light CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 217 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 217

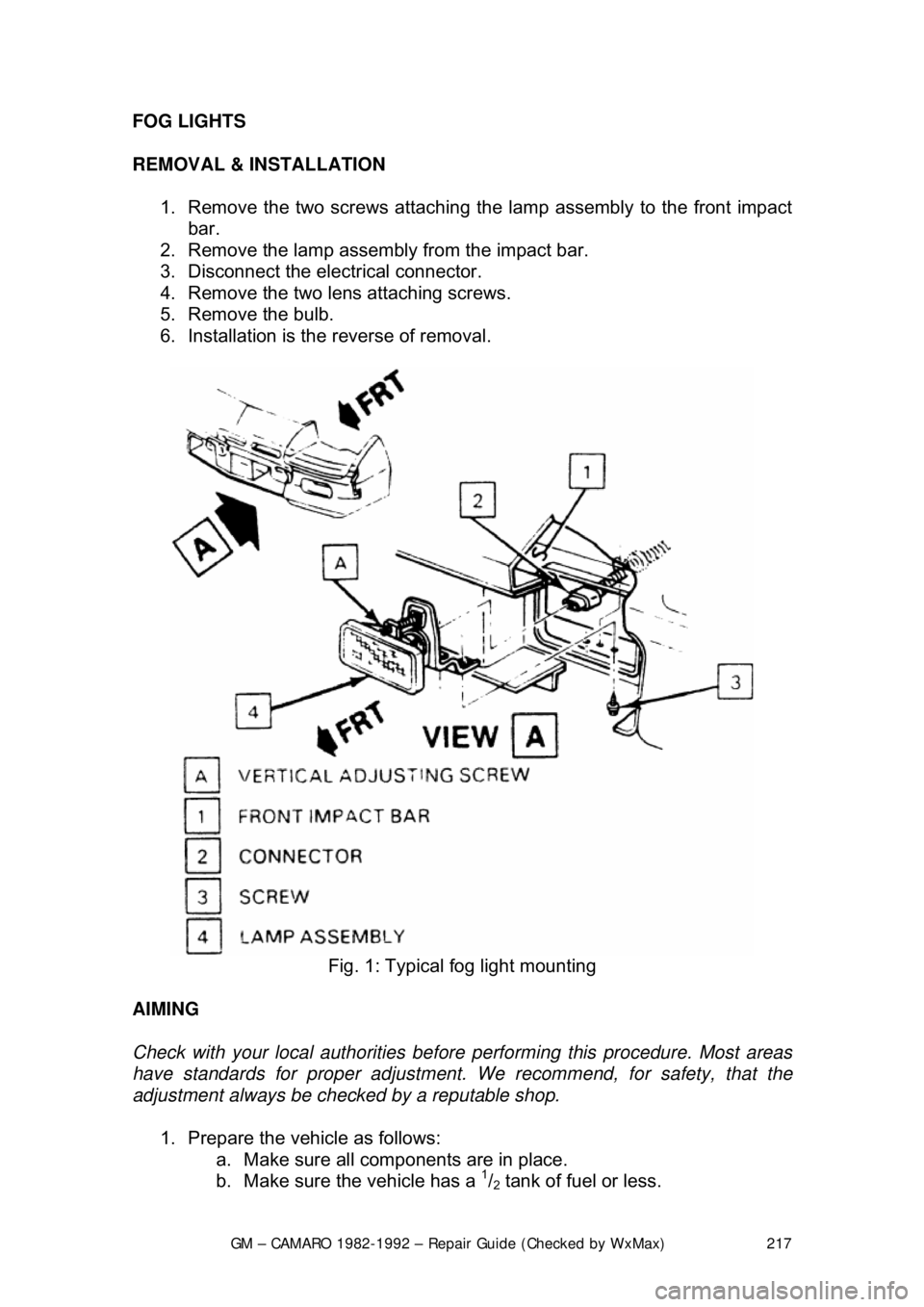

FOG LIGHTS

REMOVAL & INSTALLATION

1. Remove the two screws attaching the lamp assembly to the front impact

bar.

2. Remove the lamp assembly from the impact bar.

3. Disconnect the electrical connector.

4. Remove the two lens attaching screws.

5. Remove the bulb.

6. Installation is the reverse of removal.

Fig. 1: Typical fog light mounting

AIMING

Check with your local authorities before performing this procedure. Most areas

have standards for proper adjustment. We recommend, for safety, that the

adjustment always be checked by a reputable shop.

1. Prepare the vehicle as follows: a. Make sure all com ponents are in place.

b. Make sure the vehicle has a

1/2 tank of fuel or less.

Page 223 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 223

FUSIBLE LINKS

In addition to circuit breakers and fuses,

the wiring harness incorporates fusible

links to protect the wiring. Links are used rather than a fuse, in wiring circuits

that are not normally fused, such as th e ignition circuit. The fusible links are

color coded red in the charging and load circuits to match the color coding of

the circuits they protect. Each link is four gauges smaller than the cable it

protects, and is marked on the insulation with the gauge size because the

insulation makes it appear heavier than it really is. The engine compartment

wiring harness has several fusible links. The same size wire with a special

Hypalon insulation must be used w hen replacing a fusible link.

