service CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 333 of 2438

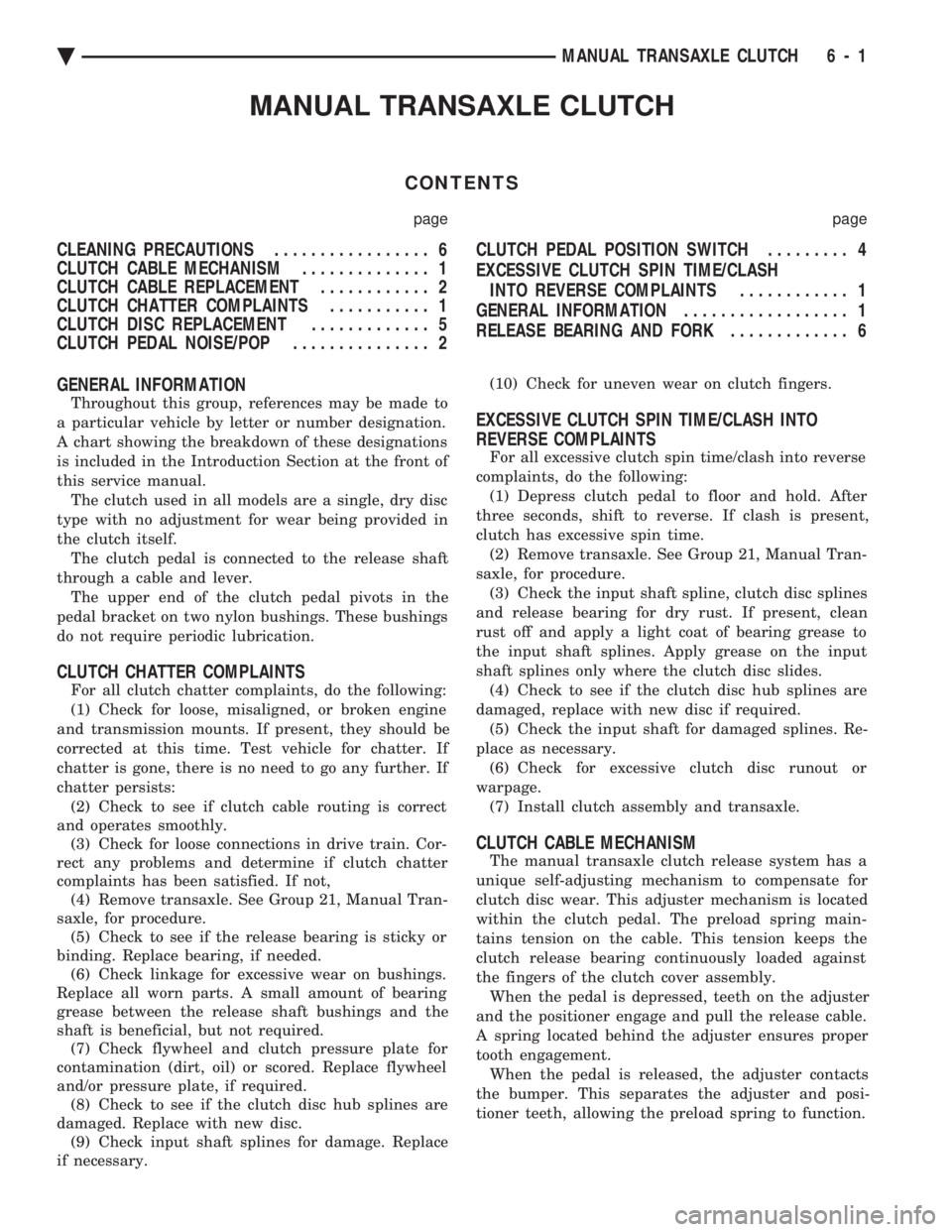

MANUAL TRANSAXLE CLUTCH

CONTENTS

page page

CLEANING PRECAUTIONS ................. 6

CLUTCH CABLE MECHANISM .............. 1

CLUTCH CABLE REPLACEMENT ............ 2

CLUTCH CHATTER COMPLAINTS ........... 1

CLUTCH DISC REPLACEMENT ............. 5

CLUTCH PEDAL NOISE/POP ............... 2 CLUTCH PEDAL POSITION SWITCH

......... 4

EXCESSIVE CLUTCH SPIN TIME/CLASH INTO REVERSE COMPLAINTS ............ 1

GENERAL INFORMATION .................. 1

RELEASE BEARING AND FORK ............. 6

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual. The clutch used in all models are a single, dry disc

type with no adjustment for wear being provided in

the clutch itself. The clutch pedal is connected to the release shaft

through a cable and lever. The upper end of the clutch pedal pivots in the

pedal bracket on two nylon bushings. These bushings

do not require periodic lubrication.

CLUTCH CHATTER COMPLAINTS

For all clutch chatter complaints, do the following:

(1) Check for loose, misaligned, or broken engine

and transmission mounts. If present, they should be

corrected at this time. Test vehicle for chatter. If

chatter is gone, there is no need to go any further. If

chatter persists: (2) Check to see if clutch cable routing is correct

and operates smoothly. (3) Check for loose connections in drive train. Cor-

rect any problems and determine if clutch chatter

complaints has been satisfied. If not, (4) Remove transaxle. See Group 21, Manual Tran-

saxle, for procedure. (5) Check to see if the release bearing is sticky or

binding. Replace bearing, if needed. (6) Check linkage for excessive wear on bushings.

Replace all worn parts. A small amount of bearing

grease between the release shaft bushings and the

shaft is beneficial, but not required. (7) Check flywheel and clutch pressure plate for

contamination (dirt, oil) or scored. Replace flywheel

and/or pressure plate, if required. (8) Check to see if the clutch disc hub splines are

damaged. Replace with new disc. (9) Check input shaft splines for damage. Replace

if necessary. (10) Check for uneven wear on clutch fingers.

EXCESSIVE CLUTCH SPIN TIME/CLASH INTO

REVERSE COMPLAINTS

For all excessive clutch spin time/clash into reverse

complaints, do the following: (1) Depress clutch pedal to floor and hold. After

three seconds, shift to reverse. If clash is present,

clutch has excessive spin time. (2) Remove transaxle. See Group 21, Manual Tran-

saxle, for procedure. (3) Check the input shaft spline, clutch disc splines

and release bearing for dry rust. If present, clean

rust off and apply a light coat of bearing grease to

the input shaft splines. Apply grease on the input

shaft splines only where the clutch disc slides. (4) Check to see if the clutch disc hub splines are

damaged, replace with new disc if required. (5) Check the input shaft for damaged splines. Re-

place as necessary. (6) Check for excessive clutch disc runout or

warpage. (7) Install clutch assembly and transaxle.

