battery CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 626 of 2438

CONDITION: MOTOR WILL STOP WHEREVER IT IS, WHEN COLUMN SWITCH IS PUT IN OFFPOSITION. THE WIPERS DO NOT CONTINUERUNNING TO PARK POSITION

PROCEDURE

(1) Remove motor wiring connector and clean ter-

minals. Reconnect connector and test motor.If prob-

lem persists, proceed to Step 2. (2) Set wiper switch to OFF position. Disconnect

motor wiring connector. Connect a voltmeter or test

lamp to the motor ground strap. Connect the other

lead to terminal 2 of wiring connector. (a) If voltage is not present, check for an open

circuit in the wiring harness or wiper control

switch. (b) If voltage is present, proceed to step 3.

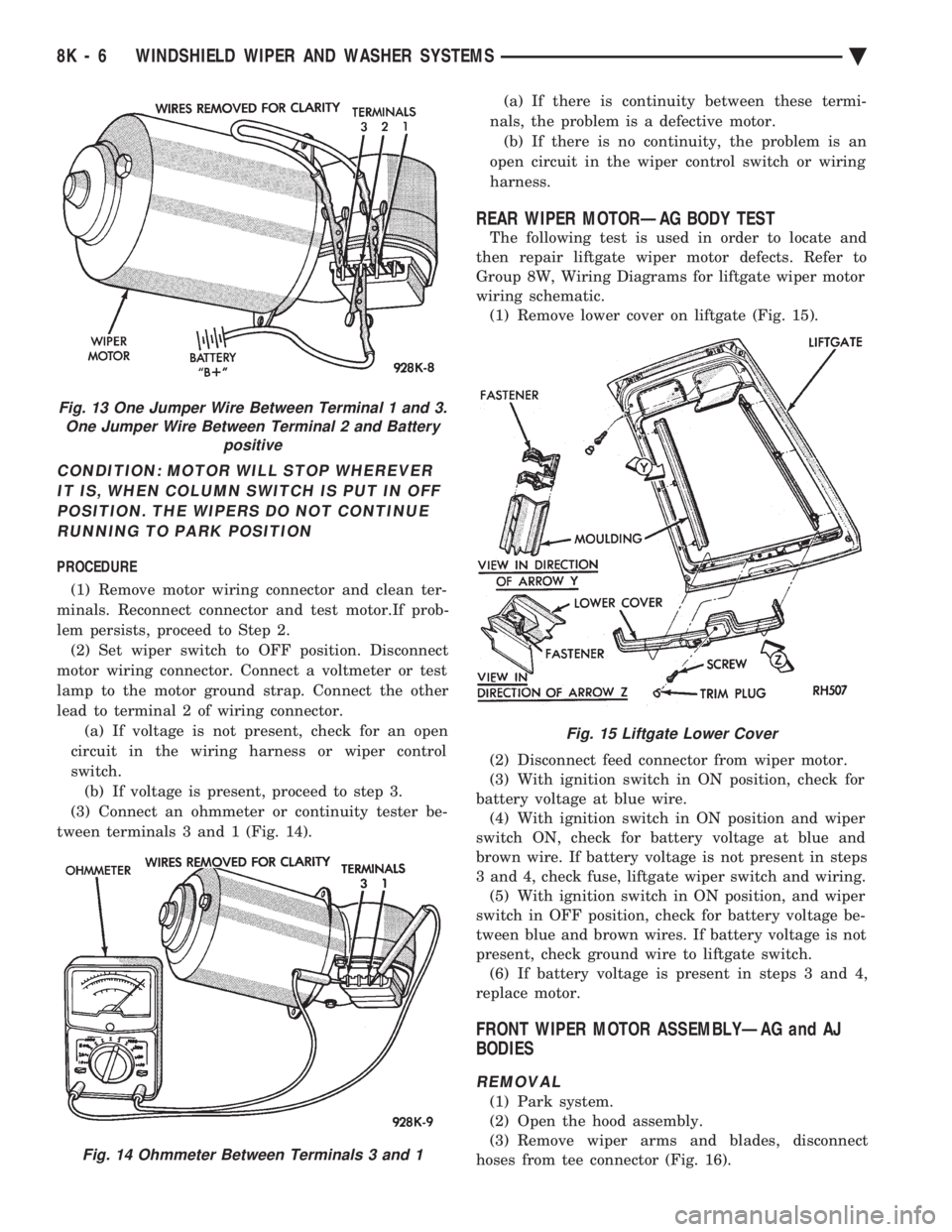

(3) Connect an ohmmeter or continuity tester be-

tween terminals 3 and 1 (Fig. 14). (a) If there is continuity between these termi-

nals, the problem is a defective motor. (b) If there is no continuity, the problem is an

open circuit in the wiper control switch or wiring

harness.

REAR WIPER MOTORÐAG BODY TEST

The following test is used in order to locate and

then repair liftgate wiper motor defects. Refer to

Group 8W, Wiring Diagrams for liftgate wiper motor

wiring schematic. (1) Remove lower cover on liftgate (Fig. 15).

(2) Disconnect feed connector from wiper motor.

(3) With ignition switch in ON position, check for

battery voltage at blue wire. (4) With ignition switch in ON position and wiper

switch ON, check for battery voltage at blue and

brown wire. If battery voltage is not present in steps

3 and 4, check fuse, liftgate wiper switch and wiring. (5) With ignition switch in ON position, and wiper

switch in OFF position, check for battery voltage be-

tween blue and brown wires. If battery voltage is not

present, check ground wire to liftgate switch. (6) If battery voltage is present in steps 3 and 4,

replace motor.

FRONT WIPER MOTOR ASSEMBLYÐAG and AJ

BODIES

REMOVAL

(1) Park system.

(2) Open the hood assembly.

(3) Remove wiper arms and blades, disconnect

hoses from tee connector (Fig. 16).

Fig. 13 One Jumper Wire Between Terminal 1 and 3. One Jumper Wire Between Terminal 2 and Battery positive

Fig. 14 Ohmmeter Between Terminals 3 and 1

Fig. 15 Liftgate Lower Cover

8K - 6 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 643 of 2438

LAMPS

CONTENTS

page page

BULB APPLICATION TABLE ............... 38

CONCEALED HEADLAMPS ................ 27

EXTERIOR LAMP SWITCHES AND HEADLAMP ALIGNMENT ........................... 3

EXTERIOR LAMP SYSTEMS .............. 25

EXTERIOR LAMPSÐAA BODY ............. 7

EXTERIOR LAMPSÐAC BODY ............ 10 EXTERIOR LAMPSÐAG BODY

............ 14

EXTERIOR LAMPSÐAJ BODY ............ 16

EXTERIOR LAMPSÐAP BODY ............ 19

EXTERIOR LAMPSÐAY-BODY ............ 22

GENERAL INFORMATION .................. 1

ILLUMINATED ENTRY SYSTEM ........... 33

GENERAL INFORMATION

Each vehicle is equipped with lamps used for illumi-

nating and indicating purposes. A circuit must have a

good ground to be complete. Circuit ground occurs

when the lamp socket makes contact with the metal

body. On vehicles with plastic lamps, a wire between

the socket and the body makes the grounds. When changing lamp bulbs, check the socket for

corrosion. If corrosion is present, clean contacts with a

wire brush and coat the inside of the socket with

Mopar tMulti-purpose Grease or equivalent.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or any possibly oily surface, reduced

bulb life will result.

