CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 141 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 141

4. To isolate the short, probe a test point

at either end of the isolated circuit

(the light should be on or the mete r should indicate continuity).

5. Leave the test light probe engaged and sequentiall y open connectors or

switches, remove parts, etc. until t he light goes out or continuity is

broken.

6. When the light goes out, the shor t is between the last two circuit

components which were opened.

VOLTAGE

This test determines voltage available fr om the battery and should be the first

step in any electrical troubleshooting pr ocedure after visual inspection. Many

electrical problems, especially on co mputer controlled systems, can be caused

by a low state of charge in the battery. Excessive corrosion at the battery cable

terminals can cause poor contact that will prevent proper charging and f\

ull

battery current flow.

1. Set the voltmeter selector switch to the 20V position.

2. Connect the multimeter negative lead to the battery's negative (-) post or

terminal and the positive lead to t he battery's positive (+) post or

terminal.

3. Turn the ignition switch ON to provide a load.

4. A well charged battery should register over 12 volts. If the meter reads

below 11.5 volts, the battery power may be insufficient to operate the

electrical system properly.

VOLTAGE DROP

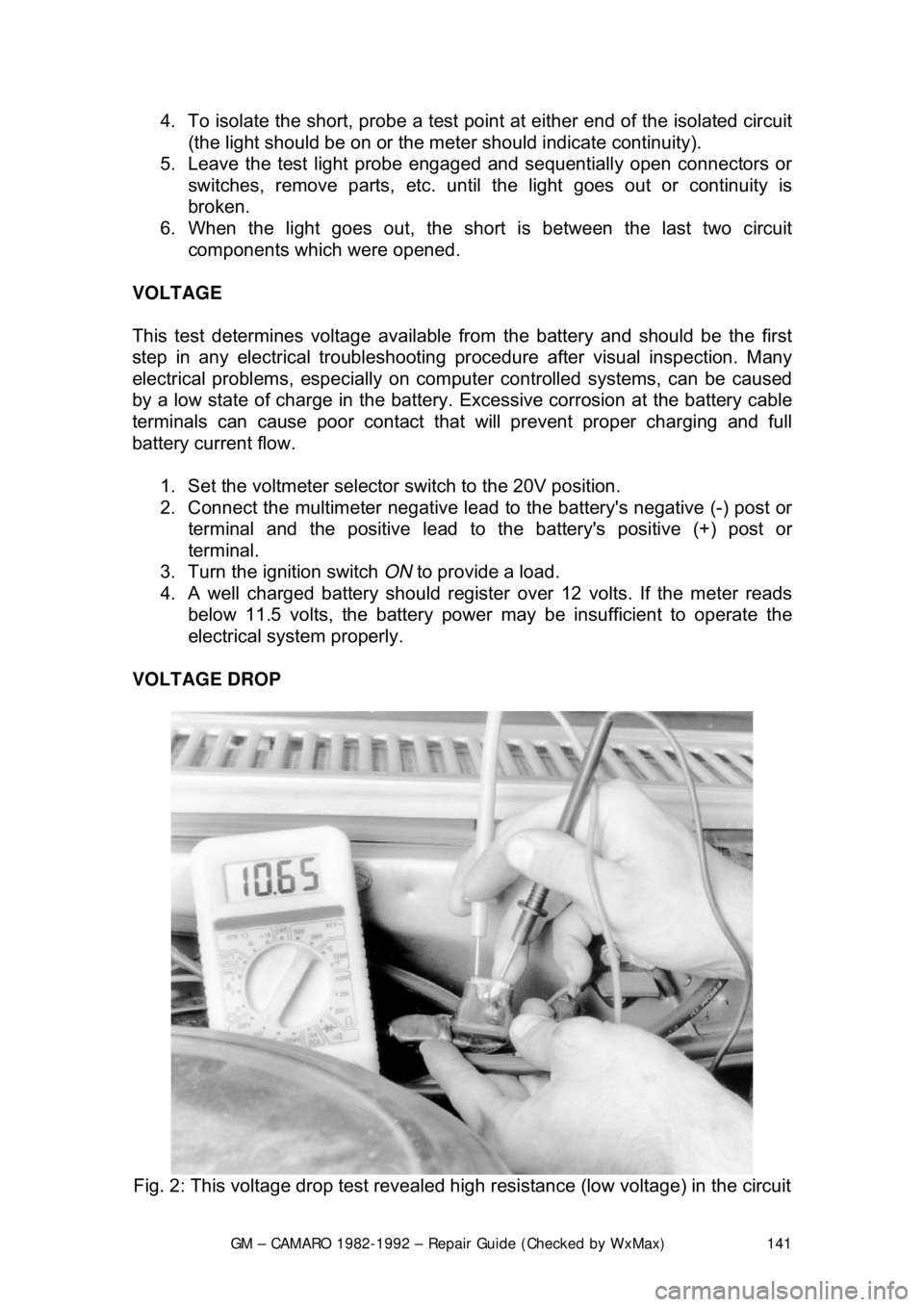

Fig. 2: This voltage drop test revealed high resistance (low voltage) in the circuit