For more details, see the information on fusible links at the beginning of this

section.

The links are located in the following areas:

1. A molded splice at the starter solenoid Bat terminal, a 14 gauge red wire.

2. A 16 gauge red fusible link at the j unction block to protect the unfused

wiring of 12 gauge or larger wire. This link stops at the bulkhead

connector.

3. The alternator warning light and fiel d circuitry is protected by a 20 gauge

red wire fusible link used in the batte ry feed-to-voltage regulator number

3 terminal. The link is installed as a molded splice in the circuit at the

junction block.

4. The ammeter circuit is protected by two 20 gauge fusible links installed

as molded splices in the circuit at t he junction block and battery to starter

circuit.

REPLACEMENT 1. Determine the circuit that is damaged.

2. Disconnect the negative battery terminal.

3. Cut the damaged fuse link from the harness and discard it.

4. Identify and procure the proper fuse link and butt connectors.

5. Strip the wire about

1/2 in. (13mm) on each end.

6. Connect the fusible link and crimp the butt connectors making sure that the wires are secure.

7. Solder each connection with resin core solder, and wrap the connections

with plastic electrical tape.

8. Reinstall the wir e in the harness.

9. Connect the negative battery terminal and test the system for proper

operation.

CIRCUIT BREAKERS

Various circuit breakers are located under the instrument panel. In order to gain

access to these components, it may be ne cessary to first remove the under

dash padding. Most of the circuit breakers are located in the convenience

center or the fuse panel.

Page 291 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 291

6. Remove the console cover.

7. Remove the shifter boot.

8. Remove the shifter mounting bolt

s and remove the shifter assembly.

9. Installation is the reverse of the removal procedure. Adjust the linkage as

detailed earlier.

BACK-UP LIGHT SWITCH

REMOVAL & INSTALLATION 1. Disconnect the negative battery terminal from the battery.

2. At the left-rear of the transmission, the back-up light switch is threaded

into the transmission case. The speed sensor is held in with a separate

bracket. Disconnect the electrical co nnector from the back-up light

switch.

3. Remove the back-up light swit ch from the transmission.

4. To install, reverse the remova l procedures. Coat the threads with

Teflon® tape. Please refer to the to rque chart for specifications. Place

the gear shift lever in the revers e position and check that the back-up

lights work.

EXTENSION HOUSING SEAL

REMOVAL & INSTALLATION

This seal controls transmission oil leakage around the driveshaft. Continued

failure of this seal usually indicates a worn output shaft bushing. If so, there will

be signs of the same wear on the driveshaft where it contacts the seal and

bushing. The seal is available and is fairly simple to install, with the proper tool.

1. Raise and safely support the rear of the vehicle to minimize transmission

oil loss when the driveshaft is removed.

2. Unbolt the driveshaft fr om the differential and center support bearing, if

equipped. Wrap tape around the bearing cu ps to keep them in place on

the universal joint and slide the sh aft out of the transmission.

3. Use an small pry tool to carefully pry out the old seal. Be careful not to

insert the tool too far into the hous ing or the bushing will be damaged.

Page 293 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 293

4. Remove the torque arm from t

he vehicle as outlined under Rear

Suspension in

Suspension & Steering of this repair guide.

5. Mark the driveshaft and the rear ax le pinion flange to indicate their

relationship. Unbolt the rear universal joint straps. Lower the rear of the

driveshaft, being careful to keep the universal joint caps in place.

Withdraw the driveshaft from the transmission and remove it from the

vehicle.

6. Disconnect the speedometer cable a nd the electrical connectors from the

transmission.

7. Remove the exhaust pipe brace.

8. Remove the transmission shifter support attaching bolts from the

transmission.

9. On 4-speed transmissions only, disconnec t the shift linkage at the shifter.

10. Raise the transmission slight ly with a jack, then remove the

crossmember attaching bolts.

11. Remove the transmission mount atta ching bolts, then remove the mount

and crossmember from the vehicle.

12. Remove the transmission attachi ng bolts, then with the aid of an

assistant, move the transmission r earward and downward out of the

vehicle.

To install: 13. Apply a light coating of high temperature grease to the main drive gear

bearing retainer and to the splined por tion of the main drive gear. This

will assure free movement of the clutch and transmission components

during assembly.

14. Install the transmission and secu re with transmission mounting bolts

Torque transmission-to-clutch housing bo lts to 55 ft. lbs. (74 Nm).

15. Install the mount and cr ossmember into the vehicle, then install the

transmission mount attaching bolts. Torque both the mount-to-

crossmember bolts and t he mount-to-transmission bolts to 35 ft. lbs. (47

Nm).

16. Install the crossmember attach ing bolts. Torque the crossmember-to-

body bolts to 35 ft. lbs.

17. On 4-speed transmissions only, connect the shift linkage at the shifter and adjust the shift linkage.

18. Install the transmission shifte r support attaching bolts to the

transmission. Torque shifter bracket-to -extension housing to 25 ft. lbs.

(35 Nm).

19. Install the exhaust pipe brace.

20. Connect the speedometer cable and the electrical connectors to the

transmission.

21. Install the driveshaft into the tr ansmission. Then, align the marks on the

driveshaft and the rear axle pinion fl ange. Bolt the rear universal joint

straps.

