light CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 86 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 86

6. Remove the piston seals from

the groove in the caliper bore.

Fig. 8: Use extreme caution when remo ving the piston seal; DO NOT scratch

the caliper bore

7. Carefully loosen the br ake bleeder valve cap and valve from the caliper

housing.

8. Inspect the caliper bores, pistons and mounting threads for scoring or excessive wear.

9. Use crocus cloth to polish out light corrosion from the piston and bore.

10. Clean all parts with denatured alcohol and dry with compressed air.

To assemble:

11. Lubricate and install th e bleeder valve and cap.

12. Install the new seals into the caliper bore grooves, making sure they are not

twisted.

13. Lubricate the piston bore.

14. Install the pistons and boots into the bores of the calipers and push to the

bottom of the bores.

15. Use a suitable driving tool to seat the boots in the housing.

Page 93 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 93

2. Remove the wheel or wheels.

3. Pull the brake drum off. It may be nec

essary to gently tap the rear edges of

the drum to start it off the studs.

4. If extreme resistance to removal is encountered, it will be necessary to

retract the adjusting screw. Knock out the access hole in the backing plate

and turn the adjuster to retract th e linings away from the drum.

5. Install a replacement hole co ver before reinstalling drum.

6. Install the drums in the same position on the hub as removed.

DRUM INSPECTION

1. Check the drums for any cracks, scores, grooves, or an out-of-round

condition. Replace if cracked. Slight scores can be removed with fine emery

cloth while extensive scoring requires turning the drum on a lathe.

2. Never have a drum turned mo re than 0.060 in. (1.524mm).

BRAKE SHOES

ADJUSTMENT

Rotate the star wheel adjuster until a sl ight drag is felt between the shoes and

drum, then back off 12 clicks on the adjusting wheel. Put the car in reverse and,

while backing up, apply the brakes seve ral times. This will allow the self-

adjusters to complete the adjustment.

