light CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 137 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 137

voltage) is present; it only means that so

me voltage is present. It is advisable

before using the test light to touch its ground clip and probe across the battery

posts or terminals to make sure the light is operating properly.

WARNING - Do not use a test light to probe electronic ignition, spark plug or

coil wires. Never use a pick-type test light to probe wiring on computer

controlled systems unless spec ifically instructed to do so. Any wire insulation

that is pierced by the test light pr obe should be taped and sealed with silicone

after testing

Like the jumper wire, the 12 volt test li ght is used to isolate opens in circuits.

But, whereas the jumper wire is used to bypass the open to operate the load,

the 12 volt test light is us ed to locate the presence of voltage in a circuit. If the

test light illuminates, there is power up to t hat point in the circuit; if the test light

does not illuminate, there is an open circui t (no power). Move the test light in

successive steps back toward the power source until the light in the handle

illuminates. The open is between the pr obe and a point which was previously

probed.

The self-powered test light is similar in design to the 12 volt test light, but

contains a 1.5 volt penlight battery in the handle. It is most often used in place

of a multimeter to check for open or shor t circuits when power is isolated from

the circuit (continuity test).

The battery in a self-powered test light does not provide much current. A weak

battery may not provide enough power to illuminate the test light even when a

complete circuit is made (especially if there is high resistance in the circuit).

Always make sure that the test battery is strong. To check the battery, briefly

touch the ground clip to the pr obe; if the light glows brightly, the battery is strong

enough for testing.

A self-powered test light should not be used on any co mputer controlled system

or component. The small amount of electr icity transmitted by the test light is

enough to damage many electr onic automotive components.

MULTIMETERS

Multimeters are an extremely useful tool for troubleshooting electrical problems.

They can be purchased in either analog or digital form and have a price range

to suit any budget. A multimeter is a voltmeter, ammeter and ohmmeter (along

with other features) combined into one instrument. It is often used when testing

solid state circuits because of its hi gh input impedance (usually 10 megaohms

or more). A brief description of the mult imeter main test functions follows:

• Voltmeter - the voltmeter is used to measure voltage at any point in a

circuit, or to measure the voltage drop across any part of a circuit.

Voltmeters usually have various scales and a selector switch to allow the

reading of different volt age ranges. The voltmeter has a positive and a

negative lead. To avoid damage to the meter, always connect the

negative lead to the negative (—) side of the circ uit (to ground or nearest

Page 138 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 138

the ground side of the circuit) and

connect the positive lead to the

positive (+) side of the circuit (to t he power source or the nearest power

source). Note that the negative voltme ter lead will always be black and

that the positive voltmeter will alwa ys be some color other than black

(usually red).

• Ohmmeter - the ohmmeter is designed to read resistance (measured in

ohms) in a circuit or component. Mo st ohmmeters will have a selector

switch which permits the measurement of different ranges of resistance

(usually the selector swit ch allows the multiplication of the meter reading

by 10, 100, 1,000 and 10,000). Some ohmmeters are "auto-ranging"

which means the meter itself will dete rmine which scale to use. Since the

meters are powered by an internal battery, the ohmmeter can be used

like a self-powered test light. When the ohmmeter is connected, current

from the ohmmeter flows through the ci rcuit or component being tested.

Since the ohmmeter's internal resi stance and voltage are known values,

the amount of current flow throug h the meter depends on the resistance

of the circuit or component being test ed. The ohmmeter can also be used

to perform a continuity test for suspected open circuits. In using the

meter for making continuity checks, do not be concerned with the actual

resistance readings. Zero resistance, or any ohm reading, indicates

continuity in the circui t. Infinite resistance indi cates an opening in the

circuit. A high resistance reading w here there should be none indicates a

problem in the circuit. Checks for s hort circuits are made in the same

manner as checks for open circuits, ex cept that the circuit must be

isolated from both power and normal gr ound. Infinite resistance indicates

no continuity, while zero resi stance indicates a dead short.

