CHRYSLER VOYAGER 1996 Service Manual

Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1731 of 1938

BODY

CONTENTS

page page

BODY COMPONENT SERVICE.............. 22

GENERAL SERVICE INFORMATION........... 1

PAINT.................................. 2SEATS .................................. 9

STATIONARY GLASS....................... 4

GENERAL SERVICE INFORMATION

INDEX

page

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS...... 1

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use

when welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body. Most of these fasteners can be

reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

NSBODY 23 - 1

Page 1732 of 1938

PAINT

INDEX

page page

GENERAL INFORMATION

AFTERMARKET PAINT REPAIR PRODUCTS.... 3

BASE COAT/CLEAR COAT FINISH............ 2PAINT CODE............................ 2

PAINTED SURFACE TOUCH-UP............. 2

WET SANDING, BUFFING, AND POLISHING.... 2

GENERAL INFORMATION

PAINT CODE

A paint code is provided on the body code plate

located in the engine compartment. Refer to the

Introduction section at the front of this manual for

body code plate description. The paint and trim codes

are also included on the Vehicle Safety Label located

on the driver's door end frame.

BASE COAT/CLEAR COAT FINISH

On most vehicles a two-part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultraviolet light and provides a dura-

ble high-gloss finish.

WET SANDING, BUFFING, AND POLISHING

Minor acid etching, orange peel, or smudging in

clear coat or single-stage finishes can be reduced

with light wet sanding, hand buffing, and polishing.

If the finish has been wet sanded in the past, it

cannot be repeated. Wet sanding operation

should be performed by a trained automotive

paint technician.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat for

durability.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use Mopart

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

TOUCH-UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MopartTar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly wet sanded (1500 grit) and pol-

ished with rubbing compound.

(6) On vehicles with clear coat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