BODY IDENTIFICATION

Throughout this Group, references are made to the

vehicle family or body code. To decode the vehicle

identification plates, refer to the Introduction Section

at the front of this manual.

DIAGNOSTIC PROCEDURES

Begin electrical system failure diagnosis by testing

all related fuses and circuit breakers in the fuse block

and engine compartment. When a vehicle experiences problems with the head-

lamp system, verify the condition of the battery con-

nections, charging system, headlamp bulbs, wire con-

nectors, relay, high beam dimmer switch and headlamp

switch. Refer to Wiring Diagrams manual for compo-

nent locations and circuit information.

SYMPTOM

Headlamps are dim when engine is idling of

with ignition turned OFF. Canada cars must

have lamps ON. ACTION

² Clean battery terminal clamps and posts. Refer to

Group 8B, Battery/Starter/Generator Service for

proper procedures.

² Test charging system output. Refer to Group 8A,

Battery/Starting/Charging Systems Diagnostics for

proper testing procedures.

² Test for high resistance in headlamp circuits.

² Defective headlamp bulb.

SYMPTOM

Bulbs burn out frequently.

ACTION

² Test charging system output. Refer to Group 8A,

Battery/Starting/Charging Systems Diagnostics for

proper testing procedures.

² Check for loose or corroded connector terminals or

splices in headlamp circuits. Refer to Wiring Diagrams

manual for component and splice locations.

SYMPTOM

Headlamps are dim with engine running above

idle. Canada cars must have lamps ON.

ACTION

² Test charging system output. Refer to Group 8A,

Battery/Starting/Charging Systems Diagnostics for

proper testing procedures.

² Test for high resistance in headlamp circuits.

² Defective headlamp bulb.

SYMPTOM

Headlamps flash randomly.

ACTION

² Test for poor circuit ground.

² Test for high resistance in headlamp circuits.

Ä LAMPS 8L - 1

Page 653 of 2438

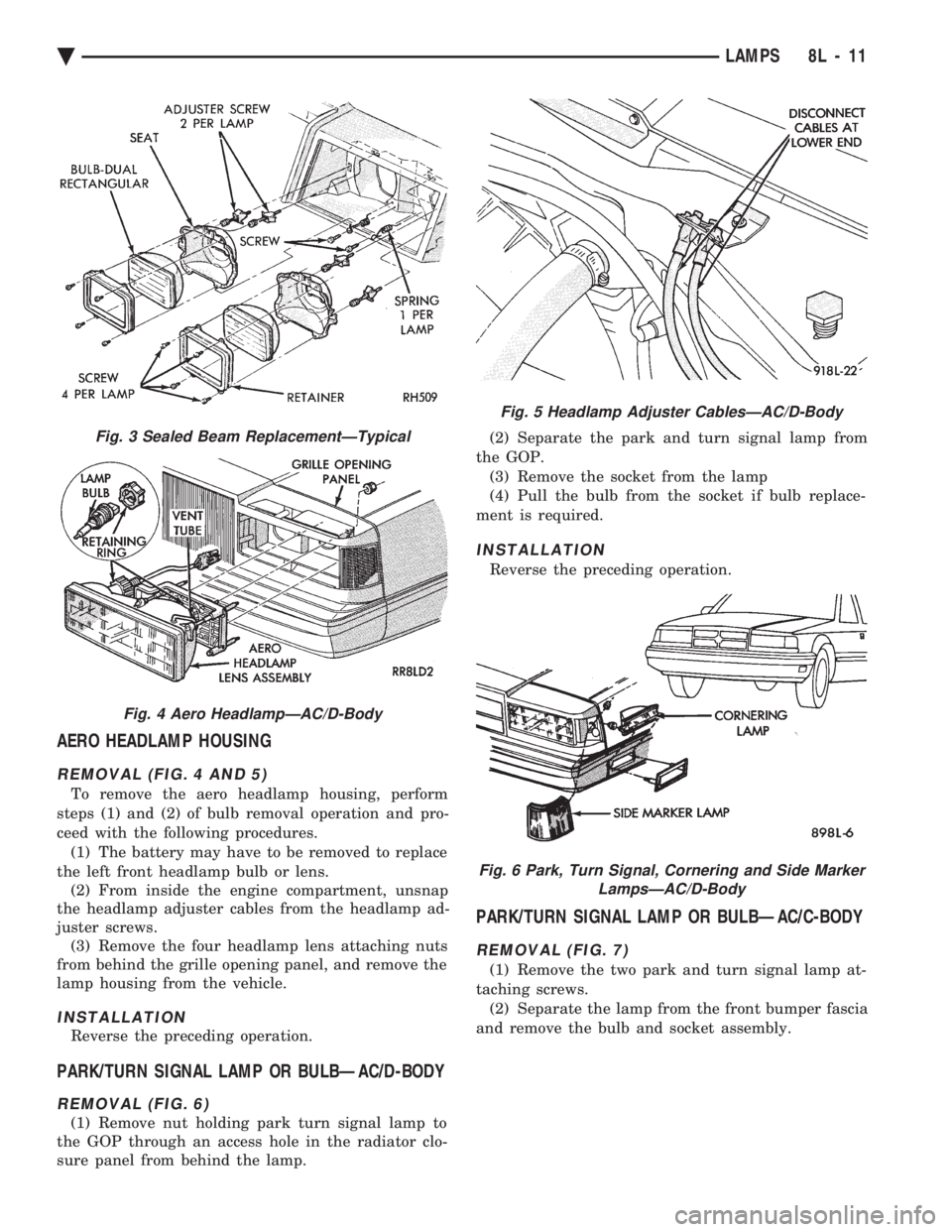

AERO HEADLAMP HOUSING

REMOVAL (FIG. 4 AND 5)

To remove the aero headlamp housing, perform

steps (1) and (2) of bulb removal operation and pro-

ceed with the following procedures. (1) The battery may have to be removed to replace

the left front headlamp bulb or lens. (2) From inside the engine compartment, unsnap

the headlamp adjuster cables from the headlamp ad-

juster screws. (3) Remove the four headlamp lens attaching nuts

from behind the grille opening panel, and remove the

lamp housing from the vehicle.

INSTALLATION

Reverse the preceding operation.

PARK/TURN SIGNAL LAMP OR BULBÐAC/D-BODY

REMOVAL (FIG. 6)

(1) Remove nut holding park turn signal lamp to

the GOP through an access hole in the radiator clo-

sure panel from behind the lamp. (2) Separate the park and turn signal lamp from

the GOP. (3) Remove the socket from the lamp

(4) Pull the bulb from the socket if bulb replace-

ment is required.

INSTALLATION

Reverse the preceding operation.