22. Install the torque arm into the vehicle.

23. Fill the transmission wi th lubricant. Then install the filler plug and torque

to 15 ft. lbs. (20 Nm).

24. Lower the vehicle.

Page 295 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 295

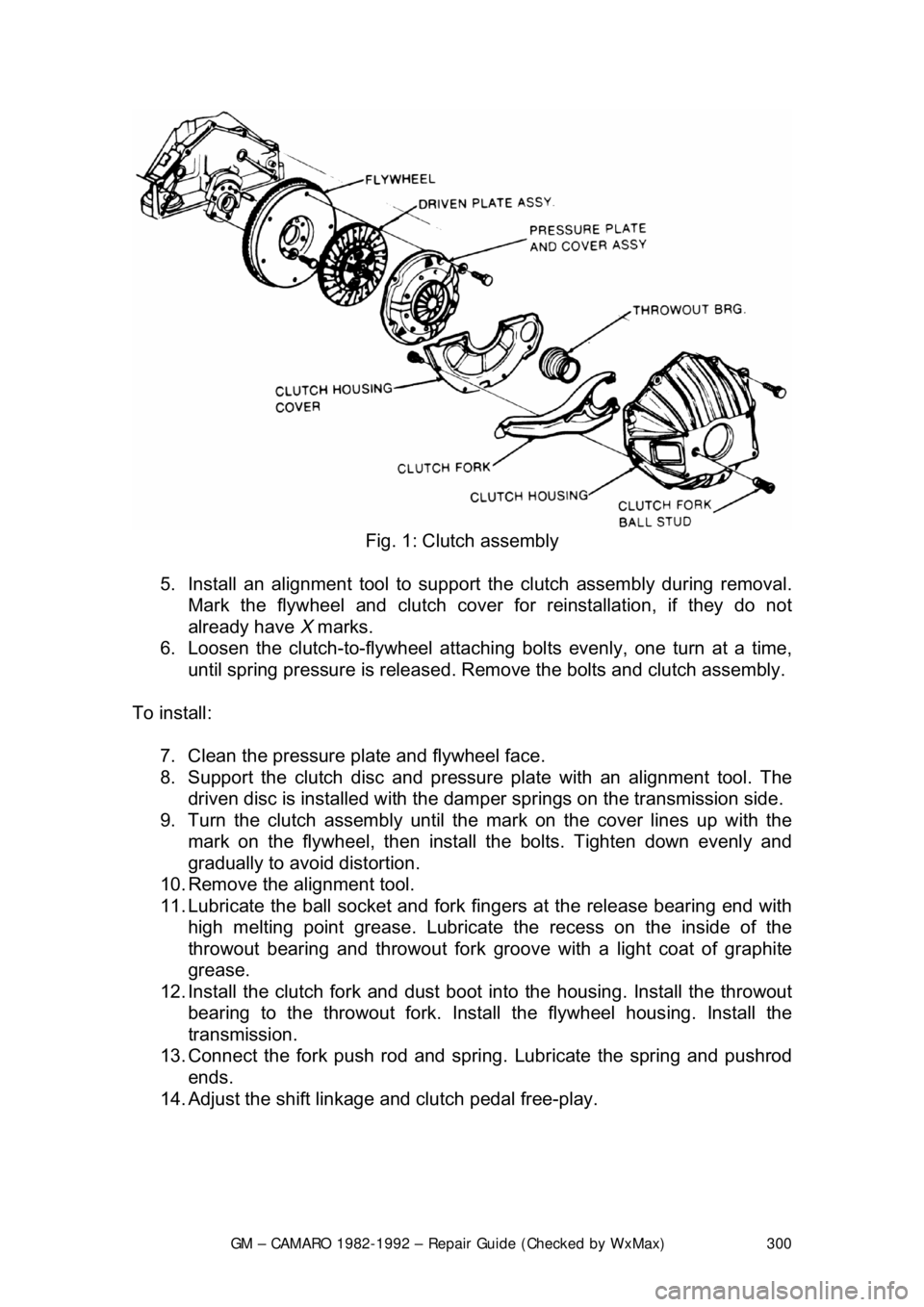

of the spring bow outward, pushing the pre

ssure plate into closer contact with

the clutch disc. As the disc and plate mo ve closer together, friction between the

two increases and slippage is reduced until, when full spring pressure is applied

(by fully releasing the pedal) the speed of the disc and plate are the same. This

stops all slipping, creating a direct connection between the plate and disc which

results in the transfer of power from t he engine to the transmission. The clutch

disc is now rotating with the pressure plate at engine speed and, because it is

splined to the transmission shaft, the shaft now turns at the same engine speed.

The clutch is operating properly if: 1. It will stall the engine when released with the vehicle held stationary.

2. The shift lever can be moved freel y between 1st and reverse gears when

the vehicle is stationary and the clutch disengaged.

APPLICATION

All 1982-83 vehicles use a mechanical (non-hydraulic) clutch; 1984-92 models

use a hydraulic clutch. With the hydraulic clutch, no adjustment of the clutch

pedal or the linkage is required. On t he mechanical type, the only required

adjustment is to maintain the proper clutch pedal freeplay. The freeplay\

adjustment is very important, for it determines the engaging and disengaging

characteristics of the clutch assembly.

