torque CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2345 of 2438

(11) Replace shaft hex nut. Tighten the hex nut to 37

N Im (27 ft. lbs.) torque.

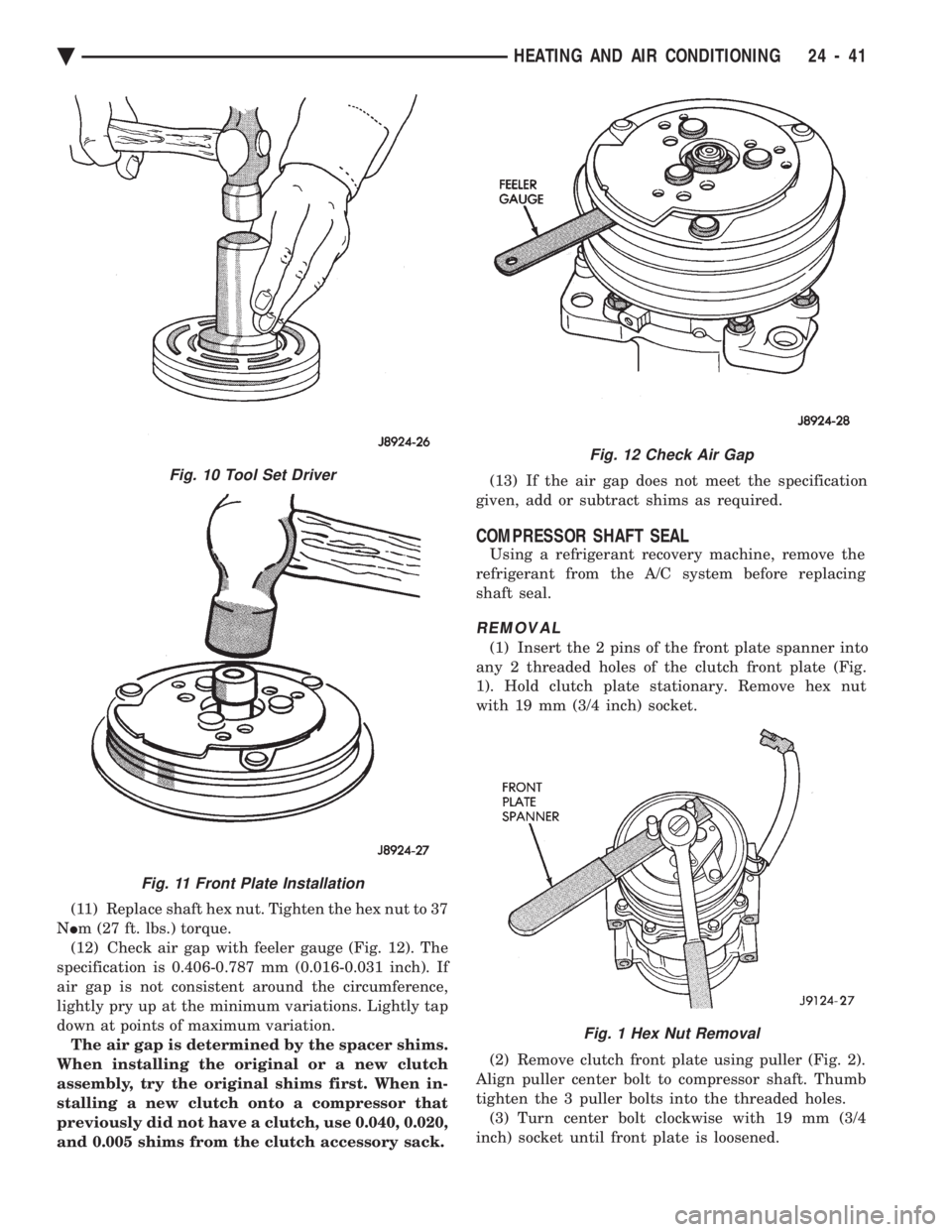

(12) Check air gap with feeler gauge (Fig. 12). The

specification is 0.406-0.787 mm (0.016-0.031 inch). If

air gap is not consistent around the circumference,

lightly pry up at the minimum variations. Lightly tap

down at points of maximum variation. The air gap is determined by the spacer shims.

When installing the original or a new clutch

assembly, try the original shims first. When in-

stalling a new clutch onto a compressor that

previously did not have a clutch, use 0.040, 0.020,

and 0.005 shims from the clutch accessory sack. (13) If the air gap does not meet the specification

given, add or subtract shims as required.

COMPRESSOR SHAFT SEAL

Using a refrigerant recovery machine, remove the

refrigerant from the A/C system before replacing

shaft seal.

REMOVAL

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

1). Hold clutch plate stationary. Remove hex nut

with 19 mm (3/4 inch) socket.

(2) Remove clutch front plate using puller (Fig. 2).

Align puller center bolt to compressor shaft. Thumb

tighten the 3 puller bolts into the threaded holes. (3) Turn center bolt clockwise with 19 mm (3/4

inch) socket until front plate is loosened.

