CHEVROLET CAMARO 1982 Repair Guide

CAMARO 1982

CHEVROLET

CHEVROLET

https://www.carmanualsonline.info/img/24/56854/w960_56854-0.png

CHEVROLET CAMARO 1982 Repair Guide

Trending: Oil change, engine diagram, gearbox, oil pressure, roof rack, gas type, service

Page 101 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 101

WHEEL CYLINDERS

REMOVAL & INSTALLATION

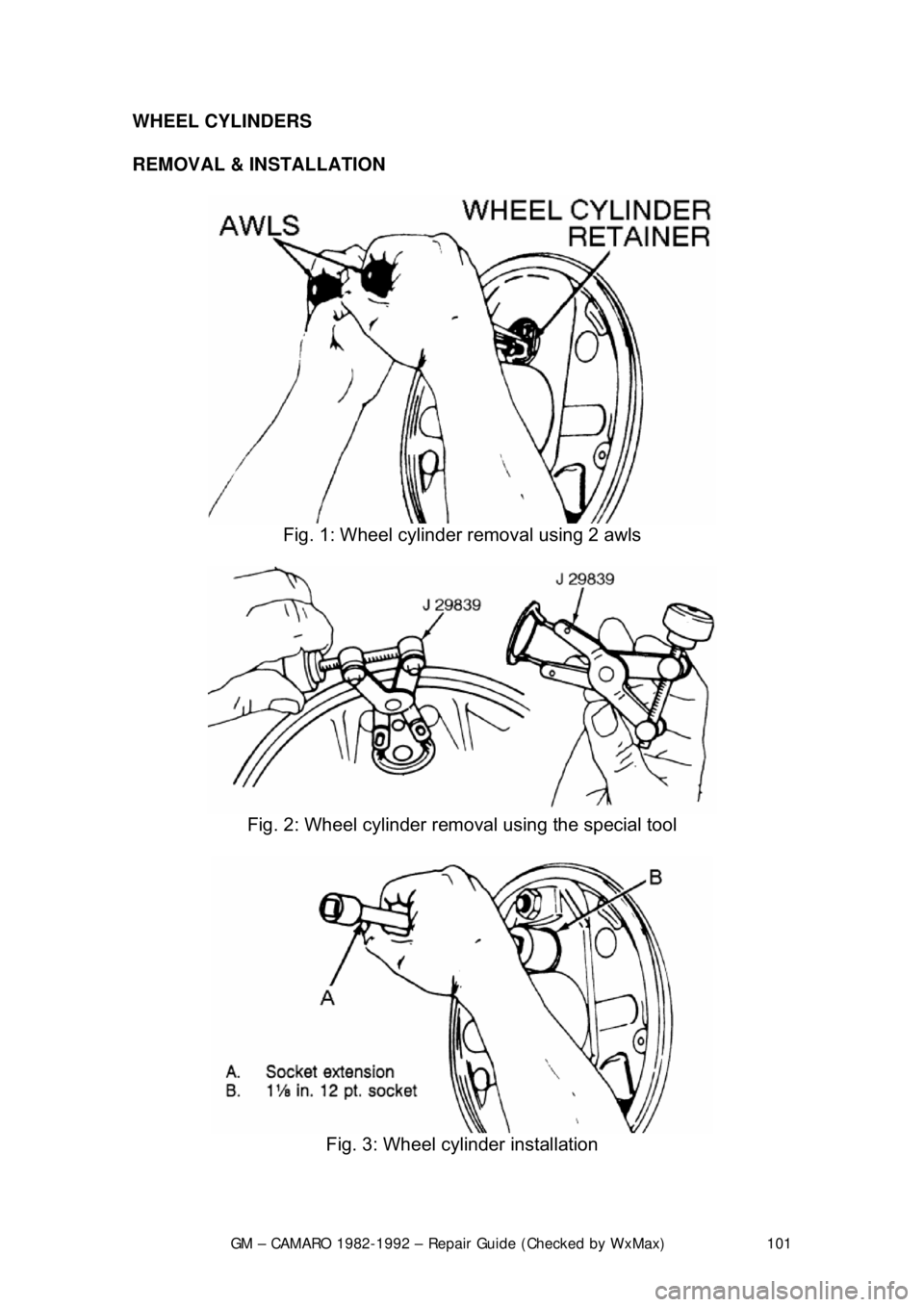

Fig. 1: Wheel cylinder removal using 2 awls

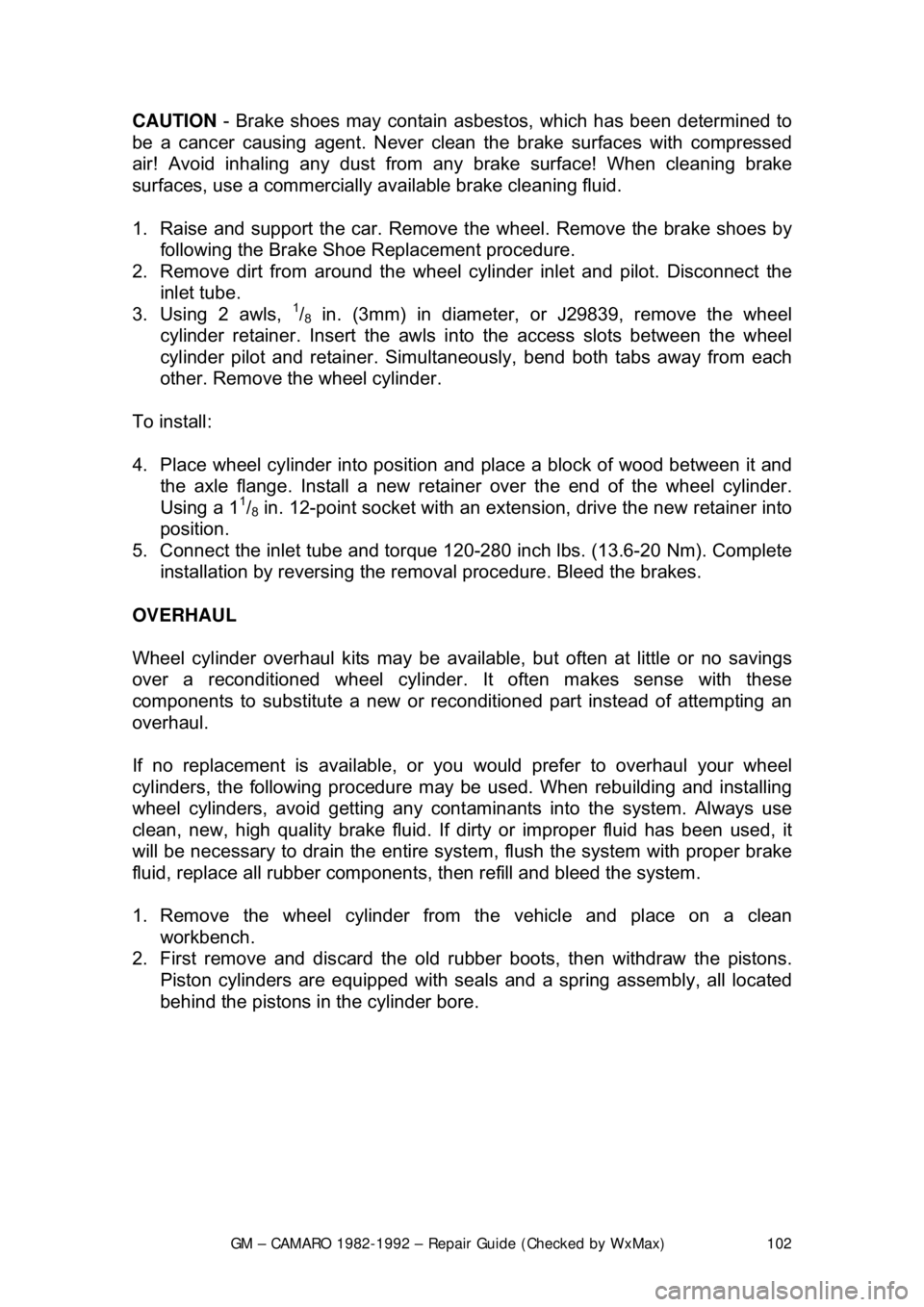

Fig. 2: Wheel cylinder remo val using the special tool

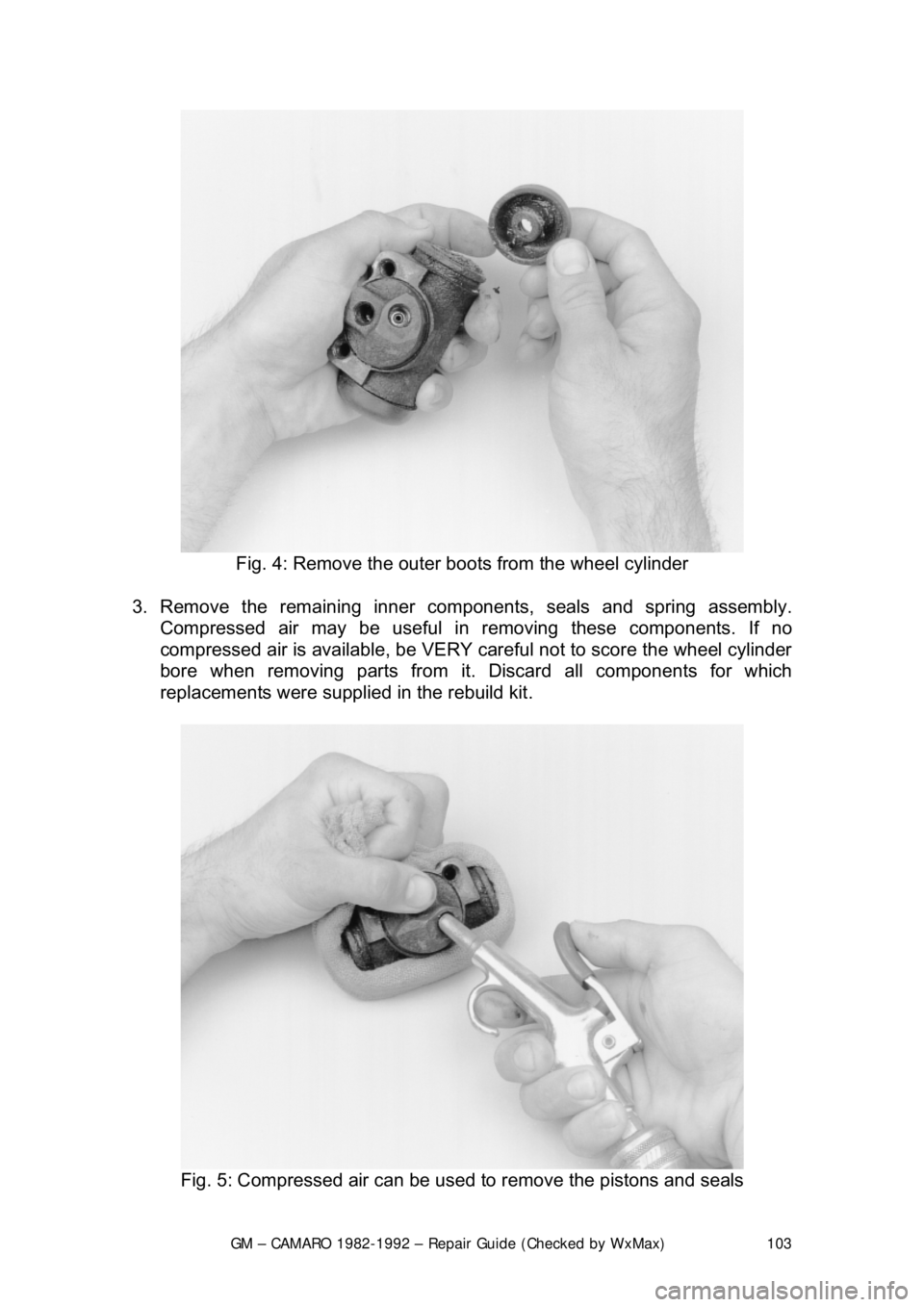

Fig. 3: Wheel cylinder installation

Page 102 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 102

CAUTION

- Brake shoes may contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

