CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 581 of 2438

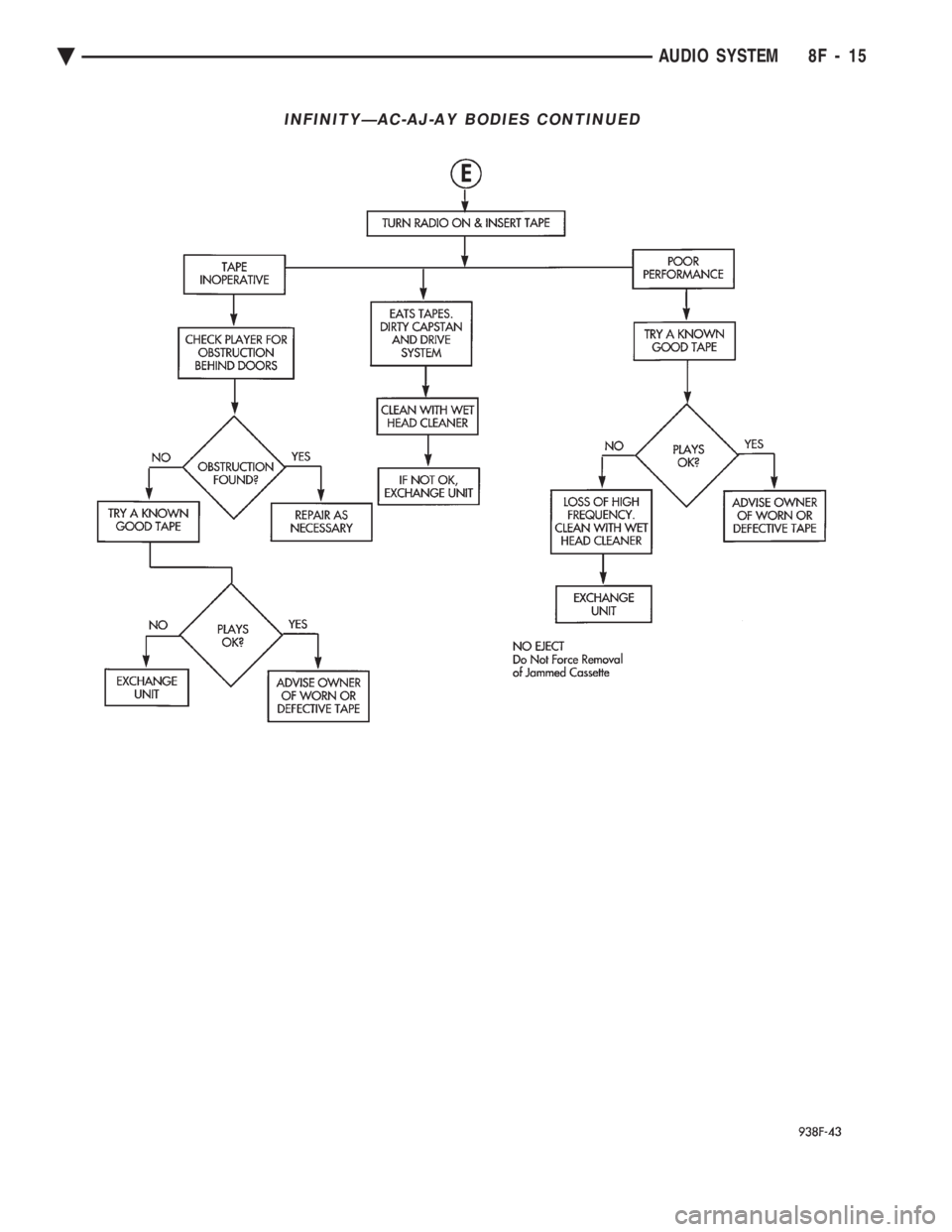

INFINITYÐAC-AJ-AY BODIES CONTINUED

Ä AUDIO SYSTEM 8F - 15

Page 582 of 2438

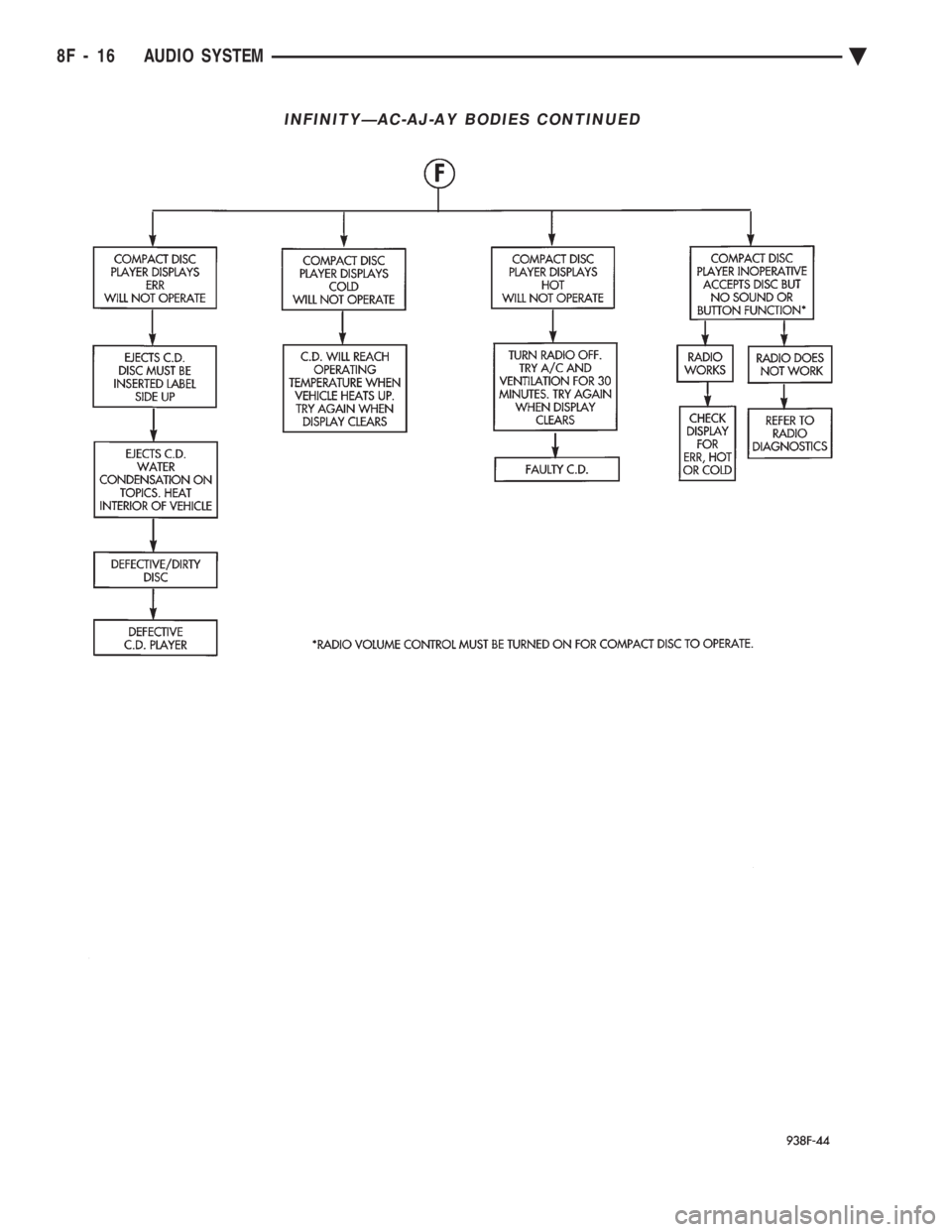

INFINITYÐAC-AJ-AY BODIES CONTINUED

8F - 16 AUDIO SYSTEM Ä

Page 583 of 2438

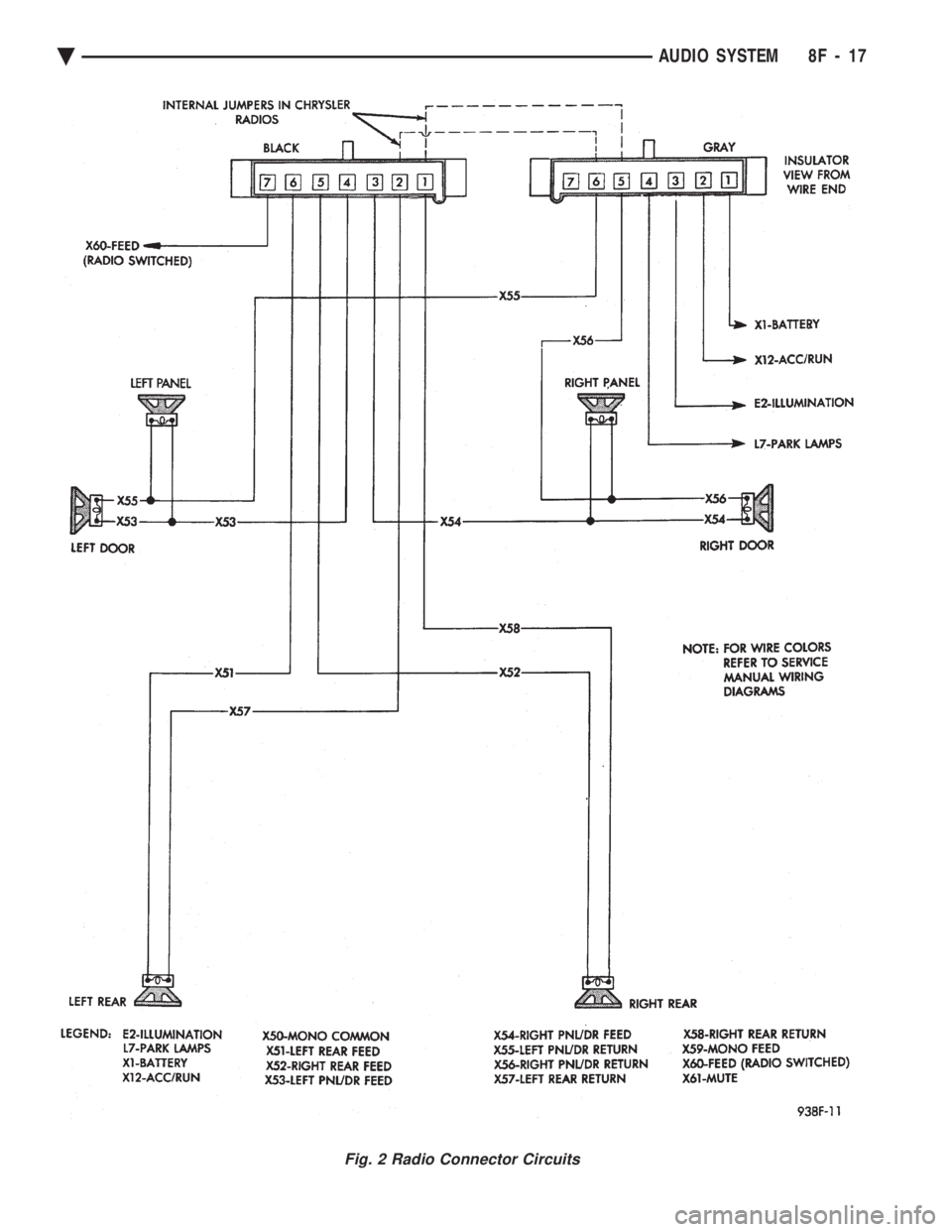

Fig. 2 Radio Connector Circuits

Ä AUDIO SYSTEM 8F - 17

Page 584 of 2438

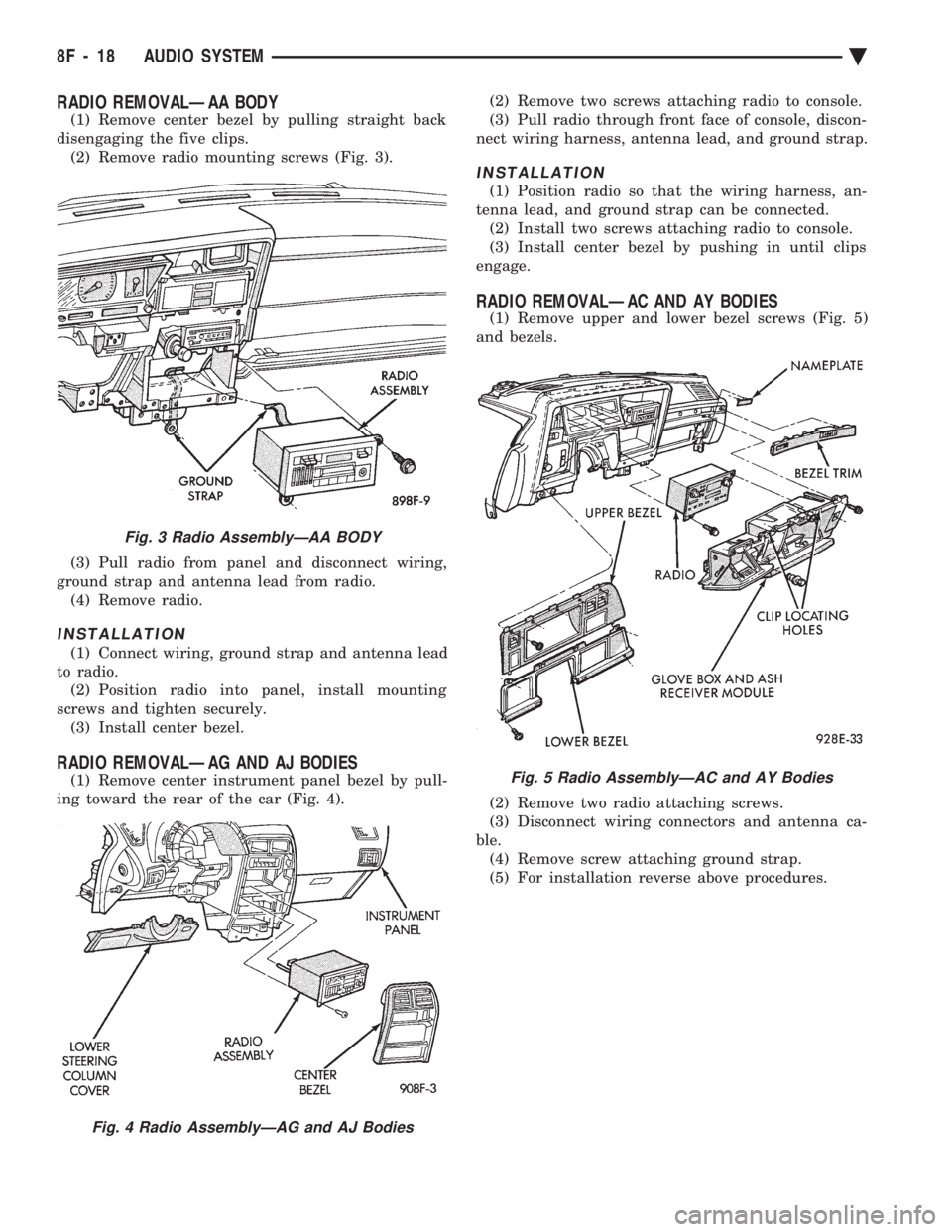

RADIO REMOVALÐAA BODY

(1) Remove center bezel by pulling straight back

disengaging the five clips. (2) Remove radio mounting screws (Fig. 3).

(3) Pull radio from panel and disconnect wiring,

ground strap and antenna lead from radio. (4) Remove radio.

INSTALLATION

(1) Connect wiring, ground strap and antenna lead

to radio. (2) Position radio into panel, install mounting

screws and tighten securely. (3) Install center bezel.

RADIO REMOVALÐAG AND AJ BODIES

(1) Remove center instrument panel bezel by pull-

ing toward the rear of the car (Fig. 4). (2) Remove two screws attaching radio to console.

(3) Pull radio through front face of console, discon-

nect wiring harness, antenna lead, and ground strap.

INSTALLATION

(1) Position radio so that the wiring harness, an-

tenna lead, and ground strap can be connected. (2) Install two screws attaching radio to console.

(3) Install center bezel by pushing in until clips

engage.

RADIO REMOVALÐAC AND AY BODIES

(1) Remove upper and lower bezel screws (Fig. 5)

and bezels.

(2) Remove two radio attaching screws.

(3) Disconnect wiring connectors and antenna ca-

ble. (4) Remove screw attaching ground strap.

(5) For installation reverse above procedures.

