wiring CHEVROLET DYNASTY 1993 Manual PDF

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 388 of 2438

relay to starter solenoid for loose or corroded connec-

tions. Particularly at starter terminals.

² Repeat test. If engine still fails to crank properly,

trouble is within starter or starter mounted solenoid,

and it must be removed for repairs. Refer to Group

8B, Battery/Starter/Generator Service, Starter re-

placement.

STARTER RELAY TEST

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN PARK OR NEUTRAL WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests. (2) Perform the preceding starter solenoid tests

BEFORE performing starter relay tests. Refer to

Starter Solenoid Test. (3) Locate and remove the starter relay. For

starter relay locations, refer to Starter Solenoid Test

(Fig. 13 or 14). (4) After the starter relay has been located and re-

moved, refer to Starter Relay Tests (Fig. 15).

NEUTRAL STARTING AND BACK-UP SWITCH

AUTOMATIC TRANSMISSION ONLY

For electrical diagnostics, when checking starter

circuits, refer to Starter Relay Tests (Fig. 15). For replacement of switch, refer to Group 21, Tran-

saxle, Neutral Starting and Switch Replacement.

STARTER INTERLOCK SWITCHÐCLUTCH PEDAL MOUNTED

MANUAL TRANSMISSION ONLY

For electrical diagnostics, refer to the Starter Relay

Tests. For replacement and/or adjustment of the switch,

refer to Group 6, Manual Transaxle Clutch, Manual

Transaxle Starter Interlock Switch.

IGNITION SWITCH TEST

After testing the starter solenoid and relay, test ig-

nition switch and wiring. Refer to Group 8D, Ignition

Systems, or the Front Wheel Drive Car Wiring Dia-

grams Service Manual. Check all wiring for opens or

shorts, and all connectors for being loose or corroded.

BENCH TESTING STARTER SOLENOID

(1) Disconnect field coil wire from field coil termi-

nal (Fig. 16 or 17). (2) Check for continuity between solenoid terminal

and field coil terminal with a continuity tester. Con-

tinuity should be detected (Fig. 18 or 19). (3) Check for continuity between solenoid terminal

and solenoid housing (Fig. 20 or 21). Continuity

should be detected. If continuity is detected, solenoid

is good. (4) If continuity is not detected in either test, sole-

noid has an open circuit and is defective. If equipped

with:

² BOSCH STARTER: Replace the solenoid.

² NIPPONDENSO STARTER: Replace the starter

assembly.

8A - 16 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 393 of 2438

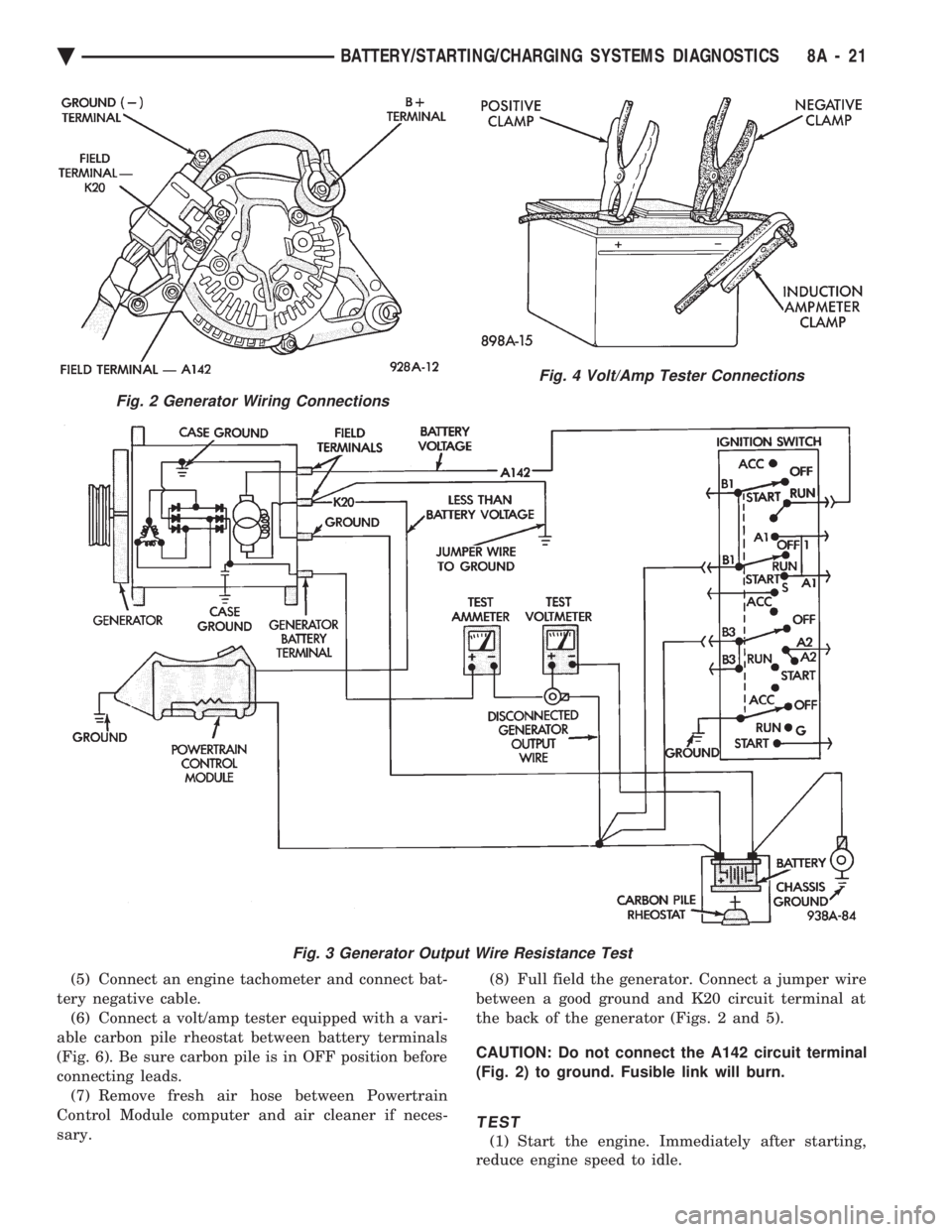

(5) Connect an engine tachometer and connect bat-

tery negative cable. (6) Connect a volt/amp tester equipped with a vari-

able carbon pile rheostat between battery terminals

(Fig. 6). Be sure carbon pile is in OFF position before

connecting leads. (7) Remove fresh air hose between Powertrain

Control Module computer and air cleaner if neces-

sary. (8) Full field the generator. Connect a jumper wire

between a good ground and K20 circuit terminal at

the back of the generator (Figs. 2 and 5).

