battery CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 686 of 2438

AIR BAG MODULE

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. UNDEPLOYED AIR BAG REMOVAL FROM THE

STEERING WHEEL: DISCONNECT BATTERY

GROUND CABLE AND ISOLATE. ALLOW SYS-

TEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES. BEGIN AIR BAG REMOVAL.

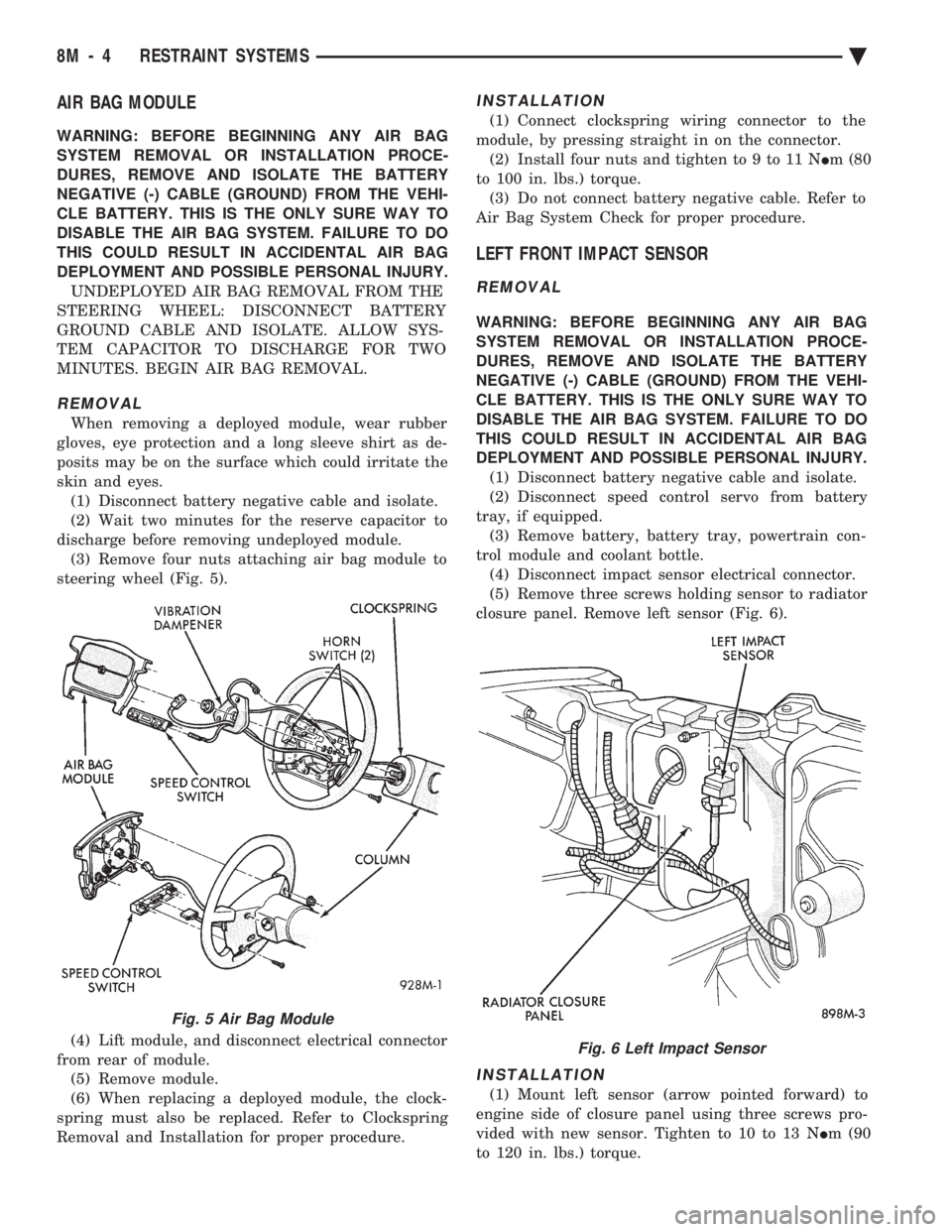

REMOVAL

When removing a deployed module, wear rubber

gloves, eye protection and a long sleeve shirt as de-

posits may be on the surface which could irritate the

skin and eyes. (1) Disconnect battery negative cable and isolate.

(2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Remove four nuts attaching air bag module to

steering wheel (Fig. 5).

(4) Lift module, and disconnect electrical connector

from rear of module. (5) Remove module.

(6) When replacing a deployed module, the clock-

spring must also be replaced. Refer to Clockspring

Removal and Installation for proper procedure.

INSTALLATION

(1) Connect clockspring wiring connector to the

module, by pressing straight in on the connector. (2) Install four nuts and tighten to 9 to 11 N Im (80

to 100 in. lbs.) torque. (3) Do not connect battery negative cable. Refer to

Air Bag System Check for proper procedure.

