CHRYSLER VOYAGER 1996 Service Manual

VOYAGER 1996

CHRYSLER

CHRYSLER

https://www.carmanualsonline.info/img/25/56867/w960_56867-0.png

CHRYSLER VOYAGER 1996 Service Manual

Trending: wheel, hood open, brake rotor, clock, boot, suspension, radio antenna

Page 1691 of 1938

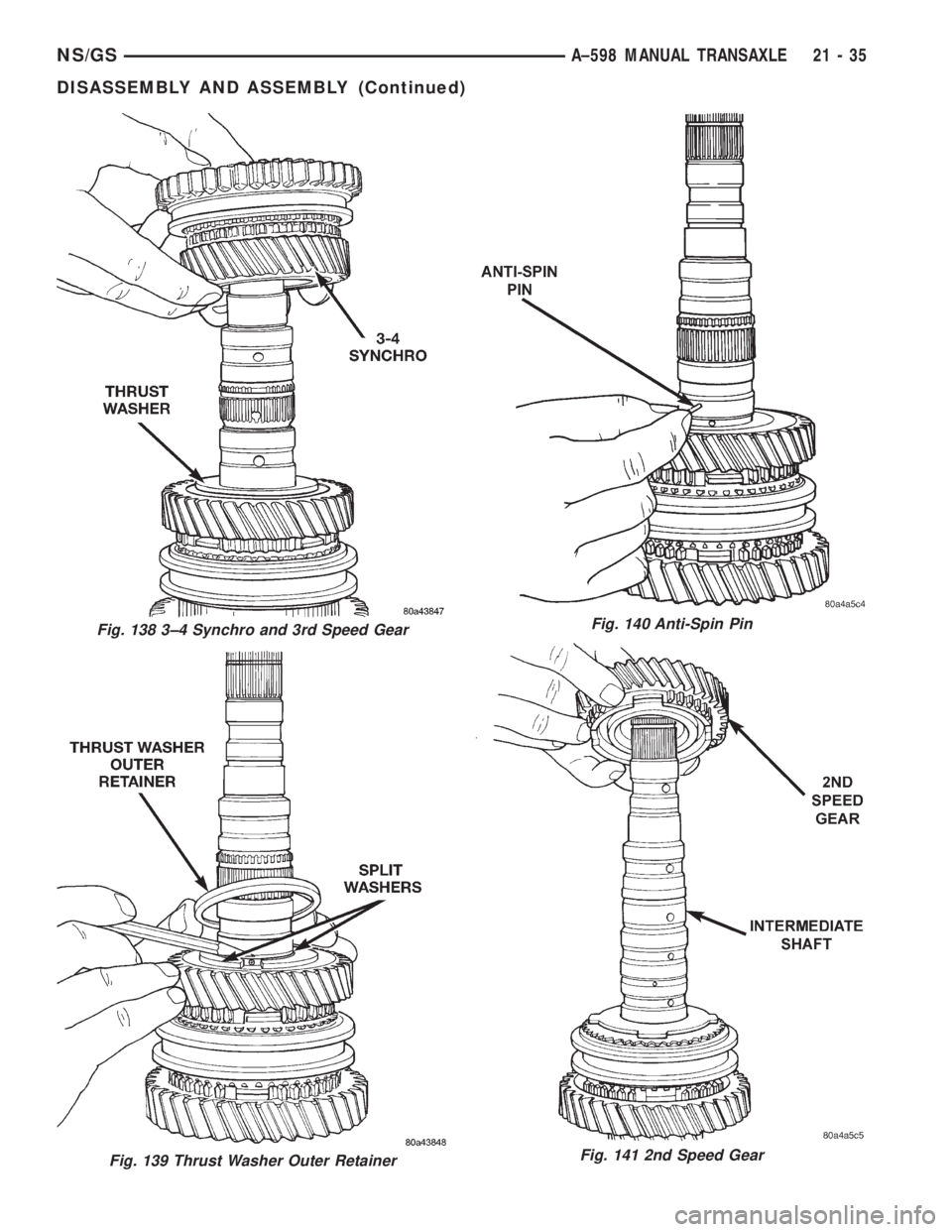

Fig. 139 Thrust Washer Outer Retainer

Fig. 138 3±4 Synchro and 3rd Speed GearFig. 140 Anti-Spin Pin

Fig. 141 2nd Speed Gear

NS/GSA±598 MANUAL TRANSAXLE 21 - 35

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1692 of 1938

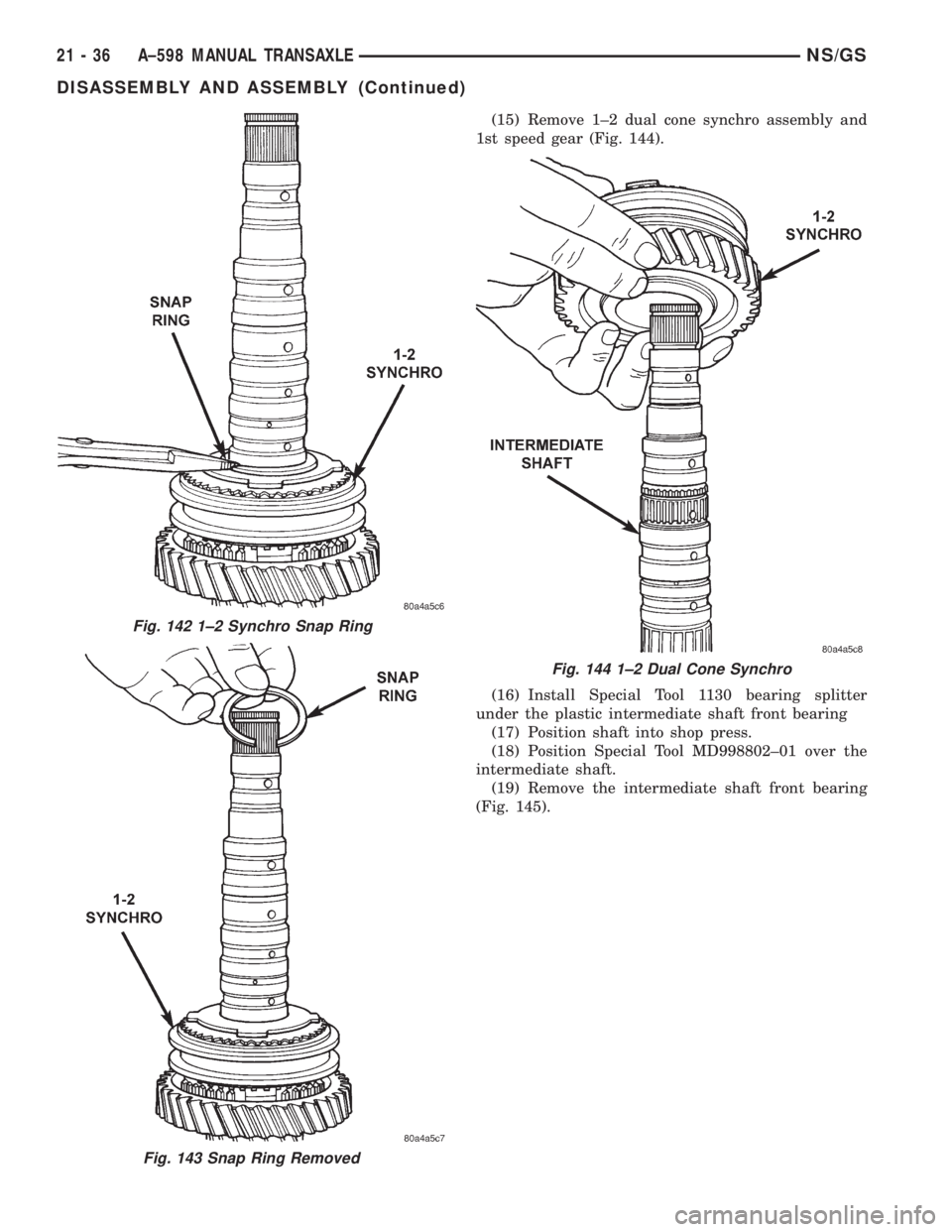

(15) Remove 1±2 dual cone synchro assembly and

1st speed gear (Fig. 144).

(16) Install Special Tool 1130 bearing splitter

under the plastic intermediate shaft front bearing

(17) Position shaft into shop press.

(18) Position Special Tool MD998802±01 over the

intermediate shaft.

(19) Remove the intermediate shaft front bearing

(Fig. 145).

