CHRYSLER VOYAGER 1996 Service Manual

Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1291 of 1938

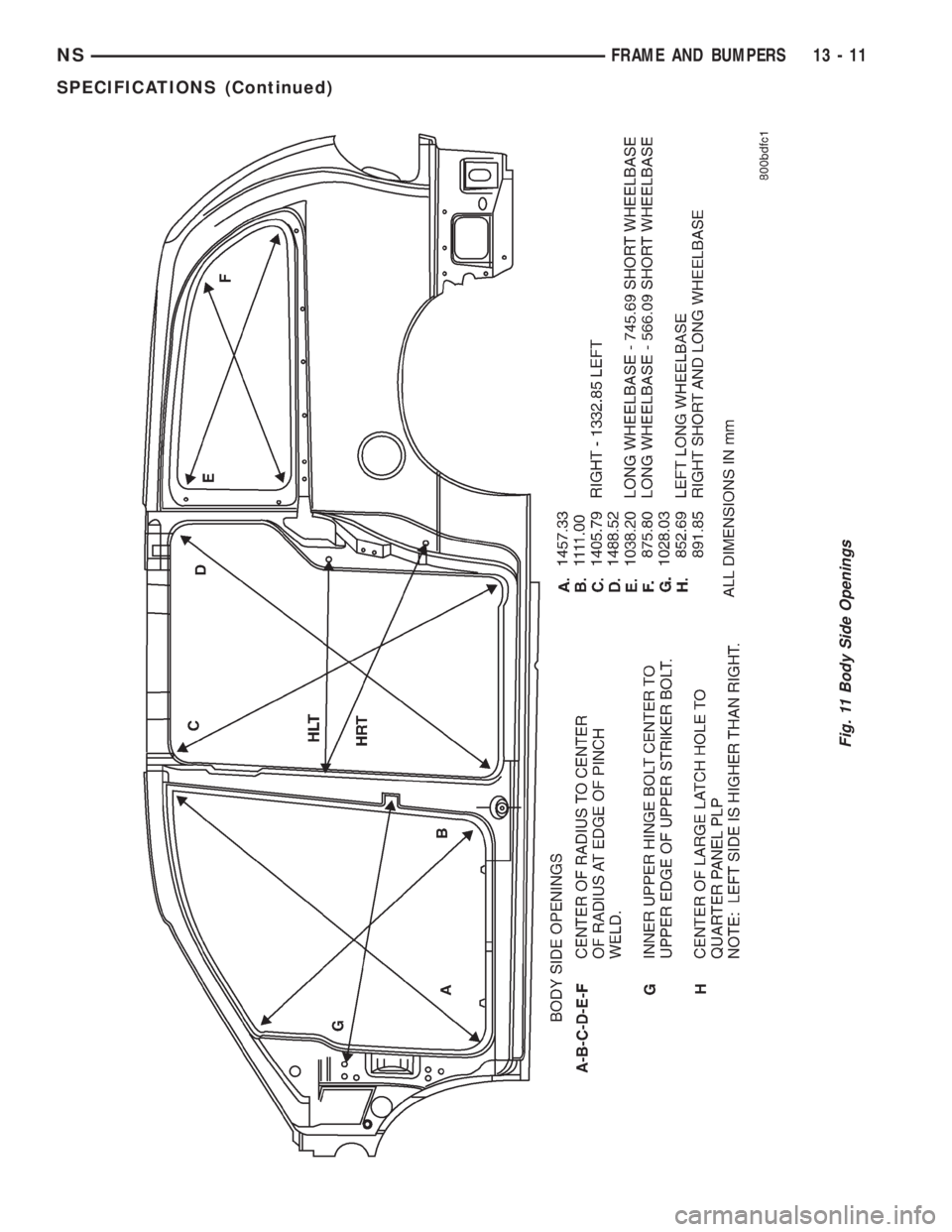

Fig. 11 Body Side Openings

NSFRAME AND BUMPERS 13 - 11

SPECIFICATIONS (Continued)