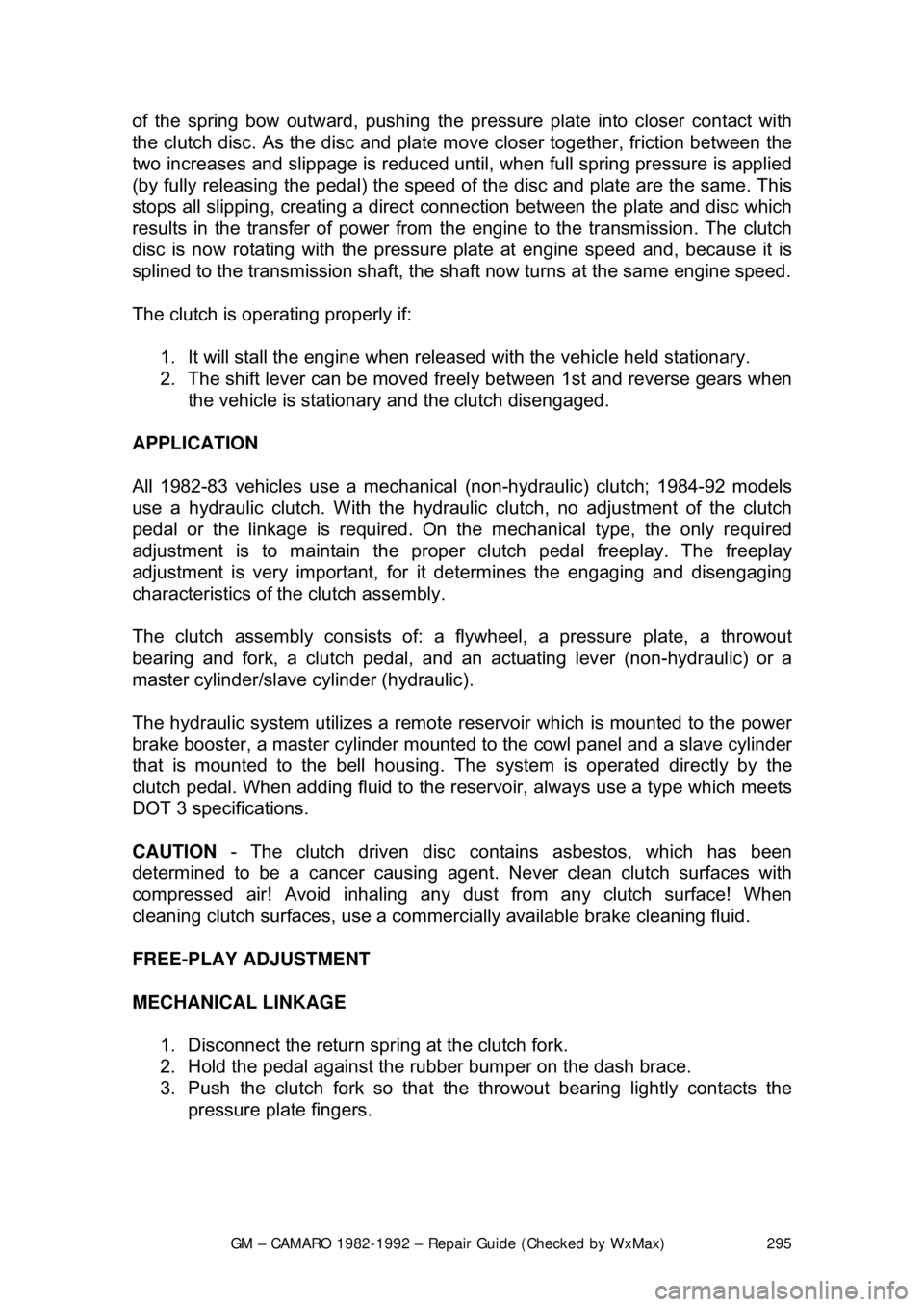

The clutch assembly consists of: a flywheel, a pressure plate, a throwout

bearing and fork, a clutch pedal, and an actuating lever (non-hydraulic) or a

master cylinder/slave cylinder (hydraulic).

The hydraulic system utilizes a remote re servoir which is mounted to the power

brake booster, a master cy linder mounted to the cowl p anel and a slave cylinder

that is mounted to the bell housing. Th e system is operated directly by the

clutch pedal. When adding fl uid to the reservoir, always use a type which meets

DOT 3 specifications.

CAUTION - The clutch driven disc contains asbestos, which has been

determined to be a cancer causing agen t. Never clean clutch surfaces with

compressed air! Avoid inhaling any dus t from any clutch surface! When

cleaning clutch surfaces, use a commercia lly available brake cleaning fluid.

FREE-PLAY ADJUSTMENT

MECHANICAL LINKAGE 1. Disconnect the return sp ring at the clutch fork.

2. Hold the pedal against the rubber bumper on the dash brace.

3. Push the clutch fork so that th e throwout bearing lightly contacts the

pressure plate fingers.

Page 300 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 300

Fig. 1: Clutch assembly

5. Install an alignment tool to support the clutch assembly during removal.

Mark the flywheel and clutch cover for reinstallation, if they do not

already have X marks.

