CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 131 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 131

•

Circuit Breaker - a circuit breaker is basically a self-repairing fuse. It will

open the circuit in the same fashio n as a fuse, but when the surge

subsides, the circuit breaker can be reset and does not need

replacement.

• Fusible Link - a fusible link (fuse link or main link) is a short length of

special, high temperatur e insulated wire that acts as a fuse. When an

excessive electrical current passes th rough a fusible link, the thin gauge

wire inside the link melt s, creating an intentional open to protect the

circuit. To repair the circuit, the link must be replaced. Some newer type

fusible links are housed in plug-in modules, which are simply replaced

like a fuse, while older type fusible lin ks must be cut and spliced if they

melt. Since this link is very early in the electrical path, it's the first place to

look if nothing on the vehicle works, yet the battery seems to be charged

and is properly connected.

CAUTION - Always replace fuses, circ uit breakers and fusible links with

identically rated component s. Under no circumstances should a component of

higher or lower amperage rating be substituted.

SWITCHES & RELAYS

Switches are used in electrical circuits to control the passage of current. The

most common use is to open and close circuits between the battery and the

various electric devices in the system. Switches are rated according to the

amount of amperage they c an handle. If a sufficient amperage rated switch is

not used in a circuit, the switch could overload and cause damage.

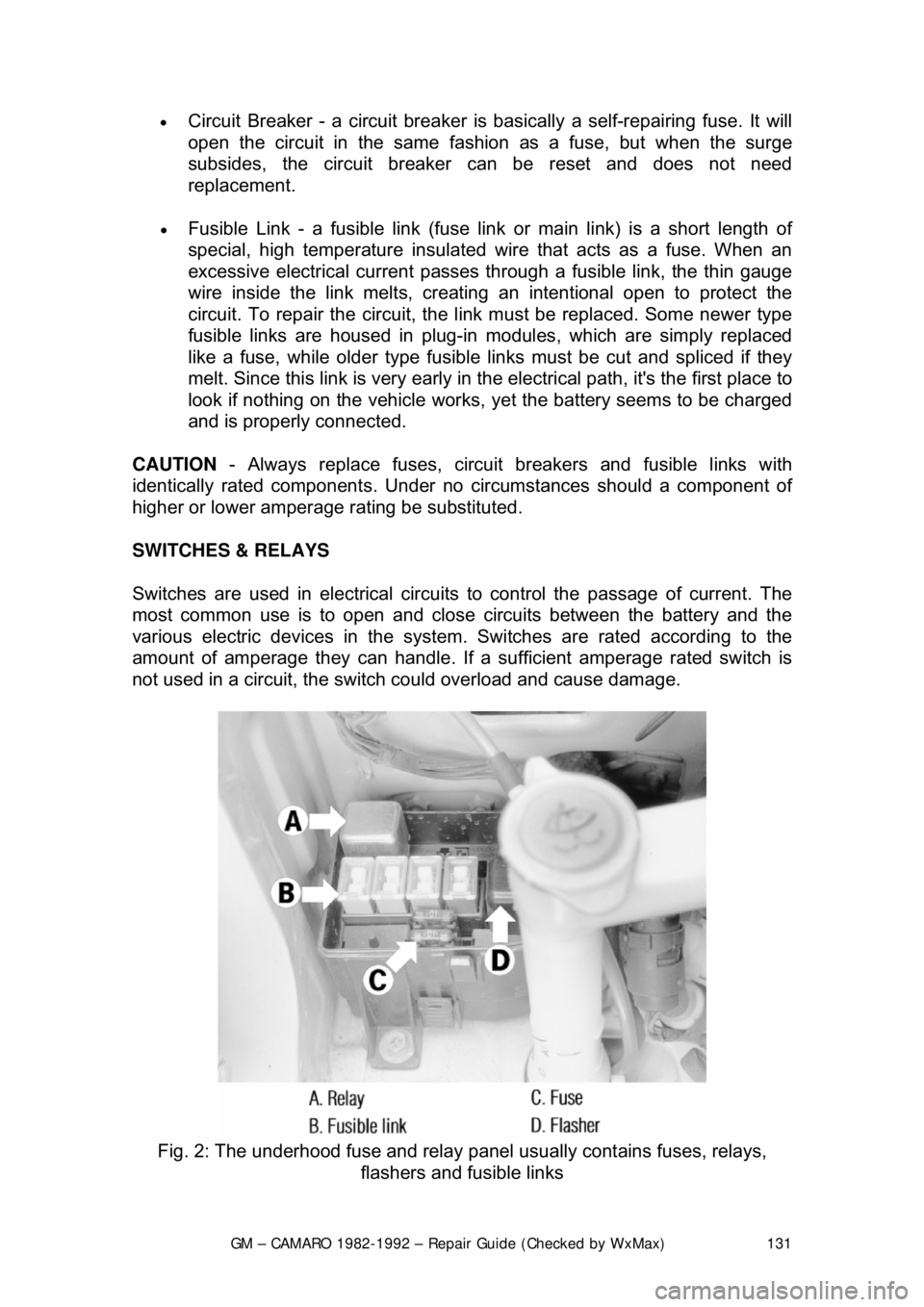

Fig. 2: The underhood fuse and relay panel usually contains fuses, relays,

flashers and fusible links

Page 132 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 132

Some electrical components which require

a large amount of current to operate

use a special switch called a relay. Sinc e these circuits carry a large amount of

current, the thickness of the wire in the ci rcuit is also greater. If this large wire

were connected from the load to the c ontrol switch, the switch would have to

carry the high amperage load and the fair ing or dash would be twice as large to

accommodate the increased size of t he wiring harness. To prevent these

problems, a relay is used.

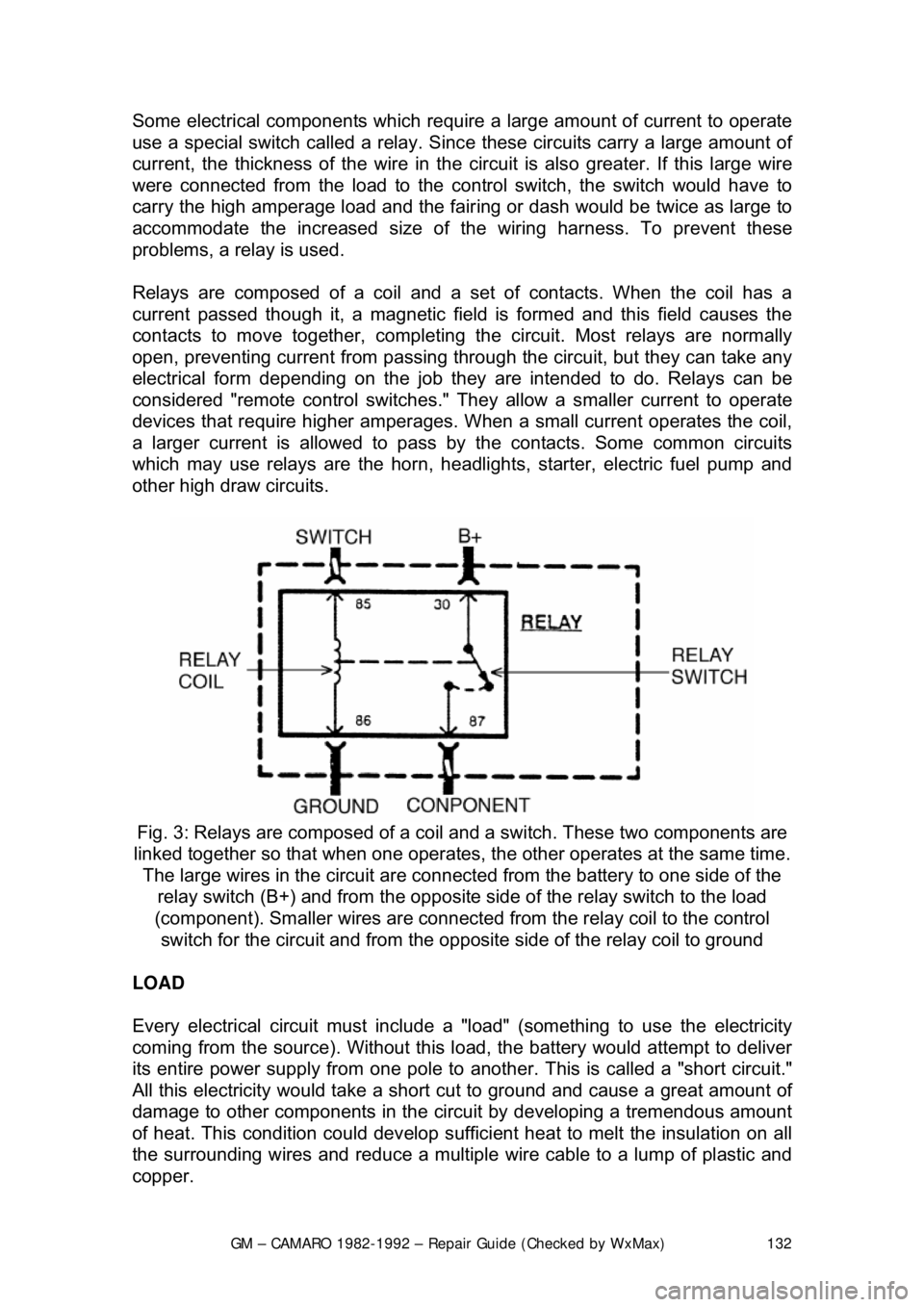

Relays are composed of a coil and a se t of contacts. When the coil has a

current passed though it, a magnetic fiel d is formed and this field causes the

contacts to move together, completing the circuit. Most relays are normally

open, preventing current from passing thr ough the circuit, but they can take any