Page 1292 of 1938

Page 1293 of 1938

FRAME AND BUMPERS

CONTENTS

page

FRAME................................ 1

FRAME

INDEX

page page

REMOVAL AND INSTALLATION

FRONT TOW HOOK BRACKET............. 1REAR TOW HOOK BRACKET.............. 1

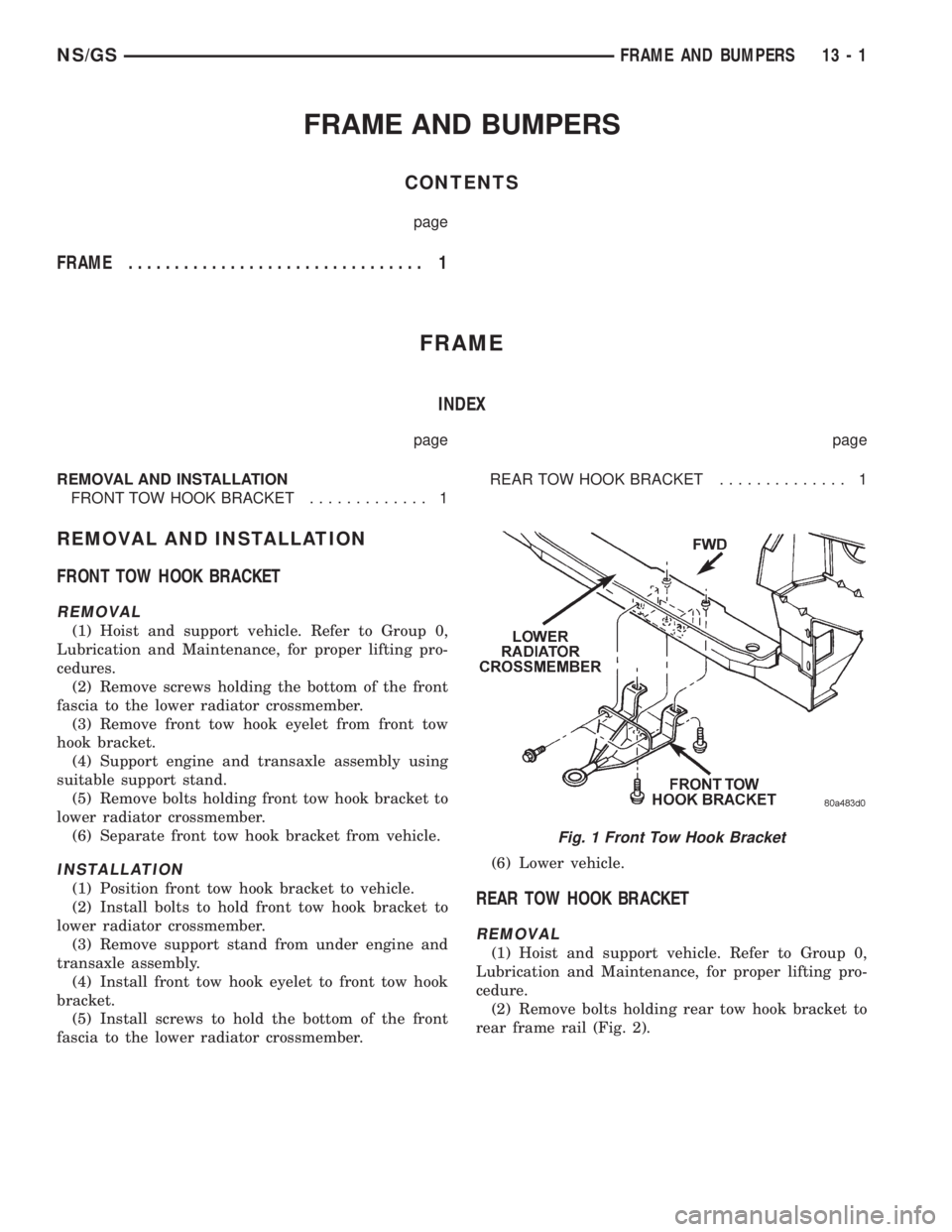

REMOVAL AND INSTALLATION

FRONT TOW HOOK BRACKET

REMOVAL

(1) Hoist and support vehicle. Refer to Group 0,

Lubrication and Maintenance, for proper lifting pro-

cedures.

(2) Remove screws holding the bottom of the front

fascia to the lower radiator crossmember.

(3) Remove front tow hook eyelet from front tow

hook bracket.

(4) Support engine and transaxle assembly using

suitable support stand.

(5) Remove bolts holding front tow hook bracket to

lower radiator crossmember.

(6) Separate front tow hook bracket from vehicle.

INSTALLATION

(1) Position front tow hook bracket to vehicle.

(2) Install bolts to hold front tow hook bracket to

lower radiator crossmember.

(3) Remove support stand from under engine and

transaxle assembly.

(4) Install front tow hook eyelet to front tow hook

bracket.

