torque CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 102 of 2438

(3) Swing the bracket into position on the engine and

loosely install the screws through the slotted holes. (4) Push the intermediate shaft assembly into the

transaxle as far as it can travel. Hold the assembly in

this position and tighten the screws (bracket to engine

block) to 54 N Im (40 ft. lbs.) torque. This will ensure

full seal engagement between the journal on the

intermediate shaft and the seal in the transaxle

extension. (5) Distribute a liberal amount of grease in side

spline and pilot bore on bearing end of intermediate

shaft. Use MOPAR Multi-Purpose Lubricant, or

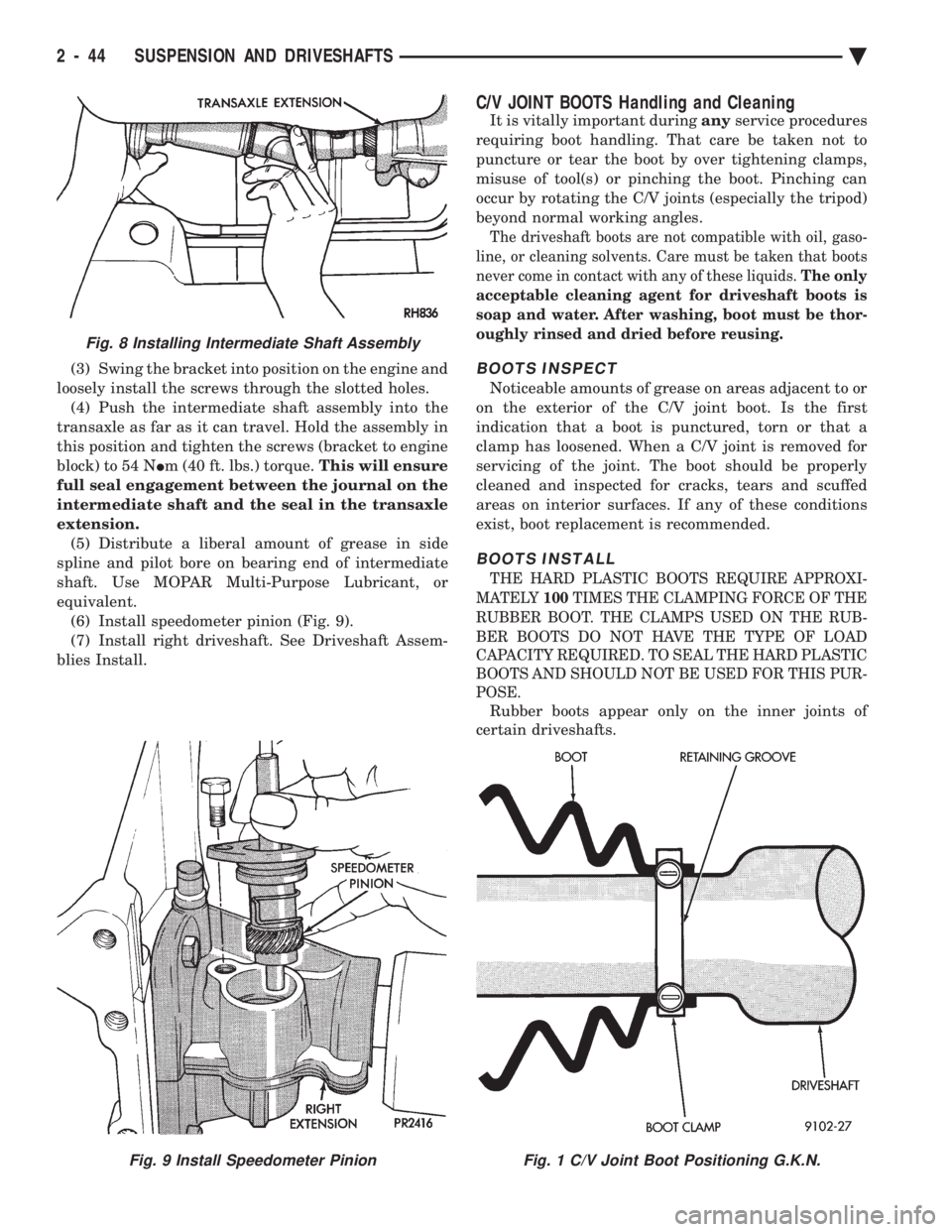

equivalent. (6) Install speedometer pinion (Fig. 9).

(7) Install right driveshaft. See Driveshaft Assem-

blies Install.

C/V JOINT BOOTS Handling and Cleaning

It is vitally important during anyservice procedures

requiring boot handling. That care be taken not to

puncture or tear the boot by over tightening clamps,

misuse of tool(s) or pinching the boot. Pinching can

occur by rotating the C/V joints (especially the tripod)

beyond normal working angles.

The driveshaft boots are not compatible with oil, gaso-

line, or cleaning solvents. Care must be taken that boots

never come in contact with any of these liquids. The only

acceptable cleaning agent for driveshaft boots is

soap and water. After washing, boot must be thor-

oughly rinsed and dried before reusing.

BOOTS INSPECT

Noticeable amounts of grease on areas adjacent to or

on the exterior of the C/V joint boot. Is the first

indication that a boot is punctured, torn or that a

clamp has loosened. When a C/V joint is removed for

servicing of the joint. The boot should be properly

cleaned and inspected for cracks, tears and scuffed

areas on interior surfaces. If any of these conditions

exist, boot replacement is recommended.

BOOTS INSTALL

THE HARD PLASTIC BOOTS REQUIRE APPROXI-

MATELY 100TIMES THE CLAMPING FORCE OF THE

RUBBER BOOT. THE CLAMPS USED ON THE RUB-

BER BOOTS DO NOT HAVE THE TYPE OF LOAD

CAPACITY REQUIRED. TO SEAL THE HARD PLASTIC

BOOTS AND SHOULD NOT BE USED FOR THIS PUR-

POSE.

Rubber boots appear only on the inner joints of

certain driveshafts.

Fig. 9 Install Speedometer PinionFig. 1 C/V Joint Boot Positioning G.K.N.

Fig. 8 Installing Intermediate Shaft Assembly

2 - 44 SUSPENSION AND DRIVESHAFTS Ä

Page 109 of 2438

to the road surface. While being able to twist as one

wheel moves vertically with respect to the other.Roll resistance is provided partly by the axle's re-

sistance to twist. But primarily by a torque tube or

rod (depending on the suspension option called for)

running through the channel and attached rigidly to

its end plates by welding. Because the torque tube/

rod is an integral part of the axle assembly, it cannot

be individually replaced. The spindles are bolted to the axle end (spindle

mounting) plates and can be individually replaced if

required. Rear wheel alignment changes require the

use of shims between the spindle and axle end plates.

