CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 121 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 121

air! Avoid inhaling any dust from any

brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

1. Raise the car and support it with jackstands.

2. Loosen the adjusting nut at the equalizer.

3. Disengage the rear cabl e at the connector.

4. Remove the wheel assembly and brake drum.

5. Bend the retainer fingers.

6. Disengage the cable at the brake shoe operating lever.

To install:

7. Engage the cable at the brake shoe operating lever.

8. Bend the retainer fingers.

9. Install the wheel a ssembly and brake drum.

10. Engage the rear cabl e at the connector.

11. Adjust the parking brake by t he adjusting nut at the equalizer.

12. Lower the car.

DISC BRAKES

1. Raise the car and support it with jackstands.

2. Loosen the adjusting nut at the equalizer.

3. Disengage the cable at the connector.

4. Push forward on the caliper parking brak e apply lever. This allows the cable

to be removed from the tang. Then, release the lever.

5. Pull on the caliper parki ng brake apply lever to engage the cable to the tang.

6. Engage the cable at the connector.

7. Adjust the parking brake cable by the adjusting nut at the equalizer.

8. Apply the parking brake 3 times with heavy pressure and repeat adjustment.

9. Lower the car.

ADJUSTMENT

The parking brake cable is adjustable only on 1982-89 vehicles. All 1990-92

vehicles feature a self- adjusting parking brake.

REAR DRUM BRAKES

1. Depress the parking brake leve r exactly two ratchet clicks.

2. Raise the rear of the vehicl e and support safely with jackstands.

3. Tighten the brake cable adjusting nut until the left rear wheel can be turned

rearward with both hands, but locks when forward rotation is attempted. \

4. Release the parking brake le ver; both rear wheels must turn freely in either

direction without brake drag.