23 - 2 BODYNS

Page 1733 of 1938

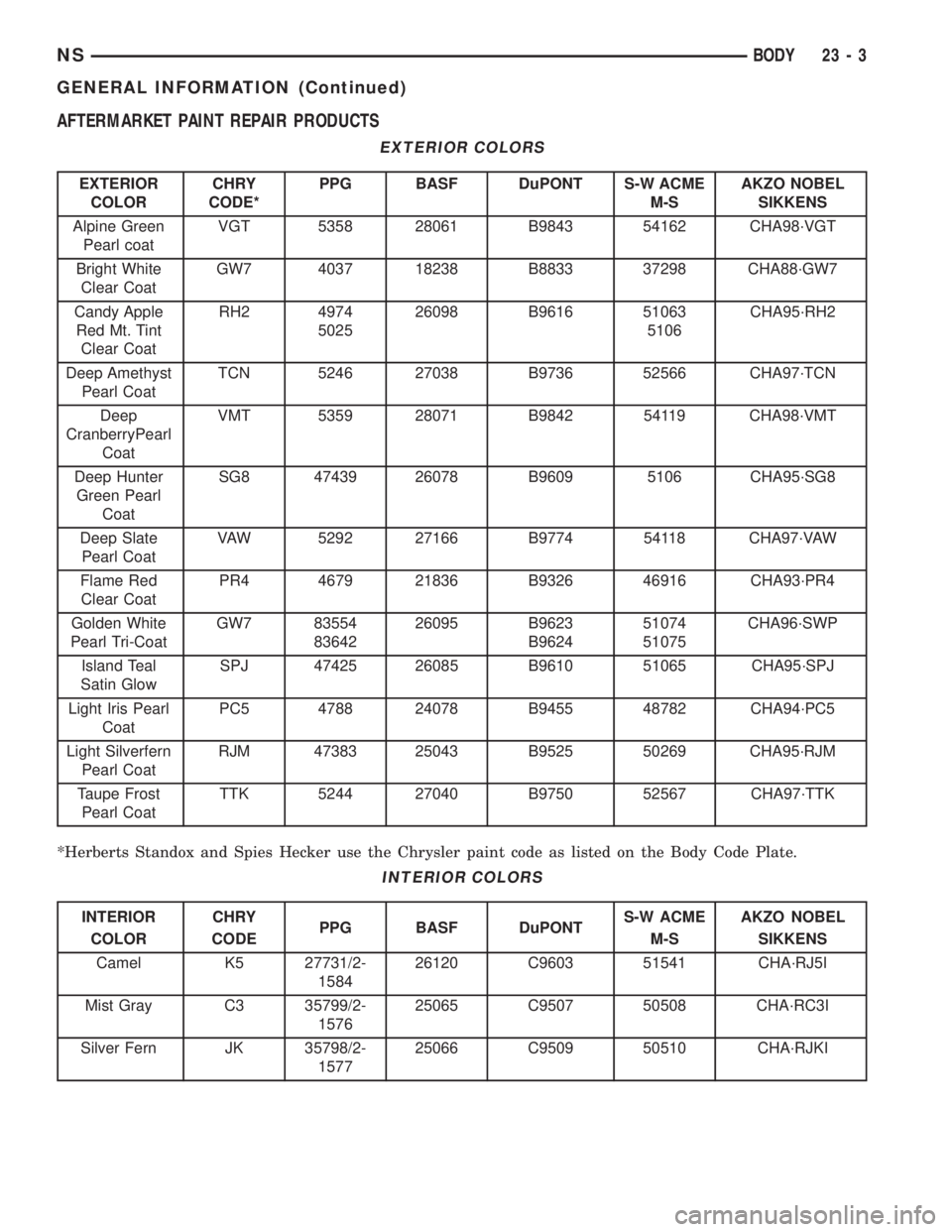

AFTERMARKET PAINT REPAIR PRODUCTS

EXTERIOR COLORS

EXTERIOR

COLORCHRY

CODE*PPG BASF DuPONT S-W ACME

M-SAKZO NOBEL

SIKKENS

Alpine Green

Pearl coatVGT 5358 28061 B9843 54162 CHA98´VGT

Bright White

Clear CoatGW7 4037 18238 B8833 37298 CHA88´GW7

Candy Apple

Red Mt. Tint

Clear CoatRH2 4974

502526098 B9616 51063

5106CHA95´RH2

Deep Amethyst

Pearl CoatTCN 5246 27038 B9736 52566 CHA97´TCN

Deep

CranberryPearl

CoatVMT 5359 28071 B9842 54119 CHA98´VMT

Deep Hunter

Green Pearl

CoatSG8 47439 26078 B9609 5106 CHA95´SG8

Deep Slate

Pearl CoatVAW 5292 27166 B9774 54118 CHA97´VAW

Flame Red

Clear CoatPR4 4679 21836 B9326 46916 CHA93´PR4

Golden White

Pearl Tri-CoatGW7 83554

8364226095 B9623

B962451074

51075CHA96´SWP

Island Teal

Satin GlowSPJ 47425 26085 B9610 51065 CHA95´SPJ

Light Iris Pearl

CoatPC5 4788 24078 B9455 48782 CHA94´PC5

Light Silverfern

Pearl CoatRJM 47383 25043 B9525 50269 CHA95´RJM

Taupe Frost

Pearl CoatTTK 5244 27040 B9750 52567 CHA97´TTK

*Herberts Standox and Spies Hecker use the Chrysler paint code as listed on the Body Code Plate.

INTERIOR COLORS

INTERIOR

COLORCHRY

CODEPPG BASF DuPONTS-W ACME

M-SAKZO NOBEL

SIKKENS

Camel K5 27731/2-

158426120 C9603 51541 CHA´RJ5I

Mist Gray C3 35799/2-

157625065 C9507 50508 CHA´RC3I

Silver Fern JK 35798/2-

157725066 C9509 50510 CHA´RJKI

NSBODY 23 - 3

GENERAL INFORMATION (Continued)

Page 1734 of 1938

STATIONARY GLASS

INDEX

page page

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS................... 4

REMOVAL AND INSTALLATION

BODY SIDE/SLIDING DOOR STATIONARY

GLASS............................... 6REAR WINDOW.......................... 7

WINDSHIELD............................ 4

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, PVC (VINYL) PRIMER AND

PINCHWELD (FENCE) PRIMER PROVIDED BY THE

ADHESIVE MANUFACTURER. IF NOT, STRUCTURAL

INTEGRITY COULD BE COMPROMISED.

CHRYSLER DOES NOT RECOMMEND GLASS

ADHESIVE BY BRAND. TECHNICIANS SHOULD

REVIEW PRODUCT LABELS AND TECHNICAL DATA

SHEETS, AND USE ONLY ADHESIVES THAT THEIR

MANUFACTURES WARRANT WILL RESTORE A

VEHICLE TO THE REQUIREMENTS OF FMVSS 212.

TECHNICIANS SHOULD ALSO INSURE THAT PRIM-

ERS AND CLEANERS ARE COMPATIBLE WITH THE

PARTICULAR ADHESIVE USED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

It is difficult to salvage a windshield during the

removal operation. The windshield is part of the

structural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficult

to cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

REMOVAL AND INSTALLATION

WINDSHIELD

The urethane adhesive holding the windshield to

the opening pinch weld (fence) can be cut using a

sharp cold knife from the exterior of the vehicle.

Using the cold knife method is effective if the wind-

shield is already broken. If the glass must be sal-

vaged, cutting the urethane adhesive from the

interior of the vehicle using a reciprocating or oscil-

lating power knife is recommended.

WINDSHIELD REMOVAL ± EXTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove windshield wiper arms.

(3) Remove cowl cover.

(4) Remove A-pillar trim panels.

(5) Disconnect wire connectors to windshield

defroster grid.

(6) Place protective covers over instrument panel

and hood.

