carb CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 620 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 620

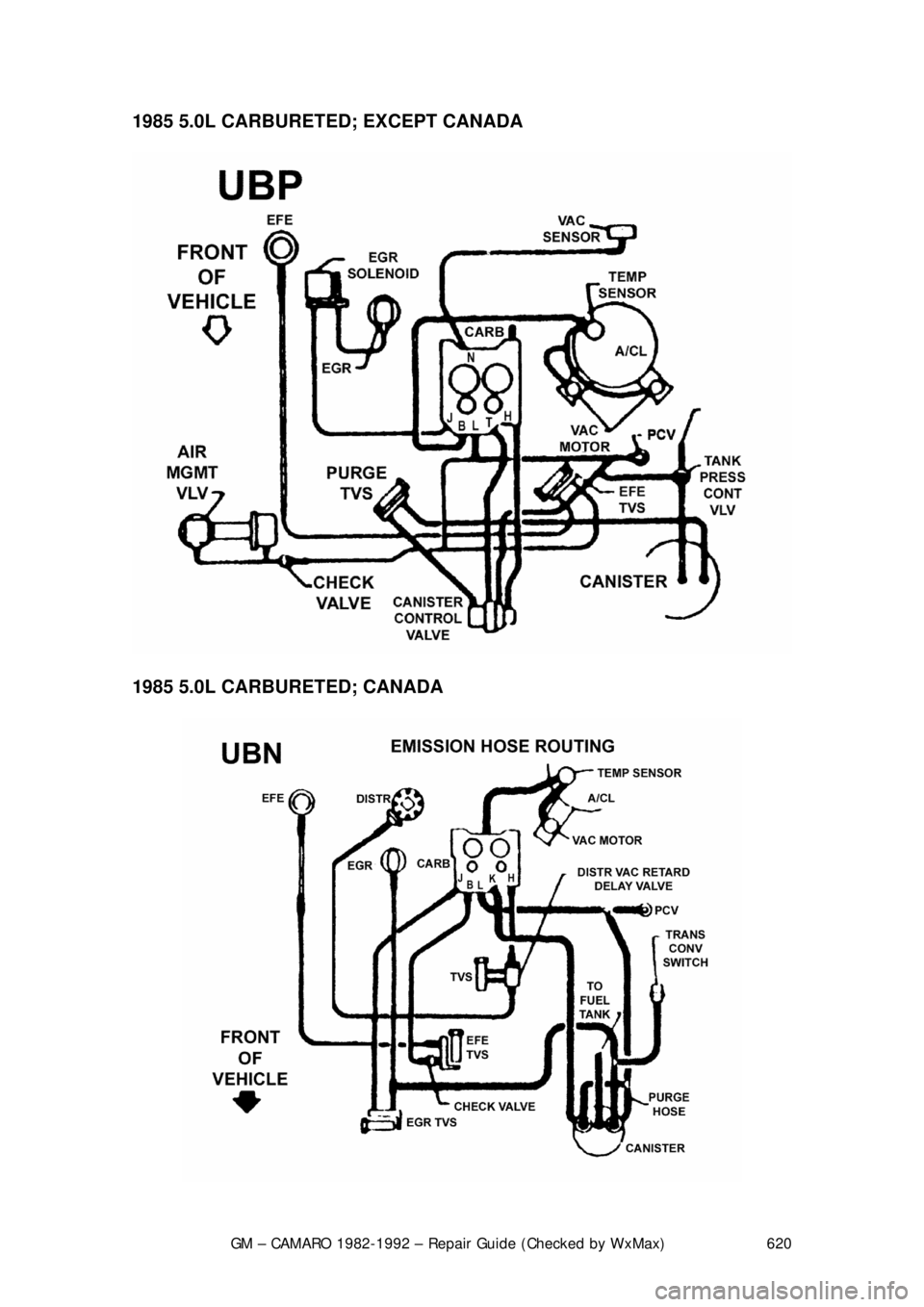

1985 5.0L CARBURETED;

