brake sensor CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 453 of 2438

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES

INDEX

page page

Coolant Temperature Sensor Test ............ 13

Failure to Start TestÐ2.5L TBI and 3.0L Engines . 12

General Information ....................... 11

Ignition Coil ............................. 11 Manifold Absolute Pressure (MAP) Sensor Test . 13

Poor Performance Test .................... 13

Spark Plugs ............................ 11

Testing for Spark at Coil ................... 11

GENERAL INFORMATION

For additional information, refer to On Board Di-

agnostics in the Fuel Injection General Diagnosis

sections of Group 14. Also, refer to the DRBII scan

tool and appropriate Powertrain Diagnostic Proce-

dures Manual.

SPARK PLUGS

Faulty or fouled spark plugs may perform well at

idle speed, but frequently fail at higher engine

speeds. Faulty plugs can be identified in a number of

ways: poor fuel economy, power loss, decrease in en-

gine speed, hard starting and, in general, poor en-

gine performance. Spark plugs also malfunction because of carbon

fouling, excessive electrode air gap, or a broken insu-

lator. Refer to the General Information Section of

this group for spark plug diagnosis.

IGNITION COIL

The ignition coil is designed to operate without an

external ballast resistor. Inspect the coil for arcing. Test the coil according

to coil tester manufacturer's instructions. Test coil

primary and secondary resistance. Replace any coil

that does not meet specifications. Refer to the Coil

Resistance chart. If the ignition coil is replaced due to a burned

tower, carbon tracking, arcing at the tower, or dam-

age to the terminal or boot on the coil end of the sec-

ondary cable, the cable must be replaced. Arcing at the tower will carbonize the nipple which, if it is con-

nected to a new coil, will cause the coil to fail. If a secondary cable shows any signs of damage,

the cable should be replaced with a new cable and

new terminal. Carbon tracking on the old cable can

cause arcing and the failure of a new coil.

TESTING FOR SPARK AT COIL

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK THE WHEELS BEFORE PERFORMING ANY

TEST WITH THE ENGINE RUNNING.

CAUTION: Spark plug cables may be damaged if

this test is performed with more than 1/4 inch clear-

ance between the cable and engine ground.

Remove the coil secondary cable from the distribu-

tor cap. Hold the end of cable about 6 mm (1/4-inch)

away from a good engine ground (Fig. 1). Crank the

engine and inspect for spark at the coil secondary ca-

ble. There must be a constant spark at the coil second-

ary cable. If the spark is constant, have a helper con-

tinue to crank engine and, while slowly moving coil

secondary cable away from ground, look for arcing at

the coil tower. If arcing occurs at the tower, replace

the coil. If spark is not constant or there is no spark,

proceed to the failure to start test. If a constant spark is present and no arcing occurs

at the coil tower, the ignition system is producing

the necessary high secondary voltage. However,

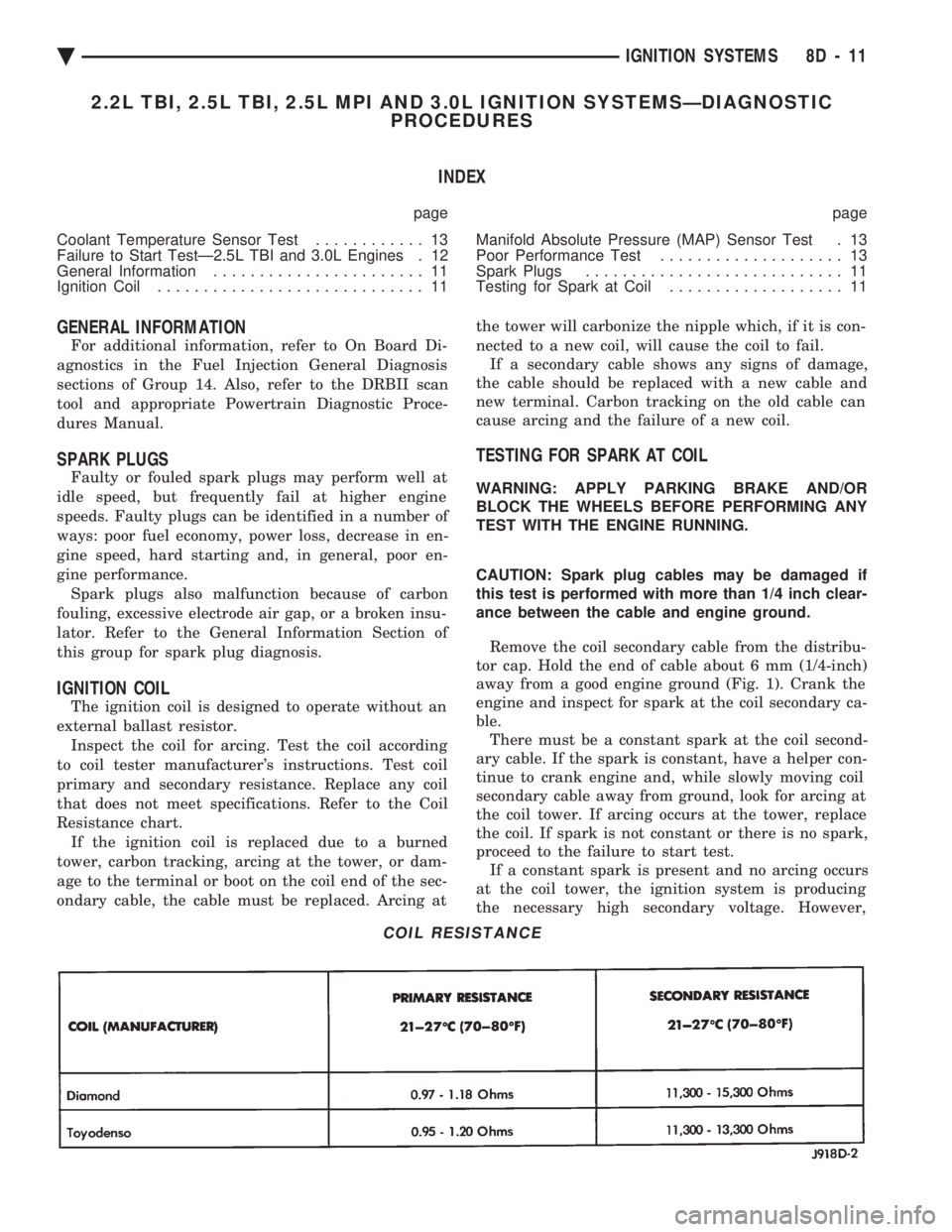

COIL RESISTANCE

Ä IGNITION SYSTEMS 8D - 11

Page 455 of 2438

(10) If no spark is produced, replace the ignition coil.

POOR PERFORMANCE TEST

To prevent unnecessary diagnostic time and

possible incorrect results, the Testing For Spark

At Coil procedure should be performed before

this test.

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

THE WHEELS BEFORE PERFORMING ANY ENGINE

RUNNING TESTS.

Check and adjust basic timing (refer to the specifica-

tion section of this group and see service procedures).