LEFT FRONT IMPACT SENSOR

REMOVAL

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

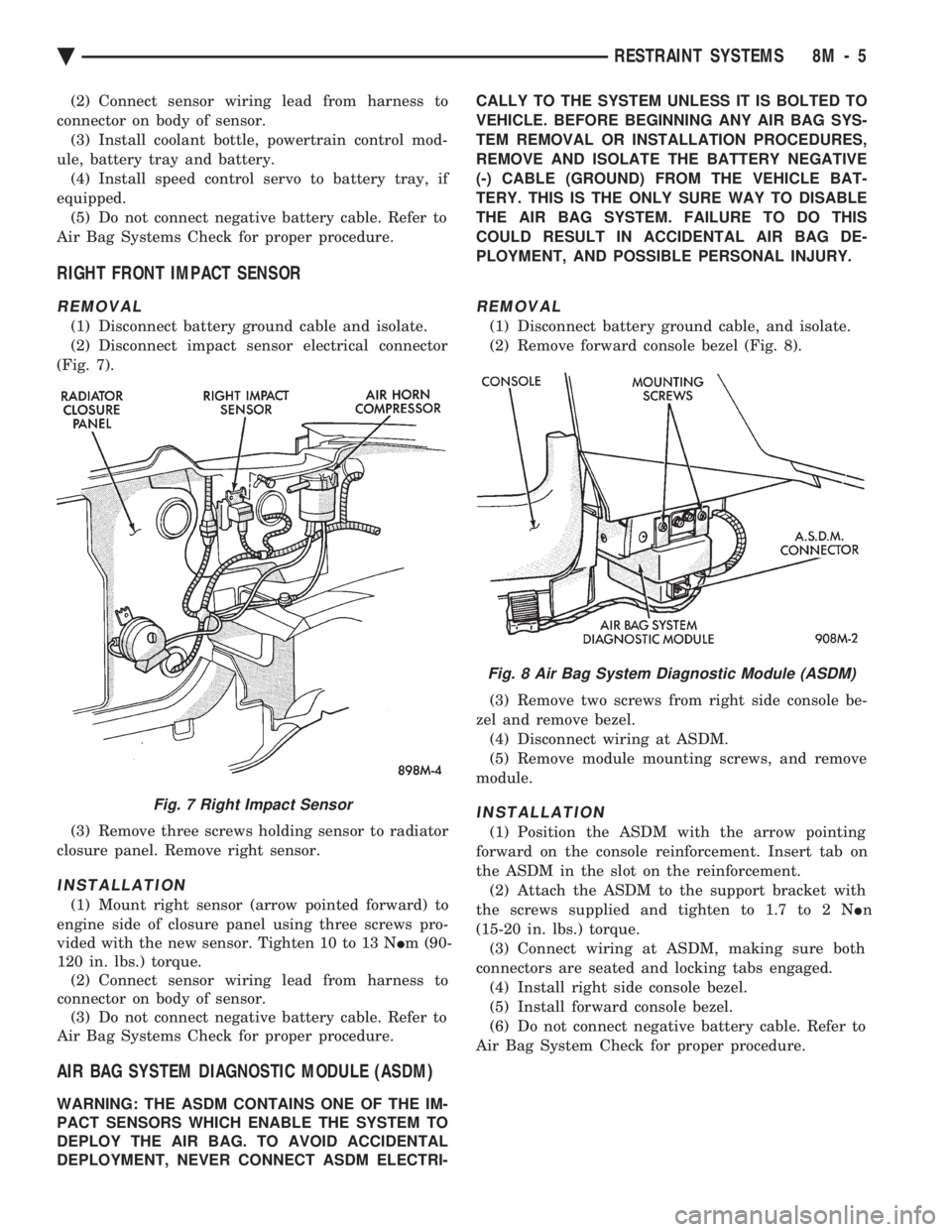

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. (1) Disconnect battery negative cable and isolate.

(2) Disconnect speed control servo from battery

tray, if equipped. (3) Remove battery, battery tray, powertrain con-

trol module and coolant bottle. (4) Disconnect impact sensor electrical connector.

(5) Remove three screws holding sensor to radiator

closure panel. Remove left sensor (Fig. 6).

INSTALLATION

(1) Mount left sensor (arrow pointed forward) to

engine side of closure panel using three screws pro-

vided with new sensor. Tighten to 10 to 13 N Im (90

to 120 in. lbs.) torque.

Fig. 5 Air Bag Module

Fig. 6 Left Impact Sensor

8M - 4 RESTRAINT SYSTEMS Ä

Page 687 of 2438

(2) Connect sensor wiring lead from harness to

connector on body of sensor. (3) Install coolant bottle, powertrain control mod-

ule, battery tray and battery. (4) Install speed control servo to battery tray, if

equipped. (5) Do not connect negative battery cable. Refer to

Air Bag Systems Check for proper procedure.

RIGHT FRONT IMPACT SENSOR

REMOVAL

(1) Disconnect battery ground cable and isolate.

(2) Disconnect impact sensor electrical connector

(Fig. 7).

(3) Remove three screws holding sensor to radiator

closure panel. Remove right sensor.

INSTALLATION

(1) Mount right sensor (arrow pointed forward) to

engine side of closure panel using three screws pro-

vided with the new sensor. Tighten 10 to 13 N Im (90-

120 in. lbs.) torque. (2) Connect sensor wiring lead from harness to

connector on body of sensor. (3) Do not connect negative battery cable. Refer to

Air Bag Systems Check for proper procedure.

AIR BAG SYSTEM DIAGNOSTIC MODULE (ASDM)

WARNING: THE ASDM CONTAINS ONE OF THE IM-

PACT SENSORS WHICH ENABLE THE SYSTEM TO

DEPLOY THE AIR BAG. TO AVOID ACCIDENTAL

DEPLOYMENT, NEVER CONNECT ASDM ELECTRI- CALLY TO THE SYSTEM UNLESS IT IS BOLTED TO

VEHICLE. BEFORE BEGINNING ANY AIR BAG SYS-

TEM REMOVAL OR INSTALLATION PROCEDURES,

REMOVE AND ISOLATE THE BATTERY NEGATIVE

(-) CABLE (GROUND) FROM THE VEHICLE BAT-

TERY. THIS IS THE ONLY SURE WAY TO DISABLE

THE AIR BAG SYSTEM. FAILURE TO DO THIS

COULD RESULT IN ACCIDENTAL AIR BAG DE-

PLOYMENT, AND POSSIBLE PERSONAL INJURY.

REMOVAL

(1) Disconnect battery ground cable, and isolate.

(2) Remove forward console bezel (Fig. 8).

(3) Remove two screws from right side console be-

zel and remove bezel. (4) Disconnect wiring at ASDM.

(5) Remove module mounting screws, and remove

module.

INSTALLATION

(1) Position the ASDM with the arrow pointing

forward on the console reinforcement. Insert tab on

the ASDM in the slot on the reinforcement. (2) Attach the ASDM to the support bracket with

the screws supplied and tighten to 1.7 to 2 N In

(15-20 in. lbs.) torque. (3) Connect wiring at ASDM, making sure both

connectors are seated and locking tabs engaged. (4) Install right side console bezel.

(5) Install forward console bezel.

(6) Do not connect negative battery cable. Refer to

Air Bag System Check for proper procedure.

Fig. 7 Right Impact Sensor

Fig. 8 Air Bag System Diagnostic Module (ASDM)

Ä RESTRAINT SYSTEMS 8M - 5

Page 688 of 2438

CLOCKSPRING

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

SO COULD RESULT IN ACCIDENTAL AIR BAG DE-

PLOYMENT, AND POSSIBLE INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES, THEN

BEGIN AIR BAG REMOVAL.

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition before starting the repair. (2) Disconnect battery negative cable and isolate.

(3) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (4) Remove the air bag module.

(5) Remove Speed Control switch and connector if

so equipped or cover. (6) Disconnect horn terminals.

(7) Remove the steering wheel.

(8) Remove upper and lower steering column

shrouds to gain access to clockspring wiring. (9) Disconnect the 2-way connector between the

clockspring and the instrument panel wiring harness

on top of the fuse block. (10) To remove, pull clockspring assembly from the

steering column by lifting locating fingers as neces-

sary. The clockspring cannot be repaired, and must

be replaced if faulty.

INSTALLATION

(1) Snap clockspring onto the steering column. If

the clockspring is not properly positioned, follow the

clockspring centering procedure before installing

steering wheel. (2) Connect the clockspring to the instrument

panel harness, ensure wiring locator clips are prop-

erly seated on wiring trough. Ensure harness locking

tabs are properly engaged. (3) Install steering column shrouds. Be sure air

bag wire is inside of shrouds. (4) Front wheels should still be in the straight-

ahead position. Install steering wheel, ensure the

flats on hub align with clockspring. Pull the horn

lead through the smaller upper hole. Pull the air bag

and speed control leads through the larger bottom

hole. Ensure leads are not pinched under the steer-

ing wheel. (5) Connect the horn lead wire, then the air bag

lead wire to the air bag module. (6) Install the air bag module and tighten nuts to

9to11N Im (80 to 100 in. lb.) torque.

