CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 1921 of 2438

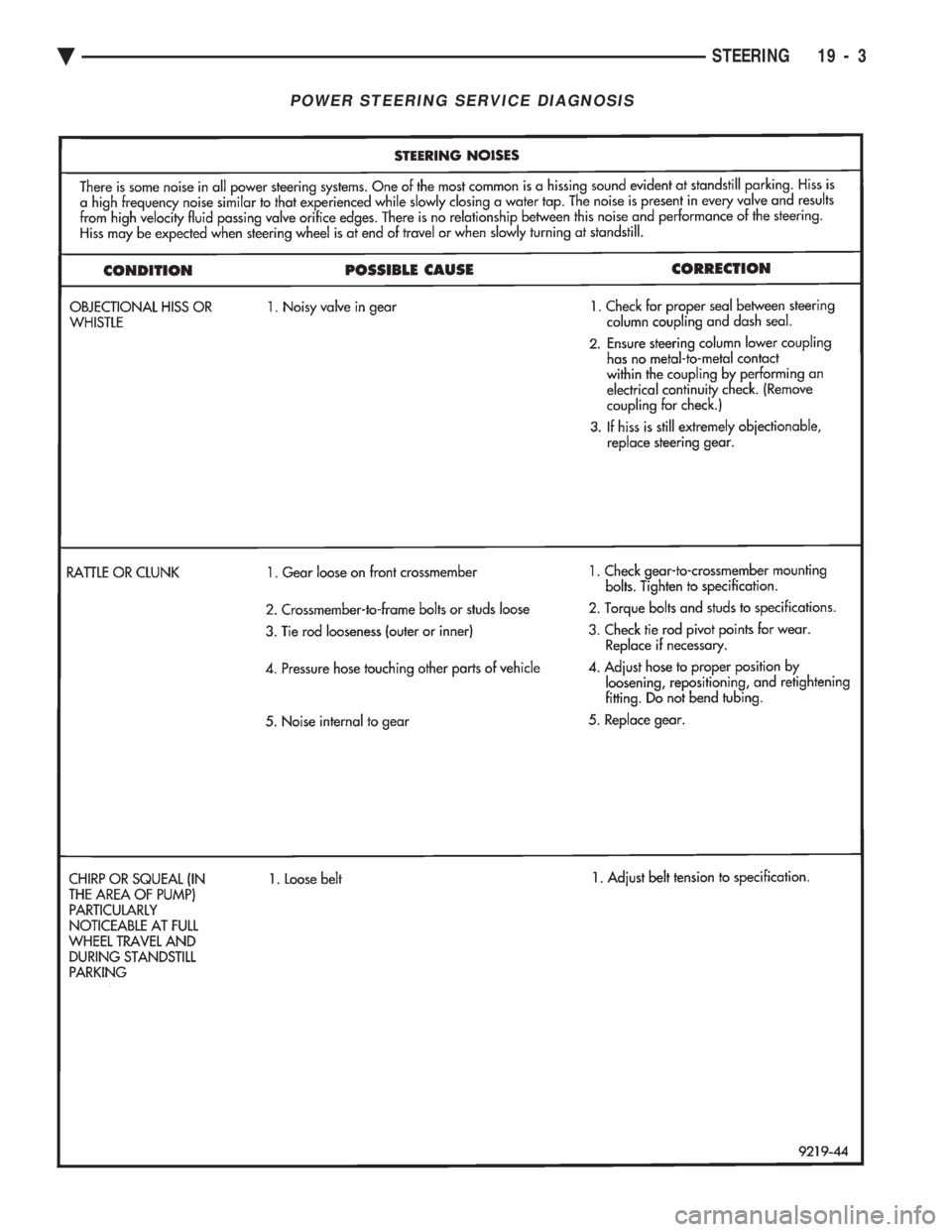

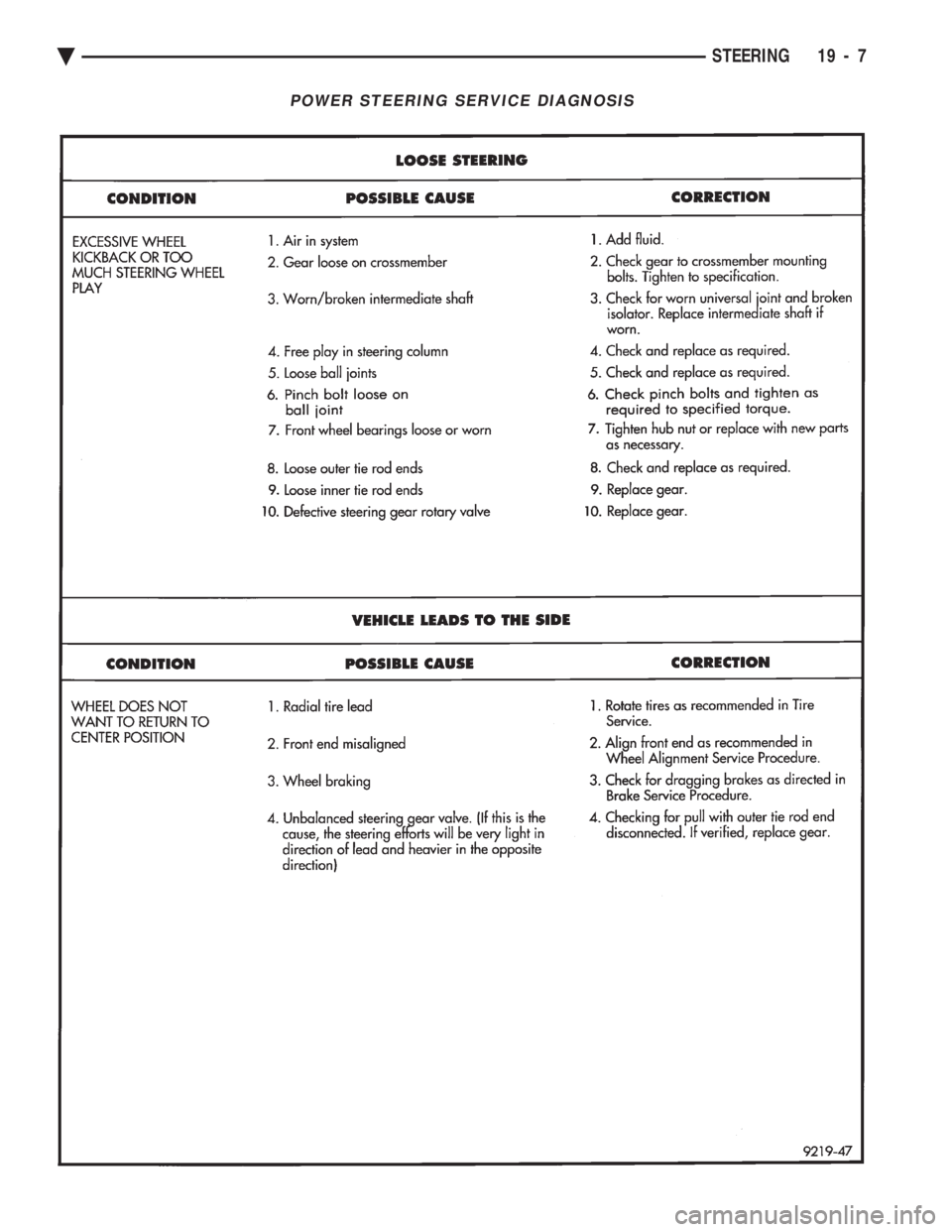

POWER STEERING SERVICE DIAGNOSIS

Ä STEERING 19 - 3

Page 1922 of 2438

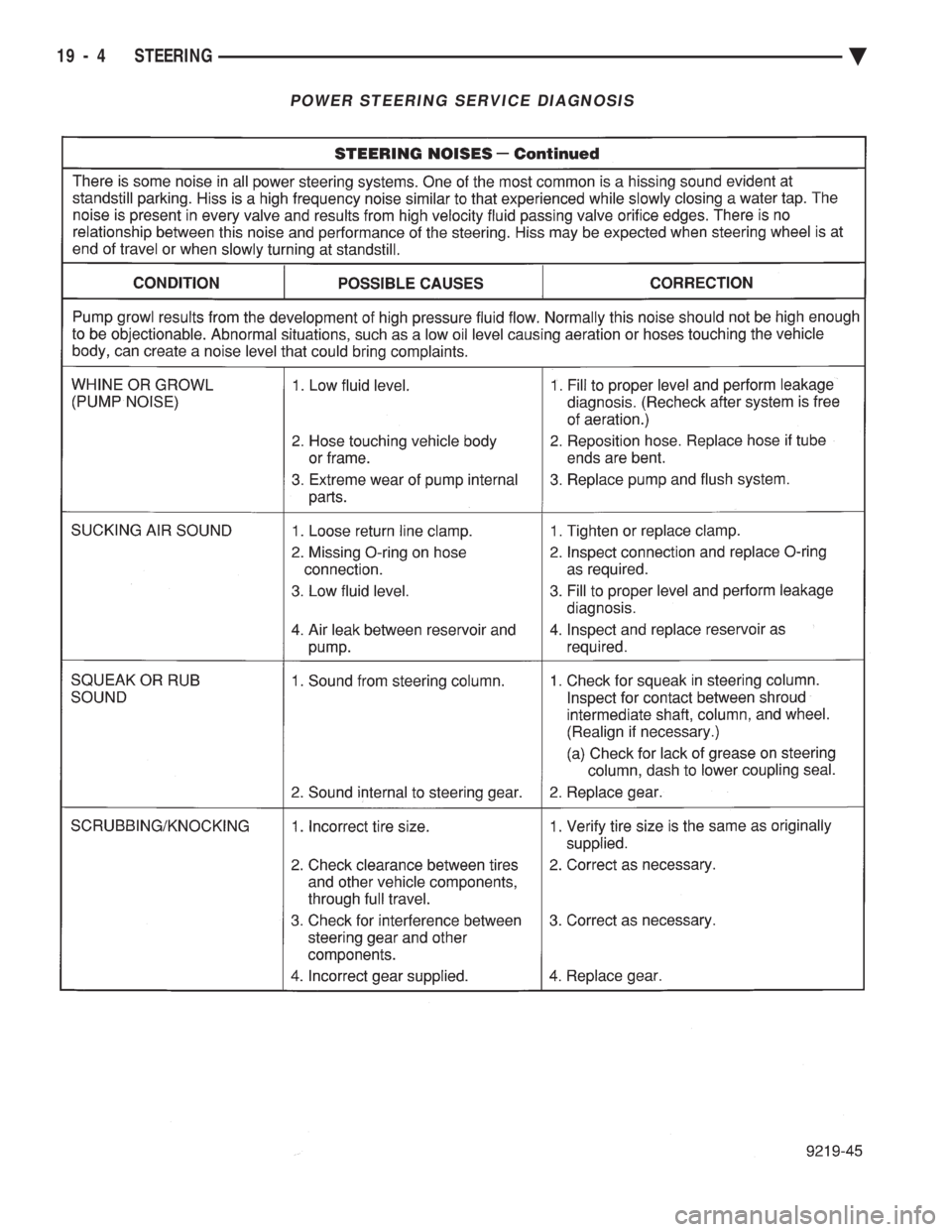

POWER STEERING SERVICE DIAGNOSIS

19 - 4 STEERING Ä

Page 1923 of 2438

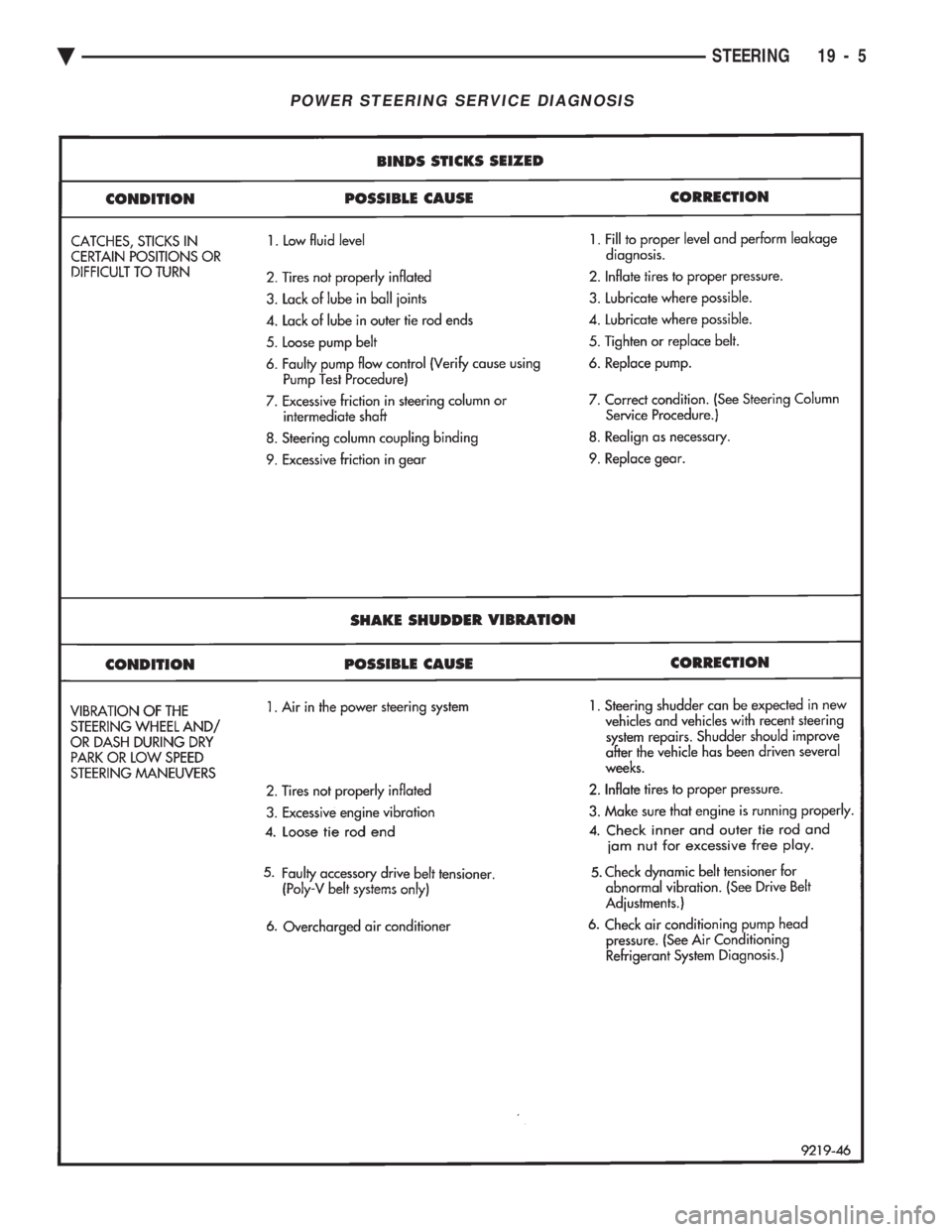

POWER STEERING SERVICE DIAGNOSIS

Ä STEERING 19 - 5