CLUTCH CABLE MECHANISM

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch pedal. The preload spring main-

tains tension on the cable. This tension keeps the

clutch release bearing continuously loaded against

the fingers of the clutch cover assembly. When the pedal is depressed, teeth on the adjuster

and the positioner engage and pull the release cable.

A spring located behind the adjuster ensures proper

tooth engagement. When the pedal is released, the adjuster contacts

the bumper. This separates the adjuster and posi-

tioner teeth, allowing the preload spring to function.

Ä MANUAL TRANSAXLE CLUTCH 6 - 1

Page 339 of 2438

hicle is steam cleaned. The facing of the disc will

absorb moisture. The force exerted by the pressure

plate will bond the facings to flywheel and/or, pres-

sure plate, if vehicle is allowed to stand for some

time before use. If this condition occurs, it will re- quire replacement of disc assembly, flywheel, and/or

clutch assembly. After cleaning, drive the vehicle to

its normal clutch operating temperature. This will

dry off disc assembly, pressure plate, and flywheel.

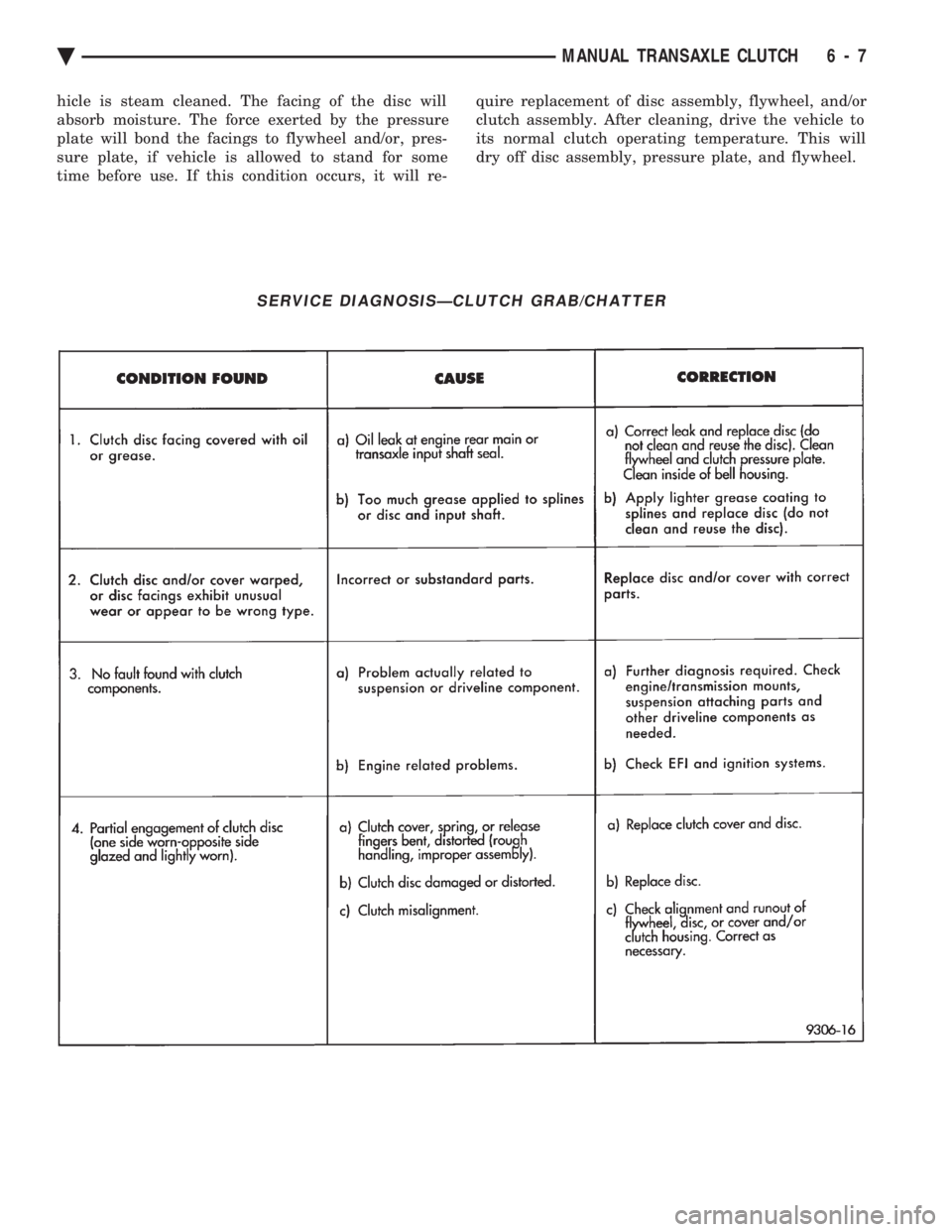

SERVICE DIAGNOSISÐCLUTCH GRAB/CHATTER

Ä MANUAL TRANSAXLE CLUTCH 6 - 7

Page 340 of 2438

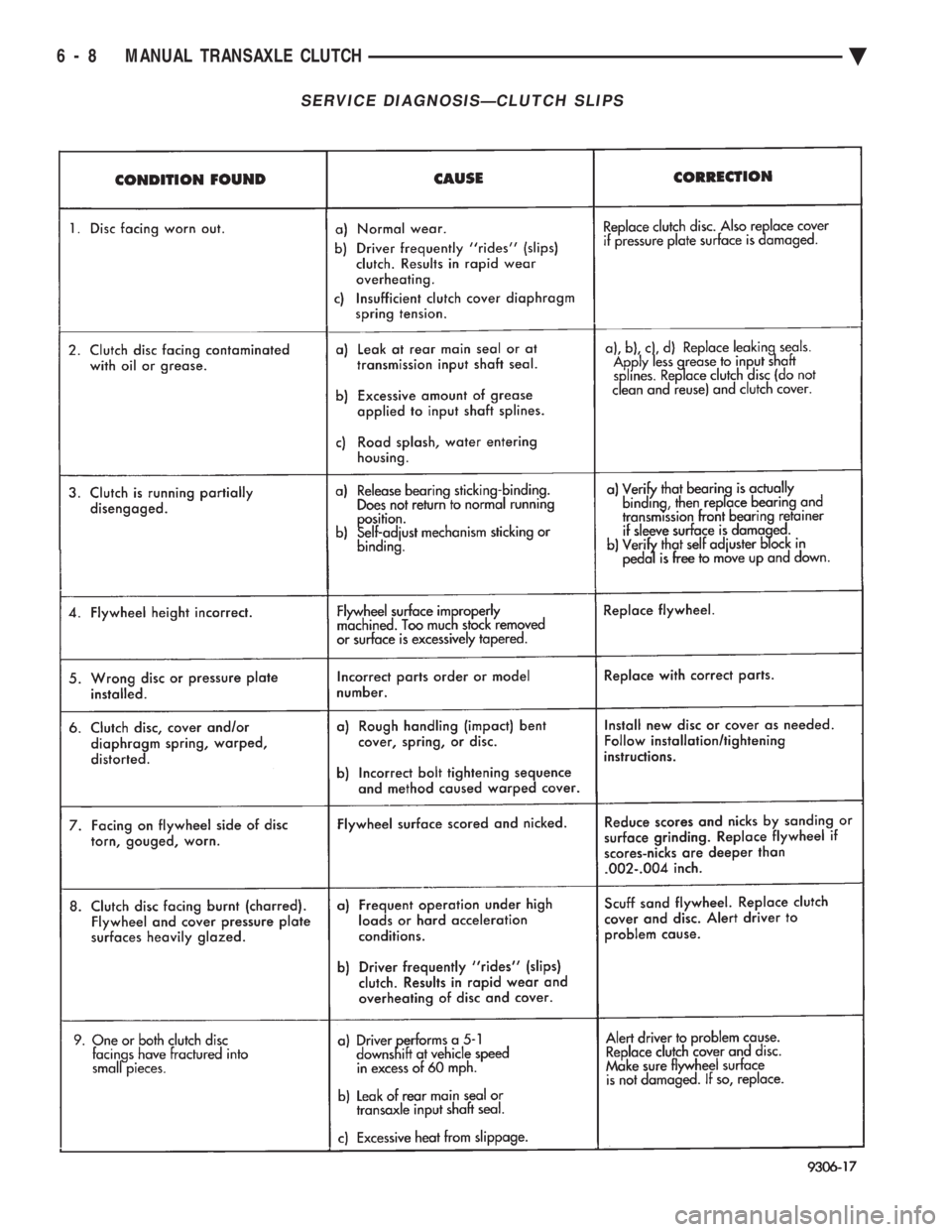

SERVICE DIAGNOSISÐCLUTCH SLIPS

6 - 8 MANUAL TRANSAXLE CLUTCH Ä

Page 341 of 2438

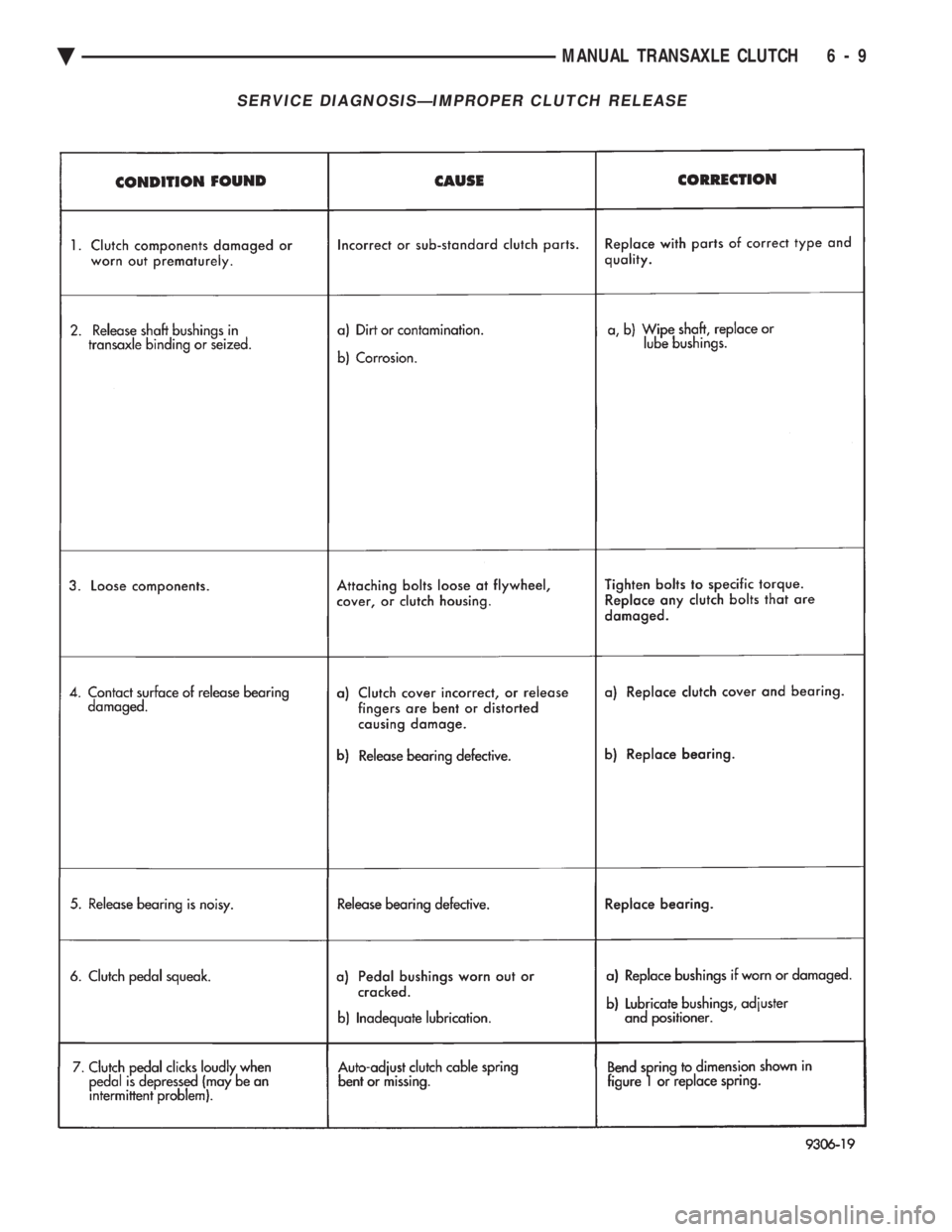

SERVICE DIAGNOSISÐIMPROPER CLUTCH RELEASE

Ä MANUAL TRANSAXLE CLUTCH 6 - 9

Page 342 of 2438

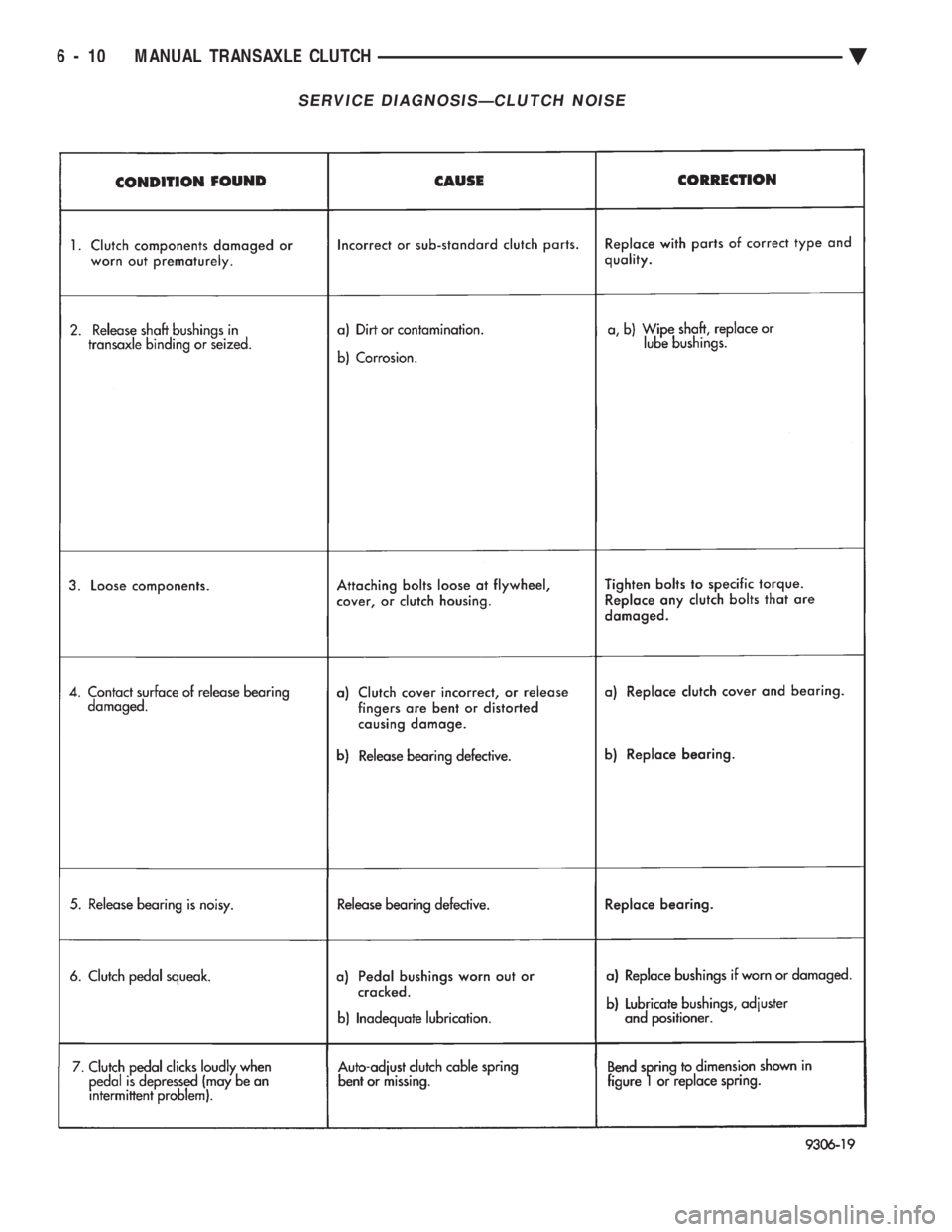

SERVICE DIAGNOSISÐCLUTCH NOISE

