tow CHEVROLET CAMARO 1967 1.G Chassis Manual Online

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 616 of 659

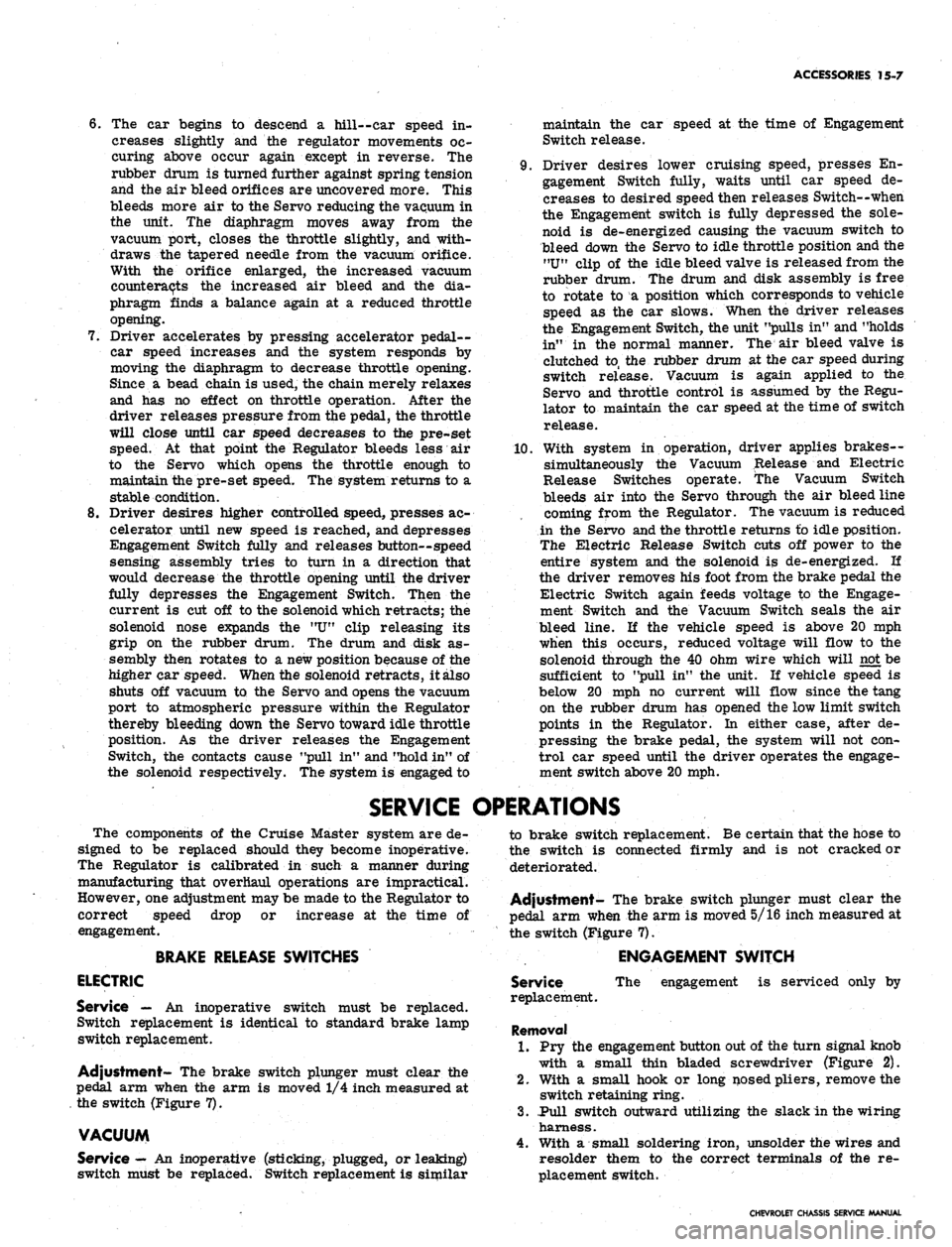

ACCESSORIES 15-7

6. The car begins to descend a hill--car speed in-

creases slightly and the regulator movements oc-

curing above occur again except in reverse. The

rubber drum is turned further against spring tension

and the air bleed orifices are uncovered more. This

bleeds more air to the Servo reducing the vacuum in

the unit. The diaphragm moves away from the

vacuum port, closes the throttle slightly, and with-

draws the tapered needle from the vacuum orifice.

With the orifice enlarged, the increased vacuum

counteracts the increased air bleed and the dia-

phragm finds a balance again at a reduced throttle

opening.

7.

Driver accelerates by pressing accelerator pedal-

car speed increases and the system responds by

moving the diaphragm to decrease throttle opening.

Since a bead chain is used, the chain merely relaxes

and has no effect on throttle operation. After the

driver releases pressure from the pedal, the throttle

will close until car speed decreases to the pre-set

speed. At that point the Regulator bleeds less air

to the Servo which opens the throttle enough to

maintain the pre-set speed. The system returns to a

stable condition.

8. Driver desires higher controlled speed, presses ac-

celerator until new speed is reached, and depresses

Engagement Switch fully and releases button--speed

sensing assembly tries to turn in a direction that

would decrease the throttle opening until the driver

fully depresses the Engagement Switch. Then the

current is cut off to the solenoid which retracts; the

solenoid nose expands the "U" clip releasing its

grip on the rubber drum. The drum and disk as-

sembly then rotates to a new position because of the

higher car speed. When the solenoid retracts, it also

shuts off vacuum to the Servo and opens the vacuum

port to atmospheric pressure within the Regulator

thereby bleeding down the Servo toward idle throttle

position. As the driver releases the Engagement

Switch, the contacts cause "pull in" and "hold in" of

the solenoid respectively. The system is engaged to

maintain the car speed at the time of Engagement

Switch release.

9. Driver desires lower cruising speed, presses En-

gagement Switch fully, waits until car speed de-

creases to desired speed then releases Switch--when

the Engagement switch is fully depressed the sole-

noid is de-energized causing the vacuum switch to

bleed down the Servo to idle throttle position and the

"U"

clip of the idle bleed valve is released from the

rubber drum. The drum and disk assembly is free

to rotate to a position which corresponds to vehicle

speed as the car slows. When the driver releases

the Engagement Switch, the unit "pulls in" and "holds

in" in the normal manner. The air bleed valve is

clutched to, the rubber drum at the car speed during

switch release. Vacuum is again applied to the

Servo and throttle control is assumed by the Regu-

lator to maintain the car speed at the time of switch

release.