5. Lower the vehicle.

Page 122 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 122

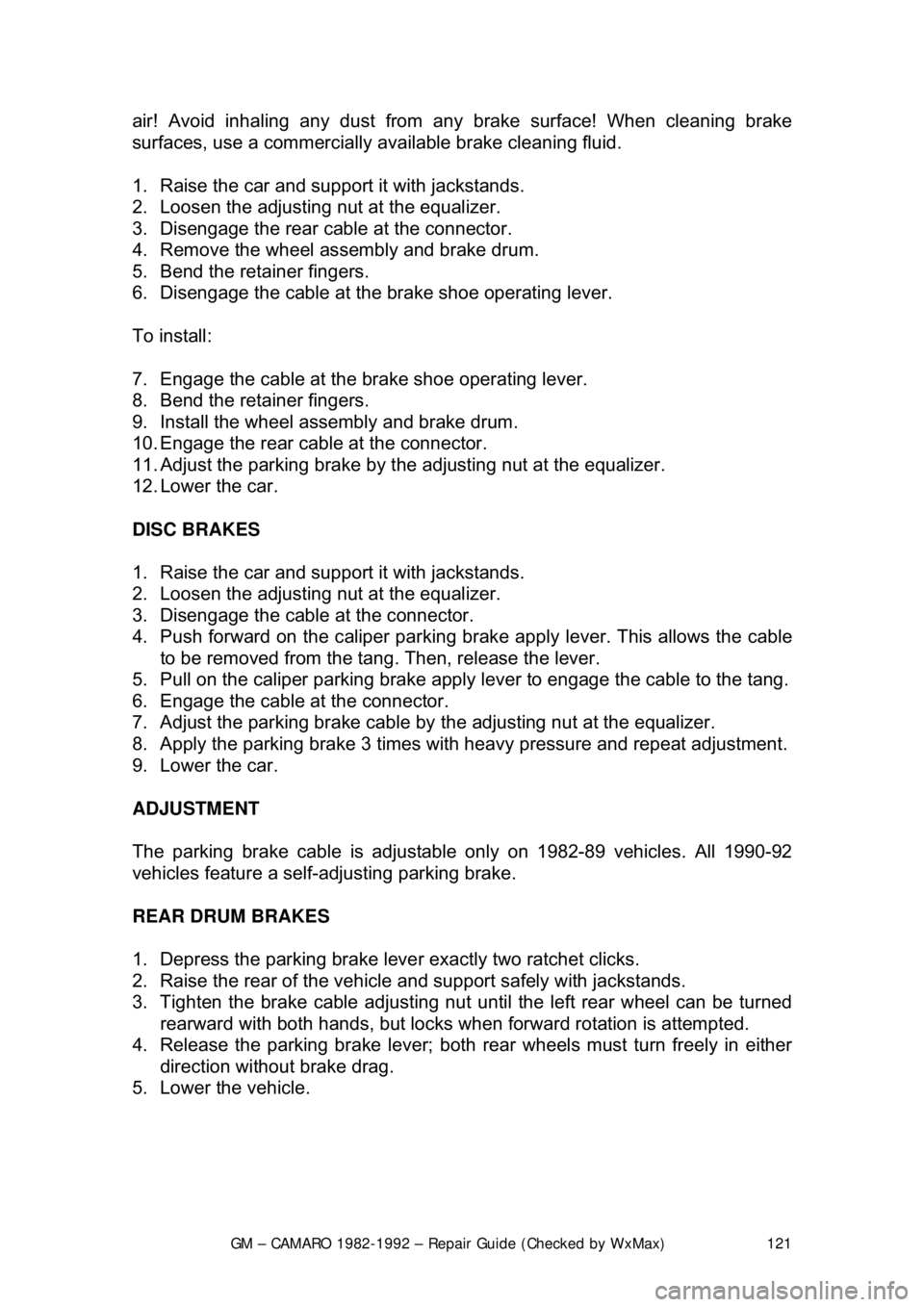

REAR DISC BRAKES

Fig. 3: Free trav el adjustment; 1990-92

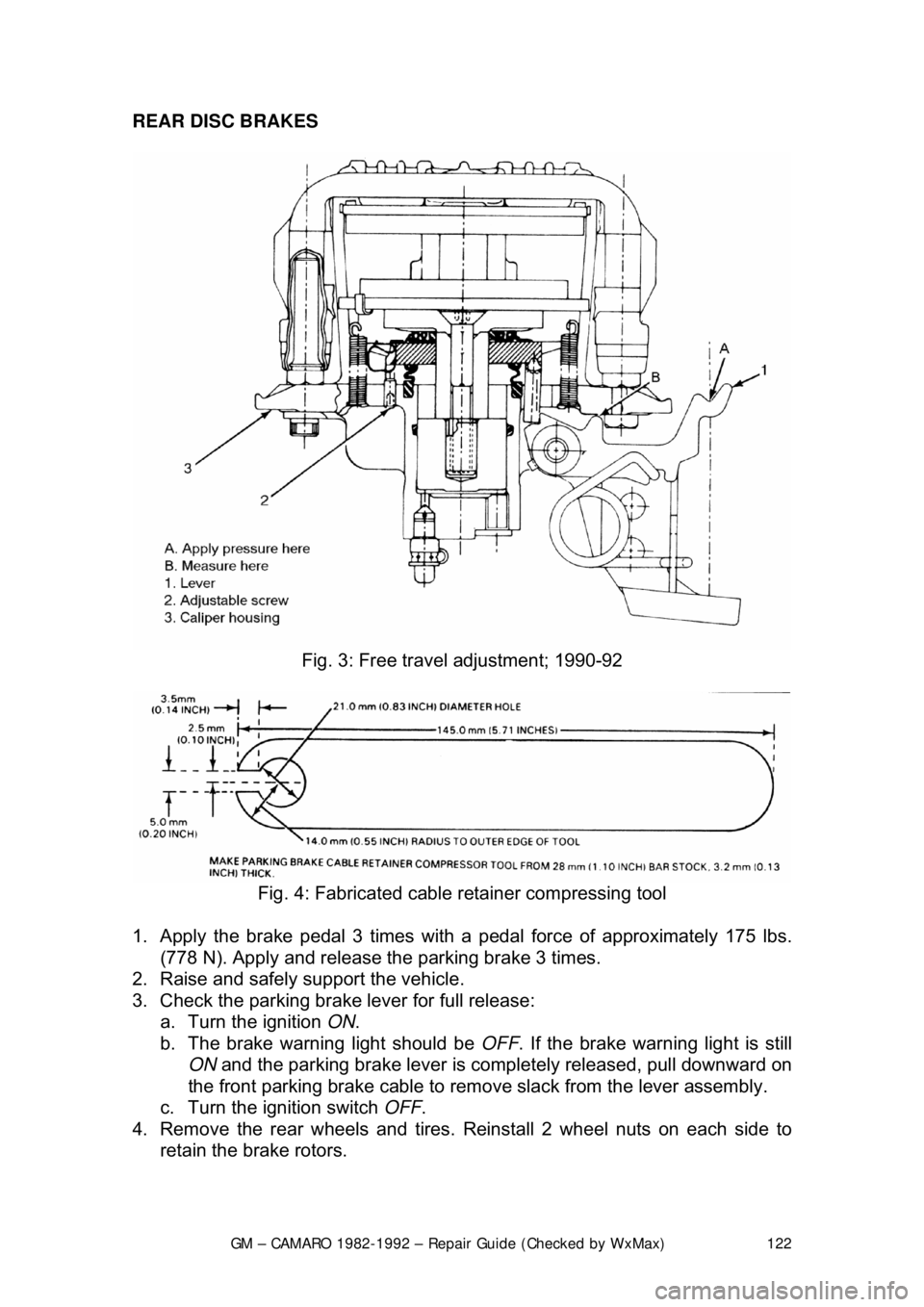

Fig. 4: Fabricated cable retainer compressing tool

1. Apply the brake pedal 3 times with a pedal force of approximately 175 lbs.

(778 N). Apply and release t he parking brake 3 times.

2. Raise and safely support the vehicle.

3. Check the parking brake lever for full release: a. Turn the ignition ON.

b. The brake warning light should be OFF. If the brake warning light is still

ON and the parking brake lever is comple tely released, pull downward on

the front parking brake cable to remove slack from the lever assembly.

c. Turn the ignition switch OFF.

4. Remove the rear wheels and tires. Reinstall 2 wheel nuts on each side to

retain the brake rotors.

Page 123 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 123

5. Pull the parking lever 4 clicks. T

he parking brake levers on both calipers

should be against the lever stops on the caliper housings. If the levers are

not against the stops, check for binding in the rear cables and/or loosen the

cables at the equalizer nut until both left and right levers are against their

stops.

6. Adjust the equalizer adjusting nut unt il the parking brake levers on both

calipers just begin to mo ve off their stops.

7. Back off the adjuster nut until the le vers move back, barely touching their

stops.

8. Operate the parking brak e lever several times to check adjustment. After

cable adjustment, the parking brake le ver should travel no more than 14

ratchet clicks. The rear wheels shoul d not turn forward when the parking

brake lever is applied 8-16 ratchet clicks.

9. Release the parking brake lever. Both rear whee ls must turn freely in both

directions. The parking brake levers on both calipers should be resting on

their stops.

10. Remove the wheel nuts retaining t he rotors. Install the wheel and tire

assemblies.