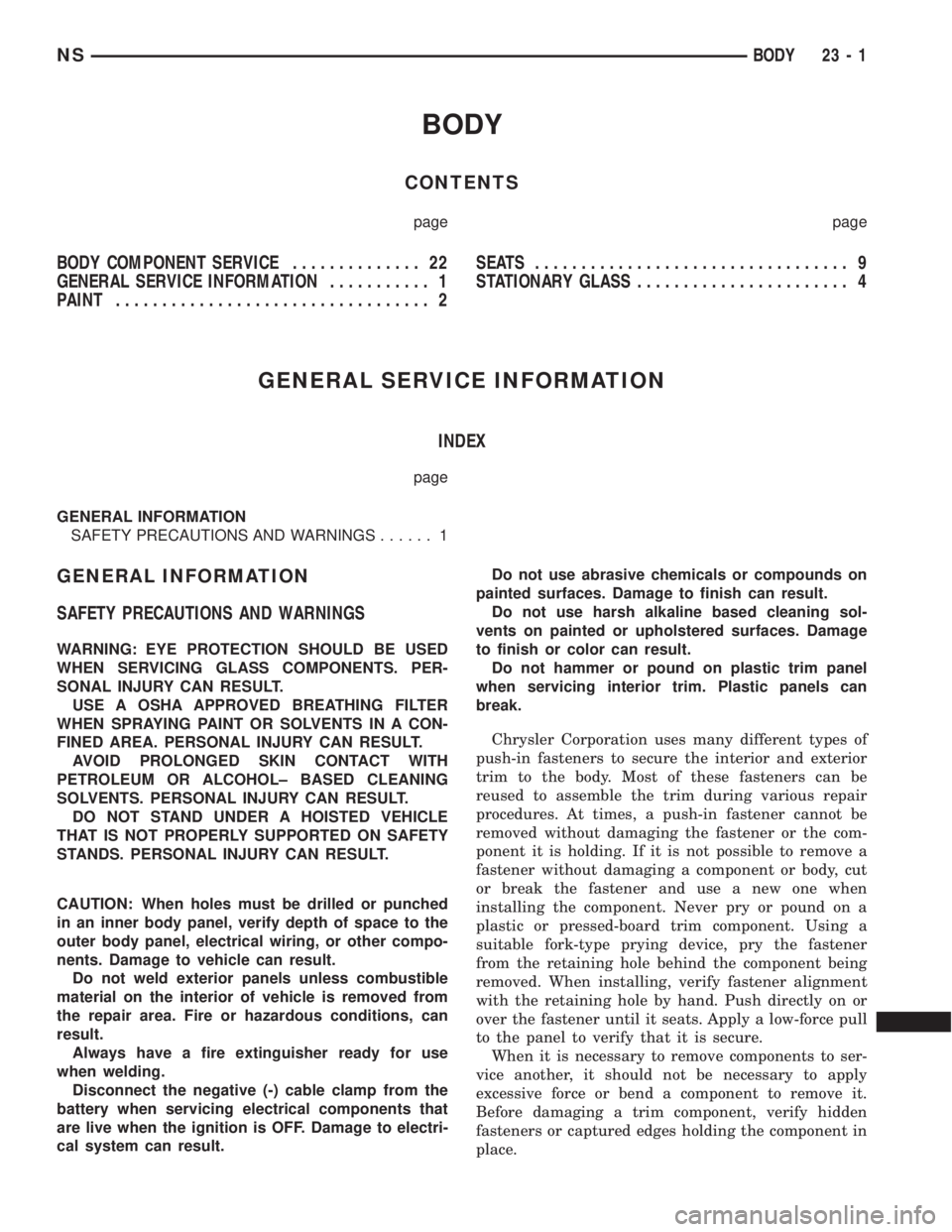

(7) Remove windshield molding (Fig. 1). Using pli-

ers, pull outward on molding at the bottom of A-pil-

lars.

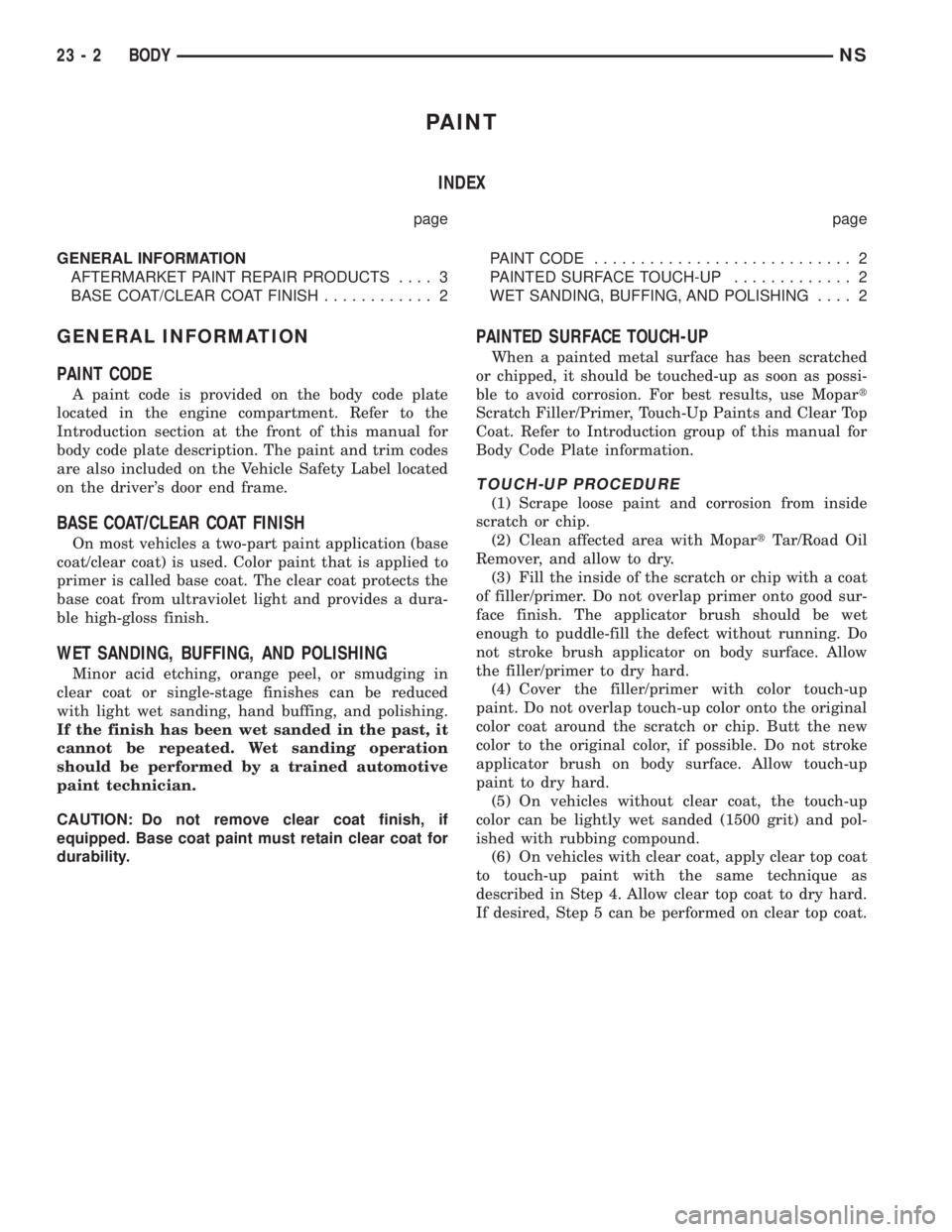

(8) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 2). A power

cutting device can be used if available.