Fig. 3 Radio AssemblyÐAA BODY

Fig. 4 Radio AssemblyÐAG and AJ Bodies

Fig. 5 Radio AssemblyÐAC and AY Bodies

8F - 18 AUDIO SYSTEM Ä

Page 585 of 2438

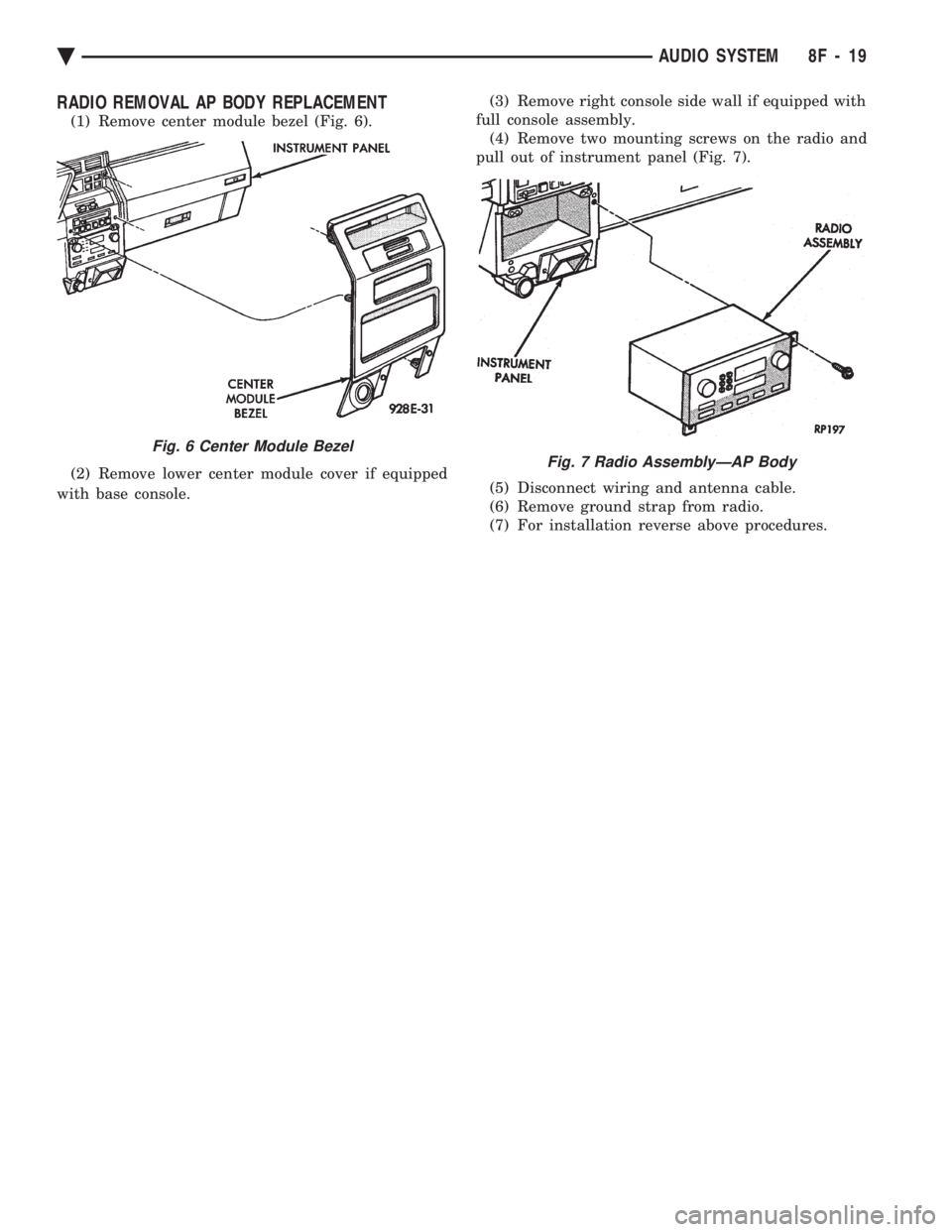

RADIO REMOVAL AP BODY REPLACEMENT

(1) Remove center module bezel (Fig. 6).

(2) Remove lower center module cover if equipped

with base console. (3) Remove right console side wall if equipped with

full console assembly. (4) Remove two mounting screws on the radio and

pull out of instrument panel (Fig. 7).

(5) Disconnect wiring and antenna cable.

(6) Remove ground strap from radio.

(7) For installation reverse above procedures.

Fig. 6 Center Module Bezel

Fig. 7 Radio AssemblyÐAP Body

Ä AUDIO SYSTEM 8F - 19

Page 586 of 2438

ANTENNAS INDEX

page page

Manual Antennas ........................ 20

Power Antenna .......................... 21 Power Antenna Mast

...................... 23

MANUAL ANTENNAS

TESTING

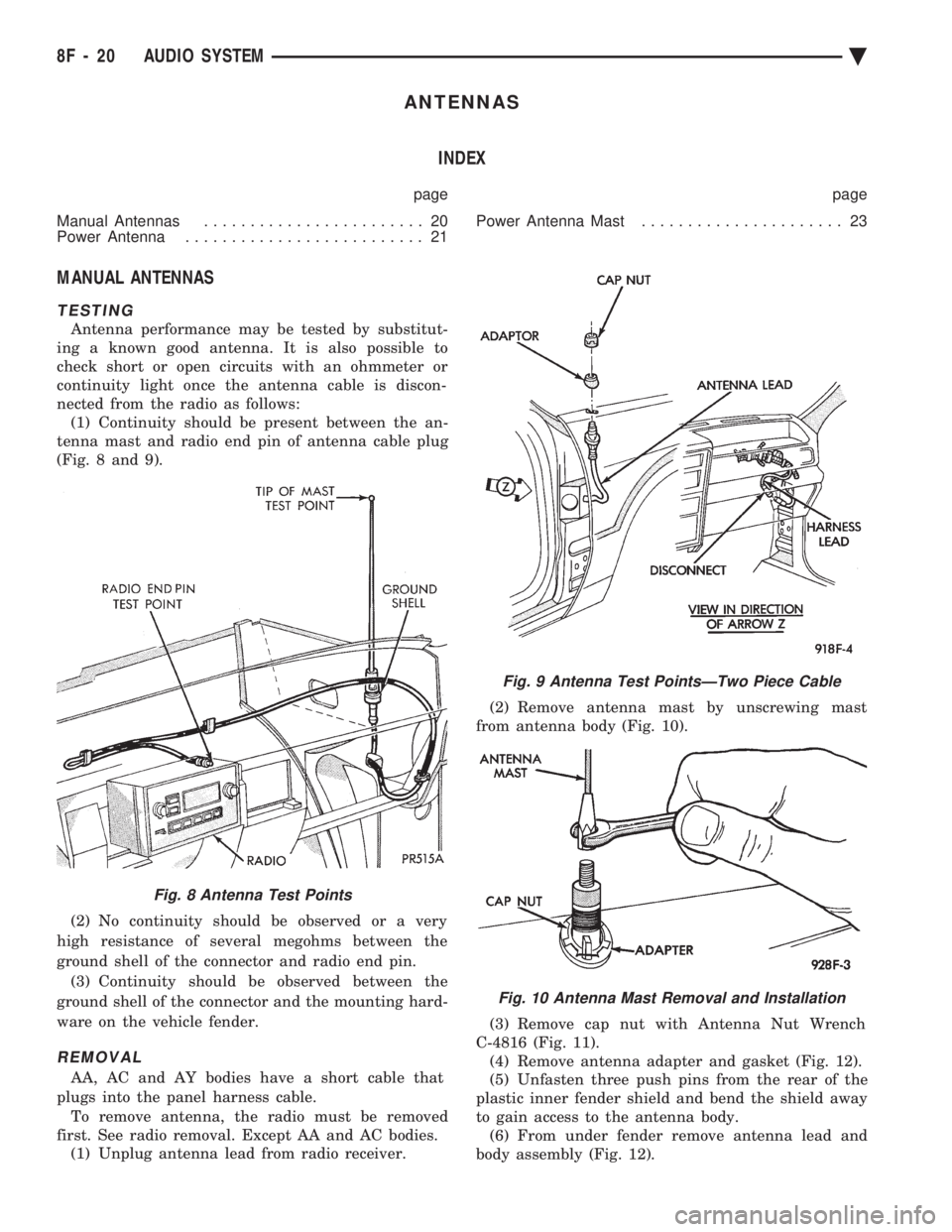

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows: (1) Continuity should be present between the an-

tenna mast and radio end pin of antenna cable plug

(Fig. 8 and 9).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin. (3) Continuity should be observed between the

ground shell of the connector and the mounting hard-

ware on the vehicle fender.

