wiring CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 507 of 2438

CONDITION: SPEEDOMETER AND ODOMETER ARE INOPERATIVE OR OPERATESINTERMITTENTLY

PROCEDURE

Check for defective vehicle speed sensor wiring.

CONDITION: OIL GAUGE, FUEL GAUGE, TEMPERATURE GAUGE, OR VOLTAGE GAUGEINOPERATIVE

PROCEDURE

Check for defective sending unit or wiring: (a) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (b) With the ignition in the ON position, a

grounded input will cause the oil, fuel, or temper-

ature gauge to read maximum.

CONDITION: CLUSTER DISPLAY DOES NOT DIM WHEN HEADLAMP SWITCH ISACTIVATED AND RHEOSTAT ROTATED

PROCEDURE

(1) Check fuses in headlamp circuit.

(2) Check for loose connections or defective wiring

from headlamp switch to the cluster. (3) Check for defective headlamp switch.

(4) The electronic instrument cluster requires both

a marker feed and illumination feed to operate cor-

rectly.

SWITCH AND PANEL COMPONENT SERVICE

HEADLAMP/FOG LAMP SWITCH REPLACEMENT

(1) Remove cluster bezel (Fig. 40).

(2) Remove three screws securing headlamp switch

mounting plate to base panel (Fig. 41). (3) Pull headlamp/fog lamp switch mounting plate

rearward. Disconnect wiring connectors from head-

lamp switch and fog lamp switch pigtail (Fig. 42). (4) Remove knob and stem by depressing button on

bottom of the switch (Fig. 43). (5) Snap-out escutcheon.

(6) Remove fog lamp switch from escutcheon.

(7) Remove nut that attaches headlamp switch to

mounting plate (Fig. 44). (8) For installation reverse above procedures.

FOG LAMP SWITCH TEST

(1) Remove the fog lamp switch from mounting lo-

cation. (2) Disconnect the wiring harness from the switch

pigtail. (3) Using a Ohmmeter, test for continuity between

the terminals of the switch pigtail (Fig. 45). (4) If not OK, replace switch.

LOWER STEERING COLUMN COVERREPLACEMENT

(1) Disconnect park brake release rod from park

brake. (2) Remove fuse box access door and remove screw

from lower column cover (Fig. 46). (3) Remove screws from lower cover, four across

the top and two on bottom. (4) Remove lower steering column cover.

(5) For installation reverse above procedures.

LEFT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) Remove screws from front of silencer (Fig. 47).

(2) Remove push nut.

(3) Remove silencer.

(4) For installation reverse above procedures.

RIGHT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) On floor shift vehicles, remove console assem-

bly and center brace bracket. (2) On column shift vehicles, remove center brace

bracket. (3) Remove screws from front of silencer (Fig. 47).

(4) Remove three push nuts from rear of silencer.

(5) Remove lower right silencer.

(6) For installation reverse above procedures.

GLOVE BOX ASSEMBLY REPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Open glove box door and disconnect check

strap. (3) Remove glove box light and switch by squeez-

ing retaining tabs from behind switch mount and

slide rearward. Disconnect wiring connectors. (4) Remove 11 screws from glove box assembly

(Fig. 48). (5) Remove glove box assembly.

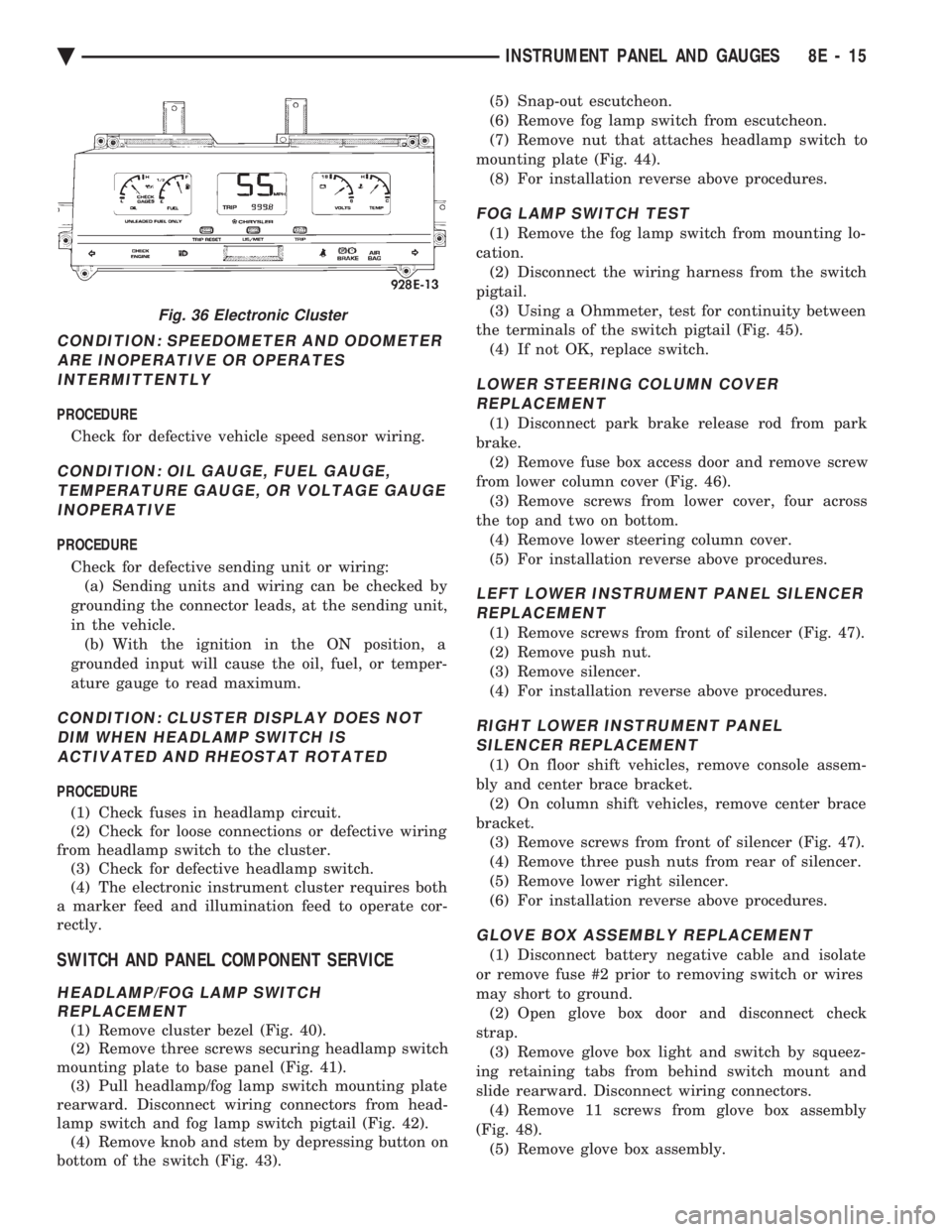

Fig. 36 Electronic Cluster

Ä INSTRUMENT PANEL AND GAUGES 8E - 15

Page 510 of 2438

(6) For installation reverse above procedures and

check operation of glove box door and adjust latch as

necessary.