(9) Remove windshield from vehicle.

23 - 4 BODYNS

Page 1735 of 1938

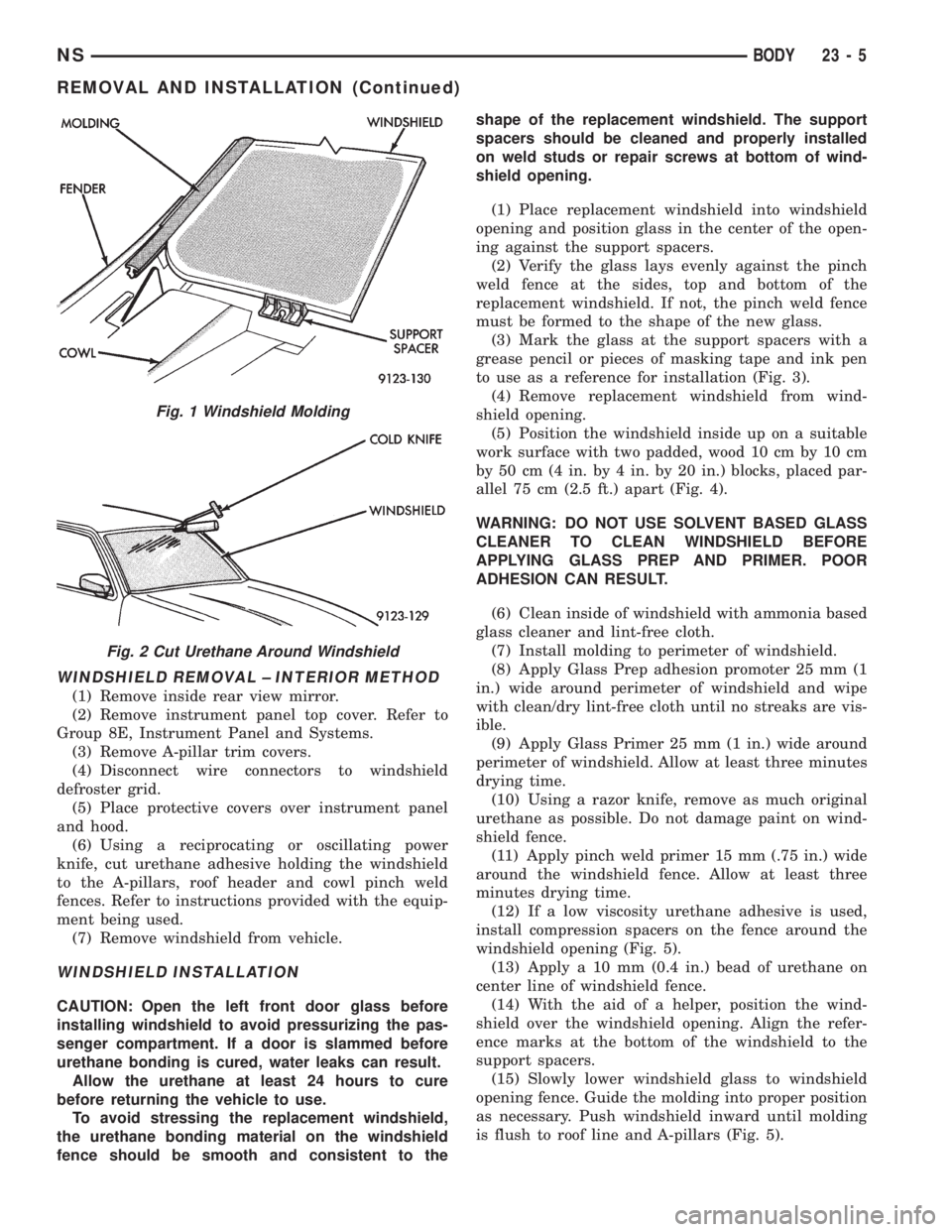

WINDSHIELD REMOVAL ± INTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove instrument panel top cover. Refer to

Group 8E, Instrument Panel and Systems.

(3) Remove A-pillar trim covers.

(4) Disconnect wire connectors to windshield

defroster grid.

(5) Place protective covers over instrument panel

and hood.

(6) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the windshield

to the A-pillars, roof header and cowl pinch weld

fences. Refer to instructions provided with the equip-

ment being used.

(7) Remove windshield from vehicle.

WINDSHIELD INSTALLATION

CAUTION: Open the left front door glass before

installing windshield to avoid pressurizing the pas-

senger compartment. If a door is slammed before

urethane bonding is cured, water leaks can result.

Allow the urethane at least 24 hours to cure

before returning the vehicle to use.

