CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 631 of 2438

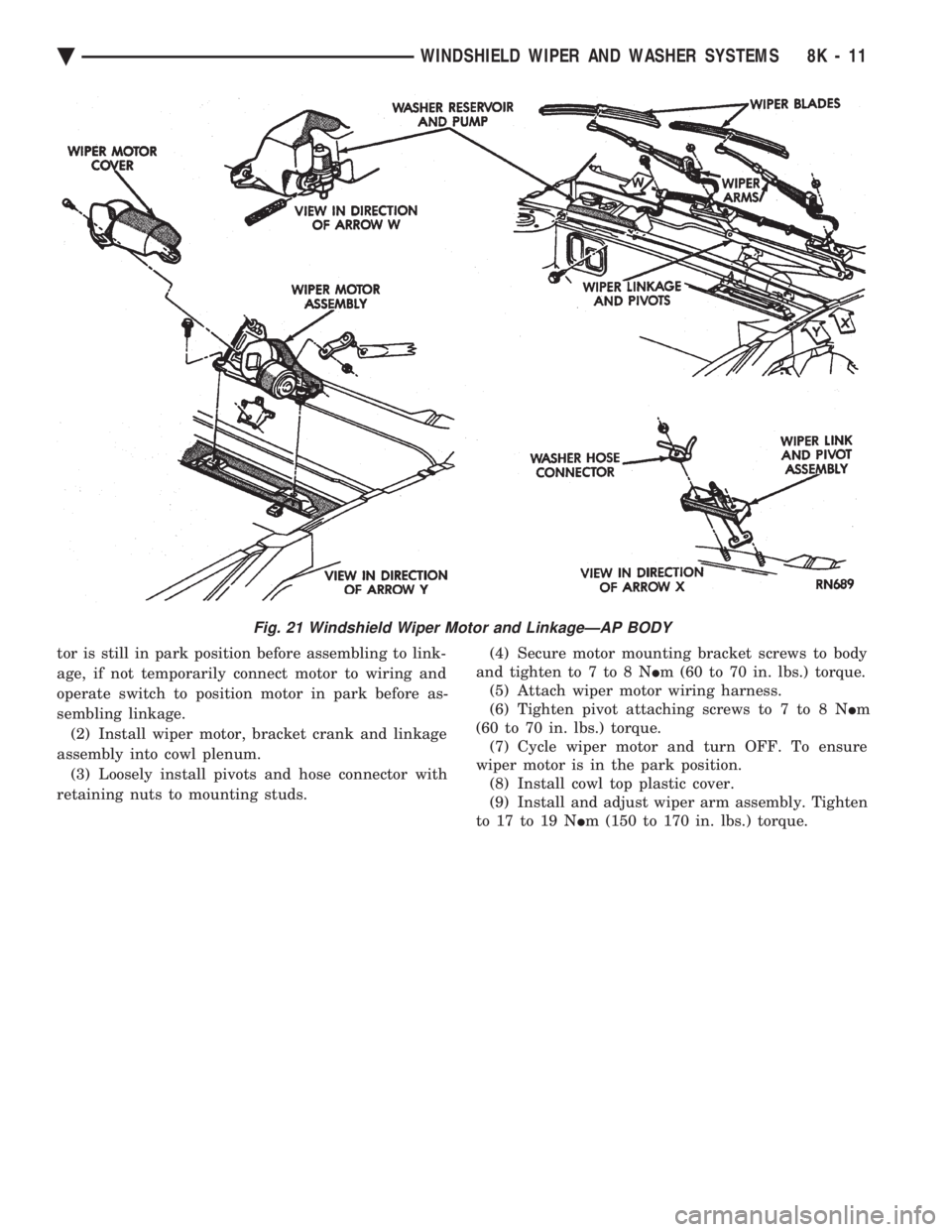

tor is still in park position before assembling to link-

age, if not temporarily connect motor to wiring and

operate switch to position motor in park before as-

sembling linkage. (2) Install wiper motor, bracket crank and linkage

assembly into cowl plenum. (3) Loosely install pivots and hose connector with

retaining nuts to mounting studs. (4) Secure motor mounting bracket screws to body

and tighten to 7 to 8 N Im (60 to 70 in. lbs.) torque.

(5) Attach wiper motor wiring harness.

(6) Tighten pivot attaching screws to 7 to 8 N Im

(60 to 70 in. lbs.) torque. (7) Cycle wiper motor and turn OFF. To ensure

wiper motor is in the park position. (8) Install cowl top plastic cover.

(9) Install and adjust wiper arm assembly. Tighten

to 17 to 19 N Im (150 to 170 in. lbs.) torque.

Fig. 21 Windshield Wiper Motor and LinkageÐAP BODY

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 11

Page 632 of 2438

INTERMITTENT WINDSHIELD WIPER MOTOR AND SWITCH SERVICE PROCEDURES

INDEX

page page

Intermittent Windshield Wiper Switch Tests ..... 12

Intermittent Wipe Switch Test ............... 14

Intermittent Wiper Function Tests ............ 14

Intermittent Wiper Motor System Test ......... 12 Pulse Intermittent Windshield Wiper Controller

(PIWWC) .............................. 15

Standard Wiper Switch Test ................ 14

Wiper Switch Service Procedure ............. 15

INTERMITTENT WIPER MOTOR SYSTEM TEST

Intermittent Wiper Motor Service Procedures for

diagnosis of problems which do not involve the delay

function, refer to the Two-Speed Motor Function

Tests. The two-speed functions of all wiper motors

are identical. If a problem occurs, only in the DELAY mode, the

following tests are to be performed.