REMOVAL

AA, AC and AY bodies have a short cable that

plugs into the panel harness cable. To remove antenna, the radio must be removed

first. See radio removal. Except AA and AC bodies. (1) Unplug antenna lead from radio receiver. (2) Remove antenna mast by unscrewing mast

from antenna body (Fig. 10).

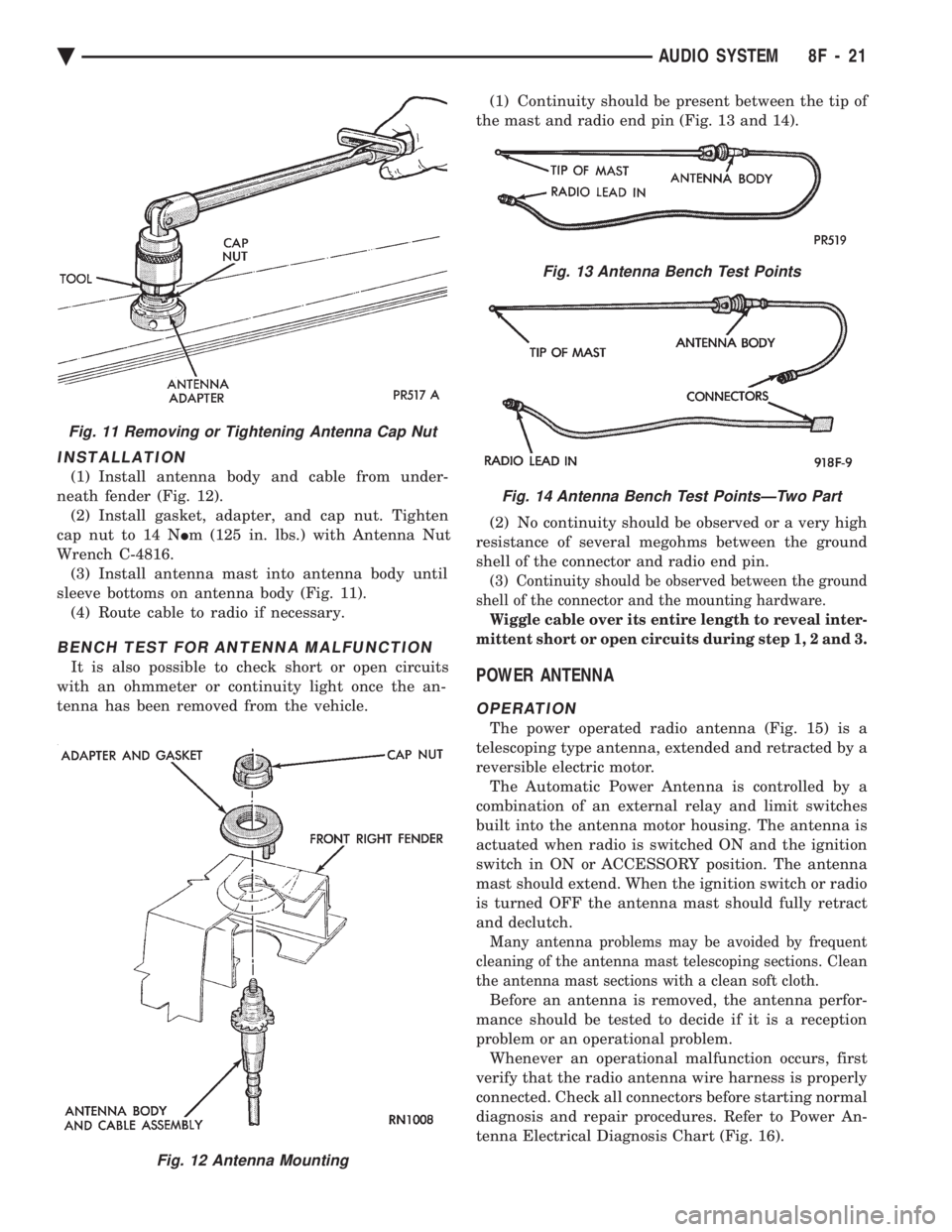

(3) Remove cap nut with Antenna Nut Wrench

C-4816 (Fig. 11). (4) Remove antenna adapter and gasket (Fig. 12).

(5) Unfasten three push pins from the rear of the

plastic inner fender shield and bend the shield away

to gain access to the antenna body. (6) From under fender remove antenna lead and

body assembly (Fig. 12).

Fig. 8 Antenna Test Points

Fig. 9 Antenna Test PointsÐTwo Piece Cable

Fig. 10 Antenna Mast Removal and Installation

8F - 20 AUDIO SYSTEM Ä

Page 587 of 2438

INSTALLATION

(1) Install antenna body and cable from under-

neath fender (Fig. 12). (2) Install gasket, adapter, and cap nut. Tighten

cap nut to 14 N Im (125 in. lbs.) with Antenna Nut

Wrench C-4816. (3) Install antenna mast into antenna body until

sleeve bottoms on antenna body (Fig. 11). (4) Route cable to radio if necessary.

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the an-

tenna has been removed from the vehicle. (1) Continuity should be present between the tip of

the mast and radio end pin (Fig. 13 and 14).

(2) No continuity should be observed or a very high

resistance of several megohms between the ground

shell of the connector and radio end pin.