11. Lower the vehicle.

PARKING BRAKE FREE-TRAVEL

ADJUSTMENT

1989-92 MODELS

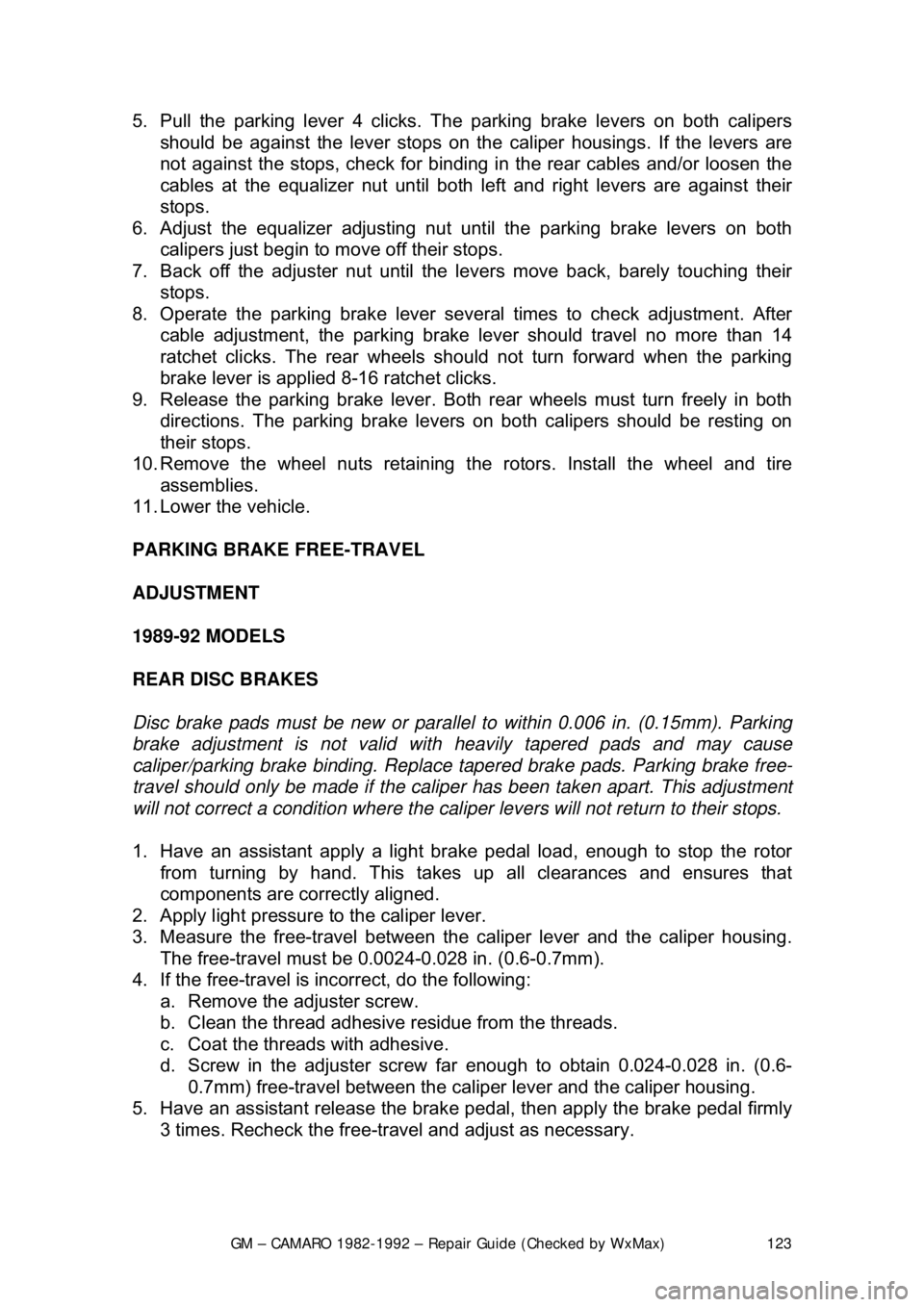

REAR DISC BRAKES

Disc brake pads must be new or parallel to within 0.006 in. (0.15mm). Parking

brake adjustment is not valid wit h heavily tapered pads and may cause

caliper/parking brake binding. Replace tapered brak e pads. Parking brake free-

travel should only be made if the caliper has been taken apart. This adjustment

will not correct a condition where the caliper levers will not return to their stops.

1. Have an assistant apply a light brake pedal load, enough to stop the rotor

from turning by hand. This takes up all clearances and ensures that

components are correctly aligned.

2. Apply light pressure to the caliper lever.

3. Measure the free-travel between t he caliper lever and the caliper housing.

The free-travel must be 0.0024-0.028 in. (0.6-0.7mm).

4. If the free-travel is incorrect, do the following: a. Remove the adjuster screw.

b. Clean the thread adhesive re sidue from the threads.

c. Coat the threads with adhesive.

d. Screw in the adjuster screw far enough to obtain 0.024-0.028 in. (0.6-

0.7mm) free-travel between the caliper lever and the caliper housing.

5. Have an assistant release the brak e pedal, then apply the brake pedal firmly

3 times. Recheck the free-travel and adjust as necessary.

Page 124 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 124

BRAKE LEVER

REMOVAL & INSTALLATION

1982-89 MODELS

1. Raise and safely support the vehicle.

2. Remove the adjusting nut

at the equalizer and remove the front cable from

the equalizer and bracket.

3. Lower the vehicle.

4. Remove the upper console and lower c onsole rear screws. Lift the rear of

the lower console to gain access to the parking brake control.

5. Remove the pin and retainer from t he control assembly and front cable.

6. Remove the cable and casing from the control assembly and bracket then

remove the cable and grommet from the vehicle. Remove the parking brake

lever mounting bolts and remove the assembly.