Page 1924 of 2438

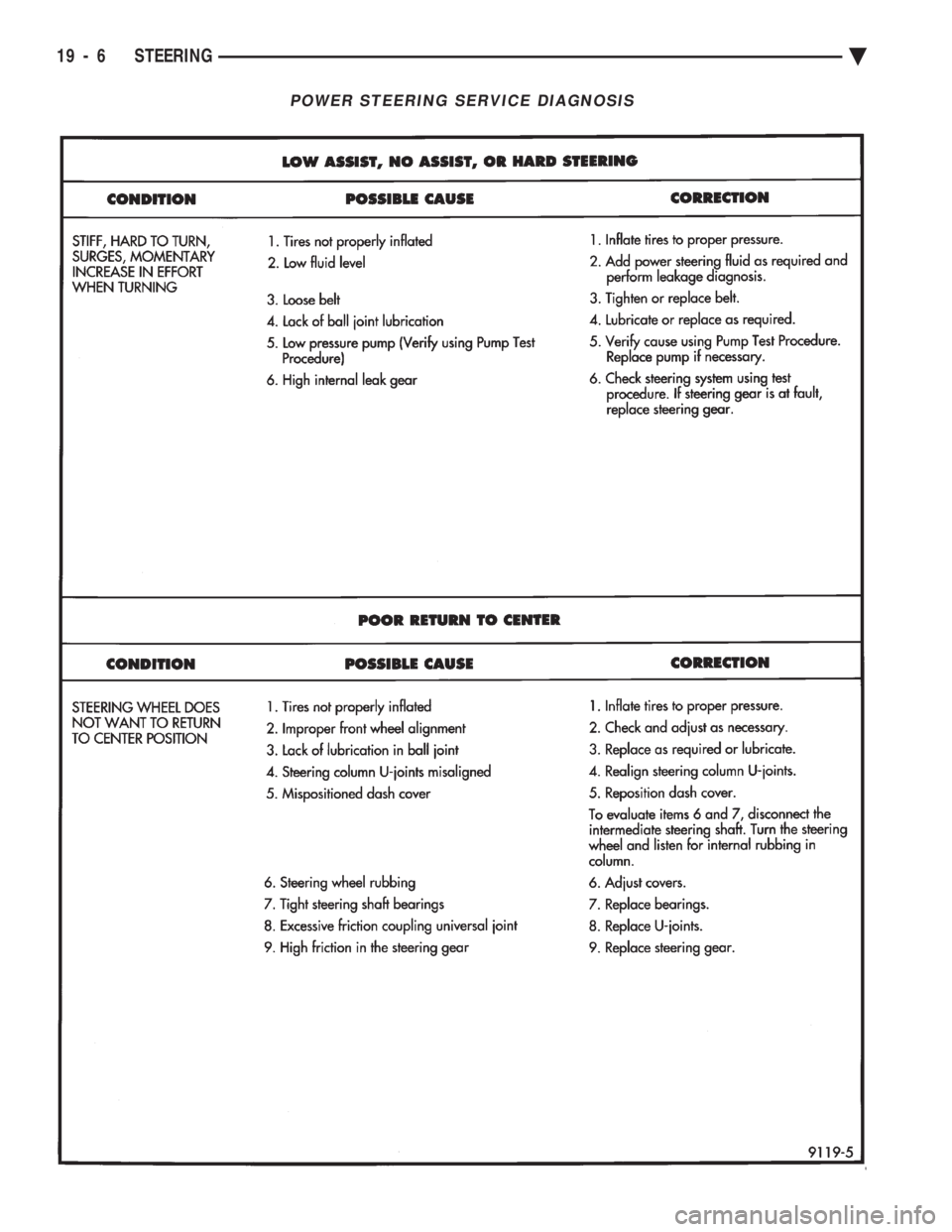

POWER STEERING SERVICE DIAGNOSIS

19 - 6 STEERING Ä

Page 1925 of 2438

POWER STEERING SERVICE DIAGNOSIS

Ä STEERING 19 - 7

Page 1926 of 2438

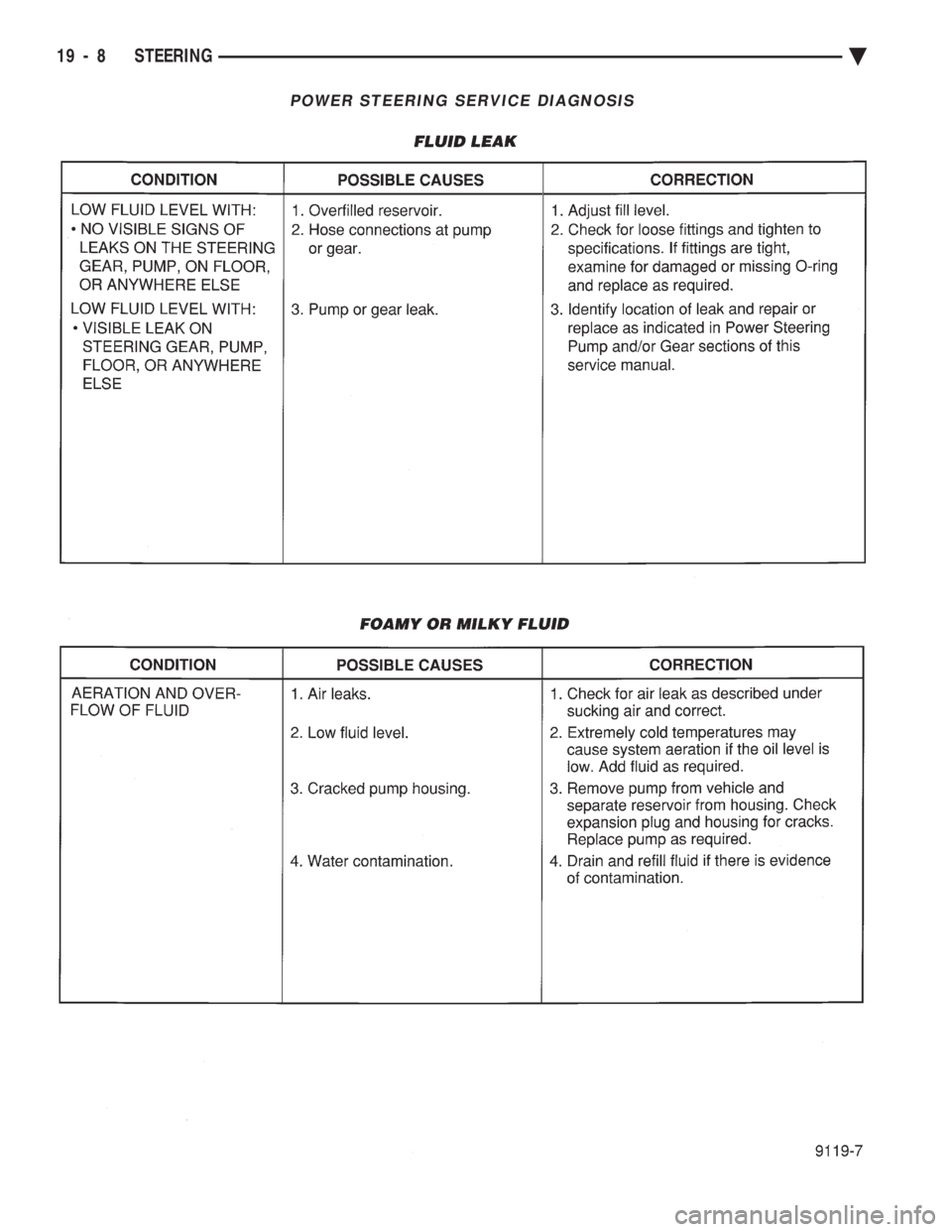

POWER STEERING SERVICE DIAGNOSIS

19 - 8 STEERING Ä

Page 1927 of 2438

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops. The pressure built up in