Fig. 143 Snap Ring Removed

Fig. 142 1±2 Synchro Snap Ring

Fig. 144 1±2 Dual Cone Synchro

21 - 36 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1693 of 1938

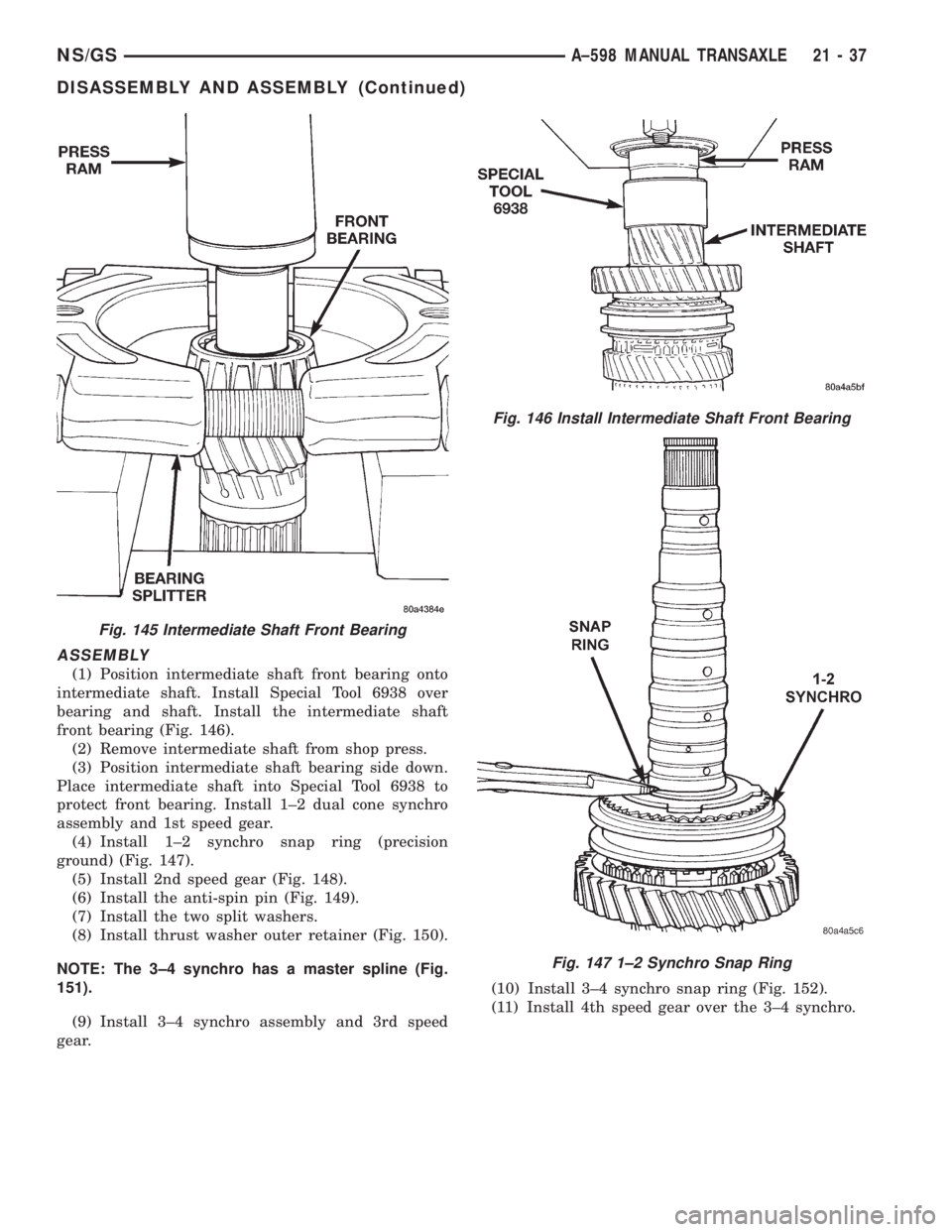

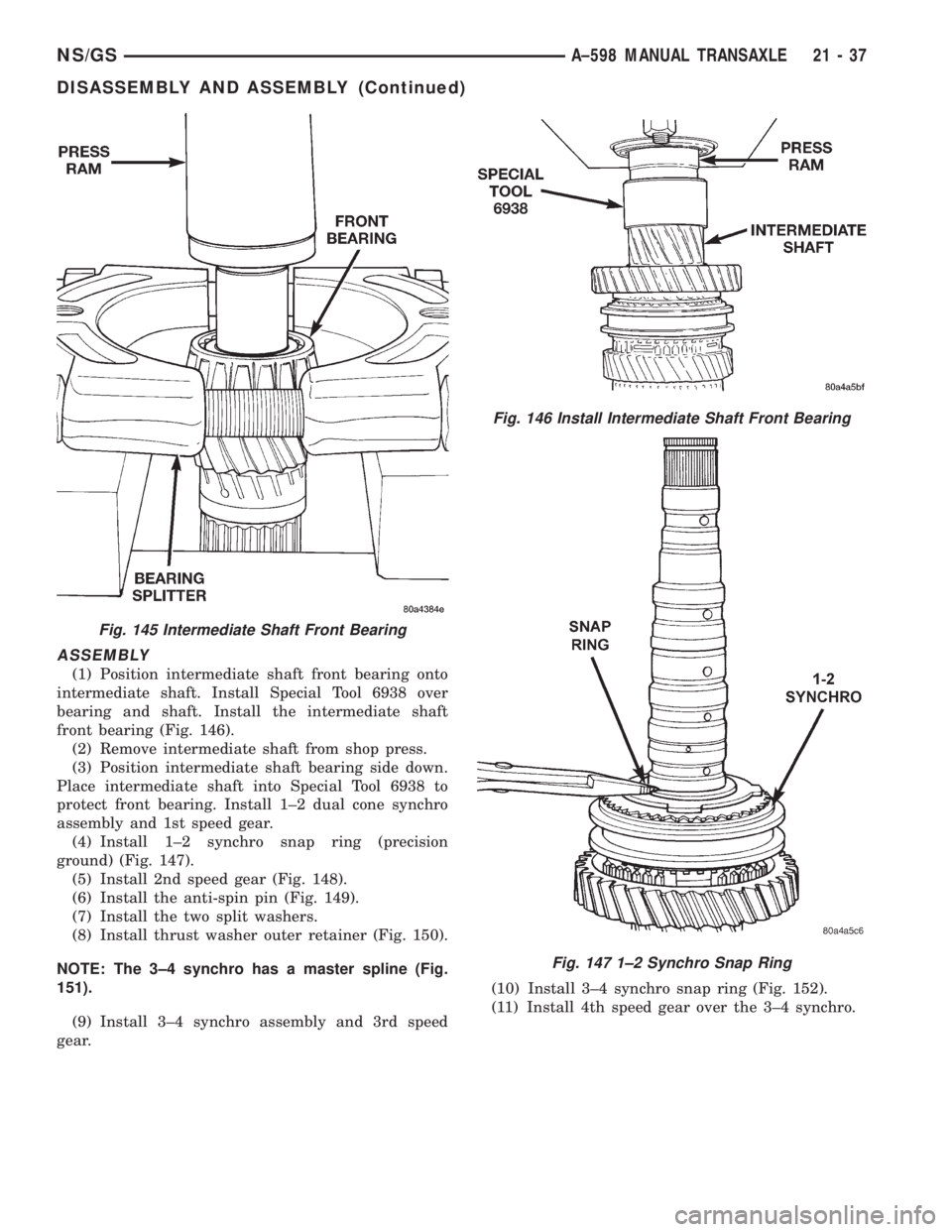

ASSEMBLY

(1) Position intermediate shaft front bearing onto

intermediate shaft. Install Special Tool 6938 over

bearing and shaft. Install the intermediate shaft

front bearing (Fig. 146).

(2) Remove intermediate shaft from shop press.

(3) Position intermediate shaft bearing side down.

Place intermediate shaft into Special Tool 6938 to