(3) Continuity should be observed between the ground

shell of the connector and the mounting hardware.

Wiggle cable over its entire length to reveal inter-

mittent short or open circuits during step 1, 2 and 3.

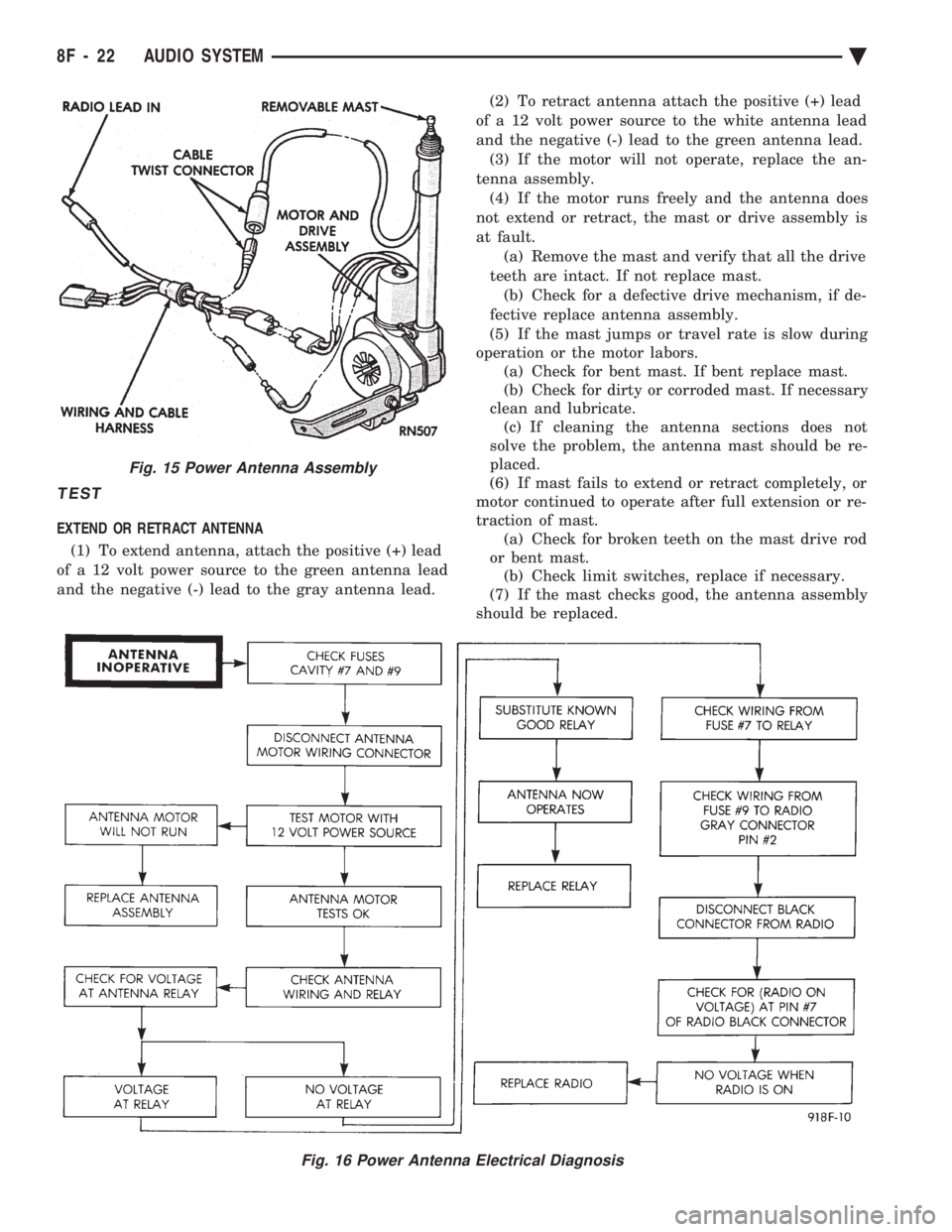

POWER ANTENNA

OPERATION

The power operated radio antenna (Fig. 15) is a

telescoping type antenna, extended and retracted by a

reversible electric motor. The Automatic Power Antenna is controlled by a

combination of an external relay and limit switches

built into the antenna motor housing. The antenna is

actuated when radio is switched ON and the ignition

switch in ON or ACCESSORY position. The antenna

mast should extend. When the ignition switch or radio

is turned OFF the antenna mast should fully retract

and declutch.

Many antenna problems may be avoided by frequent

cleaning of the antenna mast telescoping sections. Clean

the antenna mast sections with a clean soft cloth.

Before an antenna is removed, the antenna perfor-

mance should be tested to decide if it is a reception

problem or an operational problem. Whenever an operational malfunction occurs, first

verify that the radio antenna wire harness is properly

connected. Check all connectors before starting normal

diagnosis and repair procedures. Refer to Power An-

tenna Electrical Diagnosis Chart (Fig. 16).

Fig. 12 Antenna Mounting

Fig. 11 Removing or Tightening Antenna Cap Nut

Fig. 13 Antenna Bench Test Points

Fig. 14 Antenna Bench Test PointsÐTwo Part

Ä AUDIO SYSTEM 8F - 21

Page 588 of 2438

TEST

EXTEND OR RETRACT ANTENNA (1) To extend antenna, attach the positive (+) lead

of a 12 volt power source to the green antenna lead

and the negative (-) lead to the gray antenna lead. (2) To retract antenna attach the positive (+) lead

of a 12 volt power source to the white antenna lead

and the negative (-) lead to the green antenna lead. (3) If the motor will not operate, replace the an-

tenna assembly. (4) If the motor runs freely and the antenna does

not extend or retract, the mast or drive assembly is

at fault. (a) Remove the mast and verify that all the drive

teeth are intact. If not replace mast. (b) Check for a defective drive mechanism, if de-

fective replace antenna assembly.

(5) If the mast jumps or travel rate is slow during

operation or the motor labors. (a) Check for bent mast. If bent replace mast.

(b) Check for dirty or corroded mast. If necessary

clean and lubricate. (c) If cleaning the antenna sections does not

solve the problem, the antenna mast should be re-

placed.