GLOVE BOX LAMP AND SWITCH REPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Open glove box door. The lamp can be removed

without removing switch (3) Remove switch by squeezing retaining tabs

from behind switch mount and slide rearward. Dis-

connect wiring connectors. (4) Remove lamp and switch.

(5) For installation reverse above procedures.FOG LAMP RELAY REPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground.

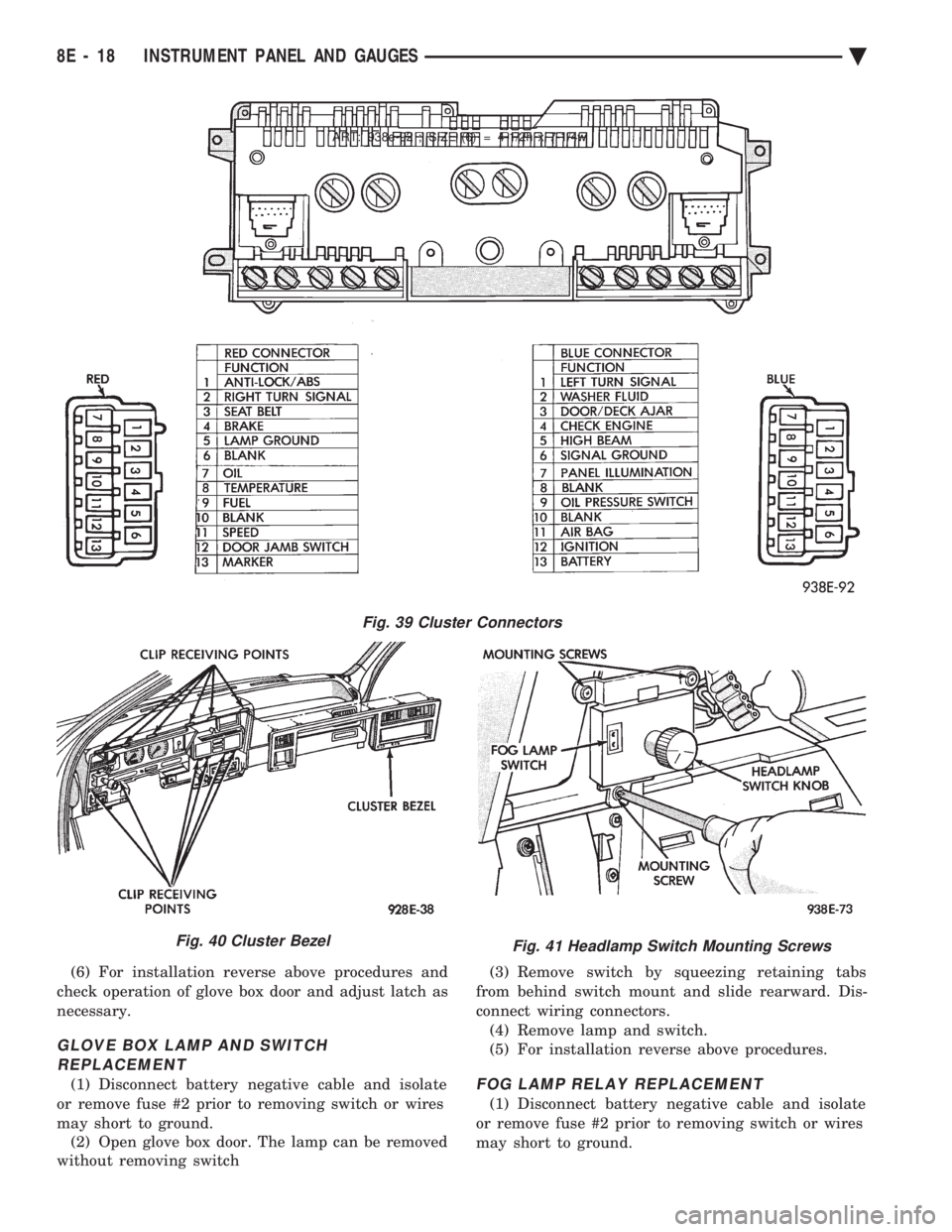

ART: 938e-92 ; SIZE (6) = 4-1/2h x 7-1/4w

Fig. 39 Cluster Connectors

Fig. 40 Cluster BezelFig. 41 Headlamp Switch Mounting Screws

8E - 18 INSTRUMENT PANEL AND GAUGES Ä

Page 511 of 2438

(2) Remove glove box assembly (Fig. 49). Refer to

Glove Box Assembly Replacement. (3) Remove screw from relay.

(4) Disconnect wiring.

(5) Remove relay. (6) For installation reverse above procedures.

REAR WINDOW DEFOGGER SWITCH

REPLACEMENT

(1) Remove left bezel by pulling straight back.

(2) Press tabs and pull switch rearward.

(3) Disconnect wiring and remove switch.

(4) For installation reverse above procedures.

INSTRUMENT PANEL CENTER BEZELREPLACEMENT

(1) Pull bezel straight back disengaging five clips.

(2) Disconnect ash receiver lamp and wiring from

bezel. (3) For installation reverse above procedures.

ASH RECEIVER/CUP HOLDER REPLACEMENT

(1) Remove center bezel. Disconnect ash receiver

lamp socket. (2) Remove four screws from center module and re-

move module.