1. Raise and support the car. Remove t he wheel. Remove the brake shoes by

following the Brake Shoe R eplacement procedure.

2. Remove dirt from ar ound the wheel cylinder inle t and pilot. Disconnect the

inlet tube.

3. Using 2 awls,

1/8 in. (3mm) in diameter, or J29839, remove the wheel

cylinder retainer. Insert the awls in to the access slots between the wheel

cylinder pilot and retainer. Simultaneous ly, bend both tabs away from each

other. Remove the wheel cylinder.

To install:

4. Place wheel cylinder into position and place a block of wood between it and

the axle flange. Install a new retainer over the end of the wheel cylinder.

Using a 1

1/8 in. 12-point socket with an extensi on, drive the new retainer into

position.

5. Connect the inlet tube and torque 120-280 inch lbs. (13.6-20 Nm). Complete

installation by reversing the remova l procedure. Bleed the brakes.

OVERHAUL

Wheel cylinder overhaul kits may be available, but often at little or no savings

over a reconditioned wheel cylinder. It often makes sense with these

components to substitute a new or re conditioned part instead of attempting an

overhaul.

If no replacement is availabl e, or you would prefer to overhaul your wheel

cylinders, the following procedure may be used. When rebuilding and installing

wheel cylinders, avoid getting any cont aminants into the system. Always use

clean, new, high quality brake fluid. If di rty or improper fluid has been used, it

will be necessary to drain the entire syst em, flush the system with proper brake

fluid, replace all rubber components , then refill and bleed the system.

