CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 621 of 2438

WINDSHIELD WIPER AND WASHER SYSTEMS

CONTENTS

page page

GENERAL WIPER INFORMATION ........... 1

INTERMITTENT WINDSHIELD WIPER MOTOR AND SWITCH SERVICE PROCEDURES .... 12

WINDSHIELD WASHERS ................. 17 WINDSHIELD WIPER BLADE AND ARM SERVICE

PROCEDURES ......................... 1

WINDSHIELD WIPER MOTOR AND LINKAGE ASSEMBLY SERVICE PROCEDURES ....... 3

GENERAL WIPER INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The windshield wipers can be operated with the

windshield wiper switch only when the ignition

switch is in the ACCESSORY or IGNITION position.

A fuse, located in the fuse block, protects the cir-

cuitry of the wiper system and the vehicle. The wiper motor has permanent magnet fields. The speeds are determined by current flow to the appro-

priate set of brushes. The intermittent wipe system, in addition to low

and high speed, has a delay mode. The delay mode

has a range of 2 to 15 seconds. This is accomplished

by a variable resistor in the wiper switch and is con-

trolled electrically by a relay. The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

WINDSHIELD WIPER BLADE AND ARM SERVICE PROCEDURES

WIPER BLADES

Wiper blades, exposed to the weather for a long pe-

riod of time, tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is suggested to

remove the accumulation of salt and road film. The

wiper blades, arms, and windshield should be cleaned

with a sponge or cloth and a mild detergent or nona-

brasive cleaner. If the blades continue to streak or

smear, they should be replaced.

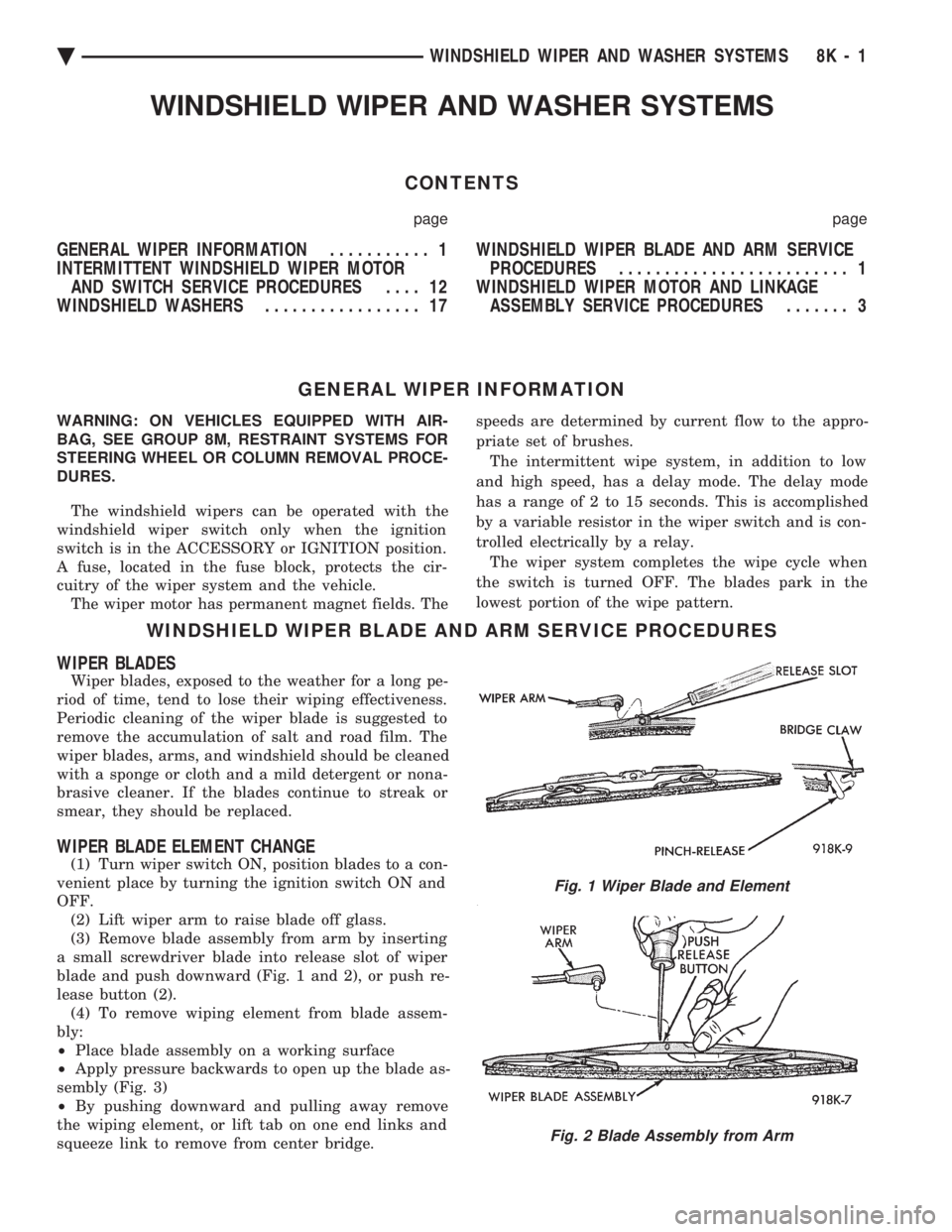

WIPER BLADE ELEMENT CHANGE

(1) Turn wiper switch ON, position blades to a con-

venient place by turning the ignition switch ON and

OFF. (2) Lift wiper arm to raise blade off glass.