7. Installation is the reverse of t he removal procedure. Adjust the parking

brake.

1990-92 MODELS

1. Remove the carpet finish molding.

2. Remove the console assembly.

3. With the parking brake lever in the do wn position, rotate the arm toward the

front of the vehicle until a 3mm metal pen can be inserted into the hole.

Insert the metal pin into the hole, locking out the self adjuster.

4. Raise and safely support the vehicle.

5. Disconnect the rear cables from the equalizer.

6. Lower the vehicle.

7. Remove the barrel-shaped butt on from the adjuster track.

8. Remove the parking brake lever mounting bolts.

9. Remove the front cable and casing from the control assembly using a

fabricated parking brake cable retainer compressor tool.

10. Installation is the reverse of the removal procedure. Cycle the lever to set

the parking lever and cables in there proper location.

Page 125 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 125

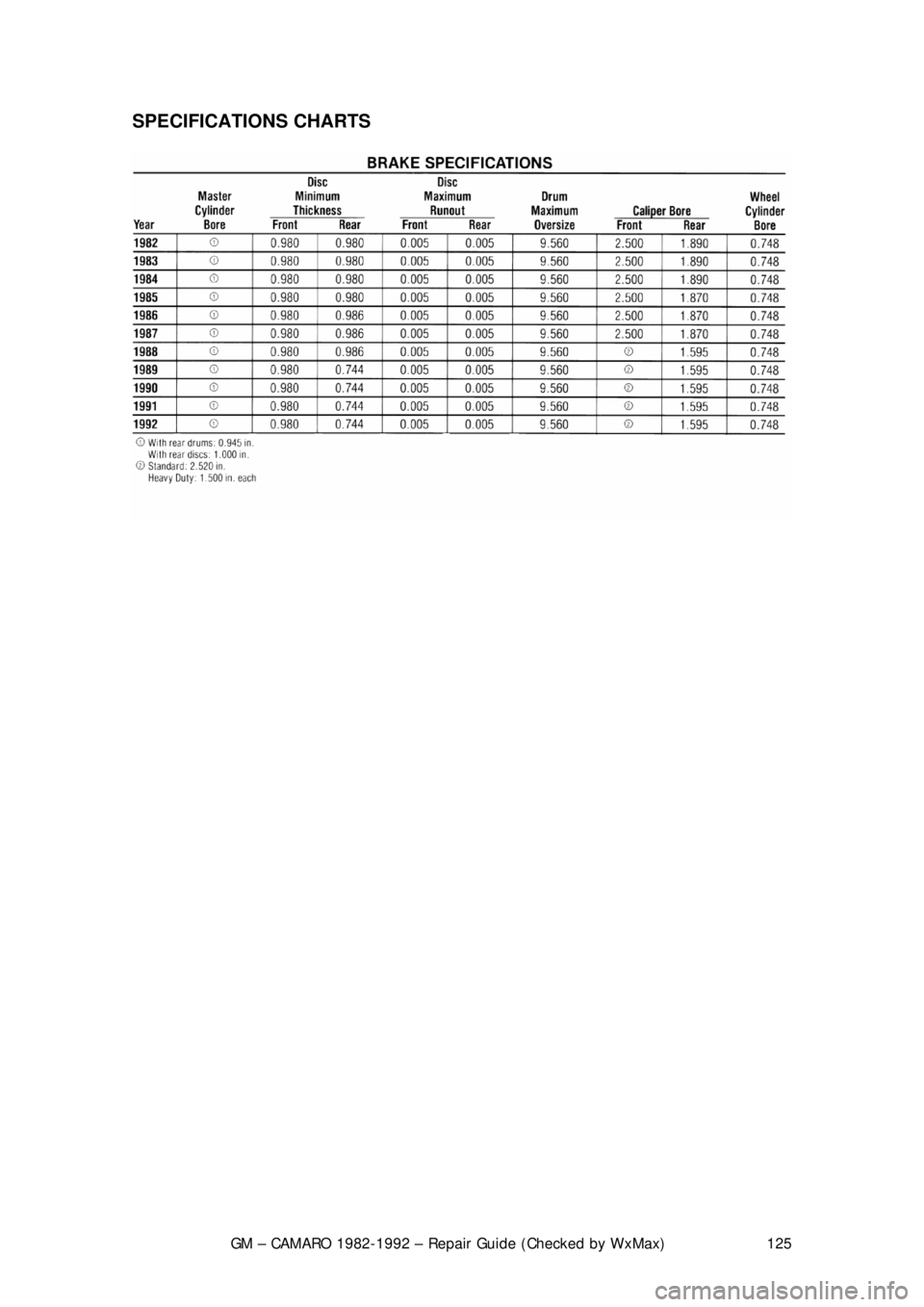

SPECIFICATIONS CHARTS

Page 126 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 126

CHASSIS ELECTRICAL

UNDERSTANDING AND TROUBLESHOOTING ELECTRICAL SYSTEMS

BASIC ELECTRICAL THEORY

For any 12 volt, negative ground, electrical system to operate, the electricity

must travel in a complete circuit. This simply means that current (power) from

the positive (+) terminal of the battery must eventually return to the negative (—

) terminal of the battery. Along the way, this current will travel through wires,

fuses, switches and components. If, for any reason, the flow of current through

the circuit is interrupted, the component f ed by that circuit will cease to function

properly.