(7) Install speed control switch and connector or

cover. (8) Do not connect battery negative cable. Refer to

Air Bag Systems Check for proper procedure.

CLOCKSPRING CENTERING PROCEDURE

If the rotating tape within the clockspring is not

positioned properly with the steering wheel and the

front wheels, the clockspring may fail during use.

The following procedure MUST BE USED to center

the clockspring if it is not known to be properly po-

sitioned, or if the front wheels were moved from the

straight ahead position.

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES, THEN

BEGIN AIR BAG REMOVAL. (1) Place front wheels in the straight ahead posi-

tion. (2) Wait two minutes for the reserve capacitor to

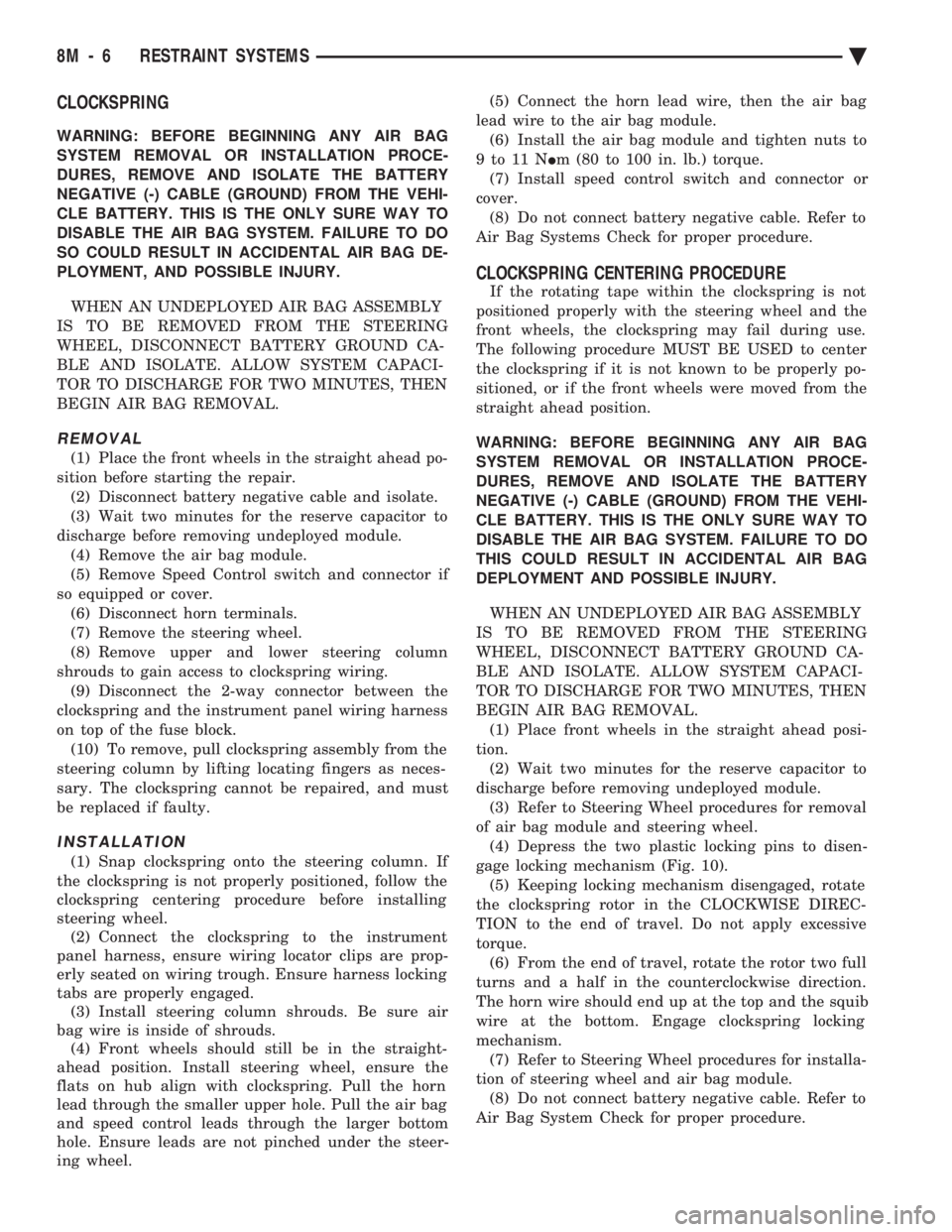

discharge before removing undeployed module. (3) Refer to Steering Wheel procedures for removal

of air bag module and steering wheel. (4) Depress the two plastic locking pins to disen-

gage locking mechanism (Fig. 10). (5) Keeping locking mechanism disengaged, rotate

the clockspring rotor in the CLOCKWISE DIREC-

TION to the end of travel. Do not apply excessive

torque. (6) From the end of travel, rotate the rotor two full

turns and a half in the counterclockwise direction.

The horn wire should end up at the top and the squib

wire at the bottom. Engage clockspring locking

mechanism. (7) Refer to Steering Wheel procedures for installa-

tion of steering wheel and air bag module. (8) Do not connect battery negative cable. Refer to

Air Bag System Check for proper procedure.

8M - 6 RESTRAINT SYSTEMS Ä

Page 689 of 2438

STEERING WHEEL

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES.

BEGIN AIR BAG REMOVAL.

REMOVAL

(1) Make sure front wheels are straight, and steer-

ing column is locked in place. (2) Disconnect battery negative cable and isolate.

(3) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (4) Remove four nuts attaching air bag module

from the back side of steering wheel. (5) Lift module, and disconnect connector from rear

of module. (6) Remove speed control switch and connector if

so equipped or cover. (7) Remove steering wheel retaining nut.

(8) Remove steering wheel with steering wheel

puller Tool C-3428B.