SHOCK ABSORBERS

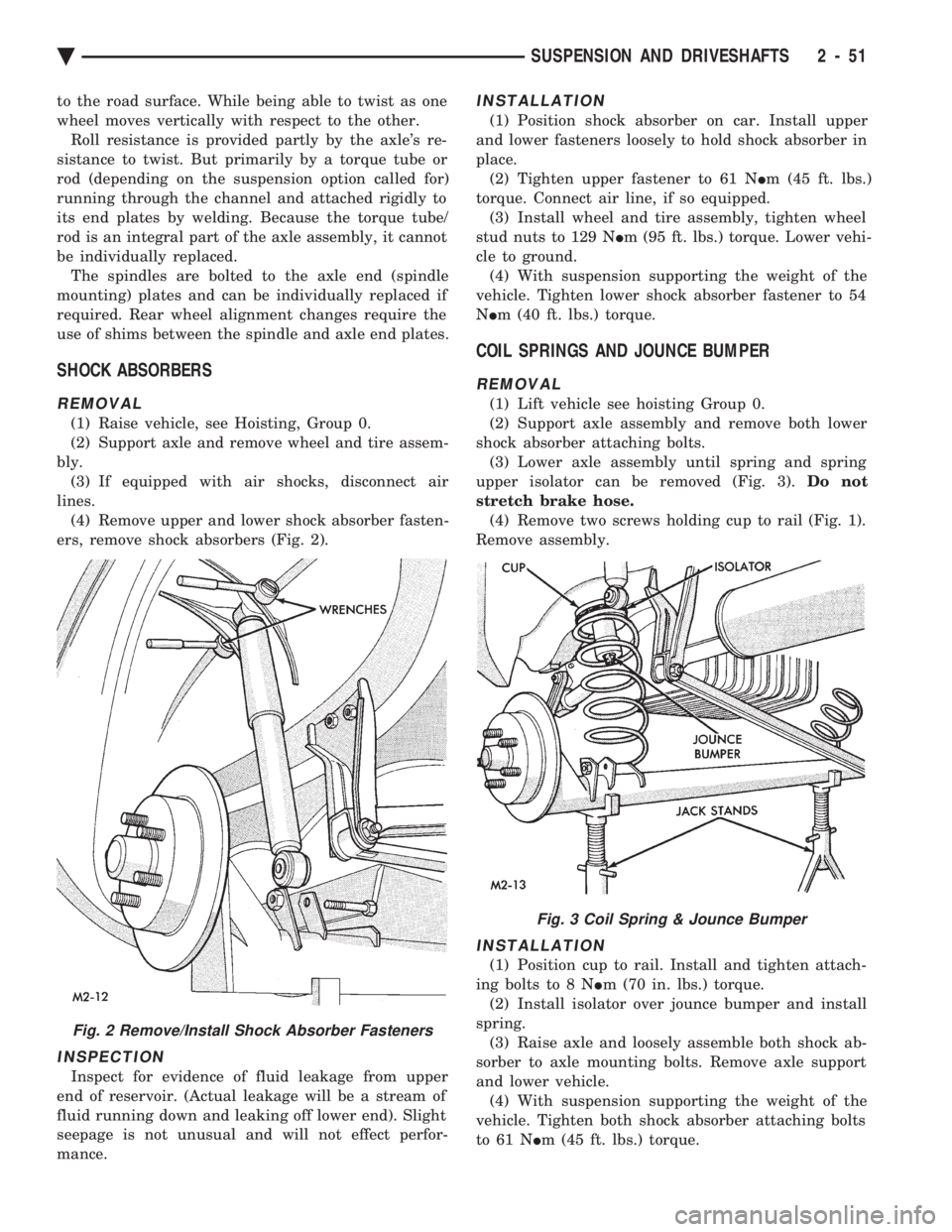

REMOVAL

(1) Raise vehicle, see Hoisting, Group 0.

(2) Support axle and remove wheel and tire assem-

bly. (3) If equipped with air shocks, disconnect air

lines. (4) Remove upper and lower shock absorber fasten-

ers, remove shock absorbers (Fig. 2).

INSPECTION

Inspect for evidence of fluid leakage from upper

end of reservoir. (Actual leakage will be a stream of

fluid running down and leaking off lower end). Slight

seepage is not unusual and will not effect perfor-

mance.

INSTALLATION

(1) Position shock absorber on car. Install upper

and lower fasteners loosely to hold shock absorber in

place. (2) Tighten upper fastener to 61 N Im (45 ft. lbs.)

torque. Connect air line, if so equipped. (3) Install wheel and tire assembly, tighten wheel

stud nuts to 129 N Im (95 ft. lbs.) torque. Lower vehi-

cle to ground. (4) With suspension supporting the weight of the

vehicle. Tighten lower shock absorber fastener to 54

N Im (40 ft. lbs.) torque.

COIL SPRINGS AND JOUNCE BUMPER

REMOVAL

(1) Lift vehicle see hoisting Group 0.

(2) Support axle assembly and remove both lower

shock absorber attaching bolts. (3) Lower axle assembly until spring and spring

upper isolator can be removed (Fig. 3). Do not

stretch brake hose. (4) Remove two screws holding cup to rail (Fig. 1).

Remove assembly.

INSTALLATION

(1) Position cup to rail. Install and tighten attach-

ing bolts to 8 N Im (70 in. lbs.) torque.

(2) Install isolator over jounce bumper and install

spring. (3) Raise axle and loosely assemble both shock ab-

sorber to axle mounting bolts. Remove axle support

and lower vehicle. (4) With suspension supporting the weight of the

vehicle. Tighten both shock absorber attaching bolts

to 61 N Im (45 ft. lbs.) torque.