WARNING - Never use an ohmmeter to check the resistance of a component or

wire while there is volt age applied to the circuit

• Ammeter - an ammeter measures the am ount of current flowing through

a circuit in units called amperes or amps. At normal operating voltage,

most circuits have a characteristic amount of amperes, called "current

draw" which can be measured usi ng an ammeter. By referring to a

specified current draw rating, then measuring the amperes and

comparing the two values, one can det ermine what is happening within

the circuit to aid in diagnosis. An open circuit, for example, will not allow

any current to flow, so the amme ter reading will be zero. A damaged

component or circuit will have an incr eased current draw, so the reading

will be high. The ammeter is always connected in series with the circuit\

being tested. All of the current that normally flows through the circuit

must also flow through the ammeter; if there is any other path for the

current to follow, the ammeter readi ng will not be accurate. The ammeter

itself has very little resistance to curr ent flow and, therefore, will not affect

the circuit, but it will measure current draw only when the circuit is closed

and electricity is flowing. Excessive current draw can blow fuses and

drain the battery, while a reduced current draw can cause motors to run \

slowly, lights to dim and other components to not operate properly.

Page 140 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 140

TESTING

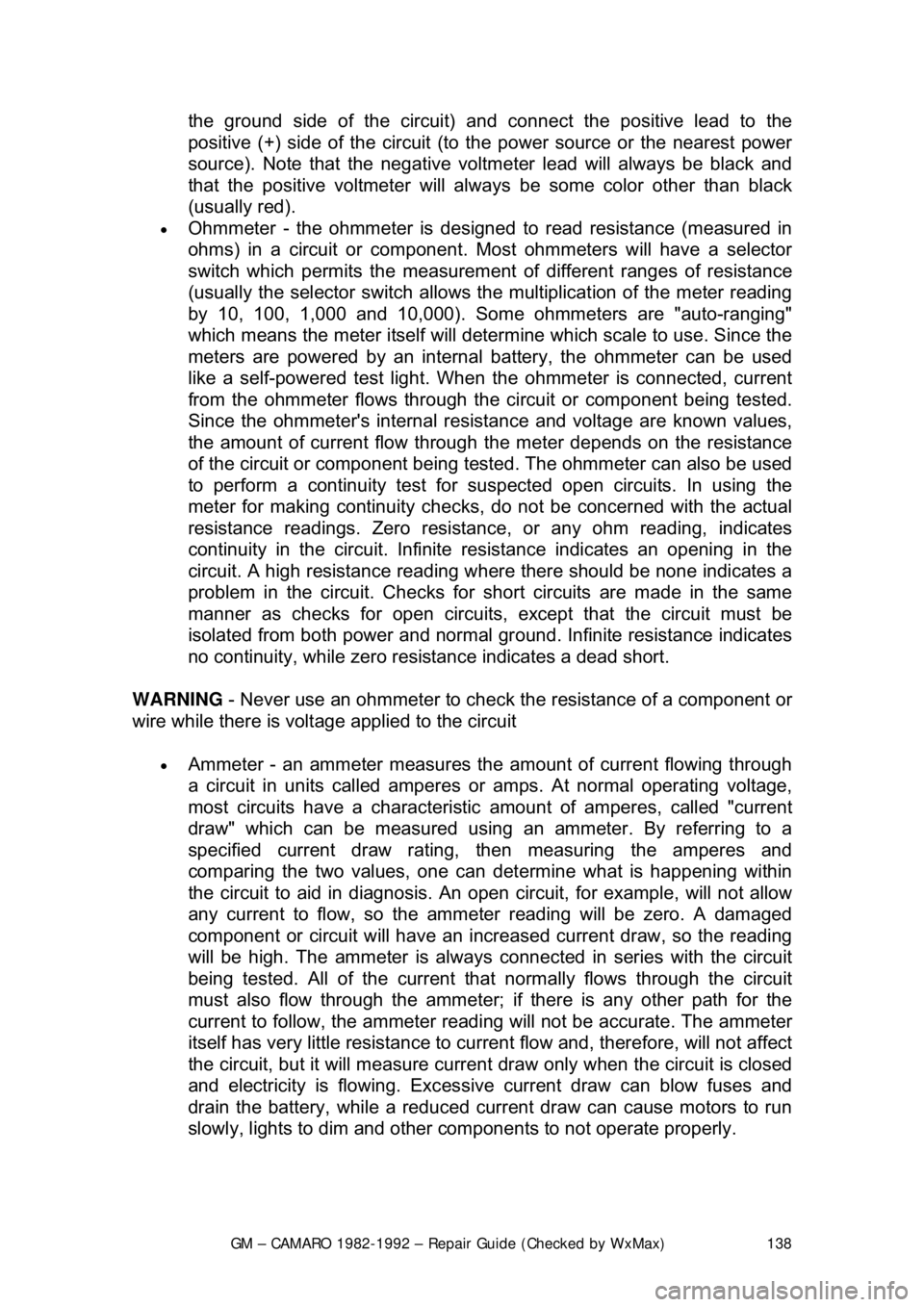

OPEN CIRCUITS

Fig. 1: The infinite reading on this mult imeter indicates that the circuit is open

This test already assumes the existence of an open in the circuit and it is used

to help locate the open portion.

1. Isolate the circuit from power and ground.

2. Connect the self-powered test light or ohmmeter ground clip to the

ground side of the circuit and probe sect ions of the circuit sequentially.

3. If the light is out or there is infinite resistanc e, the open is between the

probe and the circuit ground.

4. If the light is on or the meter s hows continuity, the open is between the

probe and the end of the circuit toward the power source.

SHORT CIRCUITS

Never use a self-powered test light to per form checks for opens or shorts when

power is applied to the circuit under te st. The test light can be damaged by

outside power.

1. Isolate the circuit from power and ground.

2. Connect the self-powered test light or ohmmeter ground clip to a good

ground and probe any easy-to-reach point in the circuit.

3. If the light comes on or there is cont inuity, there is a short somewhere in

the circuit.

Page 141 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 141

4. To isolate the short, probe a test point

at either end of the isolated circuit

(the light should be on or the mete r should indicate continuity).

5. Leave the test light probe engaged and sequentiall y open connectors or

switches, remove parts, etc. until t he light goes out or continuity is

broken.

6. When the light goes out, the shor t is between the last two circuit

components which were opened.