EXCEPT CANADA

1985 5.0L CARBURETED; CANADA

Page 621 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 621

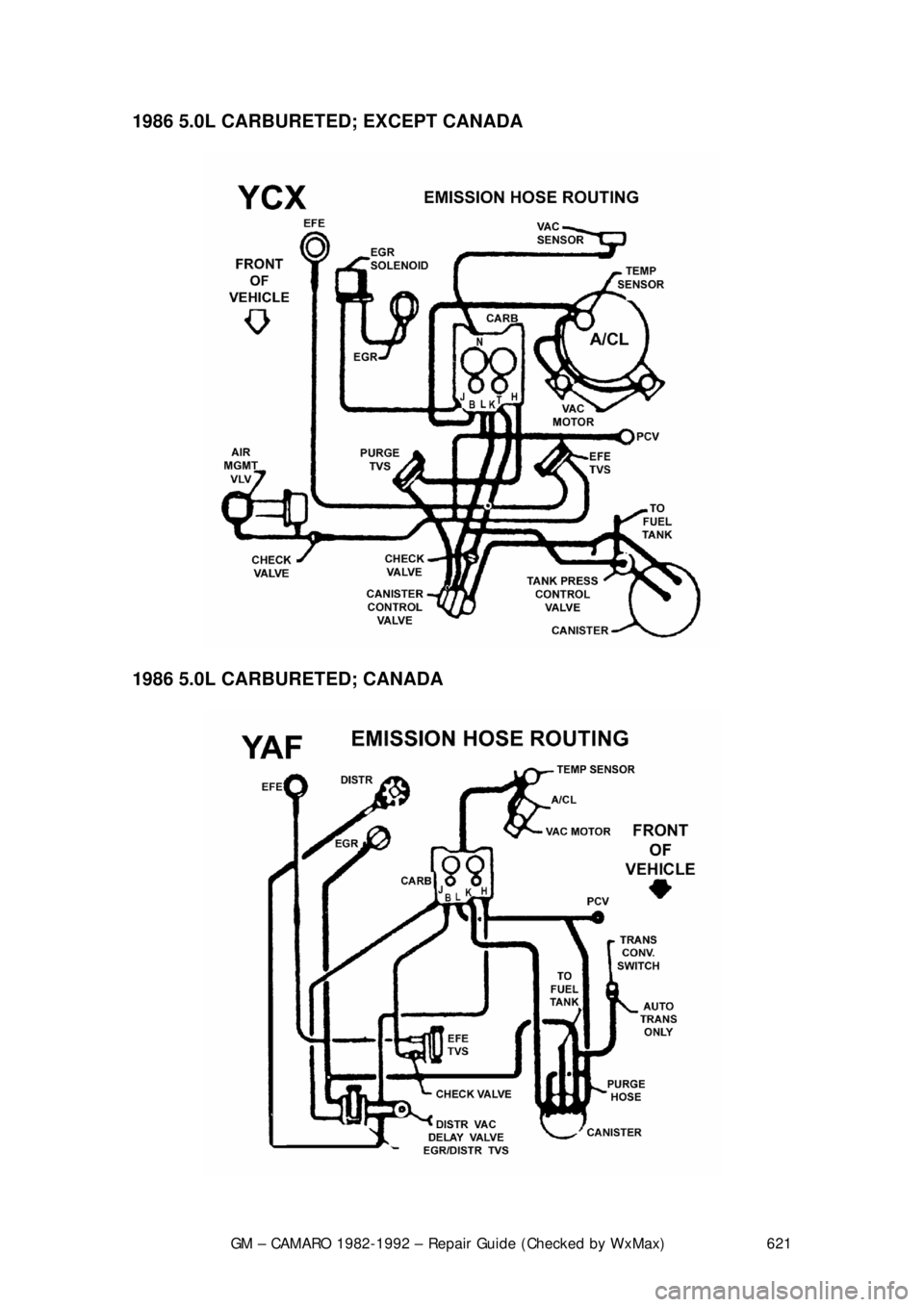

1986 5.0L CARBURETED;