To avoid stressing the replacement windshield,

the urethane bonding material on the windshield

fence should be smooth and consistent to theshape of the replacement windshield. The support

spacers should be cleaned and properly installed

on weld studs or repair screws at bottom of wind-

shield opening.

(1) Place replacement windshield into windshield

opening and position glass in the center of the open-

ing against the support spacers.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement windshield. If not, the pinch weld fence

must be formed to the shape of the new glass.

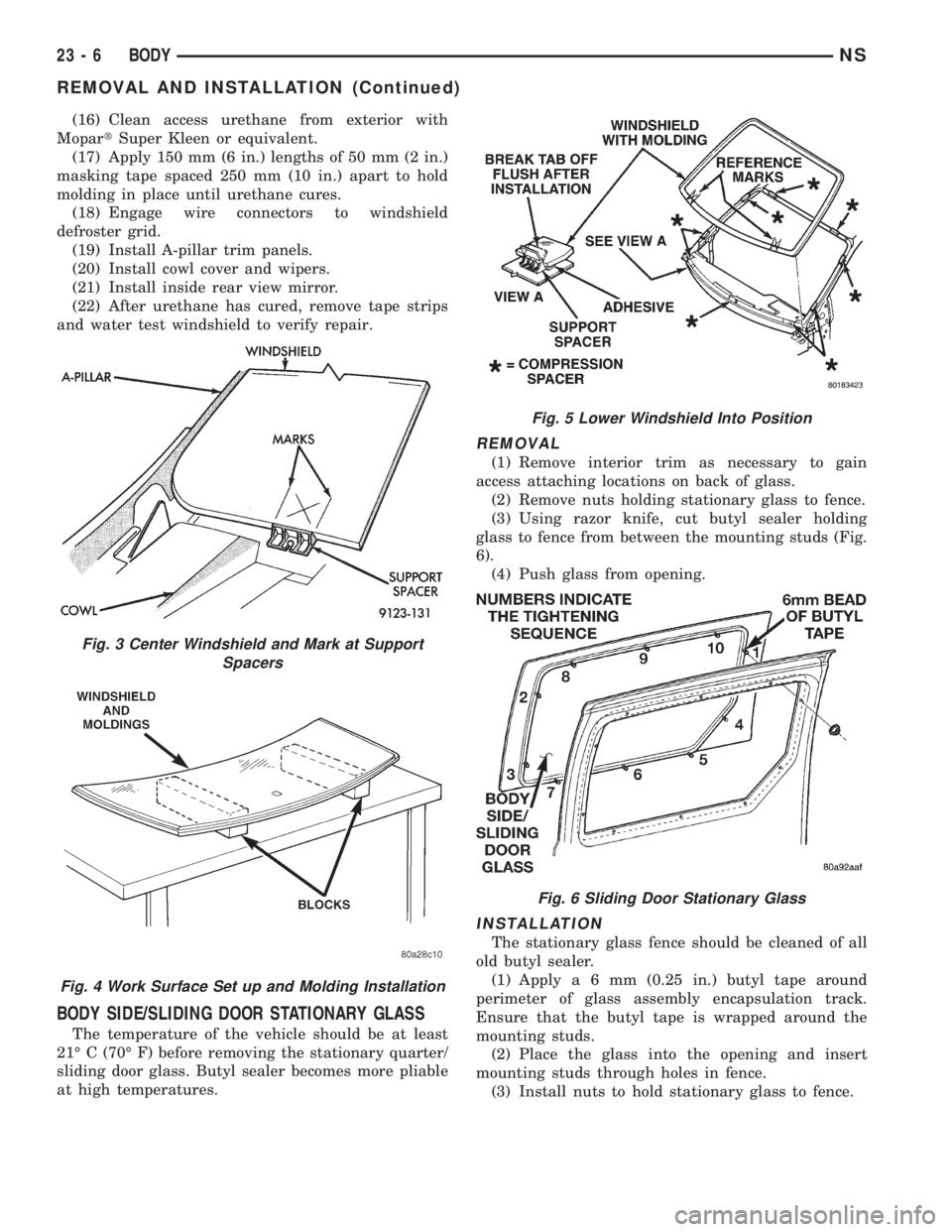

(3) Mark the glass at the support spacers with a

grease pencil or pieces of masking tape and ink pen

to use as a reference for installation (Fig. 3).

(4) Remove replacement windshield from wind-

shield opening.