10.

With system in operation, driver applies brakes--

simultaneously the Vacuum Release and Electric

Release Switches operate. The Vacuum Switch

bleeds air into the Servo through the air bleed line

coming from the Regulator. The vacuum is reduced

in the Servo and the throttle returns to idle position.

The Electric Release Switch cuts off power to the

entire system and the solenoid is de-energized. If

the driver removes his foot from the brake pedal the

Electric Switch again feeds voltage to the Engage-

ment Switch and the Vacuum Switch seals the air

bleed line. If the vehicle speed is above 20 mph

when this occurs, reduced voltage will flow to the

solenoid through the 40 ohm wire which will not be

sufficient to "pull in" the unit. If vehicle speed is

below 20 mph no current will flow since the tang

on the rubber drum has opened the low limit switch

points in the Regulator. In either case, after de-

pressing the brake pedal, the system will not con-

trol car speed until the driver operates the engage-

ment switch above 20 mph.

SERVICE OPERATIONS

The components of the Cruise Master system are de-

signed to be replaced should they become inoperative.

The Regulator is calibrated in such a manner during

manufacturing that overhaul operations are impractical.

However, one adjustment may be made to the Regulator to

correct speed drop or increase at the time of

engagement.

BRAKE RELEASE SWITCHES

ELECTRIC

Service — An inoperative switch must be replaced.

Switch replacement is identical to standard brake lamp

switch replacement.

Adjustment- The brake switch plunger must clear the

pedal arm when the arm is moved 1/4 inch measured at

the switch (Figure 7).

VACUUM

Service

—

An inoperative (sticking, plugged, or leaking)

switch must be replaced. Switch replacement is similar

to brake switch replacement. Be certain that the hose to

the switch is connected firmly and is not cracked or

deteriorated.

Adjustment- The brake switch plunger must clear the

pedal arm when the arm is moved 5/16 inch measured at

the switch (Figure 7).

ENGAGEMENT SWITCH

Service

replacement.

The engagement is serviced only by

Removal

1.

Pry the engagement button out of the turn signal knob

with a small thin bladed screwdriver (Figure 2).

2.

With a small hook or long nosed pliers, remove the

switch retaining ring.

3.

.Pull switch outward utilizing the slack in the wiring

harness.

4.

With a small soldering iron, unsolder the wires and

resolder them to the correct terminals of the re-

placement switch.

CHEVROLET CHASSIS SERVICE MANUAL

Page 624 of 659

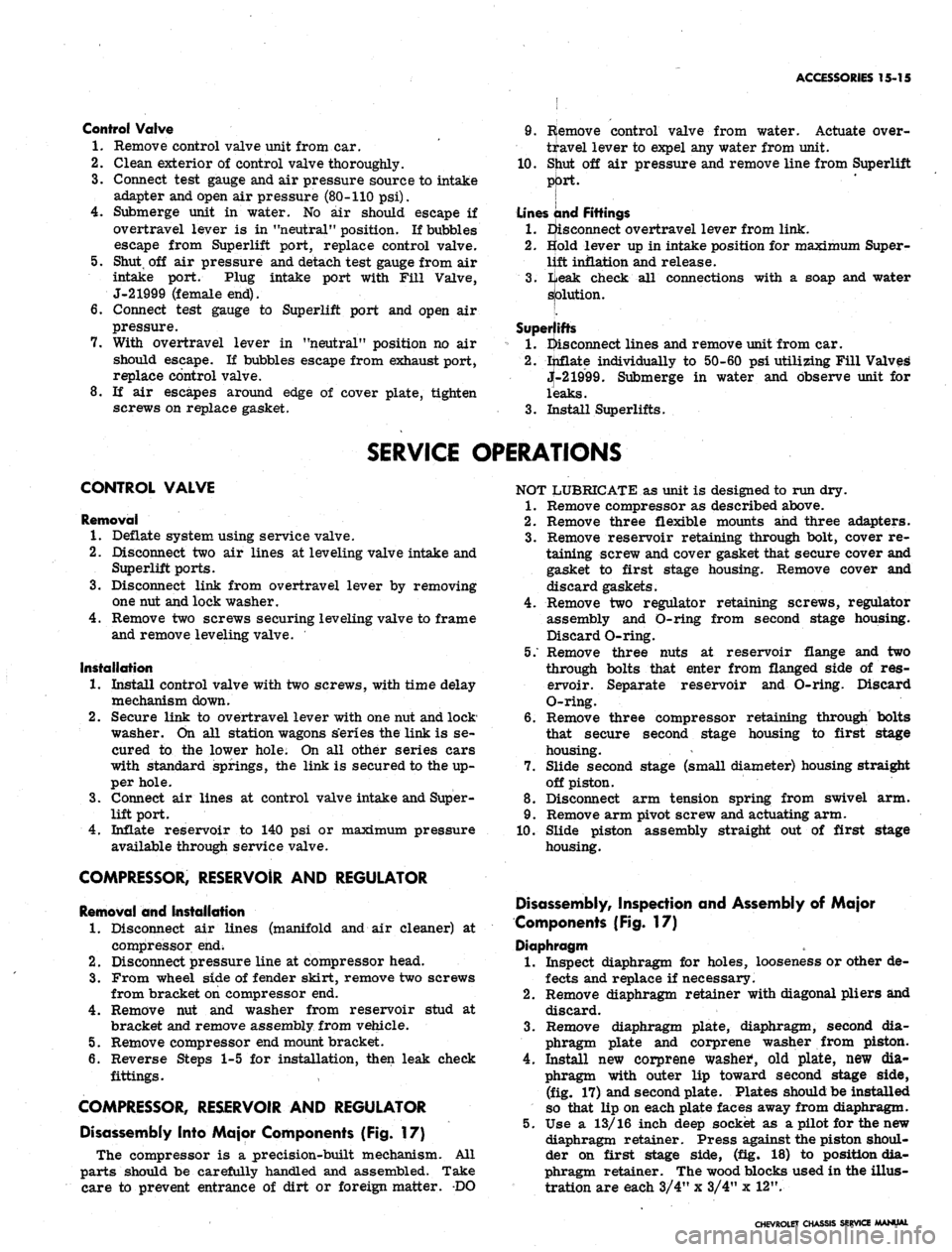

ACCESSORIES 15-15

Control Valve

1.

