torque CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 73 of 2438

made by using a (M10 x 1.5 - 6H) thread chasing tap

on the holes to restore the threads to a usable condi-

tion. If threads can be restored to a usable condition,

install sway bar retainer attaching bolts and torque

to 68 N Im (50 ft. lbs.).

CAUTION: When performing repair procedure listed

below. Be sure replacement bolts and nuts meet the

same requirements as the original equipment man-

ufactures specifications.

If damage to threaded holes in lower control arm,

can not be restored to a usable condition using the

above procedure. Drill out holes in lower control arm

using an 11 mm drill bit. Then use a bolt and nut for

attachment of sway bar retainer to lower control

arm. Torque the nut and bolt to 68 N Im (50 ft. lbs.).

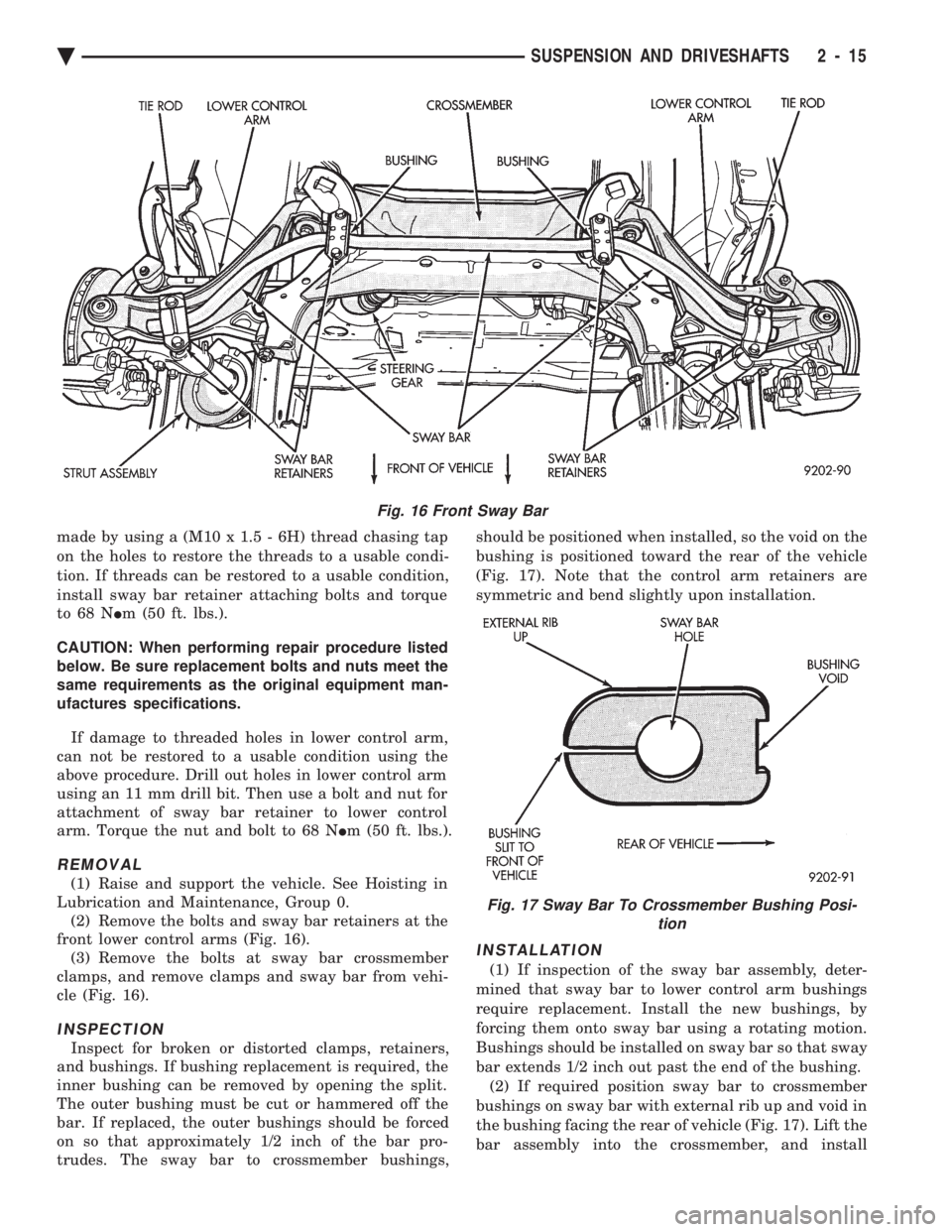

REMOVAL

(1) Raise and support the vehicle. See Hoisting in

Lubrication and Maintenance, Group 0. (2) Remove the bolts and sway bar retainers at the

front lower control arms (Fig. 16). (3) Remove the bolts at sway bar crossmember

clamps, and remove clamps and sway bar from vehi-

cle (Fig. 16).

INSPECTION

Inspect for broken or distorted clamps, retainers,

and bushings. If bushing replacement is required, the

inner bushing can be removed by opening the split.

The outer bushing must be cut or hammered off the

bar. If replaced, the outer bushings should be forced

on so that approximately 1/2 inch of the bar pro-

trudes. The sway bar to crossmember bushings, should be positioned when installed, so the void on the

bushing is positioned toward the rear of the vehicle

(Fig. 17). Note that the control arm retainers are

symmetric and bend slightly upon installation.

INSTALLATION

(1) If inspection of the sway bar assembly, deter-

mined that sway bar to lower control arm bushings

require replacement. Install the new bushings, by

forcing them onto sway bar using a rotating motion.

Bushings should be installed on sway bar so that sway

bar extends 1/2 inch out past the end of the bushing. (2) If required position sway bar to crossmember

bushings on sway bar with external rib up and void in

the bushing facing the rear of vehicle (Fig. 17). Lift the

bar assembly into the crossmember, and install

Fig. 16 Front Sway Bar

Fig. 17 Sway Bar To Crossmember Bushing Posi- tion

Ä SUSPENSION AND DRIVESHAFTS 2 - 15

Page 74 of 2438

the lower clamps and bolts. The center offset in the

sway bar should be oriented toward the front of the

vehicle (Fig. 16)(3) Position bushing retainers on lower control arms

and install bolts (Fig. 16). (4) With lower control arms raised to design height,

tighten all retainer attaching bolts to 70 N Im (50 ft.

lbs.) torque. (5) Lower vehicle.