Fig. 12 Check Air Gap

Fig. 1 Hex Nut Removal

Fig. 10 Tool Set Driver

Fig. 11 Front Plate Installation

Ä HEATING AND AIR CONDITIONING 24 - 41

Page 2347 of 2438

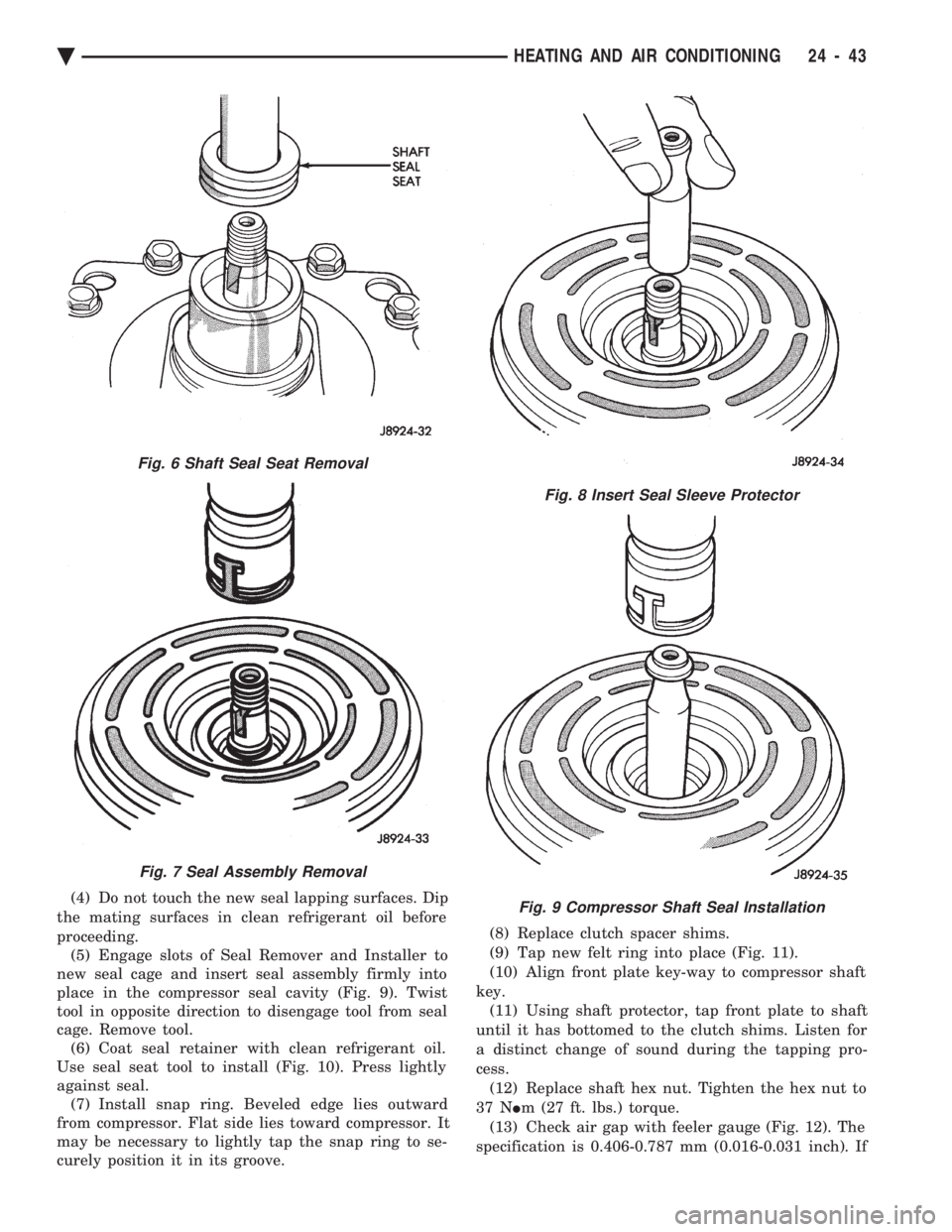

(4) Do not touch the new seal lapping surfaces. Dip

the mating surfaces in clean refrigerant oil before

proceeding. (5) Engage slots of Seal Remover and Installer to

new seal cage and insert seal assembly firmly into

place in the compressor seal cavity (Fig. 9). Twist

tool in opposite direction to disengage tool from seal

cage. Remove tool. (6) Coat seal retainer with clean refrigerant oil.

Use seal seat tool to install (Fig. 10). Press lightly

against seal. (7) Install snap ring. Beveled edge lies outward

from compressor. Flat side lies toward compressor. It

may be necessary to lightly tap the snap ring to se-

curely position it in its groove. (8) Replace clutch spacer shims.

(9) Tap new felt ring into place (Fig. 11).