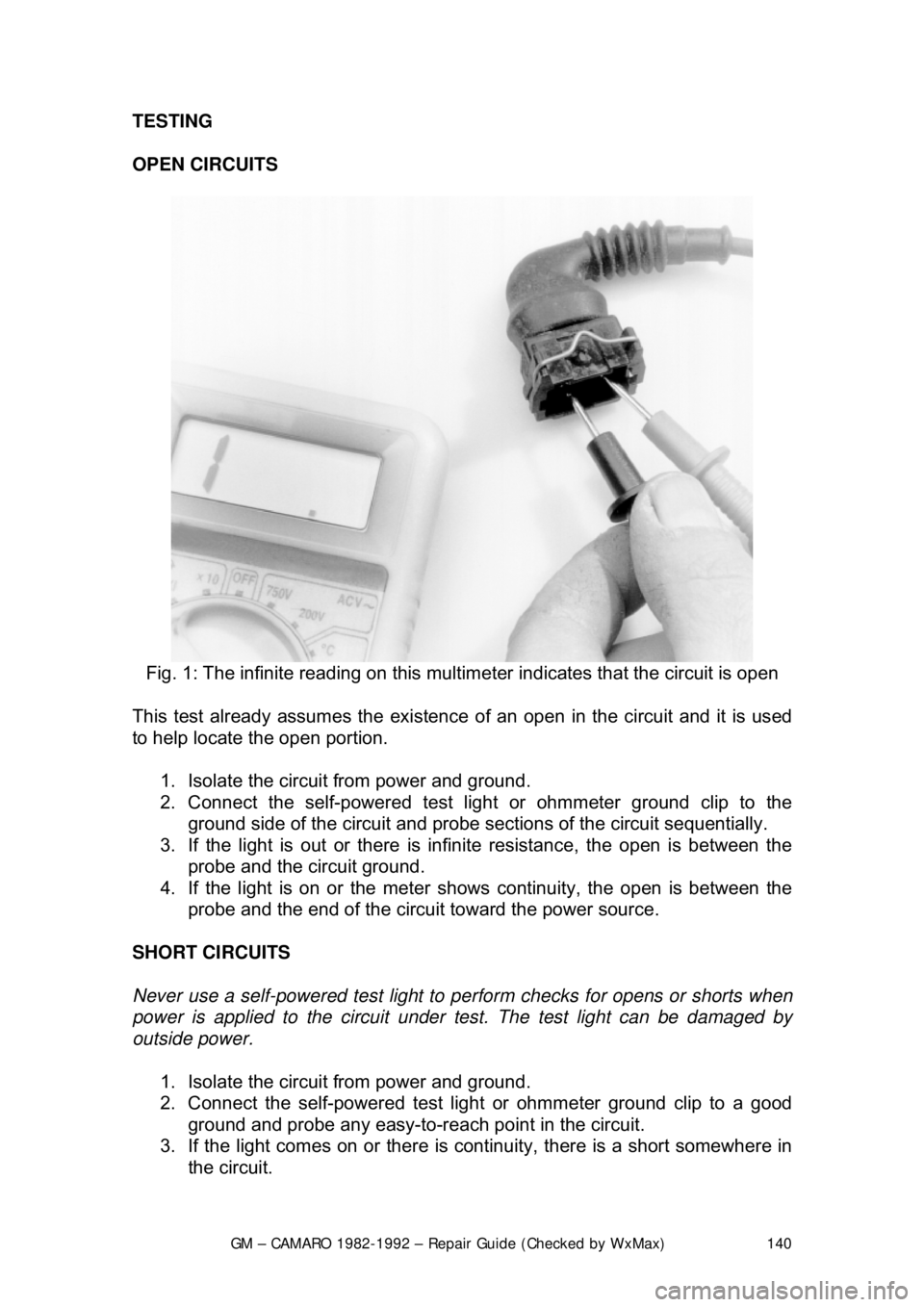

VOLTAGE

This test determines voltage available fr om the battery and should be the first

step in any electrical troubleshooting pr ocedure after visual inspection. Many

electrical problems, especially on co mputer controlled systems, can be caused

by a low state of charge in the battery. Excessive corrosion at the battery cable

terminals can cause poor contact that will prevent proper charging and f\

ull

battery current flow.

1. Set the voltmeter selector switch to the 20V position.

2. Connect the multimeter negative lead to the battery's negative (-) post or

terminal and the positive lead to t he battery's positive (+) post or

terminal.

3. Turn the ignition switch ON to provide a load.

4. A well charged battery should register over 12 volts. If the meter reads

below 11.5 volts, the battery power may be insufficient to operate the

electrical system properly.

VOLTAGE DROP

Fig. 2: This voltage drop test revealed high resistance (low voltage) in the circuit

Page 145 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 145

When the battery cable(s) are reconnecte

d (negative cable last), be sure to

check that your lights, windshield wipers and other electrically operated safety

components are all working correctly. If your vehicle contains an Electronically

Tuned Radio (ETR), don't forget to also reset your radio stations. Ditto for the

clock.

Page 200 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 200

9. Lubricate the speedometer cable

with an appropriate lubricant, being

sure to cover the lower thirds of the cable.

10. Insert the cable into the casi ng, then connect the cable and casing

assembly to the speedometer.