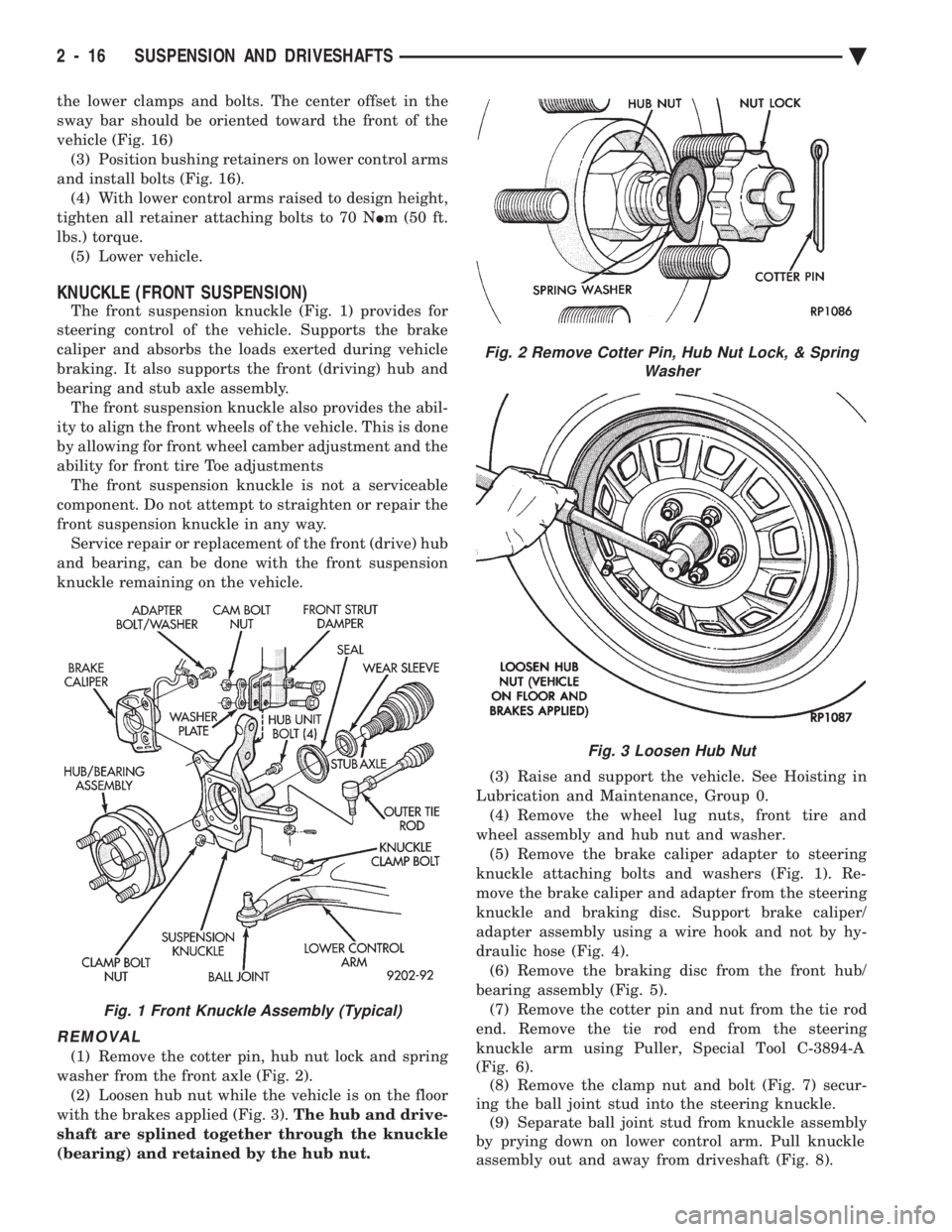

KNUCKLE (FRONT SUSPENSION)

The front suspension knuckle (Fig. 1) provides for

steering control of the vehicle. Supports the brake

caliper and absorbs the loads exerted during vehicle

braking. It also supports the front (driving) hub and

bearing and stub axle assembly. The front suspension knuckle also provides the abil-

ity to align the front wheels of the vehicle. This is done

by allowing for front wheel camber adjustment and the

ability for front tire Toe adjustments The front suspension knuckle is not a serviceable

component. Do not attempt to straighten or repair the

front suspension knuckle in any way. Service repair or replacement of the front (drive) hub

and bearing, can be done with the front suspension

knuckle remaining on the vehicle.

REMOVAL

(1) Remove the cotter pin, hub nut lock and spring

washer from the front axle (Fig. 2). (2) Loosen hub nut while the vehicle is on the floor

with the brakes applied (Fig. 3). The hub and drive-

shaft are splined together through the knuckle

(bearing) and retained by the hub nut. (3) Raise and support the vehicle. See Hoisting in

Lubrication and Maintenance, Group 0. (4) Remove the wheel lug nuts, front tire and

wheel assembly and hub nut and washer. (5) Remove the brake caliper adapter to steering

knuckle attaching bolts and washers (Fig. 1). Re-

move the brake caliper and adapter from the steering

knuckle and braking disc. Support brake caliper/

adapter assembly using a wire hook and not by hy-

draulic hose (Fig. 4). (6) Remove the braking disc from the front hub/

bearing assembly (Fig. 5). (7) Remove the cotter pin and nut from the tie rod

end. Remove the tie rod end from the steering

knuckle arm using Puller, Special Tool C-3894-A

(Fig. 6). (8) Remove the clamp nut and bolt (Fig. 7) secur-

ing the ball joint stud into the steering knuckle. (9) Separate ball joint stud from knuckle assembly

by prying down on lower control arm. Pull knuckle

assembly out and away from driveshaft (Fig. 8).

Fig. 2 Remove Cotter Pin, Hub Nut Lock, & Spring Washer

Fig. 3 Loosen Hub Nut

Fig. 1 Front Knuckle Assembly (Typical)