CAUTION: Do not connect the A142 circuit terminal

(Fig. 2) to ground. Fusible link will burn.

TEST

(1) Start the engine. Immediately after starting,

reduce engine speed to idle.

Fig. 2 Generator Wiring Connections

Fig. 3 Generator Output Wire Resistance Test

Fig. 4 Volt/Amp Tester Connections

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 21

Page 399 of 2438

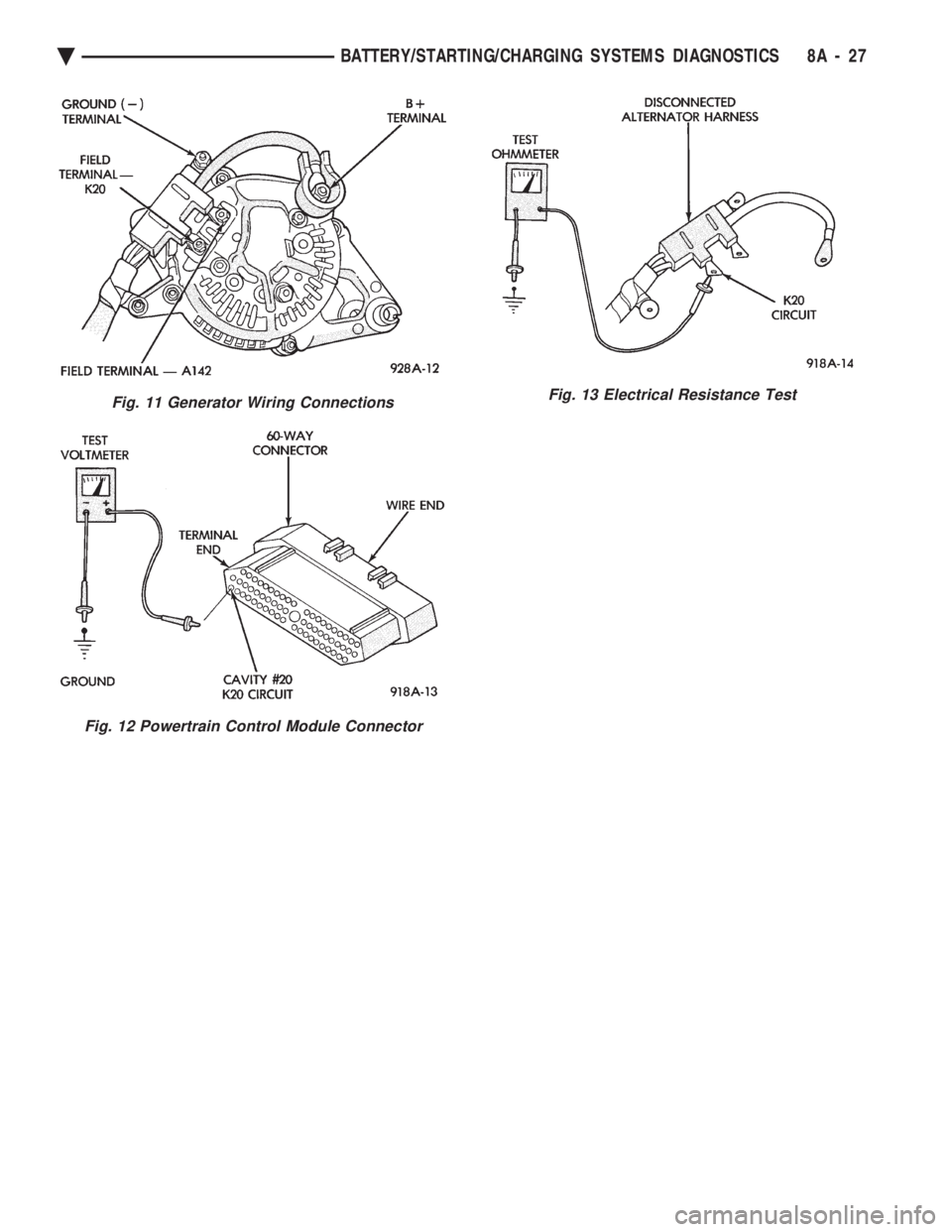

Fig. 11 Generator Wiring Connections

Fig. 12 Powertrain Control Module Connector

Fig. 13 Electrical Resistance Test

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 27

Page 406 of 2438

STARTER INDEX

page page

General Information ........................ 4

Neutral Starter and Back-Up Switch ........... 8

Starter Component Replacement .............. 5

Starter Interlock Switch: Clutch Pedal Mounted/ Manual Transmission Only ................. 7 Starter Motor Replacement

.................. 4

Starting System ........................... 4

Supply Circuit and Control Circuit ............. 4

GENERAL INFORMATION

This section will cover Starter replacement and

service procedures only. For starter diagnostic proce-

dures, refer to Group 8A, Battery/Starting/Charging

Systems Diagnostics.

STARTING SYSTEM

The starting system has:

² Ignition switch

² Starter relay

² Neutral starting and back-up switch with auto-

matic transmissions

² Clutch pedal mounted starter interlock switch

with manual transmissions

² Wiring harness

² Battery

² Starter motor with an integral solenoid

BOSCH STARTERS

²A Bosch permanent magnet starter motor is avail-

able on 2.2L, 2.5L and 3.0L engines on all vehicles.

A planetary gear train transmits power between

starter motor and pinion shaft. The fields consist of

six permanent magnets.

NIPPONDENSO STARTERS

² A Nippondenso reduction gear-field coil starter

motor is available on 3.0L, 3.3L and 3.8L engines.

SUPPLY CIRCUIT AND CONTROL CIRCUIT

Both starter systems consist of two separate cir-

cuits:

² A high amperage supply to feed the starter motor.

² A low amperage circuit to control the starter sole-

noid. For additional information on starter motor supply

and control circuits, refer to Group 8A, Battery/Start-

ing/Charging Systems Diagnostics.