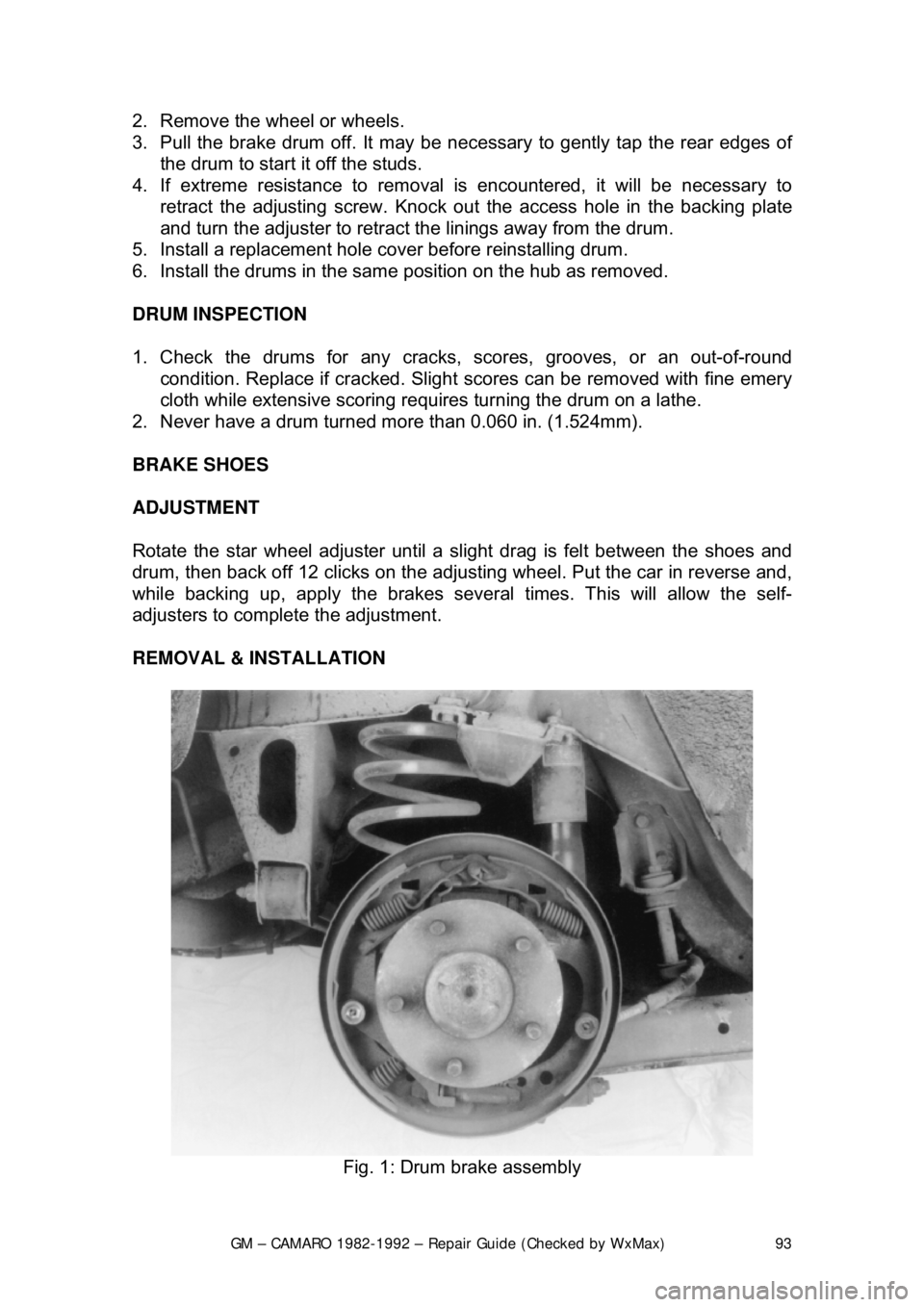

REMOVAL & INSTALLATION

Fig. 1: Drum brake assembly

Page 107 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 107

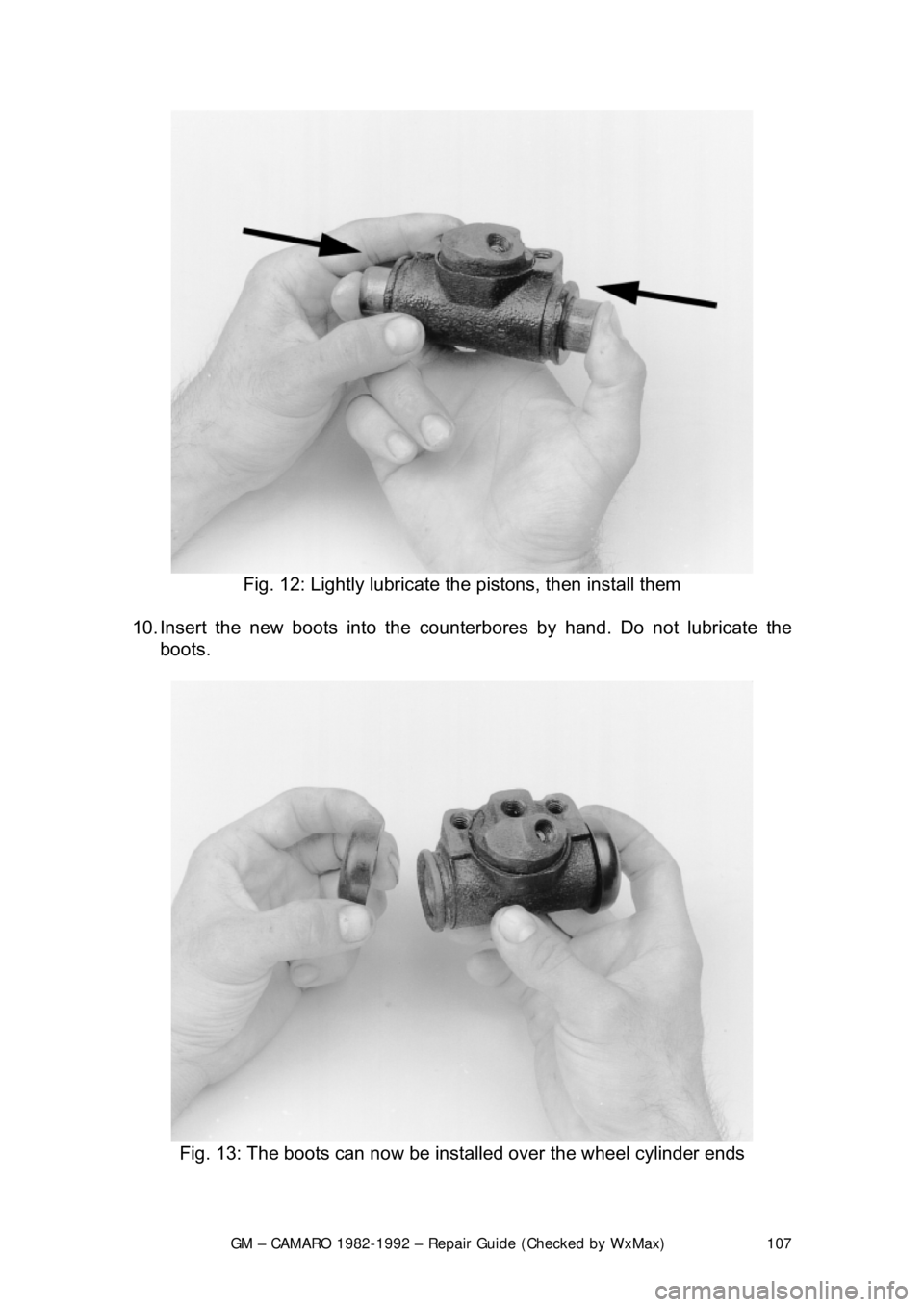

Fig. 12: Lightly lubricate t he pistons, then install them

10. Insert the new boots in to the counterbores by hand. Do not lubricate the

boots.