electrical form depending on th e job they are intended to do. Relays can be

considered "remote control switches." They allow a smaller current to operate

devices that require higher amperages. W hen a small current operates the coil,

a larger current is allo wed to pass by the contacts. Some common circuits

which may use relays are the horn, headlight s, starter, electric fuel pump and

other high draw circuits.

Fig. 3: Relays are composed of a coil and a switch. These two components are

linked together so that w hen one operates, the other operat es at the same time.

The large wires in the circuit are connect ed from the battery to one side of the

relay switch (B+) and from the opposite side of the re lay switch to the load

(component). Smaller wires are connected from the relay coil to the control

switch for the circuit and from the opposite side of the relay coil to ground

LOAD

Every electrical circuit must include a "load" (something to use the electricity

coming from the source). Without this l oad, the battery would attempt to deliver

its entire power supply from one pole to another. This is called a "short circuit."

All this electricity would take a short cut to ground and cause a great amount of

damage to other components in the circui t by developing a tremendous amount

of heat. This condition could develop suffici ent heat to melt the insulation on all

the surrounding wires and reduce a multiple wire cable to a lump of plastic and

copper.

Page 133 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 133

WIRING & HARNESSES

The average vehicle contains meters

and meters of wiring, with hundreds of

individual connections. To protect the many wires from damage and to keep

them from becoming a confusing tangl e, they are organized into bundles,

enclosed in plastic or taped together and called wiring harnesses. Different

harnesses serve different parts of the vehi cle. Individual wires are color coded

to help trace them through a harness wher e sections are hidden from view.

Automotive wiring or circuit conductors can be either single strand wire, multi-

strand wire or printed circui try. Single strand wire has a solid metal core and is

usually used inside such components as alternators, motors, relays and other

devices. Multi-strand wire has a core made of many small strands of wire

twisted together into a single conductor. Most of the wiring in an automotive

electrical system is made up of multi-strand wire, either as a single conductor or

grouped together in a harness. All wiring is color coded on the insulator, either

as a solid color or as a colored wire wit h an identification stripe. A printed circuit

is a thin film of copper or other conducto r that is printed on an insulator backing.

Occasionally, a printed circuit is sandwic hed between two sheets of plastic for

more protection and flexibility. A comp lete printed circuit, consisting of

conductors, insulating material and connec tors for lamps or other components

is called a printed circuit board. Printed ci rcuitry is used in place of individual

wires or harnesses in places where space is limit ed, such as behind instrument

panels.

Since automotive electrical systems are very sensitive to changes in resistance,

the selection of properly sized wires is critical when systems are repaired. A

loose or corroded connection or a replacem ent wire that is too small for the

circuit will add extra resistance and an addi tional voltage drop to the circuit.

The wire gauge number is an expression of the cross-section area of the

conductor. Vehicles from countries that use the metric system will typically

describe the wire size as its cross-secti onal area in square millimeters. In this

method, the larger the wire, the gr eater the number. Another common system

for expressing wire size is the Americ an Wire Gauge (AWG) system. As gauge

number increases, area decreases and the wire becomes smaller. An 18 gauge

wire is smaller than a 4 gauge wire. A wire with a higher gauge number will

carry less current than a wire with a lower gauge number. Gauge wire size

refers to the size of the strands of the conductor, not the size of the complete

wire with insulator. It is possi ble, therefore, to have two wires of the same gauge

with different diameters because one may hav e thicker insulation than the other.

It is essential to understand how a circuit works before trying to figure out why it

doesn't. An electrical schematic shows the electrical current paths when a

circuit is operating proper ly. Schematics break the enti re electrical system down

into individual circuits. In a schematic, usually no attempt is made to represent

wiring and components as they physically appear on the vehicle; switches and

other components are shown as simply as possible. Face views of harness

connectors show the cavity or terminal lo cations in all multi-pin connectors to

help locate test points.