11. Install the instrument cluster, then install the cluster attaching screws.

12. Install the instrument cluster trim plate.

13. On models without cruise control, connect the speedometer cable strap

at the power brake booste r. On models with cruise control, connect the

speedometer cable at the cr uise control transducer.

14. Connect the negative battery cable at the battery.

WIPER SWITCH

REMOVAL & INSTALLATION

The wiper switch is part of the multi-function lever, located on the steering

wheel column.

1. Disconnect the electrical connector of the multi-function lever, located

under the instrument panel.

2. Remove the protective cover from the wire.

3. Grasp the lever firmly, twist and pull (the tang on the lever must align

with the socket) the lever straight out.

4. Pull the wire through the steering column.

To install: 5. Slide a music wire tool through the steering column and connect the

lever wire to the tool wire; pull t he wire through the steering column.

6. Push the control lever into the sp ring loaded socket (be sure to align the

tang).

7. Install the protective cover to the wire.

8. Connect the electrical connector of the multi-function lever.

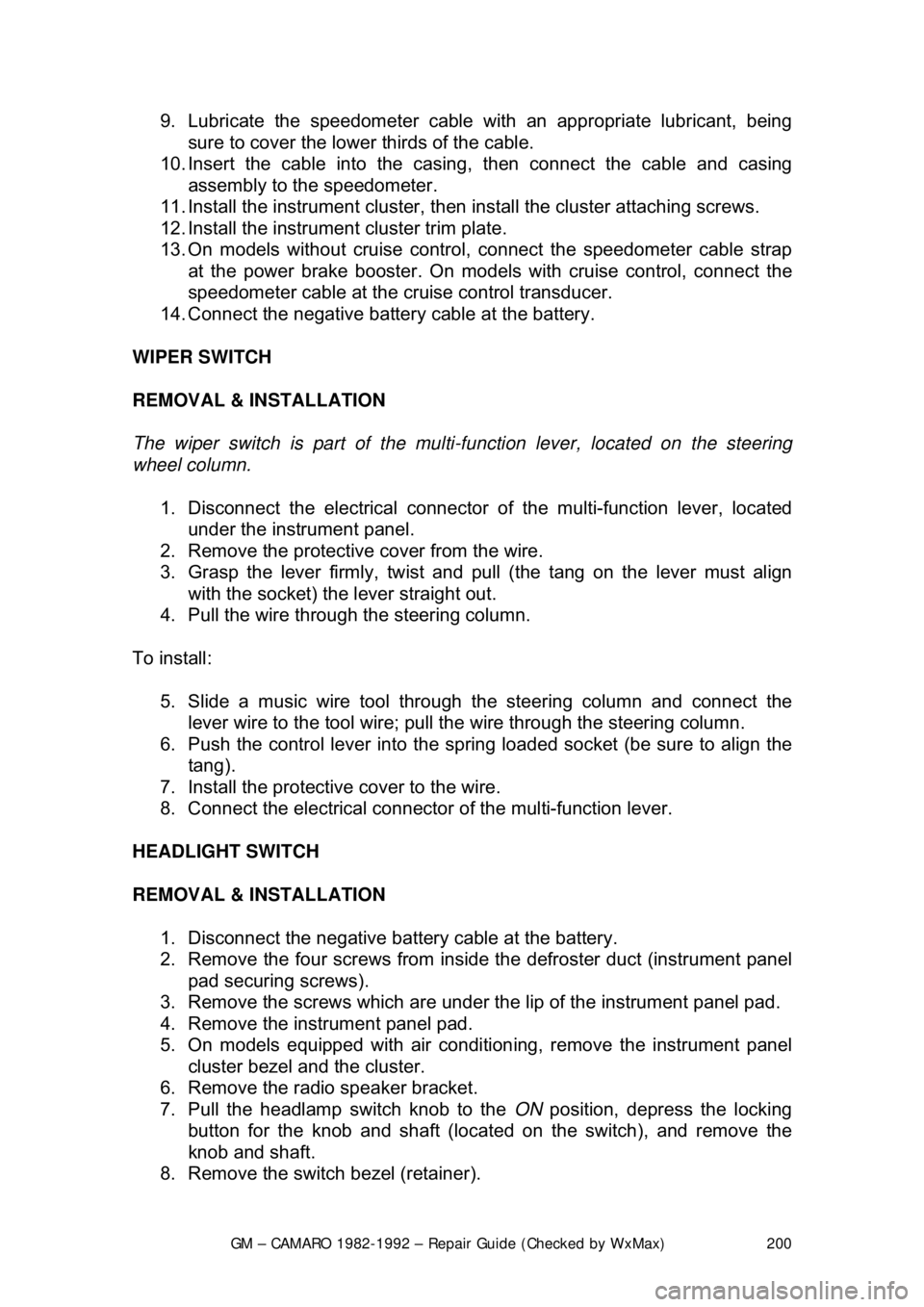

HEADLIGHT SWITCH

REMOVAL & INSTALLATION 1. Disconnect the negative batte ry cable at the battery.

2. Remove the four screws from insi de the defroster duct (instrument panel

pad securing screws).

3. Remove the screws which are under the lip of the instrument panel pad.

4. Remove the instrument panel pad.

5. On models equipped with air condition ing, remove the instrument panel

cluster bezel and the cluster.

6. Remove the radio speaker bracket.

7. Pull the headlamp switch knob to the ON position, depress the locking

button for the knob and shaft (locat ed on the switch), and remove the

knob and shaft.

8. Remove the switch bezel (retainer).

Page 201 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 201

9. Disconnect the wiring from the

switch and remove the switch.

10. To install, position t he switch into place and connect the wiring to the

switch.

11. Install the switch bezel (retainer).

12. Push the headlamp switch knob into the switch. (It may be necessary to

depress the knob release button.

13. Install the radio speaker bracket.

14. On models equipped with air conditioni ng, install the instrument panel

cluster bezel and the cluster.

15. Install the inst rument panel pad.

16. Install the screws which are under t he lip of the instrument panel pad.

17. Install the four screw s from inside the defroster duct (instrument panel

pad securing screws).