1. Remove the wheel cylinder from the vehicle and place on a clean

workbench.

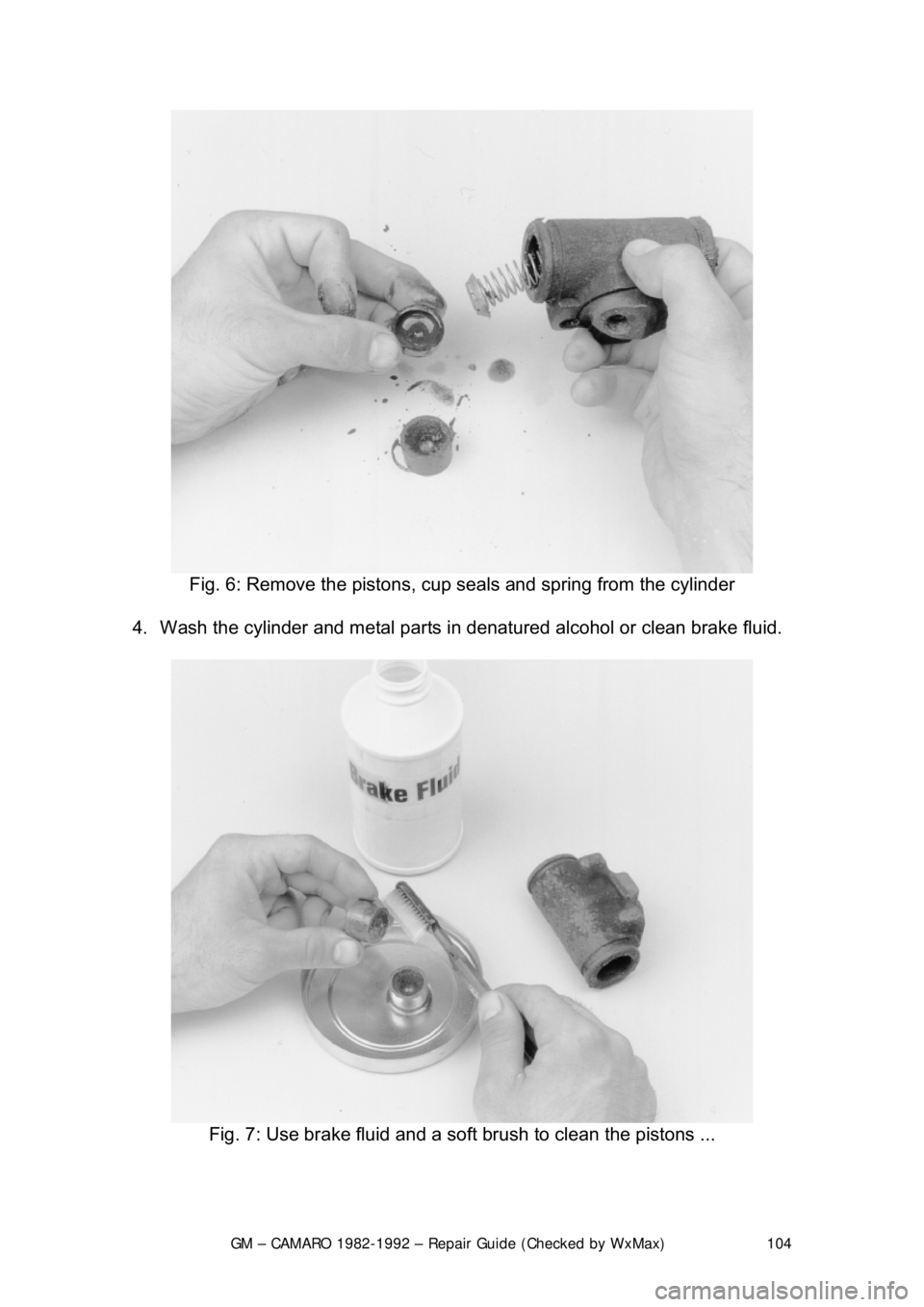

2. First remove and discard the old r ubber boots, then withdraw the pistons.

Piston cylinders are equipped with seals and a spring assembly, all located

behind the pistons in the cylinder bore.

Page 103 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 103

Fig. 4: Remove the outer boots from the wheel cylinder

3. Remove the remaining inner com ponents, seals and spring assembly.

Compressed air may be useful in removing these components. If no

compressed air is available, be VERY careful not to score the wheel cylinder

bore when removing parts from i t. Discard all components for which

replacements were supplied in the rebuild kit.

Fig. 5: Compressed air can be used to remove the pistons and seals

Page 104 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 104

Fig. 6: Remove the pistons, cup seals and spring from the cylinder

4. Wash the cylinder and metal parts in denatured alcohol or clean brake fluid.

Fig. 7: Use brake fluid and a so ft brush to clean the pistons ...