(10) Align front plate key-way to compressor shaft

key. (11) Using shaft protector, tap front plate to shaft

until it has bottomed to the clutch shims. Listen for

a distinct change of sound during the tapping pro-

cess. (12) Replace shaft hex nut. Tighten the hex nut to

37 N Im (27 ft. lbs.) torque.

(13) Check air gap with feeler gauge (Fig. 12). The

specification is 0.406-0.787 mm (0.016-0.031 inch). If

Fig. 6 Shaft Seal Seat Removal

Fig. 7 Seal Assembly Removal

Fig. 8 Insert Seal Sleeve Protector

Fig. 9 Compressor Shaft Seal Installation

Ä HEATING AND AIR CONDITIONING 24 - 43

Page 2349 of 2438

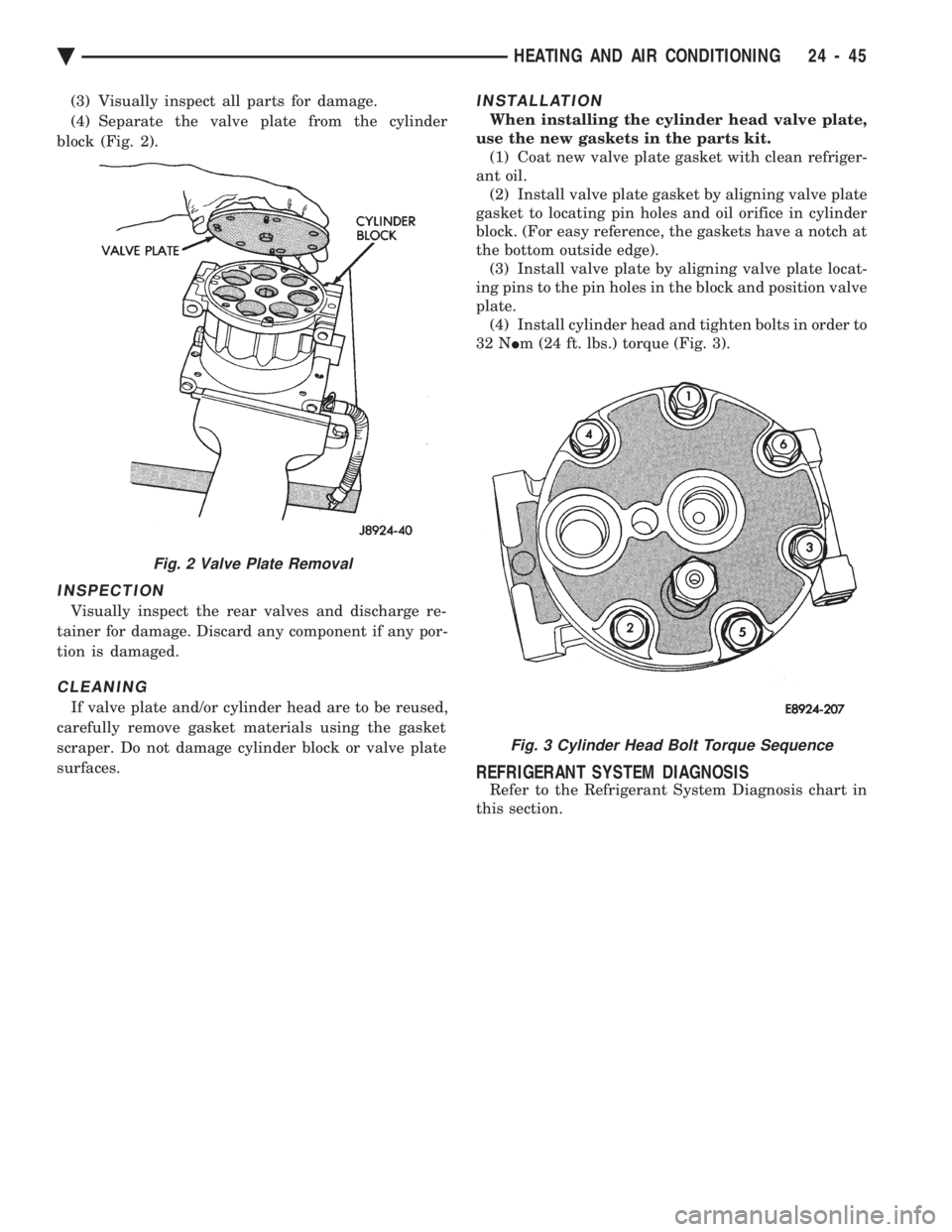

(3) Visually inspect all parts for damage.

(4) Separate the valve plate from the cylinder

block (Fig. 2).

INSPECTION

Visually inspect the rear valves and discharge re-

tainer for damage. Discard any component if any por-

tion is damaged.

CLEANING

If valve plate and/or cylinder head are to be reused,

carefully remove gasket materials using the gasket

scraper. Do not damage cylinder block or valve plate

surfaces.

INSTALLATION

When installing the cylinder head valve plate,

use the new gaskets in the parts kit. (1) Coat new valve plate gasket with clean refriger-

ant oil. (2) Install valve plate gasket by aligning valve plate

gasket to locating pin holes and oil orifice in cylinder

block. (For easy reference, the gaskets have a notch at

the bottom outside edge). (3) Install valve plate by aligning valve plate locat-

ing pins to the pin holes in the block and position valve

plate. (4) Install cylinder head and tighten bolts in order to

32 N Im (24 ft. lbs.) torque (Fig. 3).

REFRIGERANT SYSTEM DIAGNOSIS

Refer to the Refrigerant System Diagnosis chart in

this section.

Fig. 2 Valve Plate Removal

Fig. 3 Cylinder Head Bolt Torque Sequence

Ä HEATING AND AIR CONDITIONING 24 - 45

Page 2408 of 2438

(1) Disconnect oxygen sensor electrical connector.

(2) Remove sensor using Tool C-4907 (Fig. 11).

After removing the sensor, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E

tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctite

771-64 or equivalent. New sensors have compound on

the threads and do not require additional compound.

Tighten the sensor to 27 N Im (20 ft. lbs.) torque.

