length CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 23 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 23

4. Remove the No. 1 bow garni

sh molding and retainer.

5. Remove the top from the No. 1 bow by applying heat with a heat gun to the

approximately 1 in. (25mm) fr om the adhesive backed bow.

6. Remove the cable screws.

7. Remove the headliner from the No. 2 and 3 bows.

It is not necessary to remove the headliner from the No. 1 bow with the top

folded enough to allow access to the retainer screws.

8. Remove the screws from the under side of the Nos. 2 and 3 top cover

retainers.

9. Remove the No. 2 and 3 bow top cover from the pockets in the top cover.

10. Separate the outer quarter flaps fr om the main pillar post, once again using

the heat gun as necessary to loosen the adhesive.

11. Remove the side retention cables.

12. Remove screws.

13. Remove the elastic stays, folding the top rearward.

14. Remove the No. 5 bow seal.

15. Remove the black covered rive ts from the No. 5 bow using an

1/8 in. (3mm)

drill bit.

16. Remove the top cover from No. 5 bow, using heat as required to loosen th\

e adhesive.

17. Remove the convertible t op cover from the vehicle.

To install:

Use 3M® adhesive No. 8046 or equivalent on cover attaching surfaces where

noted.

18. Install the cover on the v ehicle. Slide the retention cables through the listing

pockets and check cable ends for proper locations.

19. Square the top to the frame; check fo r evenness of quarter flap positions to

the main pillar rail. Fold the t op cover to the windshield header.

20. Apply adhesive to the No . 5 bow and top, raise the No. 5 bow to the full

vertical position.

Glue

1/2 of the top cover to the No. 5 bow first, then lower the bow and check for

evenness. The length of the material ov erhanging should be uniform. Repeat

the procedure, if necessary. Trim the exce ss fabric from the No. 5 bow evenly at

the seal channel to allow atta chment of the seal later.

21. Install new

1/8 in. (3mm) by 3/16 in. (5mm) black aluminum rivets as shown in

illustration.

22. Lower and latch the tonneau cover and No. 5 bow. Raise the No. 1 bow off

the header and install the cable screws.

23. Install the No. 5 bow seal.

24. Connect the elastic stays inside of No . 5 bow seal-to-link arms. Install the

screws.