protect front bearing. Install 1±2 dual cone synchro

assembly and 1st speed gear.

(4) Install 1±2 synchro snap ring (precision

ground) (Fig. 147).

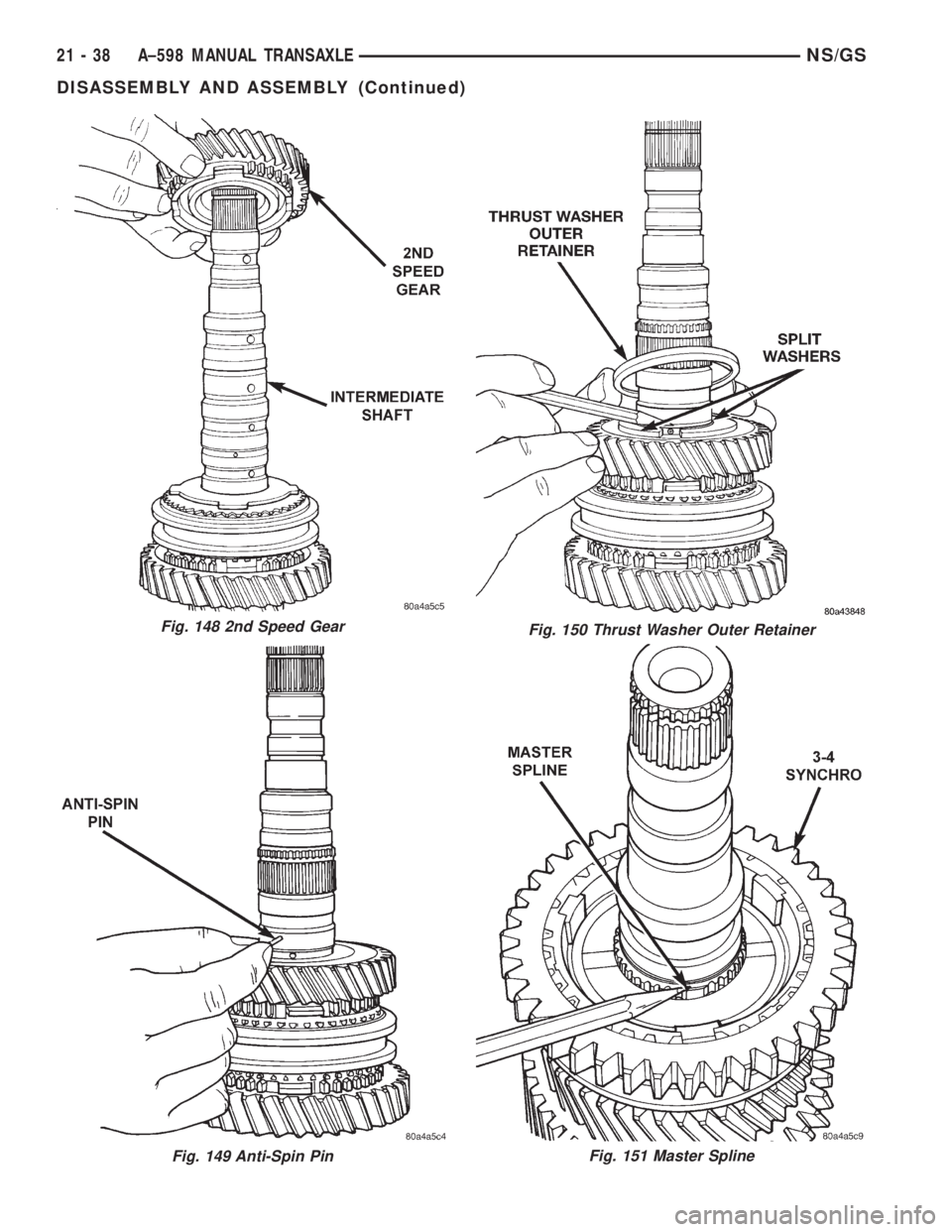

(5) Install 2nd speed gear (Fig. 148).

(6) Install the anti-spin pin (Fig. 149).

(7) Install the two split washers.

(8) Install thrust washer outer retainer (Fig. 150).

NOTE: The 3±4 synchro has a master spline (Fig.

151).

(9) Install 3±4 synchro assembly and 3rd speed

gear.(10) Install 3±4 synchro snap ring (Fig. 152).

(11) Install 4th speed gear over the 3±4 synchro.