2 - 16 SUSPENSION AND DRIVESHAFTS Ä

Page 76 of 2438

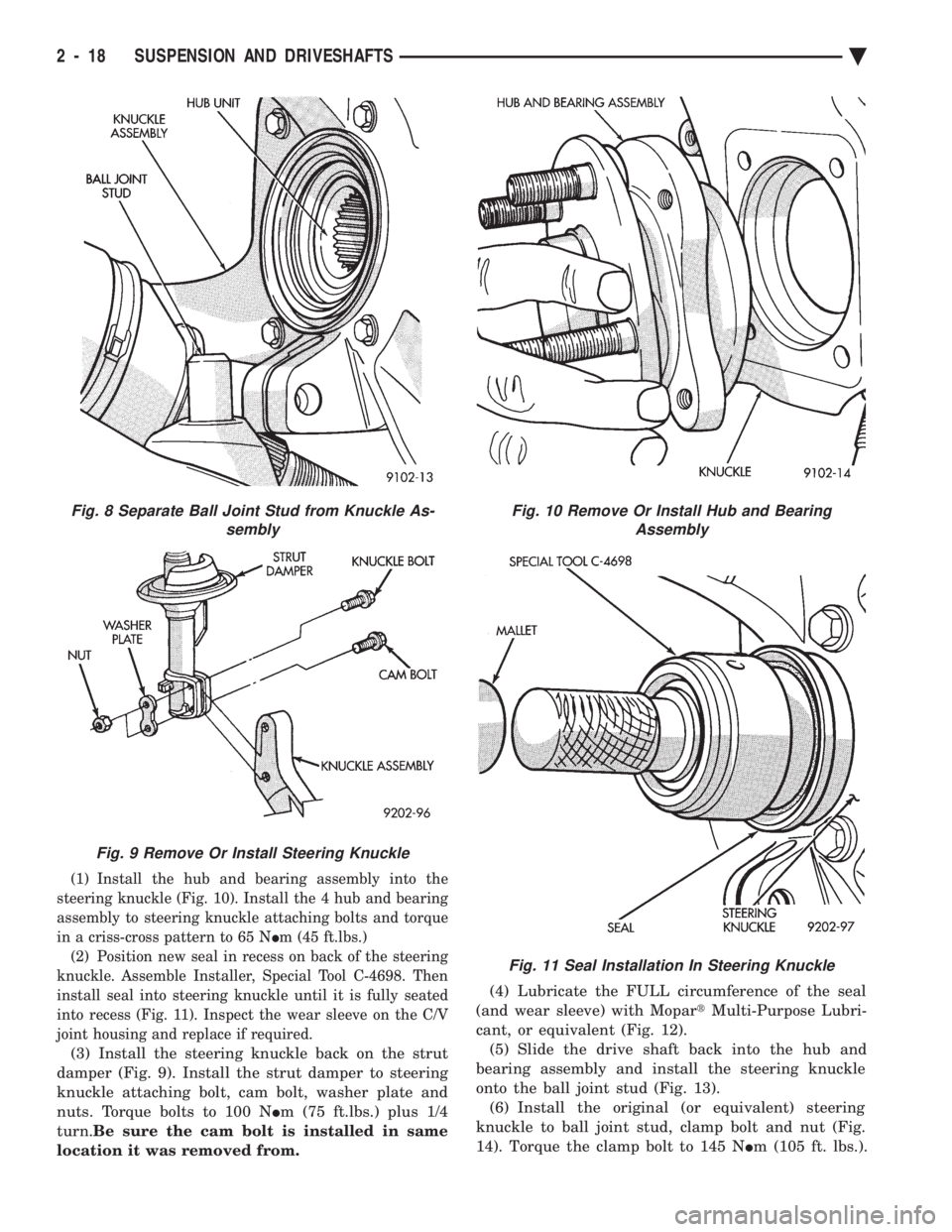

(1) Install the hub and bearing assembly into the

steering knuckle (Fig. 10). Install the 4 hub and bearing

assembly to steering knuckle attaching bolts and torque

in a criss-cross pattern to 65 N Im (45 ft.lbs.)

(2) Position new seal in recess on back of the steering

knuckle. Assemble Installer, Special Tool C-4698. Then

install seal into steering knuckle until it is fully seated

into recess (Fig. 11). Inspect the wear sleeve on the C/V

joint housing and replace if required.

(3) Install the steering knuckle back on the strut

damper (Fig. 9). Install the strut damper to steering

knuckle attaching bolt, cam bolt, washer plate and

nuts. Torque bolts to 100 N Im (75 ft.lbs.) plus 1/4

turn. Be sure the cam bolt is installed in same

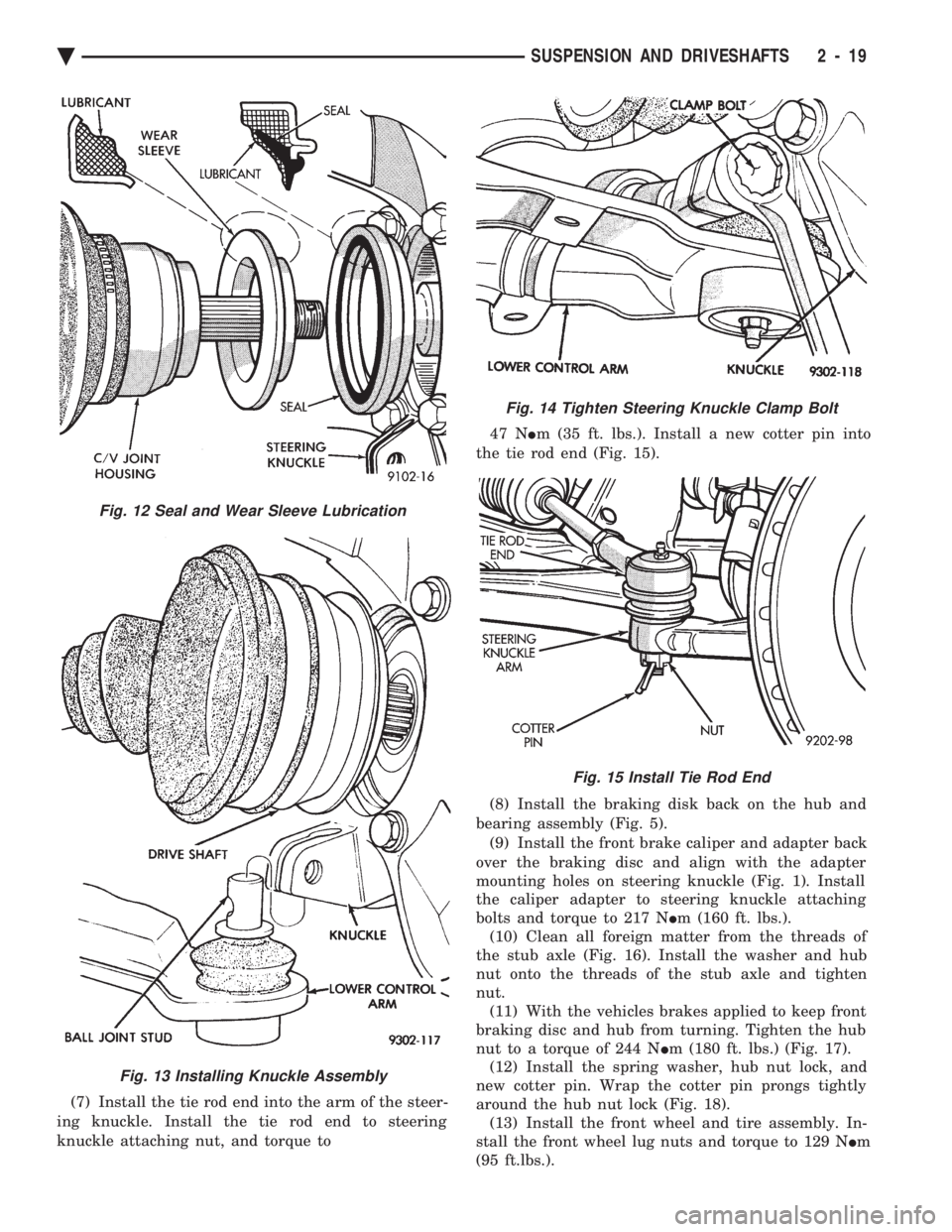

location it was removed from. (4) Lubricate the FULL circumference of the seal

(and wear sleeve) with Mopar tMulti-Purpose Lubri-

cant, or equivalent (Fig. 12). (5) Slide the drive shaft back into the hub and

bearing assembly and install the steering knuckle

onto the ball joint stud (Fig. 13). (6) Install the original (or equivalent) steering

knuckle to ball joint stud, clamp bolt and nut (Fig.