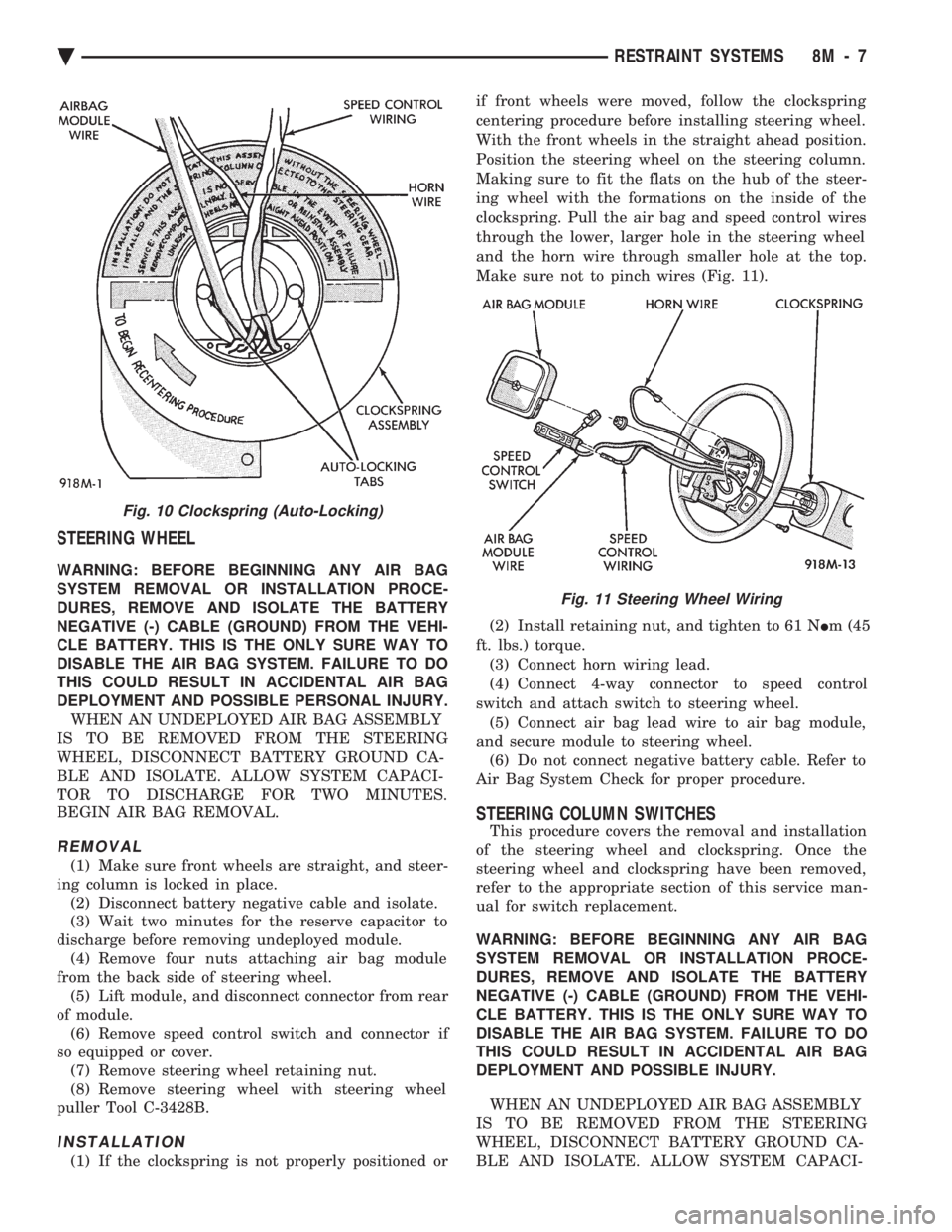

INSTALLATION

(1) If the clockspring is not properly positioned or if front wheels were moved, follow the clockspring

centering procedure before installing steering wheel.

With the front wheels in the straight ahead position.

Position the steering wheel on the steering column.

Making sure to fit the flats on the hub of the steer-

ing wheel with the formations on the inside of the

clockspring. Pull the air bag and speed control wires

through the lower, larger hole in the steering wheel

and the horn wire through smaller hole at the top.

Make sure not to pinch wires (Fig. 11).

(2) Install retaining nut, and tighten to 61 N Im (45

ft. lbs.) torque. (3) Connect horn wiring lead.

(4) Connect 4-way connector to speed control

switch and attach switch to steering wheel. (5) Connect air bag lead wire to air bag module,

and secure module to steering wheel. (6) Do not connect negative battery cable. Refer to

Air Bag System Check for proper procedure.

STEERING COLUMN SWITCHES

This procedure covers the removal and installation

of the steering wheel and clockspring. Once the

steering wheel and clockspring have been removed,

refer to the appropriate section of this service man-

ual for switch replacement.

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

Fig. 10 Clockspring (Auto-Locking)

Fig. 11 Steering Wheel Wiring

Ä RESTRAINT SYSTEMS 8M - 7

Page 690 of 2438

TOR TO DISCHARGE FOR TWO MINUTES.

BEGIN AIR BAG REMOVAL.

REMOVAL

(1) Disconnect battery negative cable, and isolate.

(2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Remove four nuts attaching air bag module

from the back side of steering wheel. (4) Lift module, and disconnect connector from rear

of module. (5) Remove speed control switch and connector if

so equipped or cover. (6) Remove steering wheel.

(7) Unsnap clockspring, and remove it. (8) Refer to the appropriate section for switch re-

placement.

INSTALLATION

(1) Snap clockspring on to steering column. Assure

the 4 way connector is still seated. (2) Install steering wheel.

(3) Install speed control switch and connector or

cover. (4) Connect clockspring wiring connector to the

module. (5) Install four nuts to module, and tighten to 9 to

11 N Im (80 to 100 in. lbs.) torque.

(6) Do not connect negative battery cable. Refer to

Air Bag System Check for proper procedure.