PARK/TURN SIGNAL LAMP OR BULBÐAC/C-BODY

REMOVAL (FIG. 7)

(1) Remove the two park and turn signal lamp at-

taching screws. (2) Separate the lamp from the front bumper fascia

and remove the bulb and socket assembly.

Fig. 3 Sealed Beam ReplacementÐTypical

Fig. 4 Aero HeadlampÐAC/D-Body

Fig. 5 Headlamp Adjuster CablesÐAC/D-Body

Fig. 6 Park, Turn Signal, Cornering and Side Marker LampsÐAC/D-Body

Ä LAMPS 8L - 11

Page 661 of 2438

EXTERIOR LAMPSÐAP BODY INDEX

page page

Center High Mounted Stop Lamp (CHMSL)Ð AP/24-44-Body ......................... 21

Center High Mounted Stop Lamp BulbÐ AP/24-44-Body ......................... 21

Fog Lamp Bulb .......................... 21

Fog Lamps ............................. 21

Front Side Marker Lamp or Bulb ............. 20

Headlamp Bulb .......................... 19 Headlamp Diagnosis

...................... 19

Headlamp Housing ....................... 19

License Plate Lamp or Bulb ................ 20

Park and Turn Signal Lamp or Bulb .......... 20

Tail, Stop, Turn Signal, Back-Up and Side Marker Lamp ................................ 20

Tail, Stop, Turn Signal, Back-Up and Side Marker Lamp Bulbs ........................... 20

HEADLAMP DIAGNOSIS

For headlamp diagnosis, refer to the headlamp di-

agnosis chart at the beginning of this group. Refer to

Wiring Diagrams manual for circuit and component

locations.

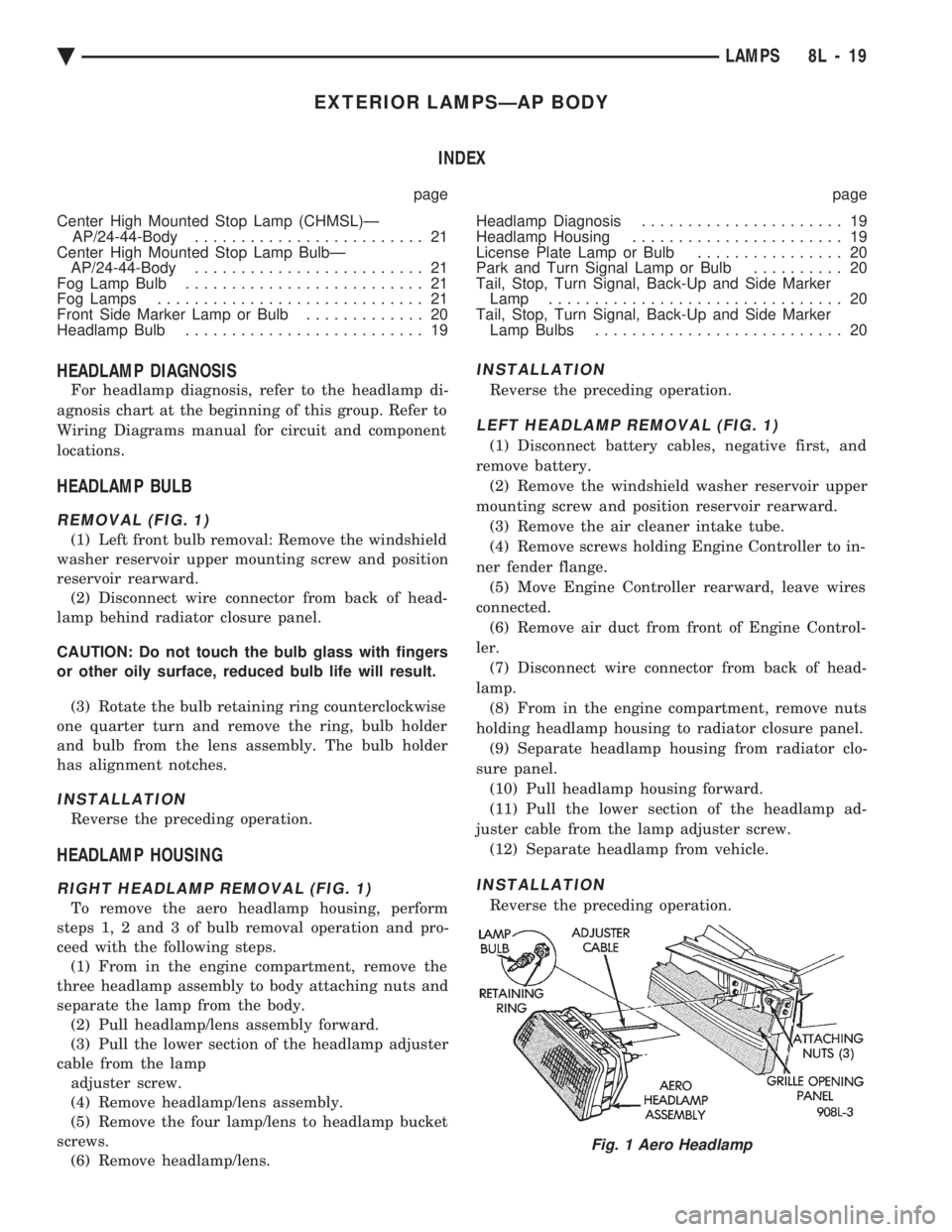

HEADLAMP BULB

REMOVAL (FIG. 1)

(1) Left front bulb removal: Remove the windshield

washer reservoir upper mounting screw and position

reservoir rearward. (2) Disconnect wire connector from back of head-

lamp behind radiator closure panel.

CAUTION: Do not touch the bulb glass with fingers

or other oily surface, reduced bulb life will result.

(3) Rotate the bulb retaining ring counterclockwise

one quarter turn and remove the ring, bulb holder

and bulb from the lens assembly. The bulb holder

has alignment notches.

INSTALLATION

Reverse the preceding operation.

HEADLAMP HOUSING

RIGHT HEADLAMP REMOVAL (FIG. 1)

To remove the aero headlamp housing, perform

steps 1, 2 and 3 of bulb removal operation and pro-

ceed with the following steps. (1) From in the engine compartment, remove the

three headlamp assembly to body attaching nuts and

separate the lamp from the body. (2) Pull headlamp/lens assembly forward.

(3) Pull the lower section of the headlamp adjuster

cable from the lamp adjuster screw.

(4) Remove headlamp/lens assembly.

(5) Remove the four lamp/lens to headlamp bucket

screws. (6) Remove headlamp/lens.

INSTALLATION

Reverse the preceding operation.

LEFT HEADLAMP REMOVAL (FIG. 1)

(1) Disconnect battery cables, negative first, and

remove battery. (2) Remove the windshield washer reservoir upper

mounting screw and position reservoir rearward. (3) Remove the air cleaner intake tube.

(4) Remove screws holding Engine Controller to in-

ner fender flange. (5) Move Engine Controller rearward, leave wires

connected. (6) Remove air duct from front of Engine Control-

ler. (7) Disconnect wire connector from back of head-

lamp. (8) From in the engine compartment, remove nuts

holding headlamp housing to radiator closure panel. (9) Separate headlamp housing from radiator clo-

sure panel. (10) Pull headlamp housing forward.