INTERMITTENT WINDSHIELD WIPER SWITCH

TESTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

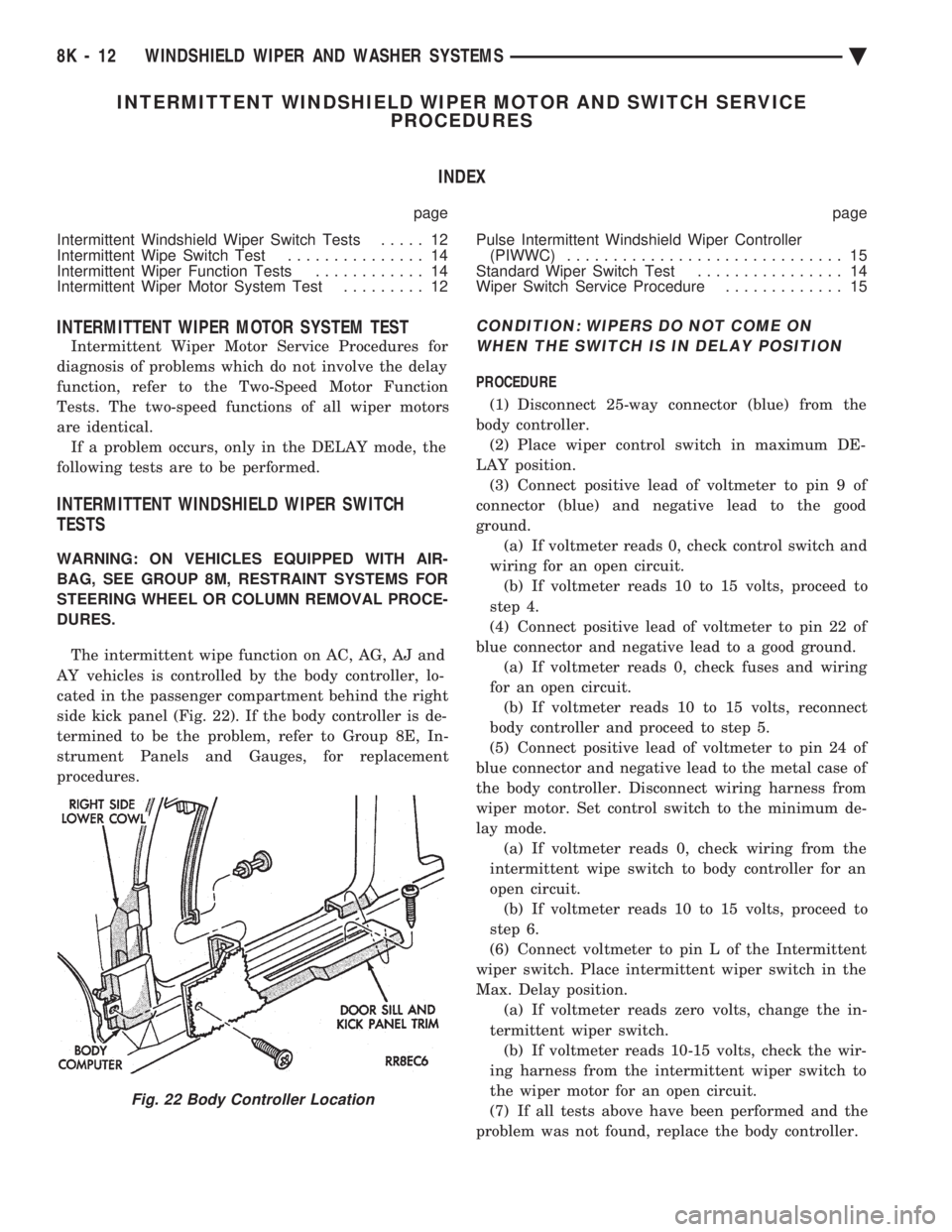

The intermittent wipe function on AC, AG, AJ and

AY vehicles is controlled by the body controller, lo-

cated in the passenger compartment behind the right

side kick panel (Fig. 22). If the body controller is de-

termined to be the problem, refer to Group 8E, In-

strument Panels and Gauges, for replacement

procedures.

CONDITION: WIPERS DO NOT COME ON WHEN THE SWITCH IS IN DELAY POSITION

PROCEDURE

(1) Disconnect 25-way connector (blue) from the

body controller. (2) Place wiper control switch in maximum DE-

LAY position. (3) Connect positive lead of voltmeter to pin 9 of

connector (blue) and negative lead to the good

ground. (a) If voltmeter reads 0, check control switch and

wiring for an open circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 4.

(4) Connect positive lead of voltmeter to pin 22 of

blue connector and negative lead to a good ground. (a) If voltmeter reads 0, check fuses and wiring

for an open circuit. (b) If voltmeter reads 10 to 15 volts, reconnect

body controller and proceed to step 5.

(5) Connect positive lead of voltmeter to pin 24 of

blue connector and negative lead to the metal case of

the body controller. Disconnect wiring harness from

wiper motor. Set control switch to the minimum de-

lay mode. (a) If voltmeter reads 0, check wiring from the

intermittent wipe switch to body controller for an

open circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 6.

(6) Connect voltmeter to pin L of the Intermittent

wiper switch. Place intermittent wiper switch in the

Max. Delay position. (a) If voltmeter reads zero volts, change the in-

termittent wiper switch. (b) If voltmeter reads 10-15 volts, check the wir-

ing harness from the intermittent wiper switch to

the wiper motor for an open circuit.

(7) If all tests above have been performed and the

problem was not found, replace the body controller.

Fig. 22 Body Controller Location

8K - 12 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 633 of 2438

CONDITION: WIPERS START TO WIPE, BUT STOP BEFORE ONE COMPLETE CYCLE ANDDO NOT RETURN TO PARK POSITION

PROCEDURE

(1) Verify that motor will park when the column

switch is put in the OFF position. (2) Set wiper control switch to maximum DELAY

and allow motor to run until it stops during the wipe

cycle. When motor stops, disconnect 25-way blue con-

nector from the body controller. (3) Connect positive lead of voltmeter to pin 20 of

blue connector and negative lead to the metal case of

the body controller. (a) If voltmeter reads 0, check wiring for an open

circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 4.

(4) Using an ohmmeter or continuity tester; (a) Check for continuity between pins 20 and 24

of blue connector of the body controller. (b) Reverse ohmmeter leads on pins 20 and 24,

again checking for continuity. (c) If continuity between pins 20 and 24 is not

observed in both steps a and b, replace the body

controller.

CONDITION: EXCESSIVE DELAY OF MORE THAN 30 SECONDS OR INADEQUATEVARIATION IN DELAY

PROCEDURE

(1) Variations in delay should be as follows: (a) Minimum delay control to extreme counter-

clockwise position before first detent of 1/2 to 2 sec-

onds. (b) Maximum delay control to extreme clockwise

position before OFF detent of 15 to 25 seconds.

(2) If there is excessive delay or no variations in

delay, remove the wiper motor wiring harness while

the motor is parked in the OFF position. (3) Remove 25-way blue connector from the body

controller. (4) Set wiper control switch to maximum DELAY

position. (5) With ignition switch in ON position, measure

voltage between pin 9 of black connector and a good

ground. (a) If voltmeter reads 0, proceed to step 6.

(b) If voltmeter reads 10 to 15 volts, proceed to

step 7.

(6) Set wiper control switch to minimum DELAY

position and measure voltage between pin 9 of blue

connector and a good ground. If voltmeter reads 0,

check for an open circuit in the intermittent wipe

wiring harness. (7) Remove wiper motor circuit fuse. (8) Using an ohmmeter, measure the resistance be-

tween pins 9 and 22 of the body controller 25-way

black connector. Set the wiper control switch first to

minimum DELAY and then maximum DELAY. (a) If resistance reading at minimum DELAY

setting is between 0 and 15 ohms, and at maxi-

mum DELAY setting the resistance is between

240,000 and 400,000 ohms, replace the body con-

troller. (b) If the resistance values above are not ob-

tained, replace the wiper control switch.