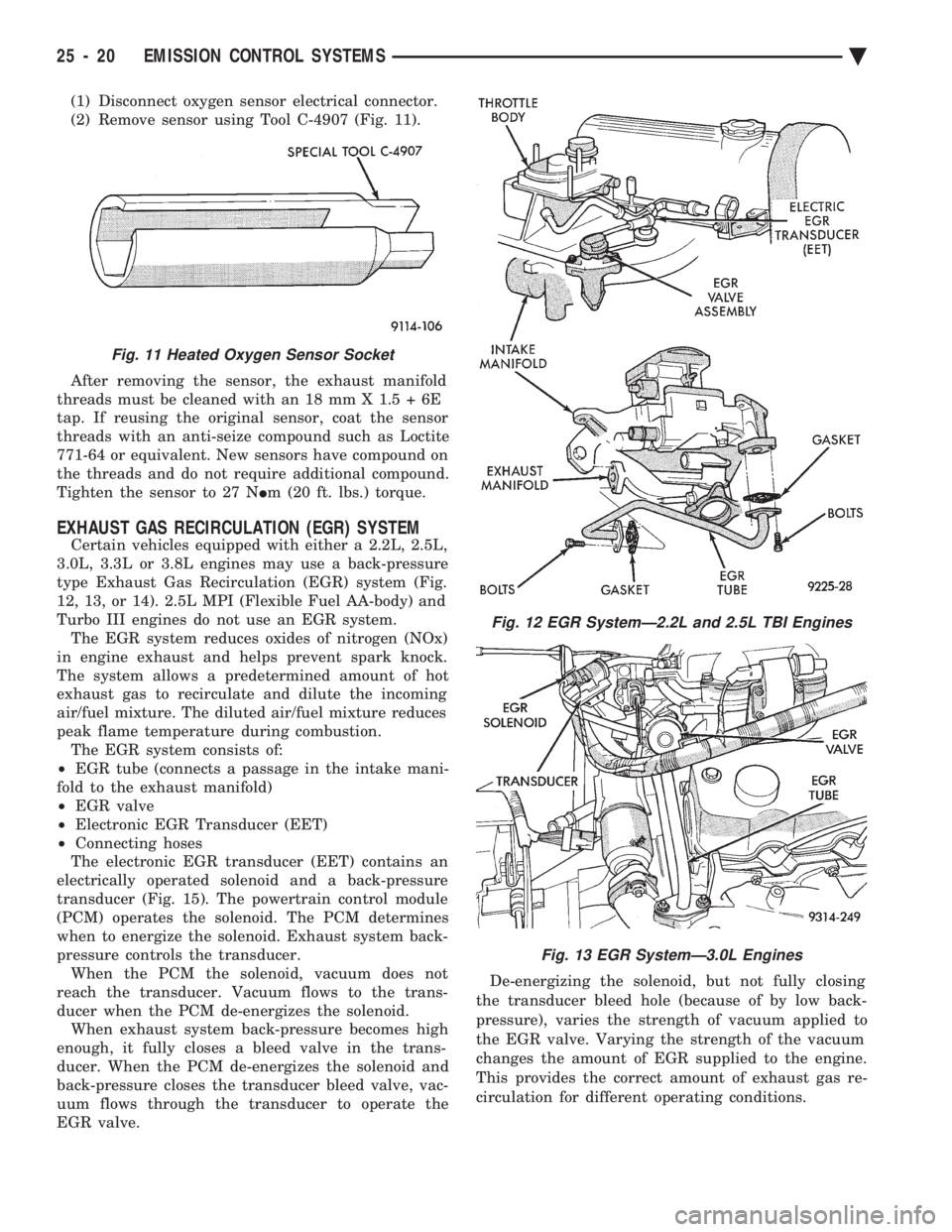

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

Certain vehicles equipped with either a 2.2L, 2.5L,

3.0L, 3.3L or 3.8L engines may use a back-pressure

type Exhaust Gas Recirculation (EGR) system (Fig.

12, 13, or 14). 2.5L MPI (Flexible Fuel AA-body) and

Turbo III engines do not use an EGR system. The EGR system reduces oxides of nitrogen (NOx)

in engine exhaust and helps prevent spark knock.

The system allows a predetermined amount of hot

exhaust gas to recirculate and dilute the incoming

air/fuel mixture. The diluted air/fuel mixture reduces

peak flame temperature during combustion. The EGR system consists of:

² EGR tube (connects a passage in the intake mani-

fold to the exhaust manifold)

² EGR valve

² Electronic EGR Transducer (EET)

² Connecting hoses

The electronic EGR transducer (EET) contains an

electrically operated solenoid and a back-pressure

transducer (Fig. 15). The powertrain control module

(PCM) operates the solenoid. The PCM determines

when to energize the solenoid. Exhaust system back-

pressure controls the transducer. When the PCM the solenoid, vacuum does not

reach the transducer. Vacuum flows to the trans-

ducer when the PCM de-energizes the solenoid. When exhaust system back-pressure becomes high

enough, it fully closes a bleed valve in the trans-

ducer. When the PCM de-energizes the solenoid and

back-pressure closes the transducer bleed valve, vac-

uum flows through the transducer to operate the

EGR valve. De-energizing the solenoid, but not fully closing

the transducer bleed hole (because of by low back-

pressure), varies the strength of vacuum applied to

the EGR valve. Varying the strength of the vacuum

changes the amount of EGR supplied to the engine.

This provides the correct amount of exhaust gas re-

circulation for different operating conditions.

Fig. 11 Heated Oxygen Sensor Socket

Fig. 12 EGR SystemÐ2.2L and 2.5L TBI Engines

Fig. 13 EGR SystemÐ3.0L Engines

25 - 20 EMISSION CONTROL SYSTEMS Ä

Page 2410 of 2438

Engine speed may drop quickly or engine may even

stall. This indicates that EGR gas is flowing through

the system.If both the EGR Gas Flow Check, System Check

and Diagnosis Chart are completed satisfactorily,

then the EGR system functions normally. If engine speed does not drop off when performing

the test, remove both the EGR valve and EGR tube

and check for plugged passages. Also, check the in-

take manifold inlet passage. Clean or replace these

components for restoration of proper flow.

EGR VALVE SERVICEÐ2.2L AND 2.5L TBI

ENGINES

REMOVAL

(1) Disconnect electrical connector and vacuum

line from the electric EGR transducer (Fig. 12). (2) Remove EGR valve bolts from intake manifold.

(3) Remove EGR valve from intake manifold.

(4) Clean gasket surface and discard old gasket.

Check for any signs of leakage or cracked surfaces.

INSTALLATION

(1) Assemble EGR valve with new gasket onto the

intake manifold. (2) Install EGR valve mounting bolts. Tighten to

22 N Im (200 in. lbs.) torque.

(3) Reconnect vacuum line and electrical connector

to Electric EGR Transducer.

EGR TUBE SERVICEÐ2.2L AND 2.5L TBI ENGINES

REMOVAL

(1) Remove EGR tube attaching bolts from intake

and exhaust manifolds. (2) Remove EGR tube.

(3) Clean intake and exhaust manifold gasket sur-

faces and EGR tube flange gasket surfaces. Discard

old gaskets. (4) Check for signs of leakage or cracked surfaces

on either manifolds or tube. Replace as necessary.

INSTALLATION

(1) Loosely position EGR tube and new gaskets in

place on intake and exhaust manifolds. Install

mounting bolts. (2) Tighten attaching bolts to 22 N Im (200 in. lbs.)

torque.