6 - 10 MANUAL TRANSAXLE CLUTCH Ä

Page 343 of 2438

COOLING SYSTEM

CONTENTS

page page

ACCESSORY DRIVE BELTS ............... 24

ENGINE BLOCK HEATER ................. 28

GENERAL INFORMATION .................. 1 SERVICE PROCEDURES

.................. 10

SPECIFICATIONS ....................... 29

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual.

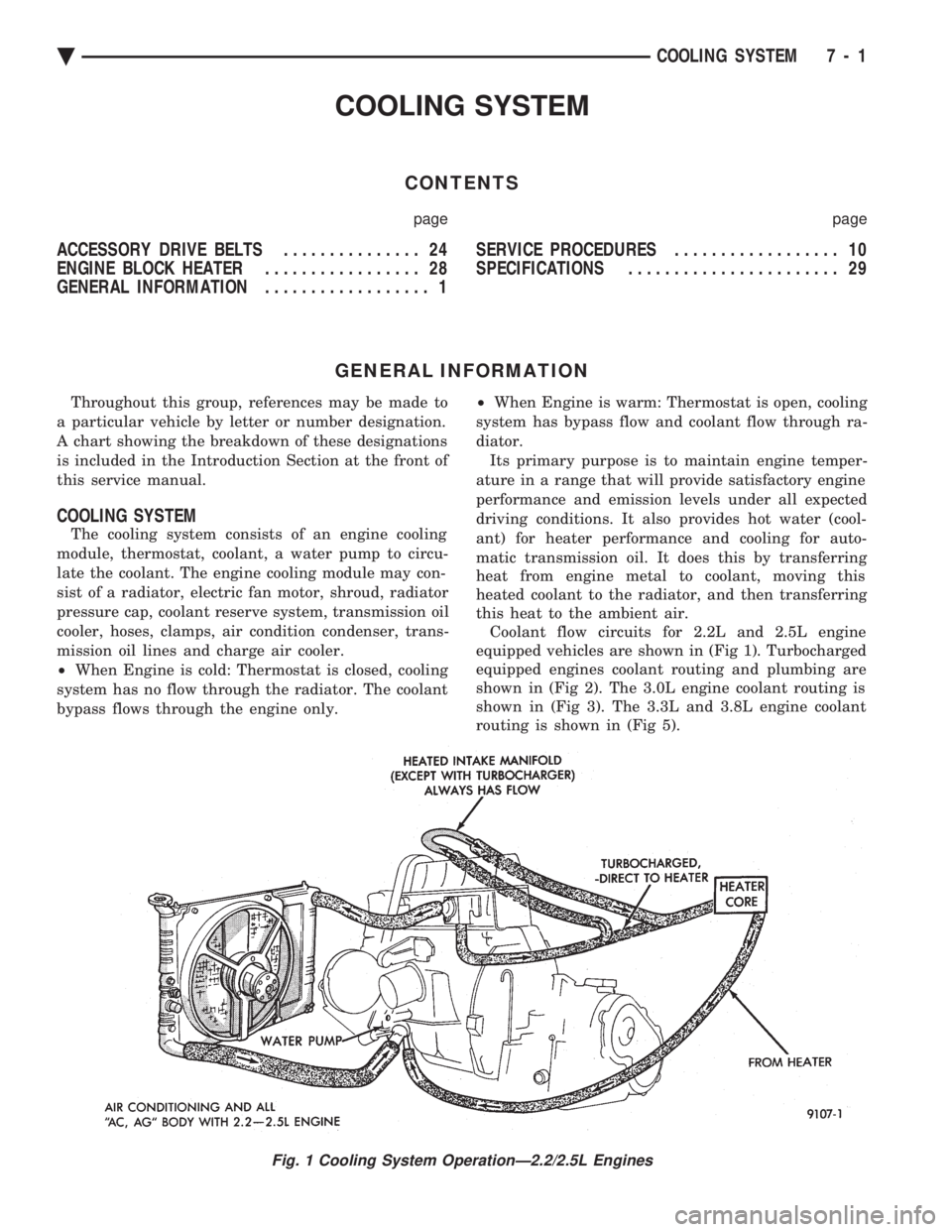

COOLING SYSTEM

The cooling system consists of an engine cooling

module, thermostat, coolant, a water pump to circu-

late the coolant. The engine cooling module may con-

sist of a radiator, electric fan motor, shroud, radiator

pressure cap, coolant reserve system, transmission oil

cooler, hoses, clamps, air condition condenser, trans-

mission oil lines and charge air cooler.