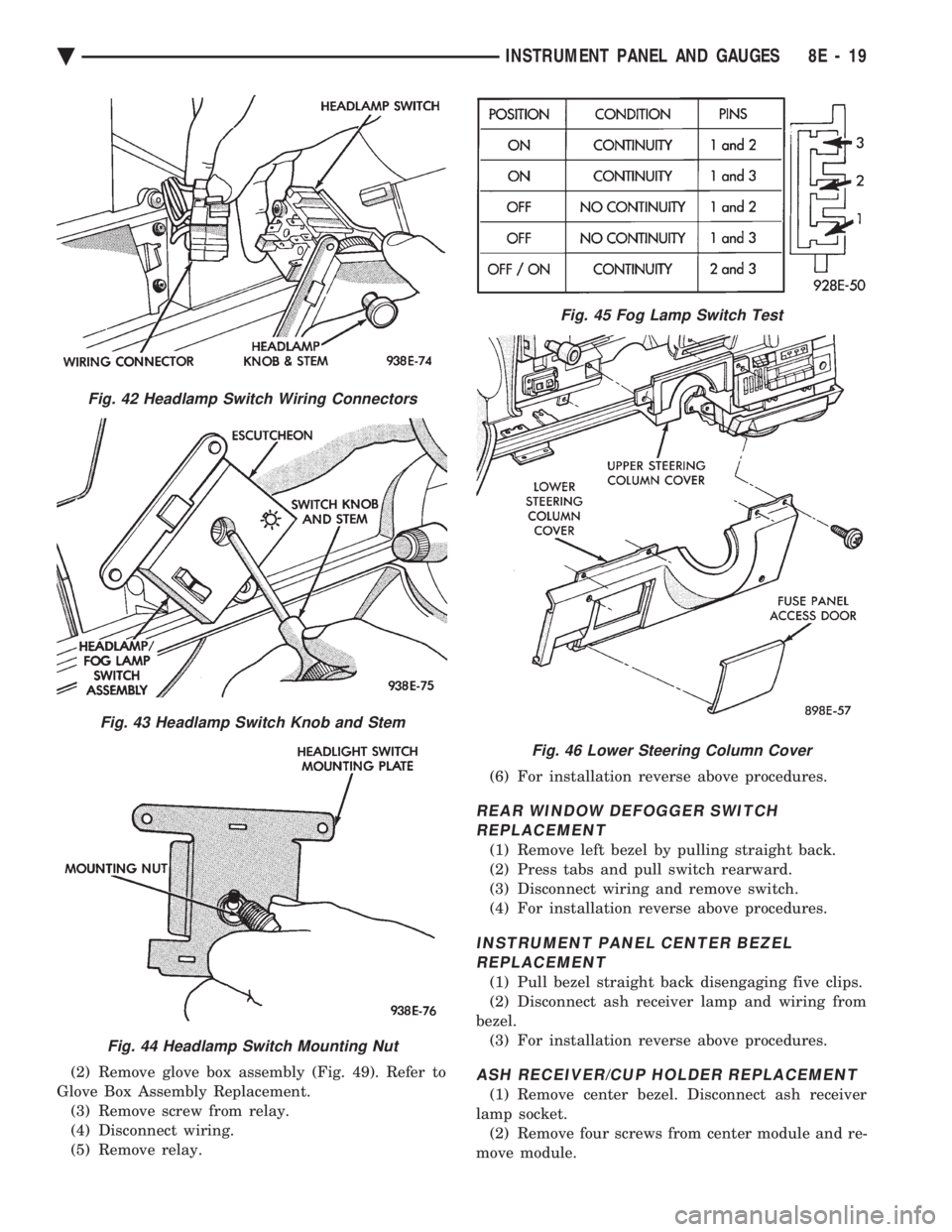

Fig. 42 Headlamp Switch Wiring Connectors

Fig. 43 Headlamp Switch Knob and Stem

Fig. 44 Headlamp Switch Mounting Nut

Fig. 45 Fog Lamp Switch Test

Fig. 46 Lower Steering Column Cover

Ä INSTRUMENT PANEL AND GAUGES 8E - 19

Page 513 of 2438

(3) Remove four screws from ash receiver/cup

holder housing. (4) For installation reverse above procedures.

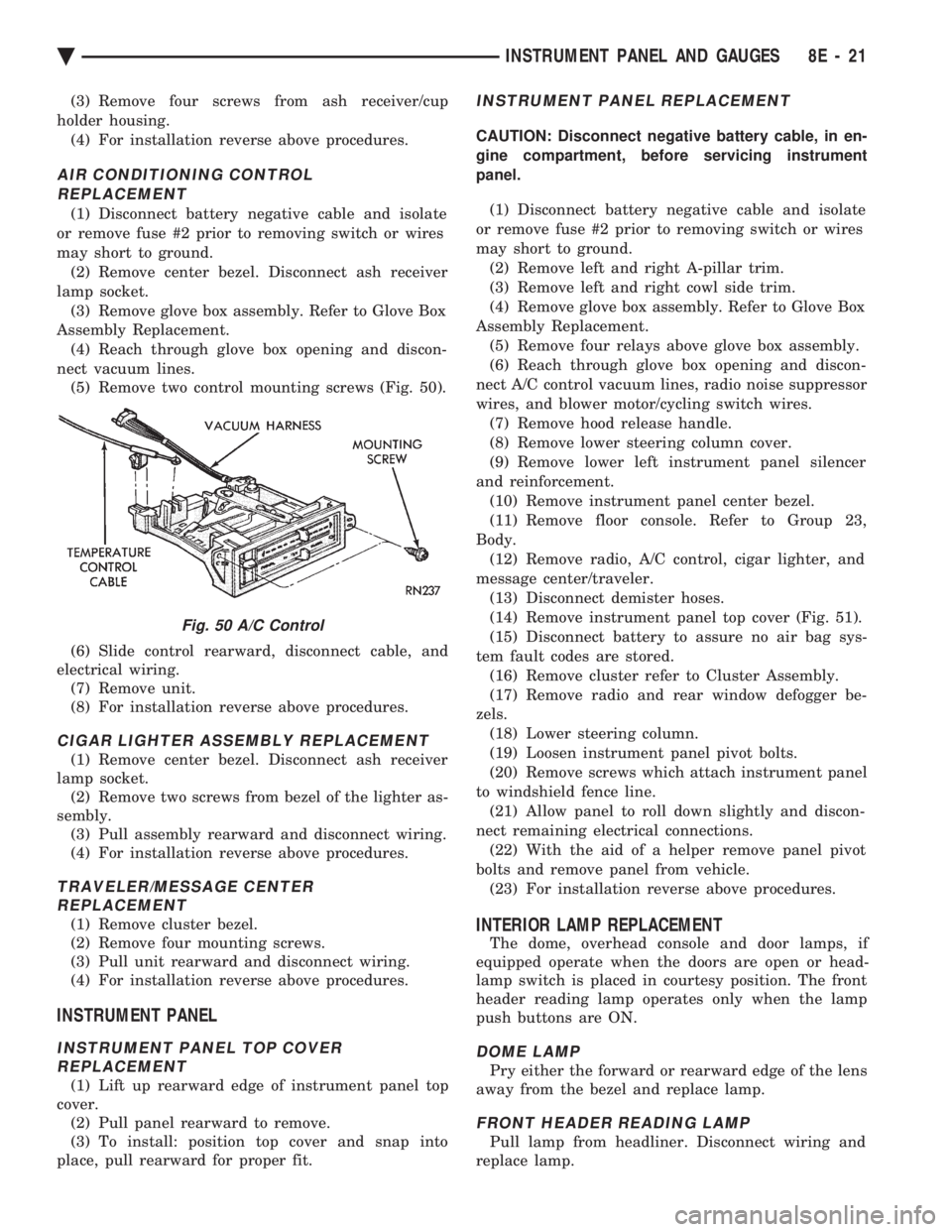

AIR CONDITIONING CONTROLREPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove center bezel. Disconnect ash receiver

lamp socket. (3) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (4) Reach through glove box opening and discon-

nect vacuum lines. (5) Remove two control mounting screws (Fig. 50).