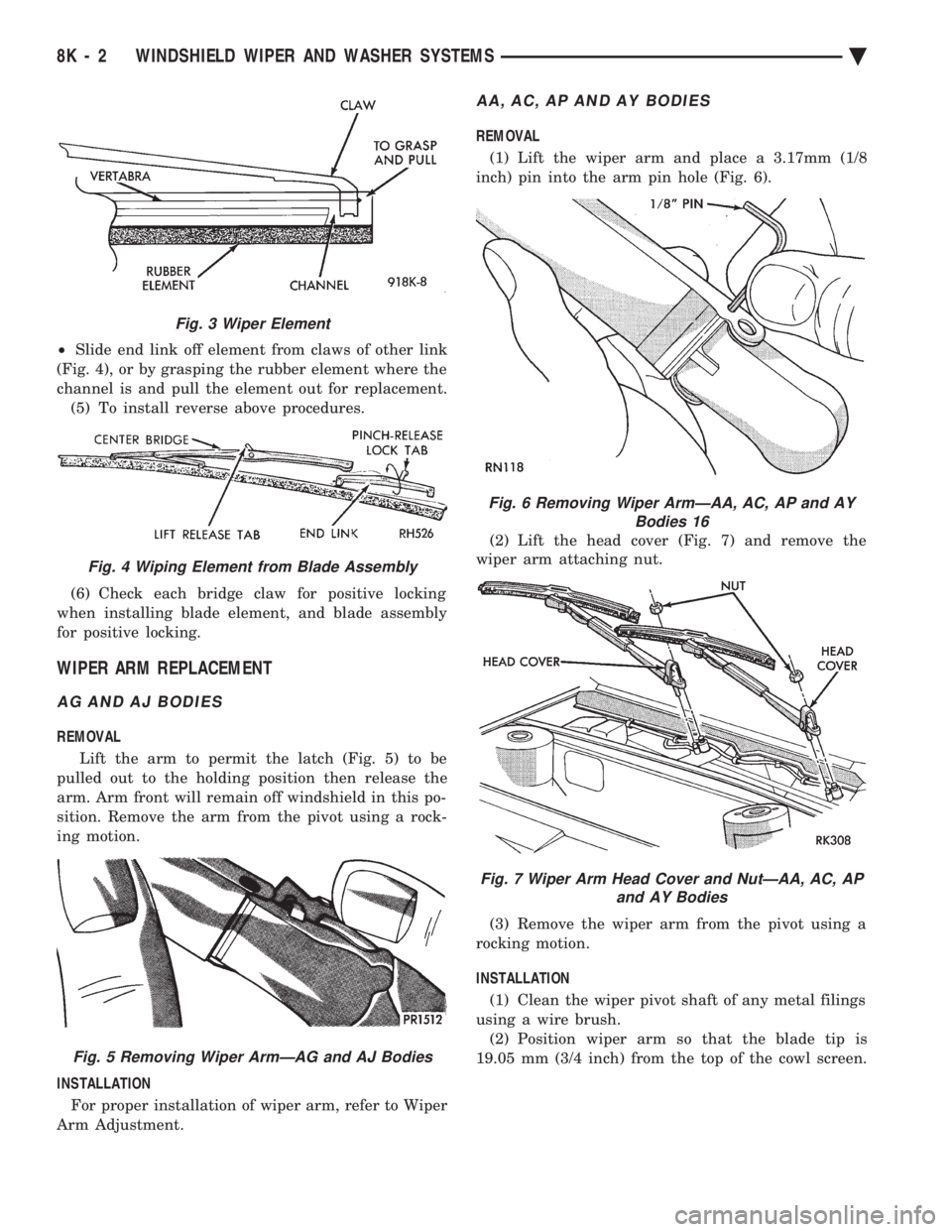

(3) Remove blade assembly from arm by inserting

a small screwdriver blade into release slot of wiper

blade and push downward (Fig. 1 and 2), or push re-

lease button (2). (4) To remove wiping element from blade assem-

bly:

² Place blade assembly on a working surface

² Apply pressure backwards to open up the blade as-

sembly (Fig. 3)

² By pushing downward and pulling away remove

the wiping element, or lift tab on one end links and

squeeze link to remove from center bridge.

Fig. 1 Wiper Blade and Element

Fig. 2 Blade Assembly from Arm

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 1

Page 622 of 2438

² Slide end link off element from claws of other link

(Fig. 4), or by grasping the rubber element where the

channel is and pull the element out for replacement. (5) To install reverse above procedures.

(6) Check each bridge claw for positive locking

when installing blade element, and blade assembly

for positive locking.

WIPER ARM REPLACEMENT

AG AND AJ BODIES

REMOVAL

Lift the arm to permit the latch (Fig. 5) to be

pulled out to the holding position then release the

arm. Arm front will remain off windshield in this po-

sition. Remove the arm from the pivot using a rock-

ing motion.

INSTALLATION For proper installation of wiper arm, refer to Wiper

Arm Adjustment.

AA, AC, AP AND AY BODIES

REMOVAL

(1) Lift the wiper arm and place a 3.17mm (1/8

inch) pin into the arm pin hole (Fig. 6).

(3) Remove the wiper arm from the pivot using a

rocking motion.

INSTALLATION

(1) Clean the wiper pivot shaft of any metal filings

using a wire brush. (2) Position wiper arm so that the blade tip is

19.05 mm (3/4 inch) from the top of the cowl screen.

Fig. 3 Wiper Element

Fig. 4 Wiping Element from Blade Assembly

Fig. 5 Removing Wiper ArmÐAG and AJ Bodies

Fig. 6 Removing Wiper ArmÐAA, AC, AP and AY Bodies 16

(2) Lift the head cover (Fig. 7) and remove the

wiper arm attaching nut.

Fig. 7 Wiper Arm Head Cover and NutÐAA, AC, AP and AY Bodies

8K - 2 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 623 of 2438

(3) Secure arm to pivot with attaching nut and

tighten 17 to 22 N Im (155 to 195 in. lbs.) torque.

(4) Close head cover and remove pin from arm pin

hole.