(6) If mast fails to extend or retract completely, or

motor continued to operate after full extension or re-

traction of mast. (a) Check for broken teeth on the mast drive rod

or bent mast. (b) Check limit switches, replace if necessary.

(7) If the mast checks good, the antenna assembly

should be replaced.

Fig. 15 Power Antenna Assembly

Fig. 16 Power Antenna Electrical Diagnosis

8F - 22 AUDIO SYSTEM Ä

Page 589 of 2438

(8) Upon establishing that the fault is in the an-

tenna assembly, it may be traced to one or more of

the following conditions: (a) Broken lead-in wire or shielding.

(b) Grounded lead-in wire or mast assembly.

(c) Moisture in support tube or lead-in assembly.

(d) Poor connection at antenna lead-in assembly

or shielding ground.

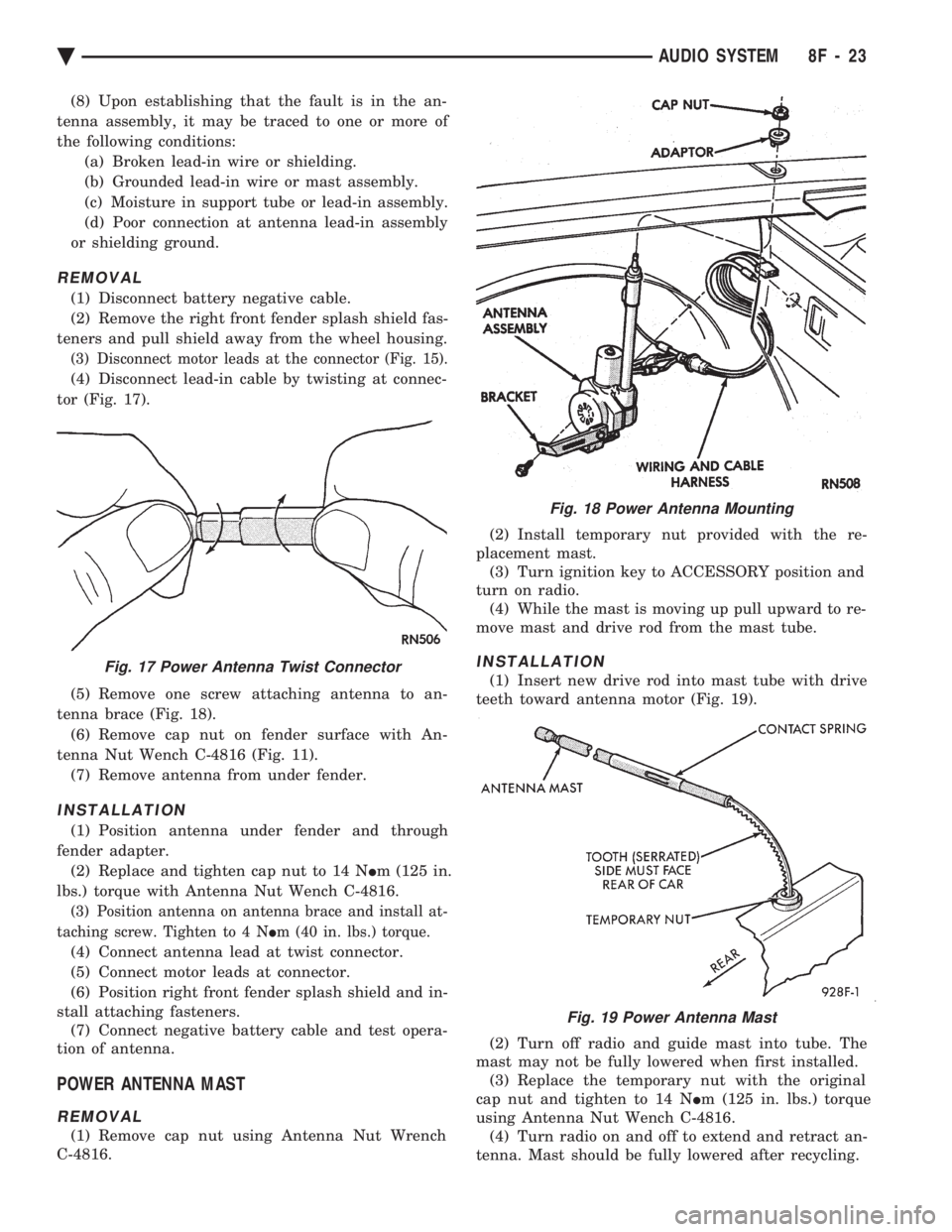

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the right front fender splash shield fas-

teners and pull shield away from the wheel housing.

(3) Disconnect motor leads at the connector (Fig. 15).

(4) Disconnect lead-in cable by twisting at connec-

tor (Fig. 17).

(5) Remove one screw attaching antenna to an-

tenna brace (Fig. 18). (6) Remove cap nut on fender surface with An-

tenna Nut Wench C-4816 (Fig. 11). (7) Remove antenna from under fender.

INSTALLATION

(1) Position antenna under fender and through

fender adapter. (2) Replace and tighten cap nut to 14 N Im (125 in.

lbs.) torque with Antenna Nut Wench C-4816.

(3) Position antenna on antenna brace and install at-

taching screw. Tighten to 4 N Im (40 in. lbs.) torque.

(4) Connect antenna lead at twist connector.

(5) Connect motor leads at connector.

(6) Position right front fender splash shield and in-

stall attaching fasteners. (7) Connect negative battery cable and test opera-

tion of antenna.

POWER ANTENNA MAST

REMOVAL

(1) Remove cap nut using Antenna Nut Wrench

C-4816. (2) Install temporary nut provided with the re-

placement mast. (3) Turn ignition key to ACCESSORY position and

turn on radio. (4) While the mast is moving up pull upward to re-

move mast and drive rod from the mast tube.

INSTALLATION

(1) Insert new drive rod into mast tube with drive

teeth toward antenna motor (Fig. 19).

(2) Turn off radio and guide mast into tube. The

mast may not be fully lowered when first installed. (3) Replace the temporary nut with the original

cap nut and tighten to 14 N Im (125 in. lbs.) torque

using Antenna Nut Wench C-4816. (4) Turn radio on and off to extend and retract an-

tenna. Mast should be fully lowered after recycling.