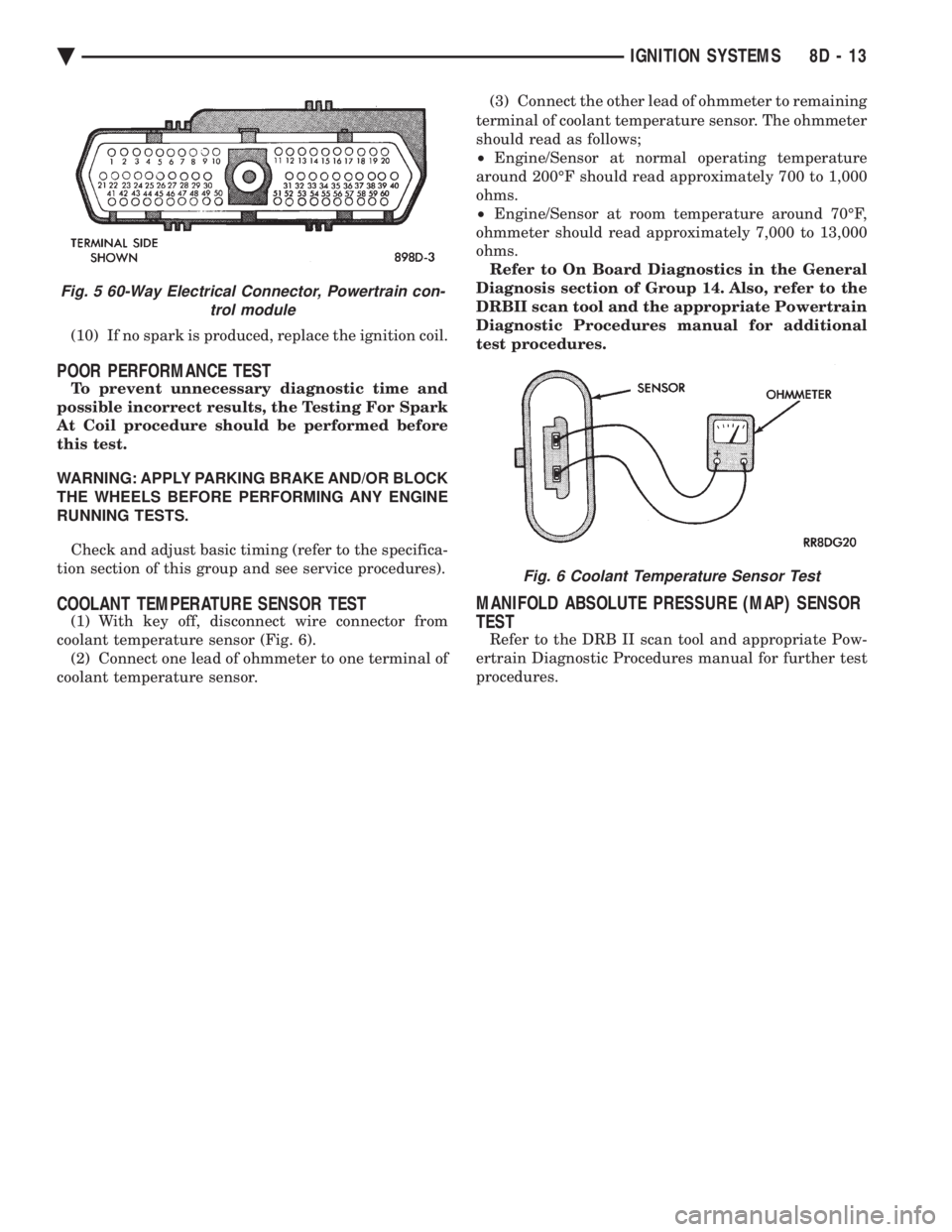

COOLANT TEMPERATURE SENSOR TEST

(1) With key off, disconnect wire connector from

coolant temperature sensor (Fig. 6). (2) Connect one lead of ohmmeter to one terminal of

coolant temperature sensor. (3) Connect the other lead of ohmmeter to remaining

terminal of coolant temperature sensor. The ohmmeter

should read as follows;

² Engine/Sensor at normal operating temperature

around 200ÉF should read approximately 700 to 1,000

ohms.

² Engine/Sensor at room temperature around 70ÉF,

ohmmeter should read approximately 7,000 to 13,000

ohms. Refer to On Board Diagnostics in the General

Diagnosis section of Group 14. Also, refer to the

DRBII scan tool and the appropriate Powertrain

Diagnostic Procedures manual for additional

test procedures.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

Refer to the DRB II scan tool and appropriate Pow-

ertrain Diagnostic Procedures manual for further test

procedures.

Fig. 5 60-Way Electrical Connector, Powertrain con- trol module

Fig. 6 Coolant Temperature Sensor Test

Ä IGNITION SYSTEMS 8D - 13

Page 458 of 2438

(3) Inspect the spark plug condition. Refer to Spark

Plug Condition in this section.

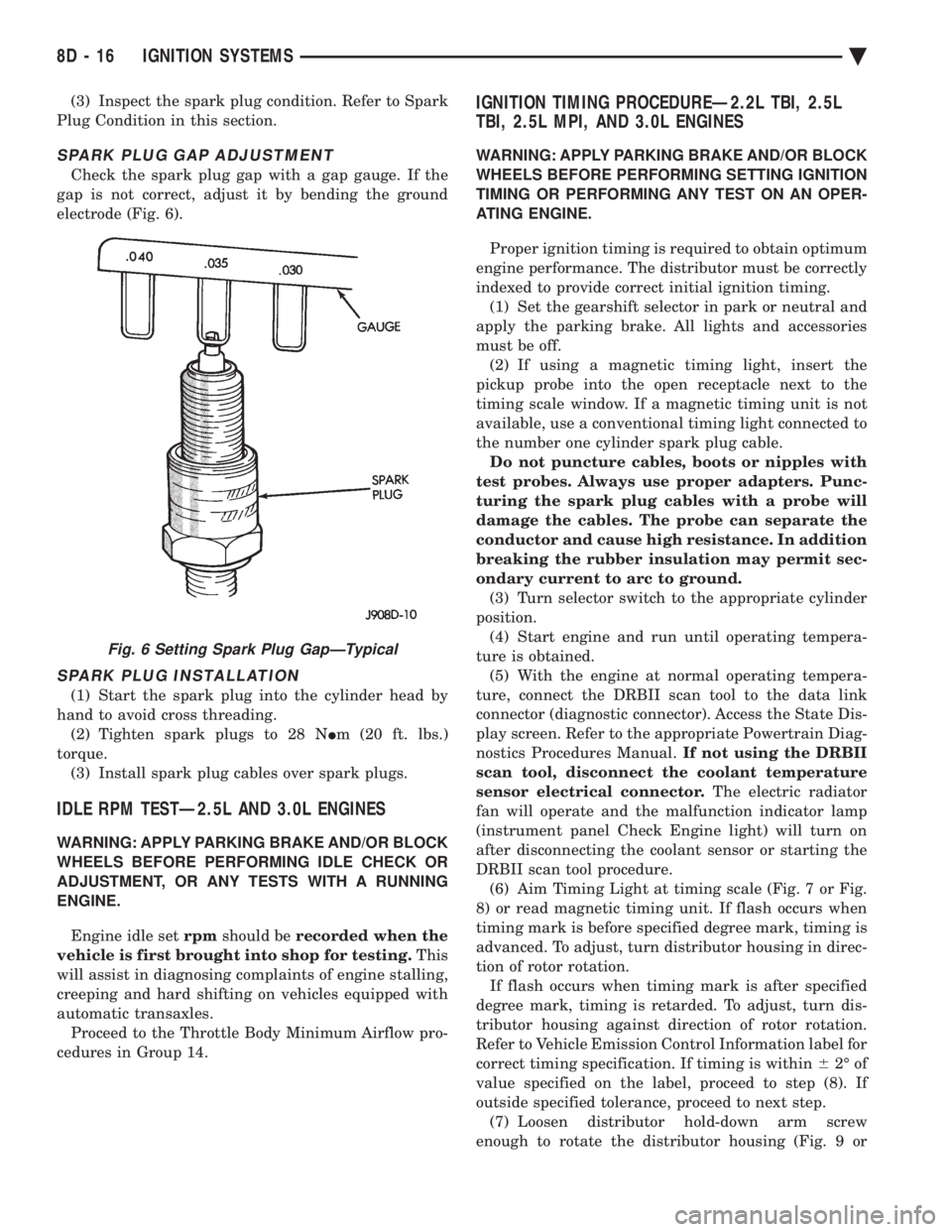

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TESTÐ2.5L AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING IDLE CHECK OR

ADJUSTMENT, OR ANY TESTS WITH A RUNNING

ENGINE.

Engine idle set rpmshould be recorded when the

vehicle is first brought into shop for testing. This

will assist in diagnosing complaints of engine stalling,

creeping and hard shifting on vehicles equipped with

automatic transaxles. Proceed to the Throttle Body Minimum Airflow pro-

cedures in Group 14.

IGNITION TIMING PROCEDUREÐ2.2L TBI, 2.5L

TBI, 2.5L MPI, AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING SETTING IGNITION

TIMING OR PERFORMING ANY TEST ON AN OPER-

ATING ENGINE.

Proper ignition timing is required to obtain optimum

engine performance. The distributor must be correctly

indexed to provide correct initial ignition timing. (1) Set the gearshift selector in park or neutral and

apply the parking brake. All lights and accessories

must be off. (2) If using a magnetic timing light, insert the

pickup probe into the open receptacle next to the

timing scale window. If a magnetic timing unit is not

available, use a conventional timing light connected to

the number one cylinder spark plug cable. Do not puncture cables, boots or nipples with

test probes. Always use proper adapters. Punc-

turing the spark plug cables with a probe will

damage the cables. The probe can separate the

conductor and cause high resistance. In addition

breaking the rubber insulation may permit sec-

ondary current to arc to ground. (3) Turn selector switch to the appropriate cylinder

position. (4) Start engine and run until operating tempera-

ture is obtained. (5) With the engine at normal operating tempera-

ture, connect the DRBII scan tool to the data link

connector (diagnostic connector). Access the State Dis-

play screen. Refer to the appropriate Powertrain Diag-

nostics Procedures Manual. If not using the DRBII

scan tool, disconnect the coolant temperature

sensor electrical connector. The electric radiator

fan will operate and the malfunction indicator lamp

(instrument panel Check Engine light) will turn on

after disconnecting the coolant sensor or starting the

DRBII scan tool procedure. (6) Aim Timing Light at timing scale (Fig. 7 or Fig.