(11) Pull the lower section of the headlamp ad-

juster cable from the lamp adjuster screw. (12) Separate headlamp from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 1 Aero Headlamp

Ä LAMPS 8L - 19

Page 667 of 2438

EXTERIOR LAMP SYSTEMS INDEX

page page

Daytime Running LampÐCanada Only ........ 25

Headlamp Time Delay System .............. 26

Lamp Outage ModuleÐAA-Body ............. 25 Lamp Outage ModuleÐAll Except AA-Body

..... 25

Lamp Outage System ..................... 25

Removal (Fig. 4) ......................... 25

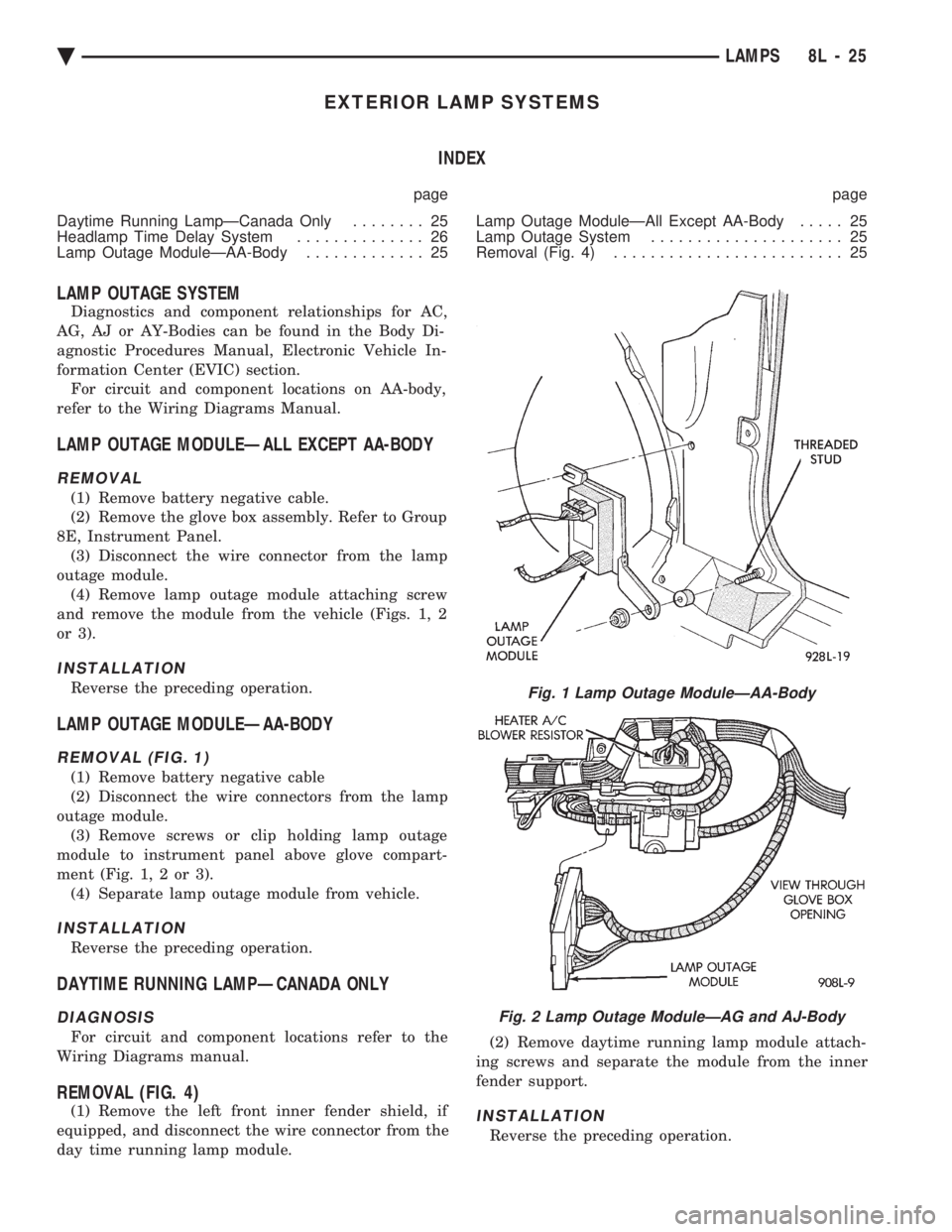

LAMP OUTAGE SYSTEM

Diagnostics and component relationships for AC,

AG, AJ or AY-Bodies can be found in the Body Di-

agnostic Procedures Manual, Electronic Vehicle In-

formation Center (EVIC) section. For circuit and component locations on AA-body,

refer to the Wiring Diagrams Manual.

LAMP OUTAGE MODULEÐALL EXCEPT AA-BODY

REMOVAL

(1) Remove battery negative cable.

(2) Remove the glove box assembly. Refer to Group

8E, Instrument Panel. (3) Disconnect the wire connector from the lamp

outage module. (4) Remove lamp outage module attaching screw

and remove the module from the vehicle (Figs. 1, 2

or 3).

INSTALLATION

Reverse the preceding operation.

LAMP OUTAGE MODULEÐAA-BODY

REMOVAL (FIG. 1)

(1) Remove battery negative cable

(2) Disconnect the wire connectors from the lamp

outage module. (3) Remove screws or clip holding lamp outage

module to instrument panel above glove compart-

ment (Fig. 1, 2 or 3). (4) Separate lamp outage module from vehicle.

INSTALLATION

Reverse the preceding operation.

DAYTIME RUNNING LAMPÐCANADA ONLY

DIAGNOSIS

For circuit and component locations refer to the

Wiring Diagrams manual.

REMOVAL (FIG. 4)

(1) Remove the left front inner fender shield, if

equipped, and disconnect the wire connector from the

day time running lamp module. (2) Remove daytime running lamp module attach-

ing screws and separate the module from the inner

fender support.INSTALLATION

Reverse the preceding operation.