Fig. 2 Remove/Install Shock Absorber Fasteners

Fig. 3 Coil Spring & Jounce Bumper

Ä SUSPENSION AND DRIVESHAFTS 2 - 51

Page 110 of 2438

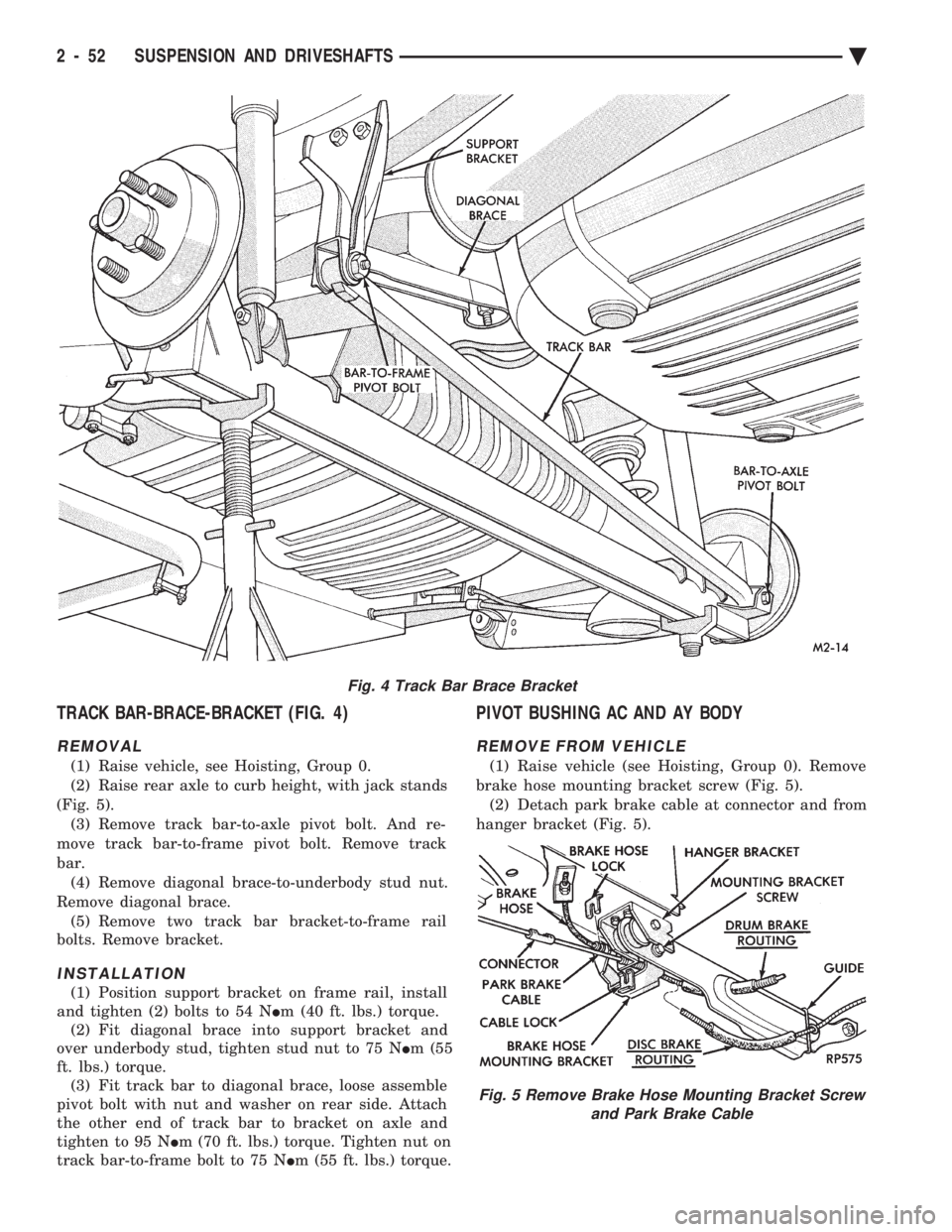

TRACK BAR-BRACE-BRACKET (FIG. 4)

REMOVAL

(1) Raise vehicle, see Hoisting, Group 0.

(2) Raise rear axle to curb height, with jack stands

(Fig. 5). (3) Remove track bar-to-axle pivot bolt. And re-

move track bar-to-frame pivot bolt. Remove track

bar. (4) Remove diagonal brace-to-underbody stud nut.

Remove diagonal brace. (5) Remove two track bar bracket-to-frame rail

bolts. Remove bracket.

INSTALLATION

(1) Position support bracket on frame rail, install

and tighten (2) bolts to 54 N Im (40 ft. lbs.) torque.

(2) Fit diagonal brace into support bracket and

over underbody stud, tighten stud nut to 75 N Im (55

ft. lbs.) torque. (3) Fit track bar to diagonal brace, loose assemble

pivot bolt with nut and washer on rear side. Attach

the other end of track bar to bracket on axle and

tighten to 95 N Im (70 ft. lbs.) torque. Tighten nut on

track bar-to-frame bolt to 75 N Im (55 ft. lbs.) torque.

PIVOT BUSHING AC AND AY BODY

REMOVE FROM VEHICLE

(1) Raise vehicle (see Hoisting, Group 0). Remove

brake hose mounting bracket screw (Fig. 5). (2) Detach park brake cable at connector and from

hanger bracket (Fig. 5).

Fig. 4 Track Bar Brace Bracket

Fig. 5 Remove Brake Hose Mounting Bracket Screw and Park Brake Cable

2 - 52 SUSPENSION AND DRIVESHAFTS Ä

Page 111 of 2438

WARNING: WHEN REMOVING THE REAR AXLE

PIVOT BUSHING ON VEHICLES EQUIPPED WITH EI-

THER REAR COIL SPRINGS OR AIR SUSPENSION.

THE REAR AXLE MUST BE SUPPORTED BY THE

AXLE AND TRAILING ARM TO ENSURE ADEQUATE

SUPPORT OF REAR AXLE.

(3) Support the rear axle assembly at both the axle

channel and the trailing arm (Fig. 6). Then remove

lower shock absorber to rear axle mounting bolt (Fig.

6).

(4) Remove hanger bracket to frame rail bolts (Fig.

7).

(5) Lower axle assembly down enough to remove

pivot bolt and hanger bracket (Fig. 7). Right side

trailing arm shown.