Page 105 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 105

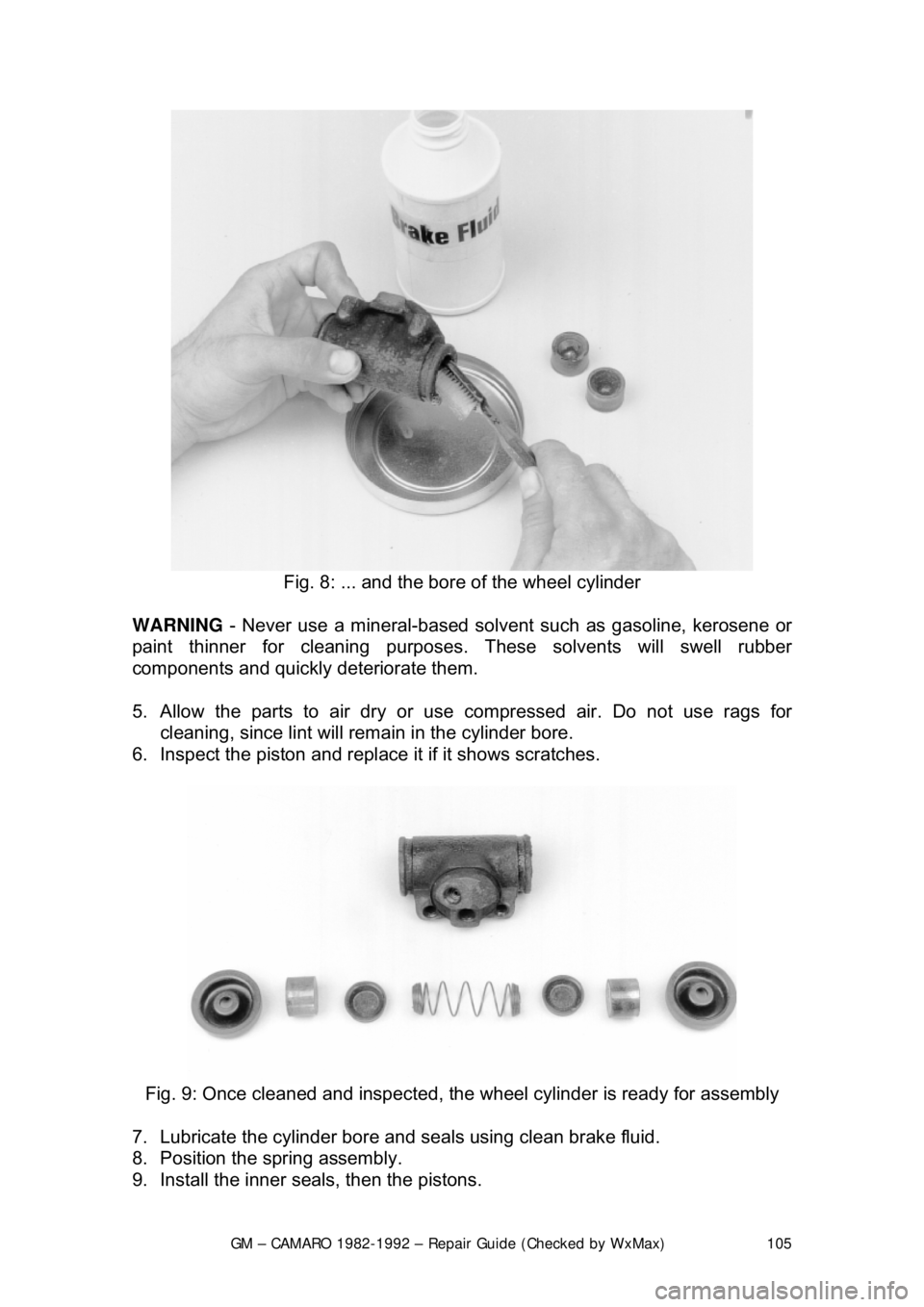

Fig. 8: ... and the bor e of the wheel cylinder

WARNING - Never use a mineral-based solvent such as gasoline, kerosene or

paint thinner for cleaning purposes . These solvents will swell rubber

components and quickly deteriorate them.

5. Allow the parts to air dry or use compressed air. Do not use rags for

cleaning, since lint will rema in in the cylinder bore.