6. Loosen the clutch-to-flywheel attachi ng bolts evenly, one turn at a time,

until spring pressure is released. Remo ve the bolts and clutch assembly.

To install: 7. Clean the pressure plate and flywheel face.

8. Support the clutch di sc and pressure plate with an alignment tool. The

driven disc is installed with the damper springs on the transmission side.

9. Turn the clutch assembly until t he mark on the cover lines up with the

mark on the flywheel, then install t he bolts. Tighten down evenly and

gradually to avoid distortion.

10. Remove the alignment tool.

11. Lubricate the ball socket and fork fi ngers at the release bearing end with

high melting point greas e. Lubricate the recess on the inside of the

throwout bearing and throwout fork groove with a light coat of graphite

grease.

12. Install the clutch fork and dust boot into the housing. Install the throwout

bearing to the throwout fork. Insta ll the flywheel housing. Install the

transmission.

13. Connect the fork push rod and spri ng. Lubricate the spring and pushrod

ends.

14. Adjust the shift linkage and clutch pedal free-play.

Page 304 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 304

Never release a depressed clutch pedal

with the bleeder screw open or air will

be drawn into the system.

AUTOMATIC TRANSMISSION

UNDERSTANDING AUTOMATIC TRANSMISSIONS

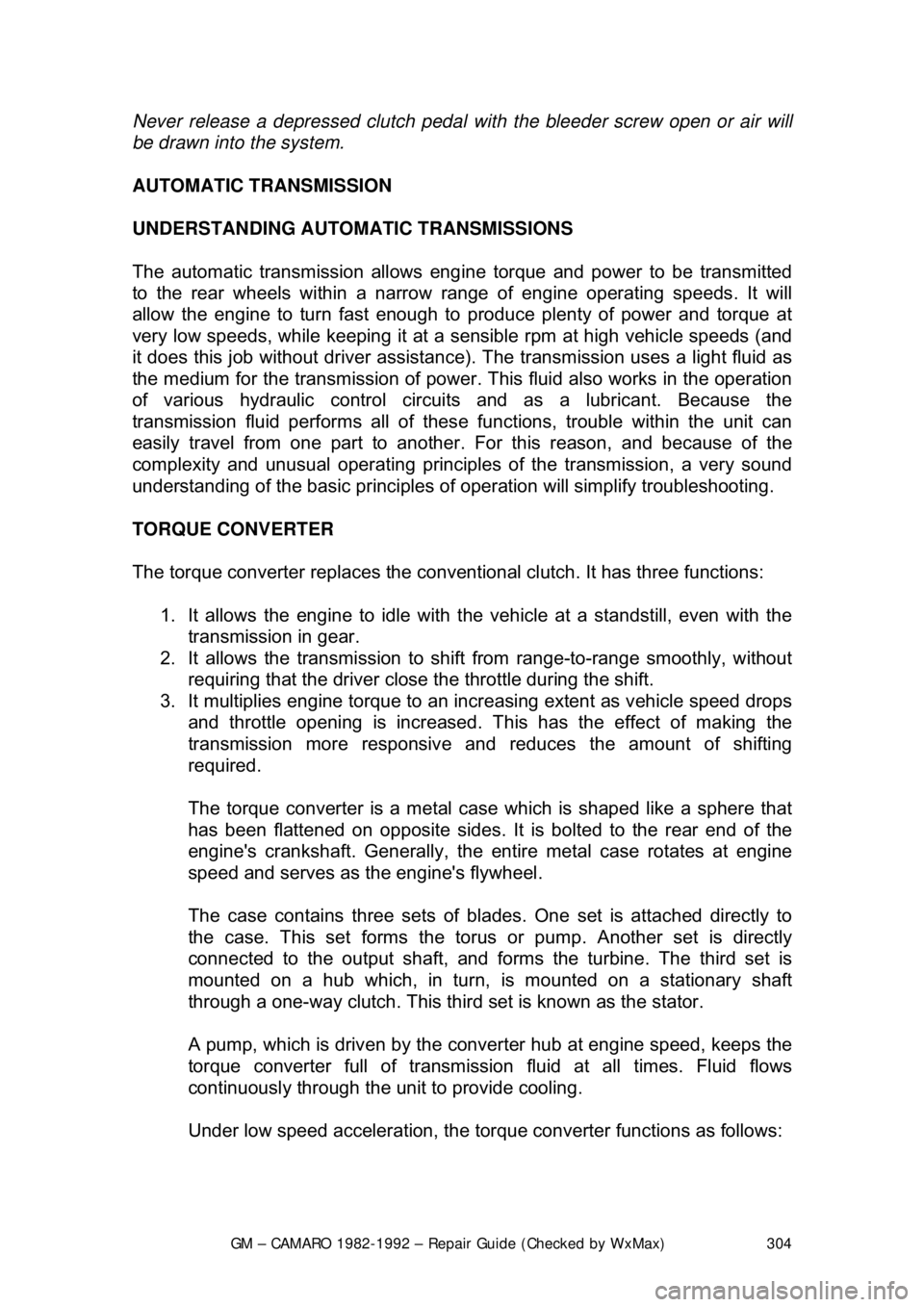

The automatic transmission allows eng ine torque and power to be transmitted

to the rear wheels within a narrow range of engine operating speeds. It will

allow the engine to turn fast enough to produce plenty of power and torque at

very low speeds, while keeping it at a s ensible rpm at high vehicle speeds (and

it does this job without driv er assistance). The transmission uses a light fluid as

the medium for the transmission of power. This fluid also works in the operation

of various hydraulic control circui ts and as a lubricant. Because the

transmission fluid performs all of thes e functions, trouble within the unit can

easily travel from one part to another. For this reason, and because of the

complexity and unusual oper ating principles of the transmission, a very sound

understanding of the basic principles of operation will simplify troubleshooting.