Page 134 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 134

CONNECTORS

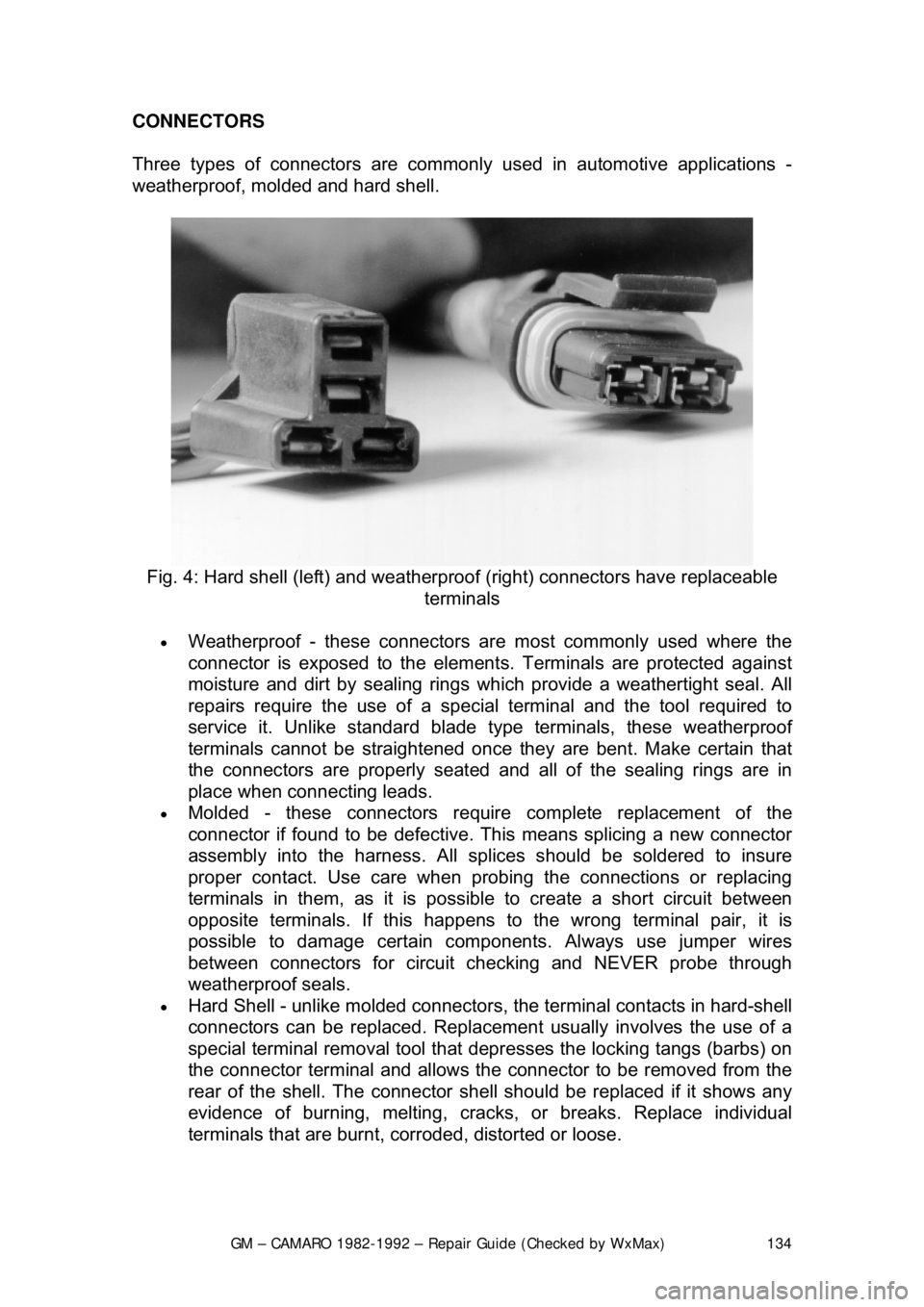

Three types of connectors

are commonly used in automotive applications -

weatherproof, molded and hard shell.