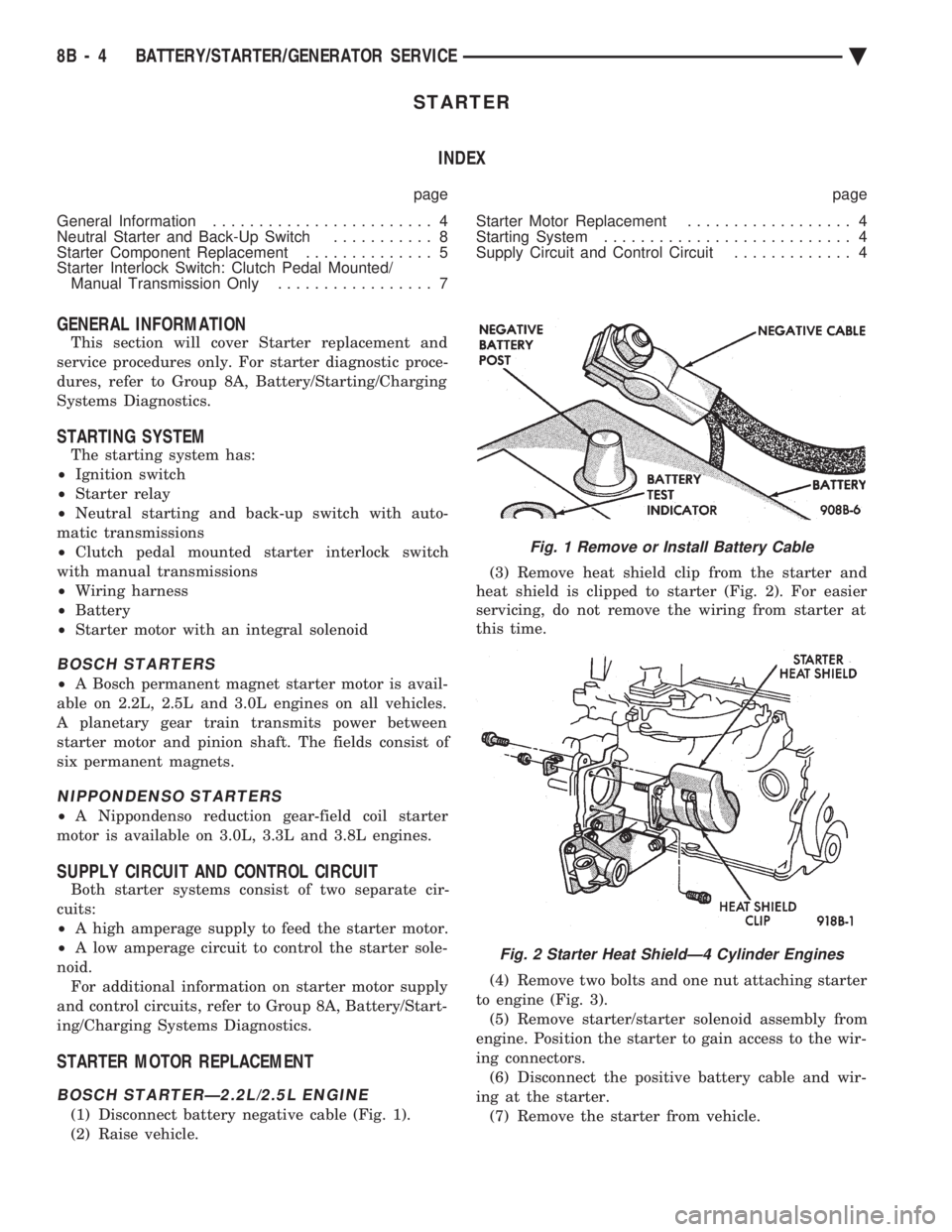

STARTER MOTOR REPLACEMENT

BOSCH STARTERÐ2.2L/2.5L ENGINE

(1) Disconnect battery negative cable (Fig. 1).

(2) Raise vehicle. (3) Remove heat shield clip from the starter and

heat shield is clipped to starter (Fig. 2). For easier

servicing, do not remove the wiring from starter at

this time.

(4) Remove two bolts and one nut attaching starter

to engine (Fig. 3). (5) Remove starter/starter solenoid assembly from

engine. Position the starter to gain access to the wir-

ing connectors. (6) Disconnect the positive battery cable and wir-

ing at the starter. (7) Remove the starter from vehicle.

Fig. 1 Remove or Install Battery Cable

Fig. 2 Starter Heat ShieldÐ4 Cylinder Engines

8B - 4 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 407 of 2438

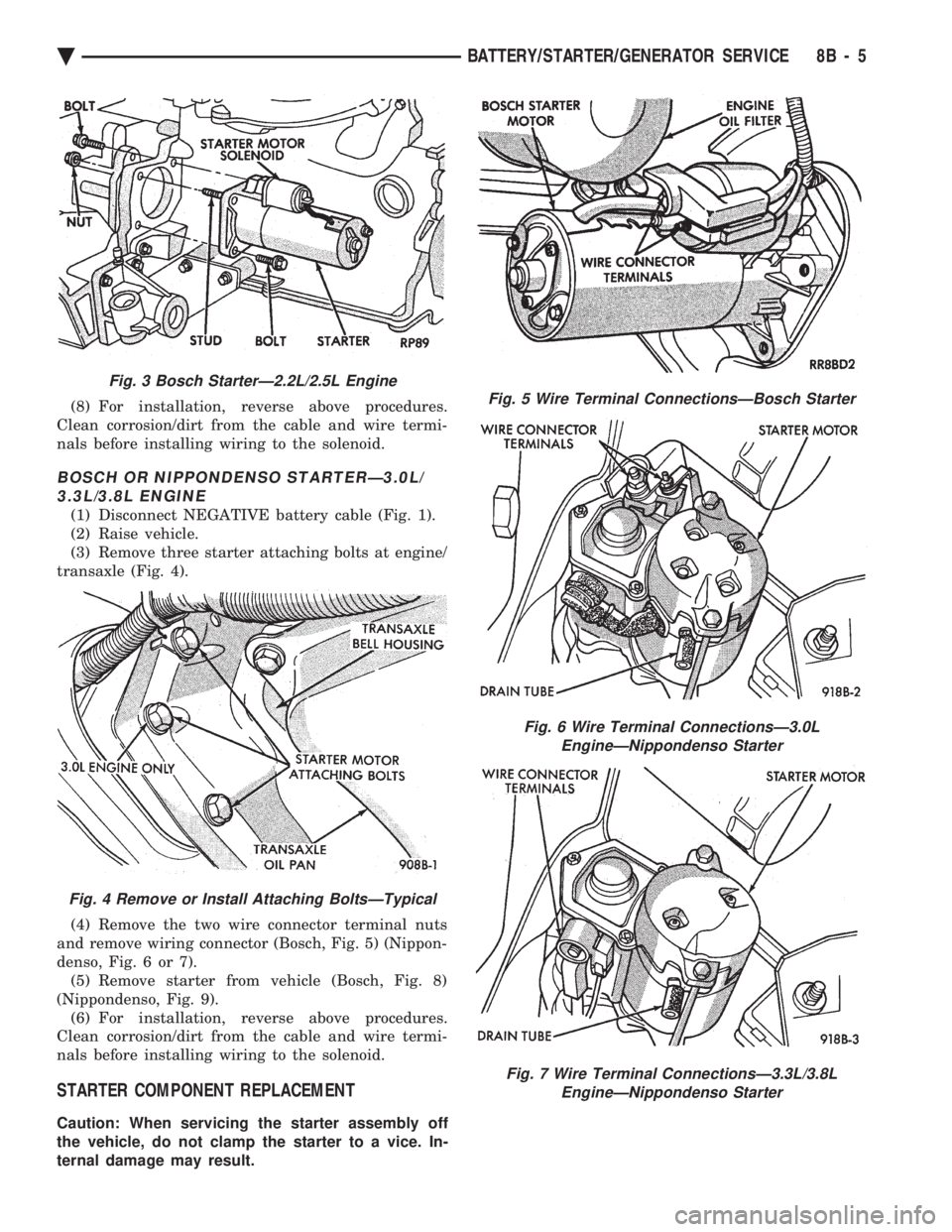

(8) For installation, reverse above procedures.