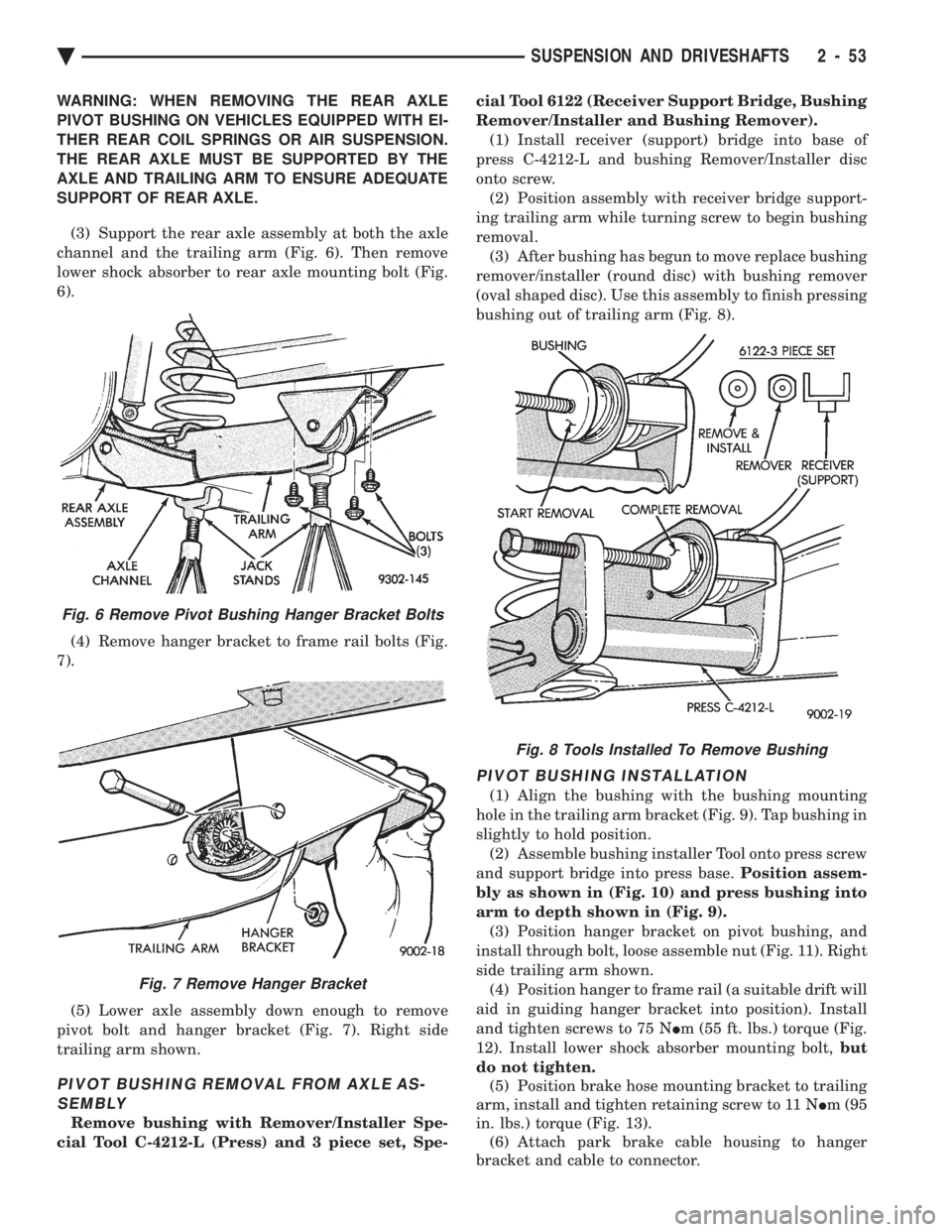

PIVOT BUSHING REMOVAL FROM AXLE AS- SEMBLY

Remove bushing with Remover/Installer Spe-

cial Tool C-4212-L (Press) and 3 piece set, Spe- cial Tool 6122 (Receiver Support Bridge, Bushing

Remover/Installer and Bushing Remover). (1) Install receiver (support) bridge into base of

press C-4212-L and bushing Remover/Installer disc

onto screw. (2) Position assembly with receiver bridge support-

ing trailing arm while turning screw to begin bushing

removal. (3) After bushing has begun to move replace bushing

remover/installer (round disc) with bushing remover

(oval shaped disc). Use this assembly to finish pressing

bushing out of trailing arm (Fig. 8).

PIVOT BUSHING INSTALLATION

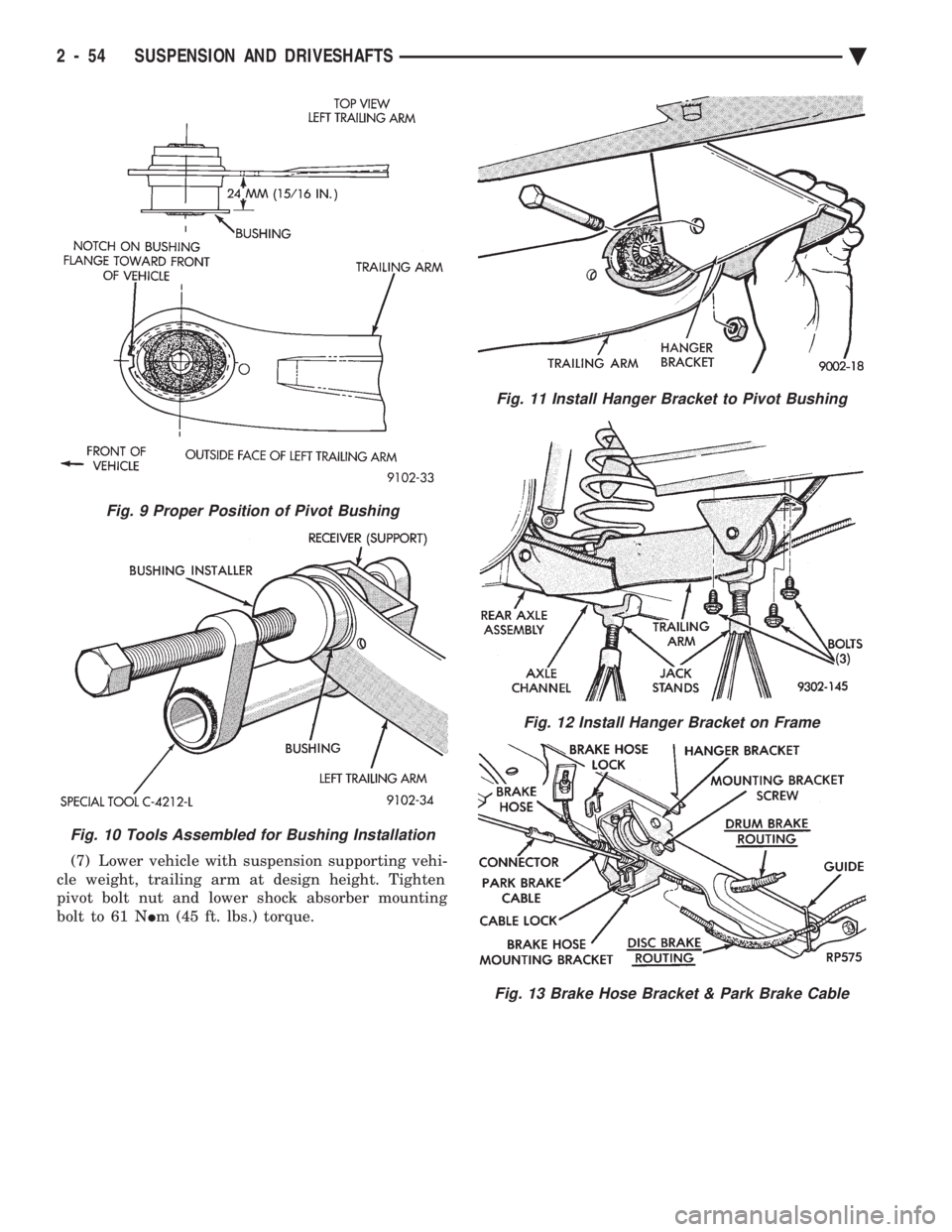

(1) Align the bushing with the bushing mounting

hole in the trailing arm bracket (Fig. 9). Tap bushing in

slightly to hold position. (2) Assemble bushing installer Tool onto press screw

and support bridge into press base. Position assem-

bly as shown in (Fig. 10) and press bushing into

arm to depth shown in (Fig. 9). (3) Position hanger bracket on pivot bushing, and

install through bolt, loose assemble nut (Fig. 11). Right

side trailing arm shown. (4) Position hanger to frame rail (a suitable drift will

aid in guiding hanger bracket into position). Install

and tighten screws to 75 N Im (55 ft. lbs.) torque (Fig.

12). Install lower shock absorber mounting bolt, but

do not tighten. (5) Position brake hose mounting bracket to trailing

arm, install and tighten retaining screw to 11 N Im (95

in. lbs.) torque (Fig. 13). (6) Attach park brake cable housing to hanger

bracket and cable to connector.

Fig. 8 Tools Installed To Remove Bushing

Fig. 6 Remove Pivot Bushing Hanger Bracket Bolts

Fig. 7 Remove Hanger Bracket

Ä SUSPENSION AND DRIVESHAFTS 2 - 53

Page 112 of 2438

(7) Lower vehicle with suspension supporting vehi-

cle weight, trailing arm at design height. Tighten

pivot bolt nut and lower shock absorber mounting

bolt to 61 N Im (45 ft. lbs.) torque.