EXCEPT CANADA

1986 5.0L CARBURETED; CANADA

Page 622 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 622

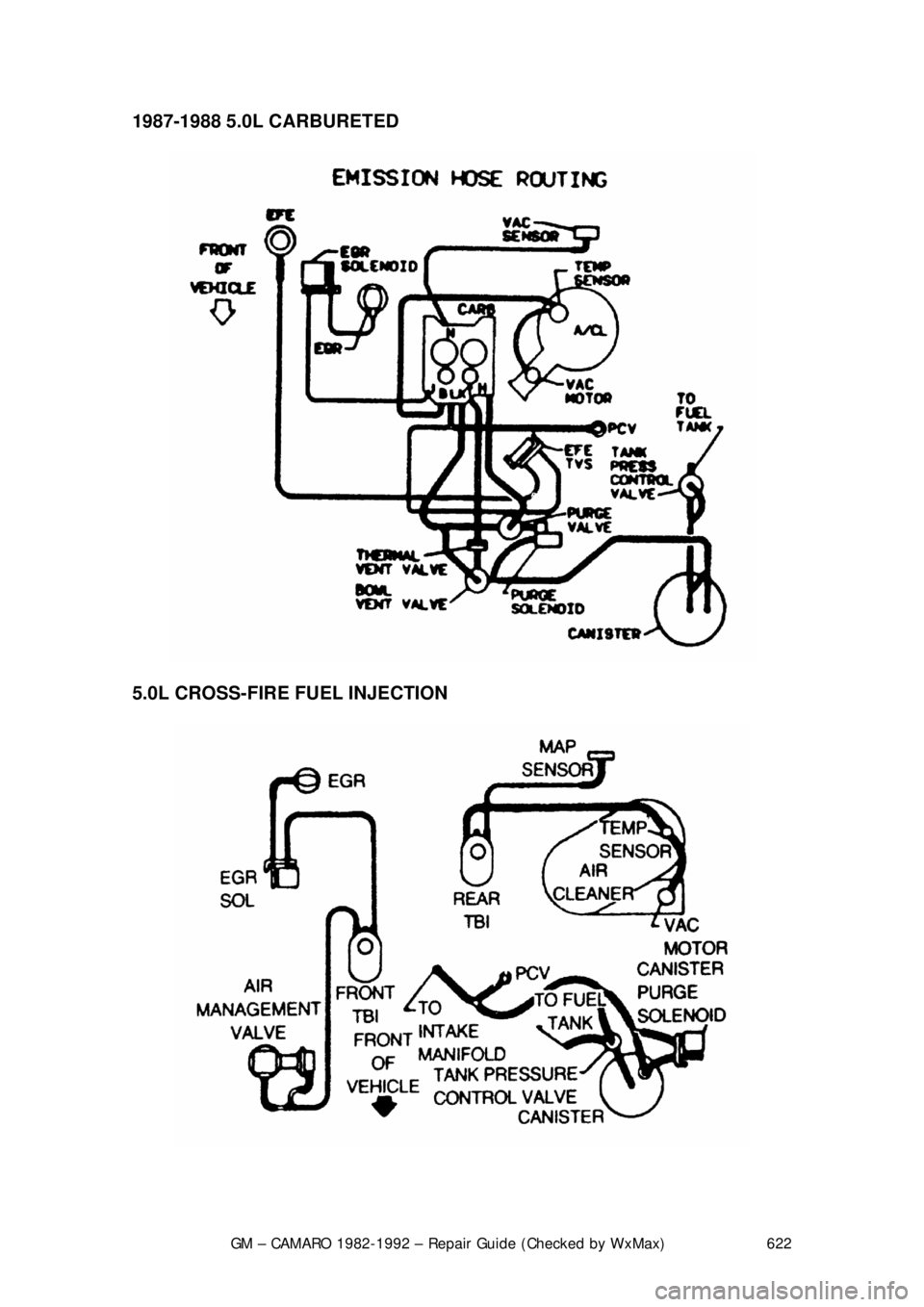

1987-1988 5.0L CARBURETED

5.0L CROSS-FIRE FUEL INJECTION

Page 628 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 628

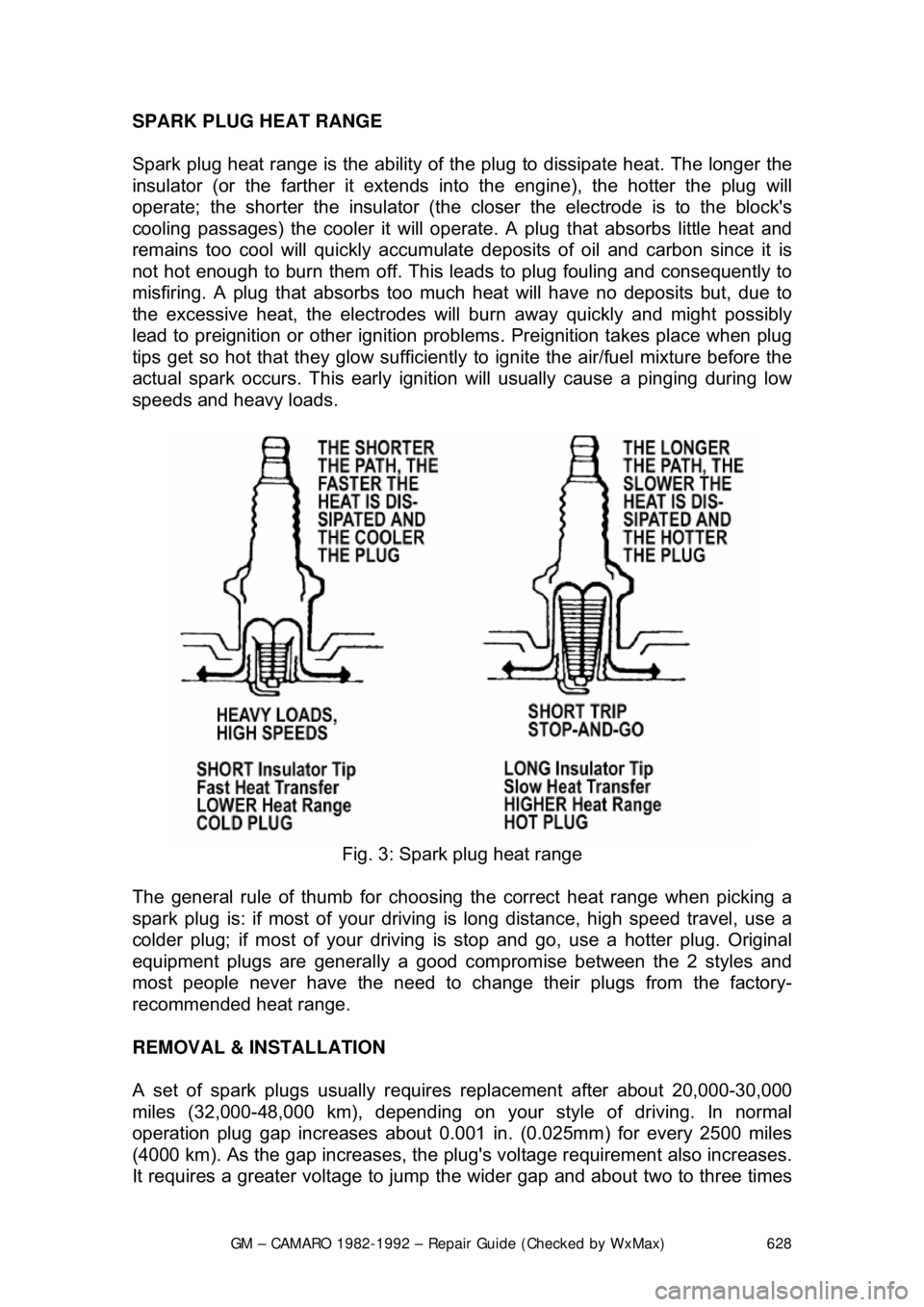

SPARK PLUG HEAT RANGE

Spark plug heat range is

the ability of the plug to dissipate heat. The longer the

insulator (or the farther it extends in to the engine), the hotter the plug will

operate; the shorter the insulator (the cl oser the electrode is to the block's

cooling passages) the cooler it will operate. A plug that absorbs little heat and

remains too cool will quickly accumulate deposits of oil and carbon since it is

not hot enough to burn them off. This leads to plug fouling and consequently to

misfiring. A plug that absorbs too much heat will have no deposits but, due to

the excessive heat, the electrodes will burn away quickly and might possibly

lead to preignition or other ignition probl ems. Preignition takes place when plug

tips get so hot that they gl ow sufficiently to ignite the air/fuel mixture before the

actual spark occurs. This early igniti on will usually cause a pinging during low

speeds and heavy loads.

Fig. 3: Spark plug heat range

The general rule of thumb for choosing the correct heat range when picking a

spark plug is: if most of your driving is long distanc e, high speed travel, use a

colder plug; if most of your driving is stop and go, use a hotter plug. Original

equipment plugs are general ly a good compromise between the 2 styles and

most people never have the need to change their plugs from the factory-

recommended heat range.

REMOVAL & INSTALLATION

A set of spark plugs usually requi res replacement after about 20,000-30,000

miles (32,000-48,000 km), depending on y our style of driving. In normal

operation plug gap increases about 0.001 in. (0.025mm) for every 2500 miles

(4000 km). As the gap increases, the plug' s voltage requirement also increases.

It requires a greater voltage to jump t he wider gap and about two to three times

Page 641 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 641

If, however, there is no spark or a weak

spark, then further ignition system

testing will have to be done. Troubleshooting techniques fall into various

categories, depending on t he nature of the problem and the system being

tested. Categories will include symptom s such as the engine cranks, but will not

start or the engine runs rough.

HEI SYSTEM

When testing the HEI system, there are 2 major categories of problems, (1)

Engine cranks, but will not star t or (2) Engine runs, but runs rough or cuts out.