18. Connect the negative battery cable at the battery.

Fig. 1: Headlight switch removal

Page 203 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 203

LIGHTING

HEADLIGHTS

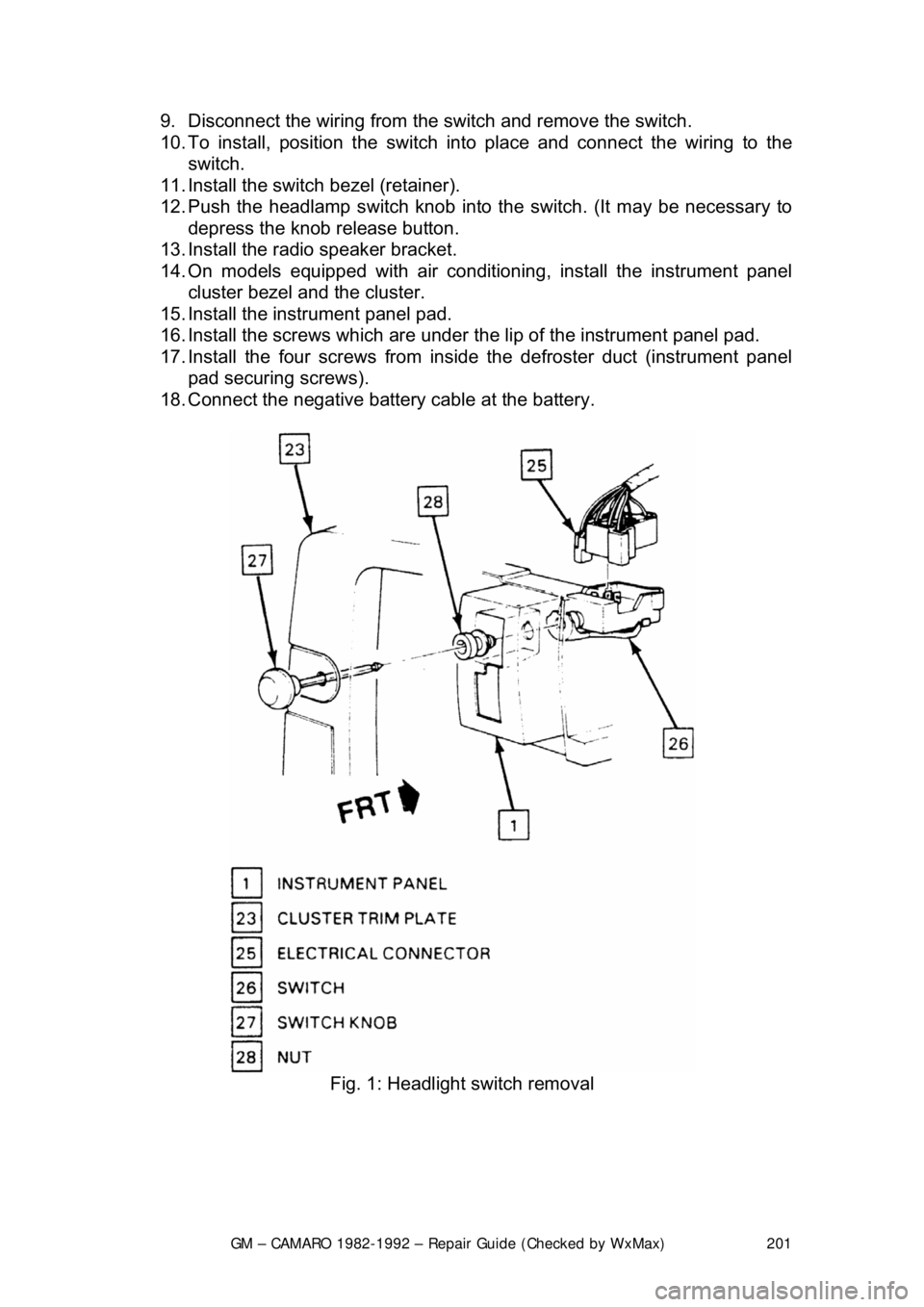

REMOVAL & INSTALLATION

1. Remove headlamp bezel retain ing screws and remove bezel.

2. Disengage spring from the retaini ng ring with a cotter pin removal tool

and remove two attaching screws.

3. Remove retaining ring, disconnect sealed beam unit at wiring connector

and remove the unit.