the steering gear exerts pressure on the spring end of

the flow control valve. The high pressure lifts the re-

lief valve ball from its seat and allows oil to flow

through a trigger orifice located in the outlet fitting.

This reduces pressure on the spring end of the flow

control valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level. Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to re-

main closed.

CHECKING POWER STEERING FLUID LEVEL

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH ENGINE OFF TO PREVENT INJURY FROM

MOVING PARTS. DO NOT USE AUTOMATIC TRANS-

MISSION FLUID IN THE POWER STEERING SYS-

TEM. DO NOT OVERFILL THE POWER STEERING

SYSTEM.

Wipe reservoir filler cap free of dirt, before check-

ing power steering fluid level. The dipstick should in- dicate FULL COLD when fluid is at normal ambient

temperature, approximately 21ÉC to 27ÉC (70ÉF to

80ÉF). In all pumps add fluid as necessary to obtain

proper level, using only MopartPower Steering

Fluid, or equivalent. DO NOT USE ANY TYPE

OF AUTOMATIC TRANSMISSION FLUID.

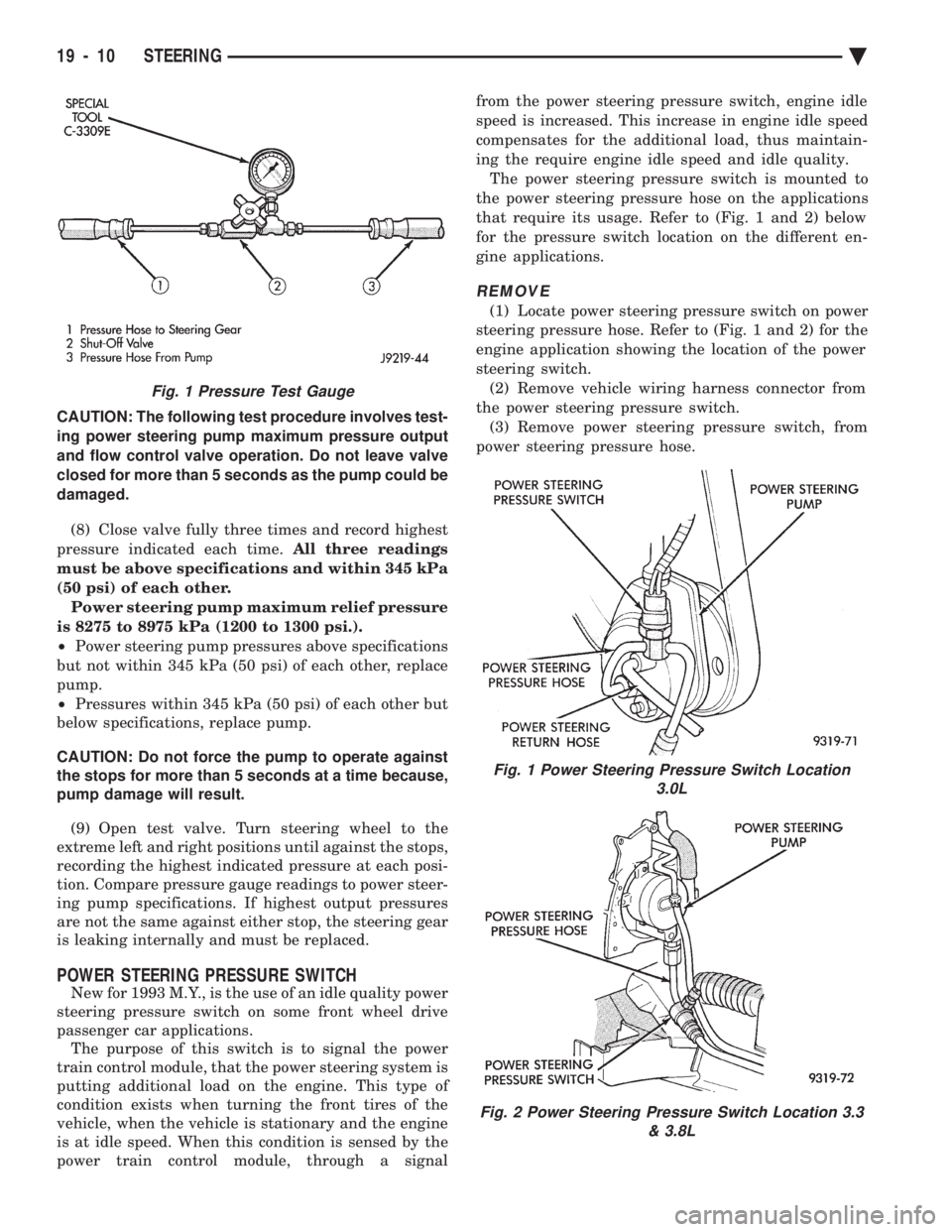

POWER STEERING PUMP PRESSURE TEST

The following procedure can be used to test the op-

eration of the power steering system on the vehicle. (1) Check power steering pump drive belt tension