Remove control valve unit from car.

2.

Clean exterior of control valve thoroughly.

3.

Connect test gauge and air pressure source to intake

adapter and open air pressure (80-110 psi).

4.

Submerge unit in water. No air should escape if

overtravel lever is in "neutral" position. If bubbles

escape from Superlift port, replace control valve.

5. Shut, off air pressure and detach test gauge from air

intake port. Plug intake port with Fill Valve,

J-21999 (female end).

6. Connect test gauge to Superlift port and open air

pressure.

7. With overtravel lever in "neutral" position no air

should escape. If bubbles escape from exhaust port,

replace control valve.

8. If air escapes around edge of cover plate, tighten

screws on replace gasket.

9. R(emove control valve from water. Actuate over-

travel lever to expel any water from unit.

10.

Sjiut off air pressure and remove line from Superlift

[

Lines and Fittings

1.

Eisconnect overtravel lever from link.

2.

Bold lever up in intake position for maximum Super-

lift inflation and release.

3.

iieak check all connections with a soap and water

splution.

[.

Superlifts

1.

disconnect lines and remove unit from car.

2.

ijiflate individually to 50-60 psi utilizing Fill Valves

jt-21999. Submerge in water and observe unit for

leaks.

3.

Install Superlifts.

SERVICE OPERATIONS

CONTROL VALVE

Removal

1.

Deflate system using service valve.

2.

Disconnect two air lines at leveling valve intake and

Superlift ports.

3.

Disconnect link from overtravel lever by removing

one nut and lock washer.

4.

Remove two screws securing leveling valve to frame

and remove leveling valve.

Installation

1.

Install control valve with two screws, with time delay

mechanism down.

2.

Secure link to overtravel lever with one nut and lock

washer. On all station wagons s'eries the link is se-

cured to the lower hole. On all other series cars

with standard springs, the link is secured to the up-

per hole.

3.

Connect air lines at control valve intake and Super-

lift port.

4.

Inflate reservoir to 140 psi or maximum pressure

available through service valve.

COMPRESSOR, RESERVOIR AND REGULATOR

Removal and Installation

1.

Disconnect air lines (manifold and air cleaner) at

compressor end;

2.

Disconnect pressure line at compressor head.

3.

From wheel side of fender skirt, remove two screws

from bracket on compressor end.

4.

Remove nut and washer from reservoir stud at

bracket and remove assembly from vehicle.

5. Remove compressor end mount bracket.

6. Reverse Steps 1-5 for installation, then leak check

fittings.

COMPRESSOR, RESERVOIR AND REGULATOR

Disassembly Into Major Components (Fig. 17)

The compressor is a precision-built mechanism. All

parts should be carefully handled and assembled. Take

care to prevent entrance of dirt or foreign matter. DO

NOT LUBRICATE as unit is designed to run dry.

1.

Remove compressor as described above.

2.

Remove three flexible mounts and three adapters.

3.

Remove reservoir retaining through bolt, cover re-

taining screw and cover gasket that secure cover and

gasket to first stage housing. Remove cover and

discard gaskets.

4.

Remove two regulator retaining screws, regulator

assembly and O-ring from second stage housing.

Discard O-ring.

5/ Remove three nuts at reservoir flange and two

through bolts that enter from flanged side of res-

ervoir. Separate reservoir and O-ring. Discard

O-ring.

6. Remove three compressor retaining through bolts

that secure second stage housing to first stage

housing.

7. Slide second stage (small diameter) housing straight

off piston.

8. Disconnect arm tension spring from swivel arm.

9. Remove arm pivot screw and actuating arm.

10.

Slide piston assembly straight out of first stage

housing.

Disassembly, Inspection and Assembly of Major

Components (Fig. 17)

Diaphragm

1.

Inspect diaphragm for holes, looseness or other de-

fects and replace if necessary.

2.

Remove diaphragm retainer with diagonal pliers and

discard.

3.

Remove diaphragm plate, diaphragm, second dia-

phragm plate and corprene washer from piston.

4.

Install new corprene washed, old plate, new dia-

phragm with outer lip toward second stage side,

(fig. 17) and second plate. Plates should be installed

so that lip on each plate faces away from diaphragm.

5. Use a 13/16 inch deep socket as a pilot for the new

diaphragm retainer. Press against the piston shoul-

der on first stage side, (fig. 18) to position dia-

phragm retainer. The wood blocks used in the illus-

tration are each 3/4" x 3/4" x 12".