WIPER ARM ADJUSTMENT

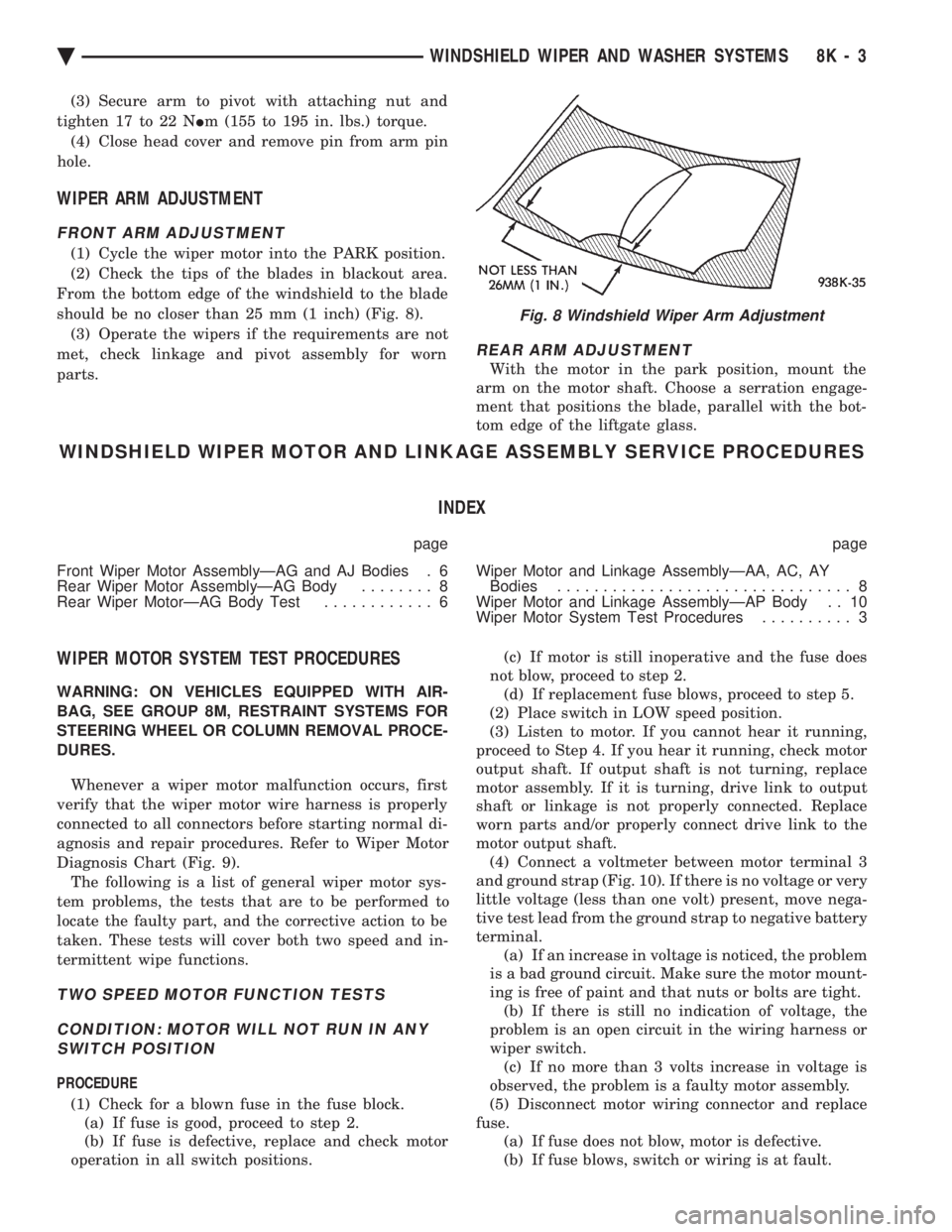

FRONT ARM ADJUSTMENT

(1) Cycle the wiper motor into the PARK position.

(2) Check the tips of the blades in blackout area.

From the bottom edge of the windshield to the blade

should be no closer than 25 mm (1 inch) (Fig. 8). (3) Operate the wipers if the requirements are not

met, check linkage and pivot assembly for worn

parts.

REAR ARM ADJUSTMENT

With the motor in the park position, mount the

arm on the motor shaft. Choose a serration engage-

ment that positions the blade, parallel with the bot-

tom edge of the liftgate glass.

WINDSHIELD WIPER MOTOR AND LINKAGE ASSEMBLY SERVICE PROCEDURES

INDEX

page page

Front Wiper Motor AssemblyÐAG and AJ Bodies . 6

Rear Wiper Motor AssemblyÐAG Body ........ 8

Rear Wiper MotorÐAG Body Test ............ 6 Wiper Motor and Linkage AssemblyÐAA, AC, AY

Bodies ................................ 8

Wiper Motor and Linkage AssemblyÐAP Body . . 10

Wiper Motor System Test Procedures .......... 3

WIPER MOTOR SYSTEM TEST PROCEDURES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

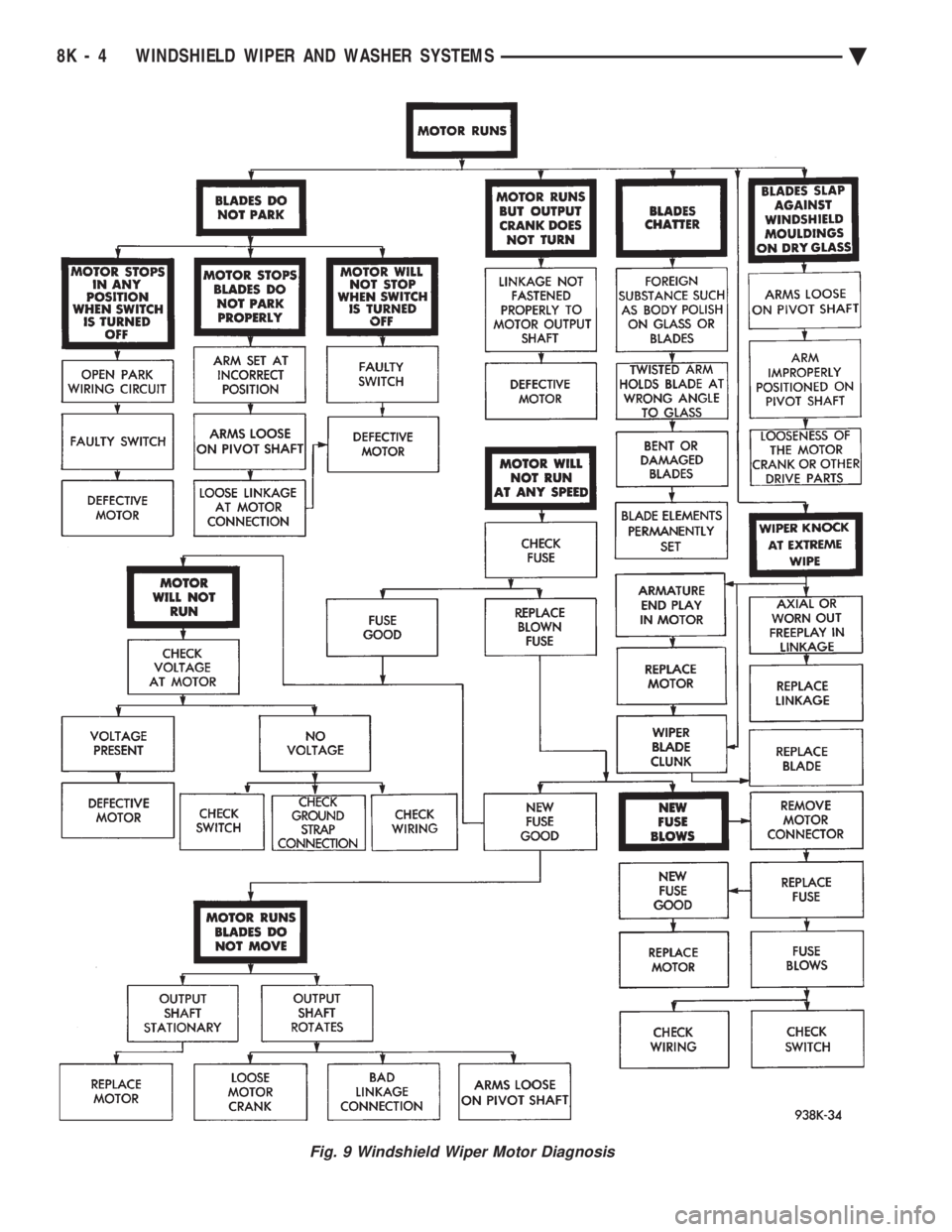

Whenever a wiper motor malfunction occurs, first

verify that the wiper motor wire harness is properly

connected to all connectors before starting normal di-

agnosis and repair procedures. Refer to Wiper Motor

Diagnosis Chart (Fig. 9). The following is a list of general wiper motor sys-

tem problems, the tests that are to be performed to

locate the faulty part, and the corrective action to be

taken. These tests will cover both two speed and in-

termittent wipe functions.