Clean corrosion/dirt from the cable and wire termi-

nals before installing wiring to the solenoid.

BOSCH OR NIPPONDENSO STARTERÐ3.0L/ 3.3L/3.8L ENGINE

(1) Disconnect NEGATIVE battery cable (Fig. 1).

(2) Raise vehicle.

(3) Remove three starter attaching bolts at engine/

transaxle (Fig. 4).

(4) Remove the two wire connector terminal nuts

and remove wiring connector (Bosch, Fig. 5) (Nippon-

denso, Fig. 6 or 7). (5) Remove starter from vehicle (Bosch, Fig. 8)

(Nippondenso, Fig. 9). (6) For installation, reverse above procedures.

Clean corrosion/dirt from the cable and wire termi-

nals before installing wiring to the solenoid.

STARTER COMPONENT REPLACEMENT

Caution: When servicing the starter assembly off

the vehicle, do not clamp the starter to a vice. In-

ternal damage may result.

Fig. 3 Bosch StarterÐ2.2L/2.5L Engine

Fig. 4 Remove or Install Attaching BoltsÐTypical

Fig. 5 Wire Terminal ConnectionsÐBosch Starter

Fig. 6 Wire Terminal ConnectionsÐ3.0L EngineÐNippondenso Starter

Fig. 7 Wire Terminal ConnectionsÐ3.3L/3.8L EngineÐNippondenso Starter

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 5

Page 413 of 2438

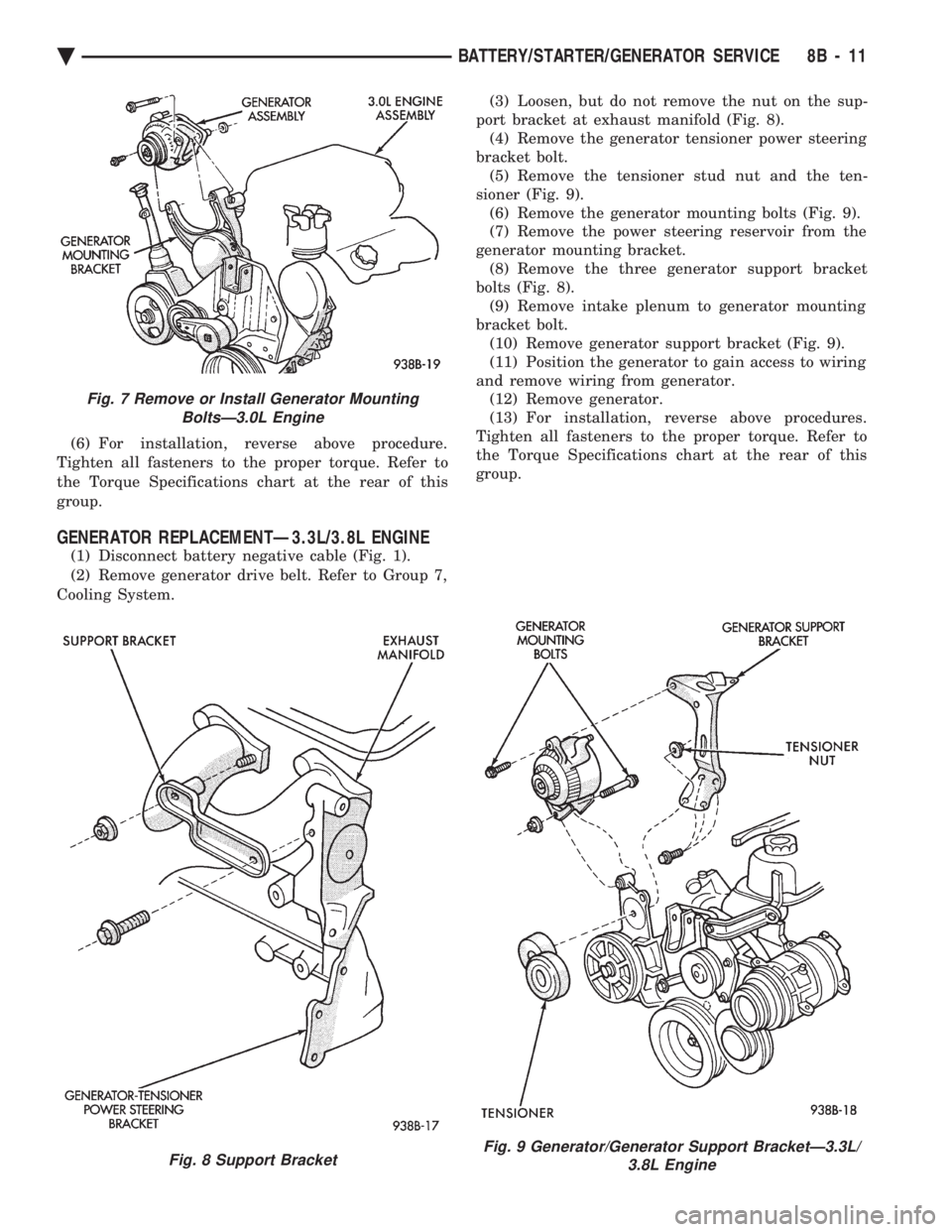

(6) For installation, reverse above procedure.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ3.3L/3.8L ENGINE

(1) Disconnect battery negative cable (Fig. 1).

(2) Remove generator drive belt. Refer to Group 7,

Cooling System. (3) Loosen, but do not remove the nut on the sup-

port bracket at exhaust manifold (Fig. 8). (4) Remove the generator tensioner power steering

bracket bolt. (5) Remove the tensioner stud nut and the ten-

sioner (Fig. 9). (6) Remove the generator mounting bolts (Fig. 9).