(6) Slide control rearward, disconnect cable, and

electrical wiring. (7) Remove unit.

(8) For installation reverse above procedures.

CIGAR LIGHTER ASSEMBLY REPLACEMENT

(1) Remove center bezel. Disconnect ash receiver

lamp socket. (2) Remove two screws from bezel of the lighter as-

sembly. (3) Pull assembly rearward and disconnect wiring.

(4) For installation reverse above procedures.

TRAVELER/MESSAGE CENTER REPLACEMENT

(1) Remove cluster bezel.

(2) Remove four mounting screws.

(3) Pull unit rearward and disconnect wiring.

(4) For installation reverse above procedures.

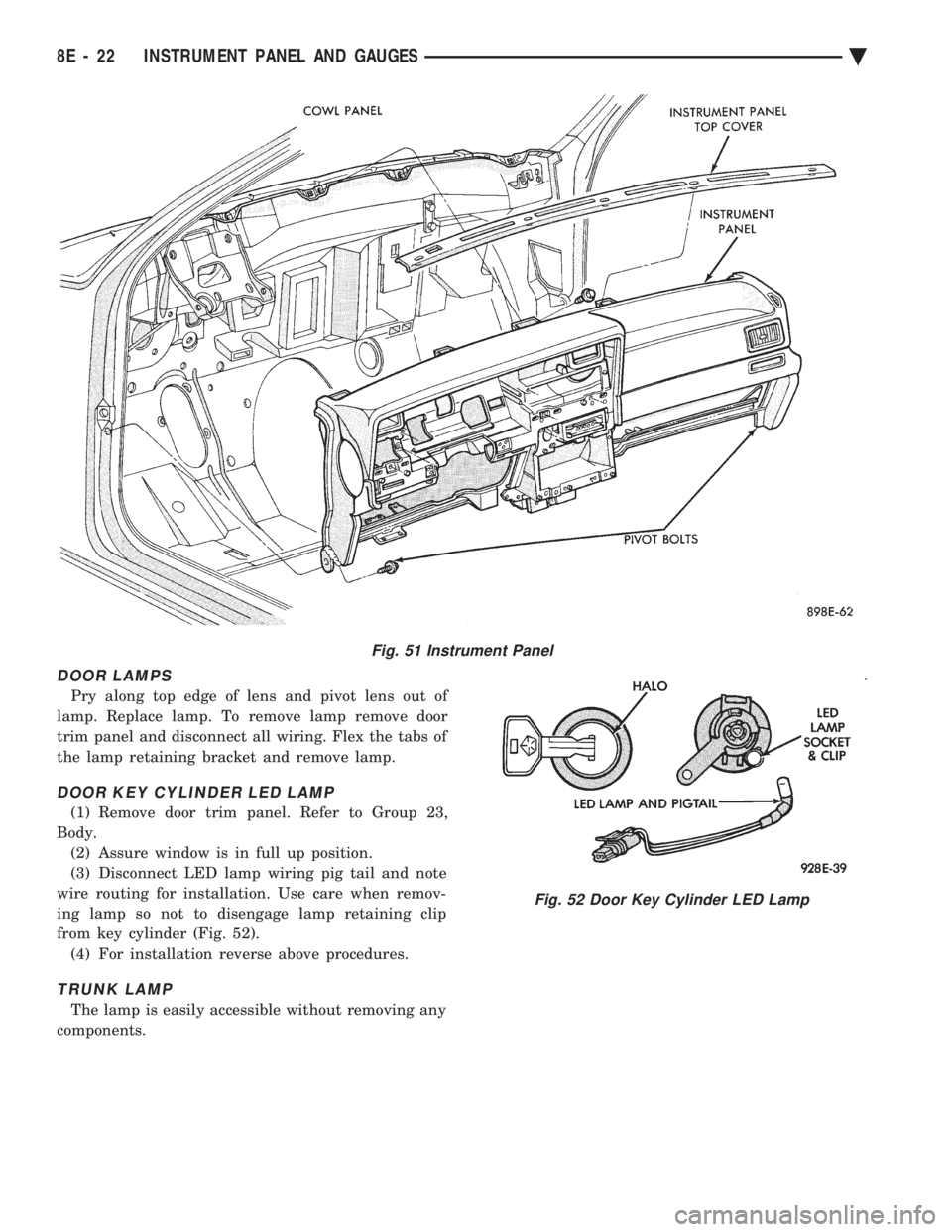

INSTRUMENT PANEL

INSTRUMENT PANEL TOP COVER REPLACEMENT

(1) Lift up rearward edge of instrument panel top

cover. (2) Pull panel rearward to remove.

(3) To install: position top cover and snap into

place, pull rearward for proper fit.

INSTRUMENT PANEL REPLACEMENT

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel.

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Remove left and right A-pillar trim.

(3) Remove left and right cowl side trim.

(4) Remove glove box assembly. Refer to Glove Box

Assembly Replacement. (5) Remove four relays above glove box assembly.

(6) Reach through glove box opening and discon-

nect A/C control vacuum lines, radio noise suppressor

wires, and blower motor/cycling switch wires. (7) Remove hood release handle.

(8) Remove lower steering column cover.

(9) Remove lower left instrument panel silencer

and reinforcement. (10) Remove instrument panel center bezel.

(11) Remove floor console. Refer to Group 23,

Body. (12) Remove radio, A/C control, cigar lighter, and

message center/traveler. (13) Disconnect demister hoses.

(14) Remove instrument panel top cover (Fig. 51).

(15) Disconnect battery to assure no air bag sys-

tem fault codes are stored. (16) Remove cluster refer to Cluster Assembly.