Page 142 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 142

When current flows through

a load, the voltage beyond the load drops. This

voltage drop is due to the resistance created by the load and also by small

resistances created by corrosion at the connectors and damaged insulation on

the wires. The maximum allo wable voltage drop under load is critical, especially

if there is more than one load in t he circuit, since all voltage drops are

cumulative.

1. Set the voltmeter selector s witch to the 20 volt position.

2. Connect the multimeter negative lead to a good ground.

3. Operate the circuit a nd check the voltage prior to the first component

(load).

4. There should be little or no voltage drop in the circuit prior to the fi\

rst component. If a voltage drop exists, the wire or connectors in the circuit

are suspect.

5. While operating the first component in the circuit, probe the ground side

of the component with the positive meter lead and observe the voltage

readings. A small voltage drop should be noticed. This voltage drop is

caused by the resistance of the component.

6. Repeat the test for each component (load) down the circuit.

7. If a large voltage drop is noticed, the preceding component, wire or

connector is suspect.

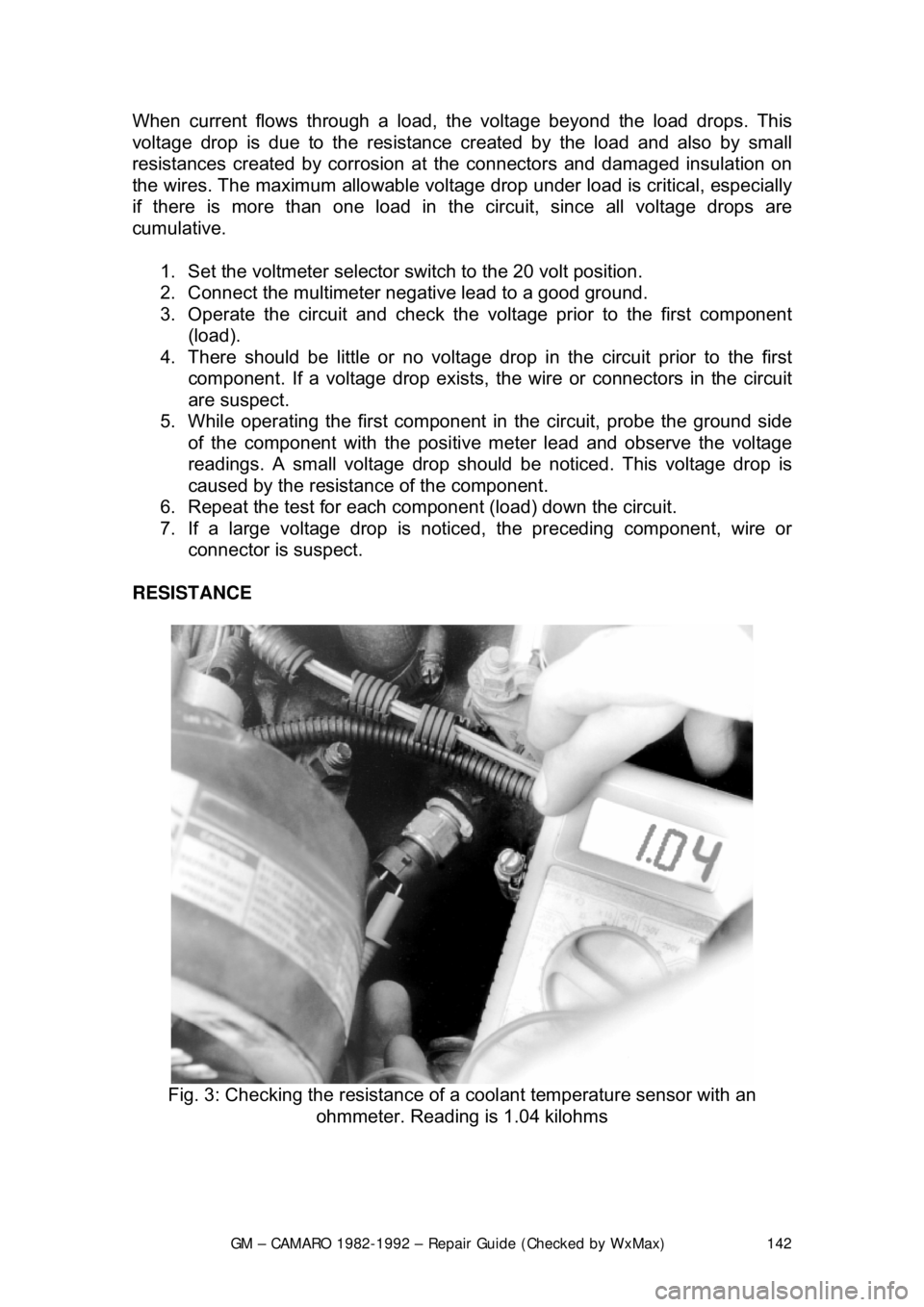

RESISTANCE

Fig. 3: Checking the resistance of a coolant temperature sensor with an

ohmmeter. Reading is 1.04 kilohms

Page 143 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 143

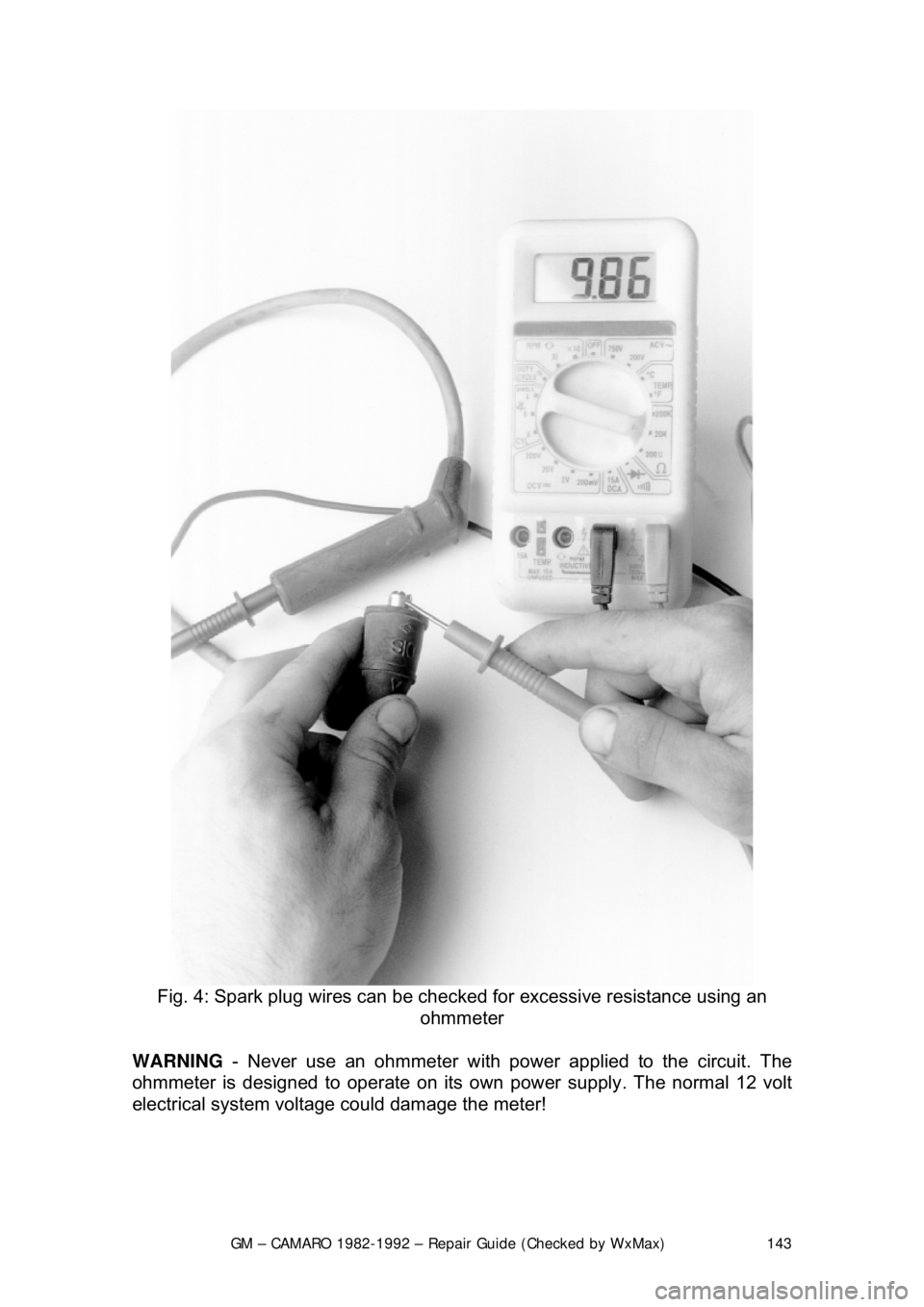

Fig. 4: Spark plug wires can be checked for excessive resistance using an

ohmmeter

WARNING - Never use an ohmmeter with power applied to the circuit. The

ohmmeter is designed to operate on its own power supply. The normal 12 volt

electrical system voltage could damage the meter!