14). Torque the clamp bolt to 145 N Im (105 ft. lbs.).

Fig. 10 Remove Or Install Hub and Bearing

Assembly

Fig. 11 Seal Installation In Steering Knuckle

Fig. 8 Separate Ball Joint Stud from Knuckle As- sembly

Fig. 9 Remove Or Install Steering Knuckle

2 - 18 SUSPENSION AND DRIVESHAFTS Ä

Page 77 of 2438

(7) Install the tie rod end into the arm of the steer-

ing knuckle. Install the tie rod end to steering

knuckle attaching nut, and torque to 47 N

Im (35 ft. lbs.). Install a new cotter pin into

the tie rod end (Fig. 15).

(8) Install the braking disk back on the hub and

bearing assembly (Fig. 5). (9) Install the front brake caliper and adapter back

over the braking disc and align with the adapter

mounting holes on steering knuckle (Fig. 1). Install

the caliper adapter to steering knuckle attaching

bolts and torque to 217 N Im (160 ft. lbs.).

(10) Clean all foreign matter from the threads of

the stub axle (Fig. 16). Install the washer and hub

nut onto the threads of the stub axle and tighten

nut. (11) With the vehicles brakes applied to keep front

braking disc and hub from turning. Tighten the hub

nut to a torque of 244 N Im (180 ft. lbs.) (Fig. 17).

(12) Install the spring washer, hub nut lock, and

new cotter pin. Wrap the cotter pin prongs tightly

around the hub nut lock (Fig. 18). (13) Install the front wheel and tire assembly. In-

stall the front wheel lug nuts and torque to 129 N Im

(95 ft.lbs.).

Fig. 13 Installing Knuckle Assembly

Fig. 12 Seal and Wear Sleeve Lubrication

Fig. 14 Tighten Steering Knuckle Clamp Bolt

Fig. 15 Install Tie Rod End

Ä SUSPENSION AND DRIVESHAFTS 2 - 19

Page 79 of 2438

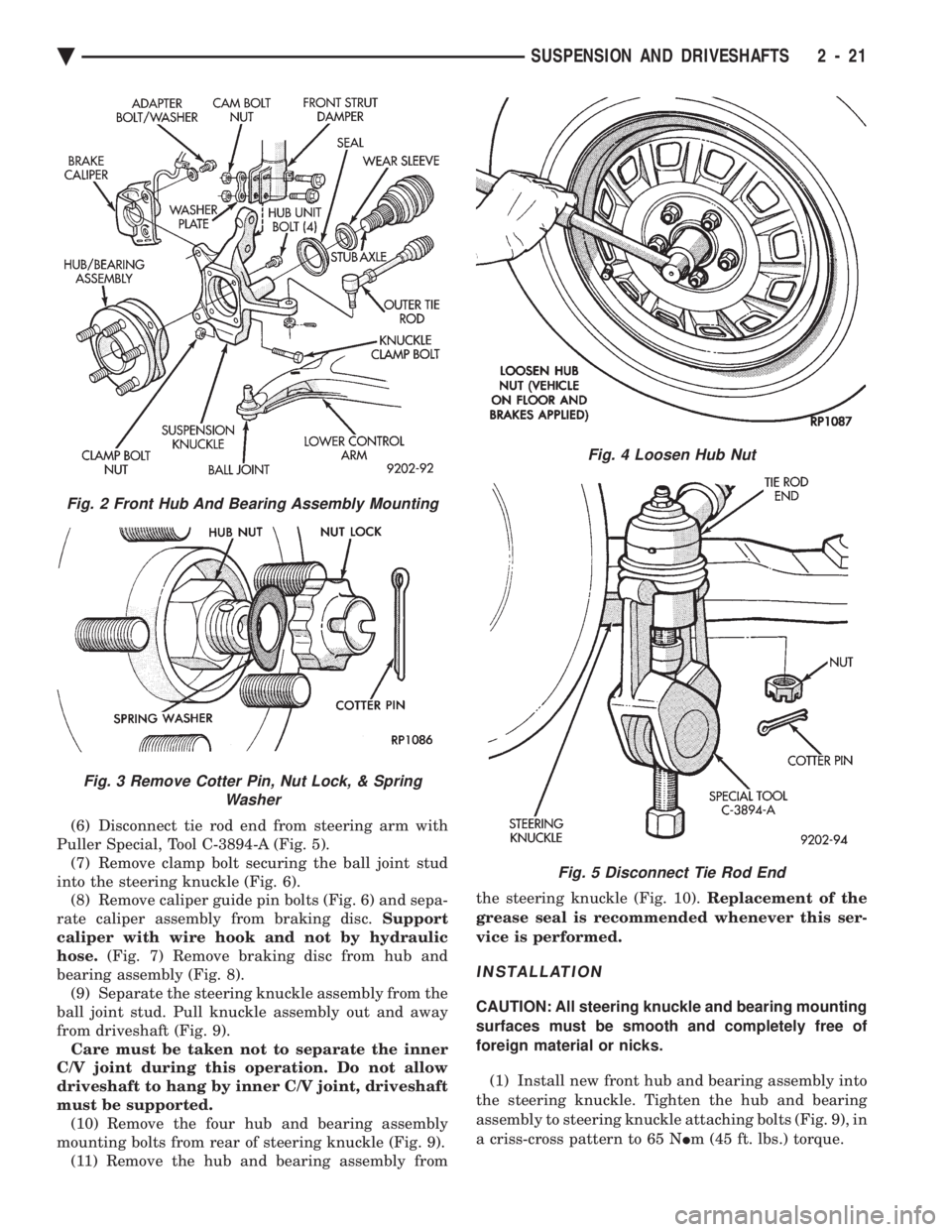

(6) Disconnect tie rod end from steering arm with

Puller Special, Tool C-3894-A (Fig. 5). (7) Remove clamp bolt securing the ball joint stud

into the steering knuckle (Fig. 6). (8) Remove caliper guide pin bolts (Fig. 6) and sepa-

rate caliper assembly from braking disc. Support

caliper with wire hook and not by hydraulic

hose. (Fig. 7) Remove braking disc from hub and

bearing assembly (Fig. 8). (9) Separate the steering knuckle assembly from the

ball joint stud. Pull knuckle assembly out and away

from driveshaft (Fig. 9). Care must be taken not to separate the inner

C/V joint during this operation. Do not allow

driveshaft to hang by inner C/V joint, driveshaft

must be supported. (10) Remove the four hub and bearing assembly

mounting bolts from rear of steering knuckle (Fig. 9). (11) Remove the hub and bearing assembly from the steering knuckle (Fig. 10).