TWO SPEED MOTOR FUNCTION TESTS

CONDITION: MOTOR WILL NOT RUN IN ANY SWITCH POSITION

PROCEDURE

(1) Check for a blown fuse in the fuse block. (a) If fuse is good, proceed to step 2.

(b) If fuse is defective, replace and check motor

operation in all switch positions. (c) If motor is still inoperative and the fuse does

not blow, proceed to step 2. (d) If replacement fuse blows, proceed to step 5.

(2) Place switch in LOW speed position.

(3) Listen to motor. If you cannot hear it running,

proceed to Step 4. If you hear it running, check motor

output shaft. If output shaft is not turning, replace

motor assembly. If it is turning, drive link to output

shaft or linkage is not properly connected. Replace

worn parts and/or properly connect drive link to the

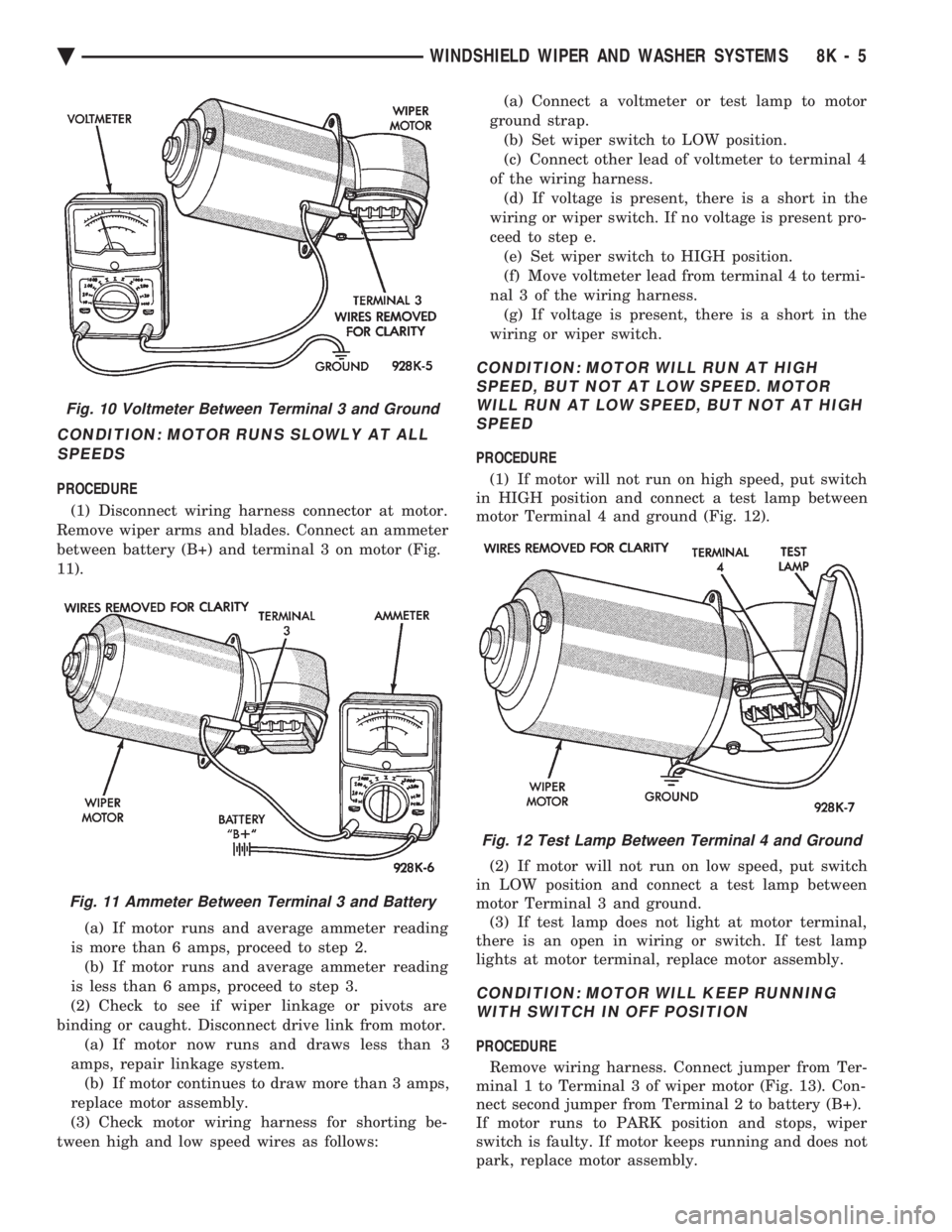

motor output shaft. (4) Connect a voltmeter between motor terminal 3

and ground strap (Fig. 10). If there is no voltage or very

little voltage (less than one volt) present, move nega-

tive test lead from the ground strap to negative battery

terminal. (a) If an increase in voltage is noticed, the problem

is a bad ground circuit. Make sure the motor mount-

ing is free of paint and that nuts or bolts are tight. (b) If there is still no indication of voltage, the

problem is an open circuit in the wiring harness or

wiper switch. (c) If no more than 3 volts increase in voltage is

observed, the problem is a faulty motor assembly.

(5) Disconnect motor wiring connector and replace

fuse. (a) If fuse does not blow, motor is defective.

(b) If fuse blows, switch or wiring is at fault.