25. Lower the No. 5 bow. Fold the inner quarter flaps inside of main pillar rails.

Fold the outer quarter flaps around the outs ide of the main pillar rails to the

Page 74 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 74

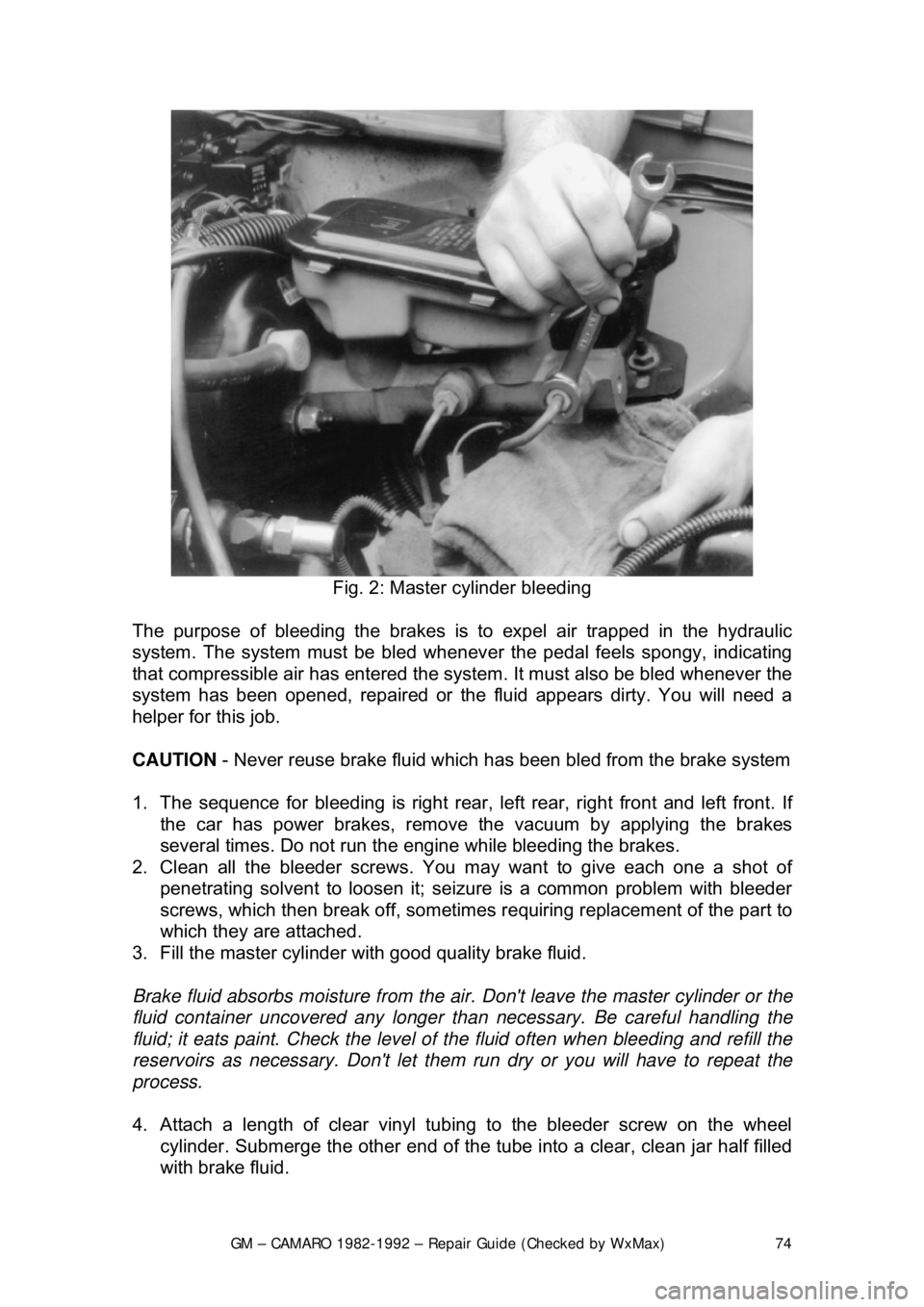

Fig. 2: Master cylinder bleeding

The purpose of bleeding the brakes is to expel air trapped in the hydraulic

system. The system must be bled whenever the pedal feels spongy, indicating

that compressible air has ent ered the system. It must also be bled whenever the

system has been opened, repaired or the fluid appears dirty. You will need a

helper for this job.

CAUTION - Never reuse brake fluid which has been bled from the brake system

1. The sequence for bleeding is right rear , left rear, right front and left front. If

the car has power brakes, remove the vacuum by applying the brakes

several times. Do not run the engine while bleeding the brakes.

2. Clean all the bleeder screws. You ma y want to give each one a shot of

penetrating solvent to loosen it; seiz ure is a common problem with bleeder

screws, which then break off, sometimes requiring replacement of the part to

which they are attached.

3. Fill the master cylinder with good quality brake fluid.

Brake fluid absorbs moisture from the air. Don't leave the master cylinder or the

fluid container uncovered any longer t han necessary. Be careful handling the

fluid; it eats paint. Check the level of the fluid often when bleeding and refill the

reservoirs as necessary. Don't let them run dry or you will have to repeat the

process.

4. Attach a length of clear vinyl t ubing to the bleeder screw on the wheel

cylinder. Submerge the other end of the tube into a clear, clean jar half filled

with brake fluid.

Page 80 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 80

4. Remove the mounting bo

lts, if equipped with single piston caliper or the

circlip and pin, if equipped with dual piston ca liper. Inspect the bolts for

corrosion and replace as necessary.

5. Remove the caliper fr om the steering knuckle an d suspend it from the body

of the car with a length of wire. Do not allow the caliper to hang by its hose.

6. Remove the pad retaining springs and remove the pads from the caliper.

7. Remove the plastic sleeves and the rubber bushings from the mounting bolt

holes.

8. Obtain a pad replacem ent kit. Lubricate and install the new sleeves and

bushings with a light coat of silicone grease.

9. Install the retainer spring on the i nboard pad, if equipped with single piston

caliper.

A new spring should be included in the pad replacement kit.

10. Install the new inboard pad into the caliper with the wear sensor at the

leading end of the shoe duri ng forward wheel rotation.

11. Install the outboard pad into the caliper.

12. Use a large pair of slip joint plie rs to bend the outer pad ears down over the

caliper, if equipped with t he single piston caliper.

13. Install the calip er onto the steering knuckle. Tighten the mounting bolts to

21-35 ft. lbs. (28-47 Nm), if equipped. In stall the wheel and lower the car. Fill

the master cylinder to its proper le vel with a good quality brake fluid.

14. Pump the brake pedal slowly a nd firmly 3 times with the engine running

before attempting to move the vehicle; bleed the brakes as required.

BRAKE CALIPER

CAUTION - Some brake pads contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

REMOVAL & INSTALATION

Page 128 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 128

•

Size - the larger the wire size being used, the less resistance the wire will

have. This is why components which use large amounts of electricity

usually have large wires suppl ying current to them.

• Length - for a given thickness of wire, the longer the wire, the greater the

resistance. The shorter the wire, the less the resistance. When

determining the proper wire for a circ uit, both size and length must be

considered to design a circuit that can handle the current needs of the

component.