CONDITION: WIPERS DO NOT RUN CONTINUALLY WHEN WASH CONTROL ISOPERATED DURING DELAY MODE

PROCEDURE

(1) Disconnect 25-way blue connector from the

body controller (2) Using a voltmeter, connect the positive lead to

pin 10 of the (Black) connector. Connect negative

lead to the body computer metal case. (3) Set wiper control switch to DELAY position.

(4) Depress wash switch.

(5) If voltage reads 0, check switch relay and wir-

ing. (6) If voltage is between 10 and 15 volts, the prob-

lem is in the body controller.

CONDITION: IN DELAY MODE, WIPERS RUN CONTINUALLY WHEN WASH IS OPERATEDBUT DO NOT PROVIDE FOUR EXTRA WIPESWHEN WASH CONTROL IS RELEASED

PROCEDURE

Replace body controller.

CONDITION: WIPERS START ERRATICALLY DURING DELAY MODE

PROCEDURE

(1) Verify that the ground connection at the in-

strument panel is making a good connection, free

from paint and is tight. (2) Verify that the motor ground strap is making

good contact and that the motor mounting bolts are

tight. (3) Verify that the wiring connections to the body

controller, wiper motor, and wiper motor switch are

tight and free of corrosion. (4) If condition is not corrected, problem is with

the body controller

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 13

Page 634 of 2438

INTERMITTENT WIPER FUNCTION TESTS

CONDITION: EXCESSIVE DELAY OF MORE THAN 30 SECONDS OR INADEQUATEVARIATION IN DELAY

PROCEDURE

Variations in delay should be as follows:

(1) Minimum delay control to extreme counter-

clockwise position before first detent of one half to

two seconds. (2) Maximum delay control to extreme clockwise

position before off detent of ten to thirty seconds. (3) If there is excessive delay or no variations in

delay proceed to intermittent wipe switch test.

CONDITION: IN DELAY MODE WIPERS RUN CONTINUALLY WHEN WASH IS OPERATEDBUT DO NOT PROVIDE AN EXTRA WIPEWHEN THE WASH CONTROL IS RELEASED

PROCEDURE

Replace the control unit.

CONDITION: WIPERS START ERRATICALLY DURING DELAY MODE

PROCEDURE

(1) Verify that the ground connection at the in-

strument panel is making good connection, free from

paint and is tight. (2) Verify that the motor ground strap is making

good contact and that the motor mounting bolts are

tight. (3) Verify that the wiring ground connections for

the intermittent wipe control unit and the wiper

switch are tight. (4) If condition is not corrected, replace control

unit.

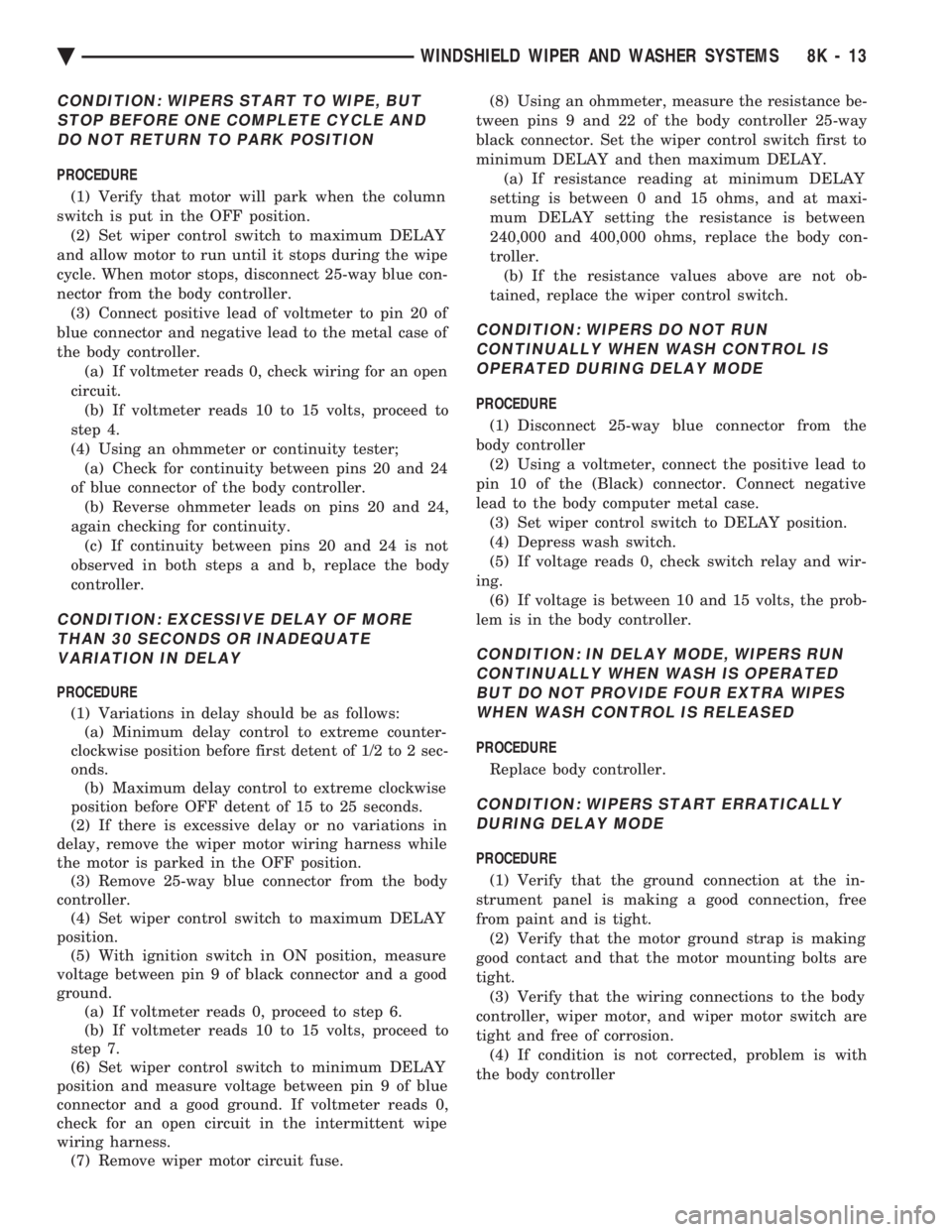

STANDARD WIPER SWITCH TEST

AP BODY

To test the switch, first disconnect the switch wires

from the body wiring in the steering column. Using

an ohmmeter, test for continuity between the termi-

nals of the switch, as indicated in the following con-

tinuity chart. The identity of each terminal is shown

in Fig. 23.

INTERMITTENT WIPE SWITCH TEST

AC AND AY BODIES

To test the switch, first disconnect the switch wires

from the body wiring in the steering column. Using

an ohmmeter, test for continuity between the termi-

nals of the switch, as indicated in the following con-

tinuity chart. The identity of each terminal is shown

in Fig. 24. For test purposes, the first position is the OFF po-

sition, next is the slide for the DELAY wipe. LOW is

the next detent position and HIGH is the full coun-

terclockwise detent position. In any wiper mode, if the knob is pushed all the

way in, the washer circuit will be completed.