Fig. 9 Proper Position of Pivot Bushing

Fig. 10 Tools Assembled for Bushing Installation

Fig. 11 Install Hanger Bracket to Pivot Bushing

Fig. 12 Install Hanger Bracket on Frame

Fig. 13 Brake Hose Bracket & Park Brake Cable

2 - 54 SUSPENSION AND DRIVESHAFTS Ä

Page 114 of 2438

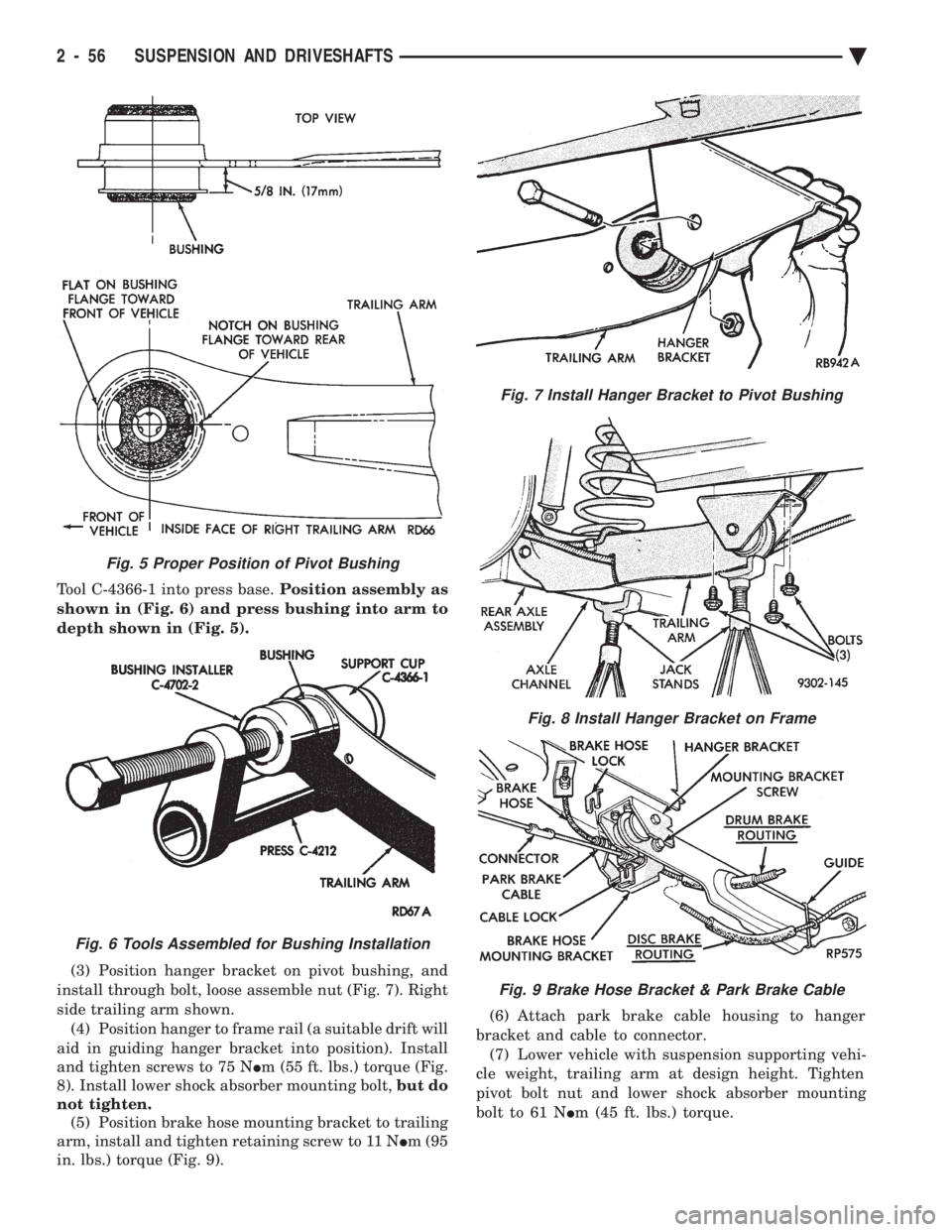

Tool C-4366-1 into press base. Position assembly as

shown in (Fig. 6) and press bushing into arm to

depth shown in (Fig. 5).

(3) Position hanger bracket on pivot bushing, and

install through bolt, loose assemble nut (Fig. 7). Right

side trailing arm shown. (4) Position hanger to frame rail (a suitable drift will

aid in guiding hanger bracket into position). Install

and tighten screws to 75 N Im (55 ft. lbs.) torque (Fig.

8). Install lower shock absorber mounting bolt, but do

not tighten. (5) Position brake hose mounting bracket to trailing

arm, install and tighten retaining screw to 11 N Im (95

in. lbs.) torque (Fig. 9). (6) Attach park brake cable housing to hanger

bracket and cable to connector. (7) Lower vehicle with suspension supporting vehi-

cle weight, trailing arm at design height. Tighten

pivot bolt nut and lower shock absorber mounting

bolt to 61 N Im (45 ft. lbs.) torque.