Fig. 1 Lamp Outage ModuleÐAA-Body

Fig. 2 Lamp Outage ModuleÐAG and AJ-Body

Ä LAMPS 8L - 25

Page 675 of 2438

ILLUMINATED ENTRY SYSTEM INDEX

page page

Body Controller ComputerÐAC, AG, AJ and AY-Body ............................. 34

Diagnostic ProceduresÐAA-Body ............ 33 Diagnostic ProceduresÐAC, AG, AJ and AY-Body . 33

General Information ....................... 33

Illuminated Entry ModuleÐAA-Body ........... 34

GENERAL INFORMATION

AA-BODY

The Illuminated Entry System (on AA Body) actu-

ates the interior courtesy and/or dome lamps (except

for the illuminated ignition switch) by lifting either

front door exterior handle. Lamp illumination is terminated 35 seconds ( 68

seconds later when battery voltage is normal), or by

turning the ignition switch to the run position,

whichever occurs first. When testing the system, all

vehicle doors must be closed to prevent the door jam

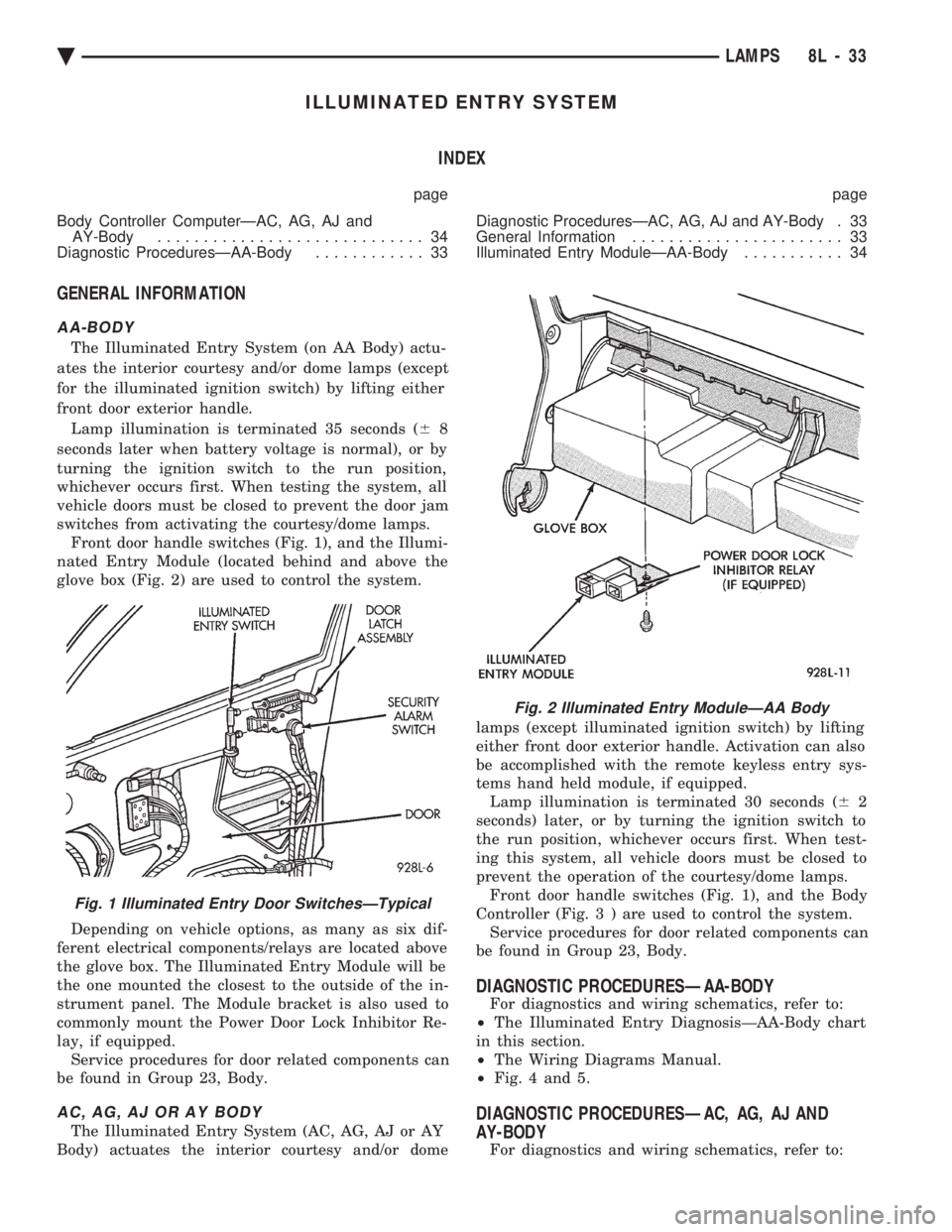

switches from activating the courtesy/dome lamps. Front door handle switches (Fig. 1), and the Illumi-

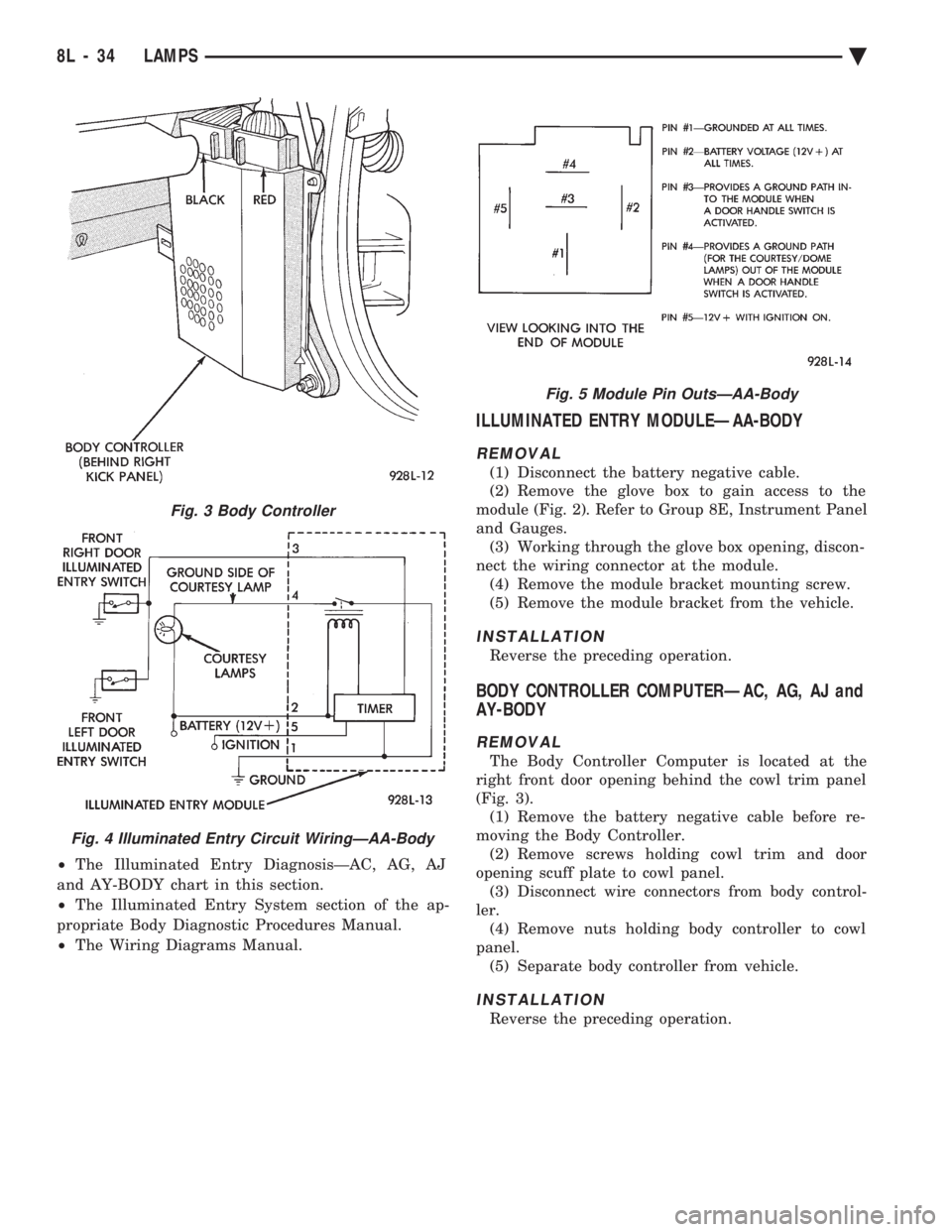

nated Entry Module (located behind and above the

glove box (Fig. 2) are used to control the system.