Fig. 13: The boots can now be installed over the wheel cylinder ends

Page 117 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 117

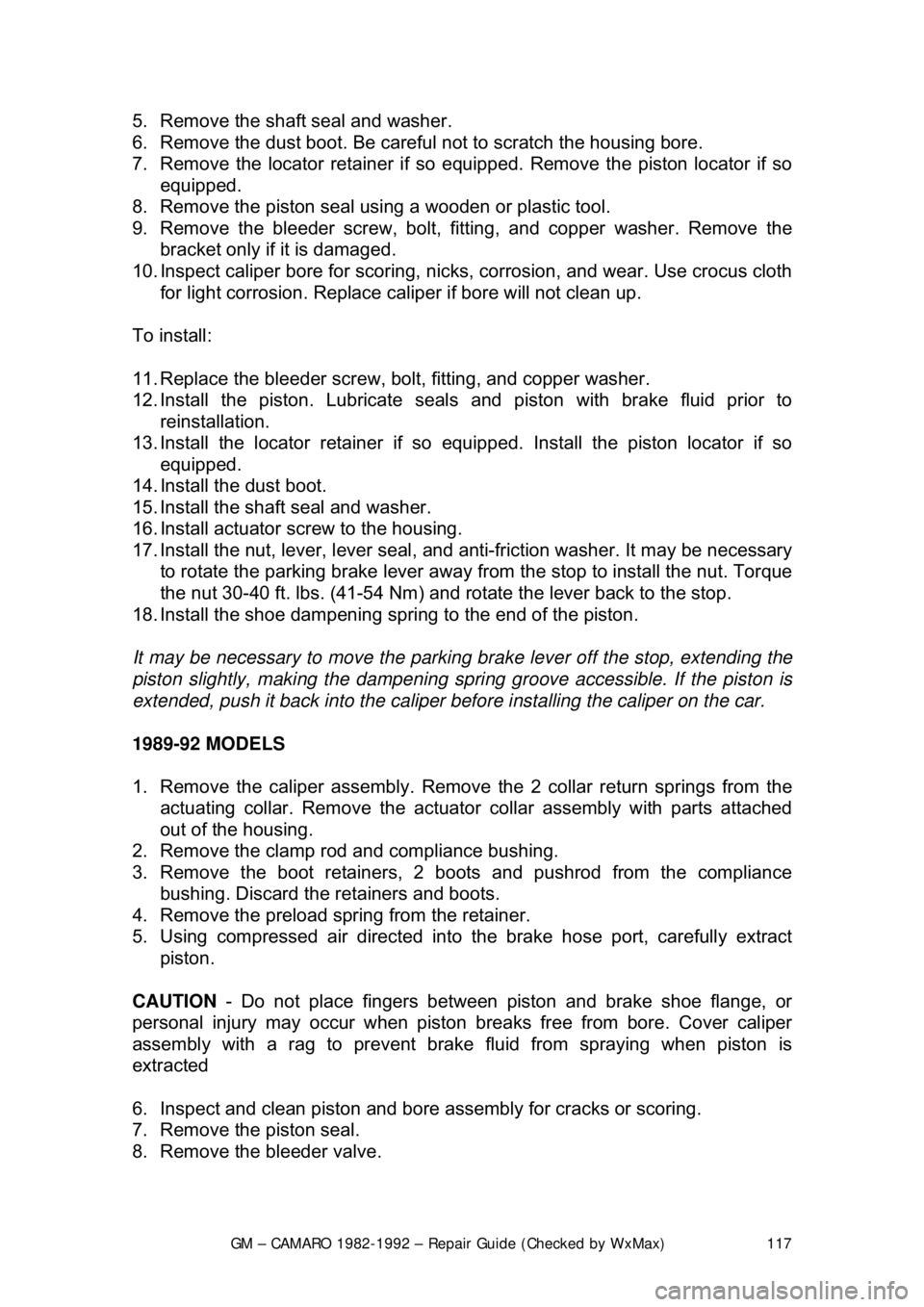

5. Remove the shaft seal and washer.

6. Remove the dust boot. Be careful not to scratch the housing bore.

7. Remove the locator retainer if so

equipped. Remove the piston locator if so

equipped.

8. Remove the piston seal usi ng a wooden or plastic tool.

9. Remove the bleeder screw, bolt, fi tting, and copper washer. Remove the

bracket only if it is damaged.

10. Inspect caliper bore for scoring, nicks, corrosion, and wear. Use crocus cloth

for light corrosion. Replace caliper if bore will not clean up.

To install:

11. Replace the bleeder screw, bolt, fitting, and copper washer.

12. Install the piston. Lubricate seal s and piston with brake fluid prior to

reinstallation.

13. Install the locator retainer if so equi pped. Install the piston locator if so

equipped.

14. Install the dust boot.

15. Install the shaft seal and washer.

16. Install actuator scr ew to the housing.

17. Install the nut, lever, lever seal, and anti-friction washer. It may be necessary

to rotate the parking brake lever away from the stop to install the nut. Torque

the nut 30-40 ft. lbs. (41-54 Nm) and ro tate the lever back to the stop.

18. Install the shoe dampening spri ng to the end of the piston.

It may be necessary to move the parking brake lever off the stop, extending the

piston slightly, making the dampening spring groove acce ssible. If the piston is

extended, push it back into the caliper before installing the caliper on the car.

1989-92 MODELS

1. Remove the caliper assembly. Remove the 2 collar return springs from the

actuating collar. Remove the actuator collar assembly with parts attached

out of the housing.

2. Remove the clamp rod and compliance bushing.

3. Remove the boot retainers, 2 boots and pushrod from the compliance

bushing. Discard the retainers and boots.

4. Remove the preload spring from the retainer.

5. Using compressed air directed into the brake hose port, carefully extract

piston.