Fig. 8 Windshield Wiper Arm Adjustment

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 3

Page 624 of 2438

Fig. 9 Windshield Wiper Motor Diagnosis

8K - 4 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 625 of 2438

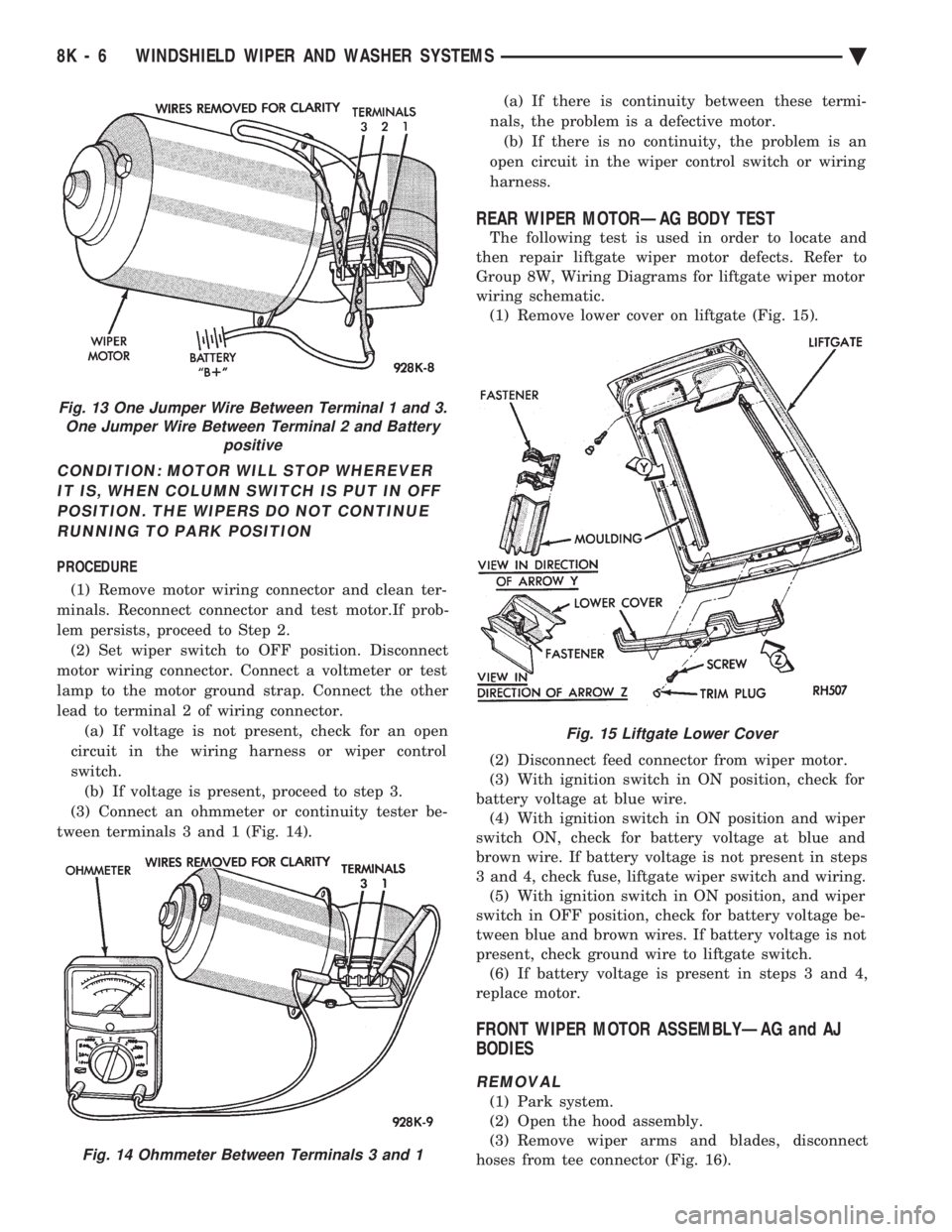

CONDITION: MOTOR RUNS SLOWLY AT ALL SPEEDS

PROCEDURE

(1) Disconnect wiring harness connector at motor.

Remove wiper arms and blades. Connect an ammeter

between battery (B+) and terminal 3 on motor (Fig.

11).

(a) If motor runs and average ammeter reading

is more than 6 amps, proceed to step 2. (b) If motor runs and average ammeter reading

is less than 6 amps, proceed to step 3.

(2) Check to see if wiper linkage or pivots are

binding or caught. Disconnect drive link from motor. (a) If motor now runs and draws less than 3

amps, repair linkage system. (b) If motor continues to draw more than 3 amps,

replace motor assembly.

(3) Check motor wiring harness for shorting be-

tween high and low speed wires as follows: (a) Connect a voltmeter or test lamp to motor

ground strap. (b) Set wiper switch to LOW position.

(c) Connect other lead of voltmeter to terminal 4

of the wiring harness. (d) If voltage is present, there is a short in the

wiring or wiper switch. If no voltage is present pro-

ceed to step e. (e) Set wiper switch to HIGH position.

(f) Move voltmeter lead from terminal 4 to termi-

nal 3 of the wiring harness. (g) If voltage is present, there is a short in the

wiring or wiper switch.

CONDITION: MOTOR WILL RUN AT HIGH SPEED, BUT NOT AT LOW SPEED. MOTORWILL RUN AT LOW SPEED, BUT NOT AT HIGHSPEED

PROCEDURE

(1) If motor will not run on high speed, put switch

in HIGH position and connect a test lamp between

motor Terminal 4 and ground (Fig. 12).

(2) If motor will not run on low speed, put switch

in LOW position and connect a test lamp between

motor Terminal 3 and ground. (3) If test lamp does not light at motor terminal,

there is an open in wiring or switch. If test lamp

lights at motor terminal, replace motor assembly.

CONDITION: MOTOR WILL KEEP RUNNING WITH SWITCH IN OFF POSITION

PROCEDURE

Remove wiring harness. Connect jumper from Ter-

minal 1 to Terminal 3 of wiper motor (Fig. 13). Con-

nect second jumper from Terminal 2 to battery (B+).

If motor runs to PARK position and stops, wiper

switch is faulty. If motor keeps running and does not

park, replace motor assembly.

Fig. 10 Voltmeter Between Terminal 3 and Ground

Fig. 11 Ammeter Between Terminal 3 and Battery

Fig. 12 Test Lamp Between Terminal 4 and Ground

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 5

Page 626 of 2438

CONDITION: MOTOR WILL STOP WHEREVER IT IS, WHEN COLUMN SWITCH IS PUT IN OFFPOSITION. THE WIPERS DO NOT CONTINUERUNNING TO PARK POSITION

PROCEDURE

(1) Remove motor wiring connector and clean ter-

minals. Reconnect connector and test motor.If prob-

lem persists, proceed to Step 2. (2) Set wiper switch to OFF position. Disconnect

motor wiring connector. Connect a voltmeter or test

lamp to the motor ground strap. Connect the other

lead to terminal 2 of wiring connector. (a) If voltage is not present, check for an open

circuit in the wiring harness or wiper control

switch. (b) If voltage is present, proceed to step 3.

(3) Connect an ohmmeter or continuity tester be-

tween terminals 3 and 1 (Fig. 14). (a) If there is continuity between these termi-

nals, the problem is a defective motor. (b) If there is no continuity, the problem is an

open circuit in the wiper control switch or wiring

harness.

REAR WIPER MOTORÐAG BODY TEST

The following test is used in order to locate and

then repair liftgate wiper motor defects. Refer to

Group 8W, Wiring Diagrams for liftgate wiper motor

wiring schematic. (1) Remove lower cover on liftgate (Fig. 15).

(2) Disconnect feed connector from wiper motor.

(3) With ignition switch in ON position, check for

battery voltage at blue wire. (4) With ignition switch in ON position and wiper

switch ON, check for battery voltage at blue and

brown wire. If battery voltage is not present in steps

3 and 4, check fuse, liftgate wiper switch and wiring. (5) With ignition switch in ON position, and wiper

switch in OFF position, check for battery voltage be-

tween blue and brown wires. If battery voltage is not

present, check ground wire to liftgate switch. (6) If battery voltage is present in steps 3 and 4,

replace motor.