Fig. 145 Intermediate Shaft Front Bearing

Fig. 146 Install Intermediate Shaft Front Bearing

Fig. 147 1±2 Synchro Snap Ring

NS/GSA±598 MANUAL TRANSAXLE 21 - 37

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1694 of 1938

Fig. 148 2nd Speed Gear

Fig. 151 Master SplineFig. 149 Anti-Spin Pin

Fig. 150 Thrust Washer Outer Retainer

21 - 38 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1695 of 1938

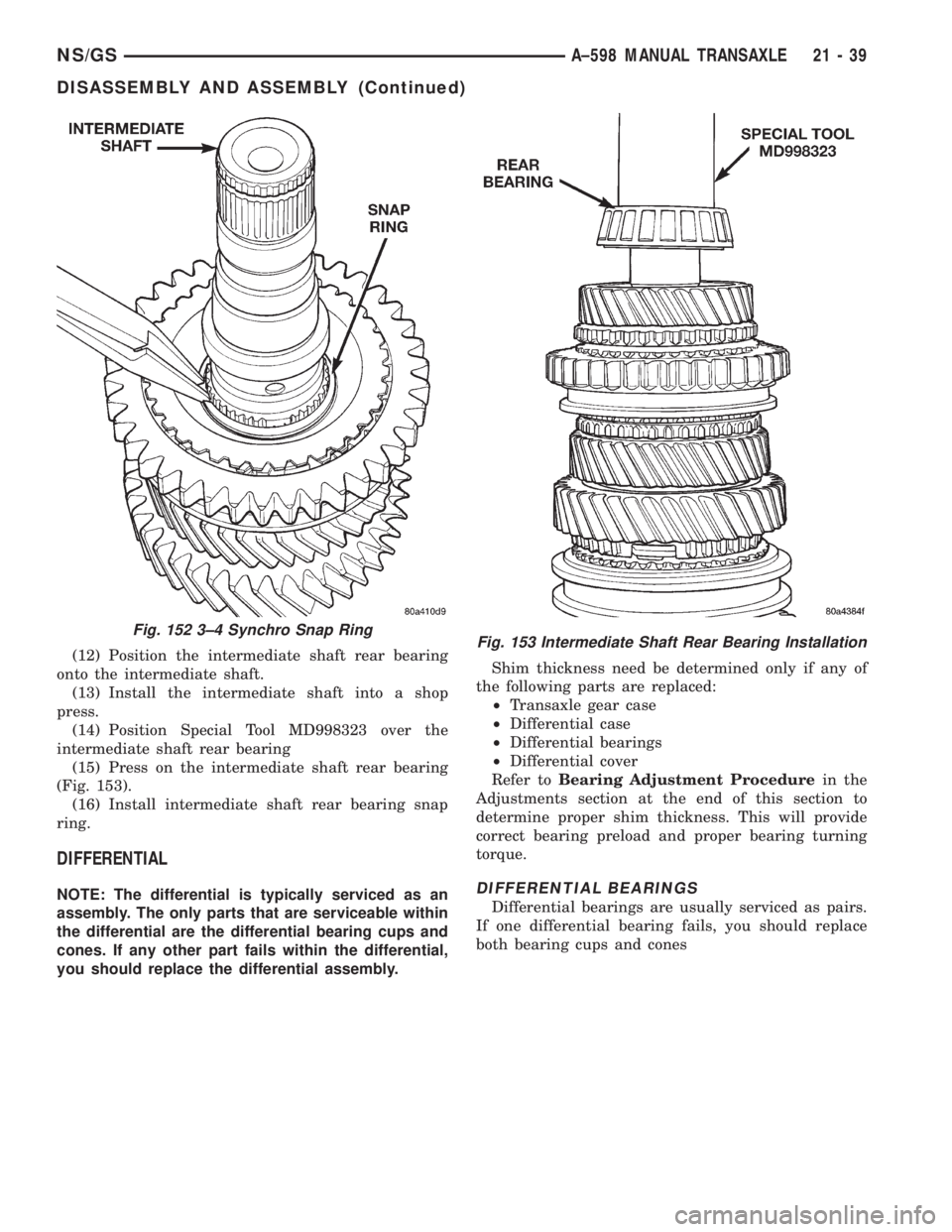

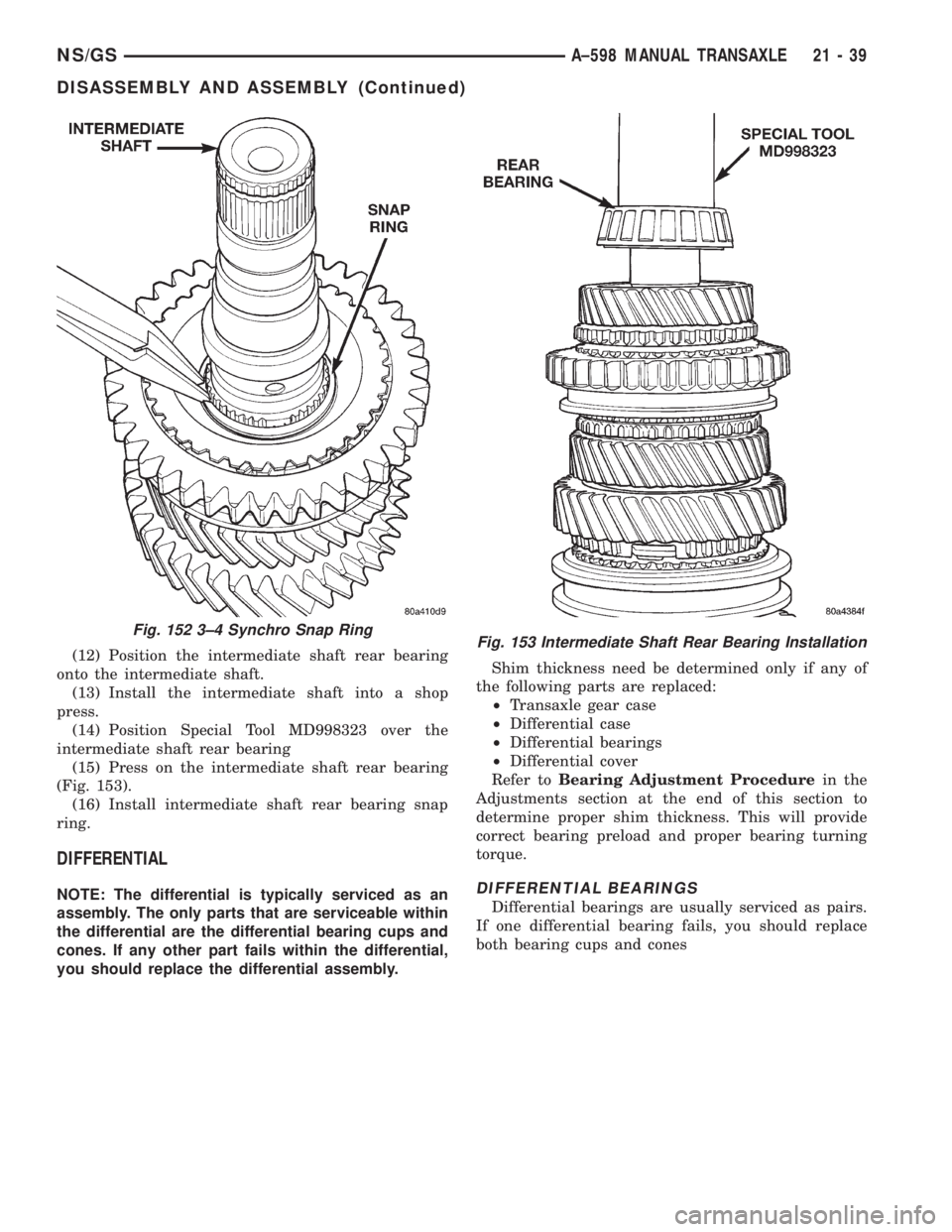

(12) Position the intermediate shaft rear bearing

onto the intermediate shaft.