and adjust as necessary. (2) Disconnect power steering fluid pressure hose,

at steering gear or power steering pump. Use a con-

tainer for dripping fluid. (3) Connect Pressure Gauge, Special Tool C-3309-E

(Fig. 1) to both hoses using adapter fittings. Connect

spare pressure hose to gear or pump. (4) Completely open valve on Special Tool

C-3309-E (Fig. 1). (5) Start engine and let idle.

(6) Check power steering fluid level, and add fluid

as necessary. (7) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the

range of 345-552 kPa (50-80 psi).

PUMP LEAKAGE DIAGNOSIS

Ä STEERING 19 - 9

Page 1928 of 2438

CAUTION: The following test procedure involves test-

ing power steering pump maximum pressure output

and flow control valve operation. Do not leave valve

closed for more than 5 seconds as the pump could be

damaged.

(8) Close valve fully three times and record highest

pressure indicated each time. All three readings

must be above specifications and within 345 kPa

(50 psi) of each other. Power steering pump maximum relief pressure

is 8275 to 8975 kPa (1200 to 1300 psi.).

² Power steering pump pressures above specifications

but not within 345 kPa (50 psi) of each other, replace

pump.

² Pressures within 345 kPa (50 psi) of each other but

below specifications, replace pump.

CAUTION: Do not force the pump to operate against

the stops for more than 5 seconds at a time because,

pump damage will result.

(9) Open test valve. Turn steering wheel to the

extreme left and right positions until against the stops,

recording the highest indicated pressure at each posi-

tion. Compare pressure gauge readings to power steer-

ing pump specifications. If highest output pressures

are not the same against either stop, the steering gear

is leaking internally and must be replaced.

POWER STEERING PRESSURE SWITCH

New for 1993 M.Y., is the use of an idle quality power

steering pressure switch on some front wheel drive

passenger car applications. The purpose of this switch is to signal the power

train control module, that the power steering system is

putting additional load on the engine. This type of

condition exists when turning the front tires of the

vehicle, when the vehicle is stationary and the engine

is at idle speed. When this condition is sensed by the

power train control module, through a signal from the power steering pressure switch, engine idle

speed is increased. This increase in engine idle speed

compensates for the additional load, thus maintain-

ing the require engine idle speed and idle quality.

The power steering pressure switch is mounted to

the power steering pressure hose on the applications

that require its usage. Refer to (Fig. 1 and 2) below

for the pressure switch location on the different en-

gine applications.

REMOVE

(1) Locate power steering pressure switch on power

steering pressure hose. Refer to (Fig. 1 and 2) for the

engine application showing the location of the power

steering switch. (2) Remove vehicle wiring harness connector from

the power steering pressure switch. (3) Remove power steering pressure switch, from

power steering pressure hose.

Fig. 1 Power Steering Pressure Switch Location 3.0L

Fig. 2 Power Steering Pressure Switch Location 3.3 & 3.8L

Fig. 1 Pressure Test Gauge

19 - 10 STEERING Ä

Page 1929 of 2438

INSTALL

(1) Install power steering pressure switch into fit-

ting on power steering pressure hose by hand until

fully seated. Then torque power steering pressure

switch to 12 N Im (106 in. lbs.).

(2) Install vehicle wiring harness connector onto

power steering pressure switch. Be sure latch on wir-

ing harness connector is fully engaged with locking

tab on power steering pressure switch.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(3) Fill power steering pump reservoir to correct