If the engine will not start, perform a spar k test as described earlier. This will

narrow the problem area down considerab ly. If no spark occurs, check for the

presence of normal battery voltage at the battery ( BAT) terminal on the ignition

coil. The ignition switch must be in the ON position for this test. Either a

voltmeter or a test light wire may be us ed for this test. Connect the test light

wire to ground and the probe end to the BAT terminal at the coil. If the light

comes on, you have voltage to the distribut or and/or spark plug wires. If the light

fails to come on, this indicates an open circuit in the ignition primary wiring

leading to the distributor. In this case , you will have to check wiring continuity

back to the ignition switch using a test li ght. If there is battery voltage at the BAT

terminal, but no spark at the plugs, t hen the problem probably lies within the

distributor assembly.

If, on the other hand, the engine starts, but runs roughly or cuts out, make sure

the plug wires are in good shape first. There should be no obvious cracks or

breaks. You can check the plug wires with an ohmmeter, but do not pierce the

wires with a probe. Check the chart for th e correct plug wire resistance. If the

plug wires are OK, remove the cap asse mbly and check for moisture, cracks,

chips, or carbon tracks, or any other hi gh voltage leads or failures. Replace the

cap if any defects are found. Make su re the timer wheel rotates when the

engine is cranked.

If the trouble has been narrowed down to t he units within the distributor, the

following tests can help pinpoint the defective component. An ohmmeter with

both high and low ranges shou ld be used. These tests are made with the cap

assembly removed and the battery wir e disconnected. If a tachometer is

connected to the TACH terminal, disconnect it before making these tests.

IGNITION COIL

EXTERNALLY MOUNTED 1. Disconnect the coil wires and se t the ohmmeter on the high scale.

2. Connect the ohmmeter to the ignition co il as illustrated in Step 1 of the

accompanying figure.

3. The ohmmeter should read near infinite or very high.

Page 659 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 659

VALVE LASH

All models utilize a hydraulic valve lifter system to obtain zero lash. No periodic

adjustment is necessary. An initial adjustm

ent is required anytime that the lifters

are removed or the valve tr ain is disturbed. This procedure is covered in Engine

& Engine Overhaul .

IDLE SPEED AND MIXTURE ADJUSTMENTS

Mixture adjustments are factory set and sealed; no adjustment attempt should

be made, except by an aut horized GM dealer or reputable shop equipped with

the necessary equipment.