8) or read magnetic timing unit. If flash occurs when

timing mark is before specified degree mark, timing is

advanced. To adjust, turn distributor housing in direc-

tion of rotor rotation. If flash occurs when timing mark is after specified

degree mark, timing is retarded. To adjust, turn dis-

tributor housing against direction of rotor rotation.

Refer to Vehicle Emission Control Information label for

correct timing specification. If timing is within 62É of

value specified on the label, proceed to step (8). If

outside specified tolerance, proceed to next step. (7) Loosen distributor hold-down arm screw

enough to rotate the distributor housing (Fig. 9 or

Fig. 6 Setting Spark Plug GapÐTypical

8D - 16 IGNITION SYSTEMS Ä

Page 507 of 2438

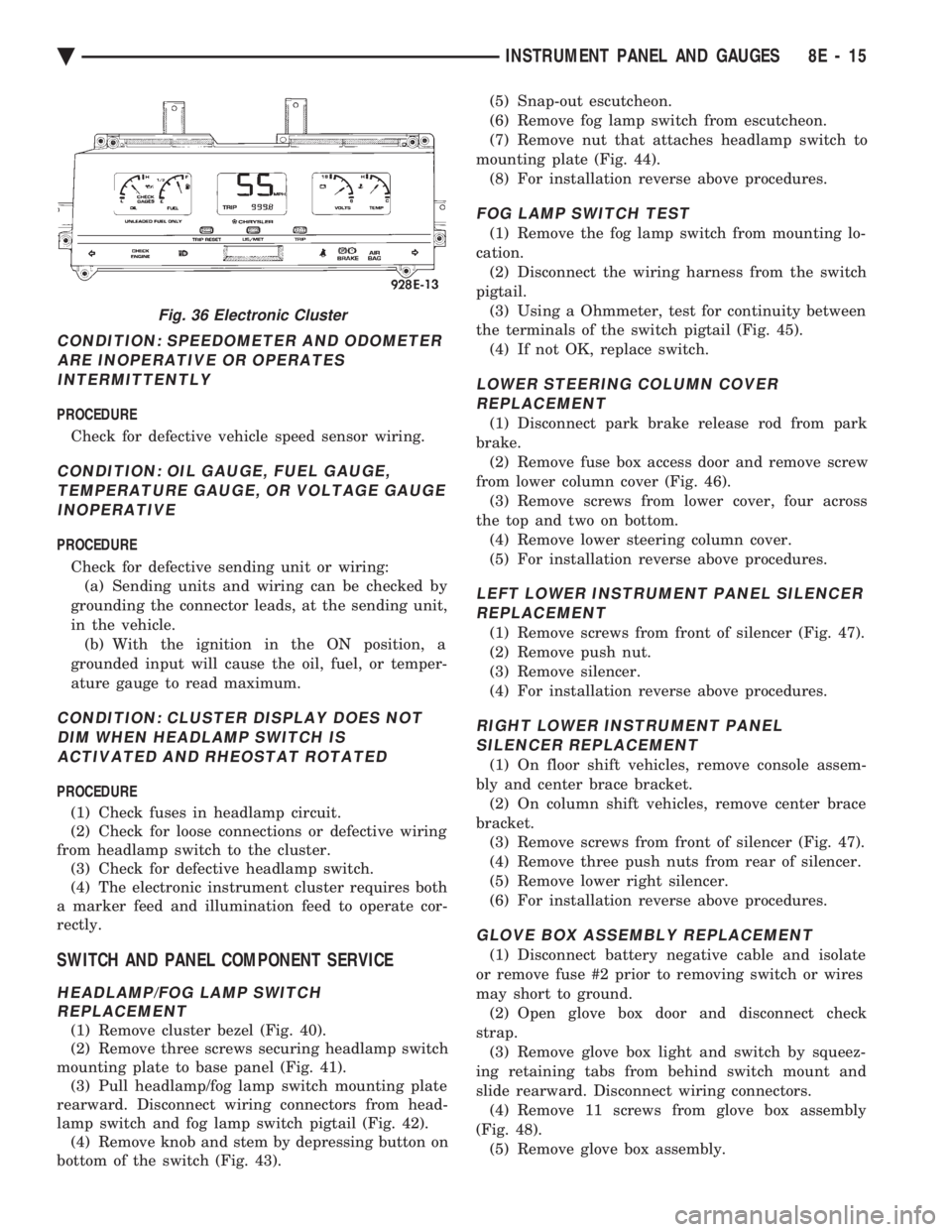

CONDITION: SPEEDOMETER AND ODOMETER ARE INOPERATIVE OR OPERATESINTERMITTENTLY

PROCEDURE

Check for defective vehicle speed sensor wiring.

CONDITION: OIL GAUGE, FUEL GAUGE, TEMPERATURE GAUGE, OR VOLTAGE GAUGEINOPERATIVE

PROCEDURE

Check for defective sending unit or wiring: (a) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (b) With the ignition in the ON position, a

grounded input will cause the oil, fuel, or temper-

ature gauge to read maximum.

CONDITION: CLUSTER DISPLAY DOES NOT DIM WHEN HEADLAMP SWITCH ISACTIVATED AND RHEOSTAT ROTATED

PROCEDURE

(1) Check fuses in headlamp circuit.

(2) Check for loose connections or defective wiring

from headlamp switch to the cluster. (3) Check for defective headlamp switch.

(4) The electronic instrument cluster requires both

a marker feed and illumination feed to operate cor-

rectly.

SWITCH AND PANEL COMPONENT SERVICE

HEADLAMP/FOG LAMP SWITCH REPLACEMENT

(1) Remove cluster bezel (Fig. 40).

(2) Remove three screws securing headlamp switch

mounting plate to base panel (Fig. 41). (3) Pull headlamp/fog lamp switch mounting plate

rearward. Disconnect wiring connectors from head-

lamp switch and fog lamp switch pigtail (Fig. 42). (4) Remove knob and stem by depressing button on

bottom of the switch (Fig. 43). (5) Snap-out escutcheon.

(6) Remove fog lamp switch from escutcheon.

(7) Remove nut that attaches headlamp switch to

mounting plate (Fig. 44). (8) For installation reverse above procedures.

FOG LAMP SWITCH TEST

(1) Remove the fog lamp switch from mounting lo-

cation. (2) Disconnect the wiring harness from the switch

pigtail. (3) Using a Ohmmeter, test for continuity between

the terminals of the switch pigtail (Fig. 45). (4) If not OK, replace switch.

LOWER STEERING COLUMN COVERREPLACEMENT

(1) Disconnect park brake release rod from park

brake. (2) Remove fuse box access door and remove screw

from lower column cover (Fig. 46). (3) Remove screws from lower cover, four across

the top and two on bottom. (4) Remove lower steering column cover.

(5) For installation reverse above procedures.

LEFT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) Remove screws from front of silencer (Fig. 47).

(2) Remove push nut.

(3) Remove silencer.

(4) For installation reverse above procedures.

RIGHT LOWER INSTRUMENT PANEL SILENCER REPLACEMENT

(1) On floor shift vehicles, remove console assem-

bly and center brace bracket. (2) On column shift vehicles, remove center brace

bracket. (3) Remove screws from front of silencer (Fig. 47).

(4) Remove three push nuts from rear of silencer.

(5) Remove lower right silencer.

(6) For installation reverse above procedures.

GLOVE BOX ASSEMBLY REPLACEMENT

(1) Disconnect battery negative cable and isolate

or remove fuse #2 prior to removing switch or wires

may short to ground. (2) Open glove box door and disconnect check

strap. (3) Remove glove box light and switch by squeez-

ing retaining tabs from behind switch mount and

slide rearward. Disconnect wiring connectors. (4) Remove 11 screws from glove box assembly

(Fig. 48). (5) Remove glove box assembly.