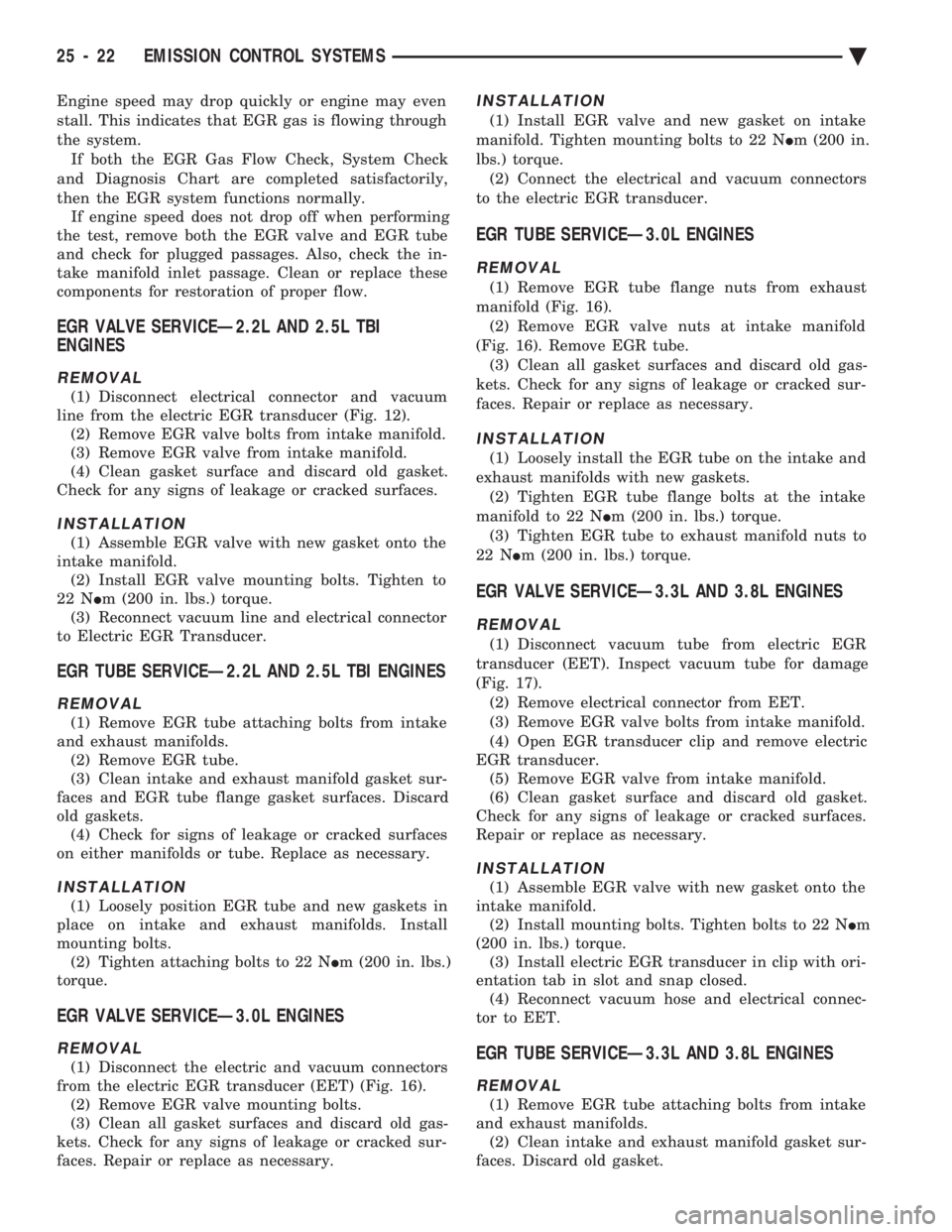

EGR VALVE SERVICEÐ3.0L ENGINES

REMOVAL

(1) Disconnect the electric and vacuum connectors

from the electric EGR transducer (EET) (Fig. 16). (2) Remove EGR valve mounting bolts.

(3) Clean all gasket surfaces and discard old gas-

kets. Check for any signs of leakage or cracked sur-

faces. Repair or replace as necessary.

INSTALLATION

(1) Install EGR valve and new gasket on intake

manifold. Tighten mounting bolts to 22 N Im (200 in.

lbs.) torque. (2) Connect the electrical and vacuum connectors

to the electric EGR transducer.

EGR TUBE SERVICEÐ3.0L ENGINES

REMOVAL

(1) Remove EGR tube flange nuts from exhaust

manifold (Fig. 16). (2) Remove EGR valve nuts at intake manifold

(Fig. 16). Remove EGR tube. (3) Clean all gasket surfaces and discard old gas-

kets. Check for any signs of leakage or cracked sur-

faces. Repair or replace as necessary.

INSTALLATION

(1) Loosely install the EGR tube on the intake and

exhaust manifolds with new gaskets. (2) Tighten EGR tube flange bolts at the intake

manifold to 22 N Im (200 in. lbs.) torque.