6. Inspect the piston and replace it if it shows scratches.

Fig. 9: Once cleaned and inspected, the wheel cylinder is ready for assembly

7. Lubricate the cylinder bore and s eals using clean brake fluid.

8. Position the spring assembly.

9. Install the inner seals, then the pistons.

Page 106 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 106

Fig. 10: Lubricate the c up seals with brake fluid

Fig. 11: Install the spring, then the cup seals in the bore

Page 107 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 107

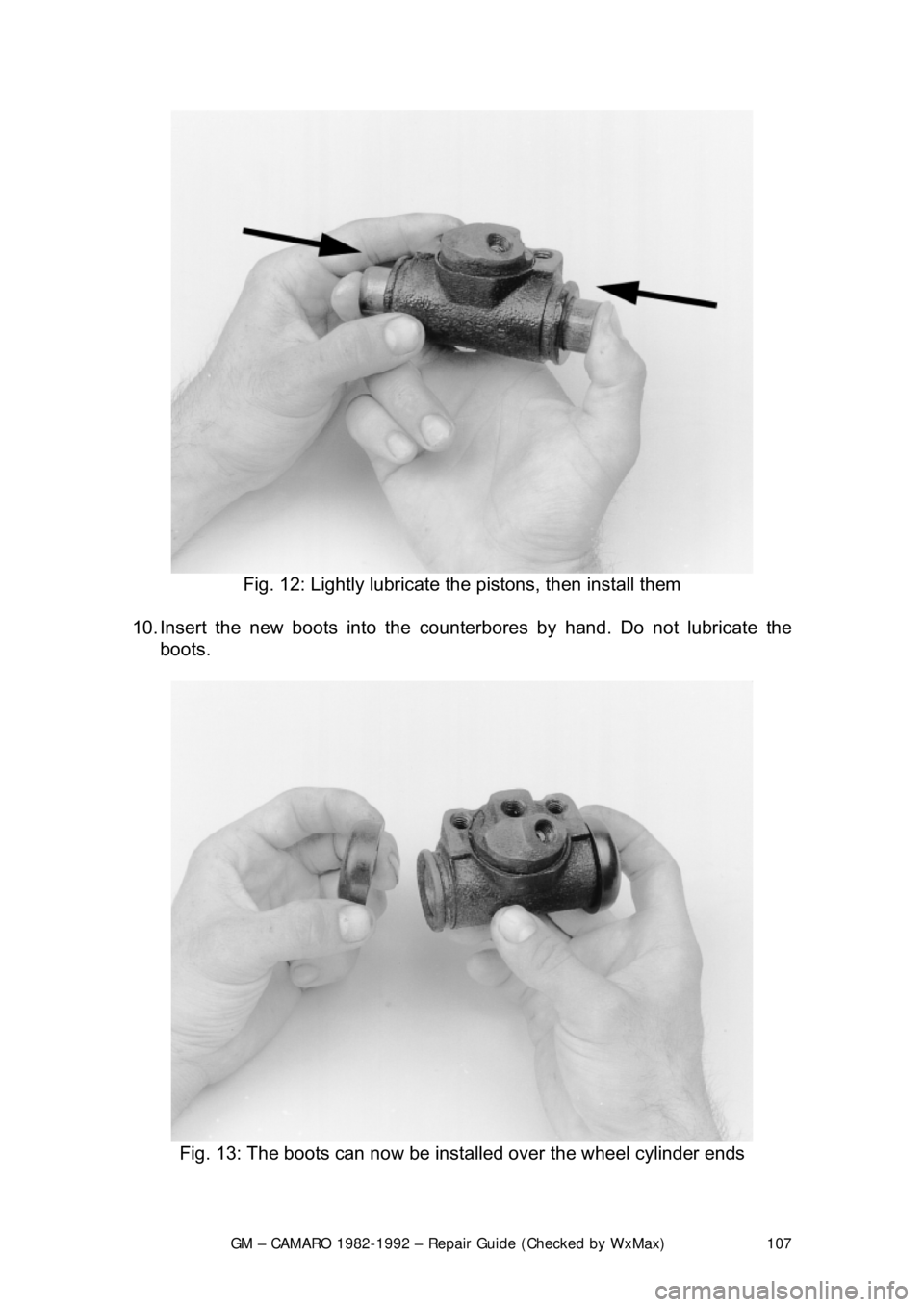

Fig. 12: Lightly lubricate t he pistons, then install them

10. Insert the new boots in to the counterbores by hand. Do not lubricate the

boots.

Fig. 13: The boots can now be installed over the wheel cylinder ends

Page 108 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 108

11. Install the wheel cylinder.

REAR DISK BRAKES

BRAKE PADS

INSPECTION

Refer to the Front Disc Brake Inspection procedure.