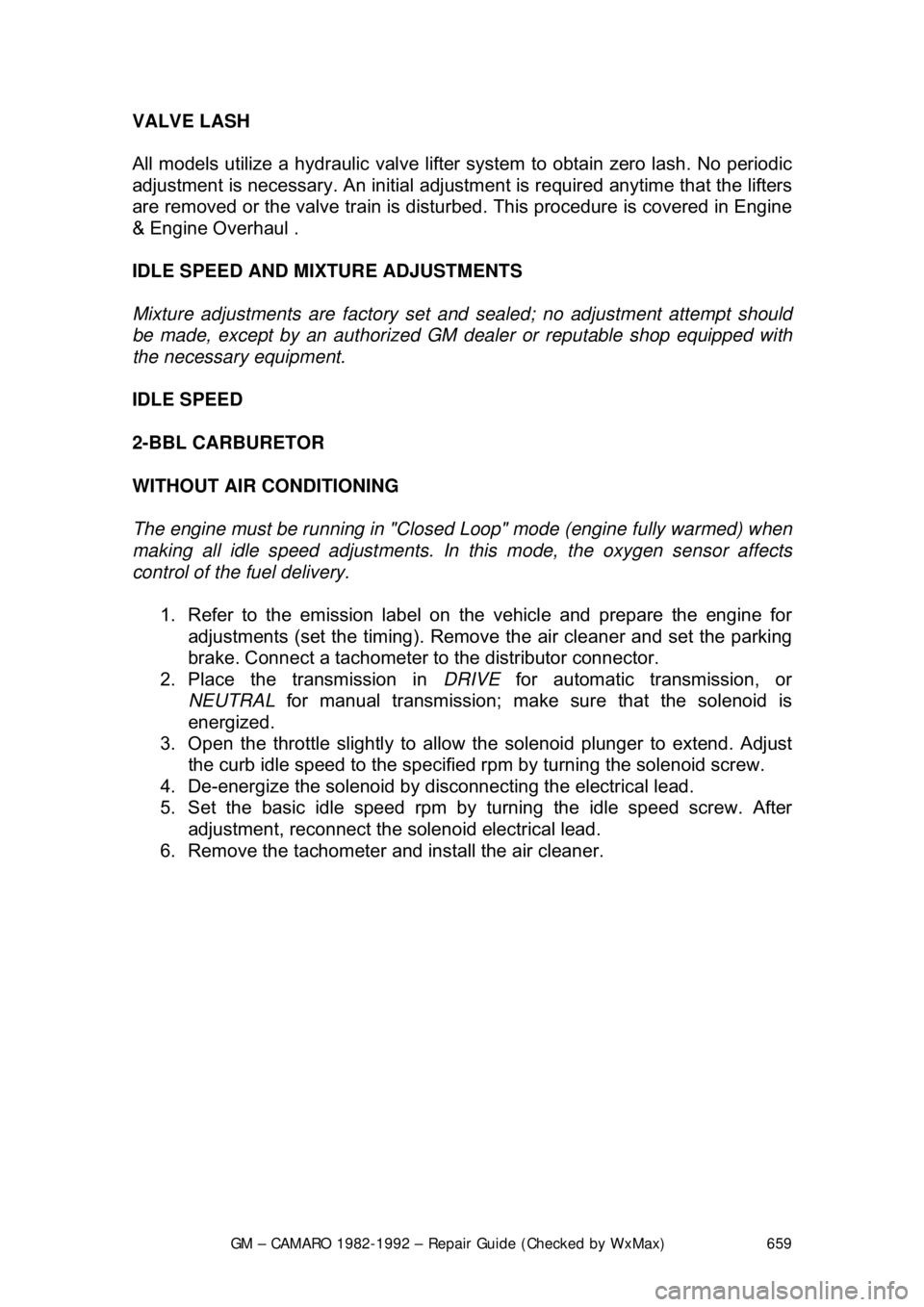

IDLE SPEED

2-BBL CARBURETOR

WITHOUT AIR CONDITIONING

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Remove the air cleaner and set the parking

brake. Connect a tachometer to the distributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission; make sure that the solenoid is

energized.

3. Open the throttle slightly to allow the solenoid plunger to extend. Adjust

the curb idle speed to the specified rpm by turning the solenoid screw.

4. De-energize the solenoid by disconnecting the electrical lead.

5. Set the basic idle speed rpm by turning the idle speed screw. After

adjustment, reconnect the solenoid electrical lead.