Fig. 7 Install Hanger Bracket to Pivot Bushing

Fig. 8 Install Hanger Bracket on Frame

Fig. 9 Brake Hose Bracket & Park Brake Cable

Fig. 5 Proper Position of Pivot Bushing

Fig. 6 Tools Assembled for Bushing Installation

2 - 56 SUSPENSION AND DRIVESHAFTS Ä

Page 115 of 2438

REAR AXLE ASSEMBLY

REMOVE

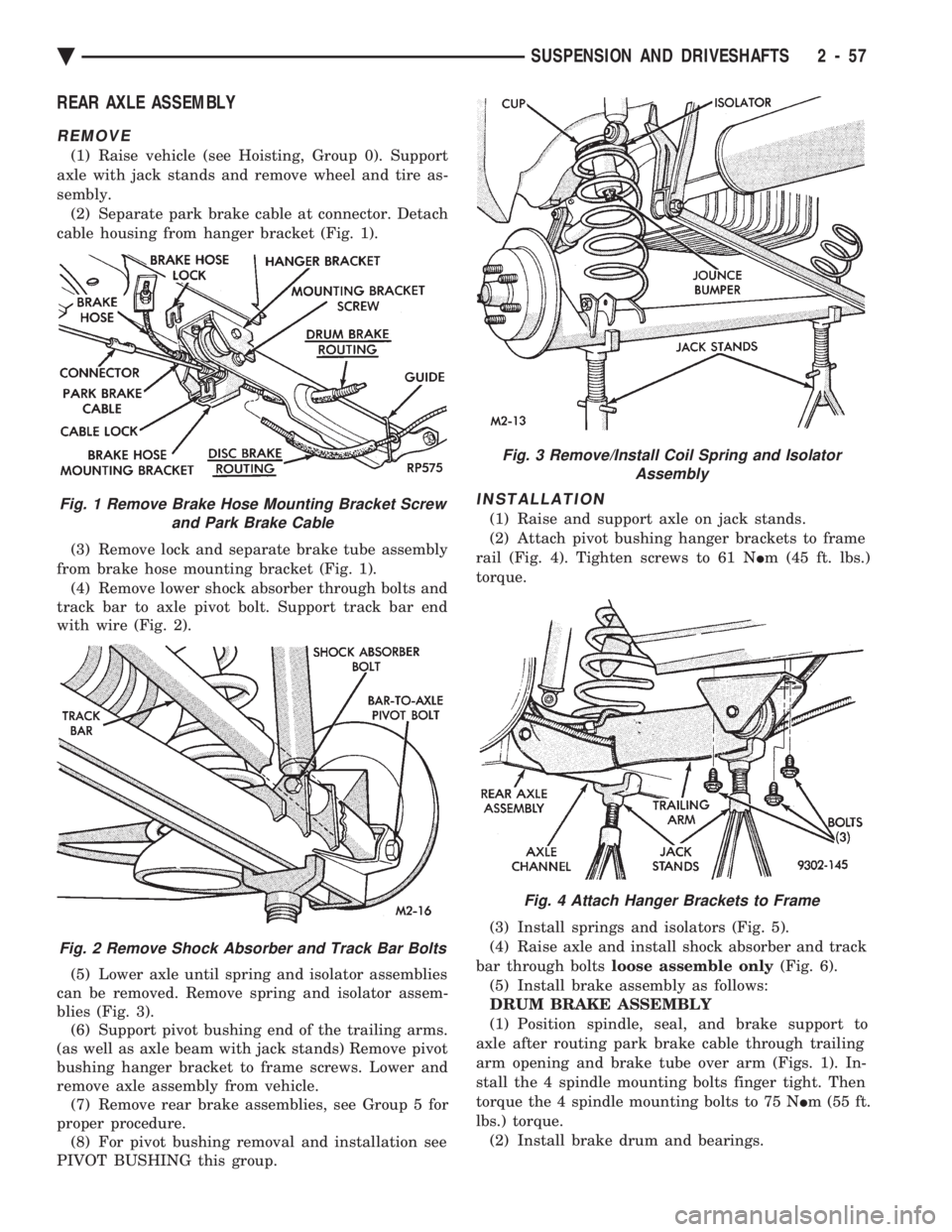

(1) Raise vehicle (see Hoisting, Group 0). Support

axle with jack stands and remove wheel and tire as-

sembly. (2) Separate park brake cable at connector. Detach

cable housing from hanger bracket (Fig. 1).

(3) Remove lock and separate brake tube assembly

from brake hose mounting bracket (Fig. 1). (4) Remove lower shock absorber through bolts and

track bar to axle pivot bolt. Support track bar end

with wire (Fig. 2).

(5) Lower axle until spring and isolator assemblies

can be removed. Remove spring and isolator assem-

blies (Fig. 3). (6) Support pivot bushing end of the trailing arms.

(as well as axle beam with jack stands) Remove pivot

bushing hanger bracket to frame screws. Lower and

remove axle assembly from vehicle. (7) Remove rear brake assemblies, see Group 5 for

proper procedure. (8) For pivot bushing removal and installation see

PIVOT BUSHING this group.

INSTALLATION

(1) Raise and support axle on jack stands.

(2) Attach pivot bushing hanger brackets to frame

rail (Fig. 4). Tighten screws to 61 N Im (45 ft. lbs.)

torque.

(3) Install springs and isolators (Fig. 5).

(4) Raise axle and install shock absorber and track

bar through bolts loose assemble only (Fig. 6).

(5) Install brake assembly as follows:

DRUM BRAKE ASSEMBLY

(1) Position spindle, seal, and brake support to

axle after routing park brake cable through trailing

arm opening and brake tube over arm (Figs. 1). In-

stall the 4 spindle mounting bolts finger tight. Then

torque the 4 spindle mounting bolts to 75 N Im (55 ft.

lbs.) torque. (2) Install brake drum and bearings.Fig. 1 Remove Brake Hose Mounting Bracket Screw and Park Brake Cable