Page 144 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 144

1. Isolate the circuit from

the vehicle's power source.

2. Ensure that the ignition key is OFF when disconnecting any components

or the battery.

3. Where necessary, also isolate at least one side of the circuit to be

checked, in order to avoid reading parallel resistances. Parallel circuit

resistances will always give a lower reading than the actual resistance of

either of the branches.

4. Connect the meter leads to both sides of the circuit (wire or component)

and read the actual measured ohms on the meter scale. Make sure the

selector switch is set to the proper ohm scale for the circuit being tested,

to avoid misreading the oh mmeter test value.

WIRE AND CONNECTOR REPAIR

Almost anyone can replace damaged wires, as long as the proper tools and

parts are available. Wire and terminals ar e available to fit almost any need.

Even the specialized weatherproof, mol ded and hard shell connectors are now

available from aftermarket suppliers.

Be sure the ends of all the wires are fitted with t he proper terminal hardware

and connectors. Wrapping a wire around a stud is never a permanent solution

and will only cause trouble later. Repl ace wires one at a time to avoid

confusion. Always route wires exac tly the same as the factory.

If connector repair is necessary, only atte mpt it if you have the proper tools.

Weatherproof and hard shell con nectors require special tools to release the pins

inside the connector. Attempting to r epair these connectors with conventional

hand tools will damage them.

BATTERY CABLES

DISCONNECTING THE CABLES

When working on any electrical component on the vehicle, it is always a good

idea to disconnect the negative (-) battery cable. This will prevent potential

damage to many sensitive electrical co mponents such as the Engine Control

Module (ECM), radio, alternator, etc.

Any time you disengage the battery cables, it is recommended that you

disconnect the negative (&mdash) battery cable first. This will prevent your

accidentally grounding the positive (+) term inal to the body of the vehicle when

disconnecting it, thereby prevent ing damage to the above mentioned

components.

Before you disconnect the cable(s), first turn the ignition to the OFF position.

This will prevent a draw on the battery which could cause arcing (electricity

trying to ground itself to the body of a vehi cle, just like a spark plug jumping the

gap) and, of course, damaging some com ponents such as the alternator diodes.

Page 145 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 145

When the battery cable(s) are reconnecte

d (negative cable last), be sure to

check that your lights, windshield wipers and other electrically operated safety

components are all working correctly. If your vehicle contains an Electronically

Tuned Radio (ETR), don't forget to also reset your radio stations. Ditto for the

clock.