(7) Remove the power steering reservoir from the

generator mounting bracket. (8) Remove the three generator support bracket

bolts (Fig. 8). (9) Remove intake plenum to generator mounting

bracket bolt. (10) Remove generator support bracket (Fig. 9).

(11) Position the generator to gain access to wiring

and remove wiring from generator. (12) Remove generator.

(13) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

Fig. 7 Remove or Install Generator Mounting BoltsÐ3.0L Engine

Fig. 8 Support BracketFig. 9 Generator/Generator Support BracketÐ3.3L/ 3.8L Engine

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 11

Page 422 of 2438

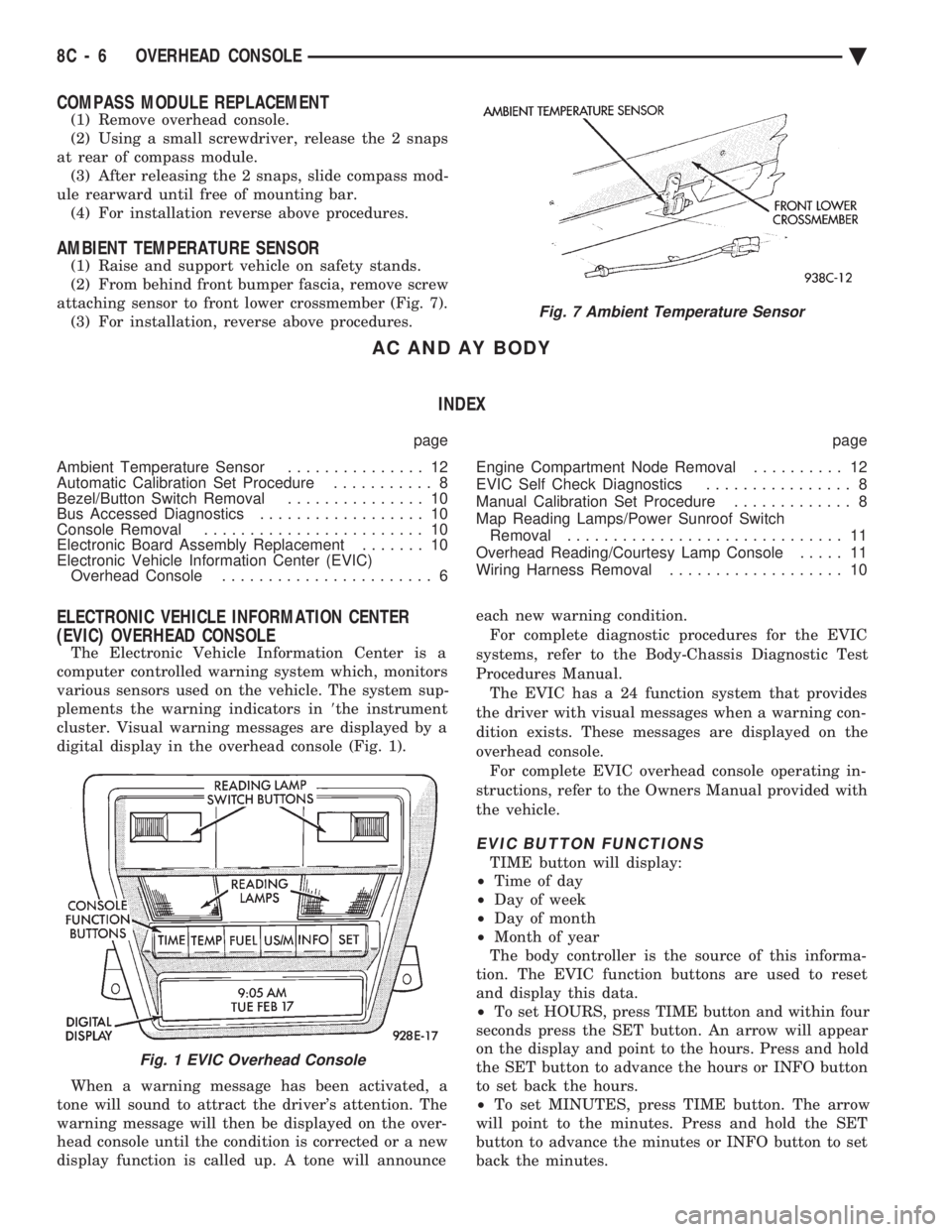

COMPASS MODULE REPLACEMENT

(1) Remove overhead console.

(2) Using a small screwdriver, release the 2 snaps

at rear of compass module. (3) After releasing the 2 snaps, slide compass mod-

ule rearward until free of mounting bar. (4) For installation reverse above procedures.

AMBIENT TEMPERATURE SENSOR

(1) Raise and support vehicle on safety stands.

(2) From behind front bumper fascia, remove screw

attaching sensor to front lower crossmember (Fig. 7). (3) For installation, reverse above procedures.

AC AND AY BODY

INDEX

page page

Ambient Temperature Sensor ............... 12

Automatic Calibration Set Procedure ........... 8

Bezel/Button Switch Removal ............... 10

Bus Accessed Diagnostics .................. 10

Console Removal ........................ 10

Electronic Board Assembly Replacement ....... 10

Electronic Vehicle Information Center (EVIC) Overhead Console ....................... 6 Engine Compartment Node Removal

.......... 12

EVIC Self Check Diagnostics ................ 8

Manual Calibration Set Procedure ............. 8

Map Reading Lamps/Power Sunroof Switch Removal .............................. 11

Overhead Reading/Courtesy Lamp Console ..... 11

Wiring Harness Removal ................... 10

ELECTRONIC VEHICLE INFORMATION CENTER

(EVIC) OVERHEAD CONSOLE

The Electronic Vehicle Information Center is a

computer controlled warning system which, monitors

various sensors used on the vehicle. The system sup-

plements the warning indicators in 8the instrument

cluster. Visual warning messages are displayed by a

digital display in the overhead console (Fig. 1).

When a warning message has been activated, a

tone will sound to attract the driver's attention. The

warning message will then be displayed on the over-

head console until the condition is corrected or a new

display function is called up. A tone will announce each new warning condition.

For complete diagnostic procedures for the EVIC

systems, refer to the Body-Chassis Diagnostic Test

Procedures Manual. The EVIC has a 24 function system that provides

the driver with visual messages when a warning con-

dition exists. These messages are displayed on the

overhead console. For complete EVIC overhead console operating in-

structions, refer to the Owners Manual provided with

the vehicle.

EVIC BUTTON FUNCTIONS

TIME button will display:

² Time of day

² Day of week

² Day of month

² Month of year

The body controller is the source of this informa-

tion. The EVIC function buttons are used to reset

and display this data.