CAUTION - Do not place fingers between piston and brake shoe flange, or

personal injury may occur when piston breaks free from bore. Cover caliper

assembly with a rag to prevent brake fluid from spraying when piston is

extracted

6. Inspect and clean piston and bore a ssembly for cracks or scoring.

7. Remove the piston seal.

8. Remove the bleeder valve.

Page 118 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 118

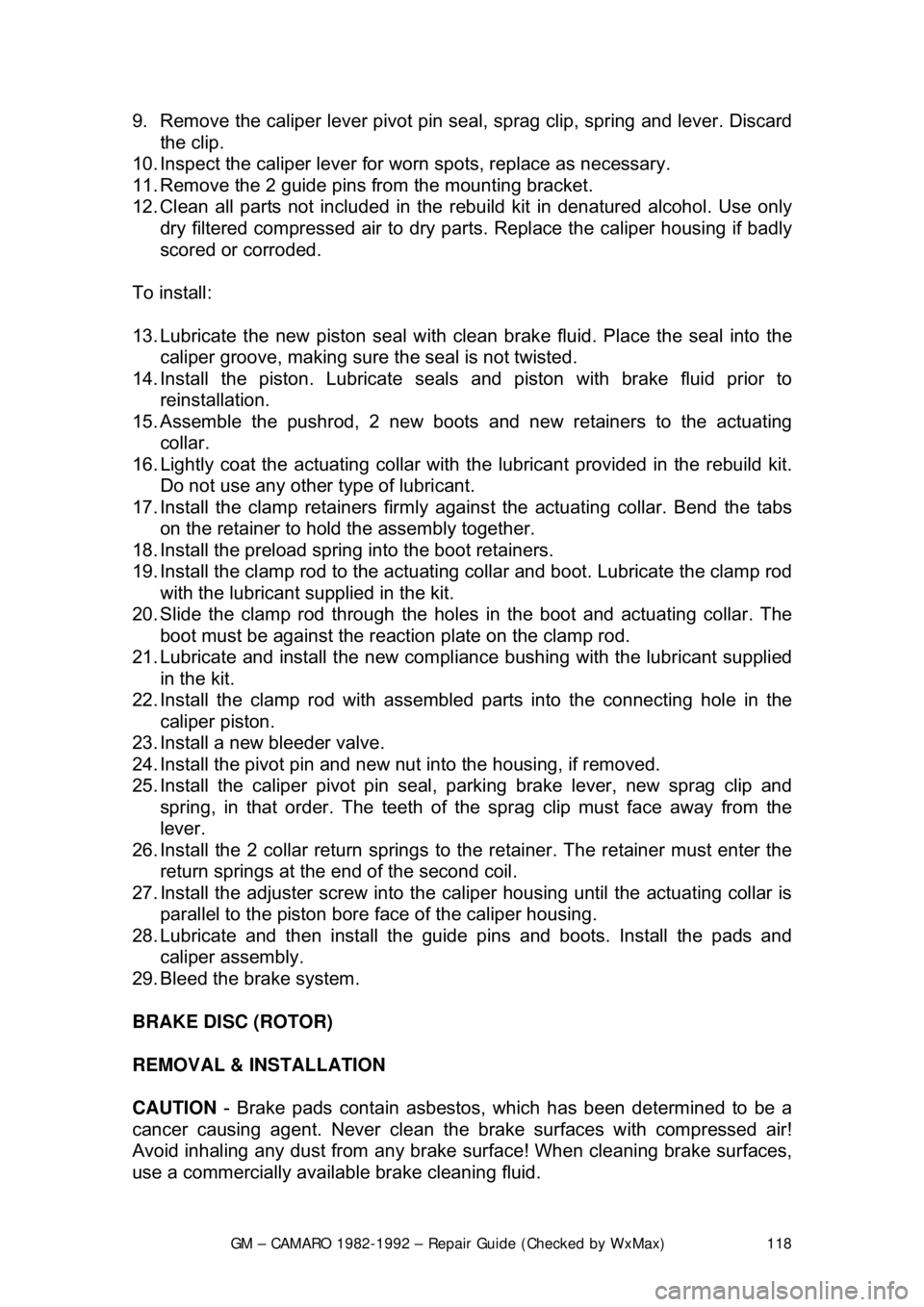

9. Remove the caliper lever pivot pin s

eal, sprag clip, spring and lever. Discard

the clip.

10. Inspect the caliper lever for worn spots, replace as necessary.

11. Remove the 2 guide pins from the mounting bracket.

12. Clean all parts not included in the r ebuild kit in denatured alcohol. Use only

dry filtered compressed air to dry parts . Replace the caliper housing if badly

scored or corroded.

To install:

13. Lubricate the new piston s eal with clean brake fluid. Place the seal into the

caliper groove, making sure t he seal is not twisted.

14. Install the piston. Lubricate seal s and piston with brake fluid prior to

reinstallation.

15. Assemble the pushrod, 2 new boots and new retainers to the actuating

collar.

16. Lightly coat the actuat ing collar with the lubricant provided in the rebuild kit.

Do not use any other type of lubricant.

17. Install the clamp retainers firmly agains t the actuating collar. Bend the tabs

on the retainer to hold the assembly together.

18. Install the preload spring into the boot retainers.

19. Install the clamp rod to the actuati ng collar and boot. Lubricate the clamp rod

with the lubricant supplied in the kit.

20. Slide the clamp rod th rough the holes in the boot and actuating collar. The

boot must be against the reacti on plate on the clamp rod.

21. Lubricate and install t he new compliance bushing with the lubricant supplied

in the kit.

22. Install the clamp rod with assembled parts into the connecting hole in the

caliper piston.

23. Install a new bleeder valve.

24. Install the pivot pin and new nut into the housing, if removed.

25. Install the caliper pivot pin seal, parking brake lever, new sprag clip and

spring, in that order. The teeth of the sprag clip mu st face away from the

lever.

26. Install the 2 collar return springs to the retainer. The retainer must enter the

return springs at the end of the second coil.

27. Install the adjuster screw into the cali per housing until the actuating collar is

parallel to the piston bore face of the caliper housing.

28. Lubricate and then install the guide pi ns and boots. Install the pads and

caliper assembly.

29. Bleed the brake system.

BRAKE DISC (ROTOR)

REMOVAL & INSTALLATION

CAUTION - Brake pads contain asbestos, which has been determined to be a

cancer causing agent. Never clean the brake surfaces with compressed air!

Avoid inhaling any dust from any brake surface! When cleaning brake surfaces,

use a commercially available brake cleaning fluid.