Page 146 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 146

SUPPLEMENTAL INFLATABLE RESTRAINT SYSTEM

GENERAL INFORMATION

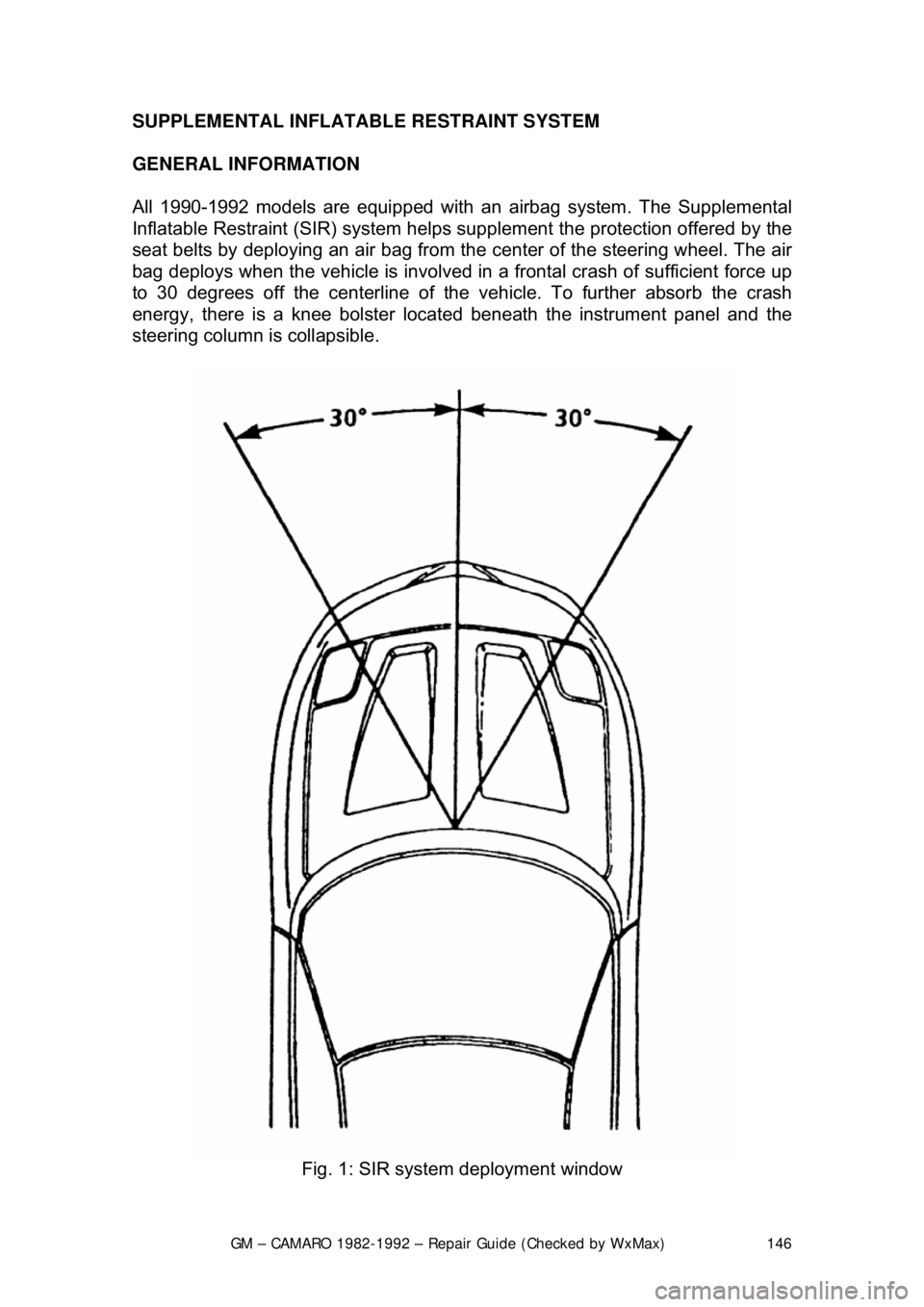

All 1990-1992 models are equi

pped with an airbag system. The Supplemental

Inflatable Restraint (SIR) syst em helps supplement the protection offered by the

seat belts by deploying an ai r bag from the center of the steering wheel. The air

bag deploys when the vehicle is involved in a frontal crash of sufficient force up

to 30 degrees off the center line of the vehicle. To further absorb the crash

energy, there is a knee bolster located beneath the instrument panel and the

steering column is collapsible.

Fig. 1: SIR system deployment window

Page 147 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 147

SYSTEM OPERATION

The main portions of the SIR system

are the deployment loops and the

Diagnostic Energy Reserve Module (D ERM). The main function of the

deployment loops is to supply current through the inflator module(s), which will

cause deployment of the air bag(s) in t he event of a frontal crash of sufficient

force. The arming sensor, SIR coil assembly (driver side only), passen\

ger

inflator module jumper (passenger side only), inflator module(s), passenger

compartment discriminating sensor and fo rward discriminating sensor make up

the deployment loops.

The DERM has two functions. One to supply the deployment loops with a 36

volt reserve to ensure sufficient energy is available to deploy the airbag(s) if the

battery voltage feed to the arming sensor is lost during a frontal crash. Another

function is SIR electrical system diagnostics.

The arming sensor switches power to th e inflator module(s) on the high side

(power side) of the deployment loops. Ei ther of the discriminating sensors can

supply ground to the inflator module(s) on the low side (ground side) of the loop.

The inflator module(s) ar e only supplied sufficient cu rrent to deploy when the

arming sensor and at least one of the two discriminating sensors are closed

simultaneously.

SYSTEM COMPONENTS

DIAGNOSTIC ENERGY RESERVE MODULE

The DERM is designed to perform the following functions in the SIR system:

• Energy Reserve - Maintains 36 volt energy reserve(s) to provide

deployment energy when the vehicle volt age is low or lost in a frontal

impact

• Malfunction Detection - Performs diagnostic monitoring of the SIR

system electrical components

• Malfunction Recording - Provides diagnostic trouble code information

• Frontal Crash Recording - Record s the SIR system status during a

frontal crash

WARNING LAMP

The "INFL REST" or "AIR BAG" warning lamp is used to do the following:

• Verify lamp and DERM oper ation by flashing seven to nine times when

the ignition key is first turned ON

• Warn the driver of SIR electrical system faults which could potentially

affect the operation of the SIR system

• Provide diagnostic information by fl ashing the fault codes when the

diagnostic mode is enabled

Page 148 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 148

ARMING SENSOR

The arming sensor is a protective switch

located in the power feed side of the

deployment loop. It is calibrated to clos e at low level velocity changes (lower

than the discriminating sens ors). This assures that the inflator module is

connected directly to the 36 volt output of the DERM or battery voltage feed

when either of the discrim inating sensors close.

