft then remove cross-shaft en-

gine bracket.

Remove rocker arm cover as outlined, then attach

engine lifting adapter at the proper cylinder head

bolt locations.

13.

Remove front mount through bolts.

14.

Attach lifting device and raise engine to take weight

off front mounts, then remove rear mount bolts.

15.

Raise engine to take weight off rear mount, then

remove crossmember.

NOTE:

On Chevrolet vehicles it will be neces-

sary to remove mount from transmission before

crossmember can be removed.

NOTE:

On Camaro vehicles it will be neces-

sary to remove mount from transmission and

loosen rear frame cushion bolts before cross-

member can be removed.

16.

Remove engine-transmission assembly from vehicle

as a unit.

17.

Remove transmission (and clutch):

Synchromesh Transmission

a. Remove clutch housing cover plate screws.

b.

Remove bolts attaching the clutch housing to en-

gine block then remove transmission and clutch

housing as a unit.

NOTE:

Support the transmission, as the last

mounting bolt is removed, and as it is being

pulled away from the engine (to prevent damage

to clutch disc).

c. Remove starter and clutch housing rear cover.

d. Loosen clutch mounting bolts a turn at a time (to

prevent distortion of clutch cover) until the spring

pressure is released. Remove all bolts, clutch

disc and pressure plate assembly.

Automatic Transmission

SL.

Lower engine, secured by the hoist, and support

engine on blocks.

b.

Remove starter and converter housing underpan.

c. Remove flywheel-to-converter attaching bolts.

d. Support transmission on blocks.

e. Remove transmission-to-engine mounting bolts.

f. With the hoist attached, remove blocks from the

engine only and slowly guide the engine from the

transmission.

18.

Mount engine in stand.

Installation

1.

Attach lifting device to engine and remove engine

from engine stand.

2.

Install transmission (and clutch):

Synchromesh Transmission

a. Install the clutch on flywheel as outlined in Sec-

tion 7.

b.

Install clutch housing rear cover and starter.

c. Install transmission and clutch housing as out-

lined in Section 7.

d. Install clutch housing cover screws and tighten

securely.

Automatic Transmission

a. Position engine adjacent to the transmission and

align the converter with the flywheel.

CHEVROLET CHASSIS SERVICE MANUAL

Page 279 of 659

ENGINE 6-14

b.

Bolt transmission to engine, then raise engine and

transmission assembly and install flywheel to

converter attaching bolts.

c. Install converter

housing*

underpan and starter.

3.

Tilt and lower engine and transmission assembly into

the chassis as a unit, guiding engine to align front

mounts with frame supports.

4.

Install front mount through bolts and torque to

specifications.

5.

Raise engine enough to install rear crossmember,

then install crossmember, install rear mount, lower

engine and torque bolts to specifications.

6. Remove lifting device and lifting adapter then install

rocker arm cover as outlined.

7.

On synchromesh equipped vehicles, install clutch

cross shaft engine bracket, then adjust and connect

clutch as outlined in Section 7.

8. Connect:

• Speedometer cable.

• Shift linkage at transmission.

9; Install propeller shaft.

10.

Remove jack stands and lower vehicle.

11.

Connect:

Power steering pump lines (if disconnected).

Vacuum line to power brake unit (if disconnected).

Fuel line at fuel pump.

Exhaust pipe at manifold flange.

Accelerator linkage at manifold bellcrank.

12.

Connect wires at:

Coil

Oil pressure switch

Temperature switch

Delcotron

Starter solenoid

13.

Install pulley, fan blade and fan belt as outlined in

Section 6K.

14.

Install radiator and shroud as outlined in Section 13.

15.

Install and adjust hood as outlined in Section 11.

16.

Connect battery cables.

17.

Fill with coolant, engine oil and transmission oil,

then start engine and check for leaks.

18.

Perform necessary adjustments and install air

cleaner.

MANIFOLD ASSEMBLY

Removal

1.

Remove air cleaner.

2.

Disconnect both throttle rods at bellcrank and re-

move throttle return spring.

3.

Disconnect fuel and vacuum lines at carburetor.

Disconnect choke cable on \A engines.

4.

Disconnect crankcase ventilation hose at rocker arm

cover.

5.

Disconnect exhaust pipe at manifold flange and dis-

card packing.

6. Remove manifold attaching bolts and clamps then

remove manifold assembly and discard gaskets.

7.

Check for cracks in manifold castings.

8. If necessary to replace either intake or exhaust

manifolds, separate them by removing one bolt and

two nuts at center of assembly. Reassemble mani-

folds using a new gasket. Tighten finger tight and

torque to specifications after assembly to cylinder

head. Transfer all necessary parts.

Installation

1.

Clean gasket surfaces on cylinder head and

manifolds*

2.

Position new gasket over manifold end studs on head

and carefully install the manifold in position making

sure the gaskets are in place.

3.

Install bolts and clamps while holding manifold in

place with hand.

4.

Torque bolts to specifications.

NOTE: On L6 engines center bolt and end bolt

torque differ.

5.

Connect exhaust pipe to manifold using a new

packing.

6. Connect crankcase ventilation hose at rocker arm

cover.

7.

Connect fuel and vacuum lines at carburetor.

8. On L4 engines connect choke cable and adjust as out-

lines in Section 6M.

9. Connect throttle rods at bellcrank and install throttle

return spring.

10.

Install air cleaner, start engine, check for leaks and

adjust carburetor idle speed and mixture.

ROCKER ARM COVER

Removal

1.

Disconnect crankcase ventilation hose(s) at rocker

arm cover.

2.

Remove air cleaner.

3.

Disconnect temperature wire from rocker arm cover

clips.

4.

Remove rocker arm cover. '

CAUTION: Do Not pry rocker arm cover loose

Gaskets adhering to cylinder head and rocker

arm cover may be sheared by bumping end of

rocker arm cover rearward with palm of hand or

a rubber mallet.

Installation

1.

Clean gasket surfaces on cylinder head and rocker

arm cover with degreaser then, using anew gasket,

install rocker arm cover and torque bolts to

specifications.

2.

Connect temperature wire at rocker arm cover clips.

3.

Install air cleaner.

4.

Connect crankcase ventilation hoses.

VALVE MECHANISM

Removal

1.

Remove rocker arm cover as outlined.

2.

Remove rocker arm nuts, rocker arm

balls,

rocker

arms and push rods.

NOTE:

Place rocker arms, rocker arm balls

and push rods in a rack so they may be rein-

stalled in the same location.

Installation and Adjustment

NOTE:

Whenever new rocker arms and/or

rocker arm balls are being installed, coat bear-

ing surfaces of rocker arms and rocker arm

balls with Molykote or its equivalent.

1.

Install push rods,

socket.

Be sure push rods seat in lifter

CHEVROLET CHASSIS SERVICE MANUAL