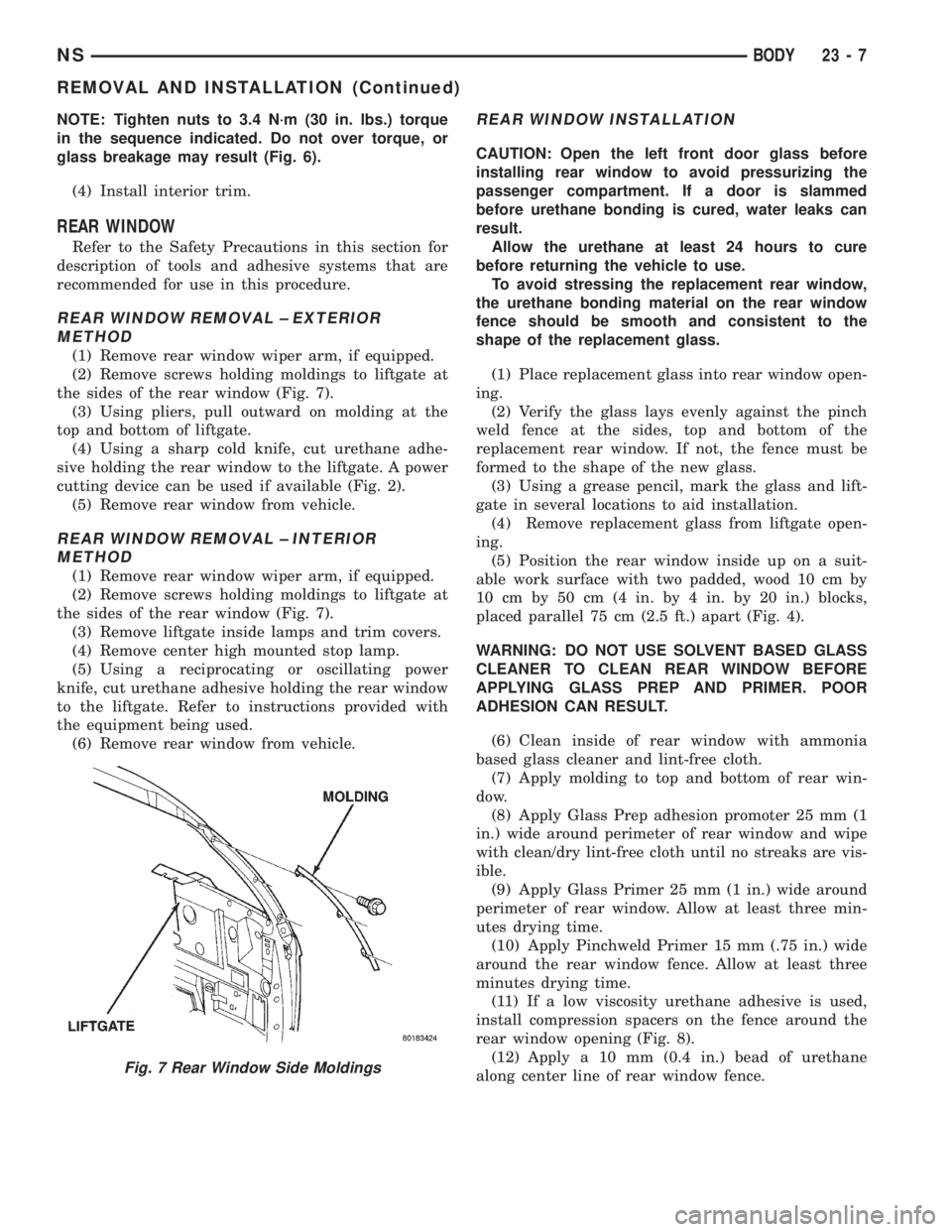

(5) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart (Fig. 4).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN WINDSHIELD BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(6) Clean inside of windshield with ammonia based

glass cleaner and lint-free cloth.

(7) Install molding to perimeter of windshield.

(8) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of windshield and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(9) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of windshield. Allow at least three minutes

drying time.

(10) Using a razor knife, remove as much original

urethane as possible. Do not damage paint on wind-

shield fence.

(11) Apply pinch weld primer 15 mm (.75 in.) wide

around the windshield fence. Allow at least three

minutes drying time.