(5) Install screws to hold the bottom of the front

fascia to the lower radiator crossmember.(6) Lower vehicle.REAR TOW HOOK BRACKET

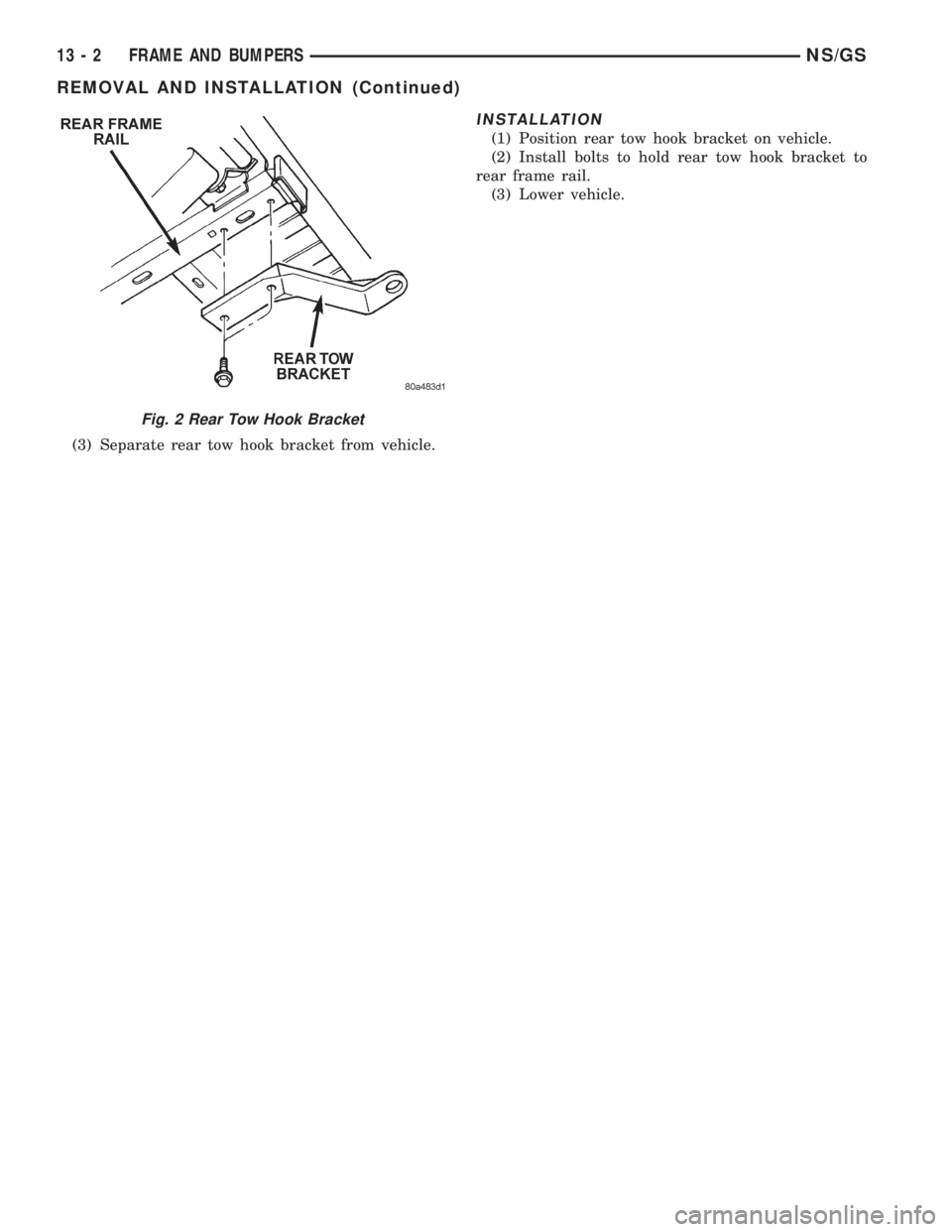

REMOVAL

(1) Hoist and support vehicle. Refer to Group 0,

Lubrication and Maintenance, for proper lifting pro-

cedure.

(2) Remove bolts holding rear tow hook bracket to

rear frame rail (Fig. 2).

Fig. 1 Front Tow Hook Bracket

NS/GSFRAME AND BUMPERS 13 - 1

Page 1294 of 1938

(3) Separate rear tow hook bracket from vehicle.

INSTALLATION

(1) Position rear tow hook bracket on vehicle.

(2) Install bolts to hold rear tow hook bracket to

rear frame rail.

(3) Lower vehicle.

Fig. 2 Rear Tow Hook Bracket

13 - 2 FRAME AND BUMPERSNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1295 of 1938

FUEL SYSTEM

CONTENTS

page page

FUEL DELIVERY SYSTEM................... 4

FUEL INJECTION SYSTEM................. 29GENERAL INFORMATION................... 1

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

CRUISING RANGE........................ 3

E-85 GENERAL INFORMATION.............. 2

ETHANOL FUEL (E-85).................... 2

FUEL REQUIREMENTS.................... 1

FUEL REQUIREMENTS.................... 2GASOLINE/OXYGENATE BLENDS............ 2

INTRODUCTION......................... 1

PCM REPLACEMENT..................... 1

REPLACEMENT PARTS.................... 3

STARTING.............................. 2

GENERAL INFORMATION

INTRODUCTION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual.

The Evaporation Control System, is also considered

part of the fuel system. The system reduces the emis-

sion of fuel vapor into the atmosphere.

The description and function of the Evaporation

Control System is found in Group 25 of this manual.

PCM REPLACEMENT

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW PCM WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE VEHICLES ORIGINAL MILEAGE. IF THIS

STEP IS NOT DONE A DIAGNOSTIC TROUBLE

CODE (DTC) MAY BE SET.

FUEL REQUIREMENTS

Your vehicle was designed to meet all emission reg-

ulations and provide excellent fuel economy when

using high quality unleaded gasoline.

Use unleaded gasolines having a minimum posted

octane of 87.

If your vehicle develops occasional light spark

knock (ping) at low engine speeds this is not harm-

ful. However; continued heavy knock at high speeds

can cause damage and should be reported to your

dealer immediately. Engine damage as a result of

heavy knock operation may not be covered by the

new vehicle warranty.