(13) Install the intermediate shaft into a shop

press.

(14) Position Special Tool MD998323 over the

intermediate shaft rear bearing

(15) Press on the intermediate shaft rear bearing

(Fig. 153).

(16) Install intermediate shaft rear bearing snap

ring.

DIFFERENTIAL

NOTE: The differential is typically serviced as an

assembly. The only parts that are serviceable within

the differential are the differential bearing cups and

cones. If any other part fails within the differential,

you should replace the differential assembly.Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle gear case

²Differential case

²Differential bearings

²Differential cover

Refer toBearing Adjustment Procedurein the

Adjustments section at the end of this section to

determine proper shim thickness. This will provide

correct bearing preload and proper bearing turning

torque.DIFFERENTIAL BEARINGS

Differential bearings are usually serviced as pairs.

If one differential bearing fails, you should replace

both bearing cups and cones

Fig. 152 3±4 Synchro Snap RingFig. 153 Intermediate Shaft Rear Bearing Installation

NS/GSA±598 MANUAL TRANSAXLE 21 - 39

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1696 of 1938

.

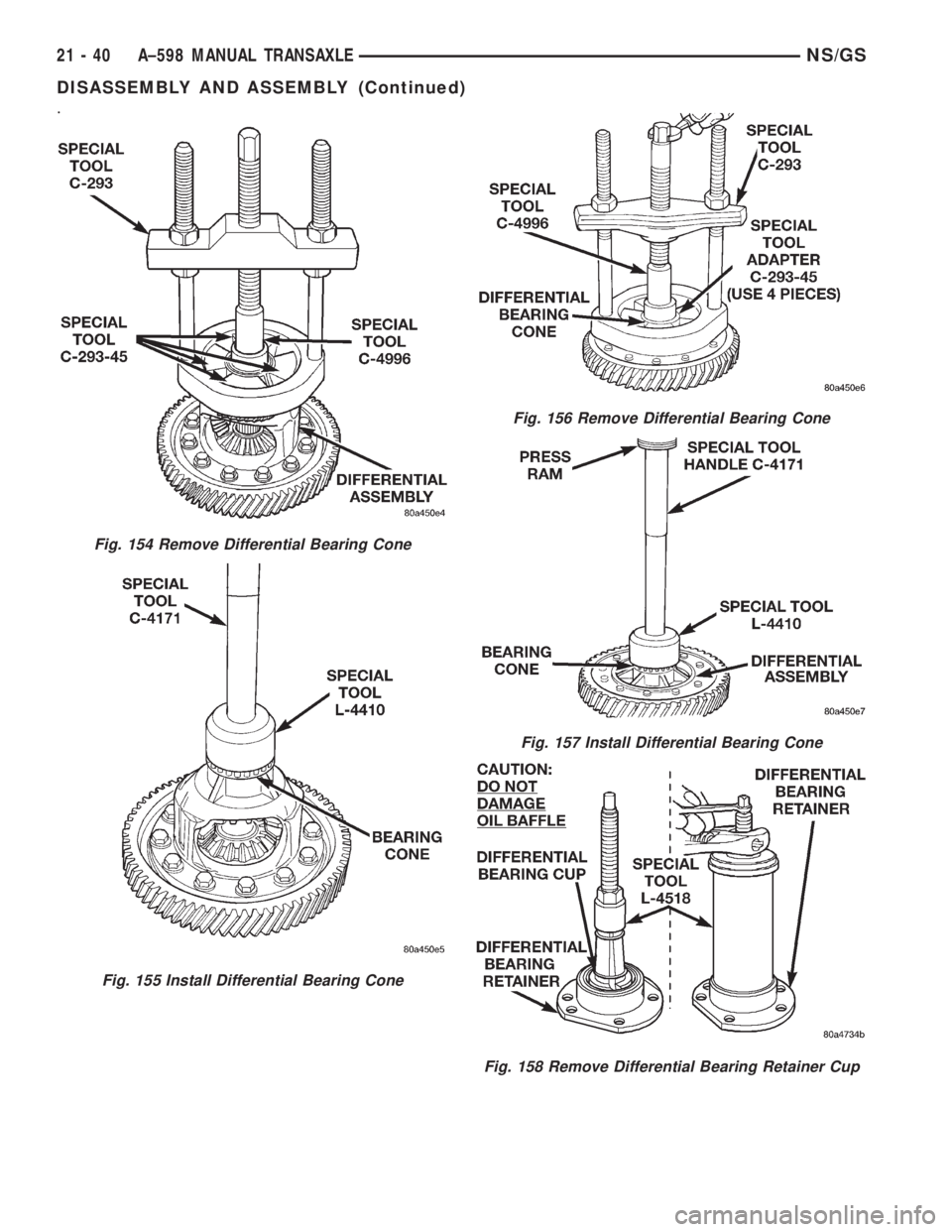

Fig. 154 Remove Differential Bearing Cone

Fig. 155 Install Differential Bearing Cone

Fig. 156 Remove Differential Bearing Cone

Fig. 157 Install Differential Bearing Cone

Fig. 158 Remove Differential Bearing Retainer Cup

21 - 40 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1697 of 1938

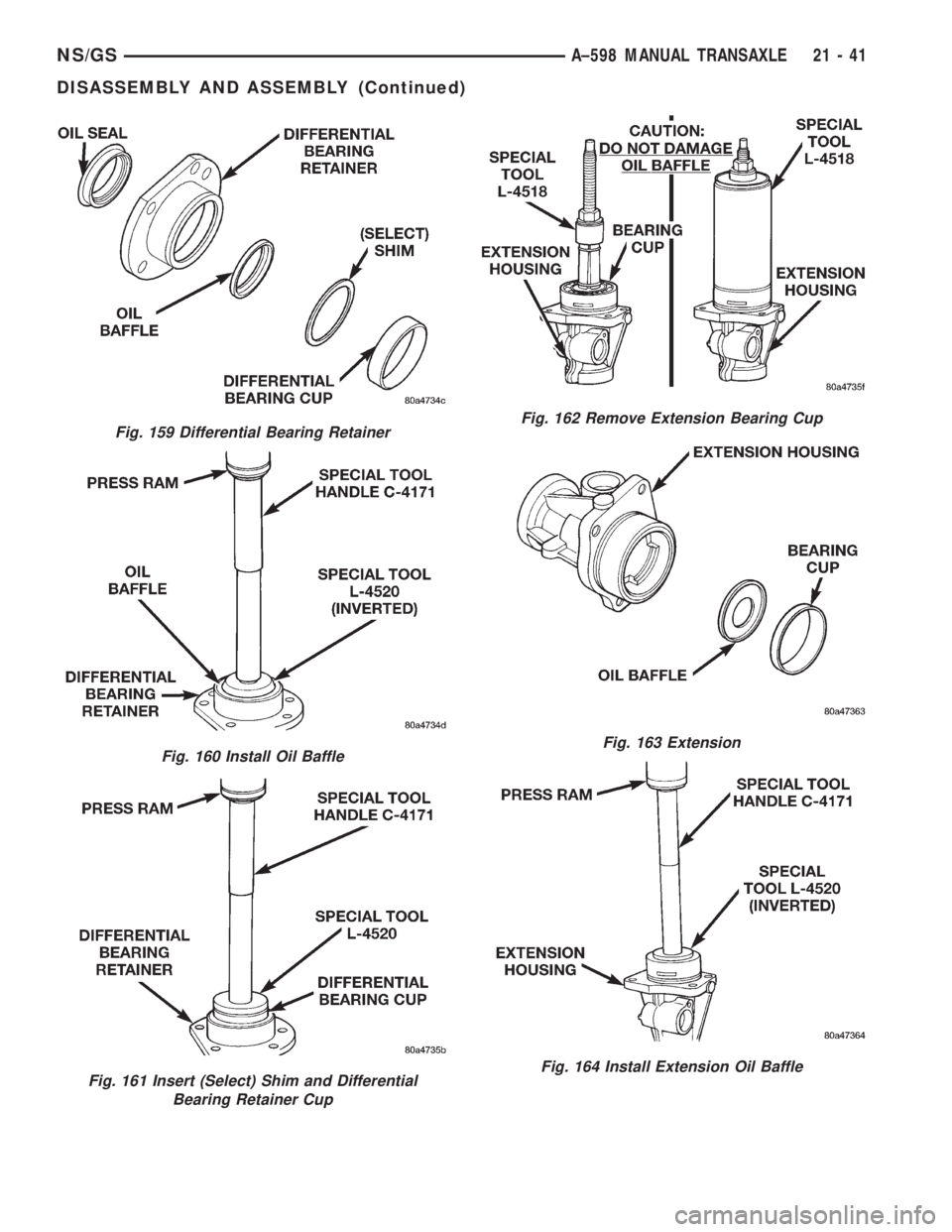

Fig. 159 Differential Bearing Retainer

Fig. 160 Install Oil Baffle

Fig. 161 Insert (Select) Shim and Differential

Bearing Retainer Cup

Fig. 162 Remove Extension Bearing Cup

Fig. 163 Extension

Fig. 164 Install Extension Oil Baffle

NS/GSA±598 MANUAL TRANSAXLE 21 - 41

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1698 of 1938

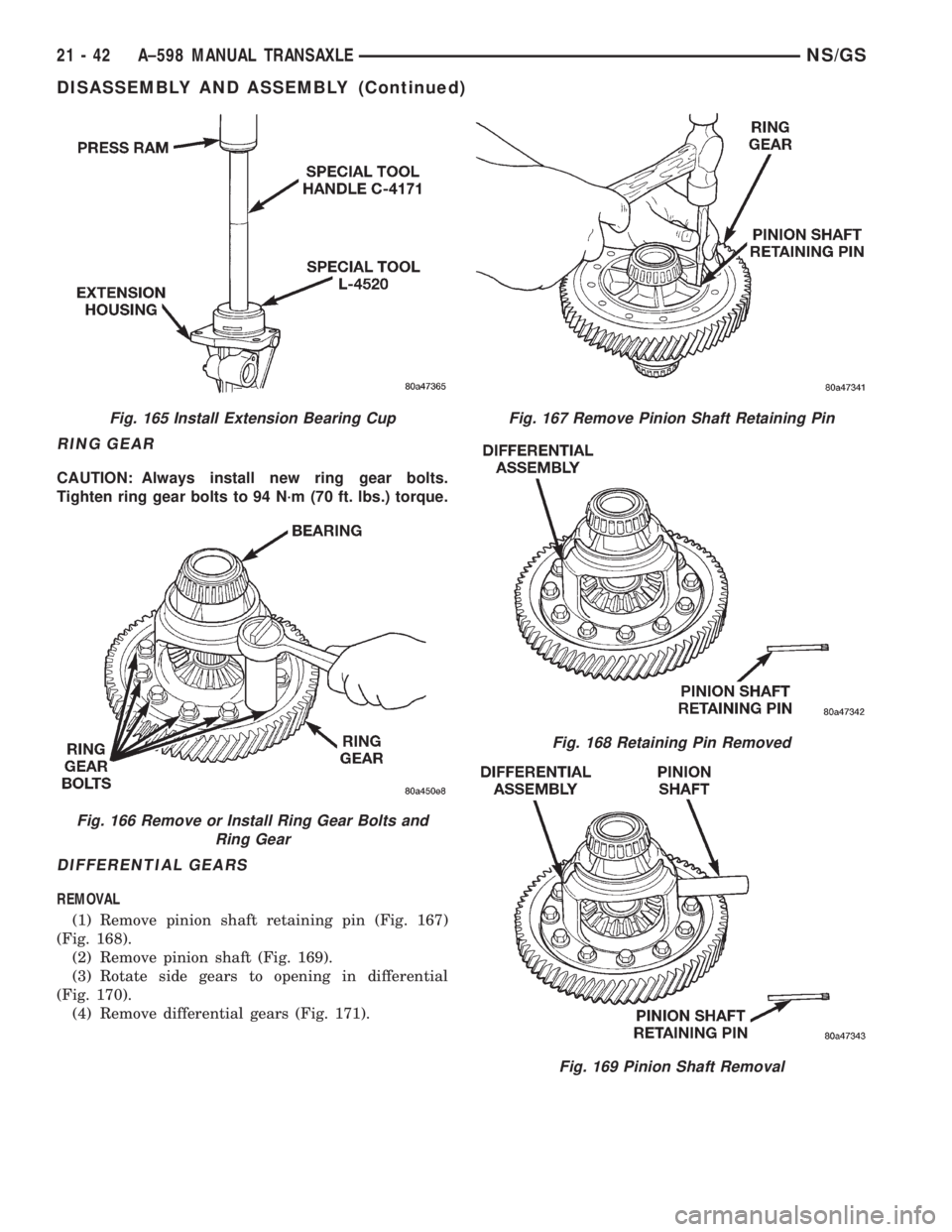

RING GEAR

CAUTION: Always install new ring gear bolts.

Tighten ring gear bolts to 94 N´m (70 ft. lbs.) torque.