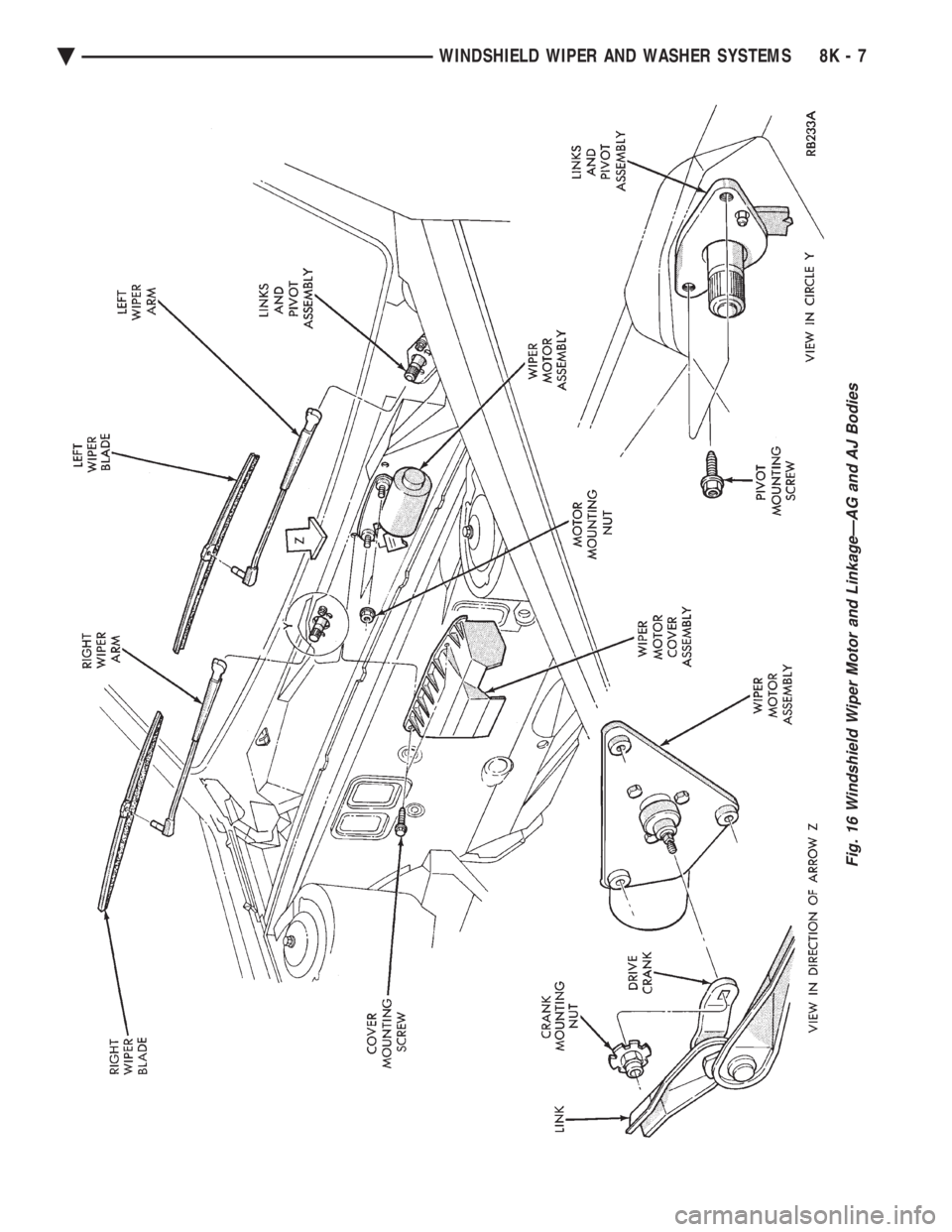

FRONT WIPER MOTOR ASSEMBLYÐAG and AJ

BODIES

REMOVAL

(1) Park system.

(2) Open the hood assembly.

(3) Remove wiper arms and blades, disconnect

hoses from tee connector (Fig. 16).

Fig. 13 One Jumper Wire Between Terminal 1 and 3. One Jumper Wire Between Terminal 2 and Battery positive

Fig. 14 Ohmmeter Between Terminals 3 and 1

Fig. 15 Liftgate Lower Cover

8K - 6 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 627 of 2438

Fig. 16 Windshield Wiper Motor and LinkageÐAG and AJ Bodies

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 7

Page 628 of 2438

(4) Remove the cowl top plastic screen.

(5) Remove pivot screws.

(6) Remove wiper motor cover and disconnect wiring

harness. (7) Remove three motor mounting nuts.

(8) Push pivots down into plenum chamber and pull

motor out until it clears the mounting studs. Then

move it as far to the drivers side or outboard as it will

go. Pull right pivot and link out through opening. Shift

motor to opposite side or inboard of opening and

remove motor, left link and pivot. (9) Clamp motor crank in a vise and remove nut

from end of motor shaft. Do not rotate motor output

shaft from PARK position.

INSTALLATION

(1) Assemble linkage to motor. Make sure crank fits

over D slot on motor shaft. Tighten mounting nut to 10

to 11 N Im (90 to 100 in. lbs.) torque. Be sure motor is

still in park position before assembling to linkage, if

not temporarily connect motor to wiring and operate

switch to position motor in park before assembling

linkage. (2) Place left pivot and link into plenum chamber.(a) Slide it all the way to the left or outboard side

until motor clears studs and crank is behind sheet

metal. (b) Push right pivot and link through opening.

(c) Move assembly right and position motor on

studs.

(3) Install three motor mounting nuts and tighten 7

to8N Im (60 70 in. lbs.) torque.

(4) Position pivots and install pivot screws and

tighten 7 to 8 N Im (60 to 70 in. lbs.) torque.

(5) Connect wiring to motor.

(6) Install motor cover. Tighten screws to 4 N Im (35

in. lbs.) torque. (7) Attach reservoir hose to T-connector through hole

provided in cowl screen. (8) Use plastic fasteners to install cowl screen.

(9) Install arm and blade assemblies. Refer to Wiper

Arm Adjustment. Connect arm washer hoses to

T-connector.