CHEVROLET CHASSIS SERVICE MANUAL

Page 629 of 659

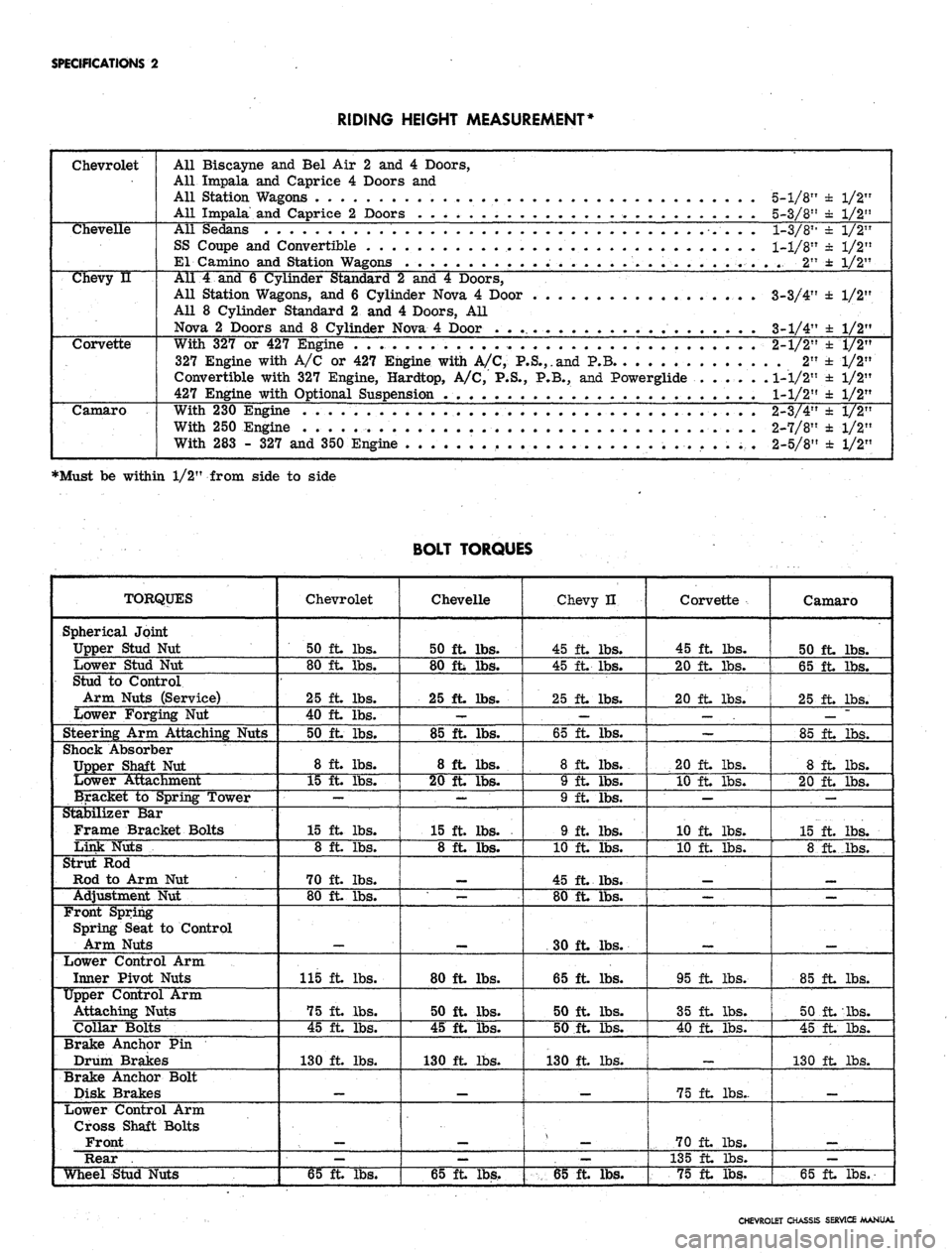

SPECIFICATIONS

2

RIDING HEIGHT MEASUREMENT*

Chevrolet

All Biscayne

and Bel Air 2 and 4

Doors,

All Impala

and

Caprice

4

Doors

and

All Station Wagons

. . . .

All Impala

and

Caprice

2

Doors

. . . . .

5-1/8"

± 1/2"

5-3/8"

± 1/2"

Chevelle

All Sedans

SS Coupe

and

Convertible

El Camino

and

Station W*

1-3/811

± 1/2"

1-1/8"

± 1/2"

..

2" ± 1/2"

Chevy

u

All

4 and 6

Cylinder Standard

2 and 4

Doors,

All Station Wagons,

and 6

Cylinder Nova

4

Door

All

8

Cylinder Standard

2 and 4

Doors,

All

Nova

2

Doors

and 8

Cylinder Nova

4

Door

. . .

3-3/4'

3-1/4'

±

1/2'

±

1/2'

Corvette

With

327 or 427

Engine

. . . .

327 Engine with

A/C or 427

Engine with

A/C,

P.S.,.and

P.B

Convertible with

327

Engine, Hardtop,

A/C, P.S., P.B., and

Powerglide

427 Engine with Optional Suspension

.

2-1/2"

.

2"

1-1/2"

1-1/2"

±

1/2"

±1/2"

±

1/2"

±

1/2"

Camaro

With

230

Engine

..... . . .

With

250

Engine

.... ...

With

283 - 327 and

350 Engine

2-3/4"

2-7/8"

2-5/8"

± 1/2"

± 1/2"

± 1/2"

•Must be within 1/2" from side to side

BOLT TORQUES

TORQUES

Spherical Joint

Upper Stud

Nut

Lower Stud

Nut

Stud

to

Control

Arm Nuts (Service)

Lower Forging

Nut

Steering

Arm

Attaching Nuts

Shock Absorber

Upper Shaft

Nut

Lower Attachment

Bracket

to

Spring Tower

Stabilizer

Bar

Frame Bracket Bolts

Link Nuts

Strut

Rod

Rod

to Arm Nut

Adjustment

Nut

Front Spring

Spring Seat

to

Control

Arm Nuts

Lower Control

Arm

Inner Pivot Nuts

Upper Control Arm

Attaching Nuts

Collar Bolts

Brake Anchor Pin

Drum Brakes

Brake Anchor Bolt

Disk Brakes

Lower Control Arm

Cross Shaft Bolts

Front

Rear .

Wheel Stud Nuts

Chevrolet

50 ft. lbs.

80 ft lbs.

25 ft. lbs.

40 ft. lbs.

50 ft. lbs.

8 ft. lbs.

15 ft. lbs.

—

15 ft lbs.

8 ft. lbs.

70 ft lbs.

80 ft lbs.

115 ft lbs.

75 ft lbs.

45 ft lbs.

130 ft lbs.

—

65 ft lbs.

Chevelle

50 ft lbs.

80 ft lbs.

25 ft. lbs.

—

85 ft lbs.

8 ft lbs.

20 ft lbs.

—

15 ft lbs.

8 ft lbs.

—

80 ft lbs.

50 ft. lbs.

45 ft. lbs.

130 ft lbs.

—

65 ft lbs.

Chevy H

45 ft lbs.

45 ft lbs.

25 ft lbs.

—

65 ft. lbs.

8 ft lbs.

9 ft lbs.

9 ft. lbs.

9 ft. lbs.

10 ft. lbs.

45 ft lbs.

80 ft lbs.

30 ft lbs.

65 ft lbs.

50 ft. lbs.

50 ft lbs.

130 ft lbs.

_

—

65 ft lbs.

Corvette

45 ft lbs.

20 ft lbs.

20 ft lbs.

—

20 ft lbs.

10 ft lbs.

—

10 ft lbs.

10 ft. lbs.

—

95 ft lbs.

35 ft lbs.

40 ft lbs.

75 ft lbs..

70 ft lbs.

135 ft lbs.

75 ft lbs.

Camaro

50 ft lbs.

65 ft lbs.

25 ft lbs.