Depending on vehicle options, as many as six dif-

ferent electrical components/relays are located above

the glove box. The Illuminated Entry Module will be

the one mounted the closest to the outside of the in-

strument panel. The Module bracket is also used to

commonly mount the Power Door Lock Inhibitor Re-

lay, if equipped. Service procedures for door related components can

be found in Group 23, Body.

AC, AG, AJ OR AY BODY

The Illuminated Entry System (AC, AG, AJ or AY

Body) actuates the interior courtesy and/or dome lamps (except illuminated ignition switch) by lifting

either front door exterior handle. Activation can also

be accomplished with the remote keyless entry sys-

tems hand held module, if equipped. Lamp illumination is terminated 30 seconds ( 62

seconds) later, or by turning the ignition switch to

the run position, whichever occurs first. When test-

ing this system, all vehicle doors must be closed to

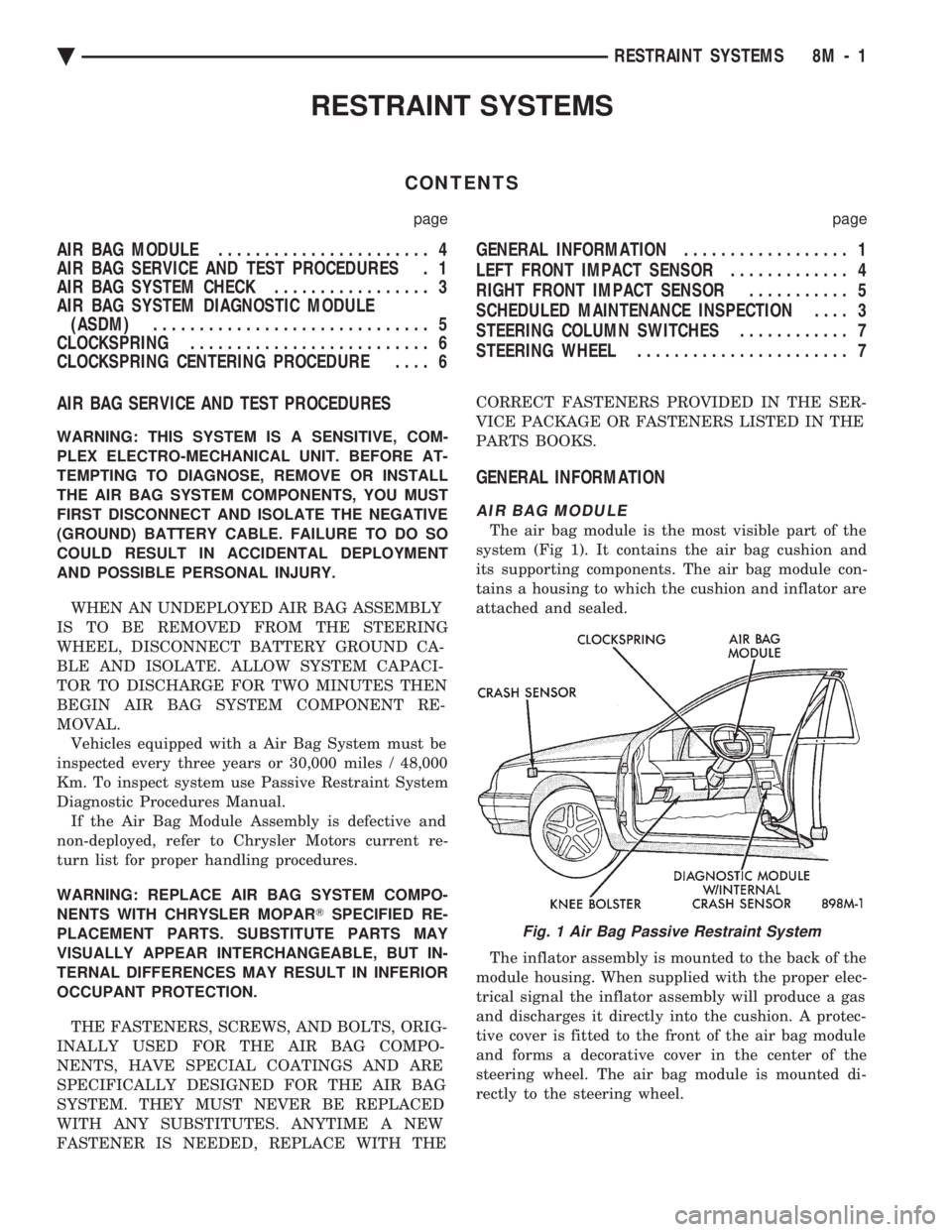

prevent the operation of the courtesy/dome lamps. Front door handle switches (Fig. 1), and the Body

Controller (Fig . 3 ) are used to control the system.

Service procedures for door related components can

be found in Group 23, Body.

DIAGNOSTIC PROCEDURESÐAA-BODY

For diagnostics and wiring schematics, refer to:

² The Illuminated Entry DiagnosisÐAA-Body chart

in this section.

² The Wiring Diagrams Manual.

² Fig. 4 and 5.

DIAGNOSTIC PROCEDURESÐAC, AG, AJ AND

AY-BODY

For diagnostics and wiring schematics, refer to:

Fig. 1 Illuminated Entry Door SwitchesÐTypical

Fig. 2 Illuminated Entry ModuleÐAA Body

Ä LAMPS 8L - 33

Page 676 of 2438

² The Illuminated Entry DiagnosisÐAC, AG, AJ

and AY-BODY chart in this section.

² The Illuminated Entry System section of the ap-

propriate Body Diagnostic Procedures Manual.

² The Wiring Diagrams Manual.

ILLUMINATED ENTRY MODULEÐAA-BODY

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the glove box to gain access to the

module (Fig. 2). Refer to Group 8E, Instrument Panel

and Gauges. (3) Working through the glove box opening, discon-

nect the wiring connector at the module. (4) Remove the module bracket mounting screw.

(5) Remove the module bracket from the vehicle.

INSTALLATION

Reverse the preceding operation.