Fig. 36 Electronic Cluster

Ä INSTRUMENT PANEL AND GAUGES 8E - 15

Page 515 of 2438

AC AND AY BODIES INDEX

page page

Electronic Cluster ........................ 34

Gauges ................................ 28

General Information ....................... 23

Interior Lamp Replacement ................. 41 Mechanical Cluster and Gauge Service

........ 24

Mechanical/Electronic Cluster Removal ........ 25

Switch and Panel Component Service ......... 37

GENERAL INFORMATION

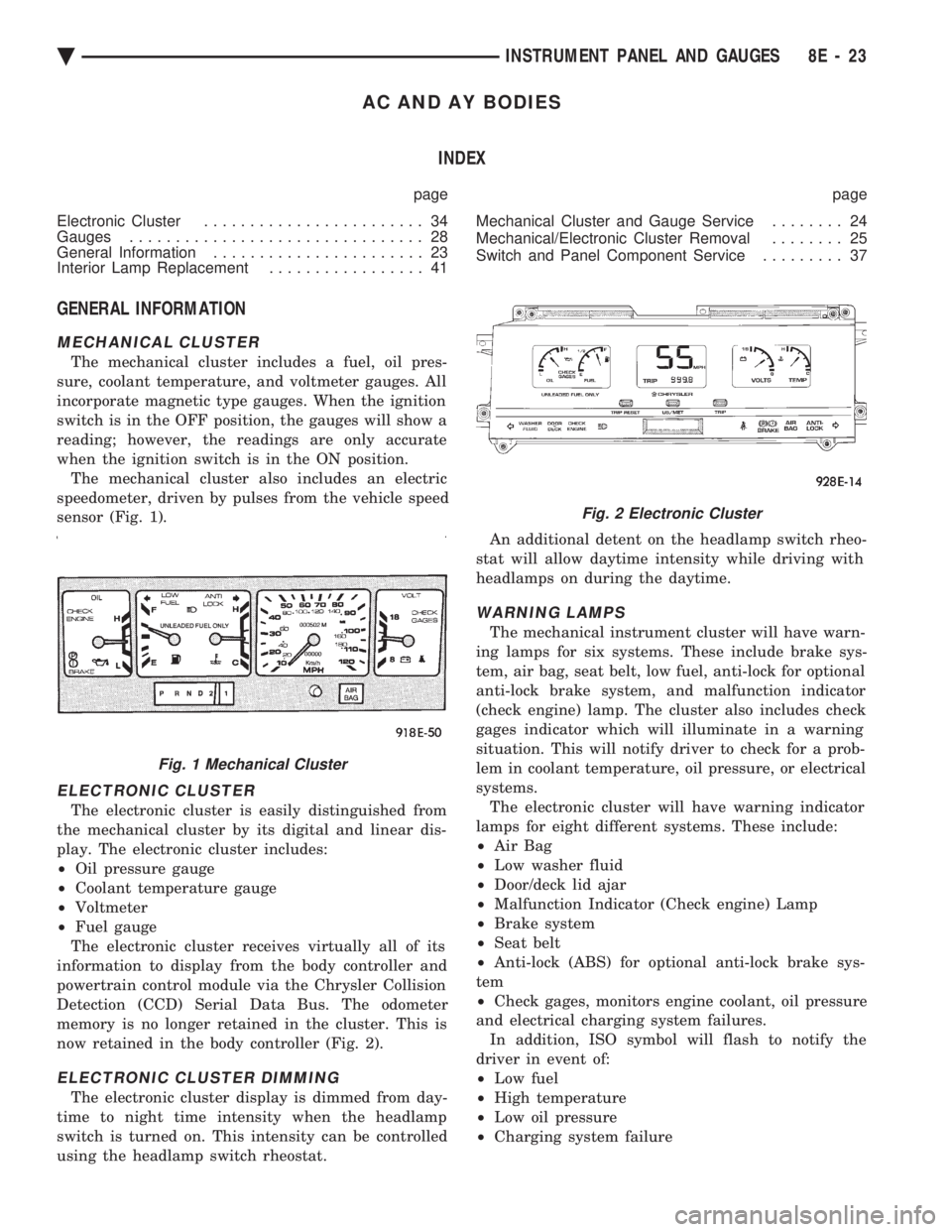

MECHANICAL CLUSTER

The mechanical cluster includes a fuel, oil pres-

sure, coolant temperature, and voltmeter gauges. All

incorporate magnetic type gauges. When the ignition

switch is in the OFF position, the gauges will show a

reading; however, the readings are only accurate

when the ignition switch is in the ON position. The mechanical cluster also includes an electric

speedometer, driven by pulses from the vehicle speed

sensor (Fig. 1).

ELECTRONIC CLUSTER

The electronic cluster is easily distinguished from

the mechanical cluster by its digital and linear dis-

play. The electronic cluster includes:

² Oil pressure gauge

² Coolant temperature gauge

² Voltmeter

² Fuel gauge

The electronic cluster receives virtually all of its

information to display from the body controller and

powertrain control module via the Chrysler Collision

Detection (CCD) Serial Data Bus. The odometer

memory is no longer retained in the cluster. This is

now retained in the body controller (Fig. 2).

ELECTRONIC CLUSTER DIMMING

The electronic cluster display is dimmed from day-

time to night time intensity when the headlamp

switch is turned on. This intensity can be controlled

using the headlamp switch rheostat. An additional detent on the headlamp switch rheo-

stat will allow daytime intensity while driving with

headlamps on during the daytime.

WARNING LAMPS

The mechanical instrument cluster will have warn-

ing lamps for six systems. These include brake sys-

tem, air bag, seat belt, low fuel, anti-lock for optional

anti-lock brake system, and malfunction indicator

(check engine) lamp. The cluster also includes check

gages indicator which will illuminate in a warning

situation. This will notify driver to check for a prob-

lem in coolant temperature, oil pressure, or electrical

systems. The electronic cluster will have warning indicator

lamps for eight different systems. These include:

² Air Bag

² Low washer fluid

² Door/deck lid ajar

² Malfunction Indicator (Check engine) Lamp

² Brake system

² Seat belt

² Anti-lock (ABS) for optional anti-lock brake sys-

tem

² Check gages, monitors engine coolant, oil pressure

and electrical charging system failures. In addition, ISO symbol will flash to notify the

driver in event of:

² Low fuel

² High temperature

² Low oil pressure

² Charging system failure

Fig. 1 Mechanical Cluster

Fig. 2 Electronic Cluster

Ä INSTRUMENT PANEL AND GAUGES 8E - 23

Page 540 of 2438

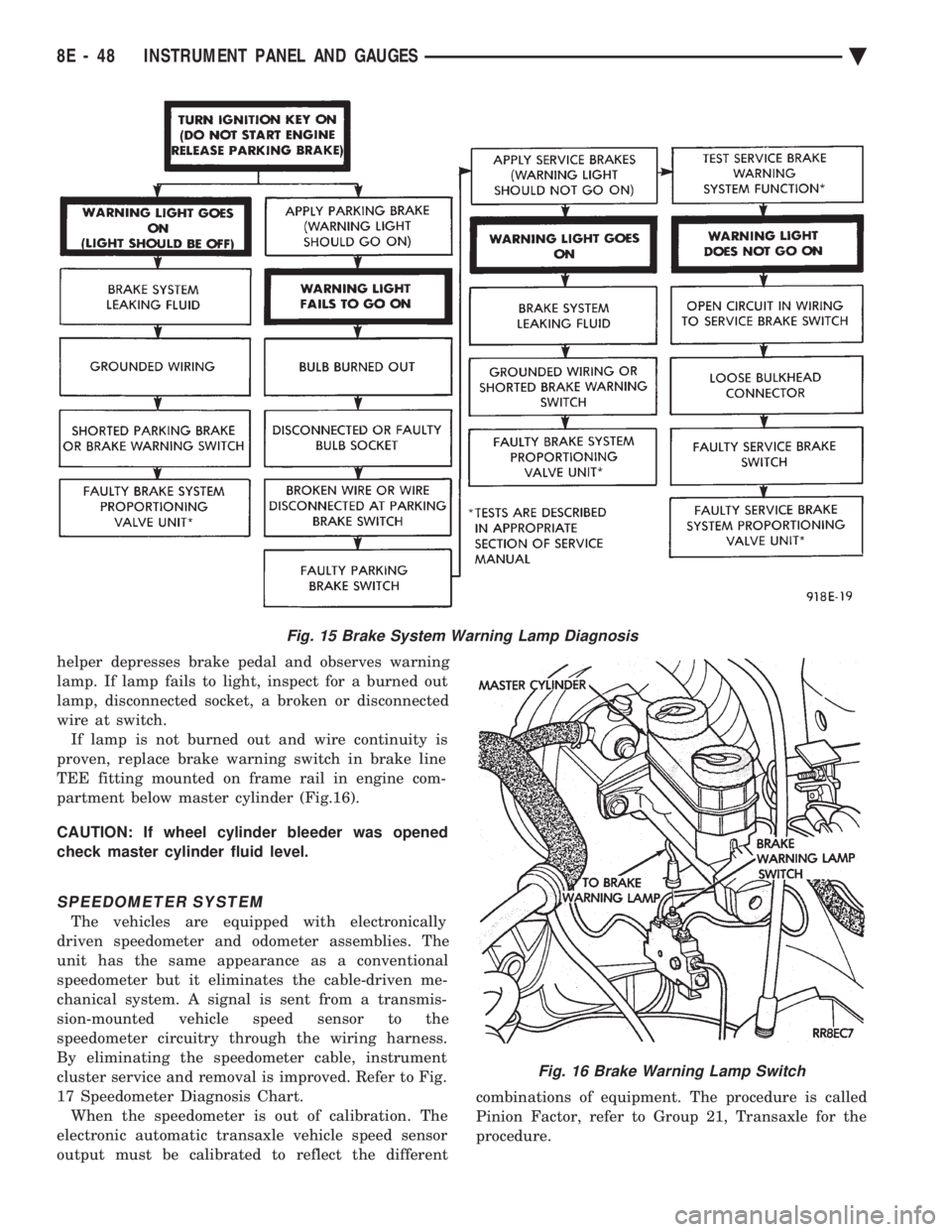

helper depresses brake pedal and observes warning

lamp. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch.If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

TEE fitting mounted on frame rail in engine com-

partment below master cylinder (Fig.16).

CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

SPEEDOMETER SYSTEM

The vehicles are equipped with electronically

driven speedometer and odometer assemblies. The

unit has the same appearance as a conventional

speedometer but it eliminates the cable-driven me-

chanical system. A signal is sent from a transmis-

sion-mounted vehicle speed sensor to the

speedometer circuitry through the wiring harness.

By eliminating the speedometer cable, instrument

cluster service and removal is improved. Refer to Fig.

17 Speedometer Diagnosis Chart. When the speedometer is out of calibration. The

electronic automatic transaxle vehicle speed sensor

output must be calibrated to reflect the different combinations of equipment. The procedure is called

Pinion Factor, refer to Group 21, Transaxle for the

procedure.

Fig. 15 Brake System Warning Lamp Diagnosis

Fig. 16 Brake Warning Lamp Switch

8E - 48 INSTRUMENT PANEL AND GAUGES Ä

Page 559 of 2438

VEHICLE SPEED SENSOR TEST

For testing of the vehicle speed sensor and related

components using DRB II, refer to the appropriate

Powertrain Diagnostics Test Procedure Manual.

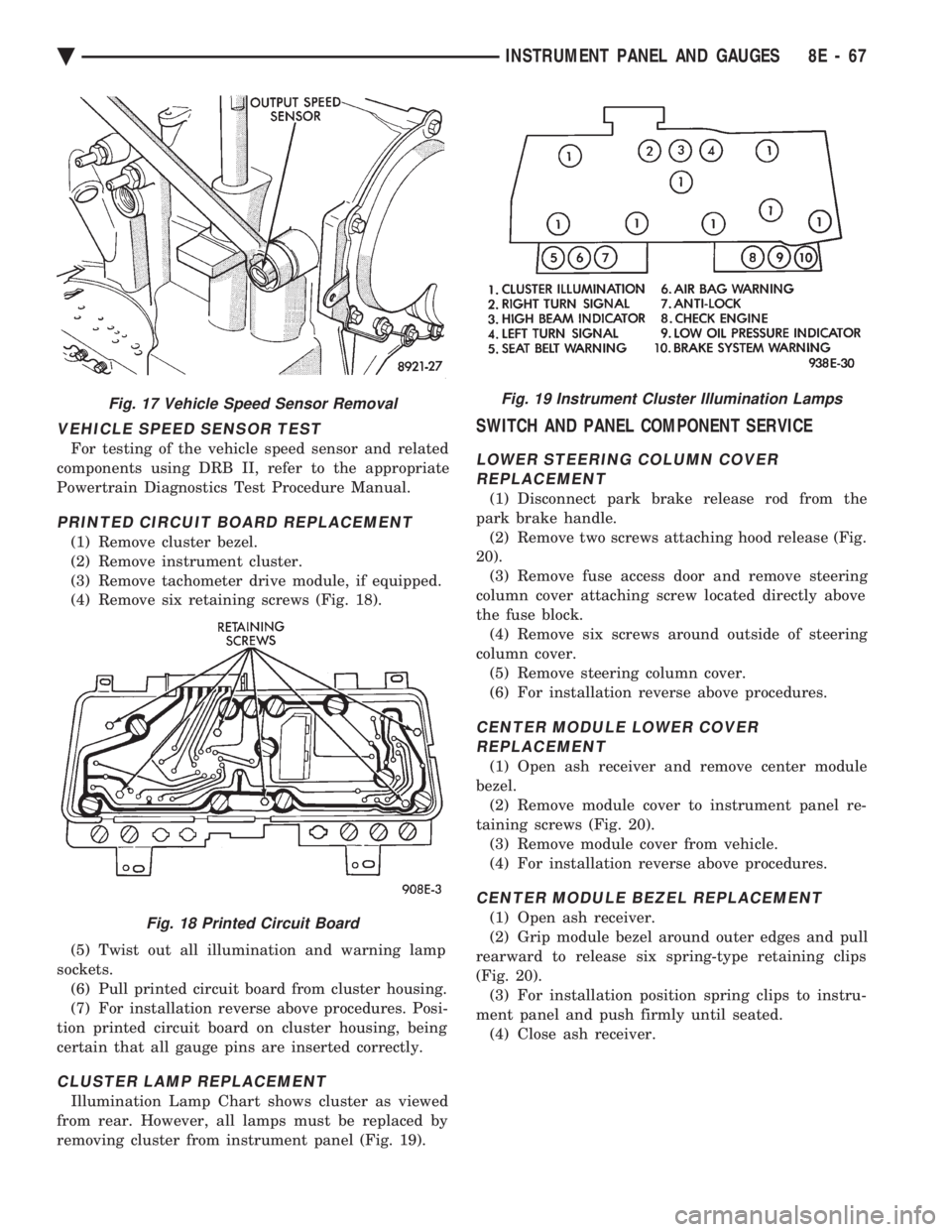

PRINTED CIRCUIT BOARD REPLACEMENT

(1) Remove cluster bezel.

(2) Remove instrument cluster.

(3) Remove tachometer drive module, if equipped.

(4) Remove six retaining screws (Fig. 18).

(5) Twist out all illumination and warning lamp

sockets. (6) Pull printed circuit board from cluster housing.

(7) For installation reverse above procedures. Posi-

tion printed circuit board on cluster housing, being

certain that all gauge pins are inserted correctly.

CLUSTER LAMP REPLACEMENT

Illumination Lamp Chart shows cluster as viewed

from rear. However, all lamps must be replaced by

removing cluster from instrument panel (Fig. 19).

SWITCH AND PANEL COMPONENT SERVICE

LOWER STEERING COLUMN COVER REPLACEMENT

(1) Disconnect park brake release rod from the

park brake handle. (2) Remove two screws attaching hood release (Fig.

20). (3) Remove fuse access door and remove steering

column cover attaching screw located directly above

the fuse block. (4) Remove six screws around outside of steering

column cover. (5) Remove steering column cover.

(6) For installation reverse above procedures.

CENTER MODULE LOWER COVER REPLACEMENT

(1) Open ash receiver and remove center module

bezel. (2) Remove module cover to instrument panel re-

taining screws (Fig. 20). (3) Remove module cover from vehicle.

(4) For installation reverse above procedures.

CENTER MODULE BEZEL REPLACEMENT

(1) Open ash receiver.

(2) Grip module bezel around outer edges and pull

rearward to release six spring-type retaining clips

(Fig. 20). (3) For installation position spring clips to instru-

ment panel and push firmly until seated. (4) Close ash receiver.