In addition to using unleaded gasoline with the

proper octane rating, those that contain detergents,

corrosion and stability additives are recommended.

Using gasolines that have these additives will help

improve fuel economy, reduce emissions, and main-

tain vehicle performance.

Poor quality gasoline can cause problems such as

hard starting, stalling, and stumble. If you experi-

ence these problems, try another brand of gasoline

before considering service for the vehicle.

NSFUEL SYSTEM 14 - 1

Page 1296 of 1938

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

materials that contain oxygen such as alcohol, MTBE

(Methyl Tertiary Butyl Ether) and ETBE (Ethyl Ter-

tiary Butyl Ether). Oxygenates are required in some

areas of the country during winter months to reduce

carbon monoxide emissions. The type and amount of

oxygenate used in the blend is important.

The following are generally used in gasoline

blends:

Ethanol- (Ethyl or Grain Alcohol) properly

blended, is used as a mixture of 10 percent ethanol

and 90 percent gasoline. Gasoline blended with etha-

nol may be used in your vehicle.

MTBE/ETBE- Gasoline and MTBE (Methyl Ter-

tiary Butyl Ether) blends are a mixture of unleaded

gasoline and up to 15 percent MTBE. Gasoline and

ETBE (Ethyl Tertiary Butyl Ether) are blends of gas-

oline and up to 17 percent ETBE. Gasoline blended

with MTBE or ETBE may be used in your vehicle.

Methanol- Methanol (Methyl or Wood Alcohol) is

used in a variety of concentrations blended with

unleaded gasoline. You may encounter fuels contain-

ing 3 percent or more methanol along with other

alcohols called cosolvents.

DO NOT USE GASOLINES CONTAINING

METHANOL.

Use of methanol/gasoline blends may result in

starting and driveability problems and damage criti-

cal fuel system components.

Problems that are the result of using methanol/

gasoline blends are not the responsibility of Chrysler

Corporation and may not be covered by the vehicle

warranty.

Reformulated Gasoline

Many areas of the country are requiring the use of

cleaner-burning fuel referred to asReformulated

Gasoline. Reformulated gasolines are specially

blended to reduce vehicle emissions and improve air

quality.

Chrysler Corporation strongly supports the use of

reformulated gasolines whenever available. Although

your vehicle was designed to provide optimum perfor-

mance and lowest emissions operating on high qual-

ity unleaded gasoline, it will perform equally well

and produce even lower emissions when operating on

reformulated gasoline.

Materials Added to Fuel

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials intended

for gum and varnish removal may contain active sol-

vents of similar ingredients that can be harmful to

fuel system gasket and diaphragm materials.

E-85 GENERAL INFORMATION

The information in this section is for Flexible Fuel

Vehicles (FFV) only. These vehicles can be identified

by the unique Fuel Filler Door Label that states

Ethanol (E-85) or Unleaded Gasoline Only. This sec-

tion only covers those subjects that are unique to

these vehicles. Please refer to the other sections of

this manual for information on features that are

common between Flexible Fuel and gasoline only

powered vehicles.

ETHANOL FUEL (E-85)

E-85 is a mixture of approximately 85% fuel etha-

nol and 15% unleaded gasoline.

WARNING: Ethanol vapors are extremely flammable

and could cause serious personal injury. Never

have any smoking materials lit in or near the vehi-

cle when removing the fuel filler tube cap (gas cap)

or filling the tank. Do not use E-85 as a cleaning

agent and never use it near an open flame.

FUEL REQUIREMENTS

Your vehicle will operate on both unleaded gasoline

with an octane rating of 87, or E-85 fuel, or any mix-

ture of these two.

For best results, a refueling pattern that alternates

between E-85 and unleaded gasoline should be

avoided. When you do switch fuels, it is recom-

mended that

²you do not switch when the fuel gauge indicates

less than 1/4 full

²you do not add less than 5 gallons when refuel-

ing

²you operate the vehicle immediately after refuel-

ing for a period of at least 5 minutes

Observing these precautions will avoid possible

hard starting and/or significant deterioration in driv-

ability during warm up.

NOTE: When the ambient temperature is above

90ÉF, you may experience hard starting and rough

idle following start up even if the above recommen-

dations are followed.

STARTING

The characteristics of E-85 fuel make it unsuitable

for use when ambient temperatures fall below 0ÉF. In

the range of 0ÉF to 32ÉF, you may experience an

increase in the time it takes for your engine to start,

and a deterioration in drivability (sags and/or hesita-

tions) until the engine is fully warmed up.

14 - 2 FUEL SYSTEMNS

GENERAL INFORMATION (Continued)

Page 1297 of 1938

CRUISING RANGE

Because E-85 fuel contains less energy per gallon

than gasoline, you will experience an increase in fuel

consumption. You can expect your MPG and your

driving range to decrease by about 30% compared to

gasoline operation.

REPLACEMENT PARTS

Many components in your Flexible Fuel Vehicle

(FFV) are designed to be compatible with ethanol.Always be sure that your vehicle is serviced with cor-

rect ethanol compatible parts.