² To set HOURS, press TIME button and within four

seconds press the SET button. An arrow will appear

on the display and point to the hours. Press and hold

the SET button to advance the hours or INFO button

to set back the hours.

² To set MINUTES, press TIME button. The arrow

will point to the minutes. Press and hold the SET

button to advance the minutes or INFO button to set

back the minutes.

Fig. 7 Ambient Temperature Sensor

Fig. 1 EVIC Overhead Console

8C - 6 OVERHEAD CONSOLE Ä

Page 426 of 2438

BUS ACCESSED DIAGNOSTICS

The following diagnostic test may be used to check

the integrity of the EVIC's internal connections and

operations. Refer to the Body Chassis Diagnostic Test

Procedure Manual for test procedures. MODULE RESET TEST, when the EVIC receives

this request from the DRB II, the EVIC will immedi-

ately enter into reset. DISPLAY TEST: The EVIC receives a request from

the DBR II, the EVIC will enter into a visual display

mode. Also checks the integrity of the display driver

to anode connections. The test shall consist of walk-

ing through the vertical and horizontal rows of an-

odes in the dot matrix display. SWITCH STATUS TEST, when the EVIC receives

this request from the DRB II, the EVIC will report

the open/closed status of each individual switch. FAULT BYTE TEST, when the EVIC receives this

request from the DRB II, the EVIC will report fault

status. Messages reported are:

² NO FAULT

² DISPLAY DRIVER FAULT

² EVIC MISSING MESSAGES

² POWER SUPPLY FAILURE

² FAULT IN RAM

² FAULT IN ROM

EVIC missing message implies that there may be a

system failure and/or the body controller is not pro-

viding EVIC with sufficient information. DISPLAY DRIVER FAULT, power supply failure

and fault in RAM/ROM implies that the EVIC is de-

fective.

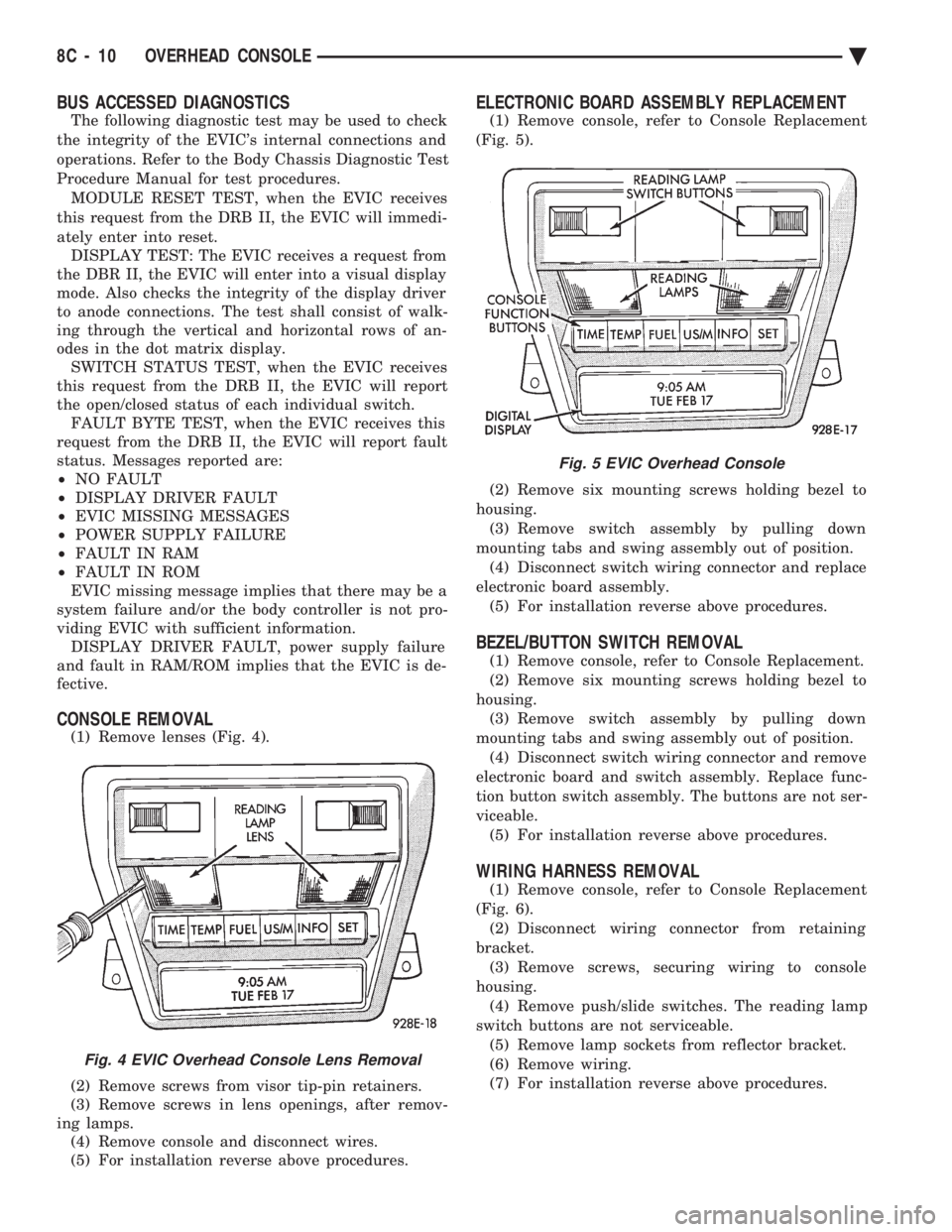

CONSOLE REMOVAL

(1) Remove lenses (Fig. 4).

(2) Remove screws from visor tip-pin retainers.

(3) Remove screws in lens openings, after remov-

ing lamps. (4) Remove console and disconnect wires.

(5) For installation reverse above procedures.

ELECTRONIC BOARD ASSEMBLY REPLACEMENT

(1) Remove console, refer to Console Replacement

(Fig. 5).

(2) Remove six mounting screws holding bezel to

housing. (3) Remove switch assembly by pulling down

mounting tabs and swing assembly out of position. (4) Disconnect switch wiring connector and replace

electronic board assembly. (5) For installation reverse above procedures.

BEZEL/BUTTON SWITCH REMOVAL

(1) Remove console, refer to Console Replacement.

(2) Remove six mounting screws holding bezel to

housing. (3) Remove switch assembly by pulling down

mounting tabs and swing assembly out of position. (4) Disconnect switch wiring connector and remove

electronic board and switch assembly. Replace func-

tion button switch assembly. The buttons are not ser-

viceable. (5) For installation reverse above procedures.