Fig. 17 Vehicle Speed Sensor Removal

Fig. 18 Printed Circuit Board

Fig. 19 Instrument Cluster Illumination Lamps

Ä INSTRUMENT PANEL AND GAUGES 8E - 67

Page 931 of 2438

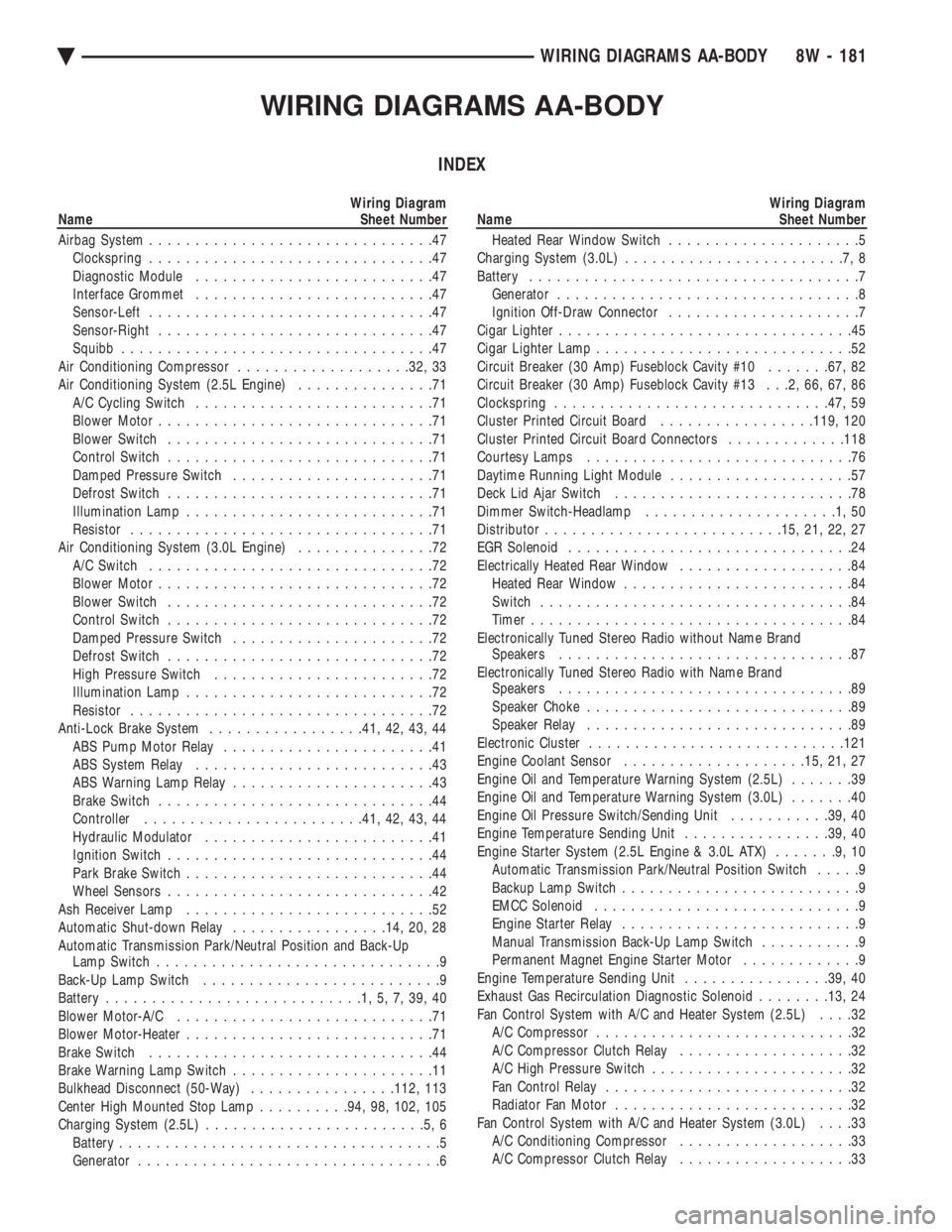

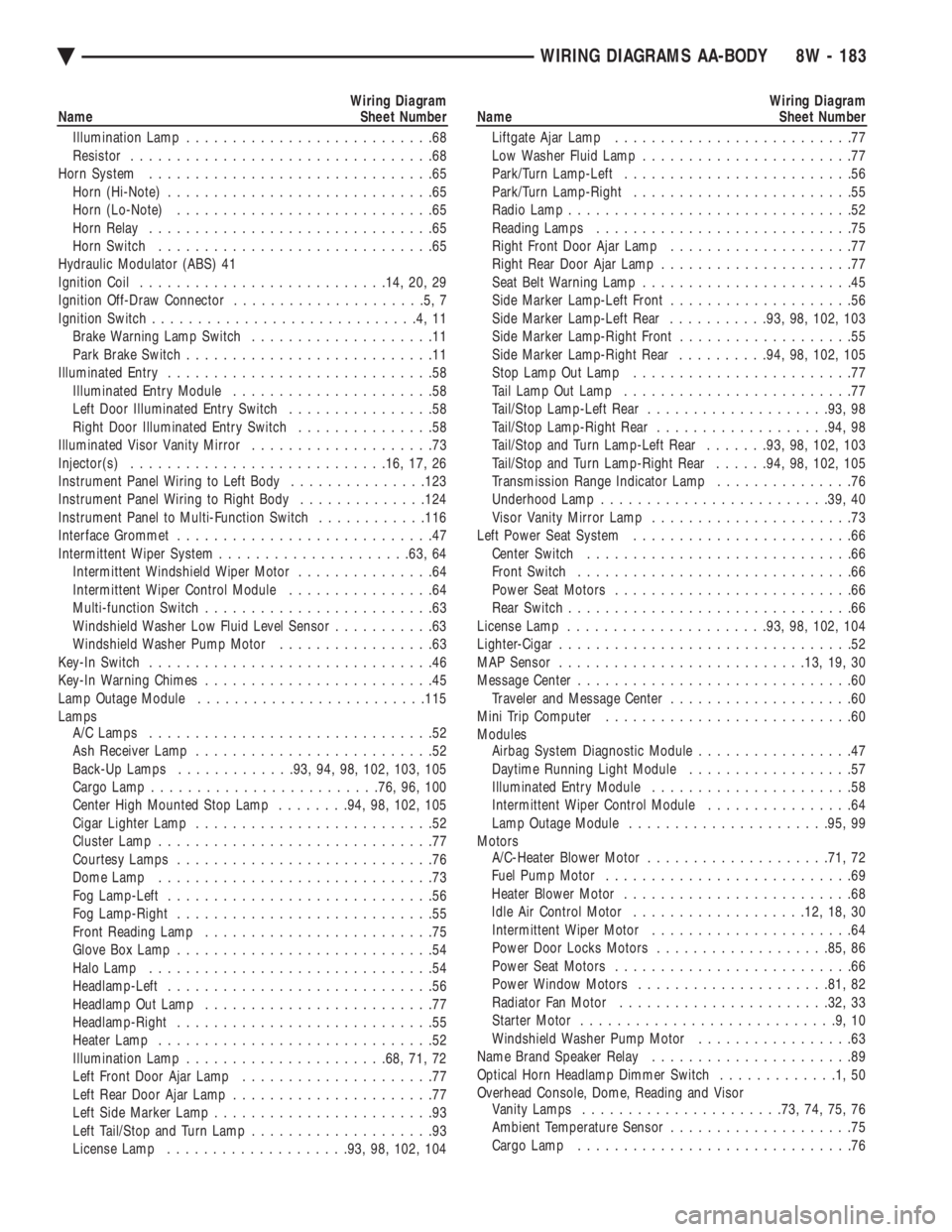

WIRING DIAGRAMS AA-BODY

INDEX

Wiring Diagram

Name Sheet Number

Airbag System ...............................47

Clockspring ...............................47

Diagnostic Module ..........................47

Interface Grommet ..........................47

Sensor-Left ...............................47

Sensor-Right ..............................47

Squibb ..................................47

Air Conditioning Compressor ...................32, 33

Air Conditioning System (2.5L Engine) ...............71

A/C Cycling Switch ..........................71

Blower Motor ..............................71

Blower Switch .............................71

Control Switch .............................71

Damped Pressure Switch ......................71

Defrost Switch .............................71

Illumination Lamp ...........................71

Resistor .................................71

Air Conditioning System (3.0L Engine) ...............72

A/C Switch ...............................72

Blower Motor ..............................72

Blower Switch .............................72

Control Switch .............................72

Damped Pressure Switch ......................72

Defrost Switch .............................72

High Pressure Switch ........................72

Illumination Lamp ...........................72

Resistor .................................72

Anti-Lock Brake System .................41, 42, 43, 44

ABS Pump Motor Relay .......................41

ABS System Relay ..........................43

ABS Warning Lamp Relay ......................43

Brake Switch ..............................44

Controller ....................... .41, 42, 43, 44

Hydraulic Modulator .........................41

Ignition Switch .............................44

Park Brake Switch ...........................44

Wheel Sensors .............................42

Ash Receiver Lamp ...........................52

Automatic Shut-down Relay .................14, 20, 28

Automatic Transmission Park/Neutral Position and Back-Up Lamp Switch ...............................9