DISCRIMINATING SENSORS

The discriminating sensors are wired in parallel on the ground side of the

deployment loop. These sensors are calib rated to close with velocity changes

which are severe enough to warrant deployment.

SIR COIL ASSEMBLY

The SIR coil assembly consists of two cu rrent carrying coils. They are attached

to the steering column and allow rotation of the steering wheel while maintaining

continuous contact of the deployment loop to the inflator module.

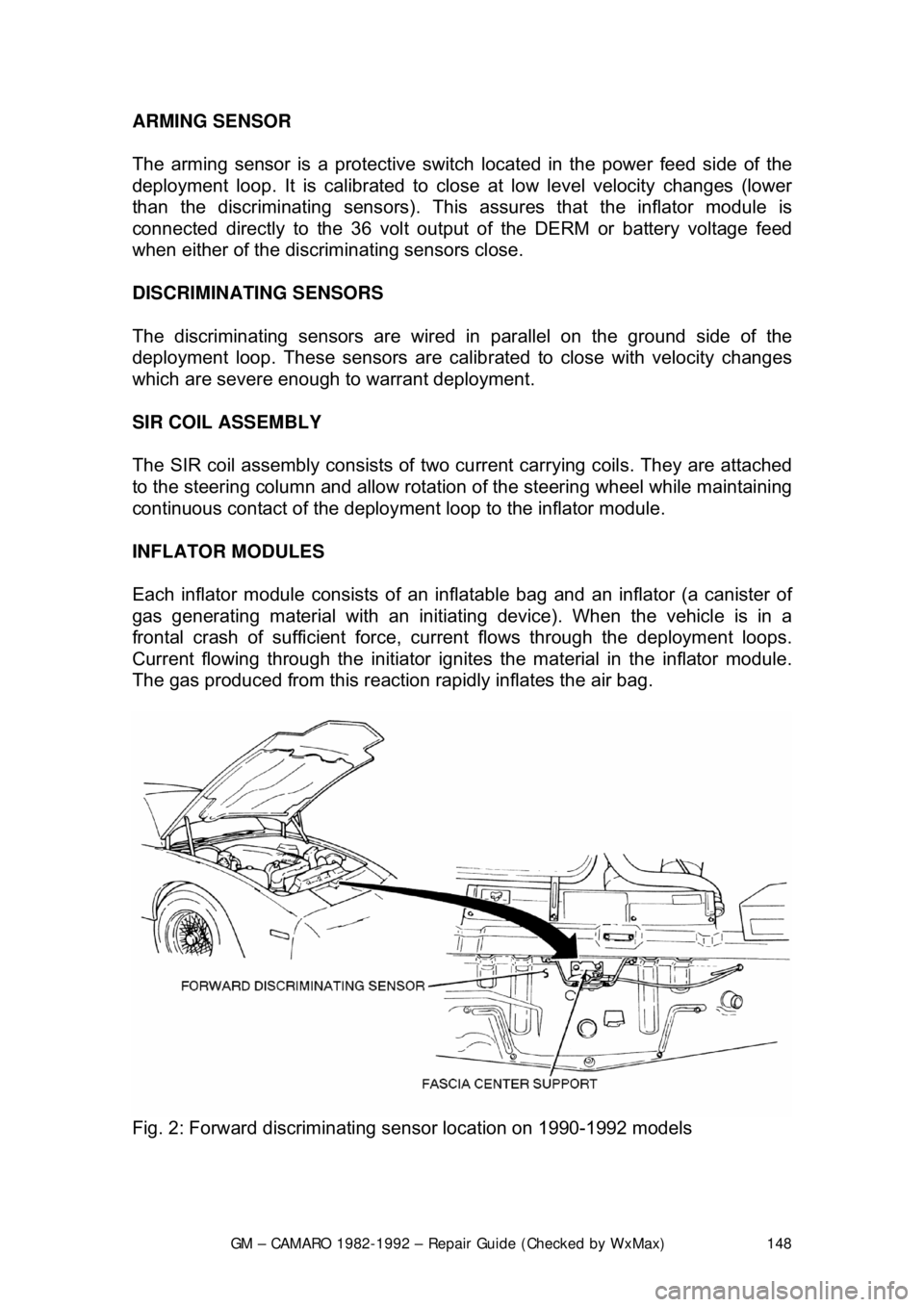

INFLATOR MODULES

Each inflator module consists of an inflat able bag and an inflator (a canister of

gas generating material with an initiati ng device). When the vehicle is in a

frontal crash of sufficient force, current flows through the deployment loops.

Current flowing through the initiator ignite s the material in the inflator module.