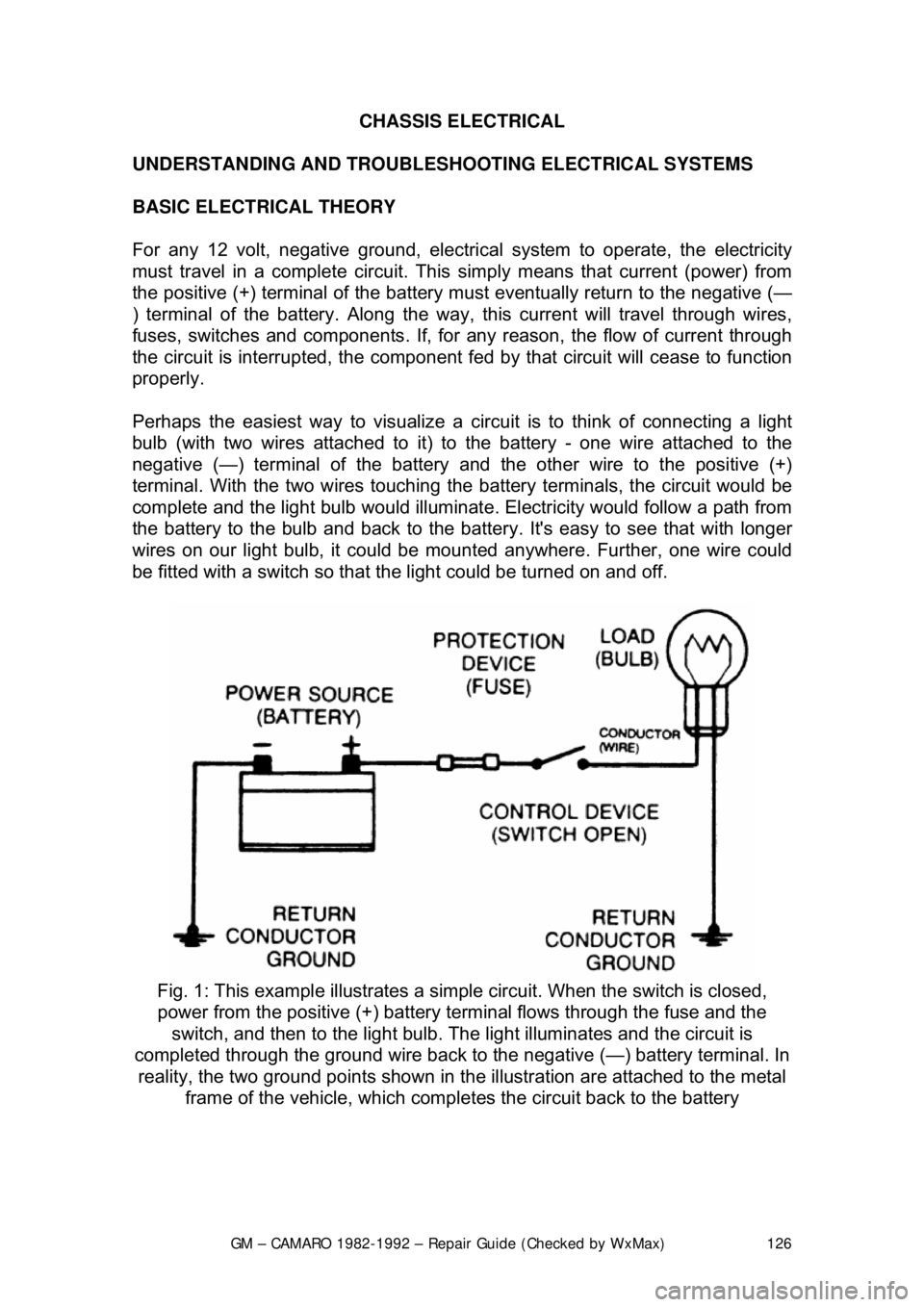

Perhaps the easiest way to visualize a circ uit is to think of connecting a light

bulb (with two wires attac hed to it) to the battery - one wire attached to the

negative (—) terminal of the battery and the other wire to the positive (+)

terminal. With the two wires touching the battery terminals, the circuit would be

complete and the light bulb would illuminat e. Electricity would follow a path from

the battery to the bulb and back to the bat tery. It's easy to see that with longer

wires on our light bulb, it could be mounted anywhere. Further, one wire could

be fitted with a switch so that t he light could be turned on and off.

Fig. 1: This example illu strates a simple circuit. Wh en the switch is closed,

power from the positive (+) battery te rminal flows through the fuse and the

switch, and then to the light bulb. The light illuminates and the circuit is

completed through the ground wire back to the negative (—) battery terminal. In

reality, the two ground point s shown in the illustration are attached to the metal

frame of the vehicle, which comple tes the circuit back to the battery

Page 127 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 127

The normal automotive circuit differs from

this simple example in two ways.

First, instead of having a return wire from the bulb to the battery, the current

travels through the frame of the vehicle. Since the negative (—) battery cable is

attached to the frame (made of electrically conductive metal), the frame of the

vehicle can serve as a ground wire to complete the circuit. Secondly, mo\

st

automotive circuits contain multiple components which receive power from a

single circuit. This lessens the amount of wire needed to power components on

the vehicle.

HOW DOES ELECTRICITY WORK: THE WATER ANALOGY

Electricity is the flow of electrons - t he subatomic particles that constitute the

outer shell of an atom. Elec trons spin in an orbit around the center core of an

atom. The center core is comprised of protons (positive charge) and neutrons

(neutral charge). Electrons have a negativ e charge and balance out the positive