(17) Remove radio and rear window defogger be-

zels. (18) Lower steering column.

(19) Loosen instrument panel pivot bolts.

(20) Remove screws which attach instrument panel

to windshield fence line. (21) Allow panel to roll down slightly and discon-

nect remaining electrical connections. (22) With the aid of a helper remove panel pivot

bolts and remove panel from vehicle. (23) For installation reverse above procedures.

INTERIOR LAMP REPLACEMENT

The dome, overhead console and door lamps, if

equipped operate when the doors are open or head-

lamp switch is placed in courtesy position. The front

header reading lamp operates only when the lamp

push buttons are ON.

DOME LAMP

Pry either the forward or rearward edge of the lens

away from the bezel and replace lamp.

FRONT HEADER READING LAMP

Pull lamp from headliner. Disconnect wiring and

replace lamp.

Fig. 50 A/C Control

Ä INSTRUMENT PANEL AND GAUGES 8E - 21

Page 514 of 2438

DOOR LAMPS

Pry along top edge of lens and pivot lens out of

lamp. Replace lamp. To remove lamp remove door

trim panel and disconnect all wiring. Flex the tabs of

the lamp retaining bracket and remove lamp.

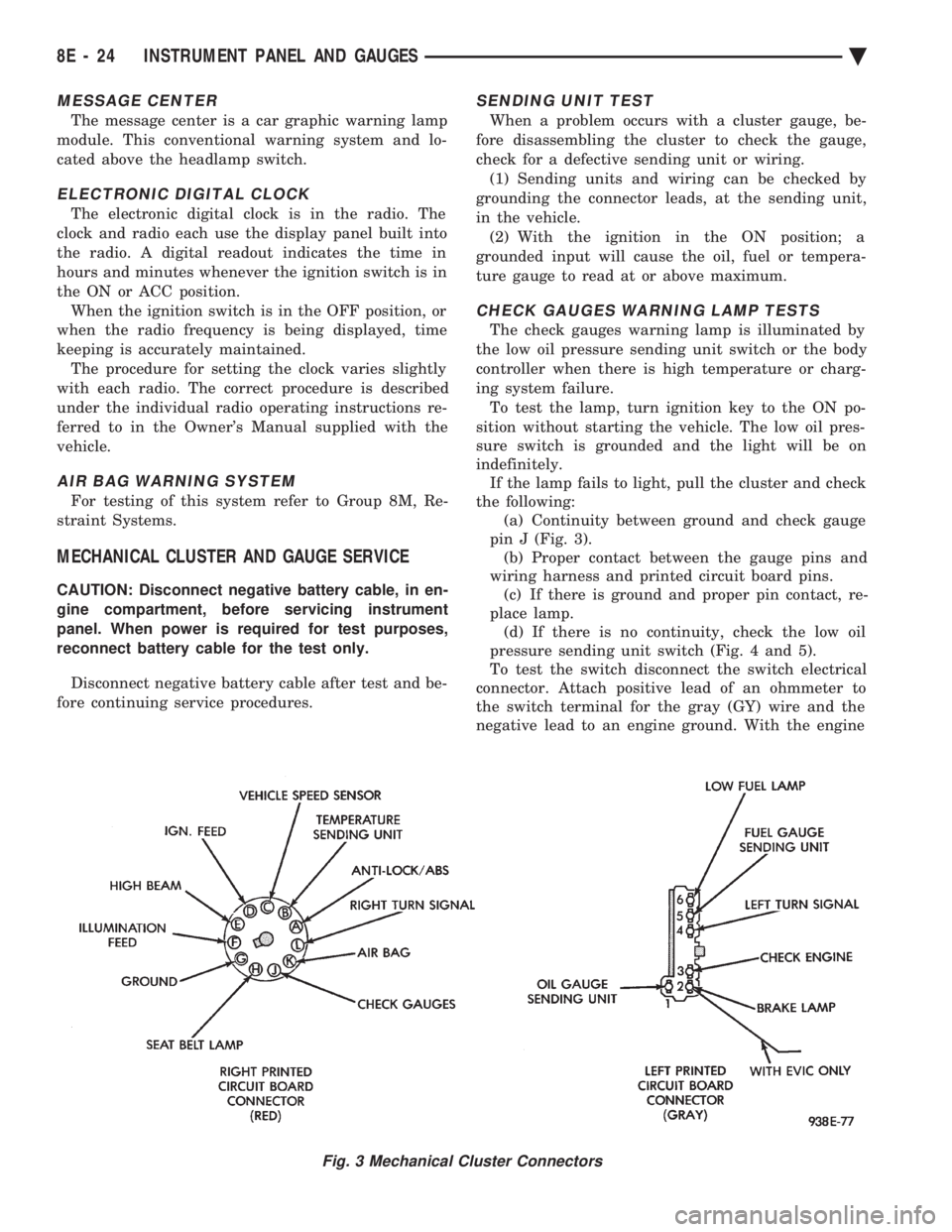

DOOR KEY CYLINDER LED LAMP

(1) Remove door trim panel. Refer to Group 23,

Body. (2) Assure window is in full up position.

(3) Disconnect LED lamp wiring pig tail and note

wire routing for installation. Use care when remov-

ing lamp so not to disengage lamp retaining clip

from key cylinder (Fig. 52). (4) For installation reverse above procedures.

TRUNK LAMP

The lamp is easily accessible without removing any

components.

Fig. 51 Instrument Panel

Fig. 52 Door Key Cylinder LED Lamp

8E - 22 INSTRUMENT PANEL AND GAUGES Ä

Page 516 of 2438

MESSAGE CENTER

The message center is a car graphic warning lamp

module. This conventional warning system and lo-

cated above the headlamp switch.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

ferred to in the Owner's Manual supplied with the

vehicle.

AIR BAG WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MECHANICAL CLUSTER AND GAUGE SERVICE

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel. When power is required for test purposes,

reconnect battery cable for the test only.

Disconnect negative battery cable after test and be-

fore continuing service procedures.

SENDING UNIT TEST

When a problem occurs with a cluster gauge, be-

fore disassembling the cluster to check the gauge,

check for a defective sending unit or wiring. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position; a

grounded input will cause the oil, fuel or tempera-

ture gauge to read at or above maximum.