TORQUE CONVERTER

The torque converter replaces the convent ional clutch. It has three functions:

1. It allows the engine to idle with t he vehicle at a standstill, even with the

transmission in gear.

2. It allows the transmission to shi ft from range-to-range smoothly, without

requiring that the driver close the throttle during the shift.

3. It multiplies engine torque to an incr easing extent as vehicle speed drops

and throttle opening is increased. This has the effect of making the

transmission more responsive and redu ces the amount of shifting

required.

The torque converter is a metal case which is shaped like a sphere that

has been flattened on opposite sides. It is bolted to the rear end of the

engine's crankshaft. Generally, the ent ire metal case rotates at engine

speed and serves as the engine's flywheel.

The case contains three sets of bl ades. One set is attached directly to

the case. This set forms the torus or pump. Another set is directly

connected to the output shaft, and forms the turbine. The third set is

mounted on a hub which, in turn, is mounted on a stationary shaft

through a one-way clutch. This third set is known as the stator.

A pump, which is driven by the conv erter hub at engine speed, keeps the

torque converter full of transmission fluid at all times. Fluid flows

continuously through the unit to provide cooling.

Under low speed acceleration, the tor que converter functions as follows:

Page 313 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 313

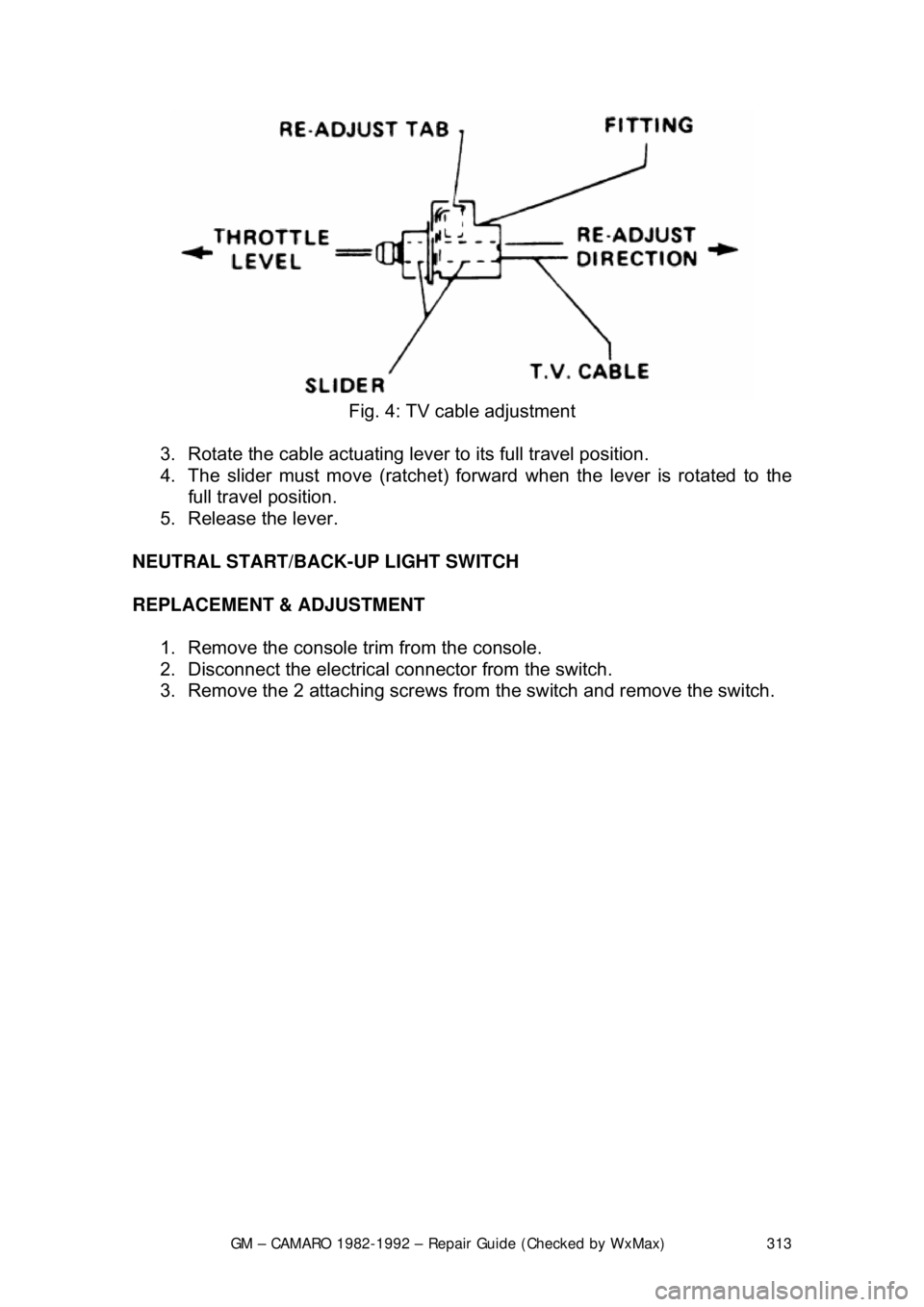

Fig. 4: TV cable adjustment

3. Rotate the cable actuating leve r to its full travel position.

4. The slider must move (ratchet) forw ard when the lever is rotated to the

full travel position.