The gas produced from this reaction rapidly inflates the air bag.

Fig. 2: Forward discriminating se nsor location on 1990-1992 models

Page 149 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 149

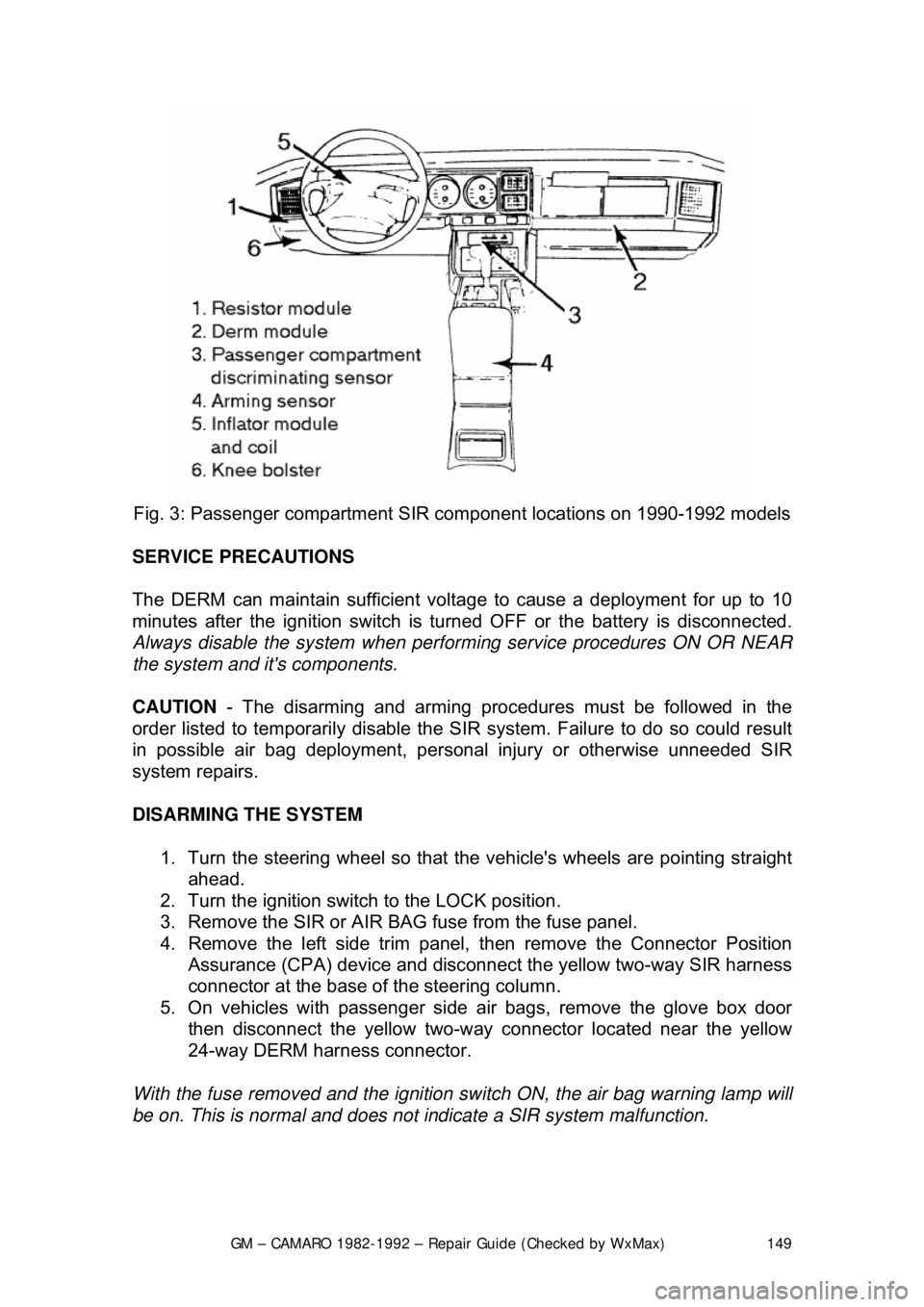

Fig. 3: Passenger com partment SIR component lo cations on 1990-1992 models

SERVICE PRECAUTIONS

The DERM can maintain sufficient volt age to cause a deployment for up to 10

minutes after the ignition switch is tur ned OFF or the battery is disconnected.

Always disable the system when perfo rming service procedures ON OR NEAR

the system and it's components.

CAUTION - The disarming and arming procedures must be followed in the

order listed to temporarily disable the SI R system. Failure to do so could result

in possible air bag deployment, pers onal injury or otherwise unneeded SIR

system repairs.

DISARMING THE SYSTEM

1. Turn the steering wheel so that t he vehicle's wheels are pointing straight

ahead.