² When Engine is cold: Thermostat is closed, cooling

system has no flow through the radiator. The coolant

bypass flows through the engine only. ²

When Engine is warm: Thermostat is open, cooling

system has bypass flow and coolant flow through ra-

diator. Its primary purpose is to maintain engine temper-

ature in a range that will provide satisfactory engine

performance and emission levels under all expected

driving conditions. It also provides hot water (cool-

ant) for heater performance and cooling for auto-

matic transmission oil. It does this by transferring

heat from engine metal to coolant, moving this

heated coolant to the radiator, and then transferring

this heat to the ambient air. Coolant flow circuits for 2.2L and 2.5L engine

equipped vehicles are shown in (Fig 1). Turbocharged

equipped engines coolant routing and plumbing are

shown in (Fig 2). The 3.0L engine coolant routing is

shown in (Fig 3). The 3.3L and 3.8L engine coolant

routing is shown in (Fig 5).

Fig. 1 Cooling System OperationÐ2.2/2.5L Engines

Ä COOLING SYSTEM 7 - 1

Page 352 of 2438

SERVICE PROCEDURES INDEX

page page

Automatic Transmission Oil Coolers .......... 23

Coolant ................................ 14

Coolant Recovery System (CRS) ............. 17

Cooling System Drain, Clean, Flush and Refill . . 15

Electric Fan Motor ........................ 22

Engine Thermostats ....................... 13

Fan Shroud ............................. 23 Fans

.................................. 21

Radiator Hoses .......................... 21

Radiator Pressure Cap .................... 18

Radiators ............................... 18

Testing System for Leaks .................. 17

Water Pumps ........................... 10

WATER PUMPS

A quick test to tell whether or not the pump is

working is to see if the heater warms properly. A

defective pump will not be able to circulate heated

coolant through the long heater hose. The water pump on all models can be replaced

without discharging the air conditioning system.

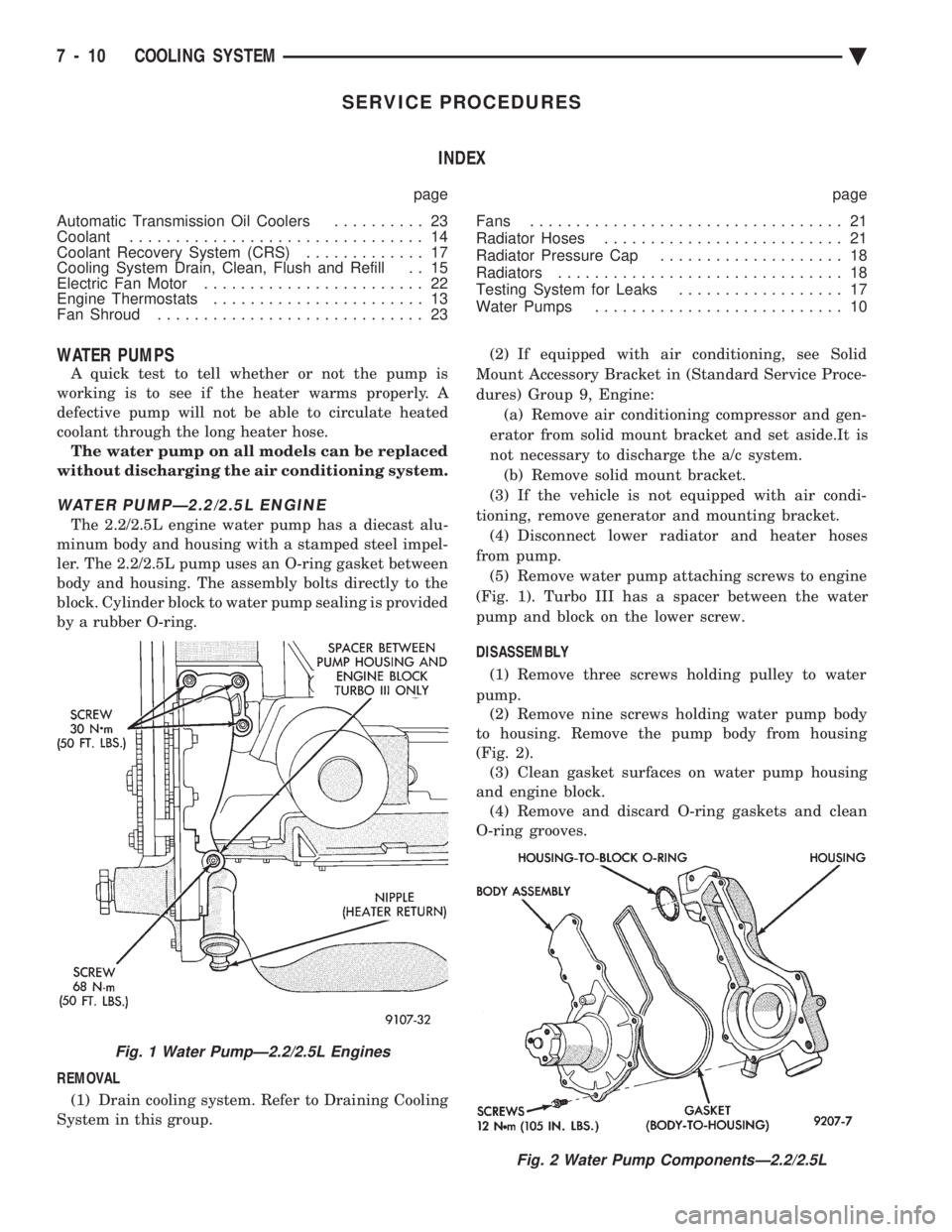

WATER PUMPÐ2.2/2.5L ENGINE

The 2.2/2.5L engine water pump has a diecast alu-

minum body and housing with a stamped steel impel-

ler. The 2.2/2.5L pump uses an O-ring gasket between

body and housing. The assembly bolts directly to the

block. Cylinder block to water pump sealing is provided

by a rubber O-ring.