6. Remove the tachometer and install the air cleaner.

Page 660 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 660

Fig. 1: Idle speed adjustm ents - 2-bbl carburetor (without air conditioning)

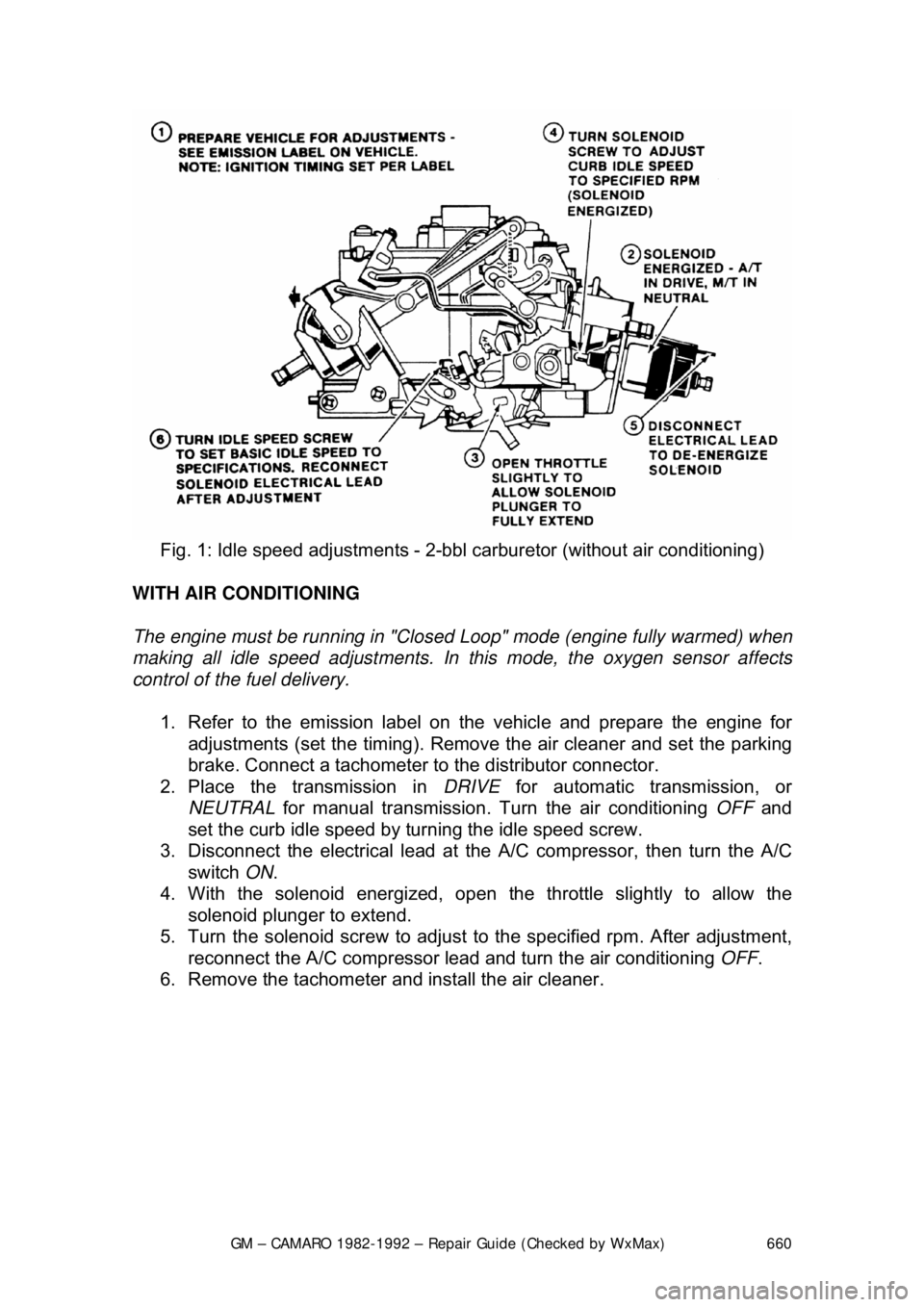

WITH AIR CONDITIONING

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Remove the air cleaner and set the parking

brake. Connect a tachometer to the distributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission. Tu rn the air conditioning OFF and

set the curb idle speed by turning the idle speed screw.

3. Disconnect the electrical lead at the A/C compressor, then turn the A/C

switch ON.

4. With the solenoid e nergized, open the throttle slightly to allow the

solenoid plunger to extend.

5. Turn the solenoid screw to adjust to the specified rpm. After adjustment,

reconnect the A/C compressor lead and turn the air conditioning OFF.

6. Remove the tachometer and install the air cleaner.

Page 661 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 661

Fig. 2: Idle speed adjustm ents - 2-bbl carburetor (with air conditioning)