Fig. 4: Hard shell (left) and weather proof (right) connectors have replaceable

terminals

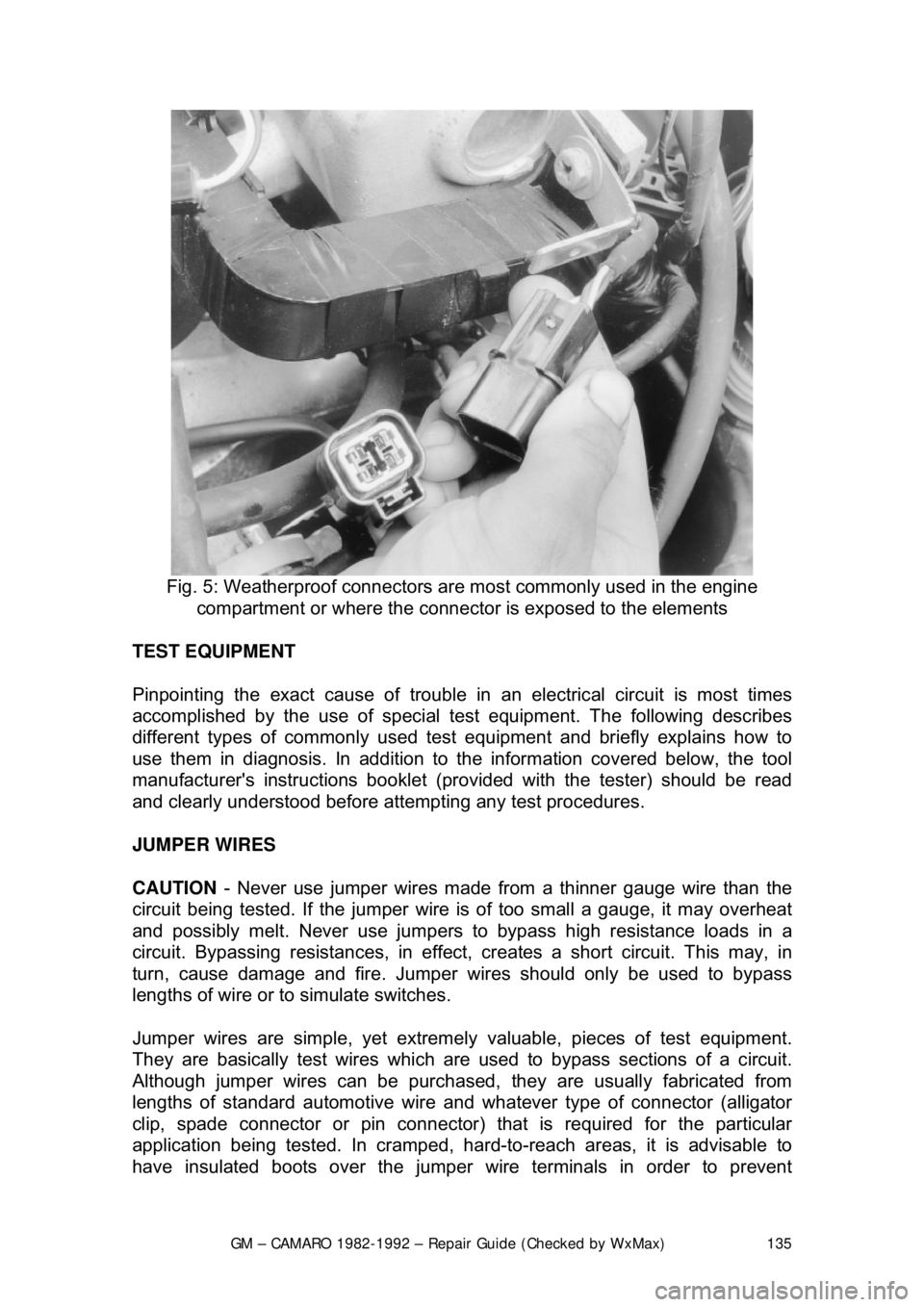

• Weatherproof - these connectors ar e most commonly used where the

connector is exposed to the element s. Terminals are protected against

moisture and dirt by sealing rings wh ich provide a weathertight seal. All

repairs require the use of a specia l terminal and the tool required to

service it. Unlike standard blade ty pe terminals, these weatherproof

terminals cannot be straightened once they are bent. Make certain that

the connectors are properly seated and all of the sealing rings are in

place when connecting leads.

• Molded - these connectors require complete replacement of the

connector if found to be defective. This means splicing a new connector

assembly into the harness. All sp lices should be soldered to insure

proper contact. Use care when probi ng the connections or replacing

terminals in them, as it is possibl e to create a short circuit between

opposite terminals. If this happens to the wrong terminal pair, it is

possible to damage certain com ponents. Always use jumper wires

between connectors for circuit c hecking and NEVER probe through

weatherproof seals.

• Hard Shell - unlike molded connectors, the terminal contacts in hard-shell

connectors can be replaced. Replacement usually involves the use of a

special terminal removal tool that depresses the locking tangs (barbs)\

on

the connector terminal and allows the connector to be removed from the

rear of the shell. The connector she ll should be replaced if it shows any

evidence of burning, melting, cracks, or breaks. Replace individual

terminals that are burnt, corroded, distorted or loose.

Page 135 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 135

Fig. 5: Weatherproof connectors ar e most commonly used in the engine

compartment or where the connecto r is exposed to the elements

TEST EQUIPMENT

Pinpointing the exact cause of trouble in an electrical circuit is most times

accomplished by the use of special te st equipment. The following describes

different types of commonly used test eq uipment and briefly explains how to

use them in diagnosis. In addition to t he information covered below, the tool

manufacturer's instructions booklet (pro vided with the tester) should be read

and clearly understood before atte mpting any test procedures.