REMOVAL (1) Drain cooling system. Refer to Draining Cooling

System in this group. (2) If equipped with air conditioning, see Solid

Mount Accessory Bracket in (Standard Service Proce-

dures) Group 9, Engine: (a) Remove air conditioning compressor and gen-

erator from solid mount bracket and set aside.It is

not necessary to discharge the a/c system. (b) Remove solid mount bracket.

(3) If the vehicle is not equipped with air condi-

tioning, remove generator and mounting bracket. (4) Disconnect lower radiator and heater hoses

from pump. (5) Remove water pump attaching screws to engine

(Fig. 1). Turbo III has a spacer between the water

pump and block on the lower screw.

DISASSEMBLY (1) Remove three screws holding pulley to water

pump. (2) Remove nine screws holding water pump body

to housing. Remove the pump body from housing

(Fig. 2). (3) Clean gasket surfaces on water pump housing

and engine block. (4) Remove and discard O-ring gaskets and clean

O-ring grooves.

Fig. 2 Water Pump ComponentsÐ2.2/2.5L

Fig. 1 Water PumpÐ2.2/2.5L Engines

7 - 10 COOLING SYSTEM Ä

Page 353 of 2438

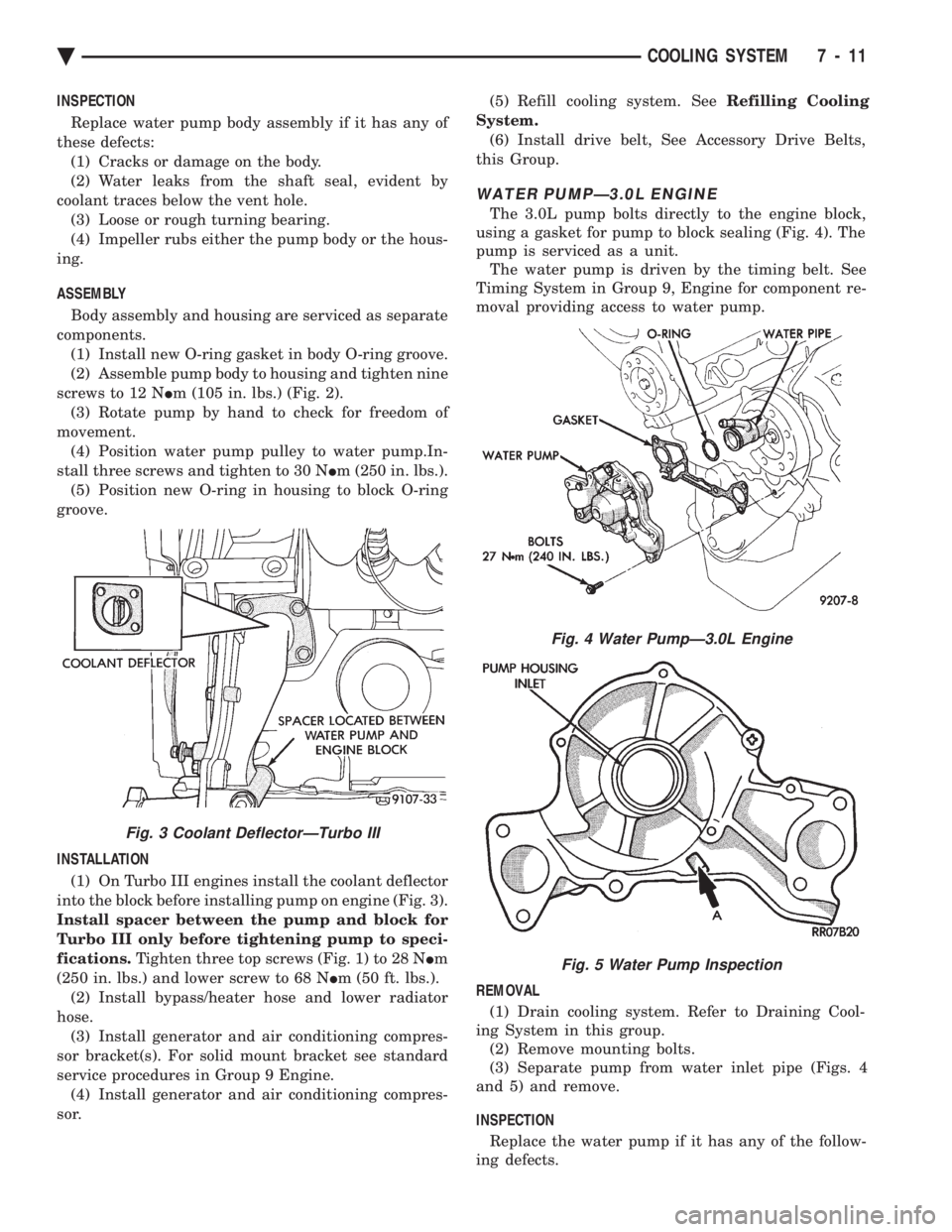

INSPECTION Replace water pump body assembly if it has any of

these defects: (1) Cracks or damage on the body.

(2) Water leaks from the shaft seal, evident by

coolant traces below the vent hole. (3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the hous-

ing.

ASSEMBLY

Body assembly and housing are serviced as separate

components. (1) Install new O-ring gasket in body O-ring groove.

(2) Assemble pump body to housing and tighten nine

screws to 12 N Im (105 in. lbs.) (Fig. 2).

(3) Rotate pump by hand to check for freedom of

movement. (4) Position water pump pulley to water pump.In-

stall three screws and tighten to 30 N Im (250 in. lbs.).

(5) Position new O-ring in housing to block O-ring

groove.

INSTALLATION (1) On Turbo III engines install the coolant deflector

into the block before installing pump on engine (Fig. 3).

Install spacer between the pump and block for

Turbo III only before tightening pump to speci-

fications. Tighten three top screws (Fig. 1) to 28 N Im

(250 in. lbs.) and lower screw to 68 N Im (50 ft. lbs.).

(2) Install bypass/heater hose and lower radiator

hose. (3) Install generator and air conditioning compres-

sor bracket(s). For solid mount bracket see standard

service procedures in Group 9 Engine. (4) Install generator and air conditioning compres-

sor. (5) Refill cooling system. See

Refilling Cooling

System. (6) Install drive belt, See Accessory Drive Belts,

this Group.

WATER PUMPÐ3.0L ENGINE

The 3.0L pump bolts directly to the engine block,

using a gasket for pump to block sealing (Fig. 4). The

pump is serviced as a unit. The water pump is driven by the timing belt. See

Timing System in Group 9, Engine for component re-

moval providing access to water pump.

REMOVAL (1) Drain cooling system. Refer to Draining Cool-

ing System in this group. (2) Remove mounting bolts.

(3) Separate pump from water inlet pipe (Figs. 4

and 5) and remove.

INSPECTION Replace the water pump if it has any of the follow-

ing defects.