Fig. 2 Remove Shock Absorber and Track Bar Bolts

Fig. 3 Remove/Install Coil Spring and Isolator Assembly

Fig. 4 Attach Hanger Brackets to Frame

Ä SUSPENSION AND DRIVESHAFTS 2 - 57

Page 116 of 2438

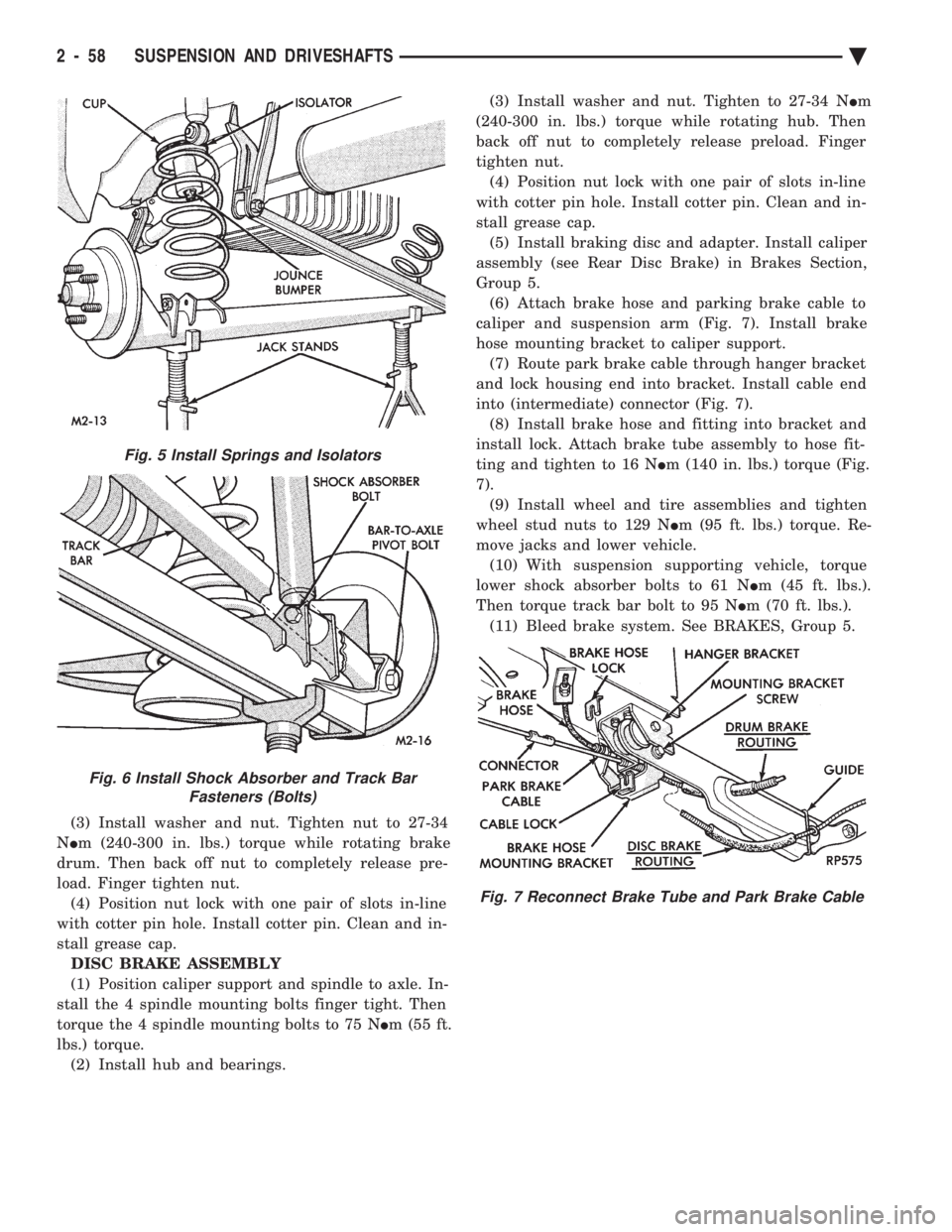

(3) Install washer and nut. Tighten nut to 27-34

N Im (240-300 in. lbs.) torque while rotating brake

drum. Then back off nut to completely release pre-

load. Finger tighten nut. (4) Position nut lock with one pair of slots in-line

with cotter pin hole. Install cotter pin. Clean and in-

stall grease cap. DISC BRAKE ASSEMBLY

(1) Position caliper support and spindle to axle. In-

stall the 4 spindle mounting bolts finger tight. Then

torque the 4 spindle mounting bolts to 75 N Im (55 ft.

lbs.) torque. (2) Install hub and bearings. (3) Install washer and nut. Tighten to 27-34 N

Im

(240-300 in. lbs.) torque while rotating hub. Then

back off nut to completely release preload. Finger

tighten nut. (4) Position nut lock with one pair of slots in-line

with cotter pin hole. Install cotter pin. Clean and in-

stall grease cap. (5) Install braking disc and adapter. Install caliper

assembly (see Rear Disc Brake) in Brakes Section,

Group 5. (6) Attach brake hose and parking brake cable to

caliper and suspension arm (Fig. 7). Install brake

hose mounting bracket to caliper support. (7) Route park brake cable through hanger bracket

and lock housing end into bracket. Install cable end

into (intermediate) connector (Fig. 7). (8) Install brake hose and fitting into bracket and

install lock. Attach brake tube assembly to hose fit-

ting and tighten to 16 N Im (140 in. lbs.) torque (Fig.

7). (9) Install wheel and tire assemblies and tighten

wheel stud nuts to 129 N Im (95 ft. lbs.) torque. Re-

move jacks and lower vehicle. (10) With suspension supporting vehicle, torque

lower shock absorber bolts to 61 N Im (45 ft. lbs.).

Then torque track bar bolt to 95 N Im (70 ft. lbs.).

(11) Bleed brake system. See BRAKES, Group 5.

Fig. 5 Install Springs and Isolators

Fig. 6 Install Shock Absorber and Track Bar Fasteners (Bolts)

Fig. 7 Reconnect Brake Tube and Park Brake Cable

2 - 58 SUSPENSION AND DRIVESHAFTS Ä

Page 120 of 2438

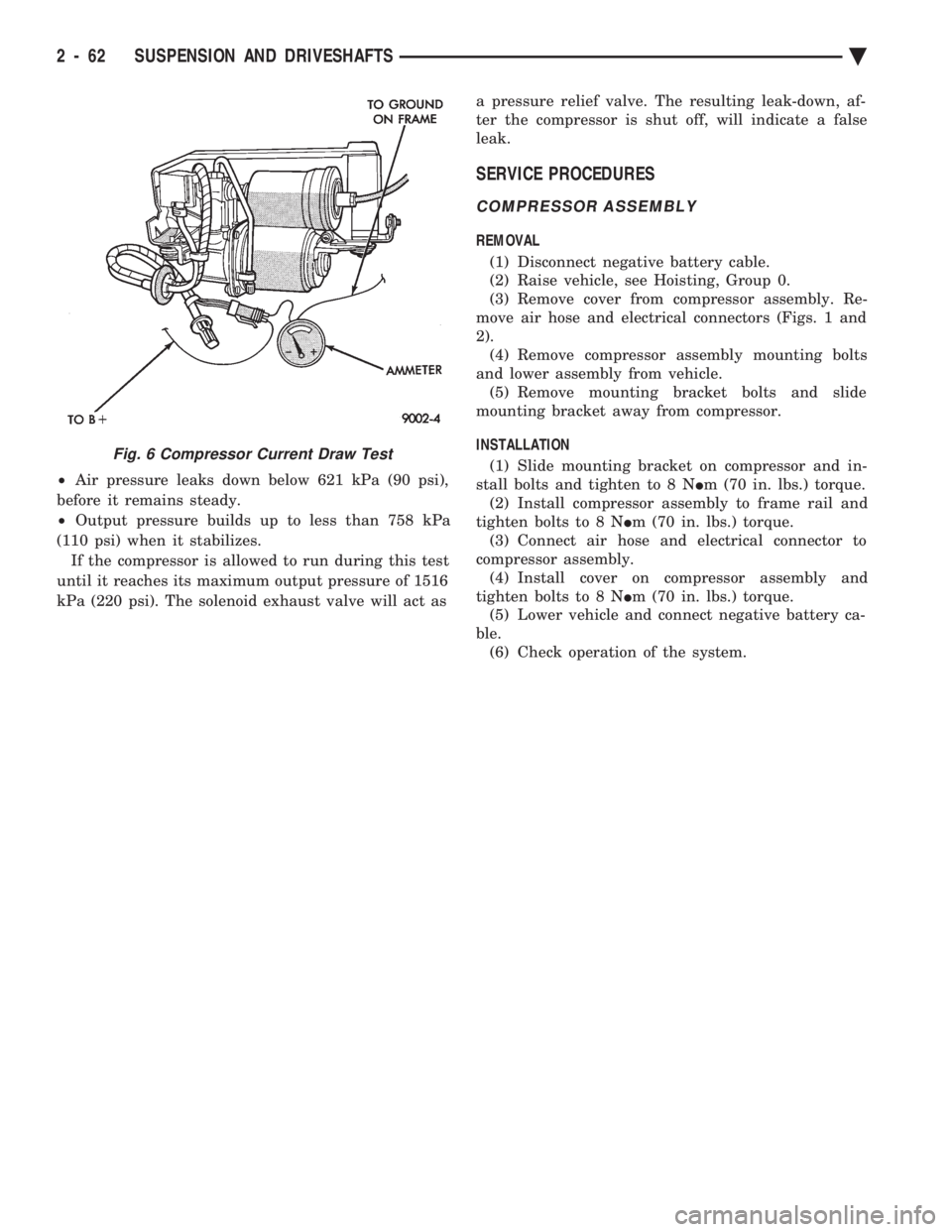

² Air pressure leaks down below 621 kPa (90 psi),

before it remains steady.

² Output pressure builds up to less than 758 kPa

(110 psi) when it stabilizes. If the compressor is allowed to run during this test

until it reaches its maximum output pressure of 1516

kPa (220 psi). The solenoid exhaust valve will act as a pressure relief valve. The resulting leak-down, af-

ter the compressor is shut off, will indicate a false

leak.