WIRING HARNESS REMOVAL

(1) Remove console, refer to Console Replacement

(Fig. 6). (2) Disconnect wiring connector from retaining

bracket. (3) Remove screws, securing wiring to console

housing. (4) Remove push/slide switches. The reading lamp

switch buttons are not serviceable. (5) Remove lamp sockets from reflector bracket.

(6) Remove wiring.

(7) For installation reverse above procedures.

Fig. 4 EVIC Overhead Console Lens Removal

Fig. 5 EVIC Overhead Console

8C - 10 OVERHEAD CONSOLE Ä

Page 427 of 2438

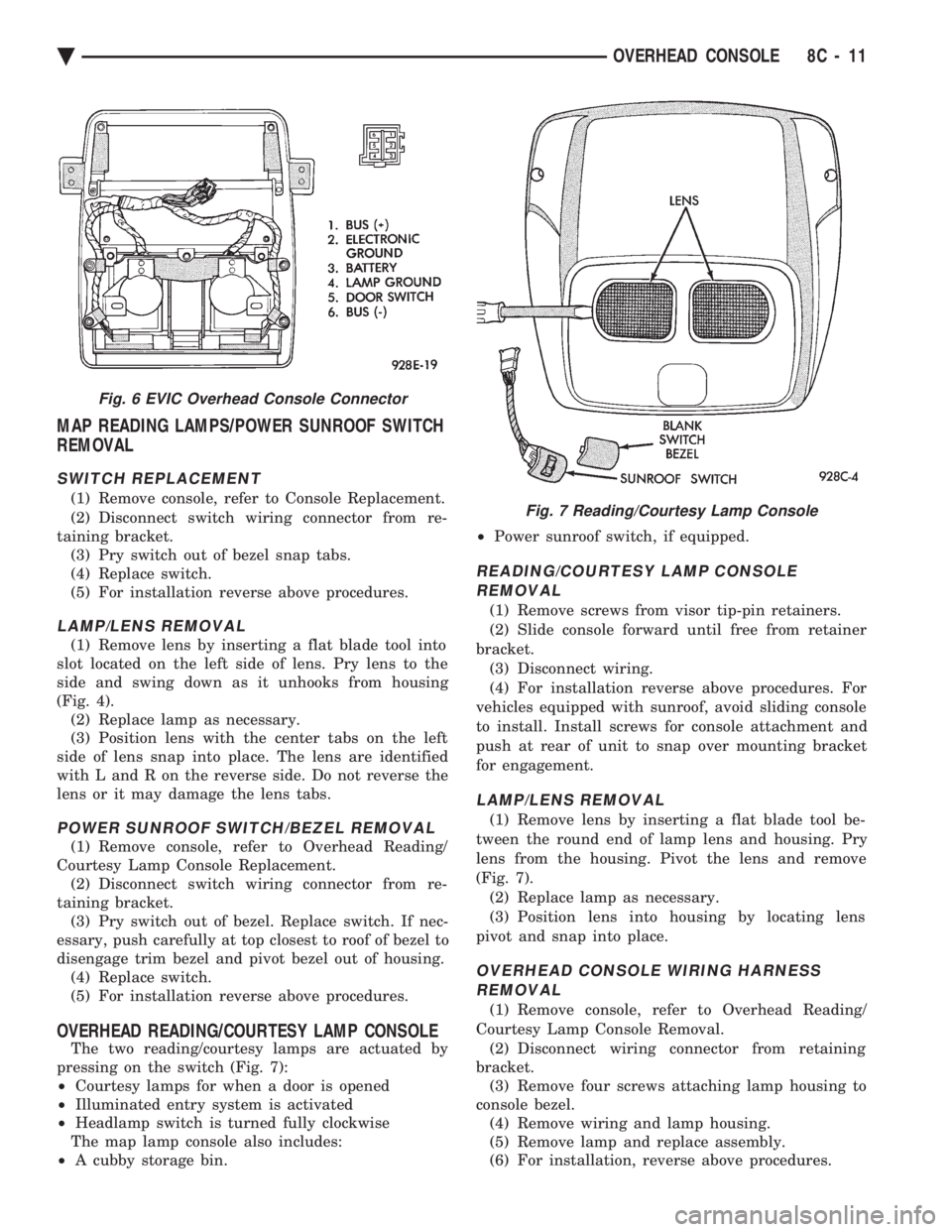

MAP READING LAMPS/POWER SUNROOF SWITCH

REMOVAL

SWITCH REPLACEMENT

(1) Remove console, refer to Console Replacement.

(2) Disconnect switch wiring connector from re-

taining bracket. (3) Pry switch out of bezel snap tabs.

(4) Replace switch.

(5) For installation reverse above procedures.

LAMP/LENS REMOVAL

(1) Remove lens by inserting a flat blade tool into

slot located on the left side of lens. Pry lens to the

side and swing down as it unhooks from housing

(Fig. 4). (2) Replace lamp as necessary.

(3) Position lens with the center tabs on the left

side of lens snap into place. The lens are identified

with L and R on the reverse side. Do not reverse the

lens or it may damage the lens tabs.

POWER SUNROOF SWITCH/BEZEL REMOVAL

(1) Remove console, refer to Overhead Reading/

Courtesy Lamp Console Replacement. (2) Disconnect switch wiring connector from re-

taining bracket. (3) Pry switch out of bezel. Replace switch. If nec-

essary, push carefully at top closest to roof of bezel to

disengage trim bezel and pivot bezel out of housing. (4) Replace switch.

(5) For installation reverse above procedures.