CAUTION: Replacing fuel system components with

non-ethanol compatible components can damage

your vehicle and may void the warranty.

NSFUEL SYSTEM 14 - 3

GENERAL INFORMATION (Continued)

Page 1298 of 1938

FUEL DELIVERY SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

FUEL DELIVERY SYSTEM.................. 4

FUEL INJECTORS........................ 5

FUEL LEVEL SENSOR..................... 5

FUEL PRESSURE REGULATOR.............. 5

FUEL PUMP MODULE..................... 4

FUEL TANK............................. 5

PRESSURE-VACUUM FILLER CAP........... 6

QUICK-CONNECT FITTINGS................ 6

DIAGNOSIS AND TESTING

FUEL INJECTORS........................ 9

FUEL LEVEL SENSOR..................... 9

FUEL PUMP PRESSURE TEST 2.4/3.3/3.8L..... 6

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.4/3.3/3.8L............... 11

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ3.0L ENGINE............. 11

HOSES AND CLAMPS.................... 12QUICK-CONNECT FITTINGS............... 12

REMOVAL AND INSTALLATION

ACCELERATOR PEDAL................... 26

FUEL FILTER........................... 12

FUEL INJECTOR RAILÐ2.4L............... 18

FUEL INJECTOR RAILÐ3.0L............... 19

FUEL INJECTOR RAILÐ3.3/3.8L............ 21

FUEL INJECTORSÐ3.0L.................. 25

FUEL INJECTORÐ2.4L................... 24

FUEL INJECTORÐ3.3/3.8L................. 26

FUEL LEVEL SENSOR.................... 15

FUEL PRESSURE REGULATOR............. 14

FUEL PUMP INLET STRAINER............. 15

FUEL PUMP MODULE.................... 13

FUEL TANK............................ 17

THROTTLE CABLE...................... 27

SPECIFICATIONS

FUEL TANK CAPACITY................... 28

TORQUE.............................. 28

DESCRIPTION AND OPERATION

FUEL DELIVERY SYSTEM

The front wheel drive van uses a plastic fuel tank

located on the left side of the vehicle.

The Fuel Delivery System consists of: the electric

fuel pump module, fuel filter, tubes/lines/hoses, fuel

rail, and fuel injectors.

The in-tank fuel pump module contains the fuel

pump and pressure regulator. The pump is serviced

as part of the fuel pump module. Refer to Fuel Pump

Module.

The fuel filter is a replaceable in-line filter. The fil-

ter attaches to a bracket mounted on top of the fuel

tank. Refer to the Maintenance Schedules in the

Introduction section of this manual for recommended

fuel filter replacement intervals.

A returnless fuel system is used on all vehicles.

Fuel is returned through the fuel pump module and

back to the fuel tank. A separate fuel return line

from the tank to the engine is no longer used.