Back-Up Lamp Switch ..........................9

Battery ............................1,5,7,39,40

Blower Motor-A/C ............................71

Blower Motor-Heater ...........................71

Brake Switch ...............................44

Brake Warning Lamp Switch ......................11

Bulkhead Disconnect (50-Way) ................112, 113

Center High Mounted Stop Lamp ..........94, 98, 102, 105

Charging System (2.5L) ........................5,6

Battery ...................................5

Generator .................................6Wiring Diagram

Name Sheet Number

Heated Rear Window Switch .....................5

Charging System (3.0L) ........................7,8

Battery ....................................7

Generator .................................8

Ignition Off-Draw Connector .....................7

Cigar Lighter ................................45

Cigar Lighter Lamp ............................52

Circuit Breaker (30 Amp) Fuseblock Cavity #10 .......67, 82

Circuit Breaker (30 Amp) Fuseblock Cavity #13 . . .2, 66, 67, 86

Clockspring ............................. .47, 59

Cluster Printed Circuit Board .................119, 120

Cluster Printed Circuit Board Connectors .............118

Courtesy Lamps .............................76

Daytime Running Light Module ....................57

Deck Lid Ajar Switch ..........................78

Dimmer Switch-Headlamp .....................1,50

Distributor ......................... .15, 21, 22, 27

EGR Solenoid ...............................24

Electrically Heated Rear Window ...................84

Heated Rear Window .........................84

Switch ..................................84

Timer ...................................84

Electronically Tuned Stereo Radio without Name Brand Speakers ................................87

Electronically Tuned Stereo Radio with Name Brand Speakers ................................89

Speaker Choke .............................89

Speaker Relay .............................89

Electronic Cluster ........................... .121

Engine Coolant Sensor ................... .15, 21, 27

Engine Oil and Temperature Warning System (2.5L) .......39

Engine Oil and Temperature Warning System (3.0L) .......40

Engine Oil Pressure Switch/Sending Unit ...........39, 40

Engine Temperature Sending Unit ................39, 40

Engine Starter System (2.5L Engine & 3.0L ATX) .......9,10

Automatic Transmission Park/Neutral Position Switch .....9

Backup Lamp Switch ..........................9

EMCC Solenoid .............................9

Engine Starter Relay ..........................9

Manual Transmission Back-Up Lamp Switch ...........9

Permanent Magnet Engine Starter Motor .............9

Engine Temperature Sending Unit ................39, 40

Exhaust Gas Recirculation Diagnostic Solenoid ........13, 24

Fan Control System with A/C and Heater System (2.5L) ....32

A/C Compressor ............................32

A/C Compressor Clutch Relay ...................32

A/C High Pressure Switch ......................32

Fan Control Relay ...........................32

Radiator Fan Motor ..........................32

Fan Control System with A/C and Heater System (3.0L) ....33

A/C Conditioning Compressor ...................33

A/C Compressor Clutch Relay ...................33

Ä WIRING DIAGRAMS AA-BODY 8W - 181

Page 933 of 2438

Wiring Diagram

Name Sheet Number

Illumination Lamp ...........................68

Resistor .................................68

Horn System ...............................65

Horn (Hi-Note) .............................65

Horn (Lo-Note) ............................65

Horn Relay ...............................65

Horn Switch ..............................65

Hydraulic Modulator (ABS) 41

Ignition Coil .......................... .14, 20, 29

Ignition Off-Draw Connector .....................5,7

Ignition Switch .............................4,11

Brake Warning Lamp Switch ....................11

Park Brake Switch ...........................11

Illuminated Entry .............................58

Illuminated Entry Module ......................58

Left Door Illuminated Entry Switch ................58

Right Door Illuminated Entry Switch ...............58

Illuminated Visor Vanity Mirror ....................73

Injector(s) ........................... .16, 17, 26

Instrument Panel Wiring to Left Body ...............123

Instrument Panel Wiring to Right Body ..............124

Instrument Panel to Multi-Function Switch ............116

Interface Grommet ............................47

Intermittent Wiper System .................... .63, 64

Intermittent Windshield Wiper Motor ...............64

Intermittent Wiper Control Module ................64

Multi-function Switch .........................63

Windshield Washer Low Fluid Level Sensor ...........63

Windshield Washer Pump Motor .................63

Key-In Switch ...............................46

Key-In Warning Chimes .........................45

Lamp Outage Module ........................ .115

Lamps A/C Lamps ...............................52

Ash Receiver Lamp ..........................52

Back-Up Lamps ............ .93, 94, 98, 102, 103, 105

Cargo Lamp ........................ .76, 96, 100

Center High Mounted Stop Lamp ........94, 98, 102, 105

Cigar Lighter Lamp ..........................52

Cluster Lamp ..............................77

Courtesy Lamps ............................76

Dome Lamp ..............................73

Fog Lamp-Left .............................56

Fog Lamp-Right ............................55

Front Reading Lamp .........................75

Glove Box Lamp ............................54

Halo Lamp ...............................54

Headlamp-Left .............................56

Headlamp Out Lamp .........................77

Headlamp-Right ............................55

Heater Lamp ..............................52

Illumination Lamp ..................... .68, 71, 72

Left Front Door Ajar Lamp .....................77

Left Rear Door Ajar Lamp ......................77

Left Side Marker Lamp ........................93

Left Tail/Stop and Turn Lamp ....................93

License Lamp ................... .93, 98, 102, 104Wiring Diagram

Name Sheet Number

Liftgate Ajar Lamp ..........................77

Low Washer Fluid Lamp .......................77

Park/Turn Lamp-Left .........................56

Park/Turn Lamp-Right ........................55

Radio Lamp ...............................52

Reading Lamps ............................75

Right Front Door Ajar Lamp ....................77

Right Rear Door Ajar Lamp .....................77

Seat Belt Warning Lamp .......................45

Side Marker Lamp-Left Front ....................56

Side Marker Lamp-Left Rear ...........93, 98, 102, 103

Side Marker Lamp-Right Front ...................55

Side Marker Lamp-Right Rear ..........94, 98, 102, 105

Stop Lamp Out Lamp ........................77

Tail Lamp Out Lamp .........................77

Tail/Stop Lamp-Left Rear ................... .93, 98

Tail/Stop Lamp-Right Rear .................. .94, 98

Tail/Stop and Turn Lamp-Left Rear .......93, 98, 102, 103

Tail/Stop and Turn Lamp-Right Rear ......94, 98, 102, 105

Transmission Range Indicator Lamp ...............76

Underhood Lamp ........................ .39, 40

Visor Vanity Mirror Lamp ......................73

Left Power Seat System ........................66

Center Switch .............................66

Front Switch ..............................66

Power Seat Motors ..........................66

Rear Switch ...............................66

License Lamp ..................... .93, 98, 102, 104

Lighter-Cigar ................................52

MAP Sensor .......................... .13, 19, 30

Message Center ..............................60

Traveler and Message Center ....................60

Mini Trip Computer ...........................60

Modules Airbag System Diagnostic Module .................47

Daytime Running Light Module ..................57

Illuminated Entry Module ......................58

Intermittent Wiper Control Module ................64

Lamp Outage Module ..................... .95, 99

Motors A/C-Heater Blower Motor ................... .71, 72

Fuel Pump Motor ...........................69

Heater Blower Motor .........................68

Idle Air Control Motor .................. .12, 18, 30

Intermittent Wiper Motor ......................64

Power Door Locks Motors .................. .85, 86

Power Seat Motors ..........................66

Power Window Motors .................... .81, 82

Radiator Fan Motor ...................... .32, 33

Starter Motor ............................9,10

Windshield Washer Pump Motor .................63

Name Brand Speaker Relay ......................89

Optical Horn Headlamp Dimmer Switch .............1,50

Overhead Console, Dome, Reading and Visor Vanity Lamps ..................... .73, 74, 75, 76