charge of the protons. When an outside forc e causes the number of electrons to

unbalance the charge of the protons, the electrons will split off the atom and

look for another atom to balance out. If th is imbalance is kept up, electrons will

continue to move and an elec trical flow will exist.

Many people have been taught electrical th eory using an analogy with water. In

a comparison with water flowing through a pipe, the electrons would be the

water and the wire is the pipe.

The flow of electricity can be measur ed much like the flow of water through a

pipe. The unit of measur ement used is amperes, frequently abbreviated as

amps (a). You can compare amperage to th e volume of water flowing through a

pipe. When connected to a circuit, an ammeter will measure the actual amount

of current flowing through the circuit. W hen relatively few electrons flow through

a circuit, the amperage is low. When many electrons flow, the amperage is high.

Water pressure is measured in units su ch as pounds per square inch (psi); The

electrical pressure is m easured in units called volts (v). When a voltmeter is

connected to a circuit, it is meas uring the electrical pressure.

The actual flow of electricity depends not only on voltage and amperage, but

also on the resistance of the circuit. T he higher the resistance, the higher the

force necessary to push the current through the circuit. The standard unit for

measuring resistance is an ohm. Resistance in a circuit varies depending on the

amount and type of components used in t he circuit. The main factors which

determine resistance are:

• Material - some materials have more resistance than others. Those with

high resistance are said to be insulato rs. Rubber materials (or rubber-like

plastics) are some of the most common insulators used in vehicles as

they have a very high resistance to electricity. Very low resistance

materials are said to be conductors. Copper wire is among the best

conductors. Silver is actually a super ior conductor to copper and is used

in some relay contacts, but its hi gh cost prohibits its use as common

wiring. Most automotive wir ing is made of copper.