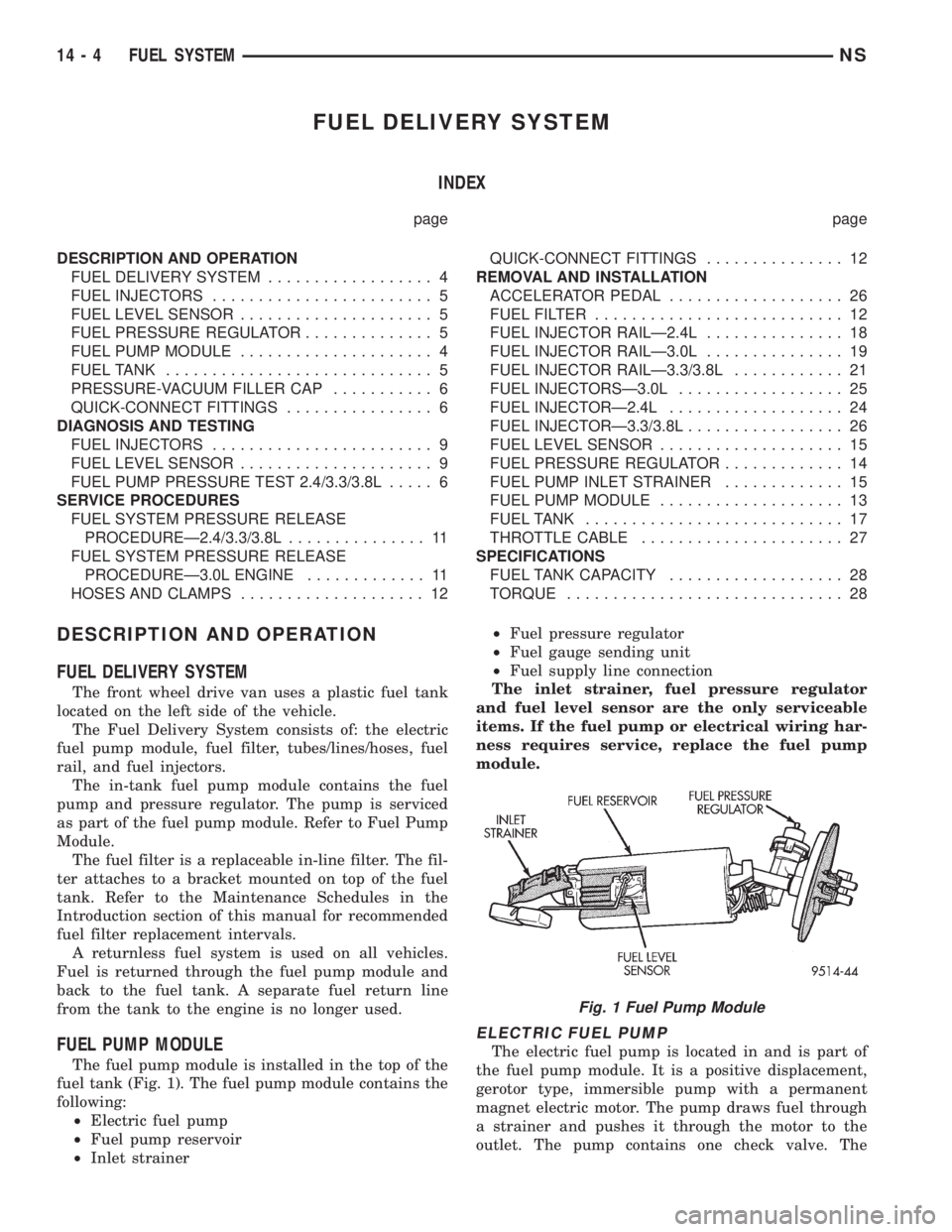

FUEL PUMP MODULE

The fuel pump module is installed in the top of the

fuel tank (Fig. 1). The fuel pump module contains the

following:

²Electric fuel pump

²Fuel pump reservoir

²Inlet strainer²Fuel pressure regulator

²Fuel gauge sending unit

²Fuel supply line connection

The inlet strainer, fuel pressure regulator

and fuel level sensor are the only serviceable

items. If the fuel pump or electrical wiring har-

ness requires service, replace the fuel pump

module.

ELECTRIC FUEL PUMP

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor. The pump draws fuel through

a strainer and pushes it through the motor to the

outlet. The pump contains one check valve. The

Fig. 1 Fuel Pump Module

14 - 4 FUEL SYSTEMNS

Page 1299 of 1938

check valve, in the pump outlet, maintains pump

pressure during engine off conditions. The fuel pump

relay provides voltage to the fuel pump.

The fuel pump has a maximum deadheaded pres-

sure output of approximately 635 kPa (95 psi). The

regulator adjusts fuel system pressure to approxi-

mately 338 kPa (49 psi).

FUEL PUMP ELECTRICAL CONTROL

Voltage to operate the electric pump is supplied

through the fuel pump relay. For an electrical opera-

tional description of the fuel pump refer to fuel Pump

RelayÐPCM Output.

ELECTRICAL PUMP REPLACEMENT

The electric fuel pump is not serviceable. If the

fuel pump or electrical wiring harness needs replace-

ment, the complete fuel pump module must be

replaced. Perform the Fuel System Pressure Release

procedure before servicing the fuel pump.

FUEL LEVEL SENSOR

The level sensor is attached to the side of the fuel

pump module. The level sensor consists of a float, an

arm, and a variable resistor. As the fuel level

increases, the float and arm move up. This decreases

the sending unit resistance, causing the fuel gauge

on the instrument panel to read full.

FUEL PRESSURE REGULATOR

The fuel system uses a nonadjustable pressure reg-

ulator that maintains fuel system pressure at

approximately 338 kPa (49 psi), 3.3l uses approxi-

mately 379 kPa (55 psi). The fuel pressure regulator

contains a diaphragm, calibrated spring and a fuel

return valve. The spring pushes down on the dia-

phragm and closes off the fuel return port. System

fuel pressure reflects the amount of fuel pressure

required to open the return port.

The pressure regulator is a mechanical device that

is NOT controlled by the PCM or engine vacuum.