JUMPER WIRES

CAUTION - Never use jumper wires made from a thinner gauge wire than the

circuit being tested. If the jumper wire is of too small a gauge, it may overheat

and possibly melt. Never use jumpers to bypass high resistance loads in a

circuit. Bypassing resistances, in effect, cr eates a short circuit. This may, in

turn, cause damage and fire. Jumper wi res should only be used to bypass

lengths of wire or to simulate switches.

Jumper wires are simple, yet extremel y valuable, pieces of test equipment.

They are basically test wir es which are used to bypass sections of a circuit.

Although jumper wires can be purchased, they are usually fabricated from

lengths of standard automot ive wire and whatever type of connector (alligator

clip, spade connector or pin connector) that is required for the particular

application being tested. In cramped, hard- to-reach areas, it is advisable to

have insulated boots over the jumper wire terminals in order to prevent

Page 136 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 136

accidental grounding. It is al

so advisable to include a standard automotive fuse

in any jumper wire. This is commonly referred to as a "fused jumper". By

inserting an in-line fuse holder between a set of test leads, a fused jumper wire

can be used for bypassing open circuits. Use a 5 amp fuse to provide protection

against voltage spikes.

Jumper wires are used primarily to locate open electrical circuits, on either the

ground (—) side of the circuit or on the power (+) side. If an electrical

component fails to operate, connect t he jumper wire between the component

and a good ground. If the component operates only with the jumper installed,

the ground circuit is open. If the ground circuit is good, but the component does

not operate, the circuit between the power feed and component may be open.

By moving the jumper wire successively back from the component toward the

power source, you can isolate the area of the circuit where the open is located.

When the component stops func tioning, or the power is cut off, the open is in

the segment of wire between the jumper and the point previously tested.

You can sometimes connect the jumper wir e directly from the battery to the

"hot" terminal of the component, but firs t make sure the component uses 12

volts in operation. Some electrical components, such as fuel injectors or

sensors, are designed to operate on about 4 to 5 volts, and running 12 volts

directly to these components will cause damage.

TEST LIGHTS

Fig. 1: A 12 volt test light is used to detect the presence of voltage in a circuit

The test light is used to check circuits and components while electrical current is

flowing through them. It is used for volt age and ground tests. To use a 12 volt

test light, connect the ground clip to a good ground and probe wherever

necessary with the pick. The test light will illuminate when voltage is detected.

This does not necessarily mean that 12 volts (or any particular amount of

Page 137 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 137

voltage) is present; it only means that so

me voltage is present. It is advisable

before using the test light to touch its ground clip and probe across the battery

posts or terminals to make sure the light is operating properly.

WARNING - Do not use a test light to probe electronic ignition, spark plug or

coil wires. Never use a pick-type test light to probe wiring on computer

controlled systems unless spec ifically instructed to do so. Any wire insulation

that is pierced by the test light pr obe should be taped and sealed with silicone

after testing

Like the jumper wire, the 12 volt test li ght is used to isolate opens in circuits.

But, whereas the jumper wire is used to bypass the open to operate the load,

the 12 volt test light is us ed to locate the presence of voltage in a circuit. If the

test light illuminates, there is power up to t hat point in the circuit; if the test light

does not illuminate, there is an open circui t (no power). Move the test light in

successive steps back toward the power source until the light in the handle

illuminates. The open is between the pr obe and a point which was previously

probed.

The self-powered test light is similar in design to the 12 volt test light, but

contains a 1.5 volt penlight battery in the handle. It is most often used in place

of a multimeter to check for open or shor t circuits when power is isolated from

the circuit (continuity test).

The battery in a self-powered test light does not provide much current. A weak

battery may not provide enough power to illuminate the test light even when a

complete circuit is made (especially if there is high resistance in the circuit).

Always make sure that the test battery is strong. To check the battery, briefly

touch the ground clip to the pr obe; if the light glows brightly, the battery is strong

enough for testing.

A self-powered test light should not be used on any co mputer controlled system

or component. The small amount of electr icity transmitted by the test light is

enough to damage many electr onic automotive components.

MULTIMETERS

Multimeters are an extremely useful tool for troubleshooting electrical problems.

They can be purchased in either analog or digital form and have a price range

to suit any budget. A multimeter is a voltmeter, ammeter and ohmmeter (along

with other features) combined into one instrument. It is often used when testing

solid state circuits because of its hi gh input impedance (usually 10 megaohms

or more). A brief description of the mult imeter main test functions follows:

• Voltmeter - the voltmeter is used to measure voltage at any point in a

circuit, or to measure the voltage drop across any part of a circuit.