BODY CONTROLLER COMPUTERÐAC, AG, AJ and

AY-BODY

REMOVAL

The Body Controller Computer is located at the

right front door opening behind the cowl trim panel

(Fig. 3). (1) Remove the battery negative cable before re-

moving the Body Controller. (2) Remove screws holding cowl trim and door

opening scuff plate to cowl panel. (3) Disconnect wire connectors from body control-

ler. (4) Remove nuts holding body controller to cowl

panel. (5) Separate body controller from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 3 Body Controller

Fig. 4 Illuminated Entry Circuit WiringÐAA-Body

Fig. 5 Module Pin OutsÐAA-Body

8L - 34 LAMPS Ä

Page 683 of 2438

RESTRAINT SYSTEMS

CONTENTS

page page

AIR BAG MODULE ....................... 4

AIR BAG SERVICE AND TEST PROCEDURES . 1

AIR BAG SYSTEM CHECK ................. 3

AIR BAG SYSTEM DIAGNOSTIC MODULE (ASDM) .............................. 5

CLOCKSPRING .......................... 6

CLOCKSPRING CENTERING PROCEDURE .... 6 GENERAL INFORMATION

.................. 1

LEFT FRONT IMPACT SENSOR ............. 4

RIGHT FRONT IMPACT SENSOR ........... 5

SCHEDULED MAINTENANCE INSPECTION .... 3

STEERING COLUMN SWITCHES ............ 7

STEERING WHEEL ....................... 7

AIR BAG SERVICE AND TEST PROCEDURES

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO-MECHANICAL UNIT. BEFORE AT-

TEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS, YOU MUST

FIRST DISCONNECT AND ISOLATE THE NEGATIVE

(GROUND) BATTERY CABLE. FAILURE TO DO SO

COULD RESULT IN ACCIDENTAL DEPLOYMENT

AND POSSIBLE PERSONAL INJURY. WHEN AN UNDEPLOYED AIR BAG ASSEMBLY

IS TO BE REMOVED FROM THE STEERING

WHEEL, DISCONNECT BATTERY GROUND CA-

BLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES THEN

BEGIN AIR BAG SYSTEM COMPONENT RE-

MOVAL. Vehicles equipped with a Air Bag System must be

inspected every three years or 30,000 miles / 48,000

Km. To inspect system use Passive Restraint System

Diagnostic Procedures Manual. If the Air Bag Module Assembly is defective and

non-deployed, refer to Chrysler Motors current re-

turn list for proper handling procedures.

WARNING: REPLACE AIR BAG SYSTEM COMPO-

NENTS WITH CHRYSLER MOPAR TSPECIFIED RE-

PLACEMENT PARTS. SUBSTITUTE PARTS MAY

VISUALLY APPEAR INTERCHANGEABLE, BUT IN-

TERNAL DIFFERENCES MAY RESULT IN INFERIOR

OCCUPANT PROTECTION.

THE FASTENERS, SCREWS, AND BOLTS, ORIG-

INALLY USED FOR THE AIR BAG COMPO-

NENTS, HAVE SPECIAL COATINGS AND ARE

SPECIFICALLY DESIGNED FOR THE AIR BAG

SYSTEM. THEY MUST NEVER BE REPLACED

WITH ANY SUBSTITUTES. ANYTIME A NEW

FASTENER IS NEEDED, REPLACE WITH THE CORRECT FASTENERS PROVIDED IN THE SER-

VICE PACKAGE OR FASTENERS LISTED IN THE

PARTS BOOKS.

GENERAL INFORMATION

AIR BAG MODULE

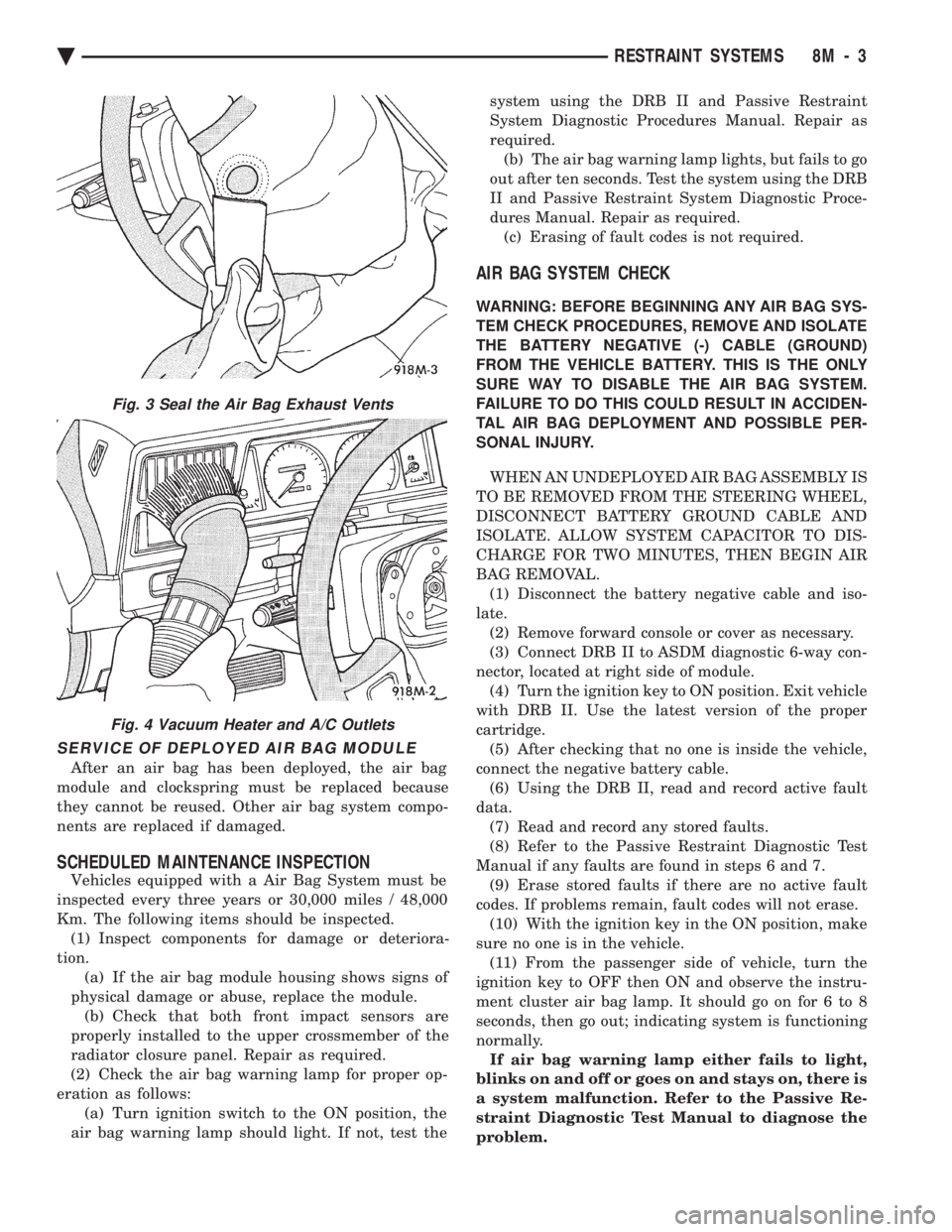

The air bag module is the most visible part of the

system (Fig 1). It contains the air bag cushion and

its supporting components. The air bag module con-

tains a housing to which the cushion and inflator are

attached and sealed.

The inflator assembly is mounted to the back of the

module housing. When supplied with the proper elec-

trical signal the inflator assembly will produce a gas

and discharges it directly into the cushion. A protec-

tive cover is fitted to the front of the air bag module

and forms a decorative cover in the center of the

steering wheel. The air bag module is mounted di-

rectly to the steering wheel.