8M - 8 RESTRAINT SYSTEMS Ä

Page 691 of 2438

REAR WINDOW DEFOGGER

CONTENTS

page page

CONTROL SWITCH/TIMER RELAY MODULE . . 1

GENERAL INFORMATION .................. 1REPAIR GRID LINES, TERMINALS AND PIGTAILS.3

SERVICE PROCEDURES ................... 1

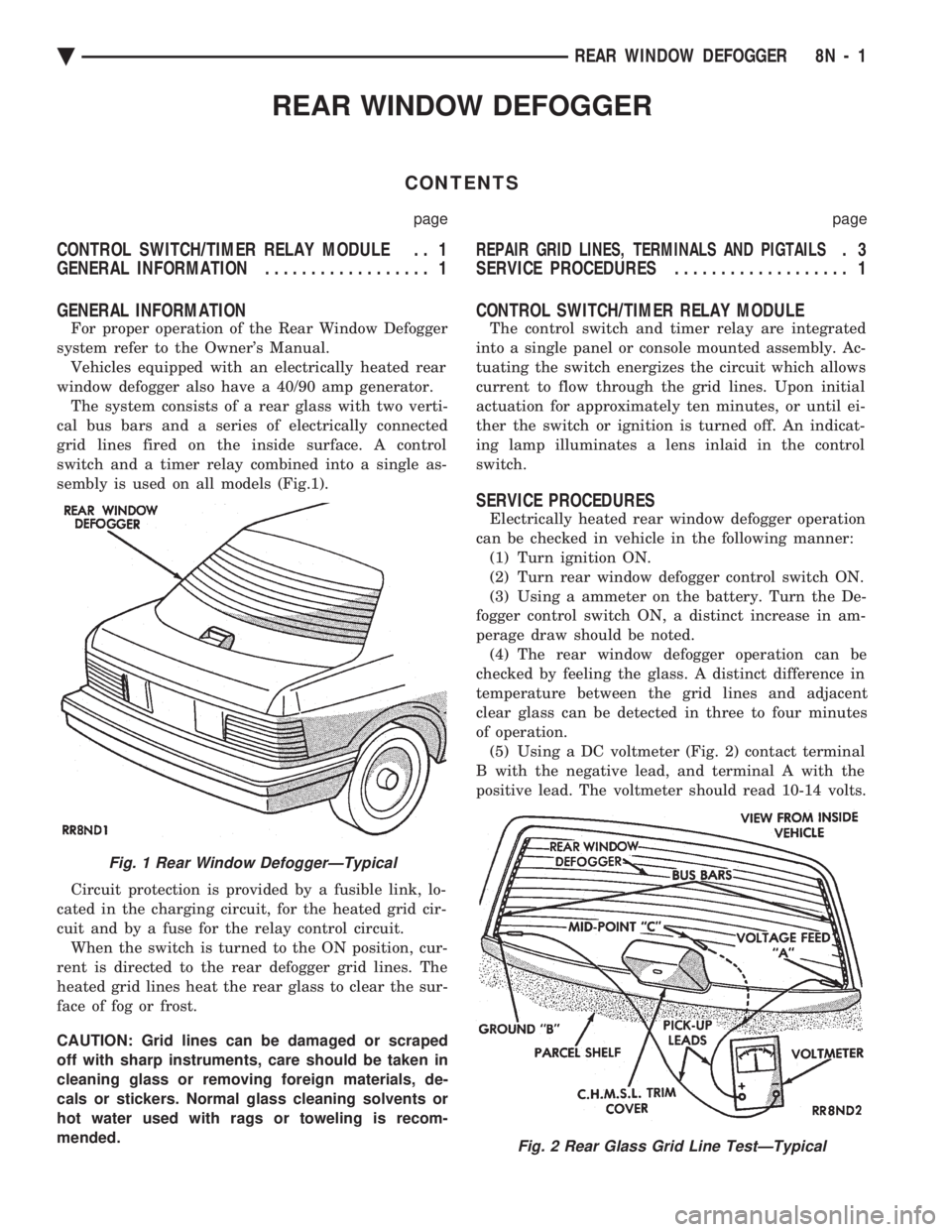

GENERAL INFORMATION

For proper operation of the Rear Window Defogger

system refer to the Owner's Manual. Vehicles equipped with an electrically heated rear

window defogger also have a 40/90 amp generator. The system consists of a rear glass with two verti-

cal bus bars and a series of electrically connected

grid lines fired on the inside surface. A control

switch and a timer relay combined into a single as-

sembly is used on all models (Fig.1).

Circuit protection is provided by a fusible link, lo-

cated in the charging circuit, for the heated grid cir-

cuit and by a fuse for the relay control circuit. When the switch is turned to the ON position, cur-

rent is directed to the rear defogger grid lines. The

heated grid lines heat the rear glass to clear the sur-

face of fog or frost.

CAUTION: Grid lines can be damaged or scraped

off with sharp instruments, care should be taken in

cleaning glass or removing foreign materials, de-

cals or stickers. Normal glass cleaning solvents or

hot water used with rags or toweling is recom-

mended.

CONTROL SWITCH/TIMER RELAY MODULE

The control switch and timer relay are integrated

into a single panel or console mounted assembly. Ac-

tuating the switch energizes the circuit which allows

current to flow through the grid lines. Upon initial

actuation for approximately ten minutes, or until ei-

ther the switch or ignition is turned off. An indicat-

ing lamp illuminates a lens inlaid in the control

switch.

SERVICE PROCEDURES

Electrically heated rear window defogger operation

can be checked in vehicle in the following manner: (1) Turn ignition ON.

(2) Turn rear window defogger control switch ON.

(3) Using a ammeter on the battery. Turn the De-

fogger control switch ON, a distinct increase in am-

perage draw should be noted. (4) The rear window defogger operation can be

checked by feeling the glass. A distinct difference in

temperature between the grid lines and adjacent

clear glass can be detected in three to four minutes

of operation. (5) Using a DC voltmeter (Fig. 2) contact terminal

B with the negative lead, and terminal A with the

positive lead. The voltmeter should read 10-14 volts.

Fig. 1 Rear Window DefoggerÐTypical

Fig. 2 Rear Glass Grid Line TestÐTypical

Ä REAR WINDOW DEFOGGER 8N - 1

Page 695 of 2438

POWER LOCKS

CONTENTS

page page

CIRCUIT BREAKER TEST .................. 1

DECK LID OPERATION ................... 3

DECK LID PULL-DOWN SYSTEMÐAC and AY BODIES .............................. 3

DOOR LOCK INHIBIT ..................... 6

DOOR LOCK INHIBIT ..................... 1

DOOR LOCK MOTOR REPLACEMENT ........ 3

DOOR LOCK SYSTEM TEST ............... 3

ELECTRIC MOTOR TEST .................. 2 GENERAL INFORMATION

.................. 1

KEYLESS ENTRY SYSTEM ................ 1

LAMP OUTAGE MODULE REPLACEMENT .... 6

POWER DOOR LOCKS .................... 2

POWER PULL DOWN .................... 4

REMOTE KEYLESS ENTRY ................ 5

REMOTE KEYLESS MODULE REPLACEMENT . . 6

SWITCH TEST .......................... 1

WIRING VOLTAGE TEST .................. 1

GENERAL INFORMATION

All doors can be locked or unlocked electrically by

operating the switch on a front door panel or arm

rest. The rear doors can be locked or unlocked by actu-

ation of the front door switch, or can be locked or un-

locked mechanically and independently with their

respective locking knobs. The front doors can be locked or unlocked mechan-

ically with the locking knob regardless of electrical

locking and unlocking actuation with the front door

knobs. The right and left front door on all car lines can be

locked or unlocked mechanically from the outside

with the key or electrically as described above. The

left front can also be unlocked by actuation of the in-

side remote door handle. The right front door on AC,

AG, AJ and AY can be unlocked by actuation of the

inside remote door handle. The deck lid lock consists of a latch with internal

solenoid and push button switch. The solenoid is en-

ergized only when the push button is depressed.

DOOR LOCK INHIBIT

The power door lock inhibit system prevents the

doors from being locked using the power door locks

when either of two conditions occur: (1) The key is in the ignition switch and any of the

doors are open. The ignition switch does not have to

be ON. (2) The key is in the ignition switch and the head-

lamp are on.

KEYLESS ENTRY SYSTEM

The system allows locking and unlocking of vehicle

door(s) and Trunk lid by remote control using a hand

held radio transmitter. The ignition switch must be

OFF before the trunk lid can be unlocked with the

transmitter. The receiver may receive signals from two trans-

mitters. Each transmitter has its own code, and the

code has been stored in memory. If the transmitter is

replaced or a second transmitter is add, the code on

both units have to be placed in memory.

CIRCUIT BREAKER TEST

Find correct circuit breaker on fuse block. Pull out

slightly but be sure that circuit breaker terminals

still contact terminals in fuse block. Connect ground

wire of voltmeter to a good ground. With probe of

voltmeter positive wire, check both terminals of cir-

cuit breaker for 12 volts. If only one terminal checks

at 12 volts, circuit breaker is defective and must be

replaced. If neither terminal shows 12 volts, check

for open or shorted circuit to circuit breaker.

WIRING VOLTAGE TEST

The following wiring test sequence determines

whether or not voltage is continuous through the

body harness to switch. (1) Remove left side switch from trim panel.

(2) Carefully separate multiple terminal block on

wiring harness from switch body. (3) Connect one lead of test light to a ground ter-

minal:

² Black Wire AA and AC Bodies

² Gray wire AG and AJ Bodies

² Touch other test light lead to Red Wire terminal.