(3) Tighten EGR tube to exhaust manifold nuts to

22 N Im (200 in. lbs.) torque.

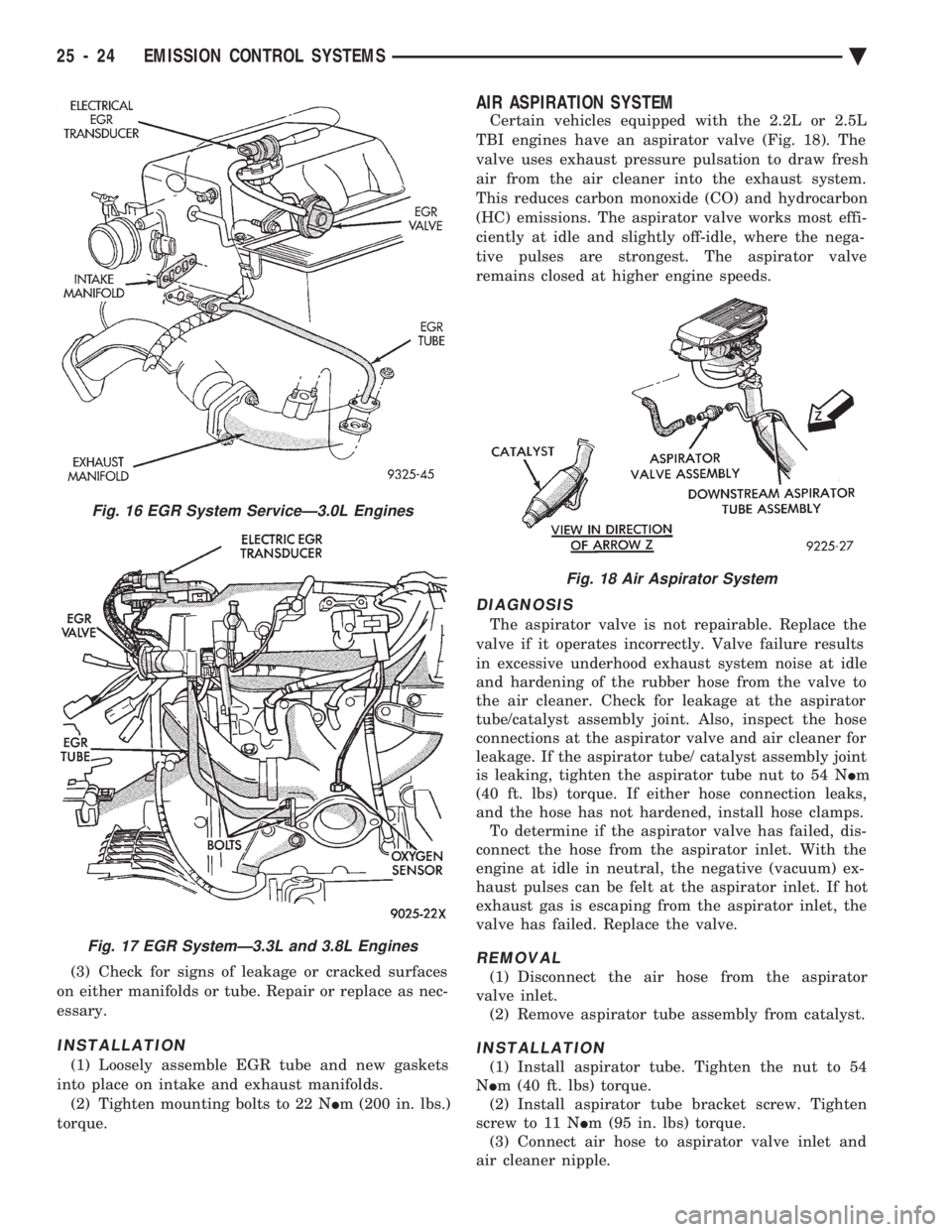

EGR VALVE SERVICEÐ3.3L AND 3.8L ENGINES

REMOVAL

(1) Disconnect vacuum tube from electric EGR

transducer (EET). Inspect vacuum tube for damage

(Fig. 17). (2) Remove electrical connector from EET.

(3) Remove EGR valve bolts from intake manifold.

(4) Open EGR transducer clip and remove electric

EGR transducer. (5) Remove EGR valve from intake manifold.

(6) Clean gasket surface and discard old gasket.

Check for any signs of leakage or cracked surfaces.

Repair or replace as necessary.

INSTALLATION

(1) Assemble EGR valve with new gasket onto the

intake manifold. (2) Install mounting bolts. Tighten bolts to 22 N Im

(200 in. lbs.) torque. (3) Install electric EGR transducer in clip with ori-

entation tab in slot and snap closed. (4) Reconnect vacuum hose and electrical connec-

tor to EET.

EGR TUBE SERVICEÐ3.3L AND 3.8L ENGINES

REMOVAL

(1) Remove EGR tube attaching bolts from intake

and exhaust manifolds. (2) Clean intake and exhaust manifold gasket sur-

faces. Discard old gasket.

25 - 22 EMISSION CONTROL SYSTEMS Ä

Page 2412 of 2438

(3) Check for signs of leakage or cracked surfaces

on either manifolds or tube. Repair or replace as nec-

essary.

INSTALLATION

(1) Loosely assemble EGR tube and new gaskets

into place on intake and exhaust manifolds. (2) Tighten mounting bolts to 22 N Im (200 in. lbs.)

torque.