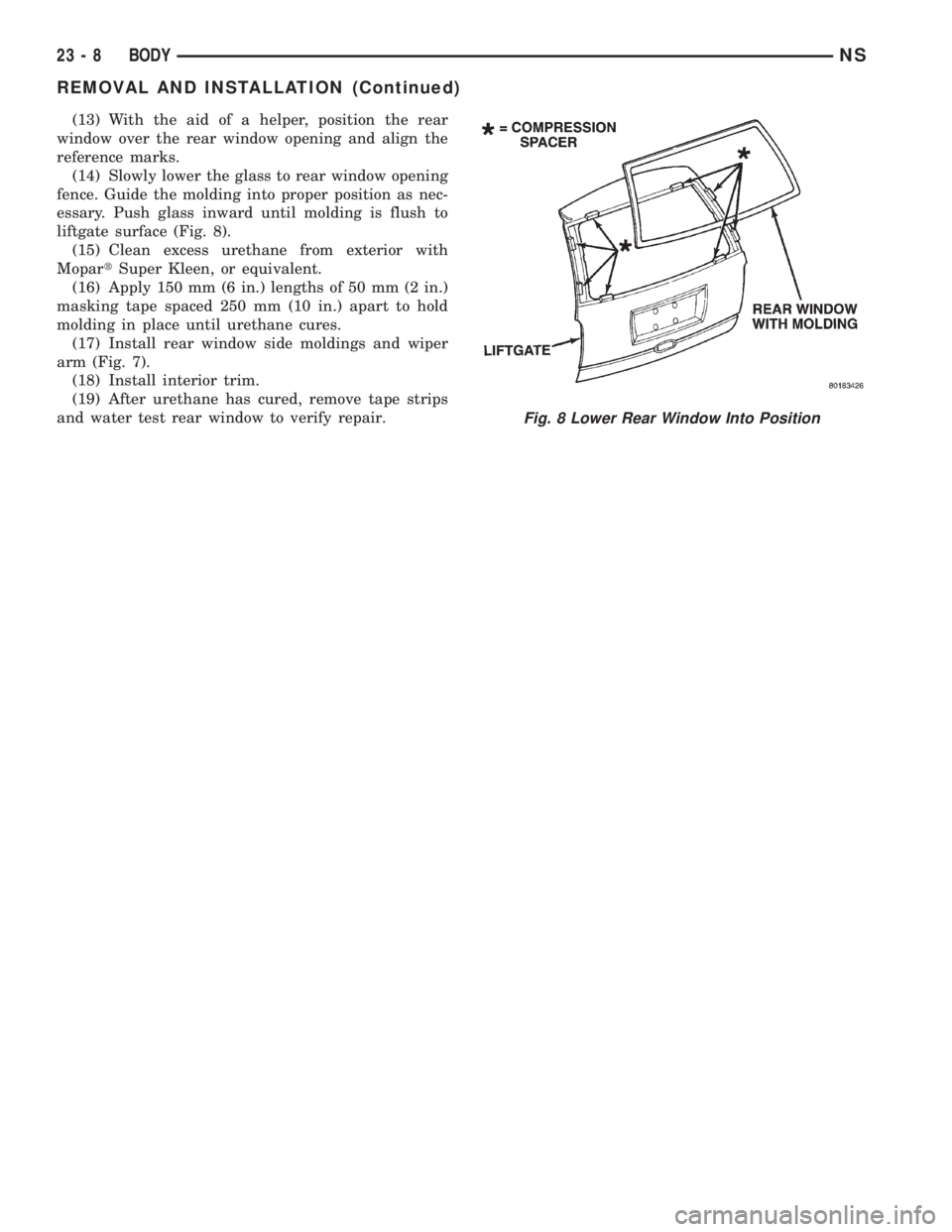

(12) If a low viscosity urethane adhesive is used,

install compression spacers on the fence around the

windshield opening (Fig. 5).

(13) Apply a 10 mm (0.4 in.) bead of urethane on

center line of windshield fence.

(14) With the aid of a helper, position the wind-

shield over the windshield opening. Align the refer-

ence marks at the bottom of the windshield to the

support spacers.

(15) Slowly lower windshield glass to windshield

opening fence. Guide the molding into proper position

as necessary. Push windshield inward until molding

is flush to roof line and A-pillars (Fig. 5).

Fig. 1 Windshield Molding

Fig. 2 Cut Urethane Around Windshield

NSBODY 23 - 5

REMOVAL AND INSTALLATION (Continued)

Page 1736 of 1938

(16) Clean access urethane from exterior with

MopartSuper Kleen or equivalent.

(17) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(18) Engage wire connectors to windshield

defroster grid.

(19) Install A-pillar trim panels.

(20) Install cowl cover and wipers.

(21) Install inside rear view mirror.

(22) After urethane has cured, remove tape strips

and water test windshield to verify repair.

BODY SIDE/SLIDING DOOR STATIONARY GLASS

The temperature of the vehicle should be at least

21É C (70É F) before removing the stationary quarter/

sliding door glass. Butyl sealer becomes more pliable

at high temperatures.

REMOVAL

(1) Remove interior trim as necessary to gain

access attaching locations on back of glass.