Voltmeters usually have various scales and a selector switch to allow the

reading of different volt age ranges. The voltmeter has a positive and a

negative lead. To avoid damage to the meter, always connect the

negative lead to the negative (—) side of the circ uit (to ground or nearest

Page 138 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 138

the ground side of the circuit) and

connect the positive lead to the

positive (+) side of the circuit (to t he power source or the nearest power

source). Note that the negative voltme ter lead will always be black and

that the positive voltmeter will alwa ys be some color other than black

(usually red).

• Ohmmeter - the ohmmeter is designed to read resistance (measured in

ohms) in a circuit or component. Mo st ohmmeters will have a selector

switch which permits the measurement of different ranges of resistance

(usually the selector swit ch allows the multiplication of the meter reading

by 10, 100, 1,000 and 10,000). Some ohmmeters are "auto-ranging"

which means the meter itself will dete rmine which scale to use. Since the

meters are powered by an internal battery, the ohmmeter can be used

like a self-powered test light. When the ohmmeter is connected, current

from the ohmmeter flows through the ci rcuit or component being tested.

Since the ohmmeter's internal resi stance and voltage are known values,

the amount of current flow throug h the meter depends on the resistance

of the circuit or component being test ed. The ohmmeter can also be used

to perform a continuity test for suspected open circuits. In using the

meter for making continuity checks, do not be concerned with the actual

resistance readings. Zero resistance, or any ohm reading, indicates

continuity in the circui t. Infinite resistance indi cates an opening in the

circuit. A high resistance reading w here there should be none indicates a

problem in the circuit. Checks for s hort circuits are made in the same

manner as checks for open circuits, ex cept that the circuit must be

isolated from both power and normal gr ound. Infinite resistance indicates

no continuity, while zero resi stance indicates a dead short.

WARNING - Never use an ohmmeter to check the resistance of a component or

wire while there is volt age applied to the circuit

• Ammeter - an ammeter measures the am ount of current flowing through

a circuit in units called amperes or amps. At normal operating voltage,

most circuits have a characteristic amount of amperes, called "current

draw" which can be measured usi ng an ammeter. By referring to a

specified current draw rating, then measuring the amperes and

comparing the two values, one can det ermine what is happening within

the circuit to aid in diagnosis. An open circuit, for example, will not allow

any current to flow, so the amme ter reading will be zero. A damaged

component or circuit will have an incr eased current draw, so the reading

will be high. The ammeter is always connected in series with the circuit\

being tested. All of the current that normally flows through the circuit

must also flow through the ammeter; if there is any other path for the

current to follow, the ammeter readi ng will not be accurate. The ammeter

itself has very little resistance to curr ent flow and, therefore, will not affect

the circuit, but it will measure current draw only when the circuit is closed

and electricity is flowing. Excessive current draw can blow fuses and

drain the battery, while a reduced current draw can cause motors to run \

slowly, lights to dim and other components to not operate properly.

Page 139 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 139

TROUBLESHOOTING ELECTRICAL SYSTEMS

When diagnosing a specific problem, or

ganized troubleshooting is a must. The

complexity of a modern automotive v ehicle demands that you approach any

problem in a logical, organized m anner. There are certain troubleshooting

techniques, however, which are standard:

• Establish when the problem occurs. D oes the problem appear only under

certain conditions? Were there any noises, odors or other unusual

symptoms? Isolate the problem area. To do this, make some simple tests

and observations, then eliminate the syst ems that are working properly.

Check for obvious problems, such as broken wires and loose or dirty

connections. Always check the obvious before assuming something

complicated is the cause.

• Test for problems systematically to determine the cause once the

problem area is isolated. Are all t he components functioning properly? Is

there power going to electrical switc hes and motors. Performing careful,

systematic checks will often turn up mo st causes on the first inspection,

without wasting time checking co mponents that have little or no

relationship to the problem.

• Test all repairs after the work is done to make sure that the problem is

fixed. Some causes can be traced to more than one component, so a

careful verification of repair work is important in order to pick up

additional malfunctions that may cause a problem to reappear or a

different problem to arise. A blown fu se, for example, is a simple problem

that may require more than another fuse to repair. If you don't look for a

problem that caused a fuse to blow, a shorted wire (for example) may go

undetected.

Experience has shown that most problem s tend to be the result of a fairly

simple and obvious cause, such as loose or corroded connectors, bad grounds

or damaged wire insulation which causes a short. This makes careful visual

inspection of components during testing essential to quick and accurate

troubleshooting.