• Temperature - with many materials, the higher the temperature, the

greater the resistance (positive temper ature coefficient). Some materials

exhibit the opposite trait of lower re sistance with higher temperatures

(negative temperature coefficient). Thes e principles are used in many of

the sensors on the engine.

OHM'S LAW

There is a direct relationship between current, voltage and resistance. The

relationship between current, voltage and resistance can be summed up by a

statement known as Ohm's law.

Voltage (E) is equal to amper age (I) times resistance (R): E=I x ROther forms of

the formula are R=E/I and I=E/R

In each of these formulas, E is the voltage in volts, I is the current in amps and

R is the resistance in ohms. The basic point to remember is that as the

resistance of a circuit goes up, the amount of current that flows in the circuit will

go down, if voltage remains the same.

The amount of work that the electricity can perform is expressed as power. The

unit of power is the watt (w). The re lationship between power, voltage and

current is expressed as:

Power (w) is equal to amperage (I) times voltage (E): W=I x EThis is only true

for direct current (DC) circuits; The alte rnating current formula is a tad different,

but since the electrical circuits in mo st vehicles are DC type, we need not get

into AC circuit theory.

ELECTRICAL COMPONENTS

POWER SOURCE

Power is supplied to the vehicle by tw o devices: The battery and the alternator.

The battery supplies electrical power dur ing starting or during periods when the

current demand of the vehicle's electrical system exceeds the output capacity of

the alternator. The alternator supplies electrical current when the engine is

running. Just not does the al ternator supply the current needs of the vehicle, but

it recharges the battery.