² If test light comes on, the wiring circuit between

the battery and switch is functional.

² If test light does not come on, check 30 amp circuit

breaker or for a open circuit.

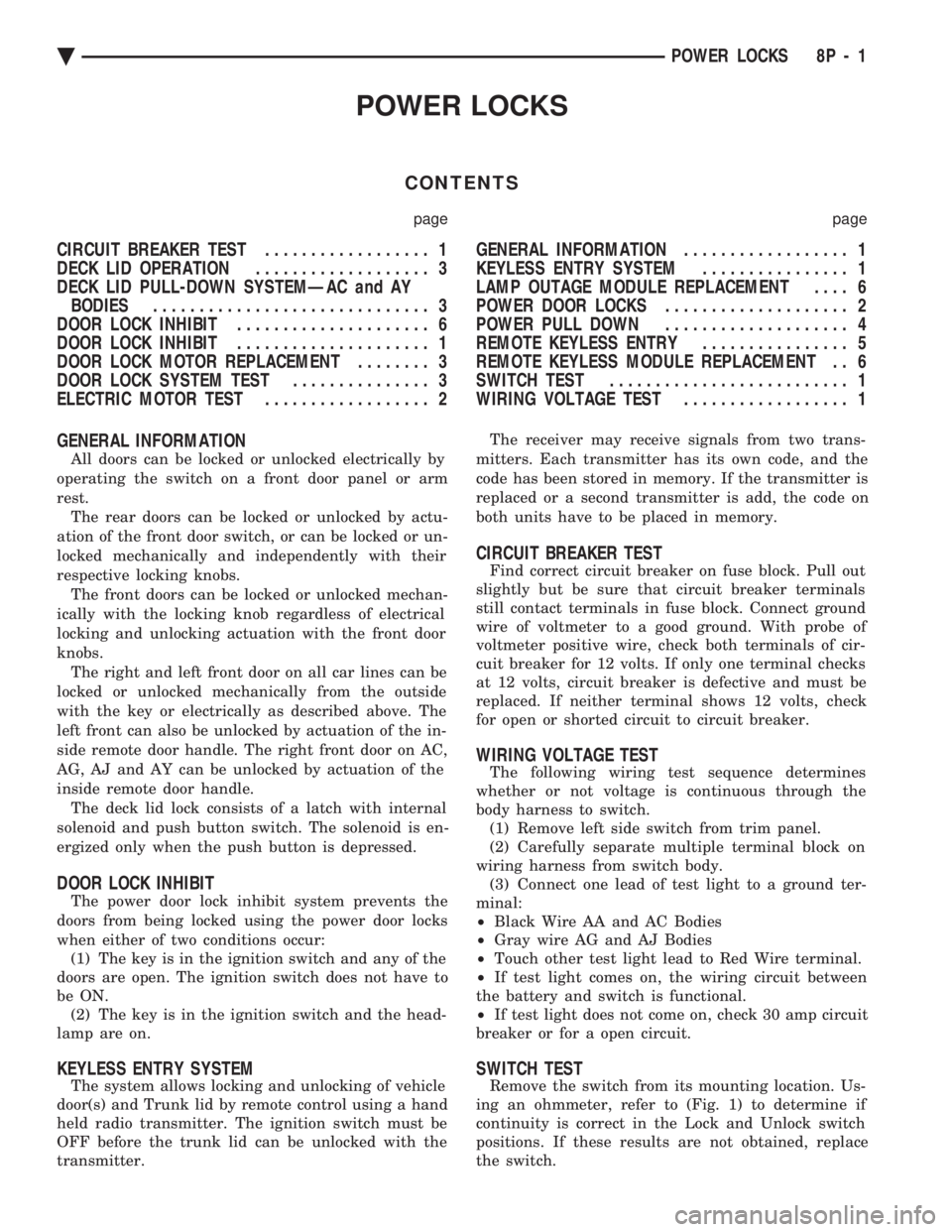

SWITCH TEST

Remove the switch from its mounting location. Us-

ing an ohmmeter, refer to (Fig. 1) to determine if

continuity is correct in the Lock and Unlock switch

positions. If these results are not obtained, replace

the switch.