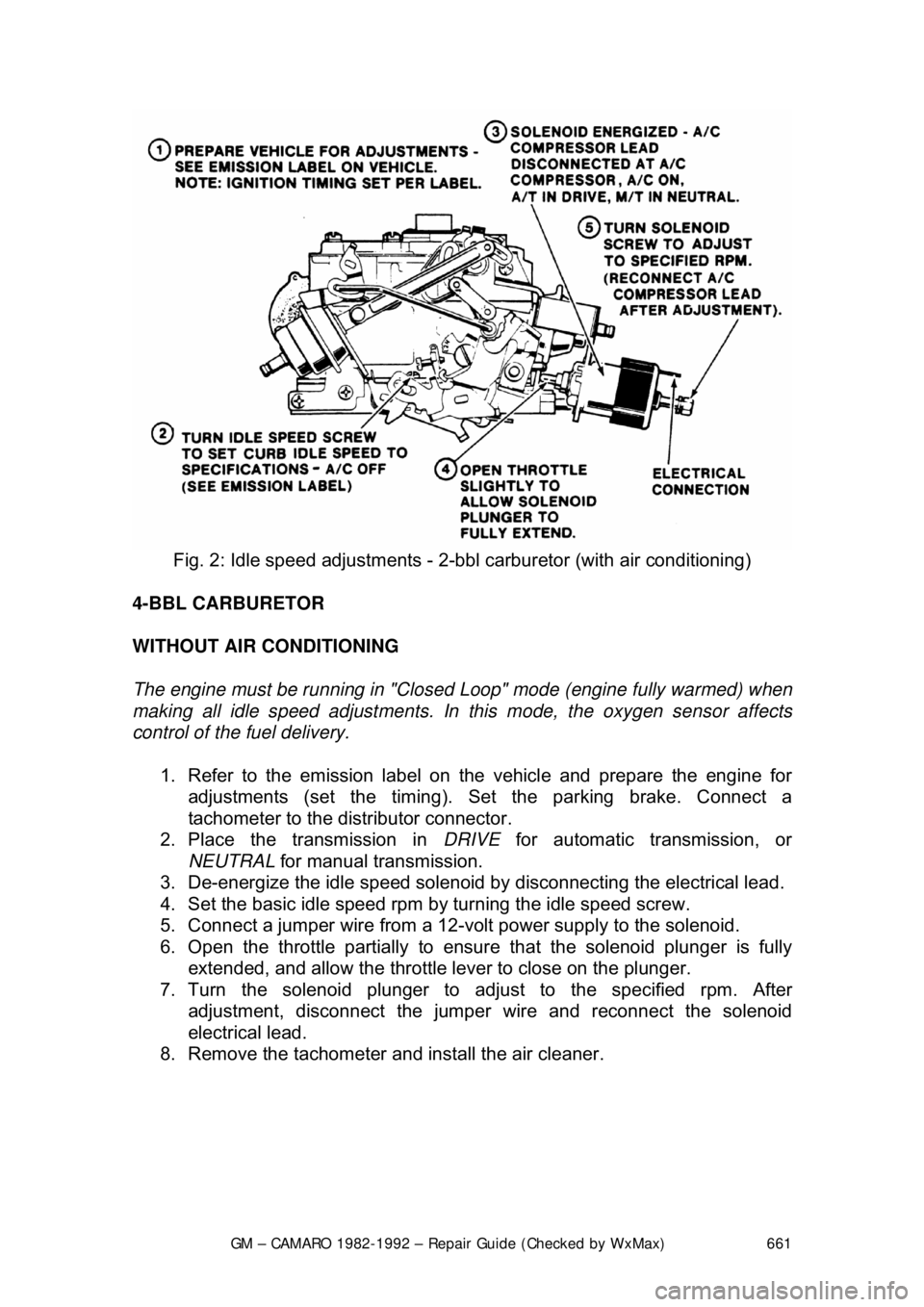

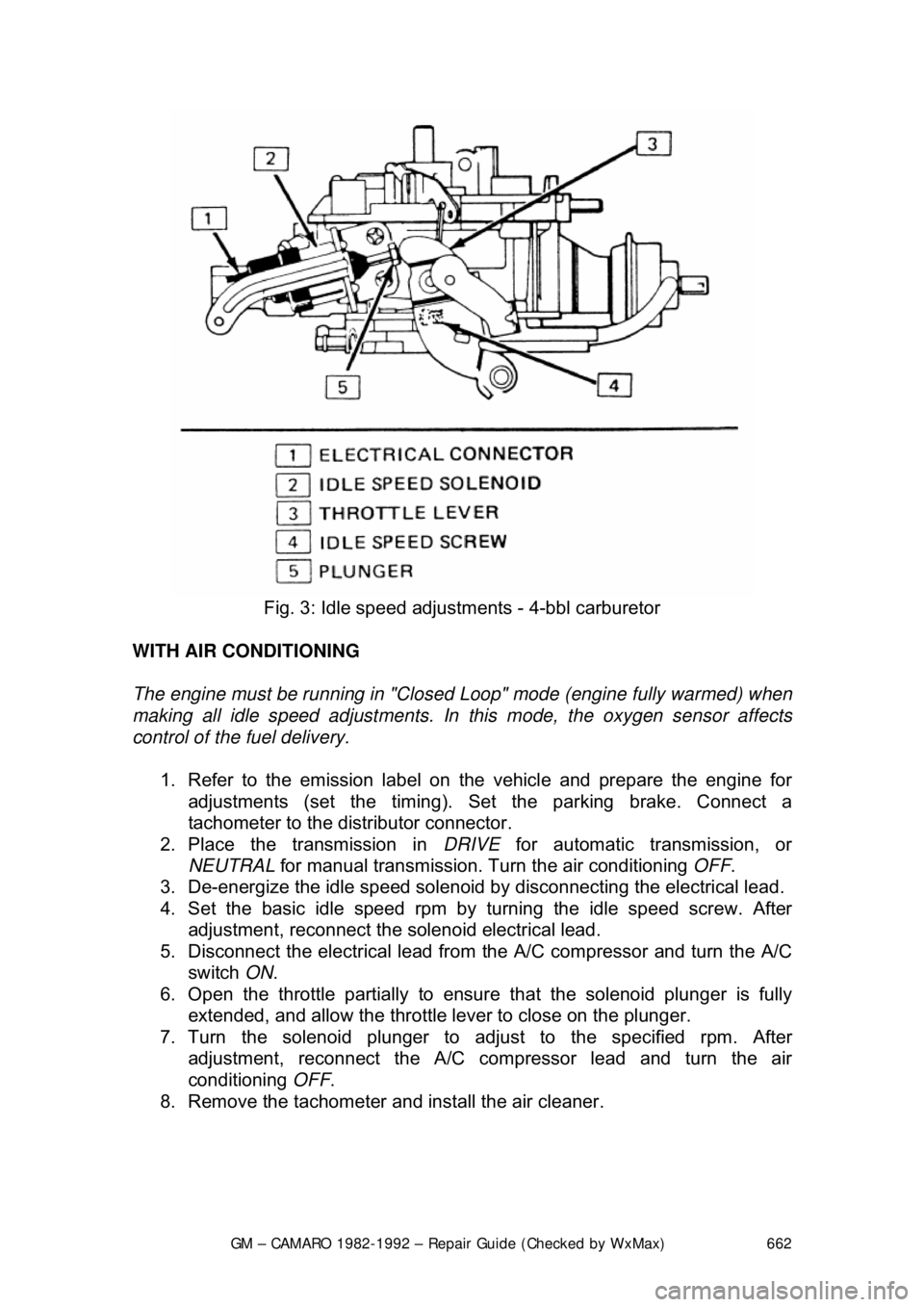

4-BBL CARBURETOR

WITHOUT AIR CONDITIONING

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Se t the parking brake. Connect a

tachometer to the dist ributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission.

3. De-energize the idle speed solenoid by disconnecting the electrical lead.

4. Set the basic idle speed rpm by turning the idle speed screw.

5. Connect a jumper wire from a 12-vo lt power supply to the solenoid.

6. Open the throttle partially to ensure that the solenoid plunger is fully

extended, and allow the throttle lever to close on the plunger.

7. Turn the solenoid plunger to adj ust to the specified rpm. After

adjustment, disconnect the jumper wire and reconnect the solenoid

electrical lead.

8. Remove the tachometer and install the air cleaner.

Page 662 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 662

Fig. 3: Idle speed adjustm ents - 4-bbl carburetor

WITH AIR CONDITIONING

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Se t the parking brake. Connect a

tachometer to the dist ributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission. Tu rn the air conditioning OFF.

3. De-energize the idle speed solenoid by disconnecting the electrical lead.

4. Set the basic idle speed rpm by turning the idle speed screw. After

adjustment, reconnect the solenoid electrical lead.

5. Disconnect the electrical lead from the A/C compressor and turn the A/C

switch ON.

6. Open the throttle partially to ensure that the solenoid plunger is fully

extended, and allow the throttle lever to close on the plunger.

7. Turn the solenoid plunger to adj ust to the specified rpm. After

adjustment, reconnect the A/C co mpressor lead and turn the air

conditioning OFF.

8. Remove the tachometer and install the air cleaner.