Fig. 1 Air Bag Passive Restraint System

Ä RESTRAINT SYSTEMS 8M - 1

Page 684 of 2438

FRONT IMPACT SENSORS

The driver air bag system is a safety device de-

signed to reduce the risk of fatality or serious injury,

caused by a frontal impact of the vehicle. The impact sensors provide verification of the di-

rection and severity of the impact. Three impact sen-

sors are used. One is called a safing sensor. It is

located inside the diagnostic module which is

mounted on the floor pan, just forward of the center

console. The other two sensors are mounted on the

upper crossmember of the radiator closure panel on

the left and right side of the vehicle under the hood. The impact sensors are threshold sensitive switches

that complete an electrical circuit when an impact

provides a sufficient G force to close the switch. The

sensors are calibrated for the specific vehicle and re-

act to the severity and direction of the impact.

CLOCKSPRING

The clockspring is mounted on the steering column

behind the steering wheel, and is used to maintain a

continuous electrical circuit between the wiring har-

ness and the driver's air bag module. This assembly

consists of a flat ribbon-like electrically conductive

tape which winds and unwinds with the steering

wheel rotation.

DIAGNOSTIC MODULE

The Air Bag System Diagnostic Module (ASDM)

contains the safing sensor and energy reserve capac-

itor. The ASDM monitors the system to determine

the system readiness. The ASDM will store sufficient

energy to deploy the air bag for only two minutes af-

ter the battery is disconnected. If both front impact

sensors are open the air bag could be deployed up to

9.5 minutes after the battery is disconnected. The

ASDM contains on-board diagnostics, and will illumi-

nate the AIR BAG warning lamp in the cluster when

a fault occurs.

STORAGE

The air bag module must be stored in its original

special container until used for service. Additionally,

it must be stored in a clean, dry environment, away

from sources of extreme heat, sparks, and sources of

high electrical energy. Always place or store the

module on a surface with the trim cover facing up to

minimize movement in case of accidental deploy-

ment.

HANDLING LIVE MODULE

At no time should any source of electricity be per-

mitted near the inflator on the back of the module.

When carrying a live module, the trim cover should

be pointed away from the body to minimize injury in

the event of accidental deployment. In addition, if

the module is placed on a bench or other surface, the plastic trim cover should be face up to minimize

movement in case of accidental deployment. When handling a steering column with an air bag

module attached, never place the column on the floor

or other surface with the steering wheel or module

face down.

DEPLOYED MODULE

The vehicle interior may contain a very small

amount of sodium hydroxide powder, a byproduct of

air bag deployment. Since this powder can irritate

the skin, eyes, nose or throat, be sure to wear safety

glasses, rubber gloves and long sleeves during

cleanup (Fig. 2).

If you find that the cleanup is irritating your skin,

run cool water over the affected area. Also, if you ex-

perience nasal or throat irritation, exit the vehicle

for fresh air until the irritation ceases. If irritation

continues, see a physician.

CLEANUP PROCEDURE

Begin the cleanup by putting tape over the two air

bag exhaust vents (Fig. 3) so that no additional pow-

der will find its way into the vehicle interior. Then

remove the air bag and air bag module from the ve-

hicle. Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in so that you avoid kneeling or sitting in a un-

cleaned area. Be sure to vacuum the heater and A/C outlets as

well (Fig. 4). In fact it's a good idea to run the blower

on low and to vacuum up any powder expelled from

the plenum. You may need to vacuum the interior of

the car a second time to recover all of the powder. Place the deployed bag and module in your auto-

motive scrap.

Fig. 2 Wear Safety Glasses and Rubber Gloves

8M - 2 RESTRAINT SYSTEMS Ä

Page 685 of 2438

SERVICE OF DEPLOYED AIR BAG MODULE

After an air bag has been deployed, the air bag

module and clockspring must be replaced because

they cannot be reused. Other air bag system compo-

nents are replaced if damaged.

SCHEDULED MAINTENANCE INSPECTION

Vehicles equipped with a Air Bag System must be

inspected every three years or 30,000 miles / 48,000

Km. The following items should be inspected. (1) Inspect components for damage or deteriora-

tion. (a) If the air bag module housing shows signs of

physical damage or abuse, replace the module. (b) Check that both front impact sensors are

properly installed to the upper crossmember of the

radiator closure panel. Repair as required.

(2) Check the air bag warning lamp for proper op-

eration as follows: (a) Turn ignition switch to the ON position, the

air bag warning lamp should light. If not, test the system using the DRB II and Passive Restraint

System Diagnostic Procedures Manual. Repair as

required.

(b) The air bag warning lamp lights, but fails to go

out after ten seconds. Test the system using the DRB

II and Passive Restraint System Diagnostic Proce-

dures Manual. Repair as required. (c) Erasing of fault codes is not required.

AIR BAG SYSTEM CHECK

WARNING: BEFORE BEGINNING ANY AIR BAG SYS-

TEM CHECK PROCEDURES, REMOVE AND ISOLATE

THE BATTERY NEGATIVE (-) CABLE (GROUND)

FROM THE VEHICLE BATTERY. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIR BAG SYSTEM.

FAILURE TO DO THIS COULD RESULT IN ACCIDEN-

TAL AIR BAG DEPLOYMENT AND POSSIBLE PER-

SONAL INJURY.

WHEN AN UNDEPLOYED AIR BAG ASSEMBLY IS

TO BE REMOVED FROM THE STEERING WHEEL,

DISCONNECT BATTERY GROUND CABLE AND

ISOLATE. ALLOW SYSTEM CAPACITOR TO DIS-

CHARGE FOR TWO MINUTES, THEN BEGIN AIR

BAG REMOVAL. (1) Disconnect the battery negative cable and iso-

late. (2) Remove forward console or cover as necessary.

(3) Connect DRB II to ASDM diagnostic 6-way con-

nector, located at right side of module. (4) Turn the ignition key to ON position. Exit vehicle

with DRB II. Use the latest version of the proper

cartridge. (5) After checking that no one is inside the vehicle,

connect the negative battery cable. (6) Using the DRB II, read and record active fault

data. (7) Read and record any stored faults.

(8) Refer to the Passive Restraint Diagnostic Test

Manual if any faults are found in steps 6 and 7. (9) Erase stored faults if there are no active fault

codes. If problems remain, fault codes will not erase. (10) With the ignition key in the ON position, make

sure no one is in the vehicle. (11) From the passenger side of vehicle, turn the

ignition key to OFF then ON and observe the instru-

ment cluster air bag lamp. It should go on for 6 to 8

seconds, then go out; indicating system is functioning

normally. If air bag warning lamp either fails to light,

blinks on and off or goes on and stays on, there is

a system malfunction. Refer to the Passive Re-

straint Diagnostic Test Manual to diagnose the

problem.

Fig. 3 Seal the Air Bag Exhaust Vents

Fig. 4 Vacuum Heater and A/C Outlets

Ä RESTRAINT SYSTEMS 8M - 3