Page 122 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 122

REAR DISC BRAKES

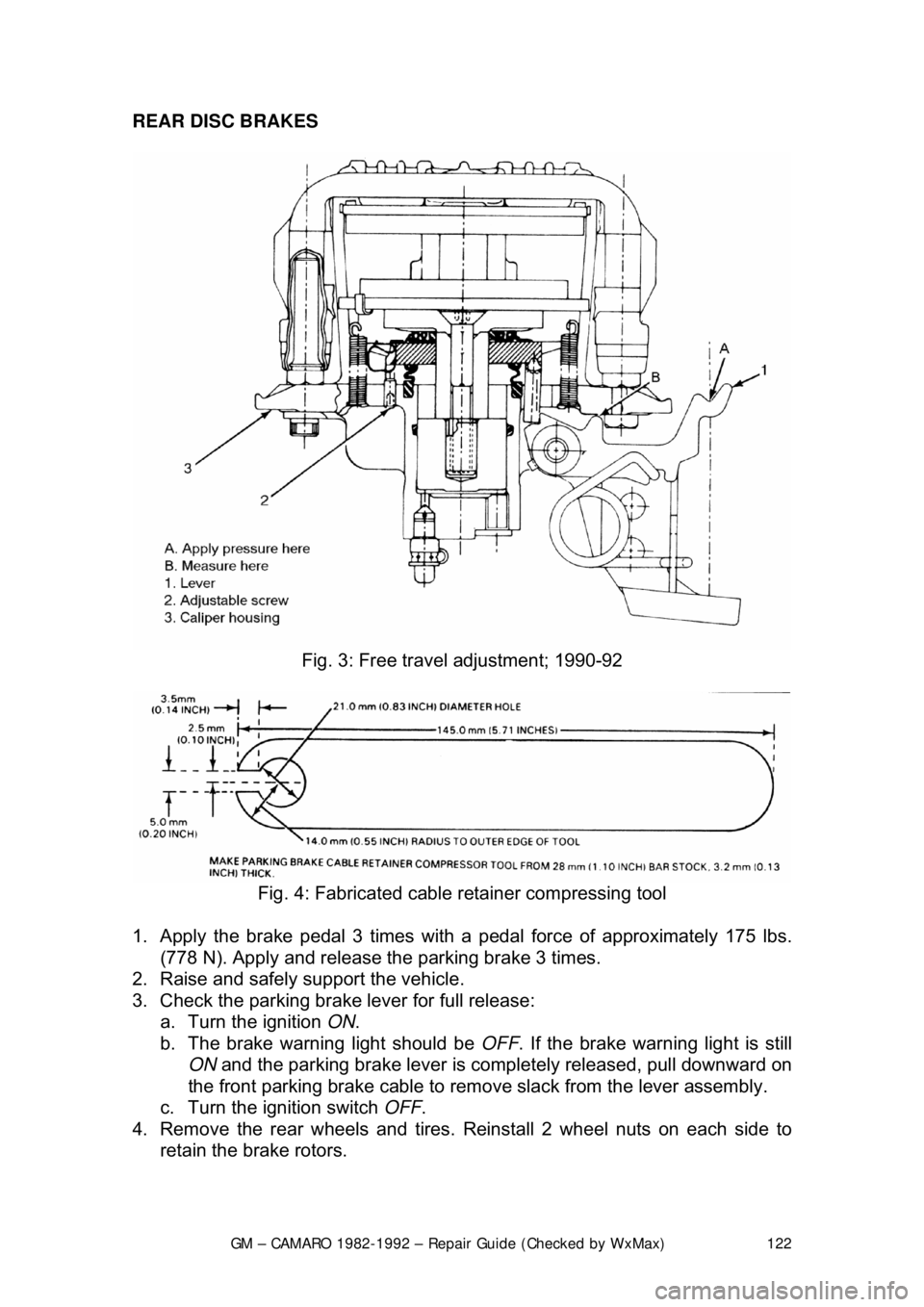

Fig. 3: Free trav el adjustment; 1990-92

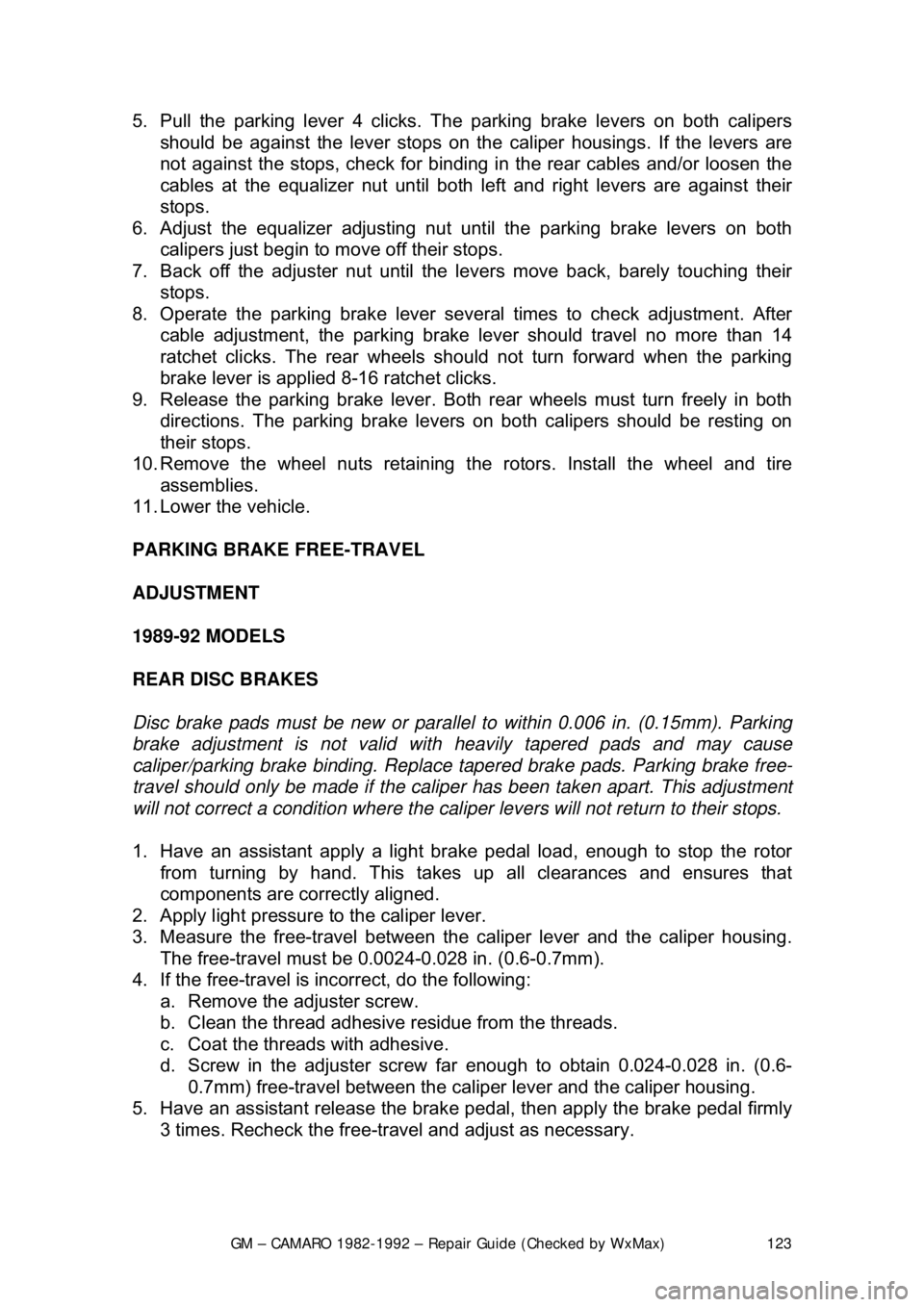

Fig. 4: Fabricated cable retainer compressing tool

1. Apply the brake pedal 3 times with a pedal force of approximately 175 lbs.

(778 N). Apply and release t he parking brake 3 times.

2. Raise and safely support the vehicle.

3. Check the parking brake lever for full release: a. Turn the ignition ON.

b. The brake warning light should be OFF. If the brake warning light is still

ON and the parking brake lever is comple tely released, pull downward on

the front parking brake cable to remove slack from the lever assembly.

c. Turn the ignition switch OFF.

4. Remove the rear wheels and tires. Reinstall 2 wheel nuts on each side to

retain the brake rotors.

Page 123 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 123

5. Pull the parking lever 4 clicks. T

he parking brake levers on both calipers

should be against the lever stops on the caliper housings. If the levers are

not against the stops, check for binding in the rear cables and/or loosen the

cables at the equalizer nut until both left and right levers are against their

stops.

6. Adjust the equalizer adjusting nut unt il the parking brake levers on both

calipers just begin to mo ve off their stops.

7. Back off the adjuster nut until the le vers move back, barely touching their

stops.

8. Operate the parking brak e lever several times to check adjustment. After

cable adjustment, the parking brake le ver should travel no more than 14