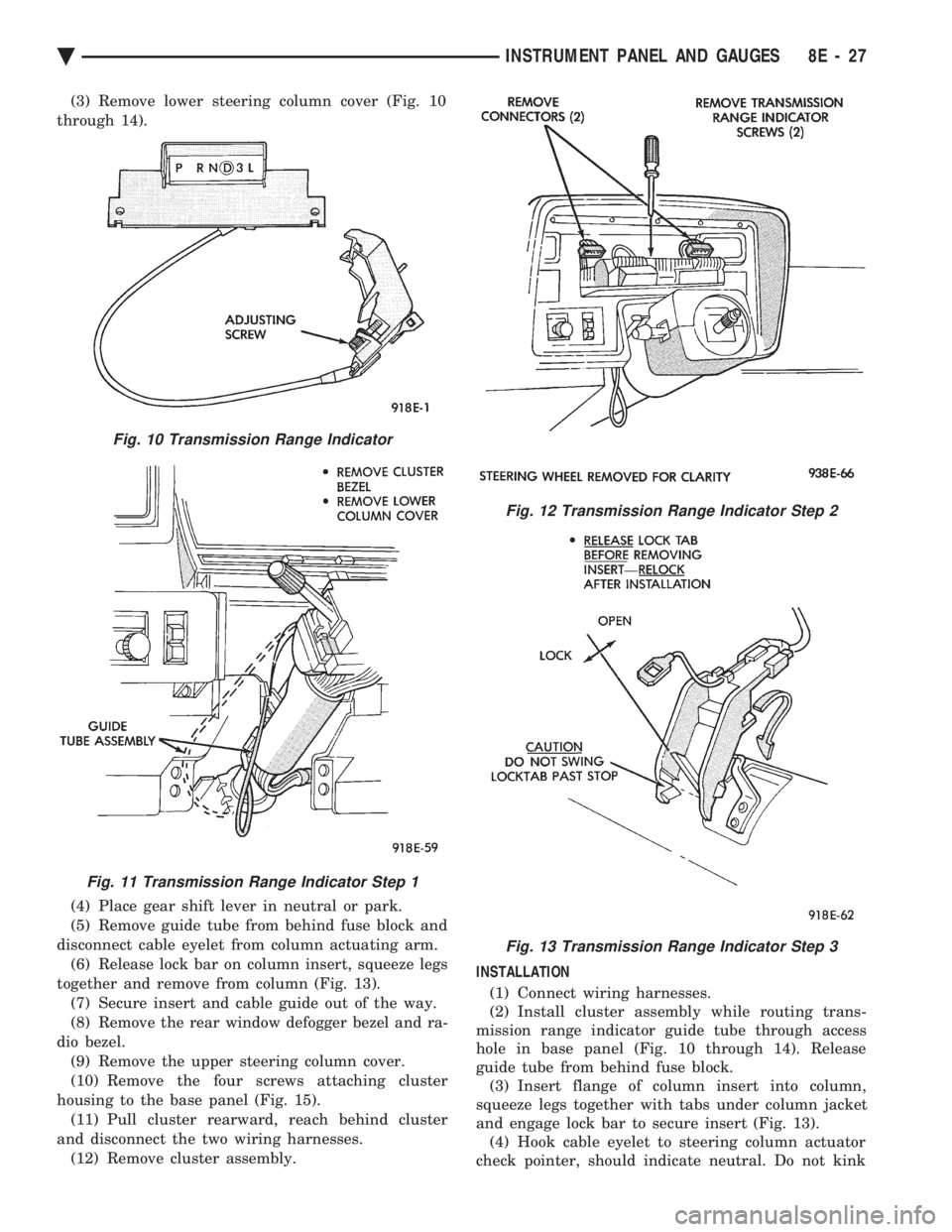

CHECK GAUGES WARNING LAMP TESTS

The check gauges warning lamp is illuminated by

the low oil pressure sending unit switch or the body

controller when there is high temperature or charg-

ing system failure. To test the lamp, turn ignition key to the ON po-

sition without starting the vehicle. The low oil pres-

sure switch is grounded and the light will be on

indefinitely. If the lamp fails to light, pull the cluster and check

the following: (a) Continuity between ground and check gauge

pin J (Fig. 3). (b) Proper contact between the gauge pins and

wiring harness and printed circuit board pins. (c) If there is ground and proper pin contact, re-

place lamp. (d) If there is no continuity, check the low oil

pressure sending unit switch (Fig. 4 and 5).

To test the switch disconnect the switch electrical

connector. Attach positive lead of an ohmmeter to

the switch terminal for the gray (GY) wire and the

negative lead to an engine ground. With the engine

Fig. 3 Mechanical Cluster Connectors

8E - 24 INSTRUMENT PANEL AND GAUGES Ä

Page 519 of 2438

(3) Remove lower steering column cover (Fig. 10

through 14).

(4) Place gear shift lever in neutral or park.

(5) Remove guide tube from behind fuse block and

disconnect cable eyelet from column actuating arm. (6) Release lock bar on column insert, squeeze legs

together and remove from column (Fig. 13). (7) Secure insert and cable guide out of the way.

(8) Remove the rear window defogger bezel and ra-

dio bezel. (9) Remove the upper steering column cover.

(10) Remove the four screws attaching cluster

housing to the base panel (Fig. 15). (11) Pull cluster rearward, reach behind cluster

and disconnect the two wiring harnesses. (12) Remove cluster assembly. INSTALLATION

(1) Connect wiring harnesses.

(2) Install cluster assembly while routing trans-

mission range indicator guide tube through access

hole in base panel (Fig. 10 through 14). Release

guide tube from behind fuse block. (3) Insert flange of column insert into column,

squeeze legs together with tabs under column jacket

and engage lock bar to secure insert (Fig. 13). (4) Hook cable eyelet to steering column actuator

check pointer, should indicate neutral. Do not kink

Fig. 10 Transmission Range Indicator

Fig. 11 Transmission Range Indicator Step 1

Fig. 12 Transmission Range Indicator Step 2

Fig. 13 Transmission Range Indicator Step 3

Ä INSTRUMENT PANEL AND GAUGES 8E - 27

Page 520 of 2438

or bind the transmission range indicator guide tube

and position guide tube in original location.(5) Adjust with tool if necessary to center pointer

on N (Neutral) and check in other gears (Fig. 14). (6) Install upper and lower steering column cover.

(7) Install the rear window defogger bezel and ra-

dio bezel. (8) Install cluster bezel.

(9) Reconnect battery.

REMOVALÐCLUSTER WITHOUT TRANSMISSION RANGE

INDICATOR FROM STEERING COLUMN

(1) Remove cluster bezel (Fig. 10).

(2) Remove four screws attaching cluster to base

panel. (3) Pull cluster rearward carefully, reach behind

and disconnect the two harness connectors. (4) Carefully rotate cluster and remove the two

transmission range indicator screws. (5) Remove cluster assembly.