Ä POWER LOCKS 8P - 1

Page 696 of 2438

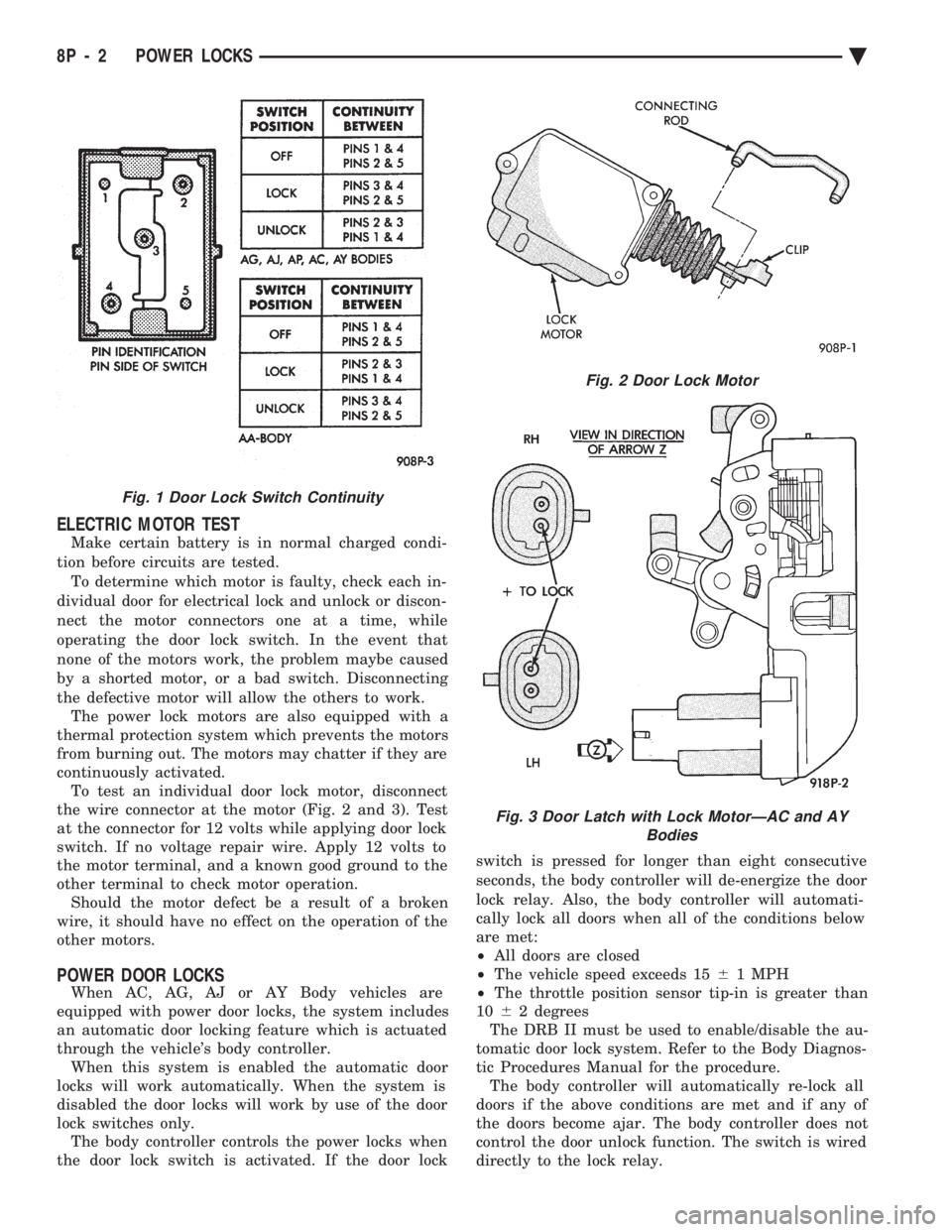

ELECTRIC MOTOR TEST

Make certain battery is in normal charged condi-

tion before circuits are tested. To determine which motor is faulty, check each in-

dividual door for electrical lock and unlock or discon-

nect the motor connectors one at a time, while

operating the door lock switch. In the event that

none of the motors work, the problem maybe caused

by a shorted motor, or a bad switch. Disconnecting

the defective motor will allow the others to work. The power lock motors are also equipped with a

thermal protection system which prevents the motors

from burning out. The motors may chatter if they are

continuously activated. To test an individual door lock motor, disconnect

the wire connector at the motor (Fig. 2 and 3). Test

at the connector for 12 volts while applying door lock

switch. If no voltage repair wire. Apply 12 volts to

the motor terminal, and a known good ground to the

other terminal to check motor operation. Should the motor defect be a result of a broken

wire, it should have no effect on the operation of the

other motors.

POWER DOOR LOCKS

When AC, AG, AJ or AY Body vehicles are

equipped with power door locks, the system includes

an automatic door locking feature which is actuated

through the vehicle's body controller. When this system is enabled the automatic door

locks will work automatically. When the system is

disabled the door locks will work by use of the door

lock switches only. The body controller controls the power locks when

the door lock switch is activated. If the door lock switch is pressed for longer than eight consecutive

seconds, the body controller will de-energize the door

lock relay. Also, the body controller will automati-

cally lock all doors when all of the conditions below

are met:

² All doors are closed

² The vehicle speed exceeds 15 61 MPH

² The throttle position sensor tip-in is greater than

10 62 degrees

The DRB II must be used to enable/disable the au-

tomatic door lock system. Refer to the Body Diagnos-

tic Procedures Manual for the procedure. The body controller will automatically re-lock all

doors if the above conditions are met and if any of

the doors become ajar. The body controller does not

control the door unlock function. The switch is wired

directly to the lock relay.

Fig. 1 Door Lock Switch Continuity

Fig. 2 Door Lock Motor

Fig. 3 Door Latch with Lock MotorÐAC and AY Bodies

8P - 2 POWER LOCKS Ä

Page 699 of 2438

to the deck lid open position. If the pull down limit

switch is depressed at this time, the motor should

stop.(c) If these results are not obtained, replace the

pull down motor assembly.

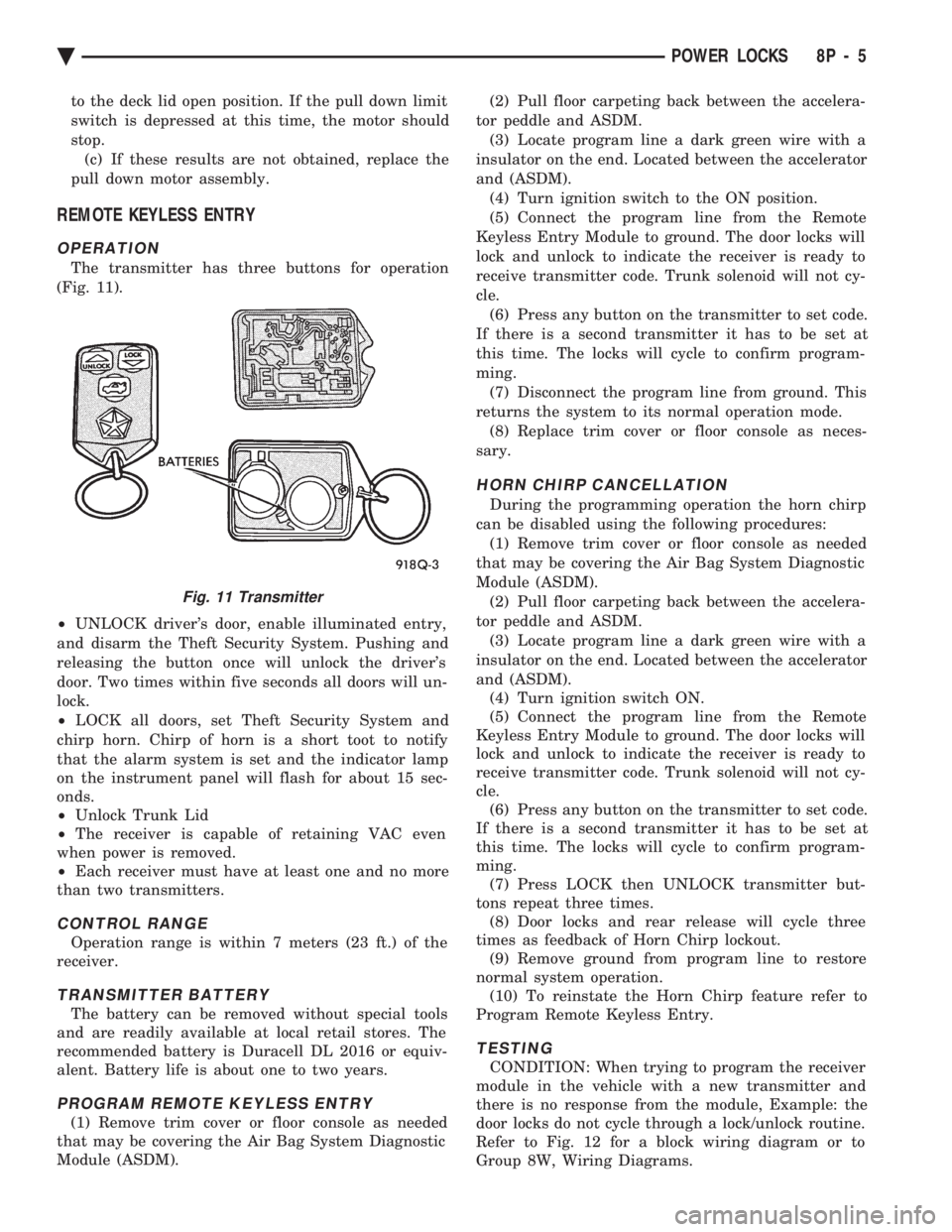

REMOTE KEYLESS ENTRY

OPERATION

The transmitter has three buttons for operation

(Fig. 11).