2. Turn the ignition switch to the LOCK position.

3. Remove the SIR or AIR BAG fuse from the fuse panel.

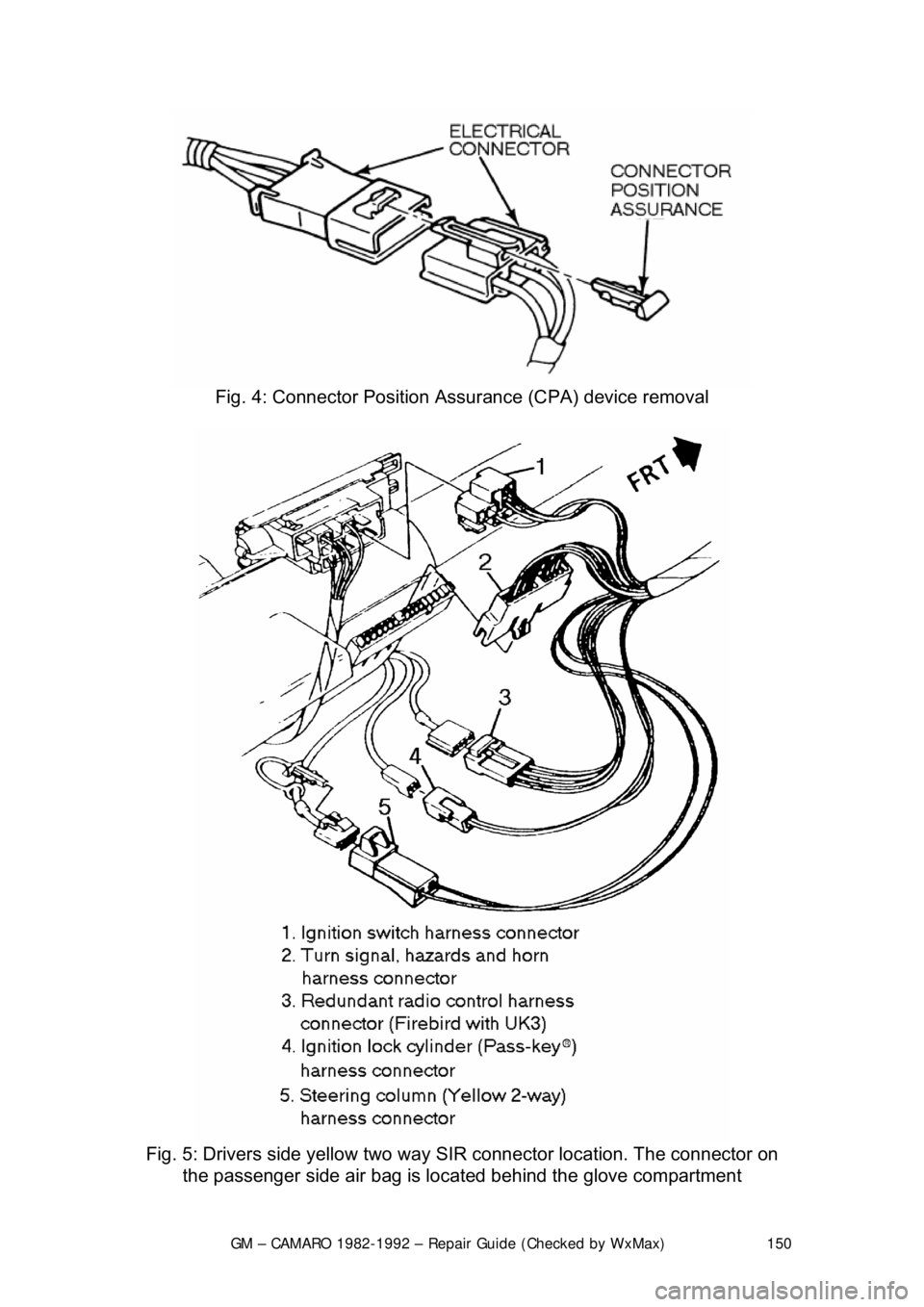

4. Remove the left side trim panel, t hen remove the Connector Position

Assurance (CPA) device and disconnec t the yellow two-way SIR harness

connector at the base of the steering column.

5. On vehicles with passenger side air bags, remove the glove box door

then disconnect the yellow two-way c onnector located near the yellow

24-way DERM harness connector.

With the fuse removed and the ignition sw itch ON, the air bag warning lamp will

be on. This is normal and does not indicate a SIR system malfunction.

Page 150 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 150

Fig. 4: Connector Position Assurance (CPA) device removal

Fig. 5: Drivers side yellow two way SIR connector location. The connecto\

r on

the passenger side air bag is loca ted behind the glove compartment