(6) For installation reverse above procedures. (a) Do not kink guide tube when installing clus-

ter. (b) Replace guide tube behind fuse block.

GAUGES

It is not necessary to remove instrument cluster

from vehicle for gauge replacement. When removing

gauge assemblies from cluster, gauge must be pulled

straight out, not twisted, or damage to gauge pins

may result.

MULTIPLE GAUGE MALFUNCTION

If all the instrument cluster gauges appear to be

malfunctioning, remove the cluster assembly.

² Check for good pin contact

² Check for ignition voltage between the IGN cavity

D and ground.

² If there is ignition voltage

² Check for continuity between the wire harness

ground cavity G and ground.

² If there is continuity, replace the print circuit

board (Fig. 16).

GAUGE INOPERATIVE (FIG. 17 THROUGH 20)

(1) Remove gauge in question.

(2) With the ignition key ON, check for ignition

voltage at ignition pin of gauge. Check for ground at

ground pin of gauge. Refer to the individual gauge

circuit test for proper pin. (a) If no voltage or ground at gauge pins. Check

cavity D red cluster connector for ignition voltage

or cavity G for ground. (b) If no voltage or ground, repair as necessary.

Refer to 8W, Wiring Diagrams.

Fig. 15 Cluster With Mask and Lens Removed

Fig. 14 Transmission Range Indicator Step 4

8E - 28 INSTRUMENT PANEL AND GAUGES Ä

Page 522 of 2438

(b) Refer to sending unit removal Group 14, Fuel.

(c) Connect sending unit wire and jumper wire

as described in the test procedure.

(5) If fuel gauge now checks within specifications,

original sending unit is electrically okay, check fol-

lowing as a possible cause: (a) Ground wire from sending unit to left side

cowl for continuity. (b) Sending unit deformed. Make sure sending

unit float arm moves freely and pick up tube is not

bent upwards creating an interference with bottom

of tank and inspect float. (c) Sending unit improperly installed. Install

properly. (d) Mounting flange on fuel tank for sending

unit deformed. Feel for interference fit of sending

unit to bottom of tank. It is permissible to bend

pick up tube down a little near mounting flange to

gain interference fit. (e) Fuel tank bottom deformed, causing improper

positioning of sending unit pick up tube. Replace or

repair tank and recheck sending unit.

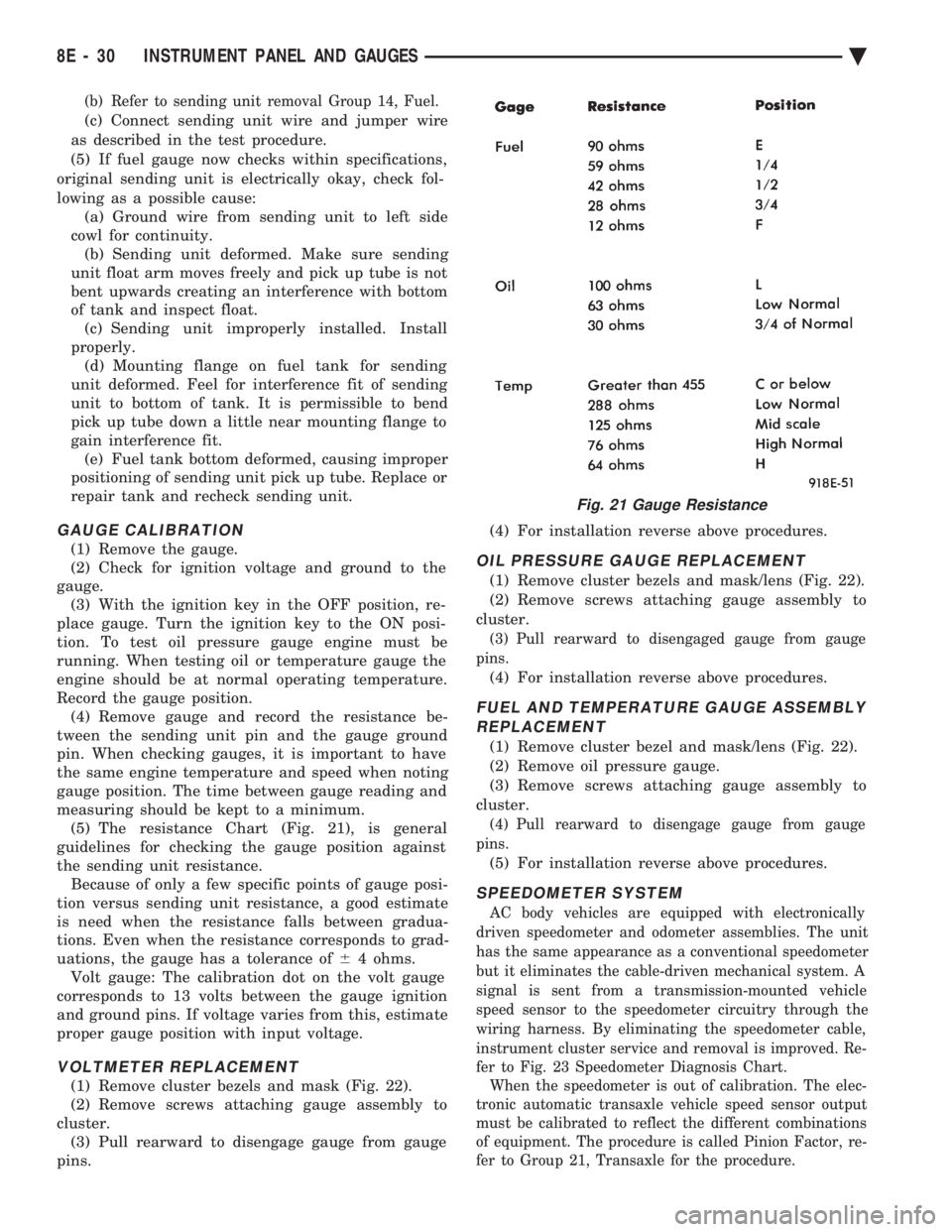

GAUGE CALIBRATION

(1) Remove the gauge.

(2) Check for ignition voltage and ground to the

gauge. (3) With the ignition key in the OFF position, re-

place gauge. Turn the ignition key to the ON posi-

tion. To test oil pressure gauge engine must be

running. When testing oil or temperature gauge the

engine should be at normal operating temperature.