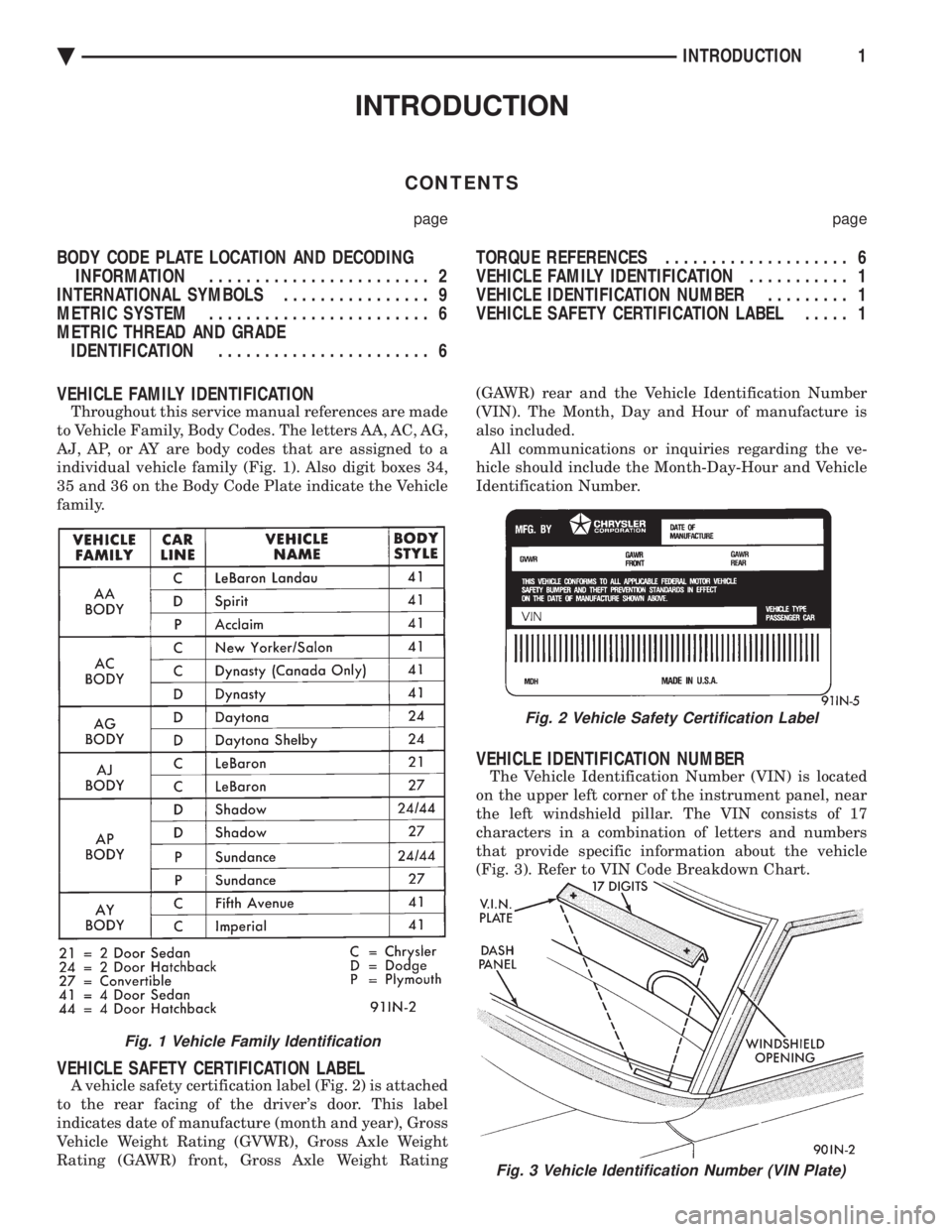

AIR ASPIRATION SYSTEM

Certain vehicles equipped with the 2.2L or 2.5L

TBI engines have an aspirator valve (Fig. 18). The

valve uses exhaust pressure pulsation to draw fresh

air from the air cleaner into the exhaust system.

This reduces carbon monoxide (CO) and hydrocarbon

(HC) emissions. The aspirator valve works most effi-

ciently at idle and slightly off-idle, where the nega-

tive pulses are strongest. The aspirator valve

remains closed at higher engine speeds.

DIAGNOSIS

The aspirator valve is not repairable. Replace the

valve if it operates incorrectly. Valve failure results

in excessive underhood exhaust system noise at idle

and hardening of the rubber hose from the valve to

the air cleaner. Check for leakage at the aspirator

tube/catalyst assembly joint. Also, inspect the hose

connections at the aspirator valve and air cleaner for

leakage. If the aspirator tube/ catalyst assembly joint

is leaking, tighten the aspirator tube nut to 54 N Im

(40 ft. lbs) torque. If either hose connection leaks,

and the hose has not hardened, install hose clamps. To determine if the aspirator valve has failed, dis-

connect the hose from the aspirator inlet. With the

engine at idle in neutral, the negative (vacuum) ex-

haust pulses can be felt at the aspirator inlet. If hot

exhaust gas is escaping from the aspirator inlet, the

valve has failed. Replace the valve.

REMOVAL

(1) Disconnect the air hose from the aspirator

valve inlet. (2) Remove aspirator tube assembly from catalyst.

INSTALLATION

(1) Install aspirator tube. Tighten the nut to 54

N Im (40 ft. lbs) torque.

(2) Install aspirator tube bracket screw. Tighten

screw to 11 N Im (95 in. lbs) torque.

(3) Connect air hose to aspirator valve inlet and

air cleaner nipple.

Fig. 16 EGR System ServiceÐ3.0L Engines

Fig. 17 EGR SystemÐ3.3L and 3.8L Engines

Fig. 18 Air Aspirator System

25 - 24 EMISSION CONTROL SYSTEMS Ä

Page 2416 of 2438

INTRODUCTION

CONTENTS

page page

BODY CODE PLATE LOCATION AND DECODING INFORMATION ........................ 2

INTERNATIONAL SYMBOLS ................ 9

METRIC SYSTEM ........................ 6

METRIC THREAD AND GRADE IDENTIFICATION ....................... 6 TORQUE REFERENCES

.................... 6

VEHICLE FAMILY IDENTIFICATION ........... 1

VEHICLE IDENTIFICATION NUMBER ......... 1

VEHICLE SAFETY CERTIFICATION LABEL ..... 1

VEHICLE FAMILY IDENTIFICATION

Throughout this service manual references are made

to Vehicle Family, Body Codes. The letters AA, AC, AG,

AJ, AP, or AY are body codes that are assigned to a

individual vehicle family (Fig. 1). Also digit boxes 34,

35 and 36 on the Body Code Plate indicate the Vehicle

family.

VEHICLE SAFETY CERTIFICATION LABEL

A vehicle safety certification label (Fig. 2) is attached

to the rear facing of the driver's door. This label

indicates date of manufacture (month and year), Gross

Vehicle Weight Rating (GVWR), Gross Axle Weight

Rating (GAWR) front, Gross Axle Weight Rating (GAWR) rear and the Vehicle Identification Number

(VIN). The Month, Day and Hour of manufacture is

also included. All communications or inquiries regarding the ve-

hicle should include the Month-Day-Hour and Vehicle

Identification Number.