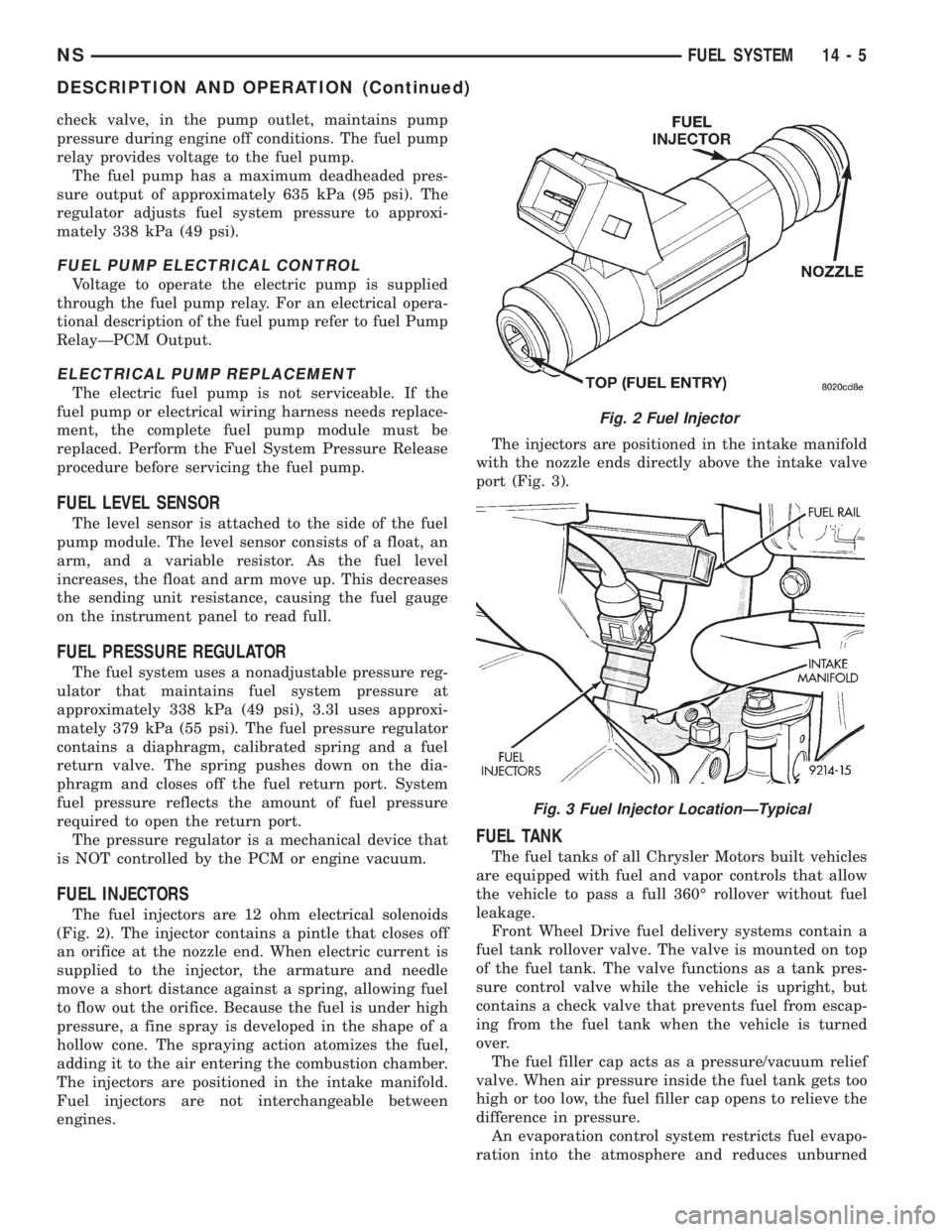

FUEL INJECTORS

The fuel injectors are 12 ohm electrical solenoids

(Fig. 2). The injector contains a pintle that closes off

an orifice at the nozzle end. When electric current is

supplied to the injector, the armature and needle

move a short distance against a spring, allowing fuel

to flow out the orifice. Because the fuel is under high

pressure, a fine spray is developed in the shape of a

hollow cone. The spraying action atomizes the fuel,

adding it to the air entering the combustion chamber.

The injectors are positioned in the intake manifold.

Fuel injectors are not interchangeable between

engines.The injectors are positioned in the intake manifold

with the nozzle ends directly above the intake valve

port (Fig. 3).

FUEL TANK

The fuel tanks of all Chrysler Motors built vehicles

are equipped with fuel and vapor controls that allow

the vehicle to pass a full 360É rollover without fuel

leakage.

Front Wheel Drive fuel delivery systems contain a

fuel tank rollover valve. The valve is mounted on top

of the fuel tank. The valve functions as a tank pres-

sure control valve while the vehicle is upright, but

contains a check valve that prevents fuel from escap-

ing from the fuel tank when the vehicle is turned

over.

The fuel filler cap acts as a pressure/vacuum relief

valve. When air pressure inside the fuel tank gets too

high or too low, the fuel filler cap opens to relieve the

difference in pressure.

An evaporation control system restricts fuel evapo-

ration into the atmosphere and reduces unburned

Fig. 2 Fuel Injector

Fig. 3 Fuel Injector LocationÐTypical

NSFUEL SYSTEM 14 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1300 of 1938

hydrocarbons. Vapors from the fuel tank are collected

in a charcoal filled canister. The vapors are held in

the canister until the engine is operating. When the

engine is running, the vapors are drawn through the

intake manifold into the combustion chambers.

PRESSURE-VACUUM FILLER CAP

The loss of any fuel or vapor out of the filler neck

is prevented by the use of a safety filler cap. The cap

will release pressure only under significant pressure

of 10.9 to 13.45 kPa (1.58 to 1.95 psi). The vacuum

release for all gas caps is between 0.97 and 2.0 kPa

(0.14 and 0.29 psi). The cap must be replaced by a

similar unit if replacement is necessary.