fluid level. (4) Connect negative cable back on negative post of

battery. (5) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

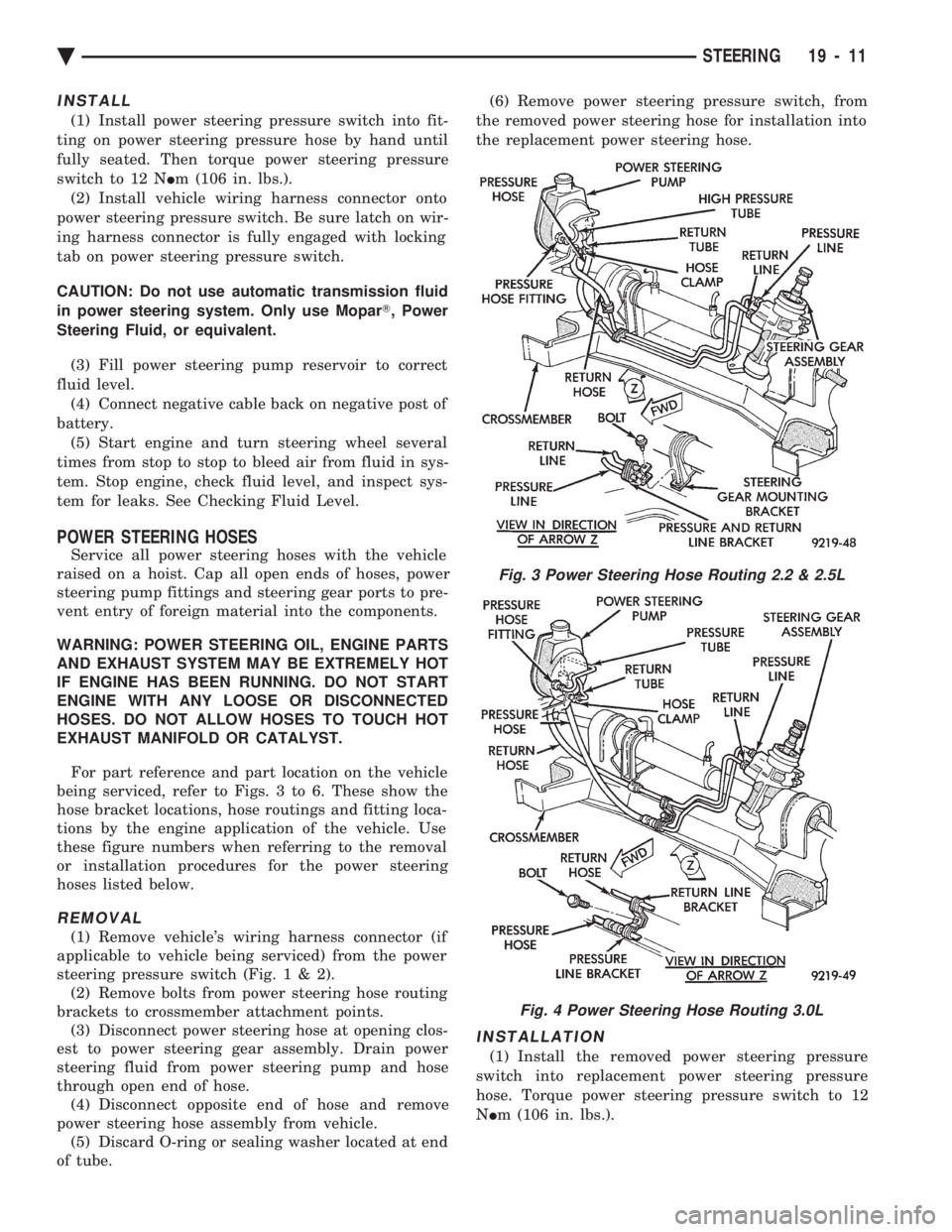

POWER STEERING HOSES

Service all power steering hoses with the vehicle

raised on a hoist. Cap all open ends of hoses, power

steering pump fittings and steering gear ports to pre-

vent entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE PARTS

AND EXHAUST SYSTEM MAY BE EXTREMELY HOT

IF ENGINE HAS BEEN RUNNING. DO NOT START

ENGINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

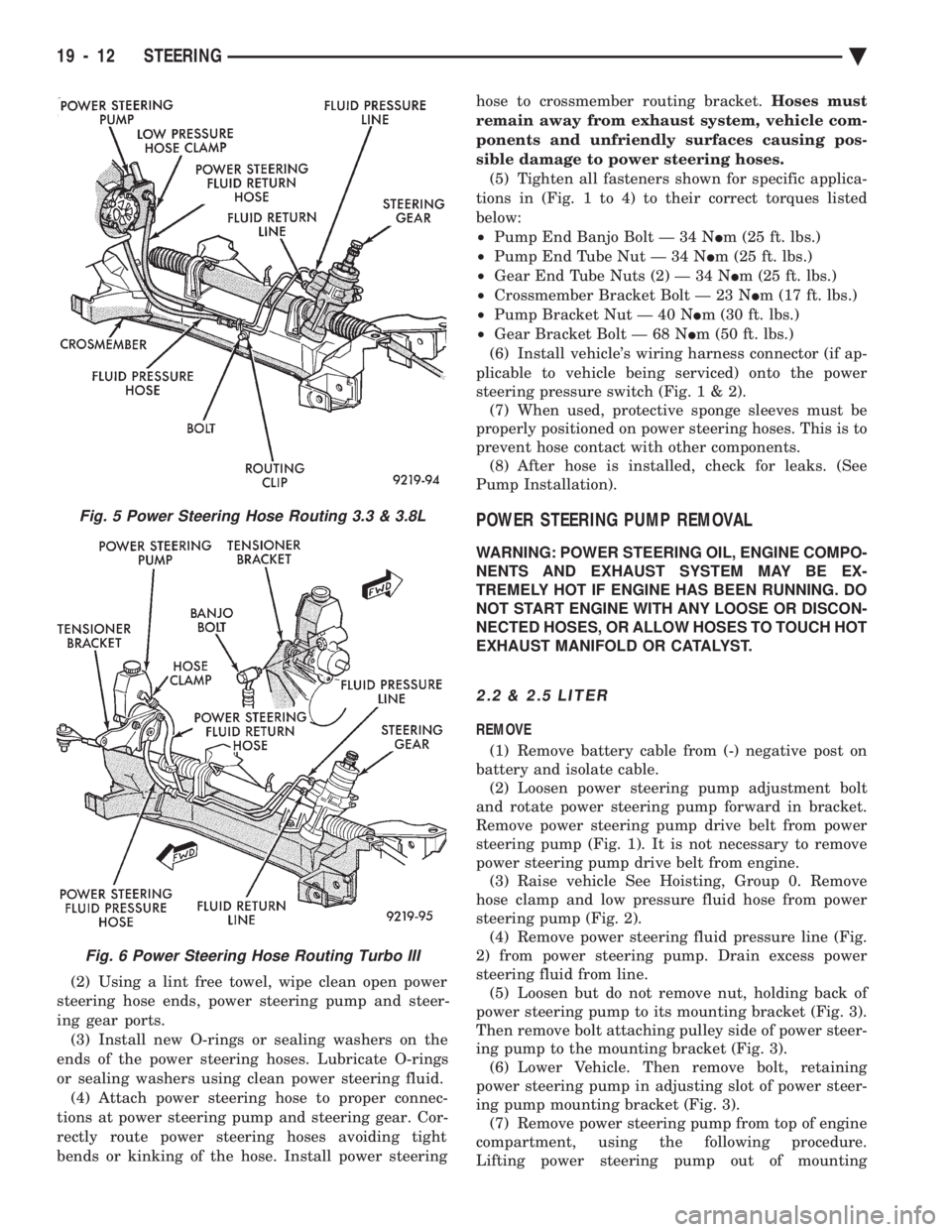

For part reference and part location on the vehicle

being serviced, refer to Figs. 3 to 6. These show the

hose bracket locations, hose routings and fitting loca-

tions by the engine application of the vehicle. Use

these figure numbers when referring to the removal

or installation procedures for the power steering

hoses listed below.

REMOVAL

(1) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig .1&2).

(2) Remove bolts from power steering hose routing

brackets to crossmember attachment points. (3) Disconnect power steering hose at opening clos-

est to power steering gear assembly. Drain power

steering fluid from power steering pump and hose

through open end of hose. (4) Disconnect opposite end of hose and remove

power steering hose assembly from vehicle. (5) Discard O-ring or sealing washer located at end

of tube. (6) Remove power steering pressure switch, from

the removed power steering hose for installation into

the replacement power steering hose.

INSTALLATION

(1) Install the removed power steering pressure

switch into replacement power steering pressure

hose. Torque power steering pressure switch to 12

N Im (106 in. lbs.).

Fig. 3 Power Steering Hose Routing 2.2 & 2.5L

Fig. 4 Power Steering Hose Routing 3.0L

Ä STEERING 19 - 11

Page 1930 of 2438

(2) Using a lint free towel, wipe clean open power

steering hose ends, power steering pump and steer-

ing gear ports. (3) Install new O-rings or sealing washers on the

ends of the power steering hoses. Lubricate O-rings

or sealing washers using clean power steering fluid. (4) Attach power steering hose to proper connec-

tions at power steering pump and steering gear. Cor-

rectly route power steering hoses avoiding tight

bends or kinking of the hose. Install power steering hose to crossmember routing bracket.