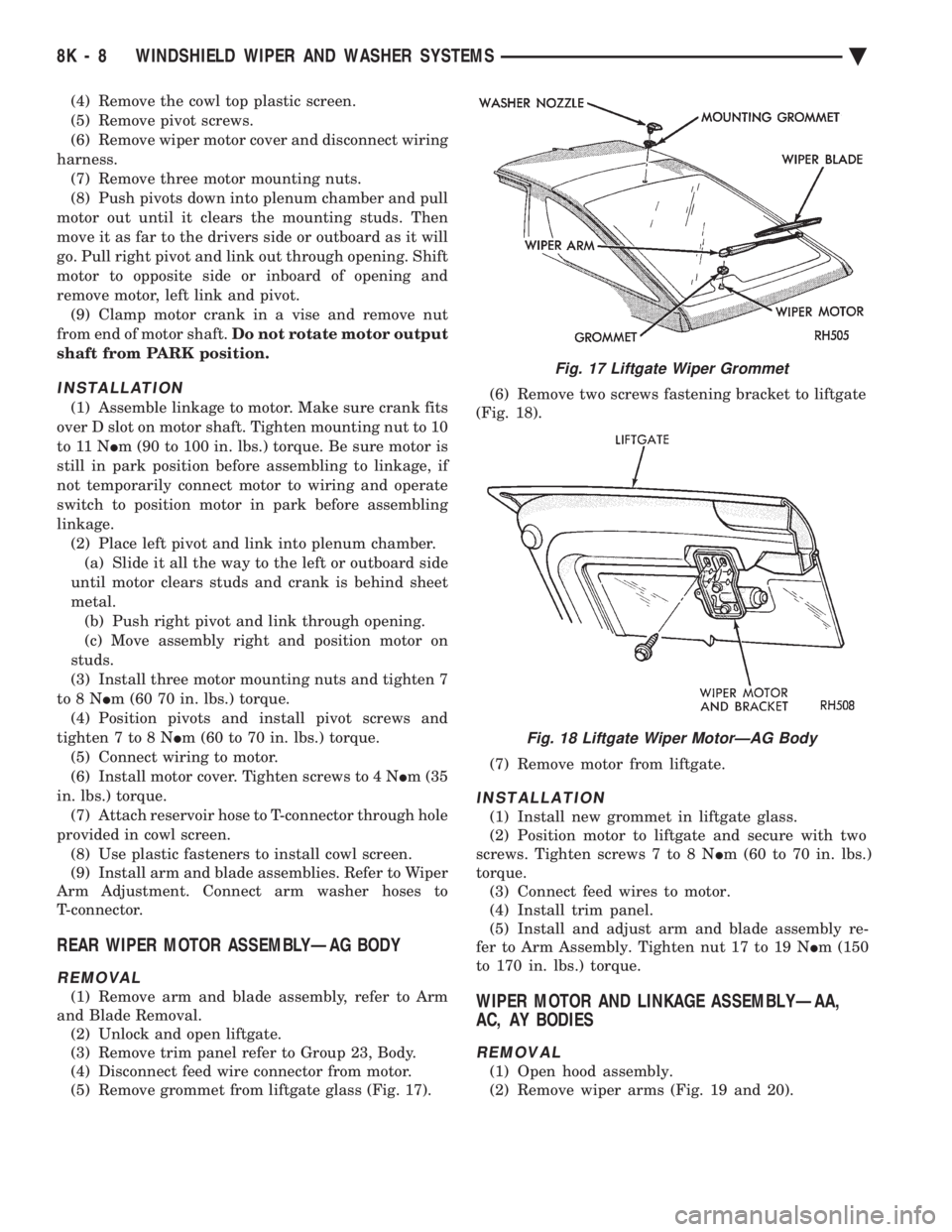

REAR WIPER MOTOR ASSEMBLYÐAG BODY

REMOVAL

(1) Remove arm and blade assembly, refer to Arm

and Blade Removal. (2) Unlock and open liftgate.

(3) Remove trim panel refer to Group 23, Body.

(4) Disconnect feed wire connector from motor.

(5) Remove grommet from liftgate glass (Fig. 17). (6) Remove two screws fastening bracket to liftgate

(Fig. 18).

(7) Remove motor from liftgate.

INSTALLATION

(1) Install new grommet in liftgate glass.

(2) Position motor to liftgate and secure with two

screws. Tighten screws 7 to 8 N Im (60 to 70 in. lbs.)

torque. (3) Connect feed wires to motor.

(4) Install trim panel.

(5) Install and adjust arm and blade assembly re-

fer to Arm Assembly. Tighten nut 17 to 19 N Im (150

to 170 in. lbs.) torque.

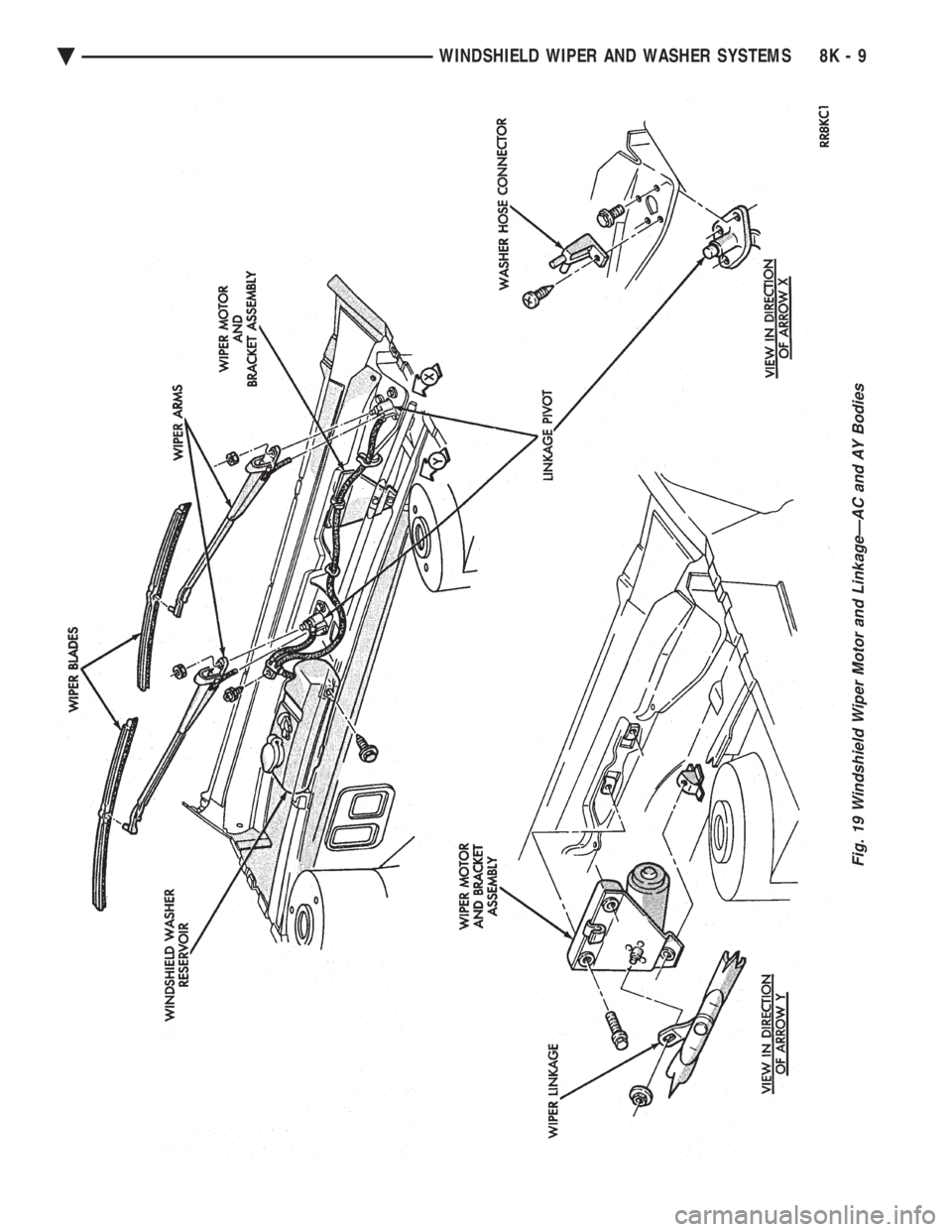

WIPER MOTOR AND LINKAGE ASSEMBLYÐAA,

AC, AY BODIES

REMOVAL

(1) Open hood assembly.