Fig. 1: Headlight removal - the lowe r bezel mounting screws only need to be

loosened, not removed

Page 204 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 204

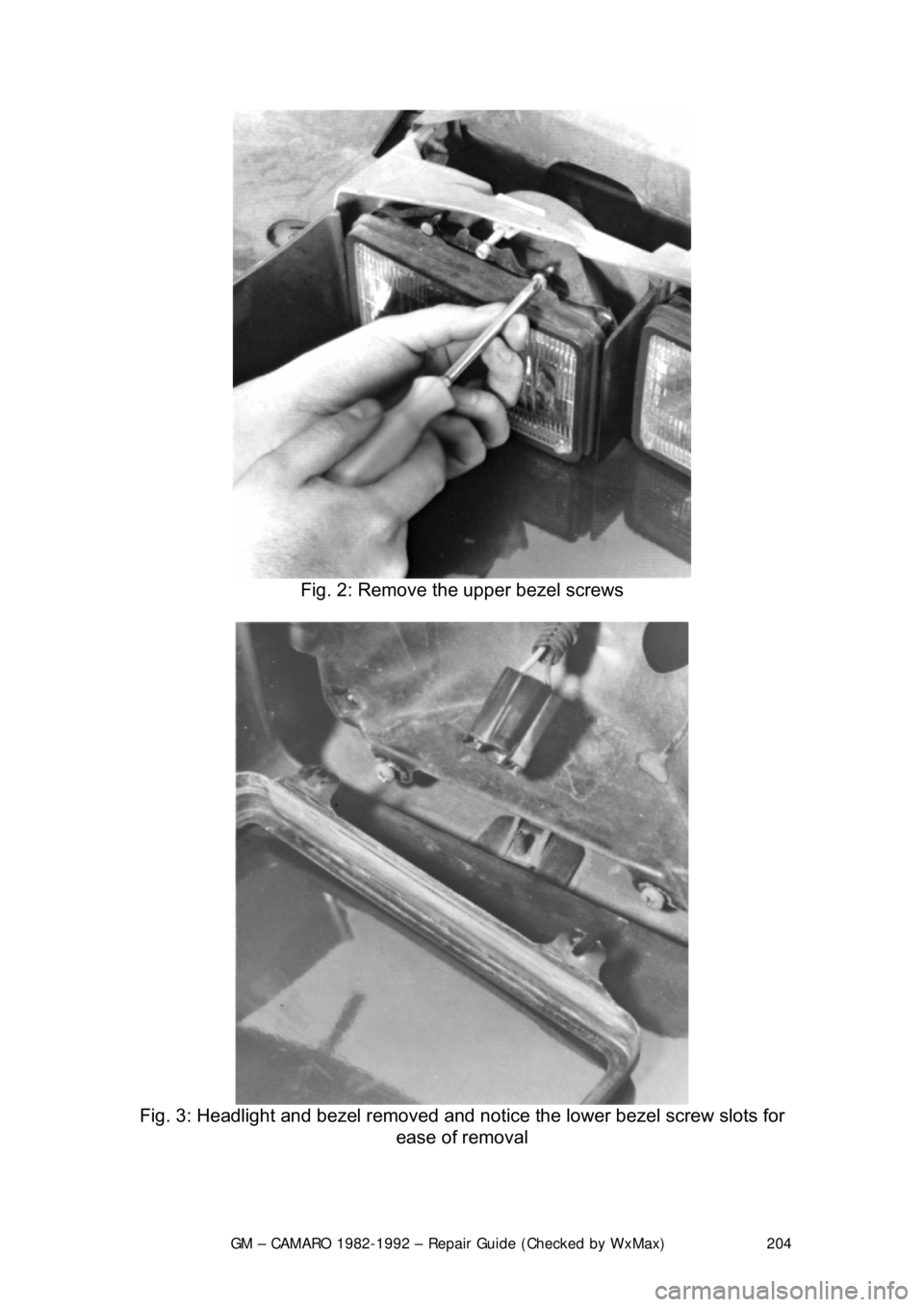

Fig. 2: Remove the upper bezel screws

Fig. 3: Headlight and bezel removed and no tice the lower bezel screw slots for

ease of removal

Page 205 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 205

Fig. 4: Plug headlight in and ens ure the headlight is right side up

4. To install, attach the connector to replacement unit and position the unit

in place making sure the number molded in to the lens face is at the top.

In the dual headlamp installation the in board unit (No. 1) takes a double

connector plug, the outboard unit (No. 2) takes a triple connector plug.

5. Position retaining ring into place and install the retaining ring attaching

screws and spring.

6. Check operation of unit and install the headlamp bezel.

AIMING THE HEADLIGHTS

The headlights must be properly aimed to provide the best, safest road

illumination. The lights should be che cked for proper aim and adjusted as

necessary. Certain state and local author ities have requirements for headlight

aiming; these should be check ed before adjustment is made.

CAUTION - About once a year, w hen the headlights are r eplaced or any time

front end work is performed on your vehicl e, the headlight should be accurately

aimed by a reputable repai r shop using the proper equipment. Headlights not

properly aimed can make it virtually impossible to see and may blind other

drivers on the road, possibly causing an accident. Note that the following

procedure is a temporary fix, until you can take your vehicle to a repair shop for

a proper adjustment.