Page 666 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 666

FUEL SYSTEM

BASIC FUEL SYSTEM DIAGNOSIS

When there is a problem star ting or driving a vehicle, two of the most important

checks involve the ignition and the fuel systems. The questions most mechanics

attempt to answer first, "is there spark?" an d "is there fuel?" will often lead to

solving most basic problems. For igni tion system diagnosis and testing, please

refer to the information on engine electr ical components and ignition systems

found earlier in this repair guide. If the ignition system checks out (there is

spark), then you must determine if the f uel system is operating properly (is there

fuel?).

CARBURETED FUEL SYSTEM

MECHANICAL FUEL PUMP

All fuel pumps used on carbureted V6 and V8 engines are of the diaphragm

type and are serviced by replacement onl y. No adjustments or repairs are

possible. The fuel pump is mounted on th e left front (V6) and right front (V8) of

the engine.

The fuel pumps are also equipped with vapor return lines for purposes of

emission control and to reduce vapor lock. All pumps are operated by an

eccentric on the camshaft. On V6 an d V8 engines, a pushrod between the

camshaft eccentric and the fuel pump operates the pump.

REMOVAL & INSTALLATION

When disconnecting the fuel pump outlet fitting, always use two wrenches to

avoid twisting the line.

1. Disconnect the fuel in take and outlet lines at the pump, then plug the

pump intake line.

2. Remove the two pump mounting bol ts and lockwashers; remove the

pump and its gasket.

3. If the pump pushrod is to be remo ved from the V8, remove the two

adapter bolts and lockwashers, then re move the adapter and its gasket.

4. Install the fuel pump with a new gasket reversing the removal procedure.

Coat the mating surfaces with sealer.

5. Connect the fuel lines and check for leaks.