Page 131 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 131

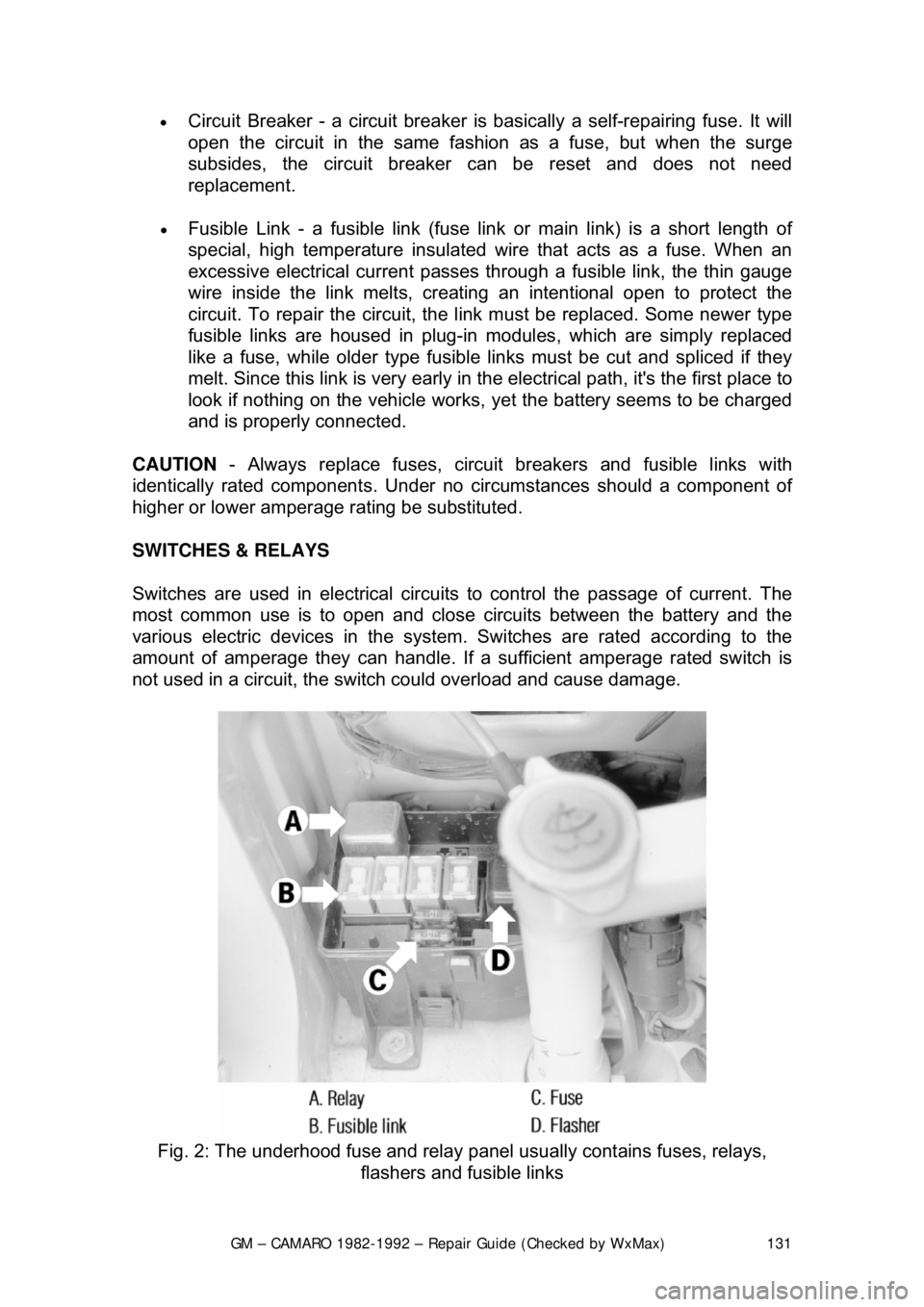

•

Circuit Breaker - a circuit breaker is basically a self-repairing fuse. It will

open the circuit in the same fashio n as a fuse, but when the surge

subsides, the circuit breaker can be reset and does not need

replacement.

• Fusible Link - a fusible link (fuse link or main link) is a short length of

special, high temperatur e insulated wire that acts as a fuse. When an

excessive electrical current passes th rough a fusible link, the thin gauge

wire inside the link melt s, creating an intentional open to protect the

circuit. To repair the circuit, the link must be replaced. Some newer type

fusible links are housed in plug-in modules, which are simply replaced

like a fuse, while older type fusible lin ks must be cut and spliced if they

melt. Since this link is very early in the electrical path, it's the first place to

look if nothing on the vehicle works, yet the battery seems to be charged

and is properly connected.

CAUTION - Always replace fuses, circ uit breakers and fusible links with

identically rated component s. Under no circumstances should a component of

higher or lower amperage rating be substituted.

SWITCHES & RELAYS

Switches are used in electrical circuits to control the passage of current. The

most common use is to open and close circuits between the battery and the

various electric devices in the system. Switches are rated according to the

amount of amperage they c an handle. If a sufficient amperage rated switch is

not used in a circuit, the switch could overload and cause damage.