(2) Remove wiper arms (Fig. 19 and 20).

Fig. 17 Liftgate Wiper Grommet

Fig. 18 Liftgate Wiper MotorÐAG Body

8K - 8 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 629 of 2438

Fig. 19 Windshield Wiper Motor and LinkageÐAC and AY Bodies

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 9

Page 630 of 2438

(3) Remove cowl top plastic cover.

(4) Remove three attaching screws from each pivot.

(5) Disconnect the wiper motor wiring harness.

(6) Remove three bolts that attach motor mounting

bracket to body. (7) Remove wiper motor, bracket, and linkage as-

sembly from cowl plenum. (8) Clamp motor crank in a vise and remove nut

from end of motor shaft. Do not rotate motor out-

put shaft from PARK position.

INSTALLATION

(1) Assemble linkage to motor. Make sure crank

fits over D slot on motor shaft. Tighten mounting nut

10 to 11 N Im (90 to 100 in. lbs.) torque. Be sure mo-

tor is still in park position before assembling to link-

age, if not temporarily connect motor to wiring and

operate switch to position motor in park before as-

sembling linkage. (2) Install wiper motor, bracket, crank and linkage

assembly into cowl plenum. (3) Loosely install pivots and hose connector with

three attaching screws. (4) Secure motor mounting bracket screws to body

and tighten to 7 to 8 N Im (60 to 70 in. lbs.) torque.

(5) Tighten pivot attaching screws to 7 to 8 N Im

(60 to 70 in. lbs.) torque. (6) Attach wiper motor wiring harness. (7) Cycle wiper motor and turn OFF. To ensure

wiper motor is in the park position. (8) Install cowl top plastic cover.

(9) Install and adjust wiper arm assembly tighten

to 17 to 19 N Im (150 to 170 in. lbs.) torque.

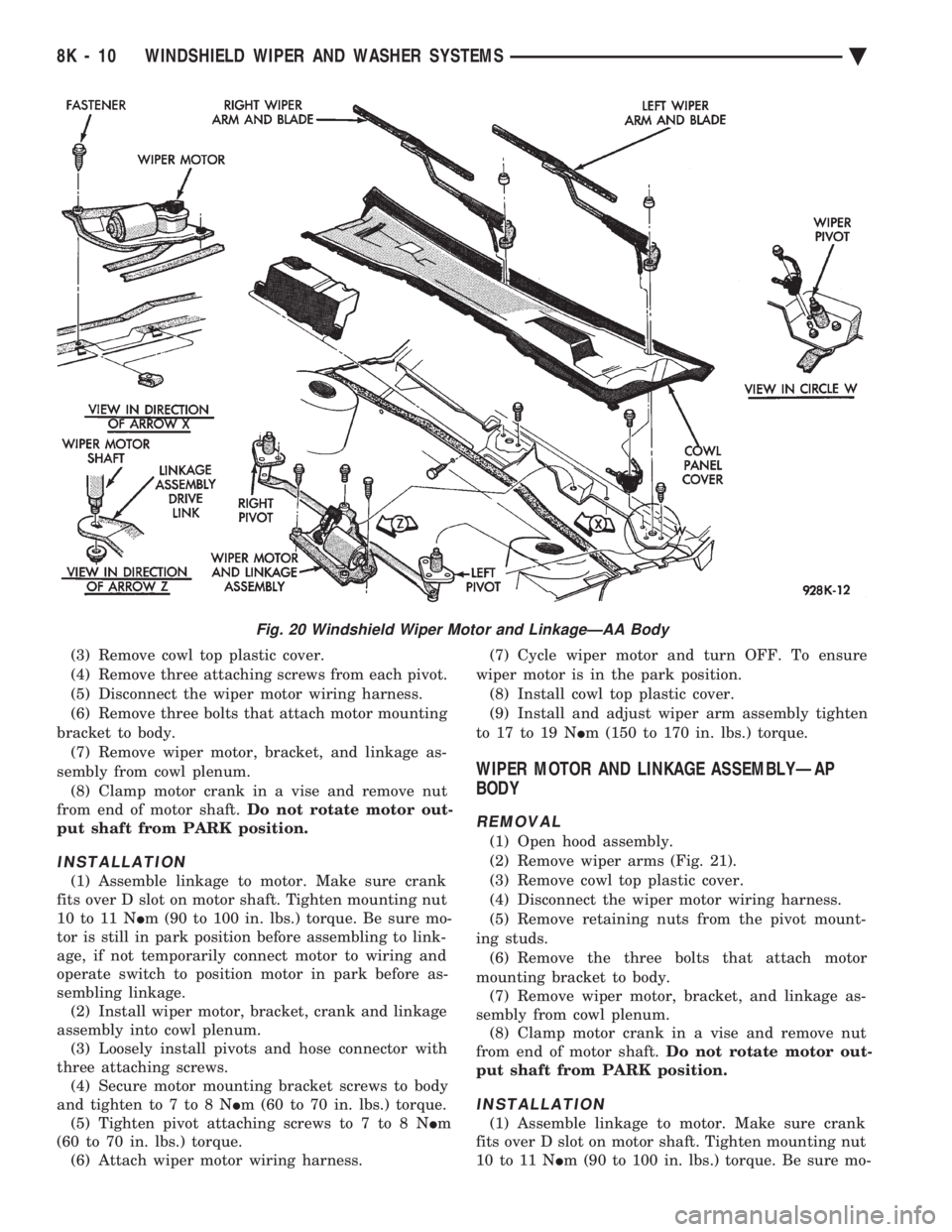

WIPER MOTOR AND LINKAGE ASSEMBLYÐAP

BODY

REMOVAL

(1) Open hood assembly.

(2) Remove wiper arms (Fig. 21).

(3) Remove cowl top plastic cover.

(4) Disconnect the wiper motor wiring harness.

(5) Remove retaining nuts from the pivot mount-

ing studs. (6) Remove the three bolts that attach motor

mounting bracket to body. (7) Remove wiper motor, bracket, and linkage as-

sembly from cowl plenum. (8) Clamp motor crank in a vise and remove nut

from end of motor shaft. Do not rotate motor out-

put shaft from PARK position.

INSTALLATION

(1) Assemble linkage to motor. Make sure crank

fits over D slot on motor shaft. Tighten mounting nut

10 to 11 N Im (90 to 100 in. lbs.) torque. Be sure mo-

Fig. 20 Windshield Wiper Motor and LinkageÐAA Body

8K - 10 WINDSHIELD WIPER AND WASHER SYSTEMS Ä