Fig. 4 Water PumpÐ3.0L Engine

Fig. 5 Water Pump Inspection

Fig. 3 Coolant DeflectorÐTurbo III

Ä COOLING SYSTEM 7 - 11

Page 357 of 2438

-37ÉC (-35ÉF) to -59ÉC (-50ÉF). If it looses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed solution.

SERVICE

Coolant should be changed at 52,500 miles or three

years, whichever occurs first, then every two years or

30,000 miles.

ROUTINE LEVEL CHECK

Do not remove radiator cap for routine coolant

level inspections. The coolant reserve system provides a quick visual

method for determining the coolant level without re-

moving the radiator cap. Simply observe, with the

engine idling and warmed up to normal operating

temperature, that the level of the coolant in the reserve

tank (Figs. 5 and 6) is between the minimum and

maximum marks.

ADDING ADDITIONAL COOLANT

The radiator cap should not be removed. When

additional coolant is needed to maintain this level, it

should be added to the coolant reserve tank. Use only

50/50 concentration of ethylene glycol type antifreeze

and water.

SERVICE COOLANT LEVEL

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator. When servicing requires a coolant level check in the

radiator, the engine must be offand notunder pres-

sure. Drain several ounces of coolant from the radiator

drain cock while observing the Coolant Recovery Sys-

tem (CRS) Tank. Coolant level in the CRS tank should

drop slightly. Then remove the radiator cap. The radia-

tor should be full to the top. If not, and the coolant level

in the CRS tank is at the MIN mark there is a air leak

in the CRS system. Check hose or hose connections to

the CRS tank, radiator filler neck or the pressure cap

seal to the radiator filler neck for leaks.

LOW COOLANT LEVEL AERATION

Low coolant level in a cross flow radiator will equal-

ize in both tanks with engine off. With engine at

running operating temperature the high pressure inlet

tank runs full and the low pressure outlet tank drops.

If this level drops below the top of the transmission oil

cooler, air will be sucked into the water pump:

² Transmission oil will become hotter.

² High reading shown on the temperature gauge.

² Air in the coolant will also cause loss of flow through

the heater.

² Exhaust gas leaks into the coolant can also cause the

same problems.

DEAERATION

Air can only be removed from the system by gather-

ing under the pressure cap. On the next heat up it will

be pushed past the pressure cap into the CRS tank by

thermal expansion of the coolant. It then escapes to the

atmosphere in the CRS tank and is replaced with solid

coolant on cool down.

COOLING SYSTEM DRAIN, CLEAN, FLUSH AND

REFILL

Drain, flush, and fill the cooling system at the

mileage or time intervals specified in the Maintenance

Schedule in this Group. If the solution is dirty or rusty

or contains a considerable amount of sediment, clean

and flush with a reliable cooling system cleaner. Care

should be taken in disposing of the used engine coolant

from your vehicle. Check governmental regulations for

disposal of used engine coolant.

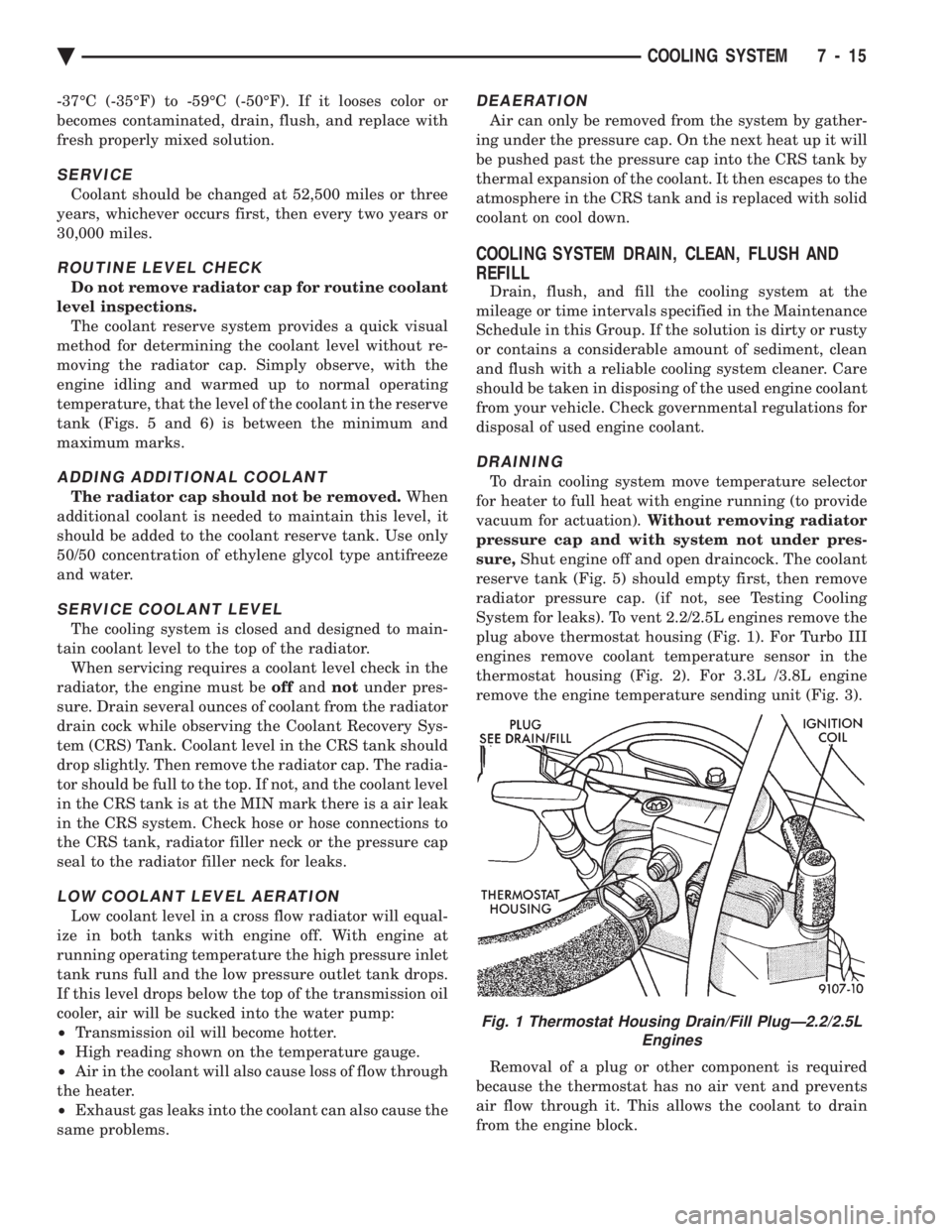

DRAINING

To drain cooling system move temperature selector

for heater to full heat with engine running (to provide

vacuum for actuation). Without removing radiator

pressure cap and with system not under pres-

sure, Shut engine off and open draincock. The coolant

reserve tank (Fig. 5) should empty first, then remove

radiator pressure cap. (if not, see Testing Cooling

System for leaks). To vent 2.2/2.5L engines remove the

plug above thermostat housing (Fig. 1). For Turbo III

engines remove coolant temperature sensor in the

thermostat housing (Fig. 2). For 3.3L /3.8L engine

remove the engine temperature sending unit (Fig. 3).