Replacement of the

grease seal is recommended whenever this ser-

vice is performed.

INSTALLATION

CAUTION: All steering knuckle and bearing mounting

surfaces must be smooth and completely free of

foreign material or nicks.

(1) Install new front hub and bearing assembly into

the steering knuckle. Tighten the hub and bearing

assembly to steering knuckle attaching bolts (Fig. 9), in

a criss-cross pattern to 65 N Im (45 ft. lbs.) torque.

Fig. 2 Front Hub And Bearing Assembly Mounting

Fig. 3 Remove Cotter Pin, Nut Lock, & Spring

Washer

Fig. 4 Loosen Hub Nut

Fig. 5 Disconnect Tie Rod End

Ä SUSPENSION AND DRIVESHAFTS 2 - 21

Page 81 of 2438

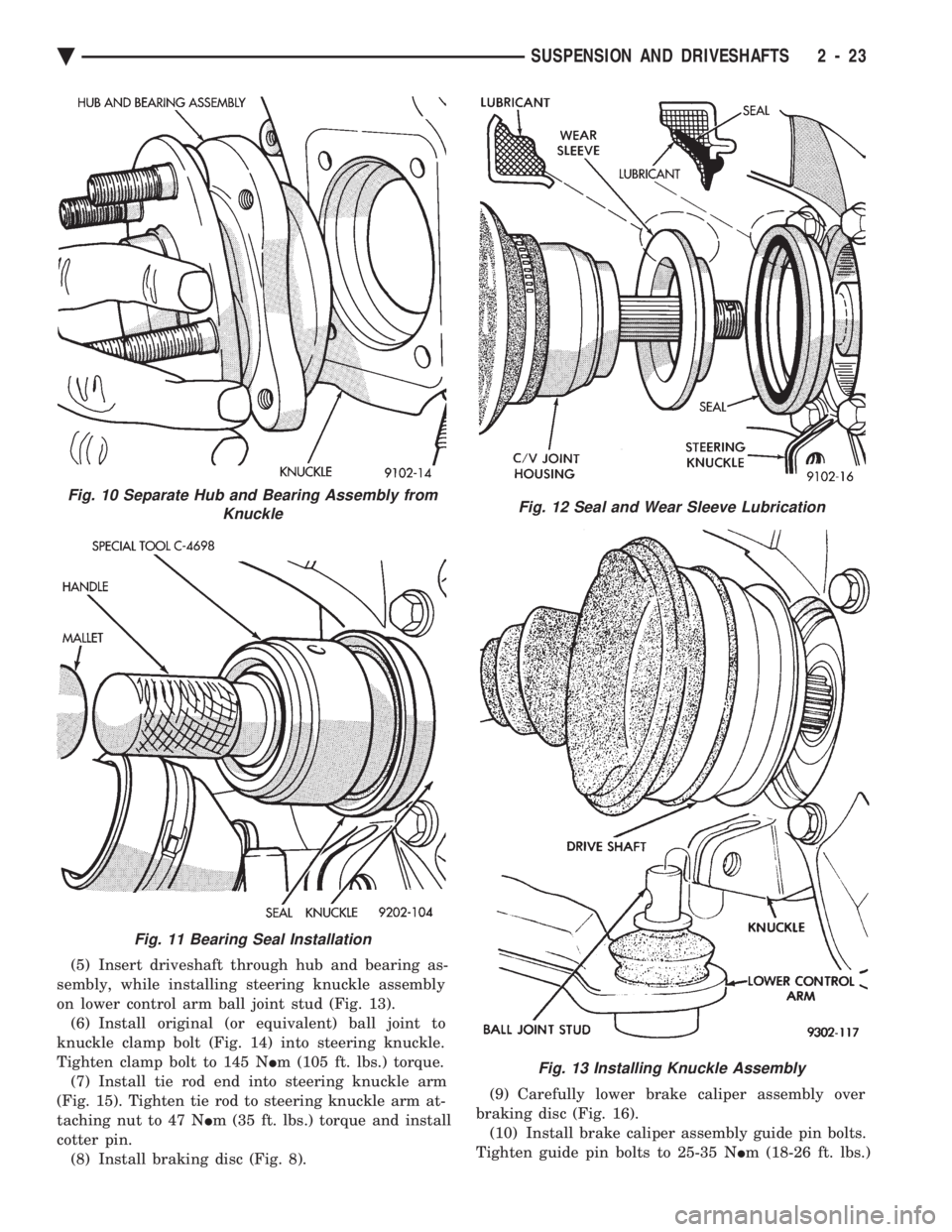

(5) Insert driveshaft through hub and bearing as-

sembly, while installing steering knuckle assembly

on lower control arm ball joint stud (Fig. 13). (6) Install original (or equivalent) ball joint to

knuckle clamp bolt (Fig. 14) into steering knuckle.

Tighten clamp bolt to 145 N Im (105 ft. lbs.) torque.

(7) Install tie rod end into steering knuckle arm

(Fig. 15). Tighten tie rod to steering knuckle arm at-

taching nut to 47 N Im (35 ft. lbs.) torque and install

cotter pin. (8) Install braking disc (Fig. 8). (9) Carefully lower brake caliper assembly over

braking disc (Fig. 16). (10) Install brake caliper assembly guide pin bolts.

Tighten guide pin bolts to 25-35 N Im (18-26 ft. lbs.)

Fig. 10 Separate Hub and Bearing Assembly from

Knuckle

Fig. 11 Bearing Seal Installation

Fig. 12 Seal and Wear Sleeve Lubrication

Fig. 13 Installing Knuckle Assembly

Ä SUSPENSION AND DRIVESHAFTS 2 - 23

Page 82 of 2438

torque. When installing guide pins, use extreme

caution not to cross the threads. (11) Clean all foreign matter from the threads of the

stub axle (Fig. 17). Install the washer and hub nut (Fig.

17) onto the threads of the stub axle and tighten nut. (12) With brakes applied, tighten front hub nut to

(244 N Im) 180 ft. lbs. torque (Fig. 18).