ratchet clicks. The rear wheels shoul d not turn forward when the parking

brake lever is applied 8-16 ratchet clicks.

9. Release the parking brake lever. Both rear whee ls must turn freely in both

directions. The parking brake levers on both calipers should be resting on

their stops.

10. Remove the wheel nuts retaining t he rotors. Install the wheel and tire

assemblies.

11. Lower the vehicle.

PARKING BRAKE FREE-TRAVEL

ADJUSTMENT

1989-92 MODELS

REAR DISC BRAKES

Disc brake pads must be new or parallel to within 0.006 in. (0.15mm). Parking

brake adjustment is not valid wit h heavily tapered pads and may cause

caliper/parking brake binding. Replace tapered brak e pads. Parking brake free-

travel should only be made if the caliper has been taken apart. This adjustment

will not correct a condition where the caliper levers will not return to their stops.

1. Have an assistant apply a light brake pedal load, enough to stop the rotor

from turning by hand. This takes up all clearances and ensures that

components are correctly aligned.

2. Apply light pressure to the caliper lever.

3. Measure the free-travel between t he caliper lever and the caliper housing.

The free-travel must be 0.0024-0.028 in. (0.6-0.7mm).

4. If the free-travel is incorrect, do the following: a. Remove the adjuster screw.

b. Clean the thread adhesive re sidue from the threads.

c. Coat the threads with adhesive.

d. Screw in the adjuster screw far enough to obtain 0.024-0.028 in. (0.6-

0.7mm) free-travel between the caliper lever and the caliper housing.

5. Have an assistant release the brak e pedal, then apply the brake pedal firmly

3 times. Recheck the free-travel and adjust as necessary.