Removal of a plug or other component is required

because the thermostat has no air vent and prevents

air flow through it. This allows the coolant to drain

from the engine block.

Fig. 1 Thermostat Housing Drain/Fill PlugÐ2.2/2.5L Engines

Ä COOLING SYSTEM 7 - 15

Page 359 of 2438

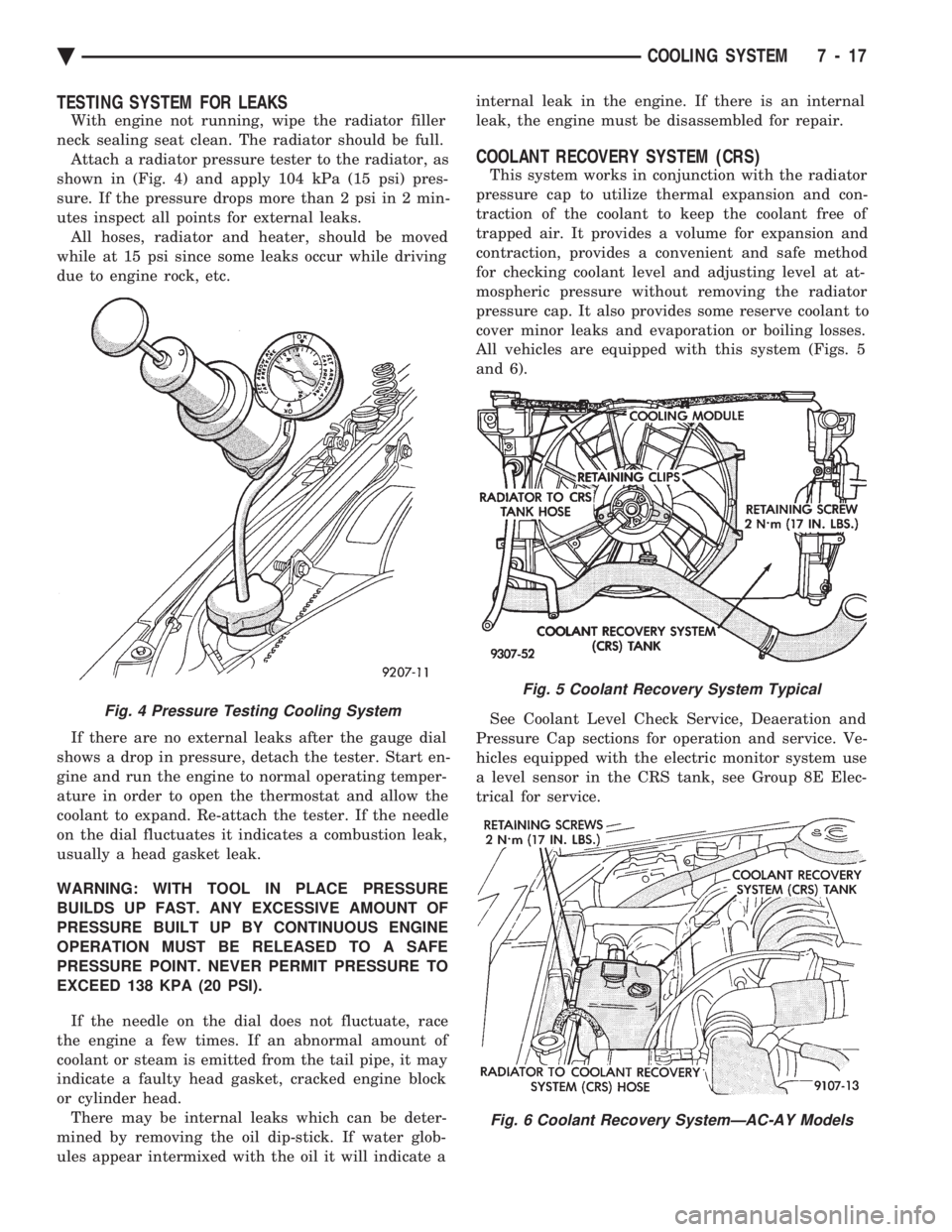

TESTING SYSTEM FOR LEAKS

With engine not running, wipe the radiator filler

neck sealing seat clean. The radiator should be full. Attach a radiator pressure tester to the radiator, as

shown in (Fig. 4) and apply 104 kPa (15 psi) pres-

sure. If the pressure drops more than 2 psi in 2 min-

utes inspect all points for external leaks. All hoses, radiator and heater, should be moved

while at 15 psi since some leaks occur while driving

due to engine rock, etc.

If there are no external leaks after the gauge dial

shows a drop in pressure, detach the tester. Start en-

gine and run the engine to normal operating temper-

ature in order to open the thermostat and allow the

coolant to expand. Re-attach the tester. If the needle

on the dial fluctuates it indicates a combustion leak,

usually a head gasket leak.

WARNING: WITH TOOL IN PLACE PRESSURE

BUILDS UP FAST. ANY EXCESSIVE AMOUNT OF

PRESSURE BUILT UP BY CONTINUOUS ENGINE

OPERATION MUST BE RELEASED TO A SAFE

PRESSURE POINT. NEVER PERMIT PRESSURE TO

EXCEED 138 KPA (20 PSI).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block

or cylinder head. There may be internal leaks which can be deter-

mined by removing the oil dip-stick. If water glob-

ules appear intermixed with the oil it will indicate a internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

COOLANT RECOVERY SYSTEM (CRS)

This system works in conjunction with the radiator

pressure cap to utilize thermal expansion and con-

traction of the coolant to keep the coolant free of

trapped air. It provides a volume for expansion and

contraction, provides a convenient and safe method

for checking coolant level and adjusting level at at-

mospheric pressure without removing the radiator

pressure cap. It also provides some reserve coolant to

cover minor leaks and evaporation or boiling losses.

All vehicles are equipped with this system (Figs. 5

and 6).

See Coolant Level Check Service, Deaeration and

Pressure Cap sections for operation and service. Ve-

hicles equipped with the electric monitor system use

a level sensor in the CRS tank, see Group 8E Elec-

trical for service.

Fig. 4 Pressure Testing Cooling System

Fig. 5 Coolant Recovery System Typical

Fig. 6 Coolant Recovery SystemÐAC-AY Models

Ä COOLING SYSTEM 7 - 17