Fig. 2: The underhood fuse and relay panel usually contains fuses, relays,

flashers and fusible links

Page 135 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 135

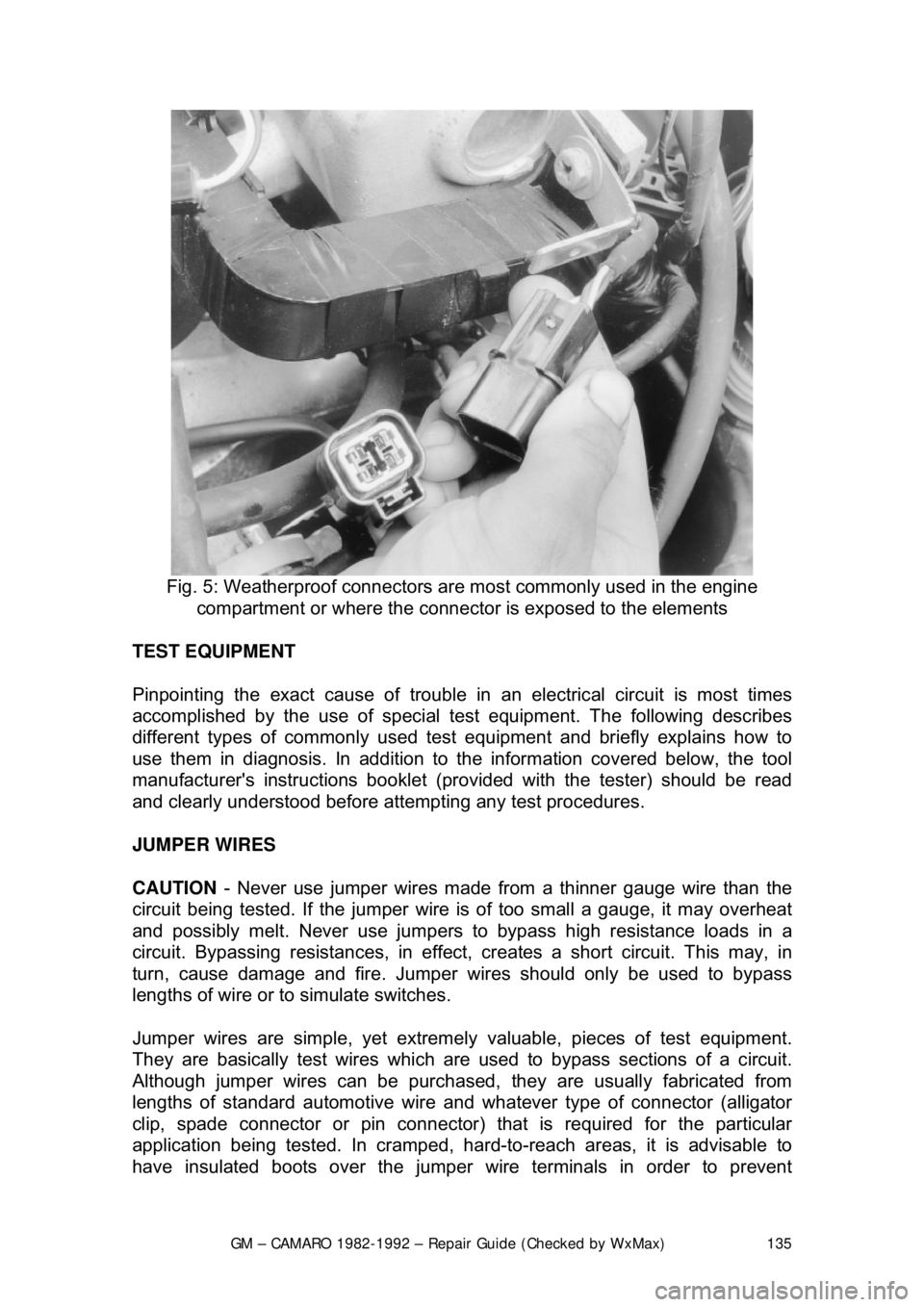

Fig. 5: Weatherproof connectors ar e most commonly used in the engine

compartment or where the connecto r is exposed to the elements

TEST EQUIPMENT

Pinpointing the exact cause of trouble in an electrical circuit is most times

accomplished by the use of special te st equipment. The following describes

different types of commonly used test eq uipment and briefly explains how to

use them in diagnosis. In addition to t he information covered below, the tool

manufacturer's instructions booklet (pro vided with the tester) should be read

and clearly understood before atte mpting any test procedures.

JUMPER WIRES

CAUTION - Never use jumper wires made from a thinner gauge wire than the

circuit being tested. If the jumper wire is of too small a gauge, it may overheat

and possibly melt. Never use jumpers to bypass high resistance loads in a

circuit. Bypassing resistances, in effect, cr eates a short circuit. This may, in

turn, cause damage and fire. Jumper wi res should only be used to bypass

lengths of wire or to simulate switches.

Jumper wires are simple, yet extremel y valuable, pieces of test equipment.

They are basically test wir es which are used to bypass sections of a circuit.