Page 126 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 126

CHASSIS ELECTRICAL

UNDERSTANDING AND TROUBLESHOOTING ELECTRICAL SYSTEMS

BASIC ELECTRICAL THEORY

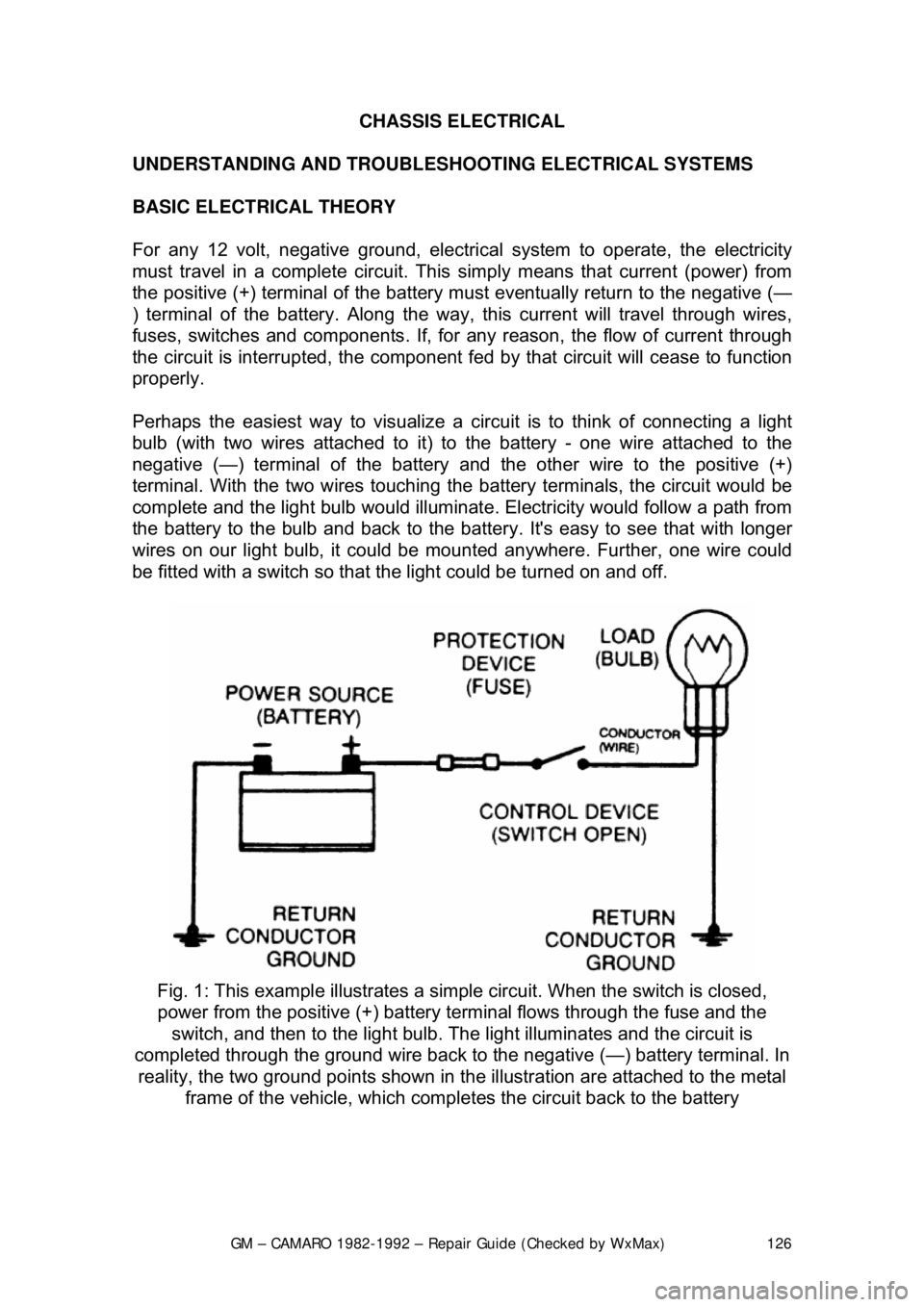

For any 12 volt, negative ground, electrical system to operate, the electricity

must travel in a complete circuit. This simply means that current (power) from

the positive (+) terminal of the battery must eventually return to the negative (—

) terminal of the battery. Along the way, this current will travel through wires,

fuses, switches and components. If, for any reason, the flow of current through

the circuit is interrupted, the component f ed by that circuit will cease to function

properly.

Perhaps the easiest way to visualize a circ uit is to think of connecting a light

bulb (with two wires attac hed to it) to the battery - one wire attached to the

negative (—) terminal of the battery and the other wire to the positive (+)

terminal. With the two wires touching the battery terminals, the circuit would be

complete and the light bulb would illuminat e. Electricity would follow a path from

the battery to the bulb and back to the bat tery. It's easy to see that with longer

wires on our light bulb, it could be mounted anywhere. Further, one wire could

be fitted with a switch so that t he light could be turned on and off.

Fig. 1: This example illu strates a simple circuit. Wh en the switch is closed,

power from the positive (+) battery te rminal flows through the fuse and the

switch, and then to the light bulb. The light illuminates and the circuit is

completed through the ground wire back to the negative (—) battery terminal. In

reality, the two ground point s shown in the illustration are attached to the metal