(13) Install spring washer, nut lock, and new cot-

ter pin. Wrap cotter pin prongs tightly around nut

lock (Fig. 19). Install wheel and tire assembly. Tighten wheel

nuts to 129 N Im (95 ft. lbs.) torque.

Fig. 15 Install Tie Rod End

Fig. 16 Installing Family Caliper

Fig. 17 Install Washer and Hub Nut

Fig. 18 Tighten Hub Nut

Fig. 19 Install Spring Washer, Nut Lock, & Cotter

Pin

Fig. 14 Tighten Clamp Bolt

2 - 24 SUSPENSION AND DRIVESHAFTS Ä

Page 87 of 2438

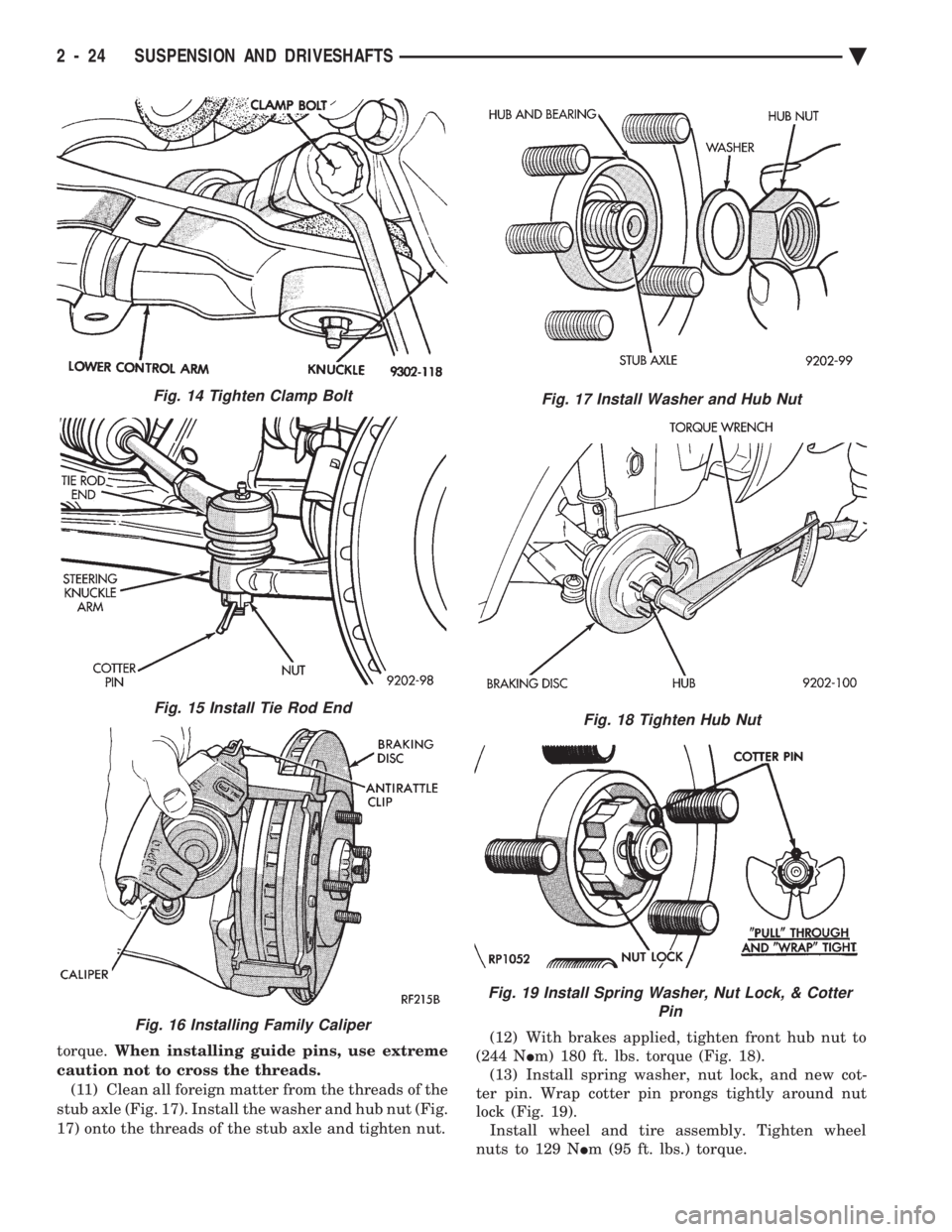

(1) Hold inner joint assembly at housing (Figs. 11

and 12) while aligning and guiding the inner joint

spline into the transaxle or intermediate shaft assem-

bly. On Equal Length System vehicles only, be

sure that the rubber washer seal is in place on

the right inner C/V joint (Fig. 1).

CAUTION: Seal/Wear Sleeve Lubrication During any

service procedures where knuckle and driveshaft are

separated. Thoroughly clean seal and wear sleeve

with suitable solvent (solvent must not touch boot)

and lubricate both components prior to installing

driveshaft. Lubricate wear sleeve and seal with Mopar

Multi-Purpose Lubricant, or equivalent.

Apply on the full circumference of the Wear Sleeve a

bead of lubricant that is 6 mm (1/4 in.) wide to seal

contact area (Fig. 13). Fill the seal lip to housing cavity

on bearing seal with lubricant. Lubricant is to be

applied around complete circumference of the seal, and

seal lip should be wet with lubricant (Fig. 13). Use

Mopar Multi-Purpose Lubricant or equivalent for lu-

brication of the Wear Sleeve and Bearing Seal. (2) Push knuckle (hub) assembly out and install

splined outer C/V joint shaft in hub (Fig. 14). CAUTION: Steering knuckle clamp bolt shown in

(Figs. 14 and 15) is Prevailing Torque Type, original

or equivalent bolt must be installed during assem-

bly.