SERVICE PROCEDURES

COMPRESSOR ASSEMBLY

REMOVAL

(1) Disconnect negative battery cable.

(2) Raise vehicle, see Hoisting, Group 0.

(3) Remove cover from compressor assembly. Re-

move air hose and electrical connectors (Figs. 1 and

2). (4) Remove compressor assembly mounting bolts

and lower assembly from vehicle. (5) Remove mounting bracket bolts and slide

mounting bracket away from compressor.

INSTALLATION (1) Slide mounting bracket on compressor and in-

stall bolts and tighten to 8 N Im (70 in. lbs.) torque.

(2) Install compressor assembly to frame rail and

tighten bolts to 8 N Im (70 in. lbs.) torque.

(3) Connect air hose and electrical connector to

compressor assembly. (4) Install cover on compressor assembly and

tighten bolts to 8 N Im (70 in. lbs.) torque.

(5) Lower vehicle and connect negative battery ca-

ble. (6) Check operation of the system.

Fig. 6 Compressor Current Draw Test

2 - 62 SUSPENSION AND DRIVESHAFTS Ä

Page 143 of 2438

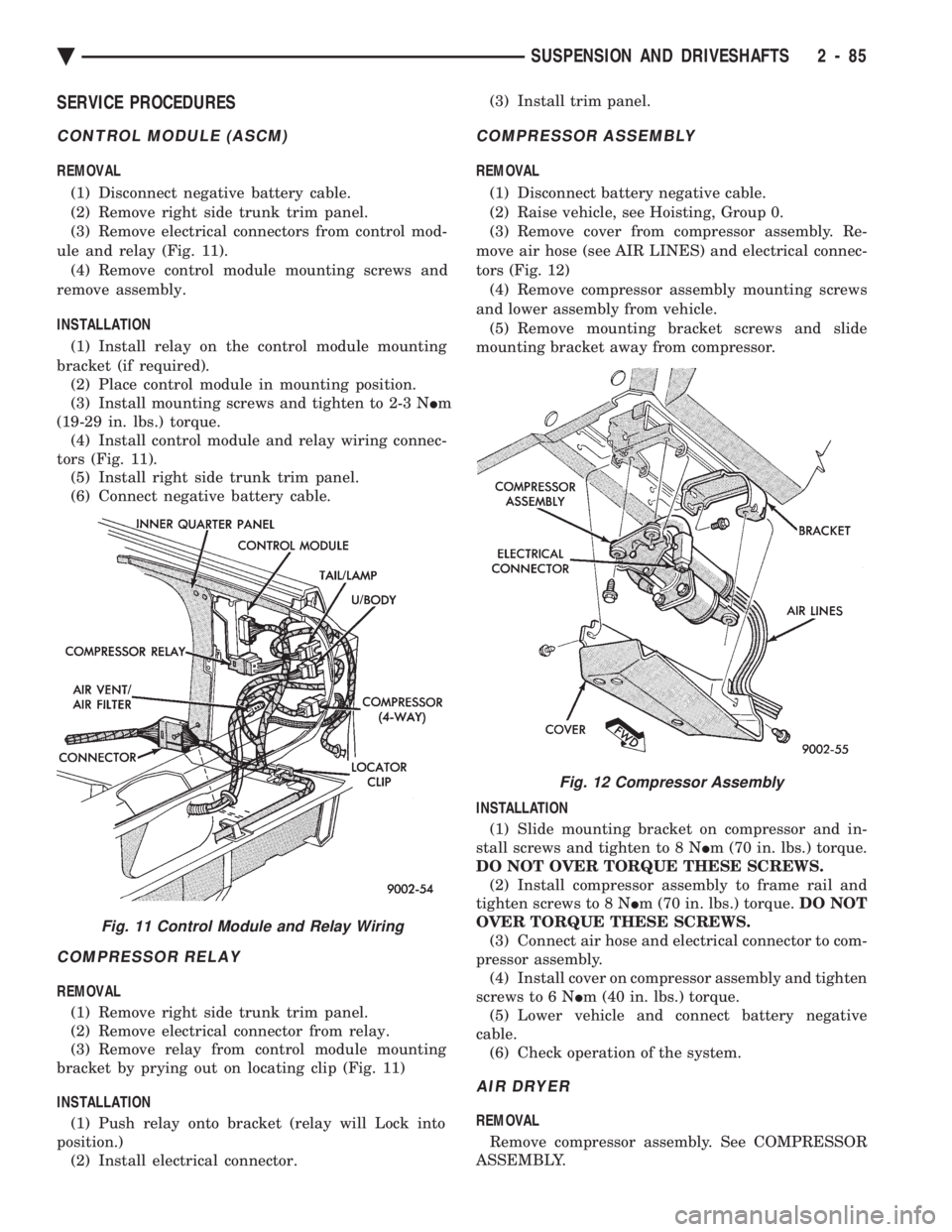

SERVICE PROCEDURES

CONTROL MODULE (ASCM)

REMOVAL (1) Disconnect negative battery cable.

(2) Remove right side trunk trim panel.

(3) Remove electrical connectors from control mod-

ule and relay (Fig. 11). (4) Remove control module mounting screws and

remove assembly.

INSTALLATION

(1) Install relay on the control module mounting

bracket (if required). (2) Place control module in mounting position.

(3) Install mounting screws and tighten to 2-3 N Im

(19-29 in. lbs.) torque. (4) Install control module and relay wiring connec-

tors (Fig. 11). (5) Install right side trunk trim panel.

(6) Connect negative battery cable.

COMPRESSOR RELAY

REMOVAL

(1) Remove right side trunk trim panel.

(2) Remove electrical connector from relay.

(3) Remove relay from control module mounting

bracket by prying out on locating clip (Fig. 11)

INSTALLATION (1) Push relay onto bracket (relay will Lock into

position.) (2) Install electrical connector. (3) Install trim panel.

COMPRESSOR ASSEMBLY

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle, see Hoisting, Group 0.

(3) Remove cover from compressor assembly. Re-

move air hose (see AIR LINES) and electrical connec-

tors (Fig. 12) (4) Remove compressor assembly mounting screws

and lower assembly from vehicle. (5) Remove mounting bracket screws and slide

mounting bracket away from compressor.

INSTALLATION (1) Slide mounting bracket on compressor and in-

stall screws and tighten to 8 N Im (70 in. lbs.) torque.

DO NOT OVER TORQUE THESE SCREWS. (2) Install compressor assembly to frame rail and

tighten screws to 8 N Im (70 in. lbs.) torque. DO NOT

OVER TORQUE THESE SCREWS. (3) Connect air hose and electrical connector to com-

pressor assembly. (4) Install cover on compressor assembly and tighten

screws to 6 N Im (40 in. lbs.) torque.

(5) Lower vehicle and connect battery negative

cable. (6) Check operation of the system.

AIR DRYER

REMOVAL

Remove compressor assembly. See COMPRESSOR

ASSEMBLY.

Fig. 11 Control Module and Relay Wiring

Fig. 12 Compressor Assembly

Ä SUSPENSION AND DRIVESHAFTS 2 - 85