REMOVAL & INSTALLATION

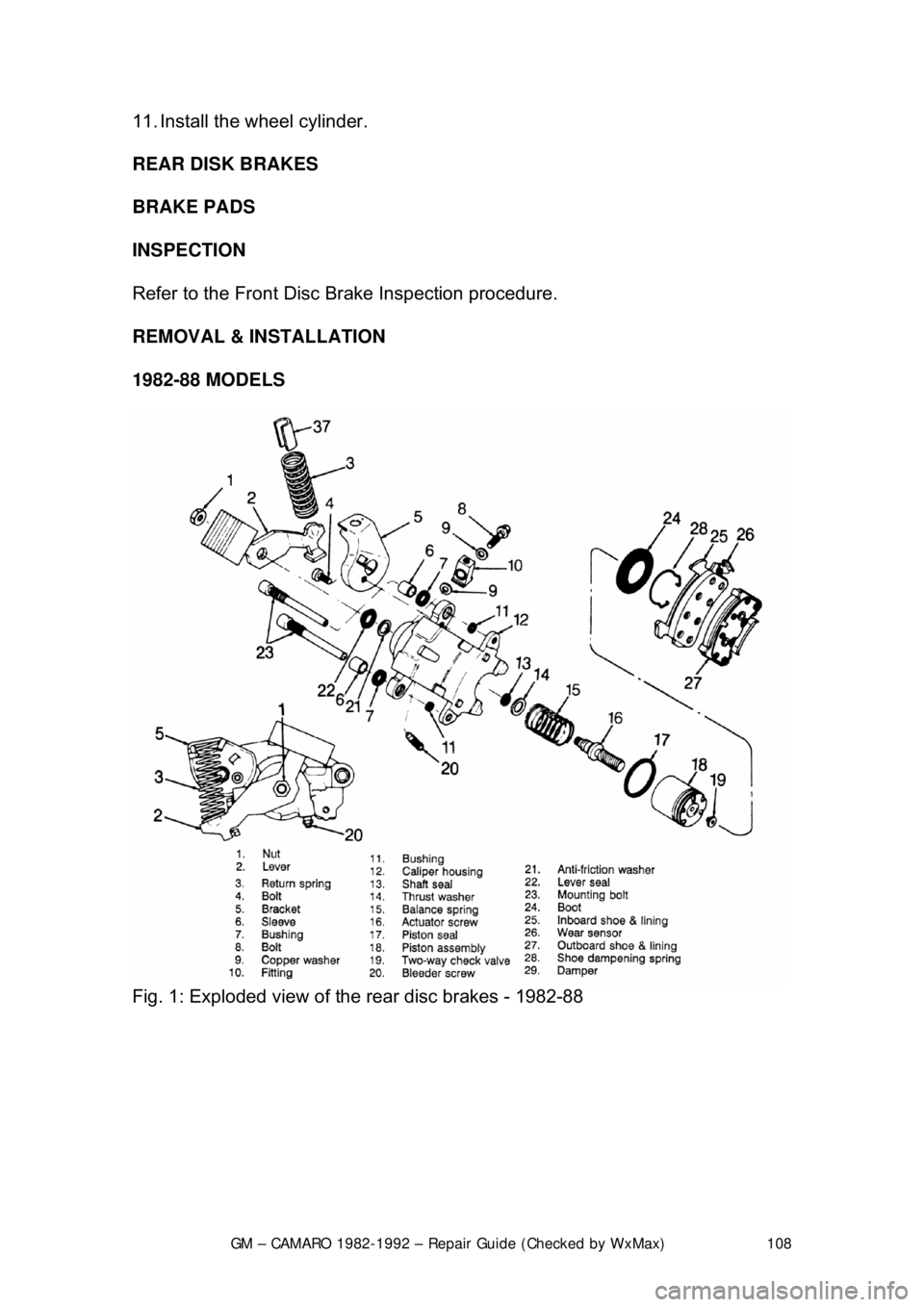

1982-88 MODELS

Fig. 1: Exploded view of t he rear disc brakes - 1982-88

Page 109 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 109

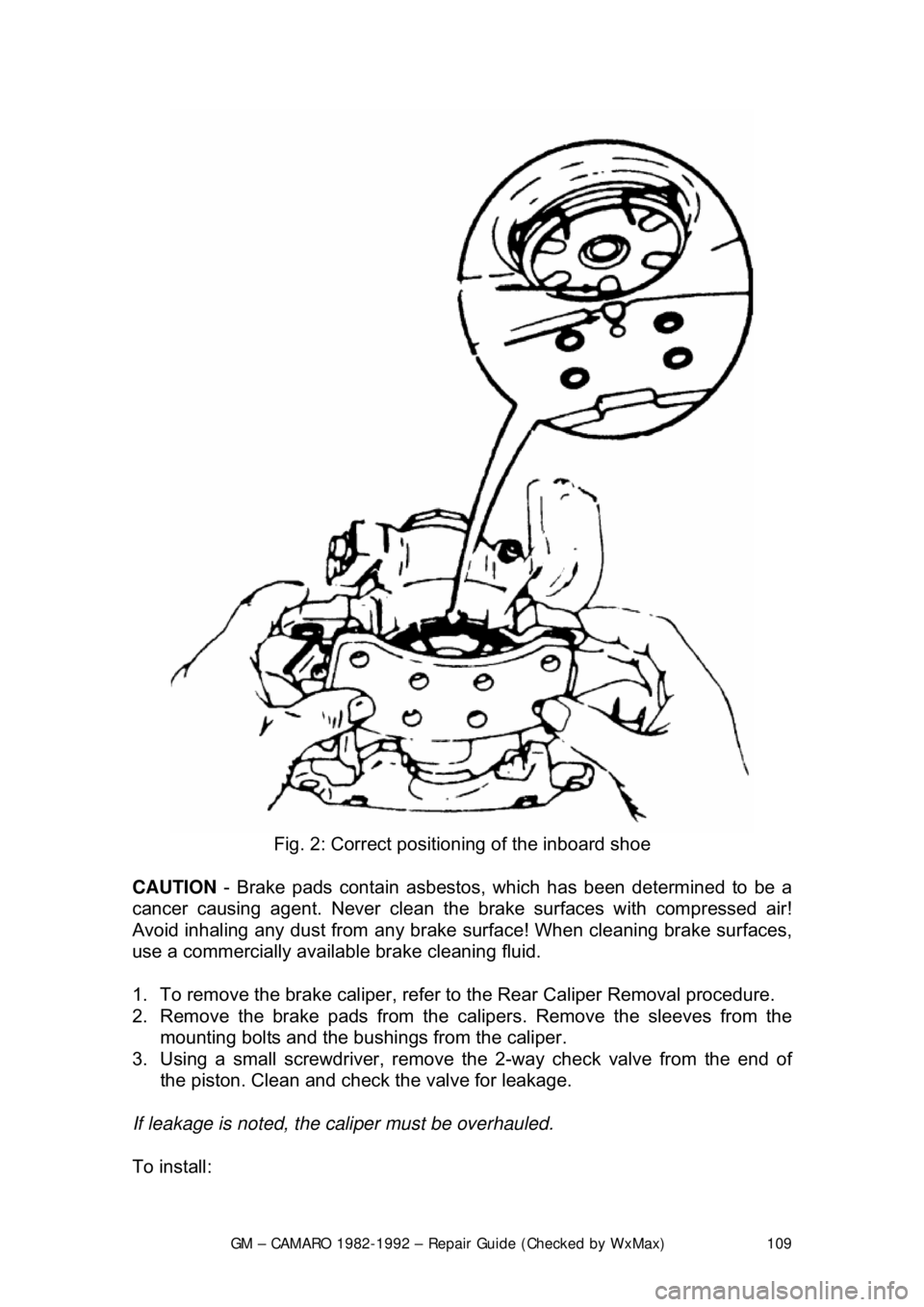

Fig. 2: Correct positioning of the inboard shoe

CAUTION - Brake pads contain asbestos, which has been determined to be a

cancer causing agent. Never clean the brake surfaces with compressed air!

Avoid inhaling any dust from any brake surface! When cleaning brake surfaces,

use a commercially available brake cleaning fluid.

1. To remove the brake caliper, refer to the Rear Caliper Removal procedure.

2. Remove the brake pads from the calipers. Remove the sleeves from the

mounting bolts and the bushi ngs from the caliper.

3. Using a small screwdriver, remove the 2-way check valve from the end of

the piston. Clean and check the valve for leakage.

If leakage is noted, the caliper must be overhauled.

To install:

Page 110 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 110

4. Position the brake pads

into the caliper. Lubricate and install new bushings,

sleeves and check valve.

5. When installing the inner brake pad, make sure that the D-shaped tab of the

pad engages with the D-shaped notch of the piston, as illustrated.

6. Upon installation of the inner pad, make sure that the wear sensor of the pad

is at the leading edge of the shoe during forward wheel rotation. Slide the

metal edge of the pad under the ends of the dampening spring and snap the

pad into position against the piston.

7. Install the outer pad and caliper. Afte r installing the caliper, apply the brakes,

then bend the ears of the out er pad against the caliper and ensure that there

is no excessive clearance.

Trending: catalytic, headlights, wiring diagram, spare tire, coolant temperature, airbag, torque