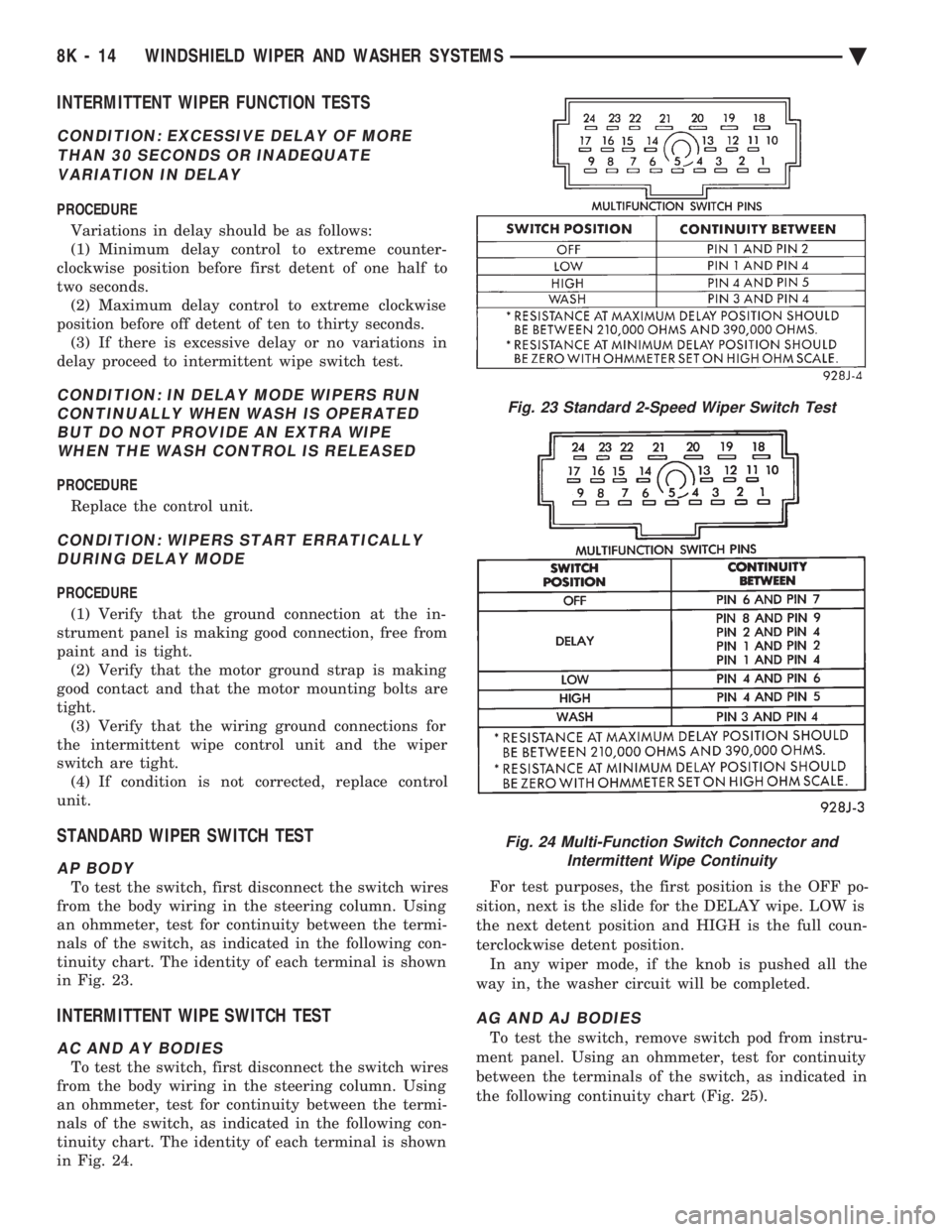

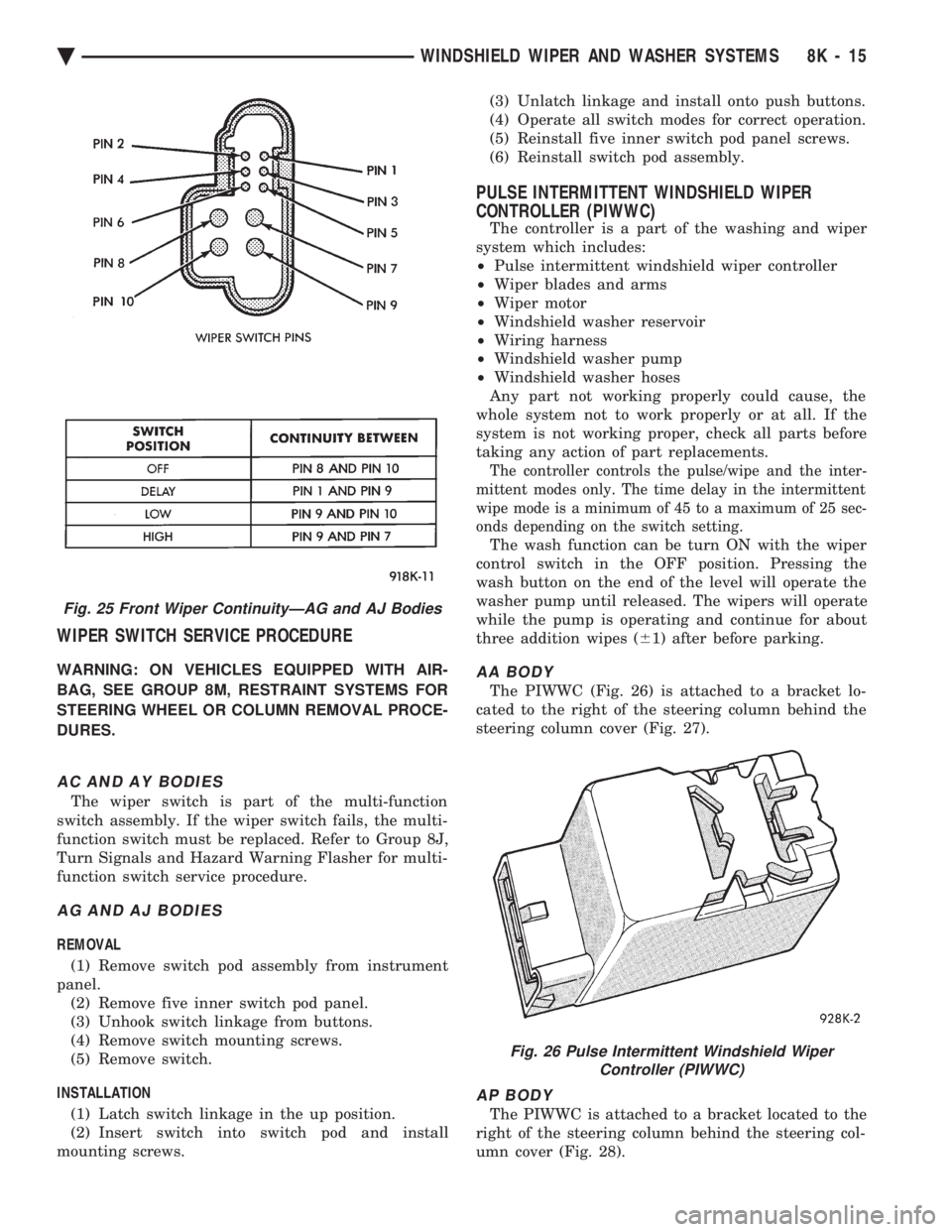

AG AND AJ BODIES

To test the switch, remove switch pod from instru-

ment panel. Using an ohmmeter, test for continuity

between the terminals of the switch, as indicated in

the following continuity chart (Fig. 25).