WARNING: REMOVE FILLER CAP TO RELIEVE

TANK PRESSURE BEFORE REMOVING OR REPAIR-

ING FUEL SYSTEM COMPONENTS.

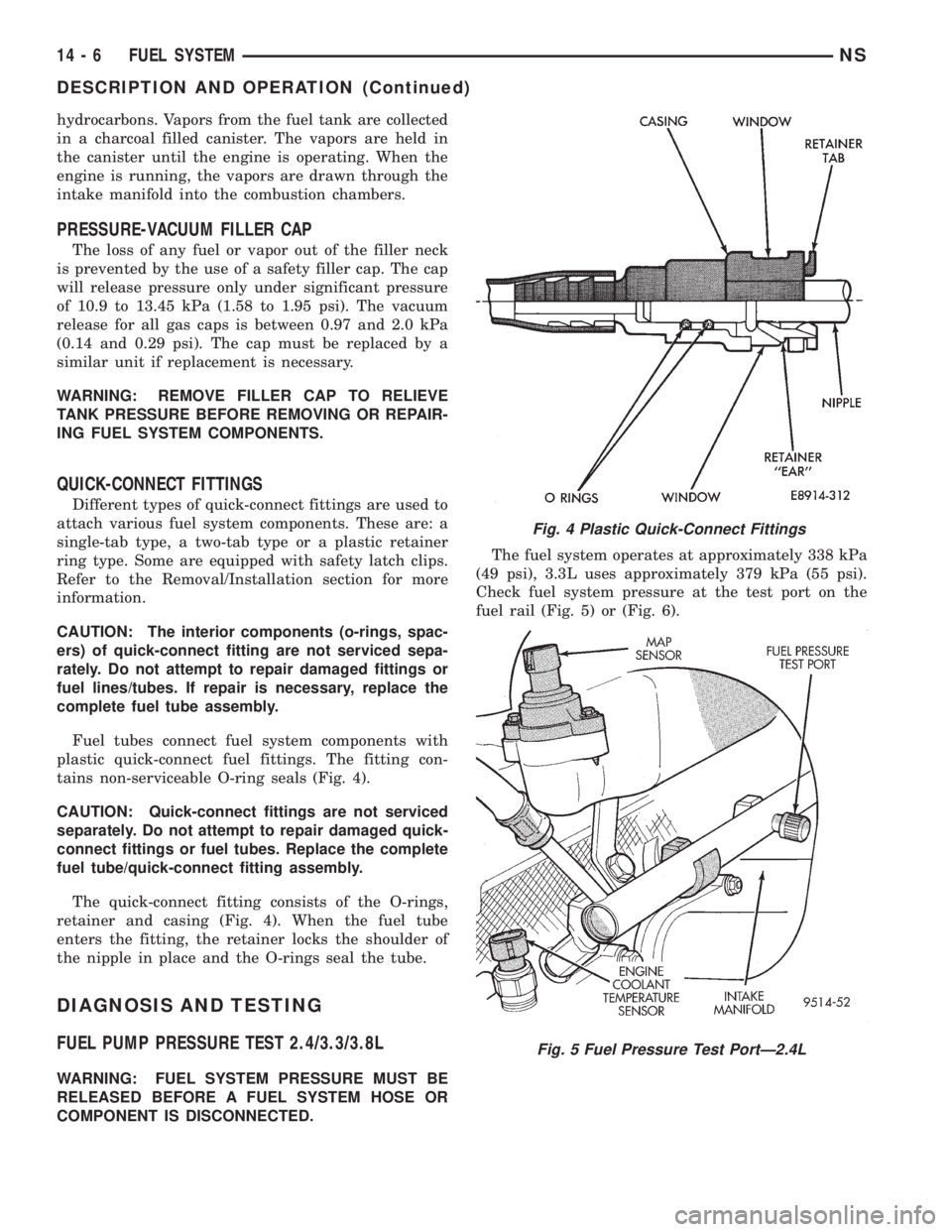

QUICK-CONNECT FITTINGS

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type. Some are equipped with safety latch clips.

Refer to the Removal/Installation section for more

information.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

Fuel tubes connect fuel system components with

plastic quick-connect fuel fittings. The fitting con-

tains non-serviceable O-ring seals (Fig. 4).

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

The quick-connect fitting consists of the O-rings,

retainer and casing (Fig. 4). When the fuel tube

enters the fitting, the retainer locks the shoulder of

the nipple in place and the O-rings seal the tube.

DIAGNOSIS AND TESTING

FUEL PUMP PRESSURE TEST 2.4/3.3/3.8L

WARNING: FUEL SYSTEM PRESSURE MUST BE

RELEASED BEFORE A FUEL SYSTEM HOSE OR

COMPONENT IS DISCONNECTED.The fuel system operates at approximately 338 kPa

(49 psi), 3.3L uses approximately 379 kPa (55 psi).

Check fuel system pressure at the test port on the

fuel rail (Fig. 5) or (Fig. 6).

Fig. 4 Plastic Quick-Connect Fittings

Fig. 5 Fuel Pressure Test PortÐ2.4L

14 - 6 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)