Page 128 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 128

•

Size - the larger the wire size being used, the less resistance the wire will

have. This is why components which use large amounts of electricity

usually have large wires suppl ying current to them.

• Length - for a given thickness of wire, the longer the wire, the greater the

resistance. The shorter the wire, the less the resistance. When

determining the proper wire for a circ uit, both size and length must be

considered to design a circuit that can handle the current needs of the

component.

• Temperature - with many materials, the higher the temperature, the

greater the resistance (positive temper ature coefficient). Some materials

exhibit the opposite trait of lower re sistance with higher temperatures

(negative temperature coefficient). Thes e principles are used in many of

the sensors on the engine.

OHM'S LAW

There is a direct relationship between current, voltage and resistance. The

relationship between current, voltage and resistance can be summed up by a

statement known as Ohm's law.

Voltage (E) is equal to amper age (I) times resistance (R): E=I x ROther forms of

the formula are R=E/I and I=E/R

In each of these formulas, E is the voltage in volts, I is the current in amps and

R is the resistance in ohms. The basic point to remember is that as the

resistance of a circuit goes up, the amount of current that flows in the circuit will

go down, if voltage remains the same.

The amount of work that the electricity can perform is expressed as power. The

unit of power is the watt (w). The re lationship between power, voltage and

current is expressed as:

Power (w) is equal to amperage (I) times voltage (E): W=I x EThis is only true

for direct current (DC) circuits; The alte rnating current formula is a tad different,

but since the electrical circuits in mo st vehicles are DC type, we need not get

into AC circuit theory.

ELECTRICAL COMPONENTS

POWER SOURCE

Power is supplied to the vehicle by tw o devices: The battery and the alternator.

The battery supplies electrical power dur ing starting or during periods when the

current demand of the vehicle's electrical system exceeds the output capacity of

the alternator. The alternator supplies electrical current when the engine is

running. Just not does the al ternator supply the current needs of the vehicle, but

it recharges the battery.

Page 129 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 129

THE BATTERY

In most modern vehicles, the battery is

a lead/acid electrochemical device

consisting of six 2 volt subs ections (cells) connected in se ries, so that the unit is

capable of producing approximately 12 volt s of electrical pressure. Each

subsection consists of a series of positive and negative plates held a short

distance apart in a solution of sulfuric acid and water.

The two types of plates are of dissim ilar metals. This sets up a chemical

reaction, and it is this r eaction which produces current flow from the battery

when its positive and negative terminals are connected to an electrical \

load .

The power removed from the battery is r eplaced by the alternator, restoring the

battery to its original chemical state.

THE ALTERNATOR

On some vehicles there isn't an alter nator, but a generator. The difference is

that an alternator supplies alternating current which is then changed to direct

current for use on the vehicle, while a generator produces direct current.

Alternators tend to be more efficient and that is why they are used.

Alternators and generators are devices t hat consist of coils of wires wound

together making big electrom agnets. One group of coils spins within another set

and the interaction of the magnetic fields causes a current to flow. This current

is then drawn off the coils and fed into the vehicles electrical system.

GROUND

Two types of grounds are used in automot ive electric circuits. Direct ground

components are grounded to the frame thr ough their mounting points. All other

components use some sort of ground wire which is attached to the frame or

chassis of the vehicle. The electrical current runs through the chassis of the

vehicle and returns to the battery thr ough the ground (—) cable; if you look,

you'll see that the battery ground cabl e connects between the battery and the

frame or chassis of the vehicle.

It should be noted that a good percentage of electrical problems can be traced

to bad grounds.

PROTECTIVE DEVICES

It is possible for large surges of current to pass through the electrical system of

your vehicle. If this surge of current we re to reach the load in the circuit, the

surge could burn it out or severely dam age it. It can also overload the wiring,

causing the harness to get hot and melt t he insulation. To prevent this, fuses,

circuit breakers and/or fusible links are connected into the supply wires of the

electrical system. These items are nothing more than a built-in weak spot in the

system. When an abnormal amount of curr ent flows through the system, these

protective devices work as fo llows to protect the circuit:

Page 130 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 130

•

Fuse - when an excessive electrical current passes through a fuse, the

fuse "blows" (the conductor melts) and opens the circuit, preventing the

passage of current.

Fig. 1: Most vehicles use one or more fuse panels. This one is located on the

driver's side kick panel