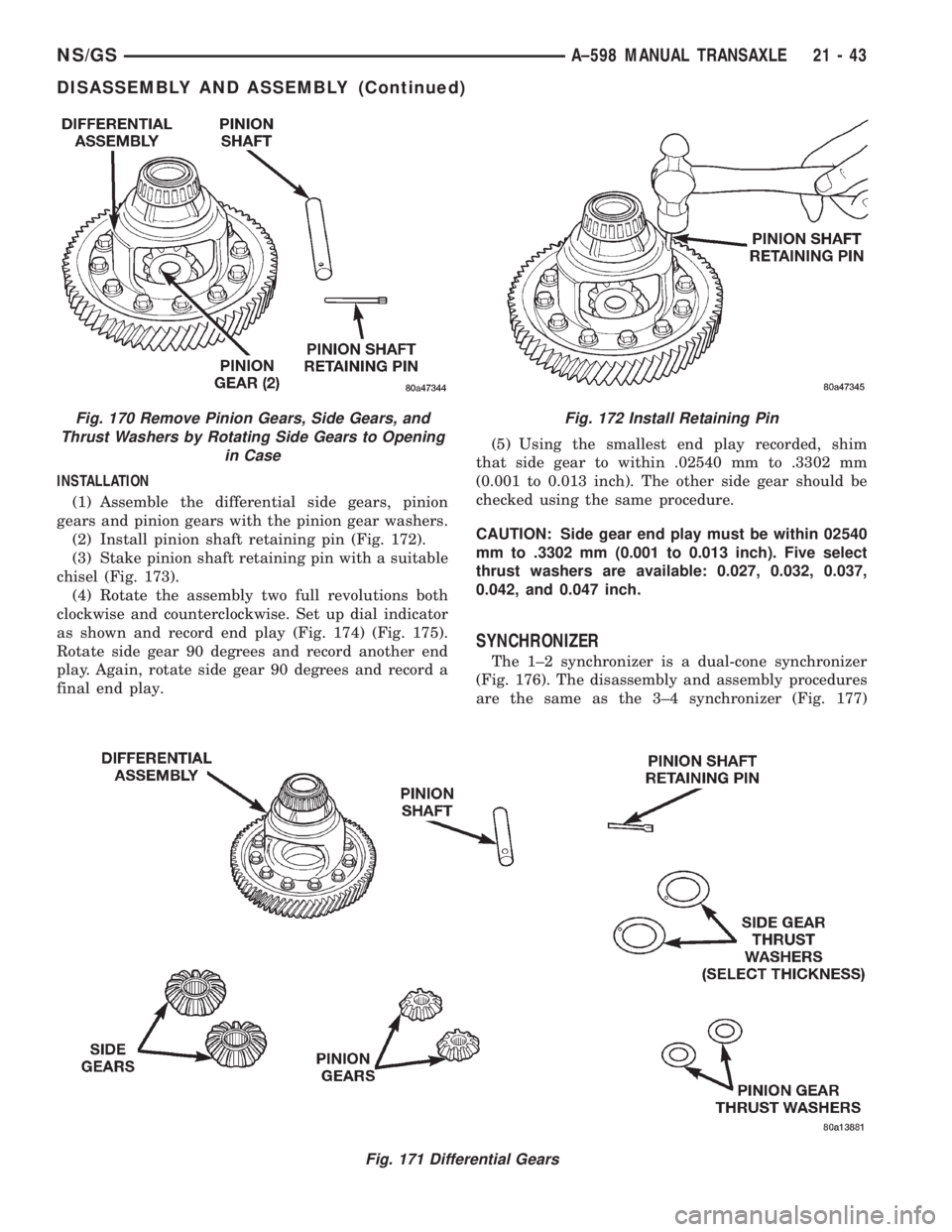

DIFFERENTIAL GEARS

REMOVAL

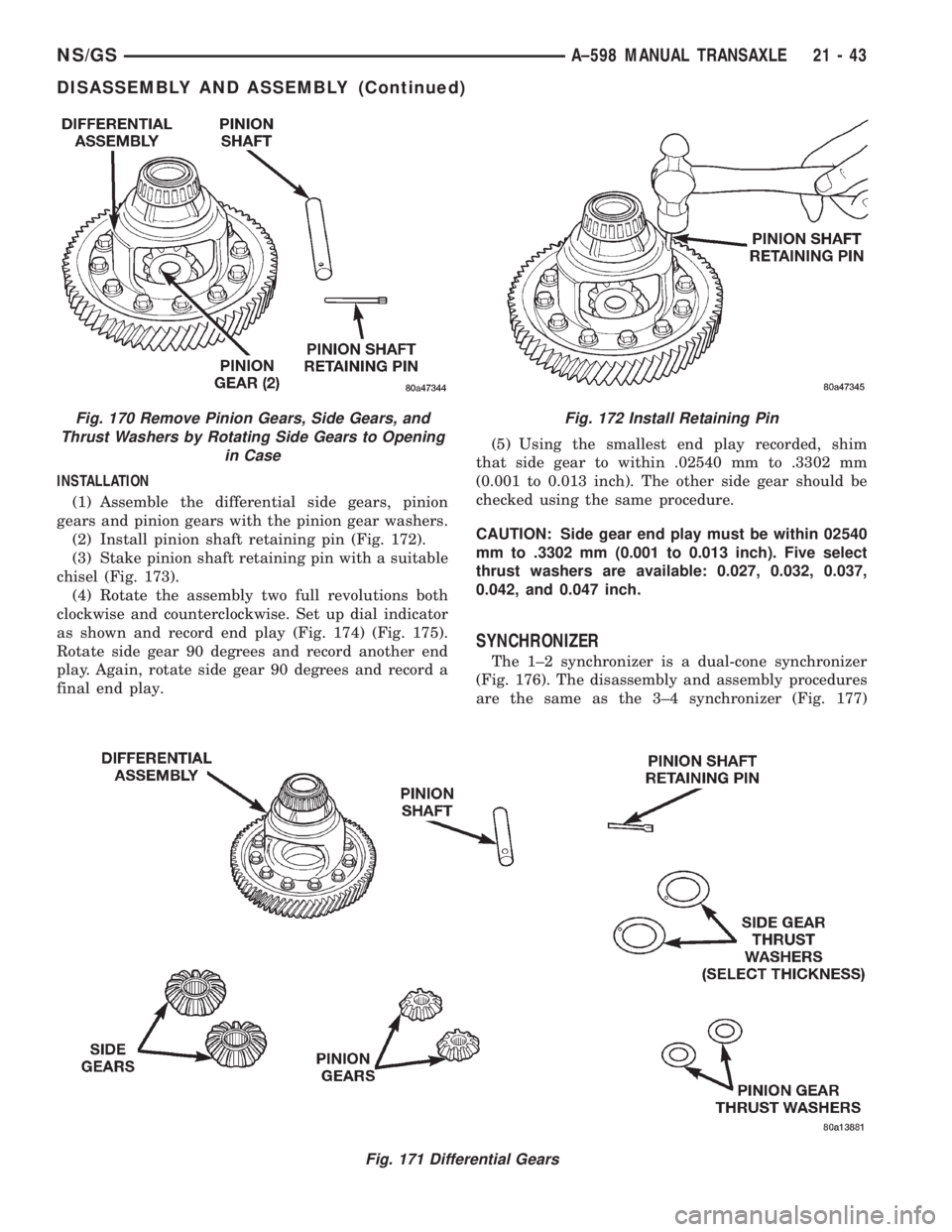

(1) Remove pinion shaft retaining pin (Fig. 167)

(Fig. 168).