Page 140 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 140

TESTING

OPEN CIRCUITS

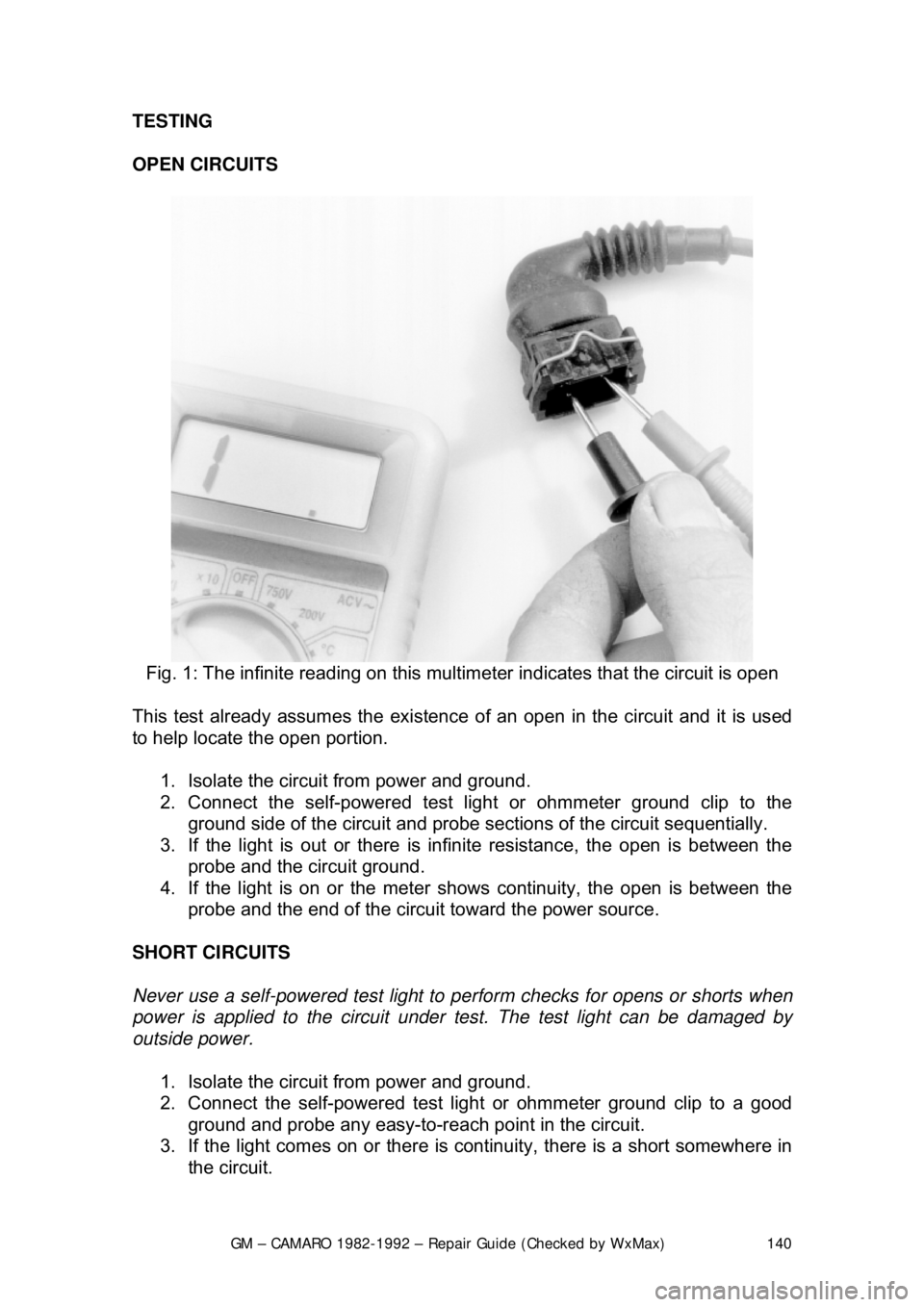

Fig. 1: The infinite reading on this mult imeter indicates that the circuit is open

This test already assumes the existence of an open in the circuit and it is used

to help locate the open portion.

1. Isolate the circuit from power and ground.

2. Connect the self-powered test light or ohmmeter ground clip to the

ground side of the circuit and probe sect ions of the circuit sequentially.

3. If the light is out or there is infinite resistanc e, the open is between the

probe and the circuit ground.

4. If the light is on or the meter s hows continuity, the open is between the

probe and the end of the circuit toward the power source.

SHORT CIRCUITS

Never use a self-powered test light to per form checks for opens or shorts when

power is applied to the circuit under te st. The test light can be damaged by

outside power.

1. Isolate the circuit from power and ground.

2. Connect the self-powered test light or ohmmeter ground clip to a good

ground and probe any easy-to-reach point in the circuit.

3. If the light comes on or there is cont inuity, there is a short somewhere in

the circuit.