Hoses must

remain away from exhaust system, vehicle com-

ponents and unfriendly surfaces causing pos-

sible damage to power steering hoses. (5) Tighten all fasteners shown for specific applica-

tions in (Fig. 1 to 4) to their correct torques listed

below:

² Pump End Banjo Bolt Ð 34 N Im (25 ft. lbs.)

² Pump End Tube Nut Ð 34 N Im (25 ft. lbs.)

² Gear End Tube Nuts (2) Ð 34 N Im (25 ft. lbs.)

² Crossmember Bracket Bolt Ð 23 N Im (17 ft. lbs.)

² Pump Bracket Nut Ð 40 N Im (30 ft. lbs.)

² Gear Bracket Bolt Ð 68 N Im (50 ft. lbs.)

(6) Install vehicle's wiring harness connector (if ap-

plicable to vehicle being serviced) onto the power

steering pressure switch (Fig .1&2).

(7) When used, protective sponge sleeves must be

properly positioned on power steering hoses. This is to

prevent hose contact with other components. (8) After hose is installed, check for leaks. (See

Pump Installation).

POWER STEERING PUMP REMOVAL

WARNING: POWER STEERING OIL, ENGINE COMPO-

NENTS AND EXHAUST SYSTEM MAY BE EX-

TREMELY HOT IF ENGINE HAS BEEN RUNNING. DO

NOT START ENGINE WITH ANY LOOSE OR DISCON-

NECTED HOSES, OR ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

2.2 & 2.5 LITER

REMOVE

(1) Remove battery cable from (-) negative post on

battery and isolate cable. (2) Loosen power steering pump adjustment bolt

and rotate power steering pump forward in bracket.

Remove power steering pump drive belt from power

steering pump (Fig. 1). It is not necessary to remove

power steering pump drive belt from engine. (3) Raise vehicle See Hoisting, Group 0. Remove

hose clamp and low pressure fluid hose from power

steering pump (Fig. 2). (4) Remove power steering fluid pressure line (Fig.

2) from power steering pump. Drain excess power

steering fluid from line. (5) Loosen but do not remove nut, holding back of

power steering pump to its mounting bracket (Fig. 3).

Then remove bolt attaching pulley side of power steer-

ing pump to the mounting bracket (Fig. 3). (6) Lower Vehicle. Then remove bolt, retaining

power steering pump in adjusting slot of power steer-

ing pump mounting bracket (Fig. 3). (7) Remove power steering pump from top of engine

compartment, using the following procedure.

Lifting power steering pump out of mounting

Fig. 5 Power Steering Hose Routing 3.3 & 3.8L

Fig. 6 Power Steering Hose Routing Turbo III

19 - 12 STEERING Ä