² UNLOCK driver's door, enable illuminated entry,

and disarm the Theft Security System. Pushing and

releasing the button once will unlock the driver's

door. Two times within five seconds all doors will un-

lock.

² LOCK all doors, set Theft Security System and

chirp horn. Chirp of horn is a short toot to notify

that the alarm system is set and the indicator lamp

on the instrument panel will flash for about 15 sec-

onds.

² Unlock Trunk Lid

² The receiver is capable of retaining VAC even

when power is removed.

² Each receiver must have at least one and no more

than two transmitters.

CONTROL RANGE

Operation range is within 7 meters (23 ft.) of the

receiver.

TRANSMITTER BATTERY

The battery can be removed without special tools

and are readily available at local retail stores. The

recommended battery is Duracell DL 2016 or equiv-

alent. Battery life is about one to two years.

PROGRAM REMOTE KEYLESS ENTRY

(1) Remove trim cover or floor console as needed

that may be covering the Air Bag System Diagnostic

Module (ASDM). (2) Pull floor carpeting back between the accelera-

tor peddle and ASDM. (3) Locate program line a dark green wire with a

insulator on the end. Located between the accelerator

and (ASDM). (4) Turn ignition switch to the ON position.

(5) Connect the program line from the Remote

Keyless Entry Module to ground. The door locks will

lock and unlock to indicate the receiver is ready to

receive transmitter code. Trunk solenoid will not cy-

cle. (6) Press any button on the transmitter to set code.

If there is a second transmitter it has to be set at

this time. The locks will cycle to confirm program-

ming. (7) Disconnect the program line from ground. This

returns the system to its normal operation mode. (8) Replace trim cover or floor console as neces-

sary.

HORN CHIRP CANCELLATION

During the programming operation the horn chirp

can be disabled using the following procedures: (1) Remove trim cover or floor console as needed

that may be covering the Air Bag System Diagnostic

Module (ASDM). (2) Pull floor carpeting back between the accelera-

tor peddle and ASDM. (3) Locate program line a dark green wire with a

insulator on the end. Located between the accelerator

and (ASDM). (4) Turn ignition switch ON.

(5) Connect the program line from the Remote

Keyless Entry Module to ground. The door locks will

lock and unlock to indicate the receiver is ready to

receive transmitter code. Trunk solenoid will not cy-

cle. (6) Press any button on the transmitter to set code.

If there is a second transmitter it has to be set at

this time. The locks will cycle to confirm program-

ming. (7) Press LOCK then UNLOCK transmitter but-

tons repeat three times. (8) Door locks and rear release will cycle three

times as feedback of Horn Chirp lockout. (9) Remove ground from program line to restore

normal system operation. (10) To reinstate the Horn Chirp feature refer to

Program Remote Keyless Entry.

TESTING

CONDITION: When trying to program the receiver

module in the vehicle with a new transmitter and

there is no response from the module, Example: the

door locks do not cycle through a lock/unlock routine.

Refer to Fig. 12 for a block wiring diagram or to

Group 8W, Wiring Diagrams.

Fig. 11 Transmitter

Ä POWER LOCKS 8P - 5

Page 700 of 2438

(1) Be sure that the module has a battery feed

from the 20 Amp breaker in cavity 1 of the black

connector. Also affected would be the optical horn

and the stop lamps. (2) Be sure that the module has an ignition feed

from 5 Amp fuse in cavity 8 of the black connector.

Also affected would be the body computer, instru-

ment cluster and message center. (3) Be sure that the module has a ground from the

right side cowl behind the body computer to the cav-

ity 5 of the black connector. (4) Be sure that you are supplying a good ground

to the programming wire. (5) If the above circuits are good, replace the Re-

ceiver Module. CONDITION: Doors can be locked or unlocked with

the Keyless Entry transmitter. But the doors will not

lock. The Vehicle Theft Alarm system will not arm,

when using only the power door LOCK switch in the

driver's door. (1) Be sure you have not left key in the ignition

column lock cylinder. (2) If step 1 is OK, check the Key in Lock switch

circuit in the steering column for a short to ground. (3) In this problem the body computer controls the

LOCK function. Be sure that it is providing a battery

voltage output to the door lock relay. The door lock

relay controls the door lock motors. CONDITION: Doors will lock but Vehicle Theft

System will not arm when using the transmitter. (1) The Keyless Entry Receiver Module controls

the door lock signal to the door lock relay. The door

lock relay controls the door lock motors. Check for

battery voltage at cavity 10 of the Theft Alarm mod-

ule from the Receiver module. (2) If voltage is OK, replace Receiver module.

CONDITION: All doors except driver's door will

lock with the transmitter. (1) Test the driver's door output of the Receiver

Module for a ground. (2) If there is no ground at the pin, replace the Re-

ceiver module. (3) If there is a ground at the output, replace the

door lock motor. CONDITION: Only driver's door will lock with the

transmitter.

² Repair ground circuit to unlock relay

² Replace unlock relay

CONDITION: Doors do not lock with the transmit-

ter, but still get horn CHIRP that indicates that they

did lock. Replace Receiver module. CONDITION: Doors will lock with the transmitter

but there is no horn CHIRP. (1) Press horn button, listen horn sound.

(2) If the horn sounded, change horn relay. (3) Still no CHIRP, check continuity between the

horn relay and the receiver output pin. Repair as

necessary. (4) Still no horn CHIRP, replace the receiver mod-

ule. (5) If using a DRB II, refer to Body Diagnostic Pro-

cedures.

REMOTE KEYLESS MODULE REPLACEMENT

(1) Remove lower right instrument panel silencer.

(2) Remove glove box assembly.

(3) Remove three screws attaching the mounting

bracket to instrument panel. (4) Lower bracket and module assembly, to discon-

nect wire connector. (5) Remove two screws attaching the Remote Key-

less entry Module to bracket. (6) Remove two screws attaching the security mod-

ule to bracket. (7) To installation reverse above procedures.

LAMP OUTAGE MODULE REPLACEMENT

(1) Remove lower right instrument panel silencer.

(2) Remove glove box and ash receiver module.

(3) Remove three screws attaching the mounting

bracket to instrument panel. (4) Lower bracket and module assembly, to discon-

nect wire connectors. (5) Remove two screws attaching the Lamp Outage

Module to bracket. (6) Remove two screws attaching the security mod-

ule to bracket. (7) To installation reverse above procedures.

DOOR LOCK INHIBIT

The power door lock inhibit system prevents the

doors from being locked using the power door locks

when either of two conditions occur: (1) The key is in the ignition switch and any of the

doors are open. The ignition switch does not have to

be ON. (2) The key is in the ignition switch and the head-

lamp are on.

AC, AG, AJ AND AY BODIES

With the ignition switch in the ON or OFF position

and the driver's door open the Body Controller will

ignore the command to lock the power door locks.

Once the key is removed, or the driver's door is

closed, the Body Controller will allow the power door

locks to lock. Refer to Body Diagnostic Procedure

Manual for further testing procedures.

8P - 6 POWER LOCKS Ä