Fig. 18 Power Antenna Mounting

Fig. 17 Power Antenna Twist Connector

Fig. 19 Power Antenna Mast

Ä AUDIO SYSTEM 8F - 23

Page 590 of 2438

SPEAKERS INDEX

page page

AA Body ............................... 24

AC and AY Bodies ....................... 27

AC and AY Bodies ....................... 24

AG and AJ Bodies ....................... 25 AP Body

............................... 26

Infinity Remote Amplifier ................... 28

Relay/ChokeÐInfinity Speaker ............... 29

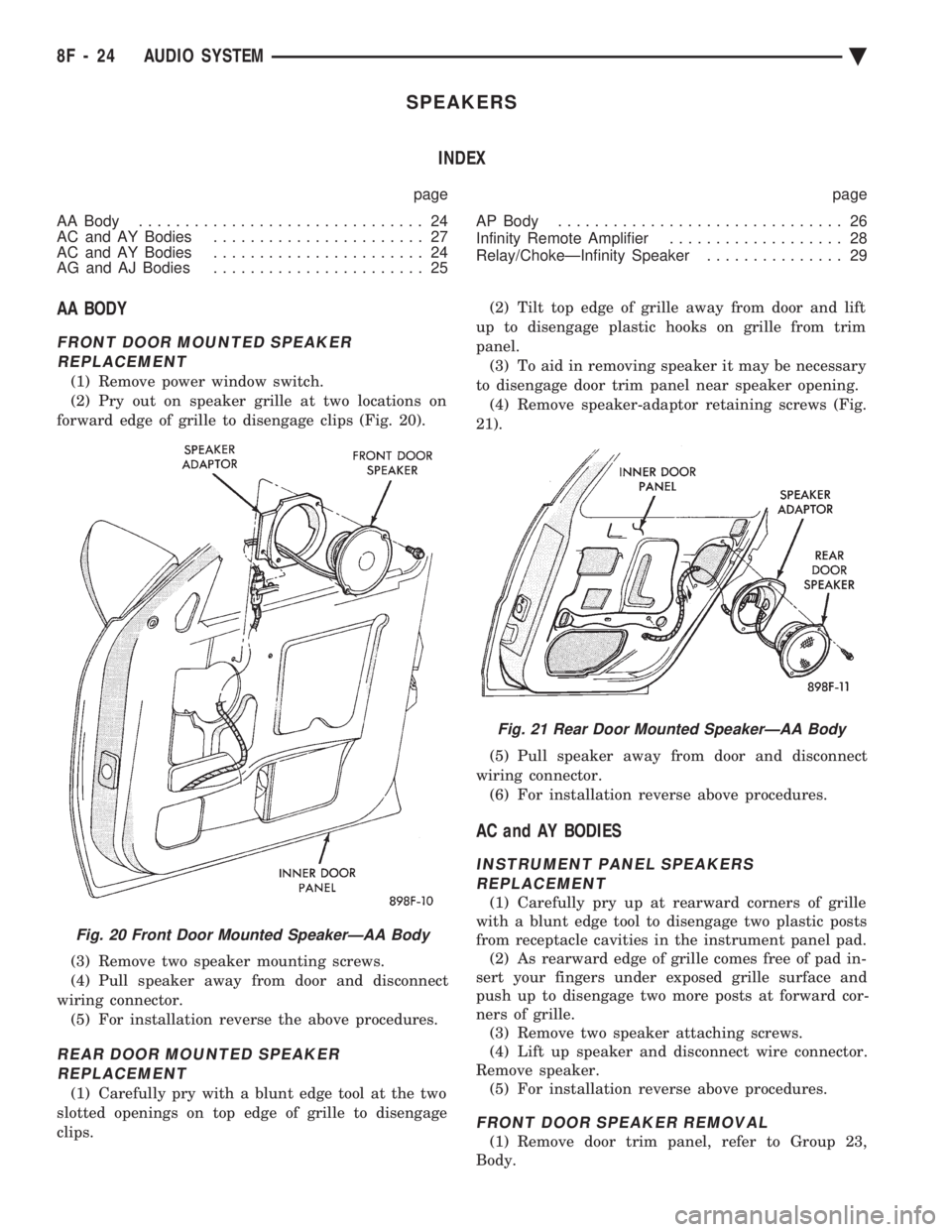

AA BODY

FRONT DOOR MOUNTED SPEAKER

REPLACEMENT

(1) Remove power window switch.

(2) Pry out on speaker grille at two locations on

forward edge of grille to disengage clips (Fig. 20).

(3) Remove two speaker mounting screws.

(4) Pull speaker away from door and disconnect

wiring connector. (5) For installation reverse the above procedures.

REAR DOOR MOUNTED SPEAKERREPLACEMENT

(1) Carefully pry with a blunt edge tool at the two

slotted openings on top edge of grille to disengage

clips. (2) Tilt top edge of grille away from door and lift

up to disengage plastic hooks on grille from trim

panel. (3) To aid in removing speaker it may be necessary

to disengage door trim panel near speaker opening. (4) Remove speaker-adaptor retaining screws (Fig.

21).

(5) Pull speaker away from door and disconnect

wiring connector. (6) For installation reverse above procedures.

AC and AY BODIES

INSTRUMENT PANEL SPEAKERSREPLACEMENT

(1) Carefully pry up at rearward corners of grille

with a blunt edge tool to disengage two plastic posts

from receptacle cavities in the instrument panel pad. (2) As rearward edge of grille comes free of pad in-

sert your fingers under exposed grille surface and

push up to disengage two more posts at forward cor-

ners of grille. (3) Remove two speaker attaching screws.

(4) Lift up speaker and disconnect wire connector.

Remove speaker. (5) For installation reverse above procedures.

FRONT DOOR SPEAKER REMOVAL

(1) Remove door trim panel, refer to Group 23,

Body.

Fig. 20 Front Door Mounted SpeakerÐAA Body

Fig. 21 Rear Door Mounted SpeakerÐAA Body

8F - 24 AUDIO SYSTEM Ä