(2) Remove pinion shaft (Fig. 169).

(3) Rotate side gears to opening in differential

(Fig. 170).

(4) Remove differential gears (Fig. 171).

Fig. 165 Install Extension Bearing Cup

Fig. 166 Remove or Install Ring Gear Bolts and

Ring Gear

Fig. 167 Remove Pinion Shaft Retaining Pin

Fig. 168 Retaining Pin Removed

Fig. 169 Pinion Shaft Removal

21 - 42 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1699 of 1938

INSTALLATION

(1) Assemble the differential side gears, pinion

gears and pinion gears with the pinion gear washers.

(2) Install pinion shaft retaining pin (Fig. 172).

(3) Stake pinion shaft retaining pin with a suitable

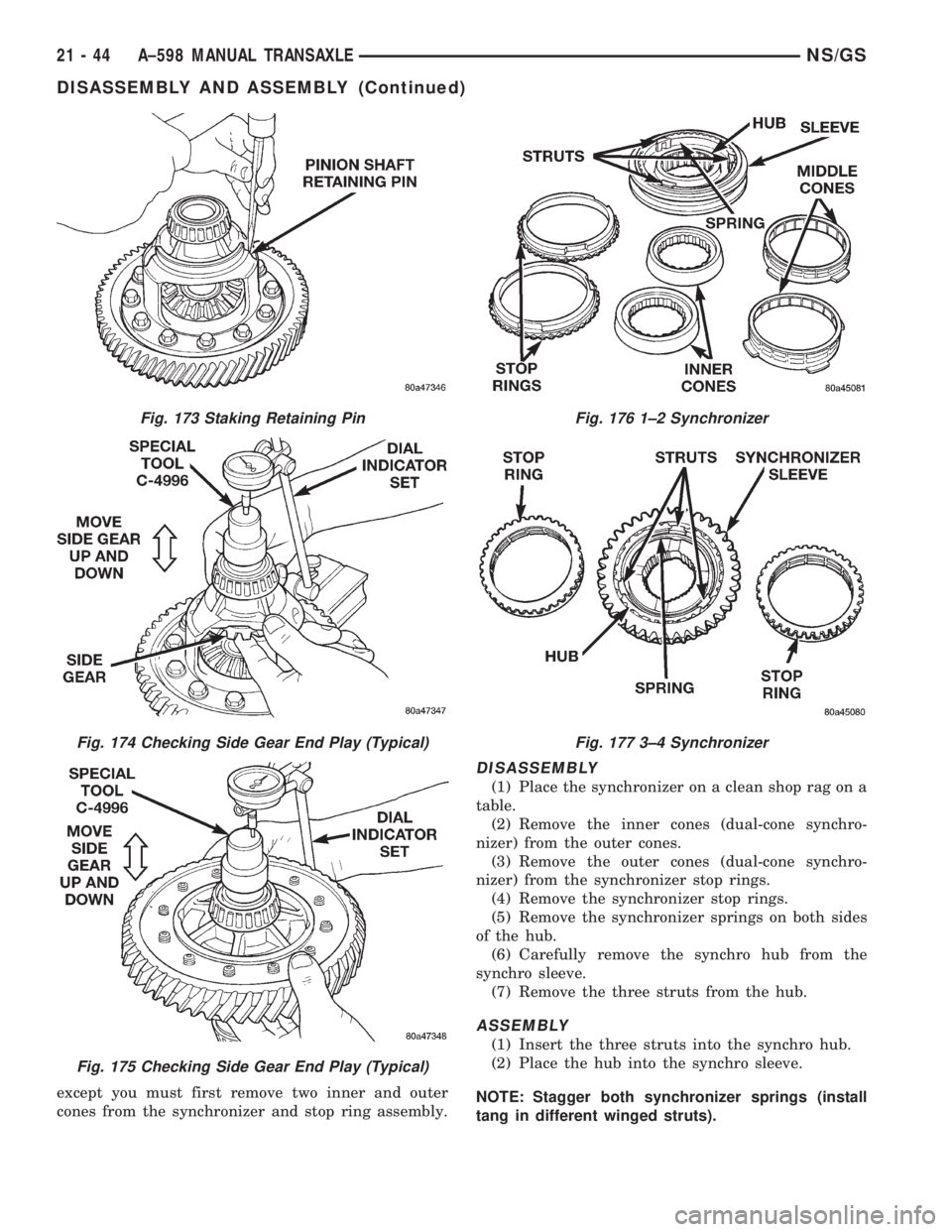

chisel (Fig. 173).

(4) Rotate the assembly two full revolutions both

clockwise and counterclockwise. Set up dial indicator

as shown and record end play (Fig. 174) (Fig. 175).

Rotate side gear 90 degrees and record another end

play. Again, rotate side gear 90 degrees and record a

final end play.(5) Using the smallest end play recorded, shim

that side gear to within .02540 mm to .3302 mm

(0.001 to 0.013 inch). The other side gear should be

checked using the same procedure.

CAUTION: Side gear end play must be within 02540

mm to .3302 mm (0.001 to 0.013 inch). Five select

thrust washers are available: 0.027, 0.032, 0.037,

0.042, and 0.047 inch.

SYNCHRONIZER

The 1±2 synchronizer is a dual-cone synchronizer

(Fig. 176). The disassembly and assembly procedures

are the same as the 3±4 synchronizer (Fig. 177)

Fig. 171 Differential Gears

Fig. 170 Remove Pinion Gears, Side Gears, and

Thrust Washers by Rotating Side Gears to Opening

in CaseFig. 172 Install Retaining Pin

NS/GSA±598 MANUAL TRANSAXLE 21 - 43

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1700 of 1938

except you must first remove two inner and outer

cones from the synchronizer and stop ring assembly.

DISASSEMBLY

(1) Place the synchronizer on a clean shop rag on a

table.

(2) Remove the inner cones (dual-cone synchro-

nizer) from the outer cones.

(3) Remove the outer cones (dual-cone synchro-

nizer) from the synchronizer stop rings.

(4) Remove the synchronizer stop rings.

(5) Remove the synchronizer springs on both sides

of the hub.

(6) Carefully remove the synchro hub from the

synchro sleeve.

(7) Remove the three struts from the hub.

ASSEMBLY

(1) Insert the three struts into the synchro hub.

(2) Place the hub into the synchro sleeve.

NOTE: Stagger both synchronizer springs (install

tang in different winged struts).

Fig. 173 Staking Retaining Pin

Fig. 174 Checking Side Gear End Play (Typical)

Fig. 175 Checking Side Gear End Play (Typical)

Fig. 176 1±2 Synchronizer

Fig. 177 3±4 Synchronizer

21 - 44 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Trending: windshield wipers, AUX, mileage, run flat, steering, service reset, oil change