—

85 ft lbs.

8 ft lbs.

20 ft lbs.

.

—

15 ft. lbs.

8 ft._lbs.

_

85 ft lbs.

50 ft lbs.

45 ft lbs.

130 ft lbs.

_

—

65 ft lbs.

CHEVROLET CHASSIS SERVICE MANUAL

Page 648 of 659

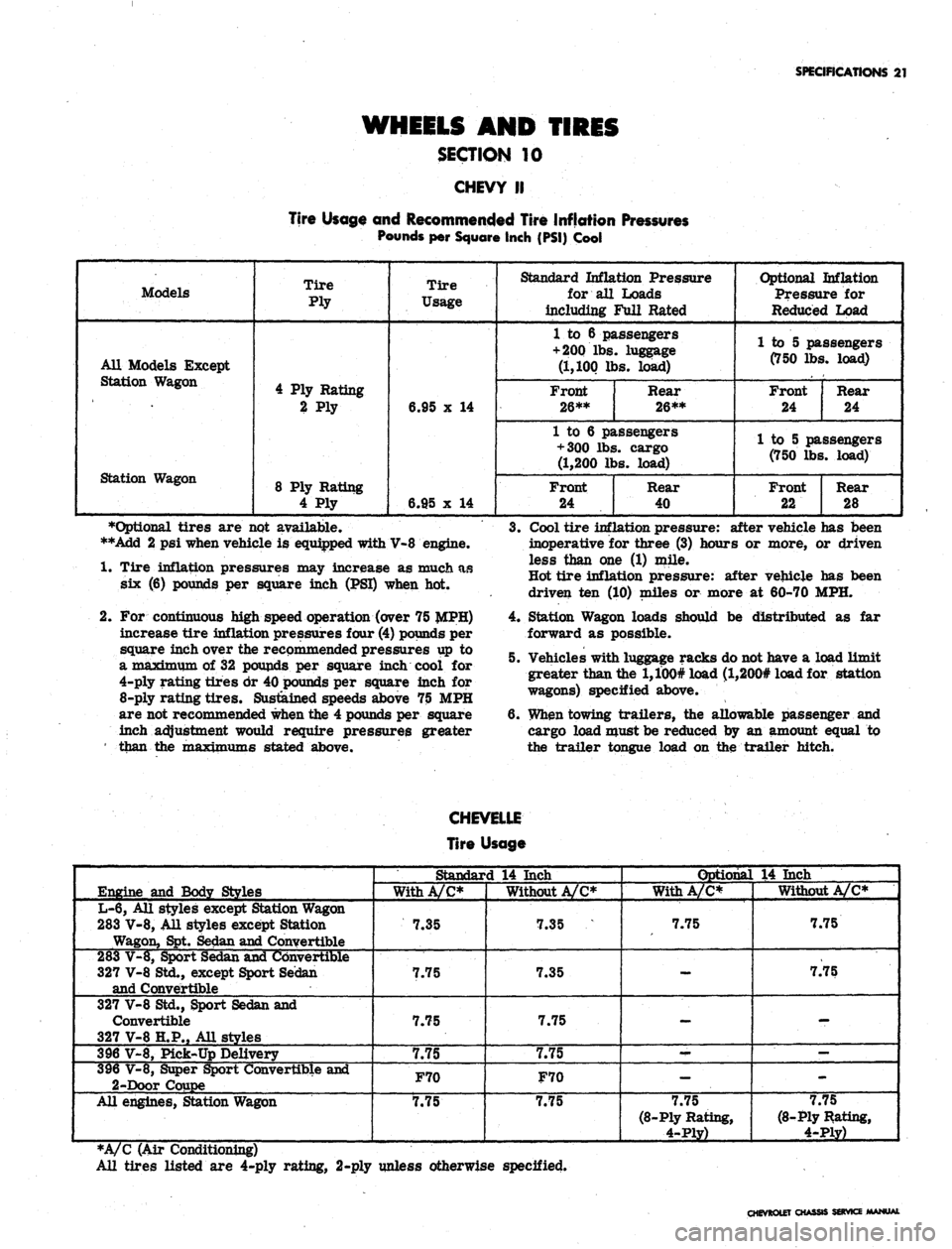

SPECIFICATIONS

21

WHEELS AND TIRES

SECTION 10

CHEVY II

Tire Usage and Recommended Tire Inflation Pressures

Pounds per Square Inch (PSI) Cool

Models

All Models Except

Station Wagon

Station Wagon

Tire

Ply

4 Ply Rating

2 Ply

8 Ply Rating

4 Ply

Tire

Usage

6.95 x 14

6.95 x 14

Standard Inflation Pressure

for all Loads

including Full Rated

1 to 6 passengers

+ 200

lbs. luggage

(1,100 lbs. load)

Front

26**

Rear

26**

1 to 6 passengers

+ 300 lbs. cargo

(1,200 lbs. load)

Front

24

Rear

40

Optional Inflation

Pressure for

Reduced Load

1 to 5 passengers

(750 lbs. load)

Front

24

Rear

24

1 to 5 passengers

(750 lbs. load)

Front

22

Rear

28

•Optional tires are not available.

**Add 2 psi when vehicle is equipped with V-8 engine.

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot.

2.

For continuous high speed operation (over 75

increase tire inflation pressures four (4) pounds per

square inch over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires dr 40 pounds per square inch for

8-ply

rating tires. Sustained speeds above 75 MPH

are not recommended when the 4 pounds per square

inch adjustment would require pressures greater

' than the TpaxiTP^Tns stated above.

3.

Cool tire inflation pressure: after vehicle has been

inoperative for three (3) hours or more, or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Station Wagon loads should be distributed as far

forward as possible.

5. Vehicles with luggage racks do not have a load limit

greater than the l,100# load (l,200# load for station

wagons) specified above.

6. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

CHEVELLE

Tire Usage

Engine and Body Styles

L-6, All styles except Station Wagon

283 V-8, All styles except Station

Wagon, Spt. Sedan and Convertible

283 V-8, Sport Sedan and Convertible

327 V-8 Std., except Sport Sedan

and Convertible

327 V-8 Std., Sport Sedan and

Convertible

327 V-8 H.P., All styles

396 V-8, Pick-Up Delivery

396 V-8, Super Sport Convertible and

2-Door Coupe

All engines, Station Wagon

Standard 14 Inch

With A/C*

7.35

7.75

7.75

7.75

F70

7.75

Without A/C*

7.35

7.35

7.75

7.75

F70

7.75

Optional 14 Inch

With A/C*

7.75

—

-

--

-

7.75

(8-Ply Rating,

4-Ply)

Without A/C*

7.75

7.75

-

—

-

7.75

(8-Ply Rating,

4-Ply)

*A/C (Air Conditioning)

All tires listed are 4-ply rating, 2-ply unless otherwise specified.