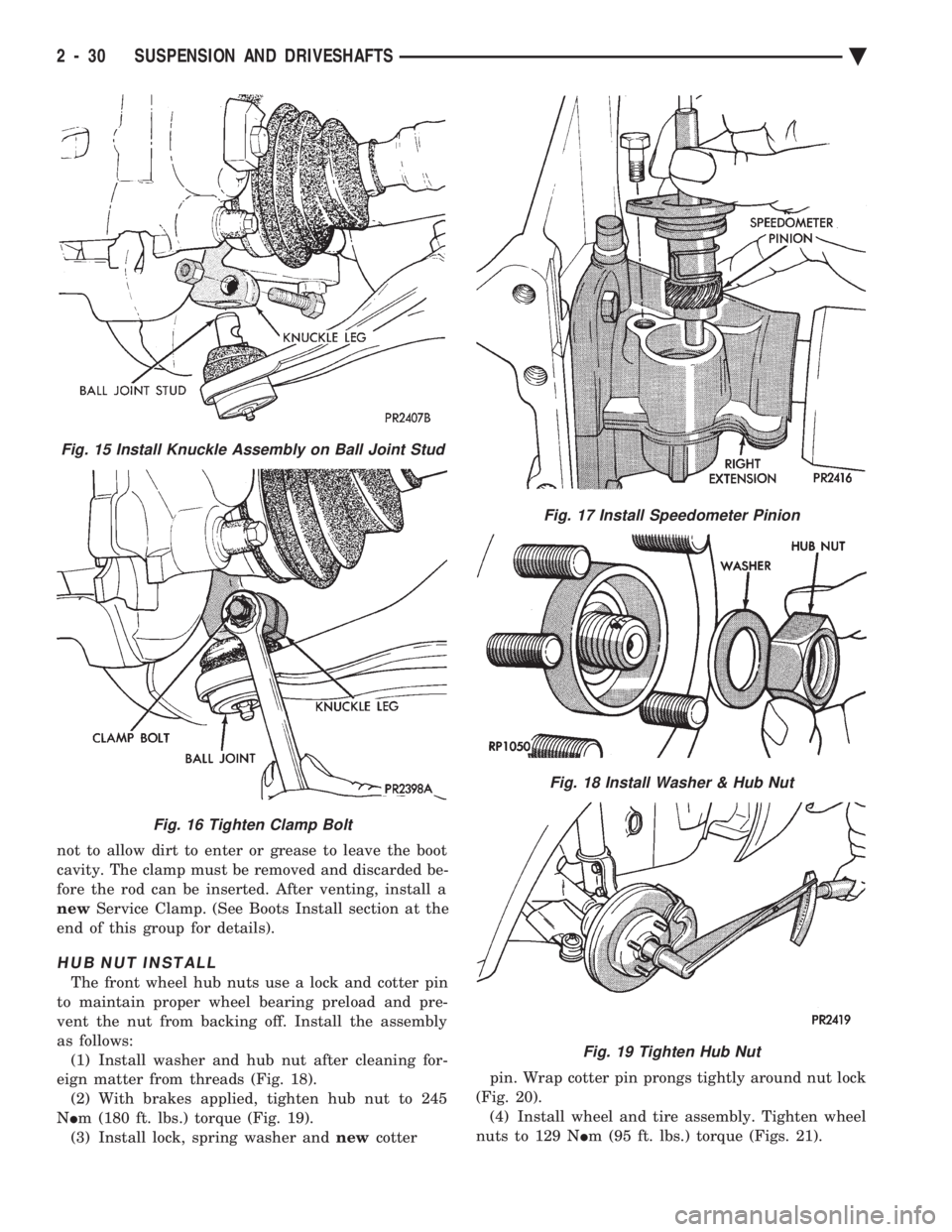

(3) Install knuckle assembly on ball joint stud

(Fig. 15). (4) Install and tighten clamp bolt to 95 N Im (70 ft.

lbs.) torque (Fig. 16). (5) Install speedometer pinion (Fig. 17).

(6) Fill differential with proper lubricant (see Lu-

brication and Maintenance Group 0). (7) Install hub nut assembly.

(8) If after installing the driveshaft assembly,the

inboard boot appears collapsed or deformed. Vent

the inner boot by inserting, a round tipped small di-

ameter rod between the boot and shaft. If necessary,

massage the boot to remove all puckers being careful

Fig. 13 Seal & Wear Sleeve Lubrication

Fig. 14 Install Outer Shaft into Hub

Fig. 11 Removing Driveshaft Assembly Equal Length

Fig. 12 Installing Inner Shaft into Transaxle

Ä SUSPENSION AND DRIVESHAFTS 2 - 29

Page 88 of 2438

not to allow dirt to enter or grease to leave the boot

cavity. The clamp must be removed and discarded be-

fore the rod can be inserted. After venting, install a

new Service Clamp. (See Boots Install section at the

end of this group for details).