Although jumper wires can be purchased, they are usually fabricated from

lengths of standard automot ive wire and whatever type of connector (alligator

clip, spade connector or pin connector) that is required for the particular

application being tested. In cramped, hard- to-reach areas, it is advisable to

have insulated boots over the jumper wire terminals in order to prevent

Page 207 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 207

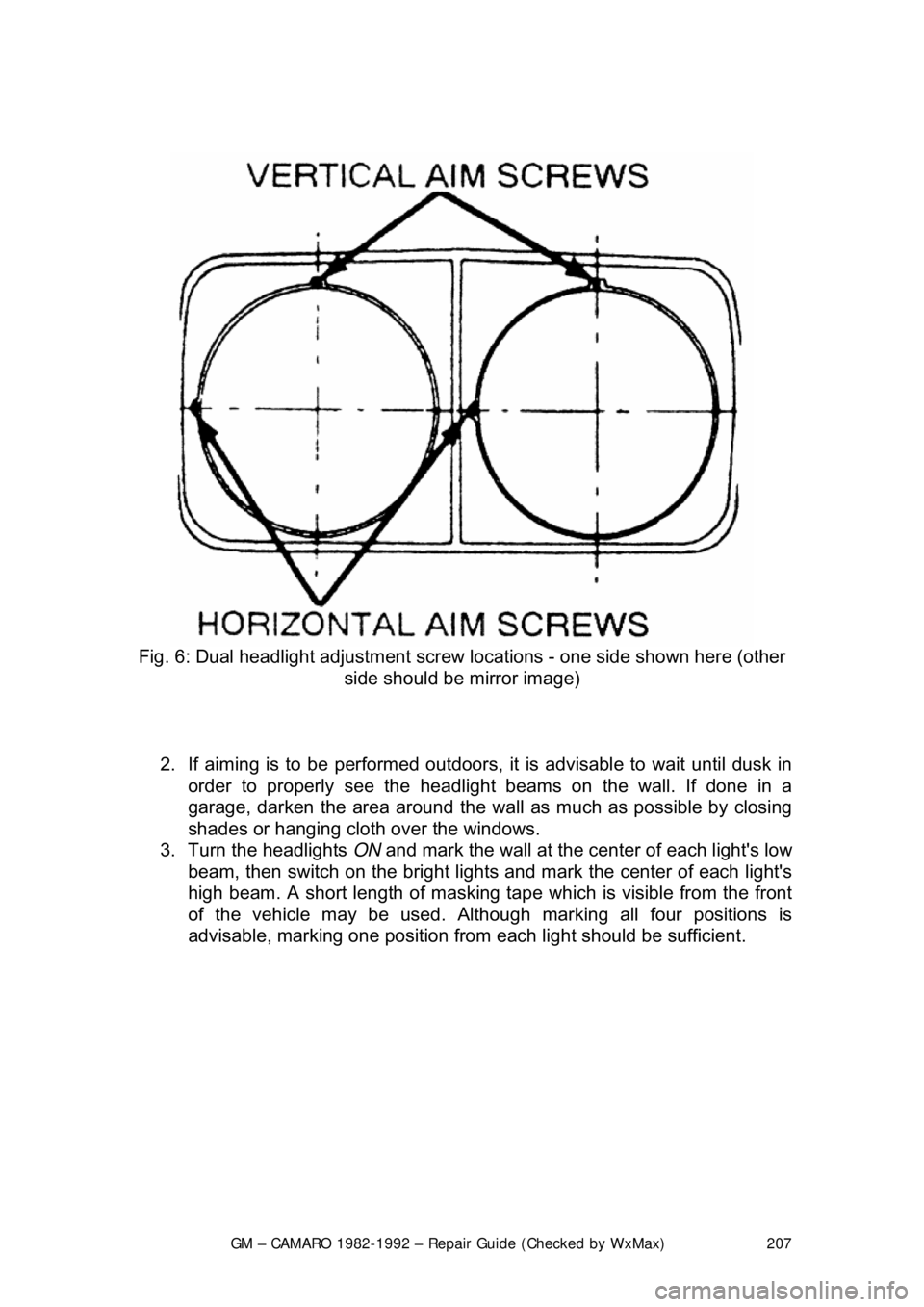

Fig. 6: Dual headlight adjustment screw locations - one side shown here (other

side should be mirror image)

2. If aiming is to be performed outdoors, it is advisable to wait until dusk in

order to properly see t he headlight beams on the wall. If done in a

garage, darken the area around the wall as much as possible by closing

shades or hanging cloth over the windows.

3. Turn the headlights ON and mark the wall at the center of each light's low

beam, then switch on the bright lights and mark the center of each light's

high beam. A short length of masking tape which is visible from the front

of the vehicle may be used. Althoug h marking all four positions is

advisable, marking one position from each light should be sufficient.