5. Release the lever.

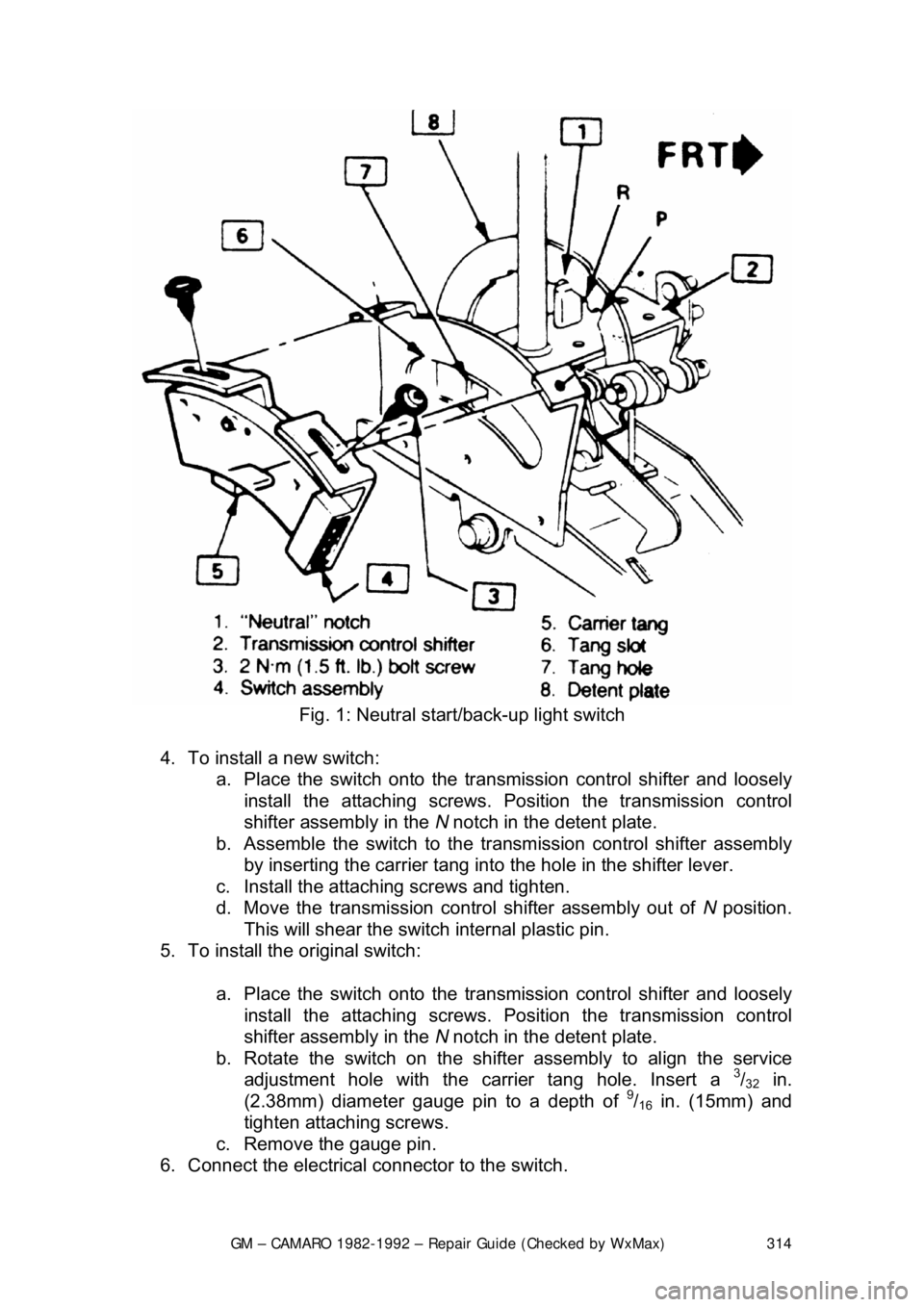

NEUTRAL START/BACK-UP LIGHT SWITCH

REPLACEMENT & ADJUSTMENT 1. Remove the console tr im from the console.

2. Disconnect the electrical connector from the switch.

3. Remove the 2 attaching screws from the switch and remove the switch.

Page 314 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 314

Fig. 1: Neutral start/back-up light switch

4. To install a new switch: a. Place the switch onto the trans mission control shifter and loosely

install the attaching screws. Po sition the transmission control

shifter assembly in the N notch in the detent plate.

b. Assemble the switch to the tr ansmission control shifter assembly

by inserting the carrier tang into the hole in the shifter lever.

c. Install the attaching screws and tighten.

d. Move the transmission control shifter assembly out of N position.