Fig. 23 Standard 2-Speed Wiper Switch Test

Fig. 24 Multi-Function Switch Connector and Intermittent Wipe Continuity

8K - 14 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 635 of 2438

WIPER SWITCH SERVICE PROCEDURE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

AC AND AY BODIES

The wiper switch is part of the multi-function

switch assembly. If the wiper switch fails, the multi-

function switch must be replaced. Refer to Group 8J,

Turn Signals and Hazard Warning Flasher for multi-

function switch service procedure.

AG AND AJ BODIES

REMOVAL

(1) Remove switch pod assembly from instrument

panel. (2) Remove five inner switch pod panel.

(3) Unhook switch linkage from buttons.

(4) Remove switch mounting screws.

(5) Remove switch.

INSTALLATION (1) Latch switch linkage in the up position.

(2) Insert switch into switch pod and install

mounting screws. (3) Unlatch linkage and install onto push buttons.

(4) Operate all switch modes for correct operation.

(5) Reinstall five inner switch pod panel screws.

(6) Reinstall switch pod assembly.

PULSE INTERMITTENT WINDSHIELD WIPER

CONTROLLER (PIWWC)

The controller is a part of the washing and wiper

system which includes:

² Pulse intermittent windshield wiper controller

² Wiper blades and arms

² Wiper motor

² Windshield washer reservoir

² Wiring harness

² Windshield washer pump

² Windshield washer hoses

Any part not working properly could cause, the

whole system not to work properly or at all. If the

system is not working proper, check all parts before

taking any action of part replacements.

The controller controls the pulse/wipe and the inter-

mittent modes only. The time delay in the intermittent

wipe mode is a minimum of 45 to a maximum of 25 sec-

onds depending on the switch setting.

The wash function can be turn ON with the wiper

control switch in the OFF position. Pressing the

wash button on the end of the level will operate the

washer pump until released. The wipers will operate

while the pump is operating and continue for about

three addition wipes ( 61) after before parking.

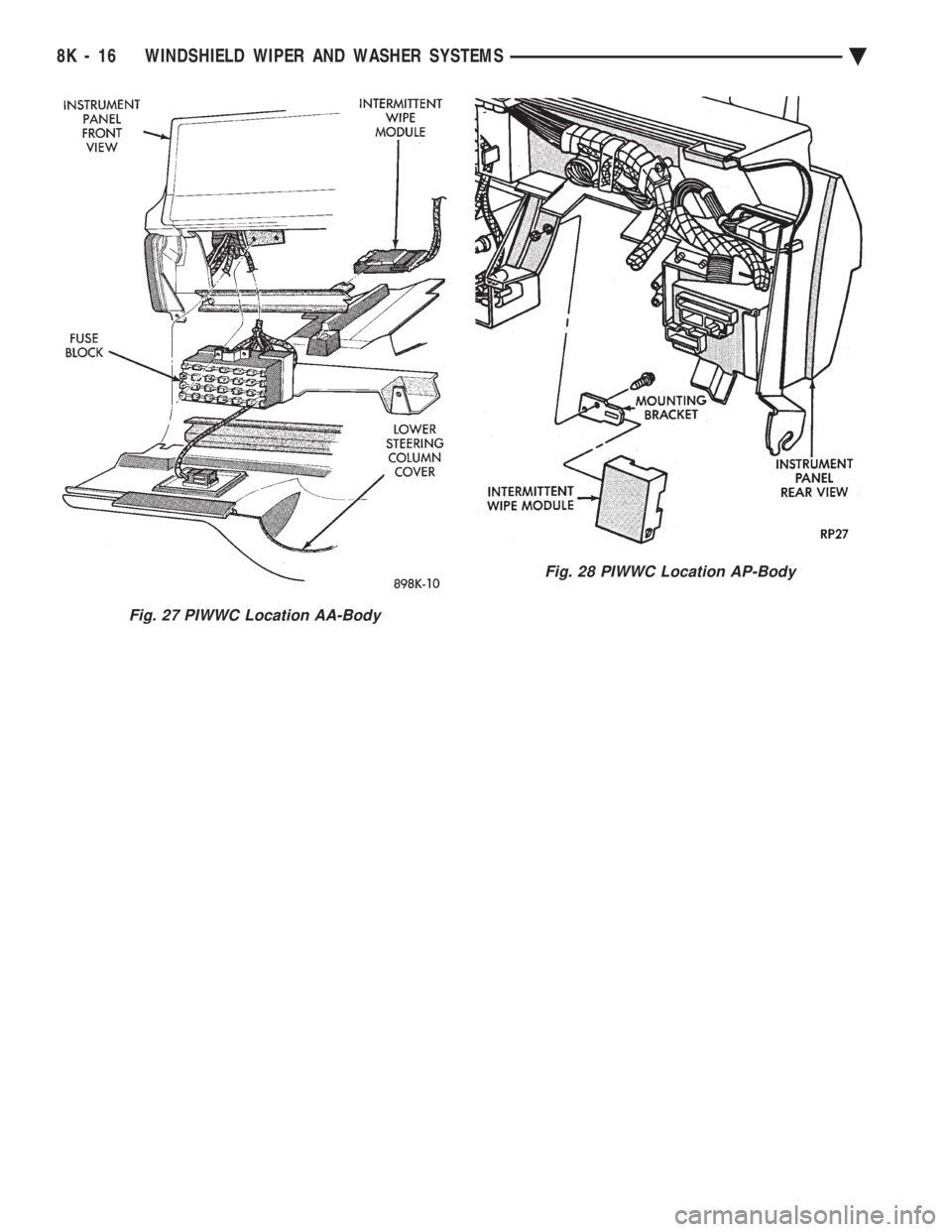

AA BODY

The PIWWC (Fig. 26) is attached to a bracket lo-

cated to the right of the steering column behind the

steering column cover (Fig. 27).

AP BODY

The PIWWC is attached to a bracket located to the

right of the steering column behind the steering col-

umn cover (Fig. 28).