frame of the vehicle, which comple tes the circuit back to the battery

Page 132 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 132

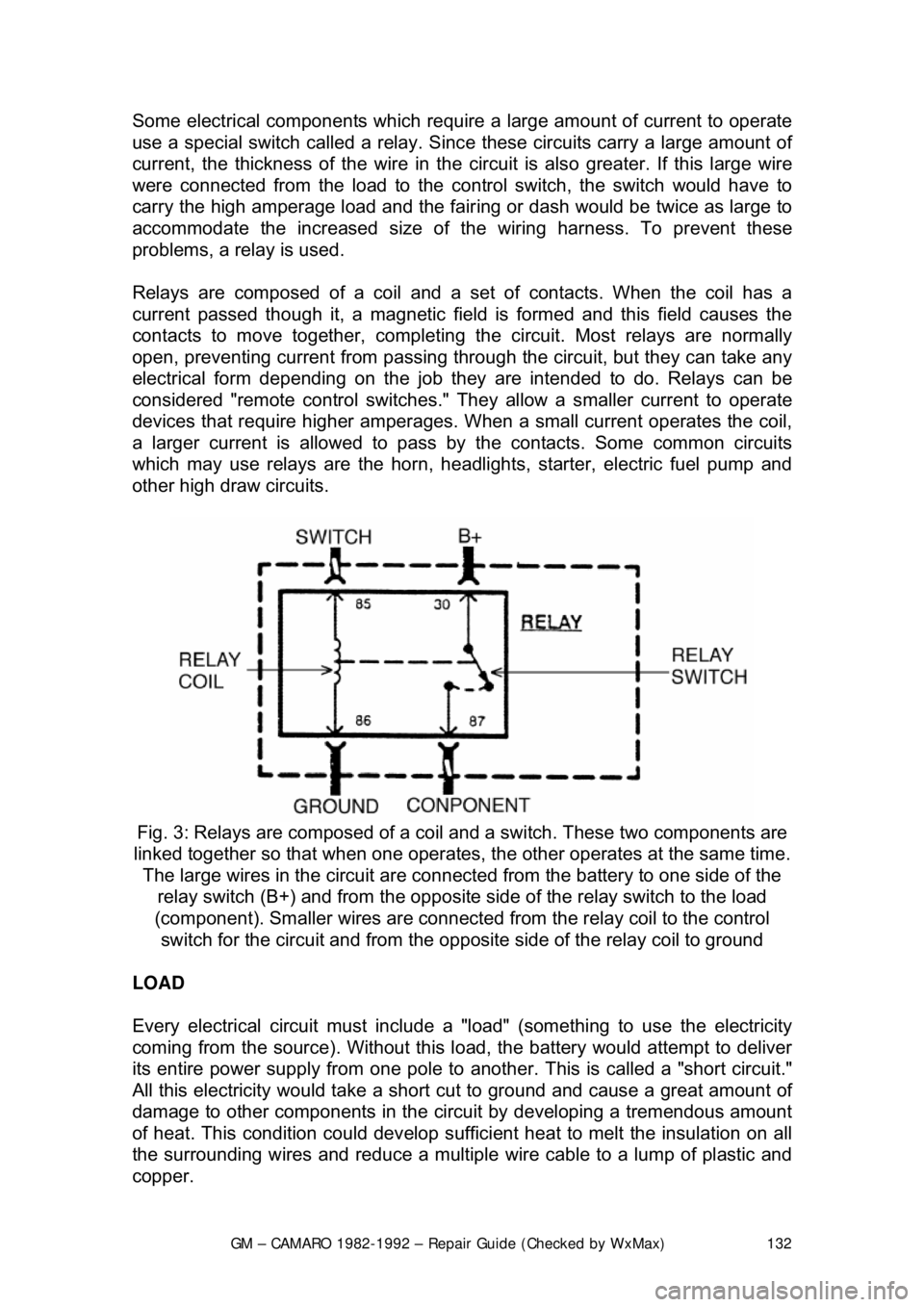

Some electrical components which require

a large amount of current to operate

use a special switch called a relay. Sinc e these circuits carry a large amount of

current, the thickness of the wire in the ci rcuit is also greater. If this large wire

were connected from the load to the c ontrol switch, the switch would have to

carry the high amperage load and the fair ing or dash would be twice as large to

accommodate the increased size of t he wiring harness. To prevent these

problems, a relay is used.

Relays are composed of a coil and a se t of contacts. When the coil has a

current passed though it, a magnetic fiel d is formed and this field causes the

contacts to move together, completing the circuit. Most relays are normally

open, preventing current from passing thr ough the circuit, but they can take any

electrical form depending on th e job they are intended to do. Relays can be

considered "remote control switches." They allow a smaller current to operate

devices that require higher amperages. W hen a small current operates the coil,

a larger current is allo wed to pass by the contacts. Some common circuits

which may use relays are the horn, headlight s, starter, electric fuel pump and

other high draw circuits.

Fig. 3: Relays are composed of a coil and a switch. These two components are

linked together so that w hen one operates, the other operat es at the same time.

The large wires in the circuit are connect ed from the battery to one side of the

relay switch (B+) and from the opposite side of the re lay switch to the load

(component). Smaller wires are connected from the relay coil to the control

switch for the circuit and from the opposite side of the relay coil to ground

LOAD

Every electrical circuit must include a "load" (something to use the electricity

coming from the source). Without this l oad, the battery would attempt to deliver

its entire power supply from one pole to another. This is called a "short circuit."

All this electricity would take a short cut to ground and cause a great amount of

damage to other components in the circui t by developing a tremendous amount

of heat. This condition could develop suffici ent heat to melt the insulation on all

the surrounding wires and reduce a multiple wire cable to a lump of plastic and

copper.

Page 136 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 136

accidental grounding. It is al

so advisable to include a standard automotive fuse

in any jumper wire. This is commonly referred to as a "fused jumper". By

inserting an in-line fuse holder between a set of test leads, a fused jumper wire

can be used for bypassing open circuits. Use a 5 amp fuse to provide protection

against voltage spikes.

Jumper wires are used primarily to locate open electrical circuits, on either the

ground (—) side of the circuit or on the power (+) side. If an electrical

component fails to operate, connect t he jumper wire between the component

and a good ground. If the component operates only with the jumper installed,

the ground circuit is open. If the ground circuit is good, but the component does

not operate, the circuit between the power feed and component may be open.

By moving the jumper wire successively back from the component toward the

power source, you can isolate the area of the circuit where the open is located.

When the component stops func tioning, or the power is cut off, the open is in

the segment of wire between the jumper and the point previously tested.

You can sometimes connect the jumper wir e directly from the battery to the

"hot" terminal of the component, but firs t make sure the component uses 12

volts in operation. Some electrical components, such as fuel injectors or

sensors, are designed to operate on about 4 to 5 volts, and running 12 volts

directly to these components will cause damage.

TEST LIGHTS

Fig. 1: A 12 volt test light is used to detect the presence of voltage in a circuit

The test light is used to check circuits and components while electrical current is

flowing through them. It is used for volt age and ground tests. To use a 12 volt

test light, connect the ground clip to a good ground and probe wherever

necessary with the pick. The test light will illuminate when voltage is detected.

This does not necessarily mean that 12 volts (or any particular amount of