This will shear the switch internal plastic pin.

5. To install the original switch:

a. Place the switch onto the trans mission control shifter and loosely

install the attaching screws. Po sition the transmission control

shifter assembly in the N notch in the detent plate.

b. Rotate the switch on the shifter assembly to align the service adjustment hole with the carrier tang hole. Insert a

3/32 in.

(2.38mm) diameter g auge pin to a depth of 9/16 in. (15mm) and

tighten attaching screws.

c. Remove the gauge pin.

6. Connect the electrical connector to the switch.

Page 321 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 321

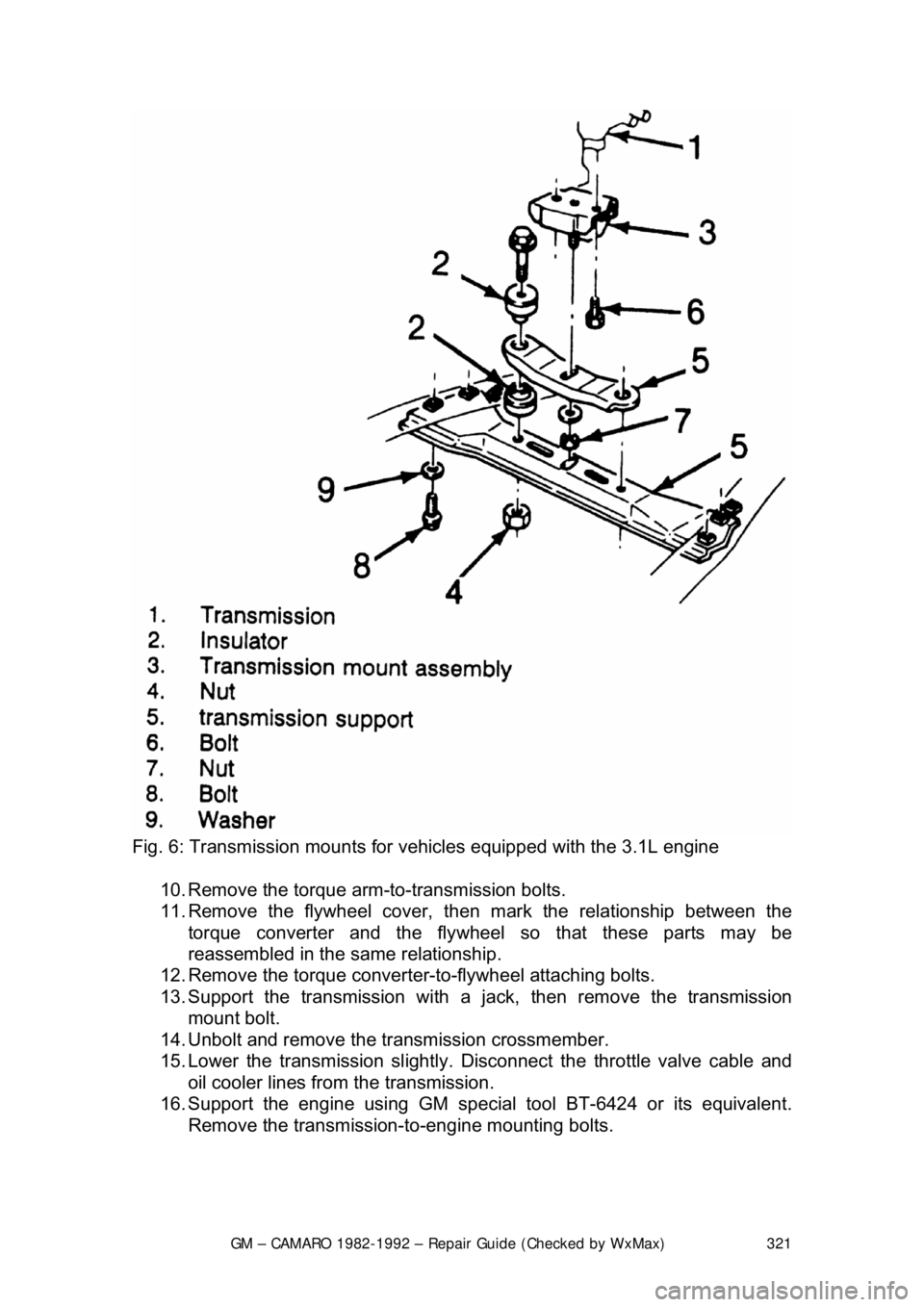

Fig. 6: Transmission mounts for vehi cles equipped with the 3.1L engine

10. Remove the torque arm-to-transmission bolts.

11. Remove the flywheel cover, t hen mark the relationship between the

torque converter and the flywheel so that these parts may be

reassembled in the same relationship.

12. Remove the torque converter-t o-flywheel attaching bolts.

13. Support the transmission with a ja ck, then remove the transmission

mount bolt.

14. Unbolt and remove the transmission crossmember.

15. Lower the transmission slightly. Disco nnect the throttle valve cable and

oil cooler lines from the transmission.

16. Support the engine using GM specia l tool BT-6424 or its equivalent.

Remove the transmission- to-engine mounting bolts.