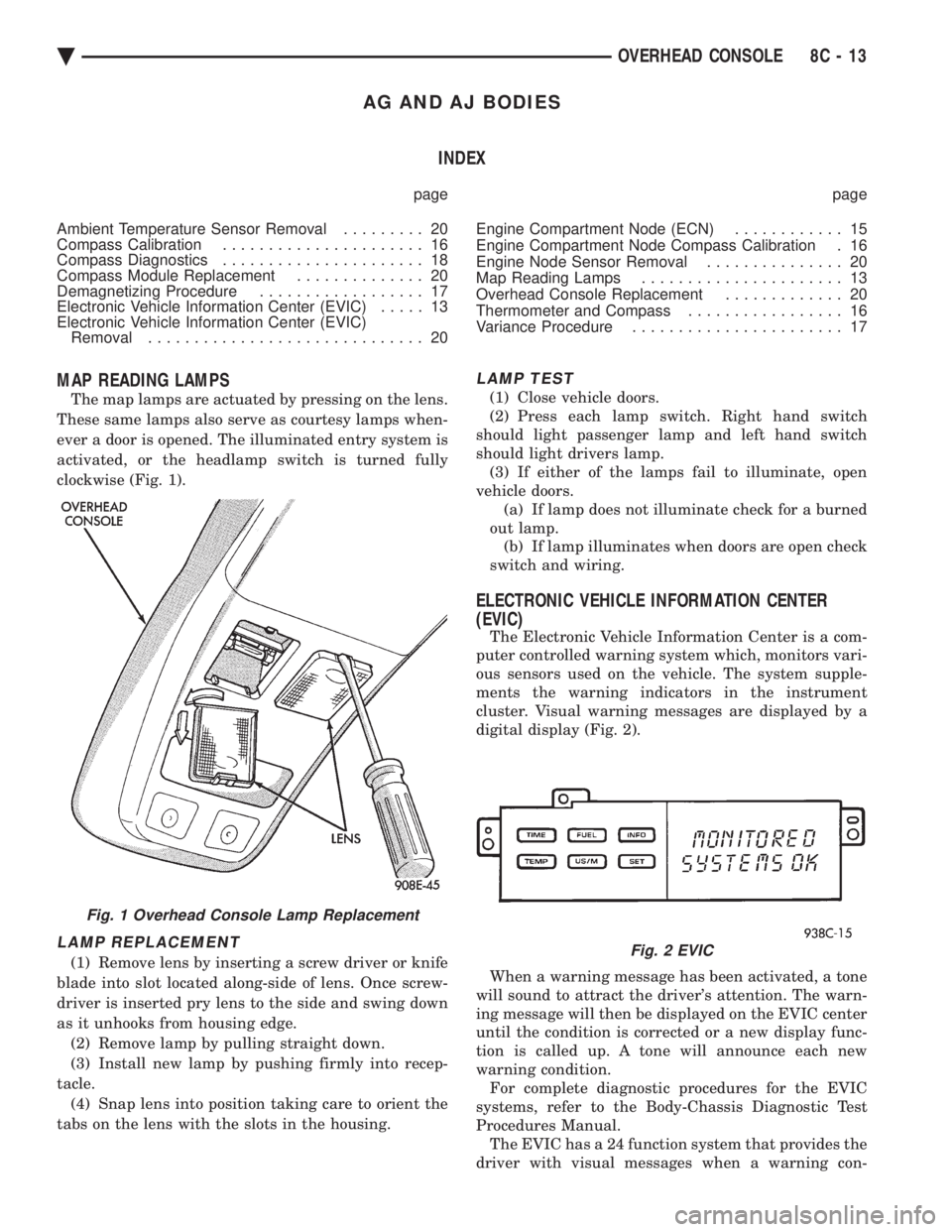

OVERHEAD READING/COURTESY LAMP CONSOLE

The two reading/courtesy lamps are actuated by

pressing on the switch (Fig. 7):

² Courtesy lamps for when a door is opened

² Illuminated entry system is activated

² Headlamp switch is turned fully clockwise

The map lamp console also includes:

² A cubby storage bin. ²

Power sunroof switch, if equipped.

READING/COURTESY LAMP CONSOLE

REMOVAL

(1) Remove screws from visor tip-pin retainers.

(2) Slide console forward until free from retainer

bracket. (3) Disconnect wiring.

(4) For installation reverse above procedures. For

vehicles equipped with sunroof, avoid sliding console

to install. Install screws for console attachment and

push at rear of unit to snap over mounting bracket

for engagement.

LAMP/LENS REMOVAL

(1) Remove lens by inserting a flat blade tool be-

tween the round end of lamp lens and housing. Pry

lens from the housing. Pivot the lens and remove

(Fig. 7). (2) Replace lamp as necessary.

(3) Position lens into housing by locating lens

pivot and snap into place.

OVERHEAD CONSOLE WIRING HARNESS REMOVAL

(1) Remove console, refer to Overhead Reading/

Courtesy Lamp Console Removal. (2) Disconnect wiring connector from retaining

bracket. (3) Remove four screws attaching lamp housing to

console bezel. (4) Remove wiring and lamp housing.

(5) Remove lamp and replace assembly.

(6) For installation, reverse above procedures.

Fig. 6 EVIC Overhead Console Connector

Fig. 7 Reading/Courtesy Lamp Console

Ä OVERHEAD CONSOLE 8C - 11

Page 429 of 2438

AG AND AJ BODIES INDEX

page page

Ambient Temperature Sensor Removal ......... 20

Compass Calibration ...................... 16

Compass Diagnostics ...................... 18

Compass Module Replacement .............. 20

Demagnetizing Procedure .................. 17

Electronic Vehicle Information Center (EVIC) ..... 13

Electronic Vehicle Information Center (EVIC) Removal .............................. 20 Engine Compartment Node (ECN)

............ 15

Engine Compartment Node Compass Calibration . 16

Engine Node Sensor Removal ............... 20

Map Reading Lamps ...................... 13

Overhead Console Replacement ............. 20

Thermometer and Compass ................. 16

Variance Procedure ....................... 17

MAP READING LAMPS

The map lamps are actuated by pressing on the lens.

These same lamps also serve as courtesy lamps when-

ever a door is opened. The illuminated entry system is

activated, or the headlamp switch is turned fully

clockwise (Fig. 1).

LAMP REPLACEMENT

(1) Remove lens by inserting a screw driver or knife

blade into slot located along-side of lens. Once screw-

driver is inserted pry lens to the side and swing down

as it unhooks from housing edge. (2) Remove lamp by pulling straight down.

(3) Install new lamp by pushing firmly into recep-

tacle. (4) Snap lens into position taking care to orient the

tabs on the lens with the slots in the housing.

LAMP TEST

(1) Close vehicle doors.

(2) Press each lamp switch. Right hand switch

should light passenger lamp and left hand switch

should light drivers lamp. (3) If either of the lamps fail to illuminate, open

vehicle doors. (a) If lamp does not illuminate check for a burned

out lamp. (b) If lamp illuminates when doors are open check

switch and wiring.

ELECTRONIC VEHICLE INFORMATION CENTER

(EVIC)

The Electronic Vehicle Information Center is a com-

puter controlled warning system which, monitors vari-

ous sensors used on the vehicle. The system supple-

ments the warning indicators in the instrument

cluster. Visual warning messages are displayed by a

digital display (Fig. 2).

When a warning message has been activated, a tone

will sound to attract the driver's attention. The warn-

ing message will then be displayed on the EVIC center

until the condition is corrected or a new display func-

tion is called up. A tone will announce each new

warning condition. For complete diagnostic procedures for the EVIC

systems, refer to the Body-Chassis Diagnostic Test

Procedures Manual. The EVIC has a 24 function system that provides the

driver with visual messages when a warning con-

Fig. 1 Overhead Console Lamp Replacement

Fig. 2 EVIC

Ä OVERHEAD CONSOLE 8C - 13