Page 296 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 296

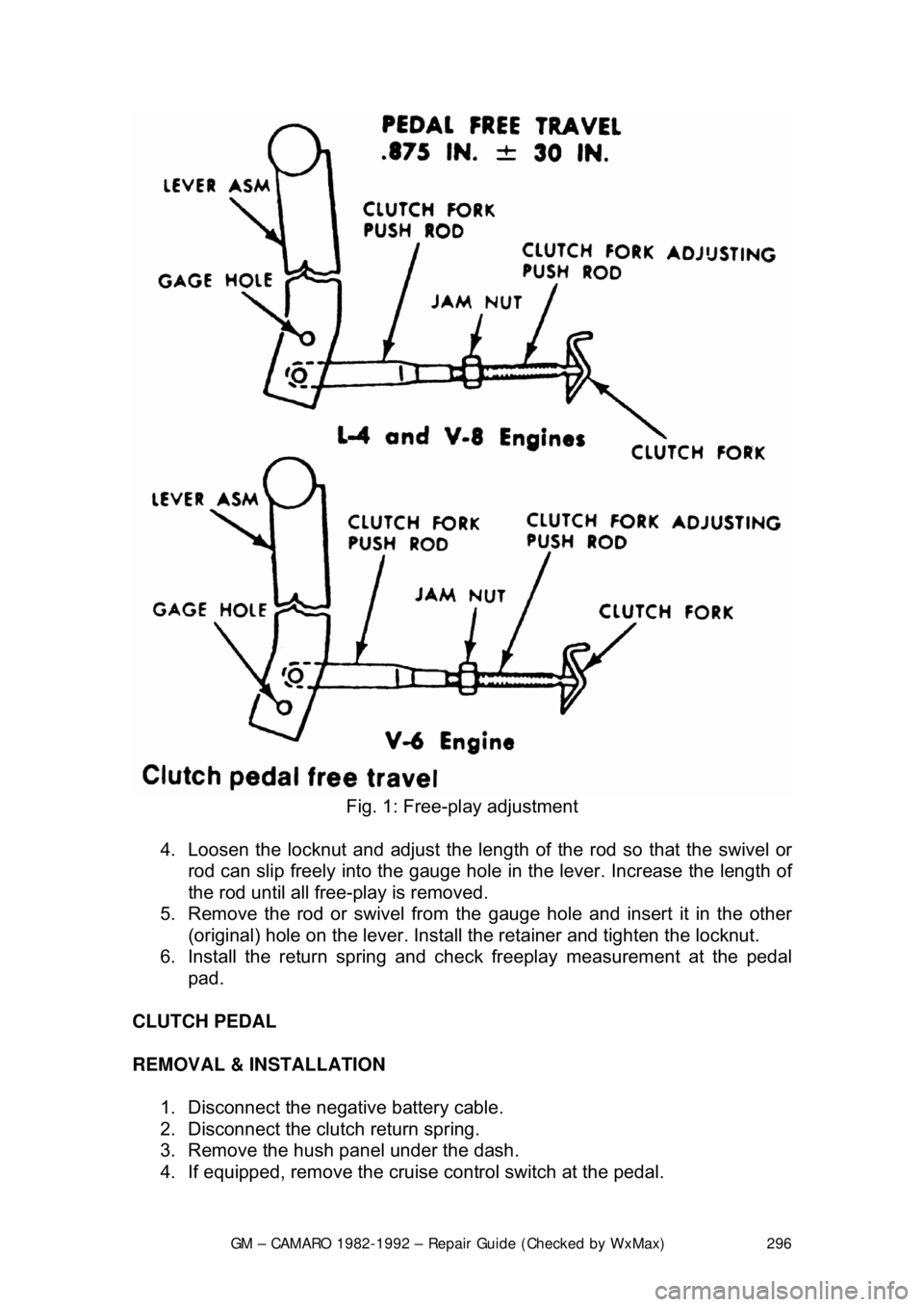

Fig. 1: Free-play adjustment

4. Loosen the locknut and adjust the length of the rod so that the swivel or

rod can slip freely into the gauge hole in the lever. Increase the length of

the rod until all free-play is removed.

5. Remove the rod or swivel from the gauge hole and insert it in the other

(original) hole on the lever. Install the retainer and tighten the loc\

knut.

6. Install the return spring and che ck freeplay measurement at the pedal

pad.

CLUTCH PEDAL

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable.

2. Disconnect the clutch return spring.

3. Remove the hush panel under the dash.

4. If equipped, remove the cruise control switch at the pedal.

Page 456 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 456

2. Drain the engine oil and remove the oil pan.

3. Remove the rear main bearing cap.

4. Insert packing tool J-29114-2 or equi

valent, against 1 end of the seal in

the cylinder block. Drive the old seal gently into the groove until it is

packed tight. This will vary from

1/4 in. (6mm) to 3/4 in. (19mm) depending

on the amount of pack required.

5. Repeat the procedure on t he other end of the seal.

6. Measure the amount the seal wa s driven up on one side and add

1/16 in.

(1.6mm). Using a suitable cutting tool, cut that length from the old seal

removed from the rear main beari ng cap. Repeat the procedure for the

other side. Use the rear main bear ing cap as a holding fixture when

cutting the seal.

7. Install guide tool J-29114-1 or equi valent, onto the cylinder block.

8. Using the packing tool, work the shor t pieces cut in Step 6 into the guide

tool and then pack into the cylinder block. The guide tool and packing

tool are machined to provide a built in stop. Use this procedure for both

sides. It may help to use oil on the short pieces of the rope seal when \

packing them into the cylinder block.

9. Remove the guide tool.

10. Apply Loctite® 414 or equivalent, to the seal groove in the rear main

bearing cap. Within 1 minute, insert a new seal into the groove and push

into place with tool J-29590 until the seal is flush with the block. Cut the

excess seal material with a sharp cu tting tool at the bearing cap parting

line.

11. Apply a thin film of chassis grease to the rope se al. Apply a thin film of

RTV sealant on the bearing cap mati ng surface around the seal groove.

Use the sealer sparingly.

12. Plastigage® the rear main bea ring cap as outlined in MEASURING

REAR MAIN CLEARANCE in this section and check with specification. If

out of specification, check for fr ying of the rope seal which may be

causing the cap to not seat properly.

13. Install all remaining com ponents and inspect for leaks.

FLYWHEEL AND RING GEAR

REMOVAL & INSTALLATION

The ring gear is an integral part of the flywheel and is not replaceable.

1. Remove the transmission.

2. Remove the six bolts attaching t he flywheel to the crankshaft flange.

Remove the flywheel.

3. Inspect the flywheel for cracks, and inspect the ring gear for burrs or

worn teeth. Replace the flywheel if any damage is apparent. Remove

burrs with a mill file.

4. Install the flywheel. Th e flywheel will only attach to the crankshaft in one

position, as the bolt holes are unevenly spaced. Install the bolts and

torque to specification. Tighten bolts in crisscross pattern.