Fig. 25 Front Wiper ContinuityÐAG and AJ Bodies

Fig. 26 Pulse Intermittent Windshield Wiper Controller (PIWWC)

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 15

Page 636 of 2438

Fig. 27 PIWWC Location AA-Body

Fig. 28 PIWWC Location AP-Body

8K - 16 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 637 of 2438

WINDSHIELD WASHERS INDEX

page page

General Information ....................... 17

Washer Nozzle .......................... 19 Washer Reservoir Pump

................... 18

Washer Reservoirs ....................... 17

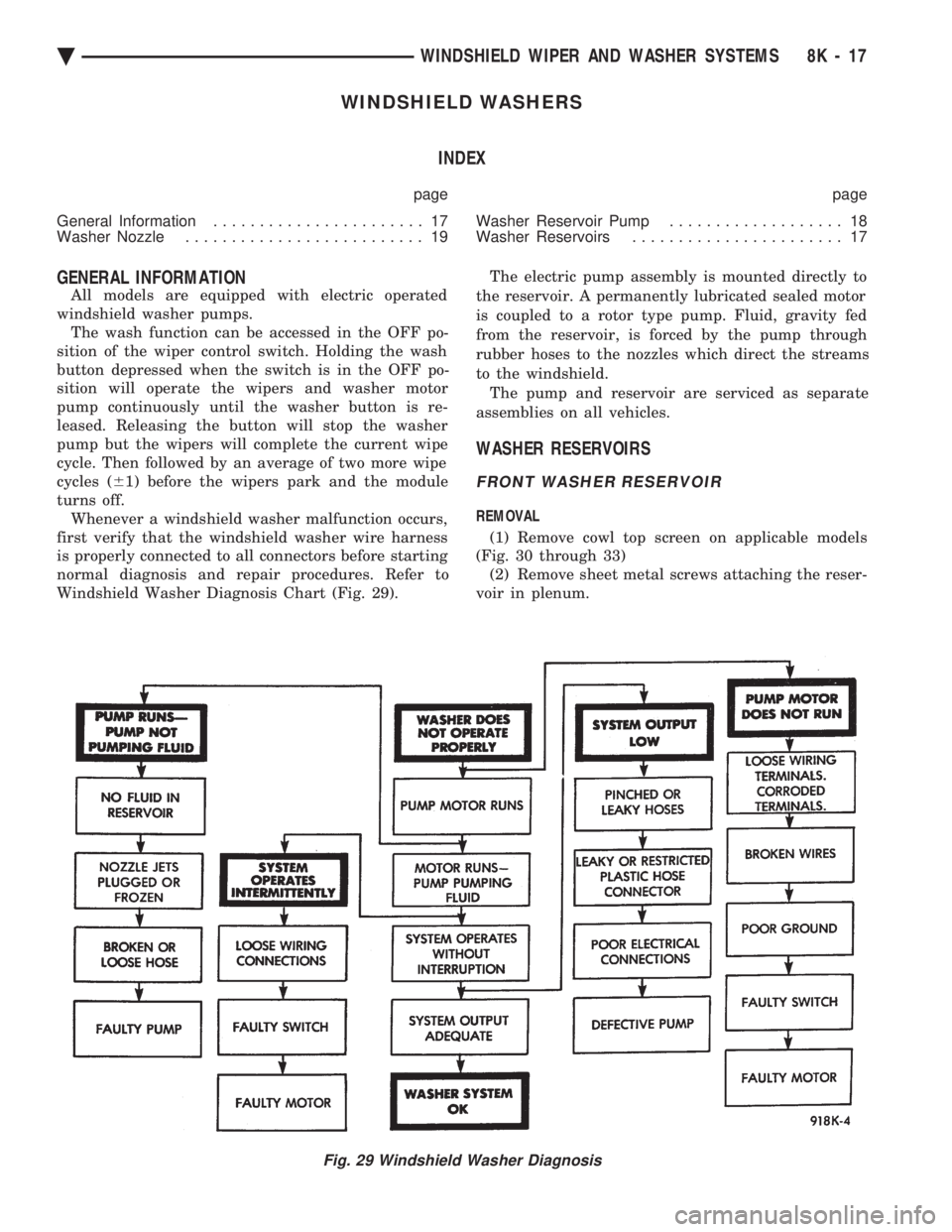

GENERAL INFORMATION

All models are equipped with electric operated

windshield washer pumps. The wash function can be accessed in the OFF po-

sition of the wiper control switch. Holding the wash

button depressed when the switch is in the OFF po-

sition will operate the wipers and washer motor

pump continuously until the washer button is re-

leased. Releasing the button will stop the washer

pump but the wipers will complete the current wipe

cycle. Then followed by an average of two more wipe

cycles ( 61) before the wipers park and the module

turns off. Whenever a windshield washer malfunction occurs,

first verify that the windshield washer wire harness

is properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to

Windshield Washer Diagnosis Chart (Fig. 29). The electric pump assembly is mounted directly to

the reservoir. A permanently lubricated sealed motor

is coupled to a rotor type pump. Fluid, gravity fed

from the reservoir, is forced by the pump through

rubber hoses to the nozzles which direct the streams

to the windshield. The pump and reservoir are serviced as separate

assemblies on all vehicles.