CHEVROLET CHASSIS SERVICE MANW

Page 649 of 659

SPECIFICATIONS

22

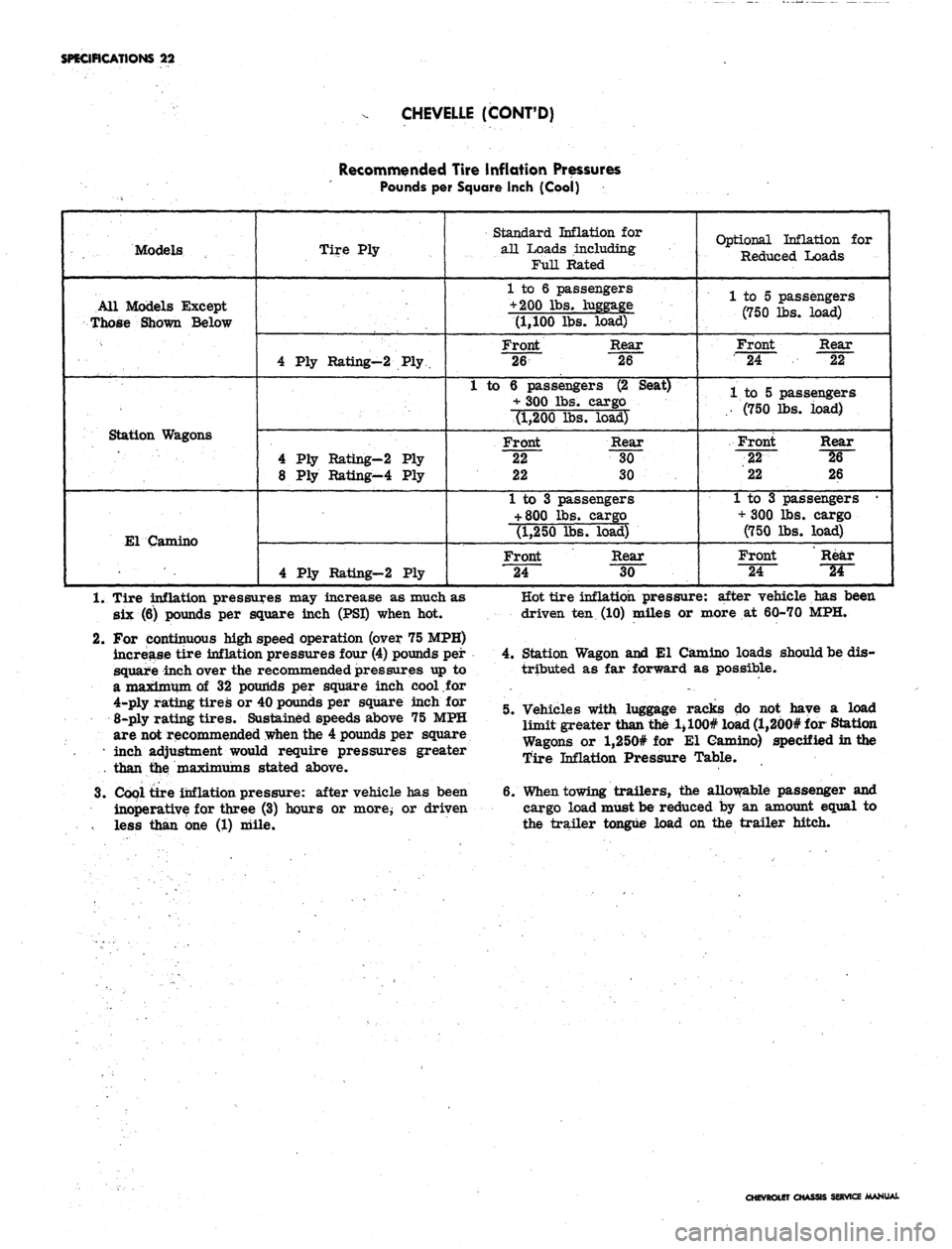

CHEVELLE (CONT'D)

Recommended Tire inflation Pressures

Pounds per Square Inch (Cool)

Models

All Models Except

Those Shown Below

Station Wagons

El Camino

Tire Ply

4 Ply Rating-2 Ply

4 Ply Rating-2 Ply

8 Ply Rating-4 Ply

4 Ply Rating-2 Ply

Standard Inflation for

all Loads including

FuH Rated

1 to 6 passengers

+ 200 lbs. luggage

(1,100 lbs. load)

Front Rear

26 26

1 to 6 passengers (2 Seat)

+ 300 lbs. cargo

(1,200 lbs. load)

Front Rear

22 30

22 30

1 to 3 passengers

+

800 lbs. cargo

(1,250 lbs. load)

Front Rear

24 30

Optional Inflation for

Reduced Loads

1 to 5 passengers

(750 lbs. load)

Front Rear

24 22

1 to 5 passengers

.. (750 lbs. load)

Front Rear

22 ^6~

22 26

1 to 3 passengers •

+ 300 lbs. cargo

(750 lbs. load)

Front Rear

"24~

~W~

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot.

2.

For continuous high speed operation (over 75 MPH)

increase tire inflation pressures four (4) pounds per

square inch over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires or 40 pounds per square inch for

8-ply rating tires. Sustained speeds above 75 MPH

are not recommended when the 4 pounds per square

• inch adjustment would require pressures greater

than the maximums stated above.

3.

Cool tire inflation pressure: after vehicle has been

inoperative for three (3) hours or more; or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Station Wagon and El Camino loads should be dis-

tributed as far forward as possible.

5. Vehicles with luggage racks do not have a load

limit greater than the 1 > 100# load (l,200# for Station

Wagons or l,250# for El Camino) specified in the

Tire Inflation Pressure Table.

6. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

OLETO

SERVICE MANUAL

Page 650 of 659

SPECIFICATIONS 23

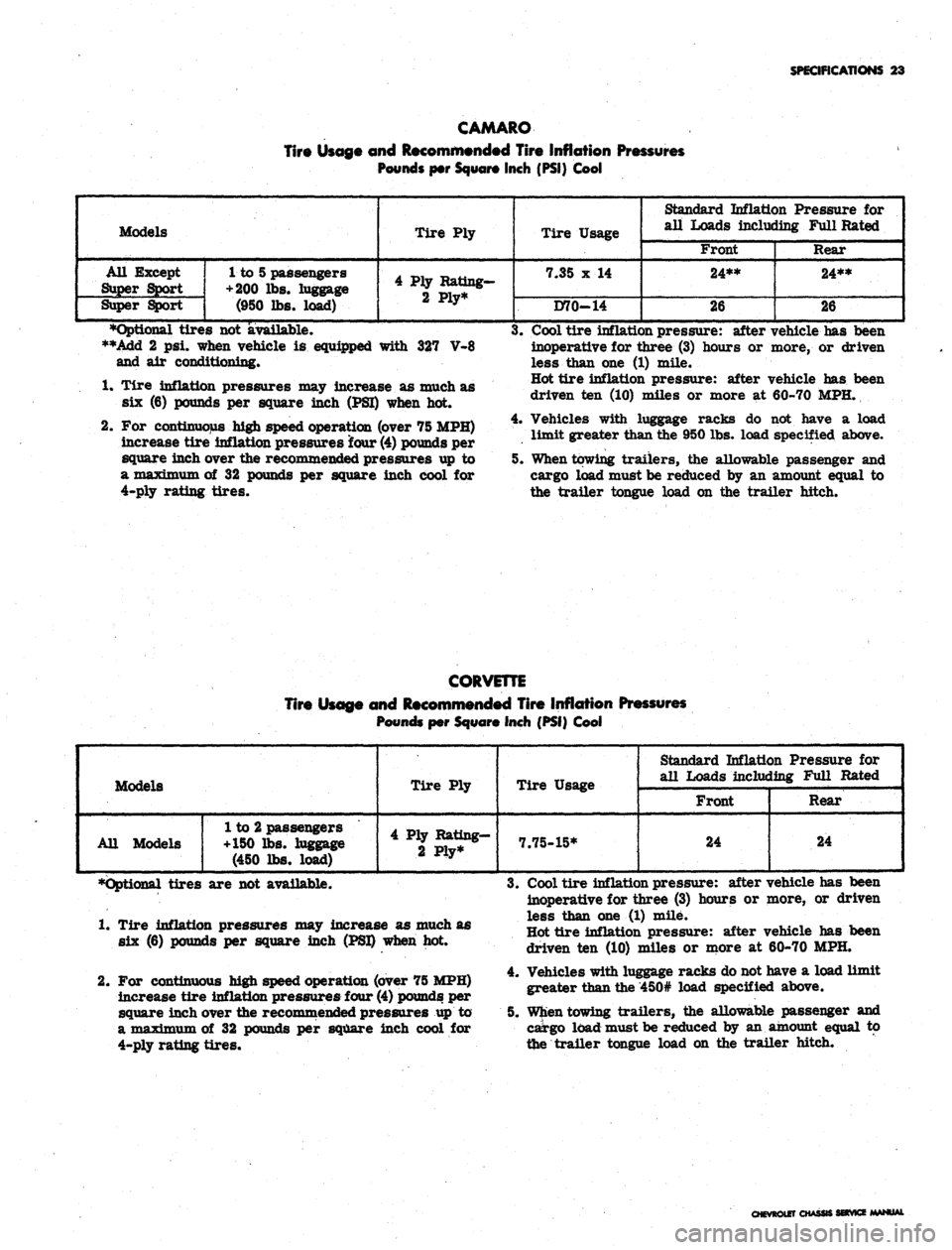

CAMARO

Tire Usage and Recommended Tire Inflation Pressures

Pounds per Square Inch (PSI) Cool

Models

All Except

Super Sport

Super Sport

1 to 5 passengers

+ 200

lbs. luggage

(950 lbs. load)

Tire Ply

4 Ply Rating-

2 Ply*

Tire Usage

7.35 x 14

D70-14

Standard Inflation Pressure for

all Loads including Full Rated

Front

24**

26

Rear

24**

26

•Optional tires not available.

**Add 2 psi. when vehicle is equipped with 327 V-8

and air conditioning*

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot.

2.

For continuous high speed operation (over 75 MPH)

increase tire inflation pressures four

(4)

pounds per

square inch over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires.

3.

Cool tire inflation pressure: after vehicle has been

inoperative for three (3) hours or more, or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Vehicles with luggage racks do not have a load

limit greater than the 950 lbs. load specified above.

5. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

CORVETTE

Tire Usage and Recommended Tire Inflation Pressures

Pounds per Square Inch (PSI) Cool

Models

All Models

1 to 2 passengers

+150 lbs. luggage

(450 lbs. load)

Tire Ply

4 Ply Rating-

2 Ply*

Tire Usage

7.75-15*

Standard Inflation Pressure for

all Loads including Full Rated

Front

24

Rear

24

•Optional tires are not available.

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot.

2.

For continuous high speed operation (over 75 MPH)

increase tire inflation pressures four

(4)

pounds per

square inch over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires.

3.

Cool tire inflation pressure: after vehicle has been

inoperative for three (3) hours or more, or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Vehicles with luggage racks do not have a load limit

greater than the 450# load specified above.

5. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

CHEVROLET CHASSIS SERVICE MANUAL

Page 651 of 659

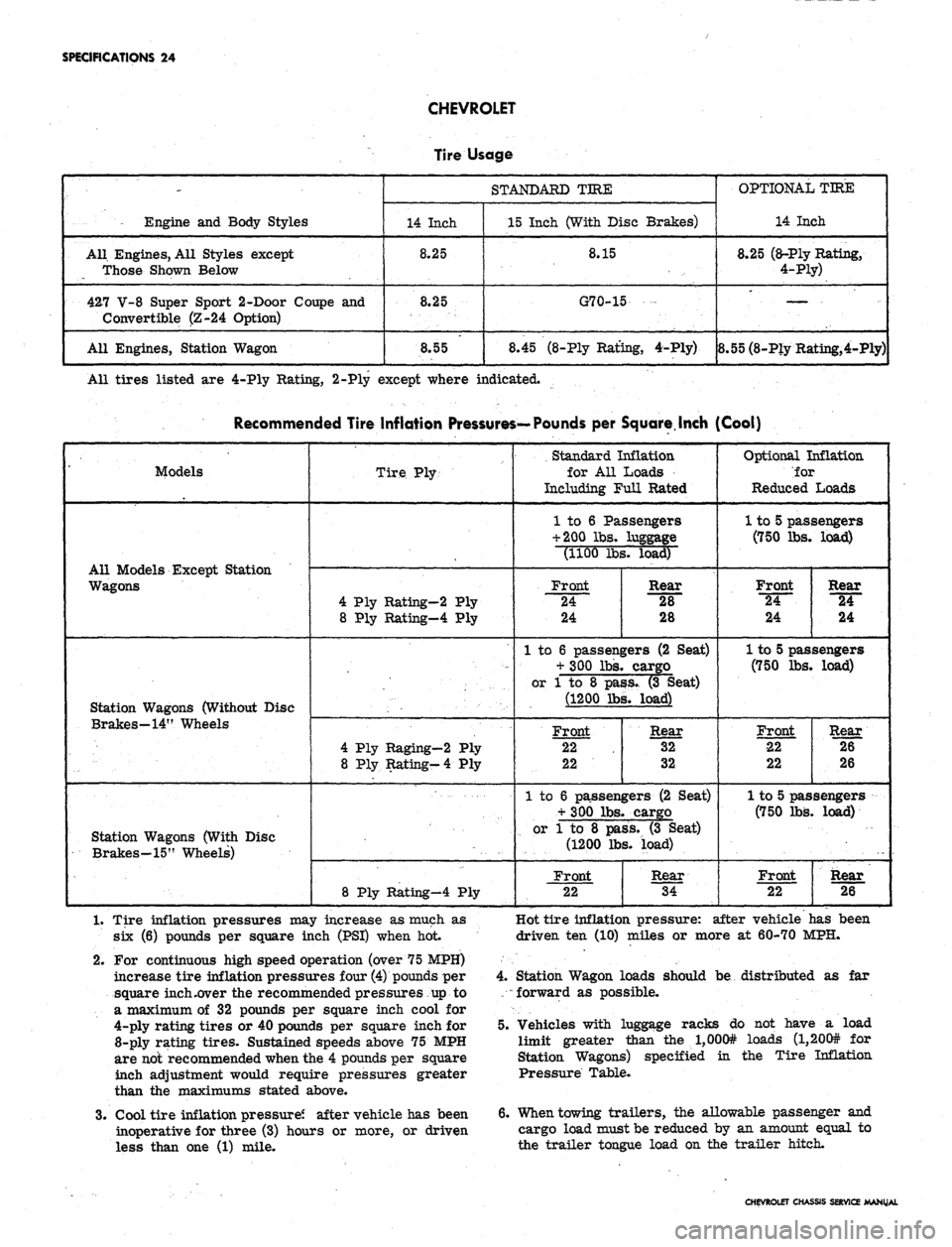

SPECIFICATIONS 24

CHEVROLET

Engine and Body Styles

All. Engines, All Styles except

Those Shown Below

427 V-8 Super Sport 2-Door Coupe and

Convertible (Z-24 Option)

All Engines, Station Wagon

Tire

14 Inch

8.25

8.25

8.55

Usage

STANDARD TIRE

15 Inch (With Disc

8.15

G70-15

8.45 (8-Ply Rating,

Brakes)

4-Ply)

OPTIONAL TIRE

14 Inch

8.25 (a-Ply Rating,

4-Ply)

. —. ...

8.55 (8-Ply Rating,4-Ply)

All tires listed are 4-Ply Rating, 2-Ply except where indicated.

Recommended Tire Inflation Pressures—Pounds per Square.Inch (Cool)

' Models

All Models Except Station

Wagons

Station Wagons (Without Disc

Brakes—14" Wheels

Station Wagons (With Disc

Brakes-15" Wheels)

Tire Ply-

4 Ply Rating-2 Ply

8 Ply Rating-4 Ply

4 Ply Raging—2 Ply

8 Ply Rating-4 Ply

8 Ply Rating-4 Ply

Standard Inflation

for All Loads

Including Full Rated

1 to 6 Passengers

+ 200 lbs. luggage

(1100 lbs. load)

Front

24

24

Rear

28

28

1 to 6 passengers (2 Seat)

+ 300 lbs. cargo

or 1 to 8 pass. (3 Seat)

(1200 lbs. load)

Front

22

22

Rear

32

32

1 to 6 passengers (2 Seat)

+ 300 lbs. cargo

or 1 to 8 pass. (3 Seat)

(1200 lbs. load)

Front

22

Rear

34

Optional Inflation

ior

Reduced Loads

1 to 5 passengers

(750 lbs. load)

Front

"24~

24

Rear

24

24

1 to 5 passengers

(750 lbs. load)

Front

22

22

Rear

26

26

1 to 5 passengers

(750 lbs. load)

Front

22

Rear

26

1.

Tire inflation pressures may increase as much as

six (6) pounds per square inch (PSI) when hot

2.

For continuous high speed operation (over 75 MPH)

increase tire inflation pressures four (4) pounds per

square inch .over the recommended pressures up to

a maximum of 32 pounds per square inch cool for

4-ply rating tires or 40 pounds per square inch for

8-ply rating tires. Sustained speeds above 75 MPH

are not recommended when the 4 pounds per square

inch adjustment would require pressures greater

than the maximums stated above.

3.

Cool tire inflation pressure? after vehicle has been

inoperative for three (3) hours or more, or driven

less than one (1) mile.

Hot tire inflation pressure: after vehicle has been

driven ten (10) miles or more at 60-70 MPH.

4.

Station Wagon loads should be distributed as far

forward as possible.

5. Vehicles with luggage racks do not have a load

limit greater than the l,000# loads (l,200# for

Station Wagons) specified in the Tire Inflation

Pressure Table.

6. When towing trailers, the allowable passenger and

cargo load must be reduced by an amount equal to

the trailer tongue load on the trailer hitch.

CHEVROLET CHASSIS SERVICE MANUAL