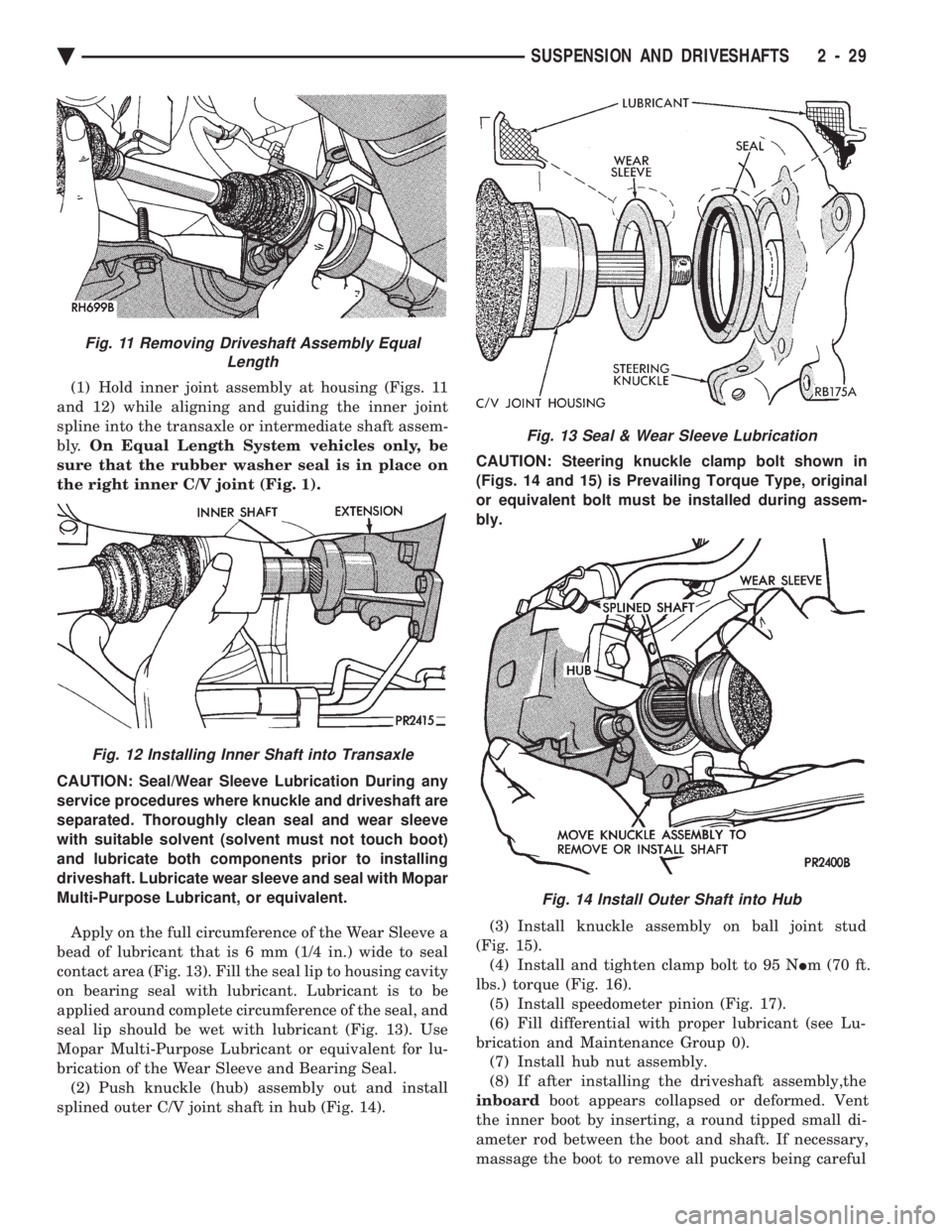

HUB NUT INSTALL

The front wheel hub nuts use a lock and cotter pin

to maintain proper wheel bearing preload and pre-

vent the nut from backing off. Install the assembly

as follows: (1) Install washer and hub nut after cleaning for-

eign matter from threads (Fig. 18). (2) With brakes applied, tighten hub nut to 245

N Im (180 ft. lbs.) torque (Fig. 19).

(3) Install lock, spring washer and newcotter pin. Wrap cotter pin prongs tightly around nut lock

(Fig. 20). (4) Install wheel and tire assembly. Tighten wheel

nuts to 129 N Im (95 ft. lbs.) torque (Figs. 21).

Fig. 15 Install Knuckle Assembly on Ball Joint Stud

Fig. 16 Tighten Clamp Bolt

Fig. 17 Install Speedometer Pinion

Fig. 18 Install Washer & Hub Nut

Fig. 19 Tighten Hub Nut

2 - 30 SUSPENSION AND DRIVESHAFTS Ä

Page 101 of 2438

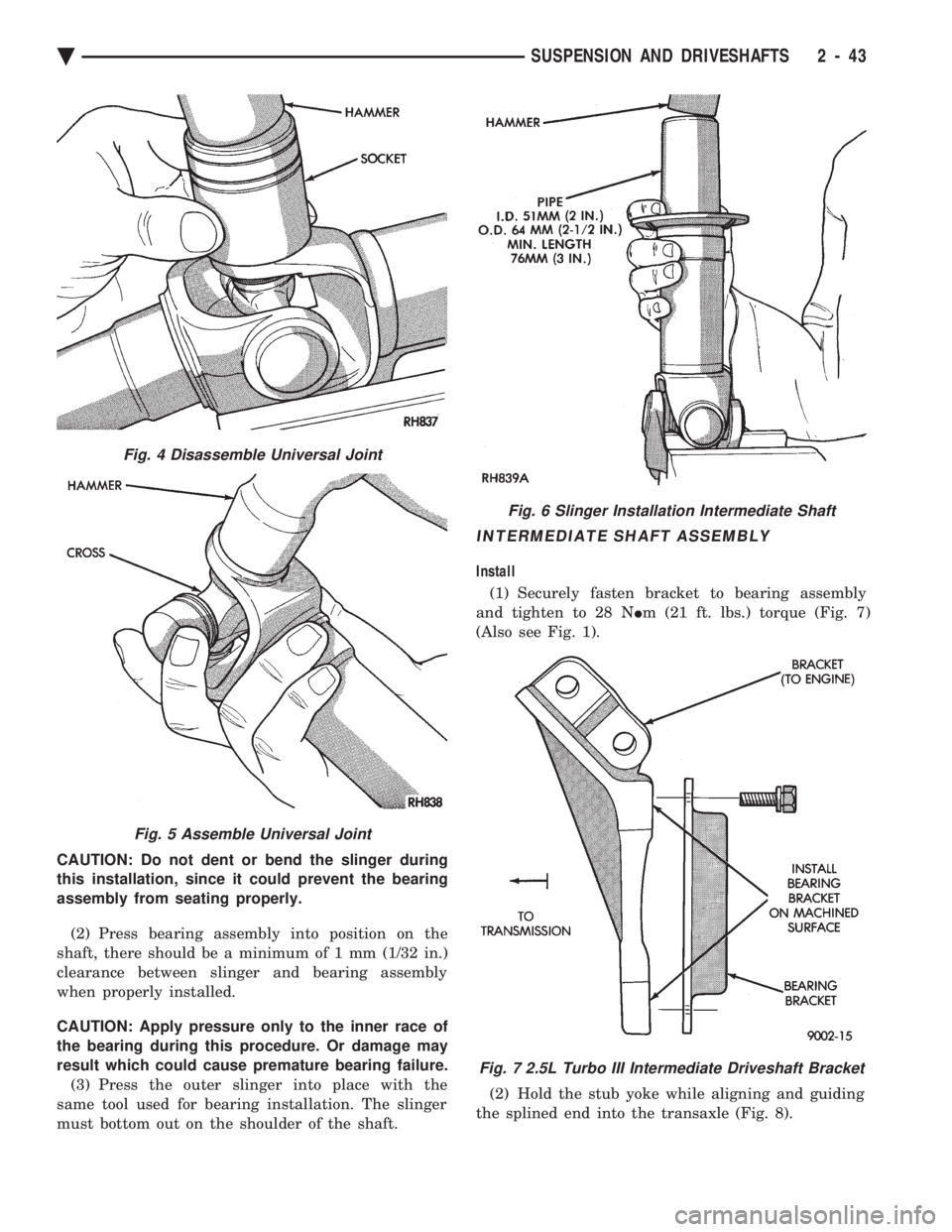

CAUTION: Do not dent or bend the slinger during

this installation, since it could prevent the bearing

assembly from seating properly. (2) Press bearing assembly into position on the

shaft, there should be a minimum of 1 mm (1/32 in.)

clearance between slinger and bearing assembly

when properly installed.

CAUTION: Apply pressure only to the inner race of

the bearing during this procedure. Or damage may

result which could cause premature bearing failure. (3) Press the outer slinger into place with the

same tool used for bearing installation. The slinger

must bottom out on the shoulder of the shaft.

INTERMEDIATE SHAFT ASSEMBLY

Install

(1) Securely fasten bracket to bearing assembly

and tighten to 28 N Im (21 ft. lbs.) torque (Fig. 7)

(Also see Fig. 1).

(2) Hold the stub yoke while aligning and guiding

the splined end into the transaxle (Fig. 8).

Fig. 4 Disassemble Universal Joint

Fig. 5 Assemble Universal Joint

Fig. 6 Slinger Installation Intermediate Shaft

Fig. 7 2.5L Turbo III Intermediate Driveshaft Bracket

Ä SUSPENSION AND DRIVESHAFTS 2 - 43