Page 482 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 482

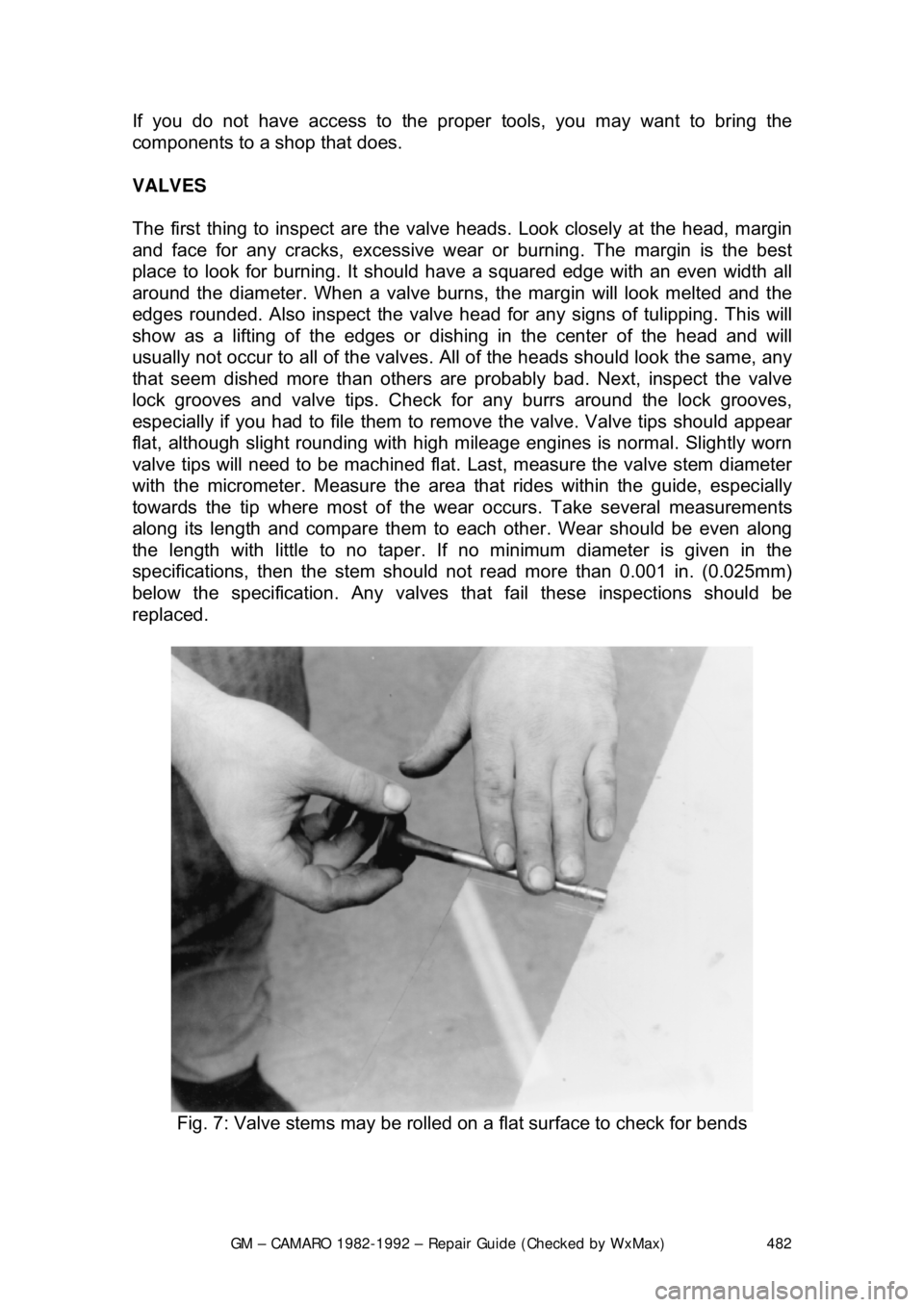

If you do not have access to the proper

tools, you may want to bring the

components to a shop that does.

VALVES

The first thing to inspect are the valve heads. Look closely at the head, margin

and face for any cracks, excessive wear or burning. The margin is the best

place to look for burning. It should have a squared edge with an even width all

around the diameter. When a valve burns, the margin will look melted and the

edges rounded. Also inspect the valve head for any signs of tulipping. This will

show as a lifting of the edges or dishi ng in the center of the head and will

usually not occur to all of the valves. All of the heads should look the same, any

that seem dished more t han others are probably bad. Next, inspect the valve

lock grooves and valve tips. Check fo r any burrs around the lock grooves,

especially if you had to file them to remove the valve. Valve tips should appear

flat, although slight rounding with high mile age engines is normal. Slightly worn

valve tips will need to be machined flat. Last, measure the valve stem diameter

with the micrometer. Measure the area that rides within the guide, especially

towards the tip where most of the wear occurs. Take several measurements

along its length and compare them to each other. Wear should be even along

the length with little to no taper. If no minimum diameter is given in the

specifications, then the stem should not read more than 0.001 in. (0.025mm)

below the specification. Any valves that fail these inspections should be

replaced.

Fig. 7: Valve stems may be rolled on a flat surface to check for bends