Record the gauge position. (4) Remove gauge and record the resistance be-

tween the sending unit pin and the gauge ground

pin. When checking gauges, it is important to have

the same engine temperature and speed when noting

gauge position. The time between gauge reading and

measuring should be kept to a minimum. (5) The resistance Chart (Fig. 21), is general

guidelines for checking the gauge position against

the sending unit resistance. Because of only a few specific points of gauge posi-

tion versus sending unit resistance, a good estimate

is need when the resistance falls between gradua-

tions. Even when the resistance corresponds to grad-

uations, the gauge has a tolerance of 64 ohms.

Volt gauge: The calibration dot on the volt gauge

corresponds to 13 volts between the gauge ignition

and ground pins. If voltage varies from this, estimate

proper gauge position with input voltage.

VOLTMETER REPLACEMENT

(1) Remove cluster bezels and mask (Fig. 22).

(2) Remove screws attaching gauge assembly to

cluster. (3) Pull rearward to disengage gauge from gauge

pins. (4) For installation reverse above procedures.

OIL PRESSURE GAUGE REPLACEMENT

(1) Remove cluster bezels and mask/lens (Fig. 22).

(2) Remove screws attaching gauge assembly to

cluster.

(3) Pull rearward to disengaged gauge from gauge

pins.

(4) For installation reverse above procedures.

FUEL AND TEMPERATURE GAUGE ASSEMBLY REPLACEMENT

(1) Remove cluster bezel and mask/lens (Fig. 22).

(2) Remove oil pressure gauge.

(3) Remove screws attaching gauge assembly to

cluster.

(4) Pull rearward to disengage gauge from gauge

pins.

(5) For installation reverse above procedures.

SPEEDOMETER SYSTEM

AC body vehicles are equipped with electronically

driven speedometer and odometer assemblies. The unit

has the same appearance as a conventional speedometer

but it eliminates the cable-driven mechanical system. A

signal is sent from a transmission-mounted vehicle

speed sensor to the speedometer circuitry through the

wiring harness. By eliminating the speedometer cable,

instrument cluster service and removal is improved. Re-

fer to Fig. 23 Speedometer Diagnosis Chart. When the speedometer is out of calibration. The elec-

tronic automatic transaxle vehicle speed sensor output

must be calibrated to reflect the different combinations

of equipment. The procedure is called Pinion Factor, re-

fer to Group 21, Transaxle for the procedure.

Fig. 21 Gauge Resistance

8E - 30 INSTRUMENT PANEL AND GAUGES Ä

Page 526 of 2438

ELECTRONIC CLUSTER

SELF DIAGNOSTIC SYSTEM

The electronic clusters have an internal diagnostics

routing to isolate problems within the cluster or CCD

Bus. Using the cluster Self-Diagnostic Test will deter-

mine whether the problem is within the cluster or

outside of cluster (Fig. 29 and 30). Successful completion of the Self Diagnostic Test

indicates that the problem is in the CCD Bus, inter-

facing modules, connectors, or sensors outside of the

cluster. Refer to Fig. 31 for terminal listing.

CONDITION: CLUSTER DISPLAYS DO NOT ILLUMINATE AFTER VEHICLE IS STARTED

PROCEDURE

(1) Check fuses and verify battery and ignition

voltage at cluster connector. (2) Check ground from cluster connector to instru-

ment panel ground stud.

CONDITION: CLUSTER ASTERISK (*) FLASHES, CLUSTER DISPLAYS NOTINDICATING CORRECT DATA.

PROCEDURE

CCD bus problem. Use the Body Chassis Diagnos-

tic Manual to diagnose CCD Bus.

CONDITION: SPEEDOMETER AND ODOMETER ARE INOPERATIVE OR OPERATESINTERMITTENTLY

PROCEDURE

(1) If speedometer reads 0, or odometer is blank,

and cluster asterisk is flashing, use the Body Chassis

Diagnostic Manual to diagnose CCD Bus problem. (2) If cluster asterisk is not flashing, check for de-

fective vehicle speed sensor or speed sensor wiring.

CONDITION: OIL GAUGE, FUEL GAUGE, TEMPERATURE GAUGE, OR VOLTAGE GAUGEINOPERATIVE

PROCEDURE

If any gauge gives no indication and cluster aster-

isk is flashing, use the Body Chassis Manual to diag-

nose CCD Bus problem. If cluster asterisk is not flashing:

(1) Check for defective sending unit or wiring. (a) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (b) With the ignition in the ON position, a

grounded input will cause the oil, fuel, or temper-

ature gauge to read maximum. (2) If the problem is with the oil, temperature, or

fuel gauge, check the body controller. If the problem

is with the voltage gauge, check the powertrain con-

trol module operation.

CONDITION: CLUSTER DISPLAY DOES NOT DIM WHEN HEADLAMP SWITCH ISACTIVATED AND RHEOSTAT ROTATED

PROCEDURE

If the cluster asterisk is flashing, Refer to the Body

Chassis Diagnostic Manual to diagnose the CCD Bus. If the cluster asterisk is not flashing:

(1) Check fuses in headlamp circuit.

(2) Check for loose connections or defective wiring

for headlamp switch to body controller. (3) Check for defective headlamp switch. The elec-

tronic instrument cluster receives the display inten-

sity status from the body controller via the CCD Bus.

CONDITION: SEAT BELT WARNING LAMP DOES NOT ILLUMINATE

PROCEDURE

Turn on ignition. Lamp should illuminate for six

seconds. If not: (1) Check for burned out lamp and retest.

(2) Replace cluster.

CONDITION: LOW WASHER, DOOR/DECK, OR MALFUNCTION INDICATOR (CHECK ENGINE)LAMP, DO NOT ILLUMINATE

PROCEDURE

(1) Perform cluster self-diagnostics to determine if

lamp will illuminate. If lamp does not, check for

burned out lamp, replace and retest. (2) If cluster asterisk is flashing, Refer to the Body

Chassis Diagnostic Manual to diagnose CCD Bus. (3) If cluster asterisk is not flashing:(a) For low washer fluid or door/deck, check in-

puts to body controller. (b) For malfunction indicator (check engine),

check powertrain control module operation.

CONDITION: ODOMETER DISPLAY IS BLANK. THE ODOMETER VALUE IS NO LONGERRETAINED IN THIS ELECTRONIC CLUSTER.THIS TAKES PLACE IN THE BODYCONTROLLER

PROCEDURE

(1) If cluster asterisk is flashing, Refer to the Body

Chassis Diagnostic Manual to diagnose CCD Bus. (2) If cluster asterisk is not flashing, perform clus-

ter self-diagnostics. If code 921 appears in the odom-

eter display, replace body controller for odometer

failure.

8E - 34 INSTRUMENT PANEL AND GAUGES Ä