WASHER RESERVOIRS

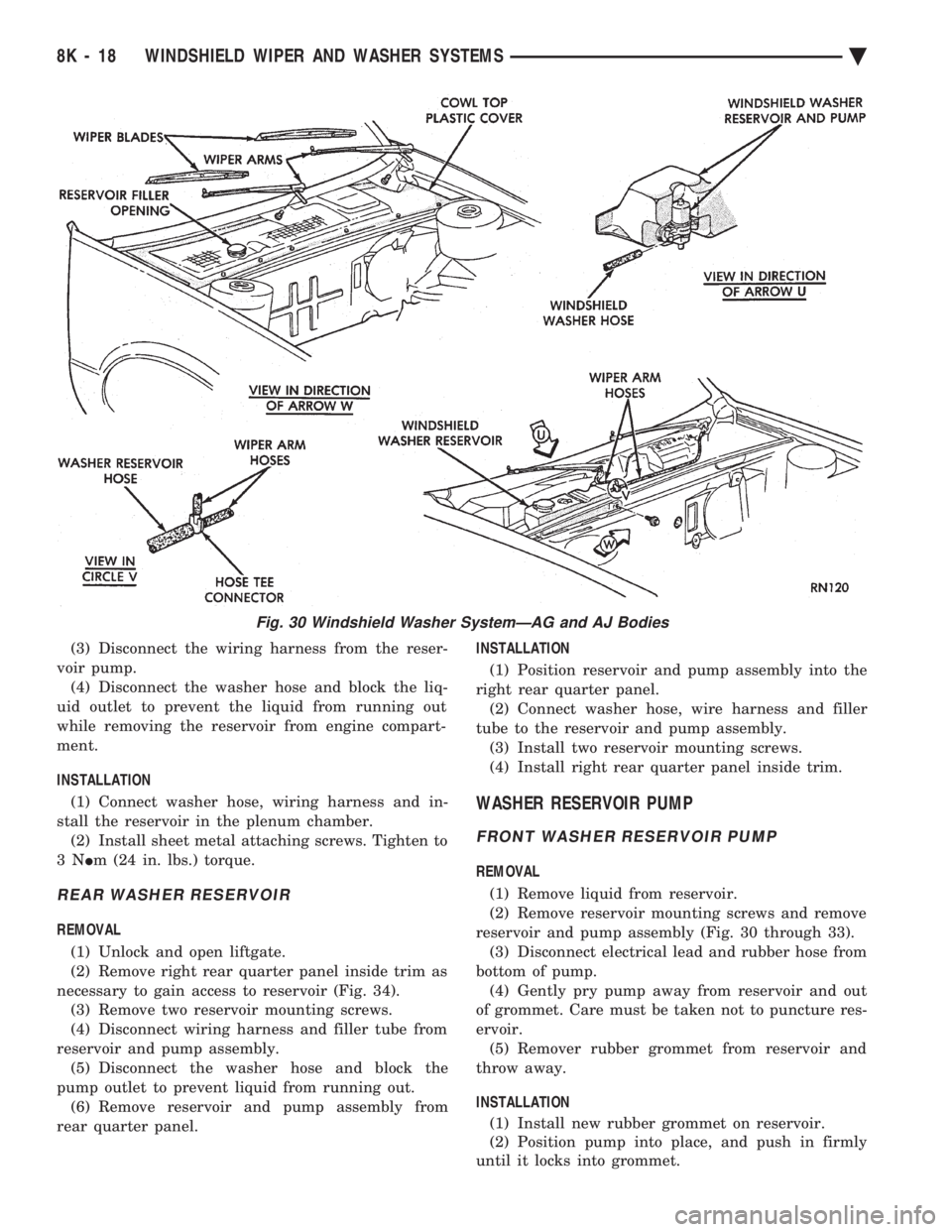

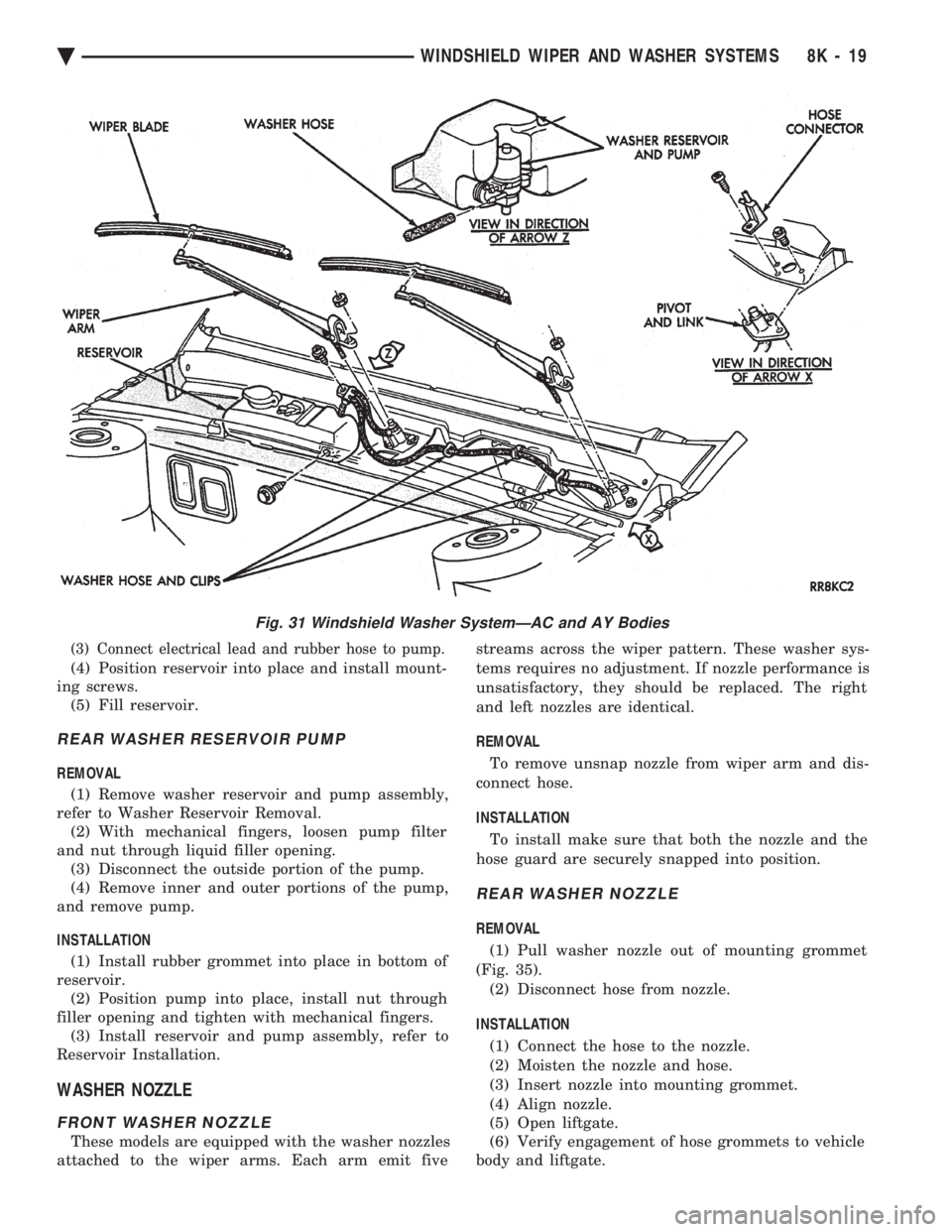

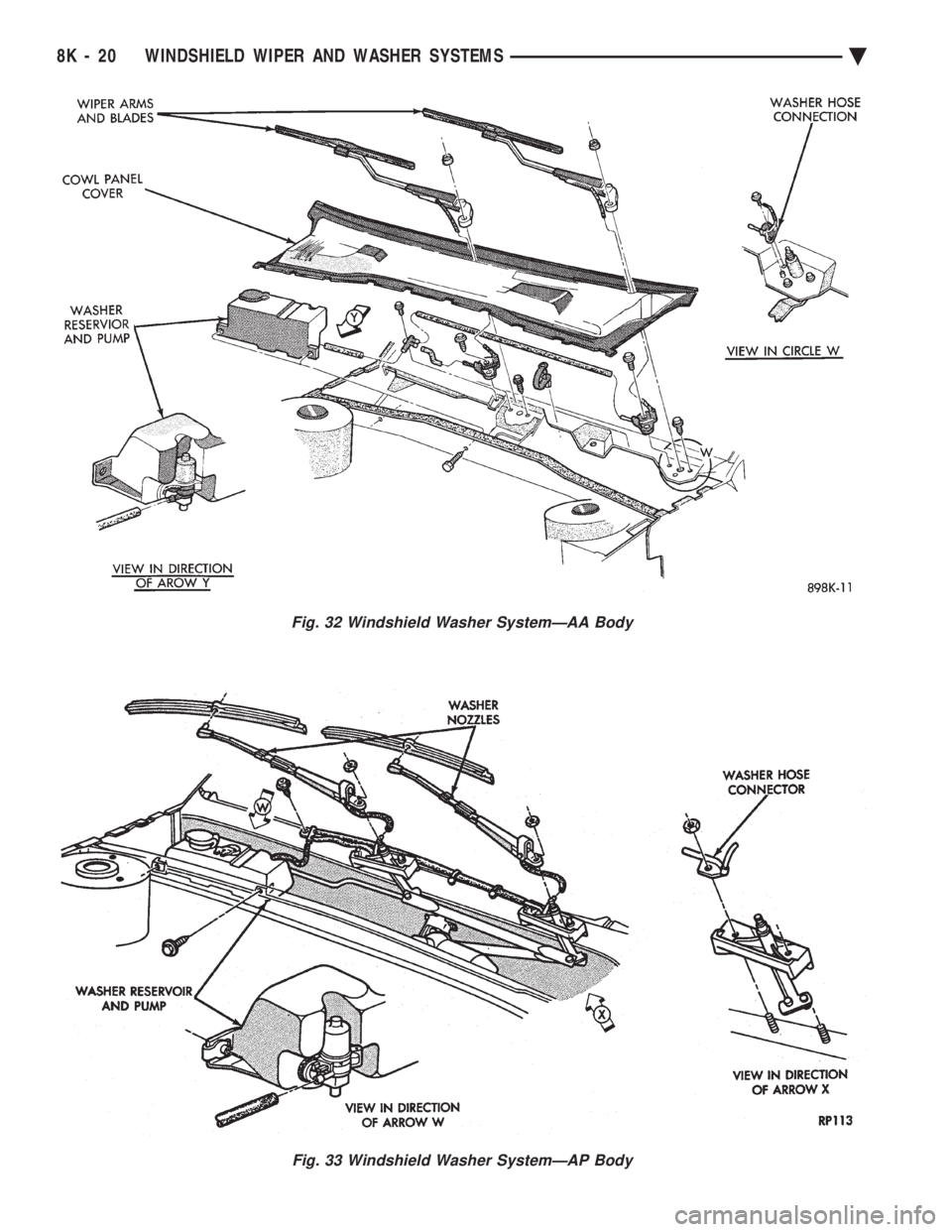

FRONT WASHER RESERVOIR

REMOVAL

(1) Remove cowl top screen on applicable models

(Fig. 30 through 33) (2) Remove sheet metal screws attaching the reser-

voir in plenum.

Fig. 29 Windshield Washer Diagnosis

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 17

Page 638 of 2438

(3) Disconnect the wiring harness from the reser-

voir pump. (4) Disconnect the washer hose and block the liq-

uid outlet to prevent the liquid from running out

while removing the reservoir from engine compart-

ment.

INSTALLATION (1) Connect washer hose, wiring harness and in-

stall the reservoir in the plenum chamber. (2) Install sheet metal attaching screws. Tighten to

3N Im (24 in. lbs.) torque.

REAR WASHER RESERVOIR

REMOVAL

(1) Unlock and open liftgate.

(2) Remove right rear quarter panel inside trim as

necessary to gain access to reservoir (Fig. 34). (3) Remove two reservoir mounting screws.

(4) Disconnect wiring harness and filler tube from

reservoir and pump assembly. (5) Disconnect the washer hose and block the

pump outlet to prevent liquid from running out. (6) Remove reservoir and pump assembly from

rear quarter panel. INSTALLATION

(1) Position reservoir and pump assembly into the

right rear quarter panel. (2) Connect washer hose, wire harness and filler

tube to the reservoir and pump assembly. (3) Install two reservoir mounting screws.

(4) Install right rear quarter panel inside trim.

WASHER RESERVOIR PUMP

FRONT WASHER RESERVOIR PUMP

REMOVAL

(1) Remove liquid from reservoir.

(2) Remove reservoir mounting screws and remove

reservoir and pump assembly (Fig. 30 through 33). (3) Disconnect electrical lead and rubber hose from

bottom of pump. (4) Gently pry pump away from reservoir and out

of grommet. Care must be taken not to puncture res-

ervoir. (5) Remover rubber grommet from reservoir and

throw away.

INSTALLATION (1) Install new rubber grommet on reservoir.