Ambient Temperature Sensor ....................75

Cargo Lamp ..............................76

Ä WIRING DIAGRAMS AA-BODY 8W - 183

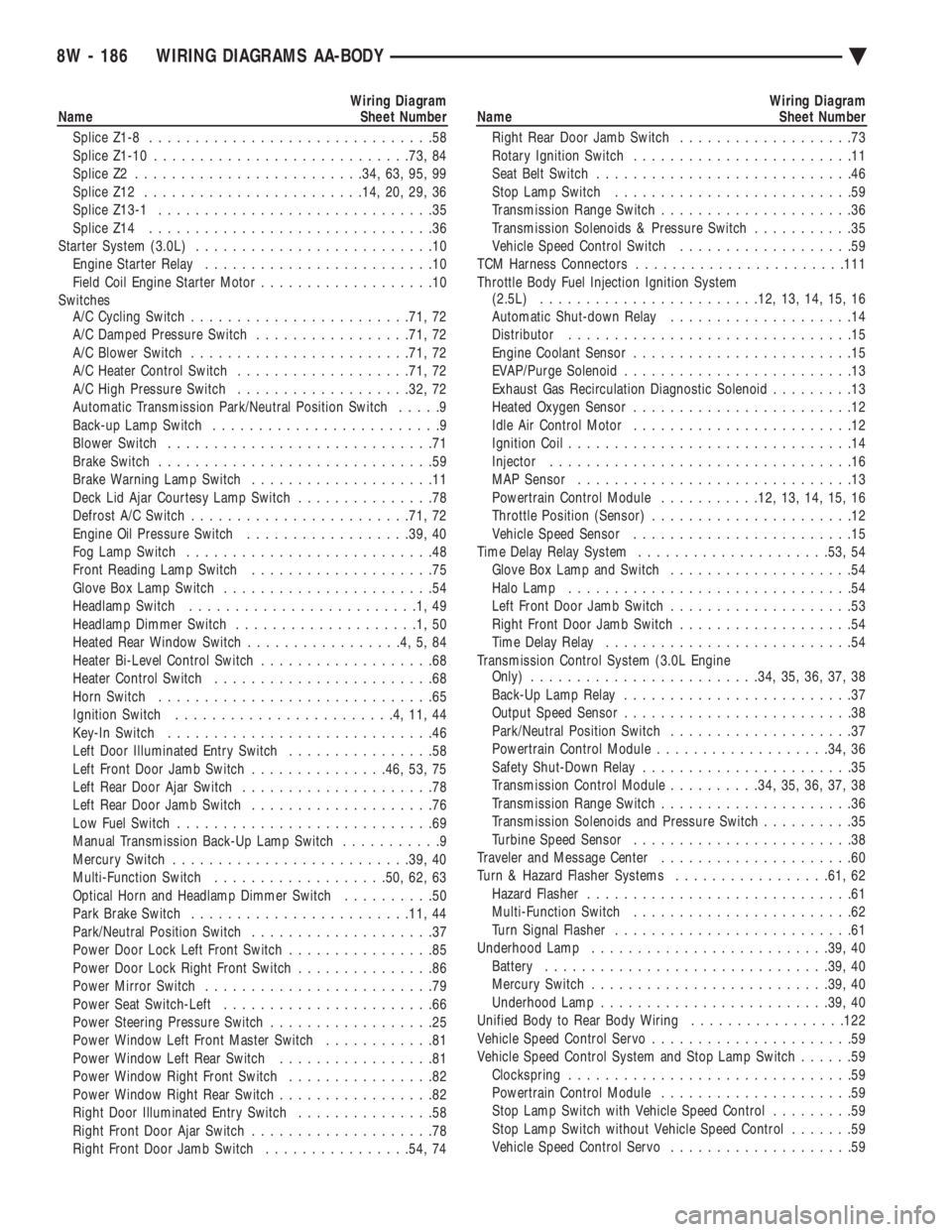

Page 936 of 2438

Wiring Diagram

Name Sheet Number

Splice Z1-8 ...............................58

Splice Z1-10 ........................... .73, 84

Splice Z2 ........................ .34, 63, 95, 99

Splice Z12 ....................... .14, 20, 29, 36

Splice Z13-1 ..............................35

Splice Z14 ...............................36

Starter System (3.0L) ..........................10

Engine Starter Relay .........................10

Field Coil Engine Starter Motor ...................10

Switches A/C Cycling Switch ....................... .71, 72

A/C Damped Pressure Switch .................71, 72

A/C Blower Switch ....................... .71, 72

A/C Heater Control Switch .................. .71, 72

A/C High Pressure Switch .................. .32, 72

Automatic Transmission Park/Neutral Position Switch .....9

Back-up Lamp Switch .........................9

Blower Switch .............................71

Brake Switch ..............................59

Brake Warning Lamp Switch ....................11

Deck Lid Ajar Courtesy Lamp Switch ...............78

Defrost A/C Switch ....................... .71, 72

Engine Oil Pressure Switch ..................39, 40

Fog Lamp Switch ...........................48

Front Reading Lamp Switch ....................75

Glove Box Lamp Switch .......................54

Headlamp Switch .........................1,49

Headlamp Dimmer Switch ....................1,50

Heated Rear Window Switch .................4,5,84

Heater Bi-Level Control Switch ...................68

Heater Control Switch ........................68

Horn Switch ..............................65

Ignition Switch ........................4,11,44

Key-In Switch .............................46

Left Door Illuminated Entry Switch ................58

Left Front Door Jamb Switch ...............46, 53, 75

Left Rear Door Ajar Switch .....................78

Left Rear Door Jamb Switch ....................76

Low Fuel Switch ............................69

Manual Transmission Back-Up Lamp Switch ...........9

Mercury Switch ......................... .39, 40

Multi-Function Switch .................. .50, 62, 63

Optical Horn and Headlamp Dimmer Switch ..........50

Park Brake Switch ....................... .11, 44

Park/Neutral Position Switch ....................37

Power Door Lock Left Front Switch ................85

Power Door Lock Right Front Switch ...............86

Power Mirror Switch .........................79

Power Seat Switch-Left .......................66

Power Steering Pressure Switch ..................25

Power Window Left Front Master Switch ............81

Power Window Left Rear Switch .................81

Power Window Right Front Switch ................82

Power Window Right Rear Switch .................82

Right Door Illuminated Entry Switch ...............58

Right Front Door Ajar Switch ....................78

Right Front Door Jamb Switch ................54, 74Wiring Diagram

Name Sheet Number

Right Rear Door Jamb Switch ...................73

Rotary Ignition Switch ........................11

Seat Belt Switch ............................46

Stop Lamp Switch ..........................59

Transmission Range Switch .....................36

Transmission Solenoids & Pressure Switch ...........35

Vehicle Speed Control Switch ...................59

TCM Harness Connectors ...................... .111

Throttle Body Fuel Injection Ignition System (2.5L) ....................... .12, 13, 14, 15, 16

Automatic Shut-down Relay ....................14

Distributor ...............................15

Engine Coolant Sensor ........................15

EVAP/Purge Solenoid .........................13

Exhaust Gas Recirculation Diagnostic Solenoid .........13

Heated Oxygen Sensor ........................12

Idle Air Control Motor ........................12

Ignition Coil ...............................14

Injector .................................16

MAP Sensor ..............................13

Powertrain Control Module ...........12, 13, 14, 15, 16

Throttle Position (Sensor) ......................12

Vehicle Speed Sensor ........................15

Time Delay Relay System .................... .53, 54

Glove Box Lamp and Switch ....................54

Halo Lamp ...............................54

Left Front Door Jamb Switch ....................53

Right Front Door Jamb Switch ...................54

Time Delay Relay ...........................54

Transmission Control System (3.0L Engine Only) ........................ .34, 35, 36, 37, 38

Back-Up Lamp Relay .........................37

Output Speed Sensor .........................38

Park/Neutral Position Switch ....................37

Powertrain Control Module .................. .34, 36

Safety Shut-Down Relay .......................35

Transmission Control Module ..........34, 35, 36, 37, 38

Transmission Range Switch .....................36

Transmission Solenoids and Pressure Switch ..........35

Turbine Speed Sensor ........................38

Traveler and Message Center .....................60

Turn & Hazard Flasher Systems .................61, 62

Hazard Flasher .............................61

Multi-Function Switch ........................62

Turn Signal Flasher ..........................61

Underhood Lamp ......................... .39, 40

Battery .............................. .39, 40

Mercury Switch ......................... .39, 40

Underhood Lamp ........................ .39, 40

Unified Body to Rear Body Wiring .................122

Vehicle Speed Control Servo ......................59

Vehicle Speed Control System and Stop Lamp Switch ......59

Clockspring ...............................59

Powertrain Control Module .....................59

Stop Lamp Switch with Vehicle Speed Control .........59

Stop Lamp Switch without Vehicle Speed Control .......59

Vehicle Speed Control Servo ....................59

8W - 186 WIRING DIAGRAMS AA-BODY Ä