VEHICLE IDENTIFICATION NUMBER

The Vehicle Identification Number (VIN) is located

on the upper left corner of the instrument panel, near

the left windshield pillar. The VIN consists of 17

characters in a combination of letters and numbers

that provide specific information about the vehicle

(Fig. 3). Refer to VIN Code Breakdown Chart.

Fig. 3 Vehicle Identification Number (VIN Plate)

Fig. 1 Vehicle Family Identification

Fig. 2 Vehicle Safety Certification Label

Ä INTRODUCTION1

Page 2421 of 2438

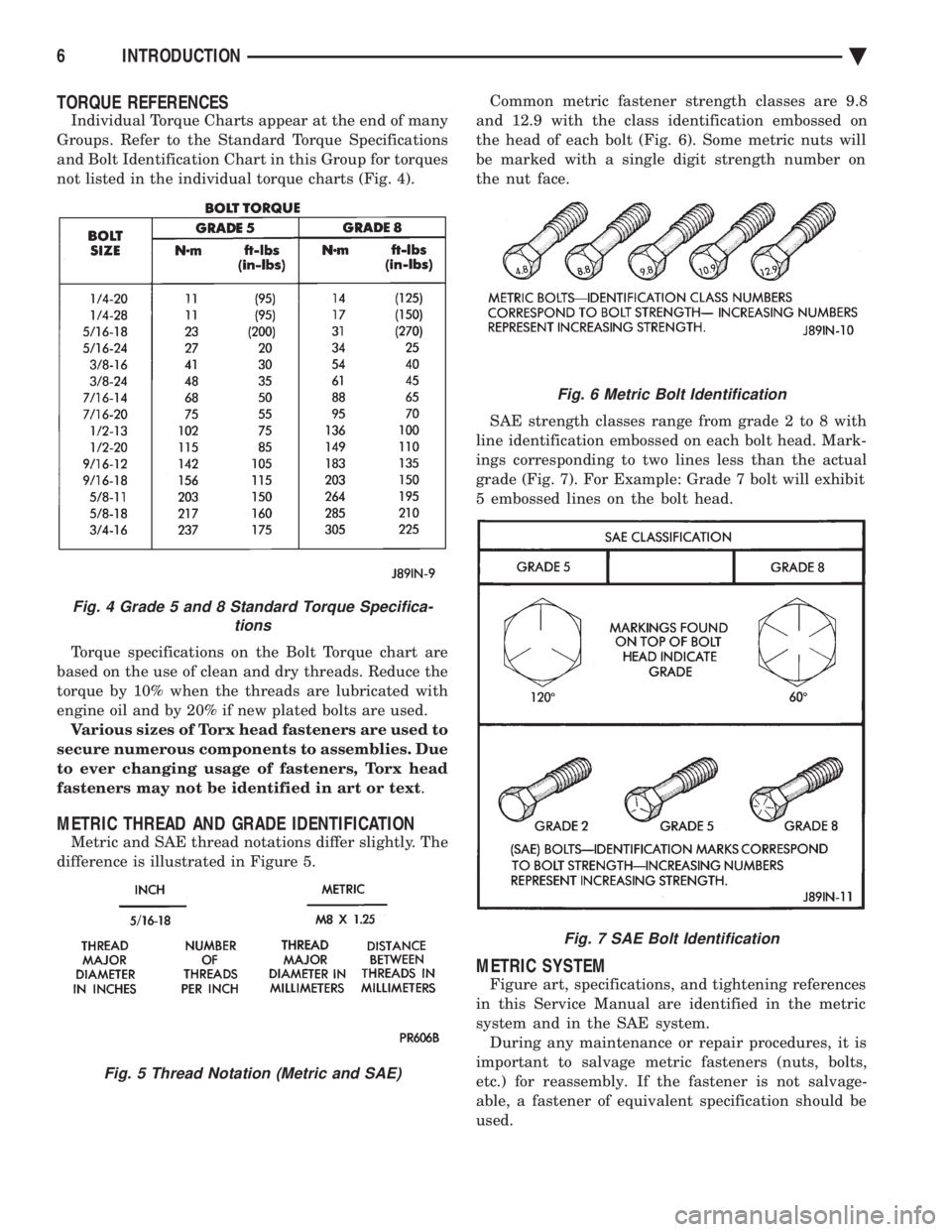

TORQUE REFERENCES

Individual Torque Charts appear at the end of many

Groups. Refer to the Standard Torque Specifications

and Bolt Identification Chart in this Group for torques

not listed in the individual torque charts (Fig. 4).

Torque specifications on the Bolt Torque chart are

based on the use of clean and dry threads. Reduce the

torque by 10% when the threads are lubricated with

engine oil and by 20% if new plated bolts are used. Various sizes of Torx head fasteners are used to

secure numerous components to assemblies. Due

to ever changing usage of fasteners, Torx head

fasteners may not be identified in art or text .

METRIC THREAD AND GRADE IDENTIFICATION

Metric and SAE thread notations differ slightly. The

difference is illustrated in Figure 5. Common metric fastener strength classes are 9.8

and 12.9 with the class identification embossed on

the head of each bolt (Fig. 6). Some metric nuts will

be marked with a single digit strength number on

the nut face.

SAE strength classes range from grade 2 to 8 with

line identification embossed on each bolt head. Mark-

ings corresponding to two lines less than the actual

grade (Fig. 7). For Example: Grade 7 bolt will exhibit

5 embossed lines on the bolt head.

METRIC SYSTEM

Figure art, specifications, and tightening references

in this Service Manual are identified in the metric

system and in the SAE system. During any maintenance or repair procedures, it is

important to salvage metric fasteners (nuts, bolts,

etc.) for reassembly. If the fastener is not salvage-

able, a fastener of equivalent specification should be

used.

Fig. 6 Metric Bolt Identification

Fig. 7 SAE Bolt Identification

Fig. 4 Grade 5 and 8 Standard Torque Specifica- tions

Fig. 5 Thread Notation (Metric and SAE)

6 INTRODUCTION Ä