(2) Position pump into place, and push in firmly

until it locks into grommet.

Fig. 30 Windshield Washer SystemÐAG and AJ Bodies

8K - 18 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 639 of 2438

(3) Connect electrical lead and rubber hose to pump.

(4) Position reservoir into place and install mount-

ing screws. (5) Fill reservoir.

REAR WASHER RESERVOIR PUMP

REMOVAL

(1) Remove washer reservoir and pump assembly,

refer to Washer Reservoir Removal. (2) With mechanical fingers, loosen pump filter

and nut through liquid filler opening. (3) Disconnect the outside portion of the pump.

(4) Remove inner and outer portions of the pump,

and remove pump.

INSTALLATION (1) Install rubber grommet into place in bottom of

reservoir. (2) Position pump into place, install nut through

filler opening and tighten with mechanical fingers. (3) Install reservoir and pump assembly, refer to

Reservoir Installation.

WASHER NOZZLE

FRONT WASHER NOZZLE

These models are equipped with the washer nozzles

attached to the wiper arms. Each arm emit five streams across the wiper pattern. These washer sys-

tems requires no adjustment. If nozzle performance is

unsatisfactory, they should be replaced. The right

and left nozzles are identical.

REMOVAL To remove unsnap nozzle from wiper arm and dis-

connect hose.

INSTALLATION

To install make sure that both the nozzle and the

hose guard are securely snapped into position.

REAR WASHER NOZZLE

REMOVAL

(1) Pull washer nozzle out of mounting grommet

(Fig. 35). (2) Disconnect hose from nozzle.

INSTALLATION (1) Connect the hose to the nozzle.

(2) Moisten the nozzle and hose.

(3) Insert nozzle into mounting grommet.

(4) Align nozzle.

(5) Open liftgate.

(6) Verify engagement of hose grommets to vehicle

body and liftgate.

Fig. 31 Windshield Washer SystemÐAC and AY Bodies

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 19

Page 640 of 2438

Fig. 32 Windshield Washer SystemÐAA Body

Fig. 33 Windshield Washer SystemÐAP Body

8K - 20 WINDSHIELD WIPER AND WASHER SYSTEMS Ä