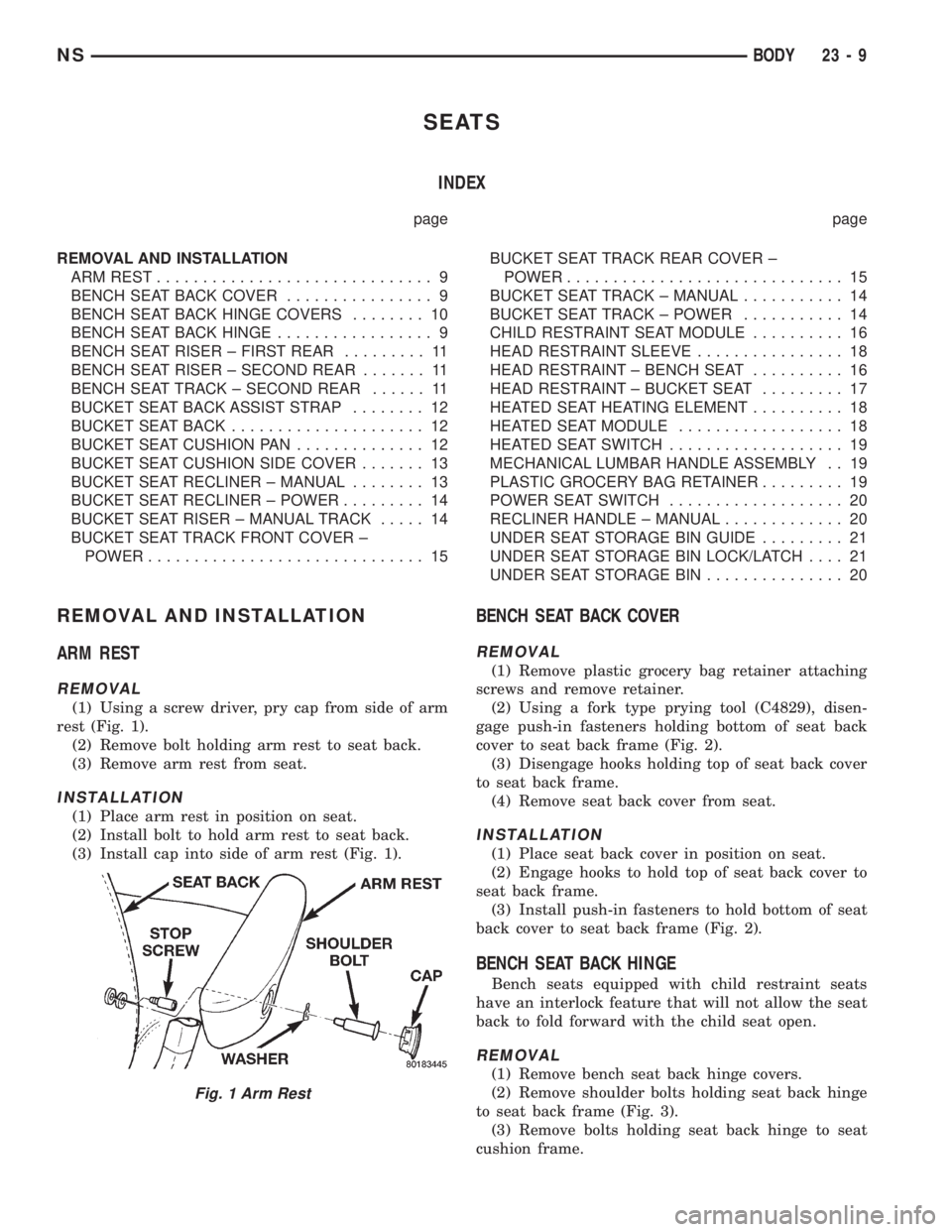

(2) Remove nuts holding stationary glass to fence.

(3) Using razor knife, cut butyl sealer holding

glass to fence from between the mounting studs (Fig.

6).

(4) Push glass from opening.

INSTALLATION

The stationary glass fence should be cleaned of all

old butyl sealer.

(1) Applya6mm(0.25 in.) butyl tape around

perimeter of glass assembly encapsulation track.

Ensure that the butyl tape is wrapped around the

mounting studs.

(2) Place the glass into the opening and insert

mounting studs through holes in fence.

(3) Install nuts to hold stationary glass to fence.

Fig. 3 Center Windshield and Mark at Support

Spacers

Fig. 4 Work Surface Set up and Molding Installation

Fig. 5 Lower Windshield Into Position

Fig. 6 Sliding Door Stationary Glass

23 - 6 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1737 of 1938

NOTE: Tighten nuts to 3.4 N´m (30 in. lbs.) torque

in the sequence indicated. Do not over torque, or

glass breakage may result (Fig. 6).

(4) Install interior trim.

REAR WINDOW

Refer to the Safety Precautions in this section for

description of tools and adhesive systems that are

recommended for use in this procedure.

REAR WINDOW REMOVAL ± EXTERIOR

METHOD

(1) Remove rear window wiper arm, if equipped.

(2) Remove screws holding moldings to liftgate at

the sides of the rear window (Fig. 7).

(3) Using pliers, pull outward on molding at the

top and bottom of liftgate.

(4) Using a sharp cold knife, cut urethane adhe-

sive holding the rear window to the liftgate. A power

cutting device can be used if available (Fig. 2).

(5) Remove rear window from vehicle.

REAR WINDOW REMOVAL ± INTERIOR

METHOD

(1) Remove rear window wiper arm, if equipped.

(2) Remove screws holding moldings to liftgate at

the sides of the rear window (Fig. 7).

(3) Remove liftgate inside lamps and trim covers.

(4) Remove center high mounted stop lamp.

(5) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the rear window

to the liftgate. Refer to instructions provided with

the equipment being used.

(6) Remove rear window from vehicle.

REAR WINDOW INSTALLATION

CAUTION: Open the left front door glass before

installing rear window to avoid pressurizing the

passenger compartment. If a door is slammed

before urethane bonding is cured, water leaks can

result.

Allow the urethane at least 24 hours to cure

before returning the vehicle to use.

To avoid stressing the replacement rear window,

the urethane bonding material on the rear window

fence should be smooth and consistent to the

shape of the replacement glass.

(1) Place replacement glass into rear window open-

ing.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement rear window. If not, the fence must be

formed to the shape of the new glass.

(3) Using a grease pencil, mark the glass and lift-

gate in several locations to aid installation.

(4) Remove replacement glass from liftgate open-

ing.

(5) Position the rear window inside up on a suit-

able work surface with two padded, wood 10 cm by

10 cm by 50 cm (4 in. by 4 in. by 20 in.) blocks,

placed parallel 75 cm (2.5 ft.) apart (Fig. 4).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN REAR WINDOW BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(6) Clean inside of rear window with ammonia

based glass cleaner and lint-free cloth.

(7) Apply molding to top and bottom of rear win-

dow.

(8) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of rear window and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(9) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of rear window. Allow at least three min-

utes drying time.

(10) Apply Pinchweld Primer 15 mm (.75 in.) wide

around the rear window fence. Allow at least three

minutes drying time.

(11) If a low viscosity urethane adhesive is used,

install compression spacers on the fence around the

rear window opening (Fig. 8).

(12) Apply a 10 mm (0.4 in.) bead of urethane

along center line of rear window fence.

Fig. 7 Rear Window Side Moldings

NSBODY 23 - 7

REMOVAL AND INSTALLATION (Continued)

Page 1738 of 1938

(13) With the aid of a helper, position the rear

window over the rear window opening and align the

reference marks.

(14) Slowly lower the glass to rear window opening

fence. Guide the molding into proper position as nec-

essary. Push glass inward until molding is flush to

liftgate surface (Fig. 8).

(15) Clean excess urethane from exterior with

MopartSuper Kleen, or equivalent.

(16) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(17) Install rear window side moldings and wiper

arm (Fig. 7).

(18) Install interior trim.

(19) After urethane has cured, remove tape strips

and water test rear window to verify repair.

Fig. 8 Lower Rear Window Into Position

23 - 8 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1739 of 1938

SEATS

INDEX

page page

REMOVAL AND INSTALLATION

ARM REST.............................. 9

BENCH SEAT BACK COVER................ 9

BENCH SEAT BACK HINGE COVERS........ 10

BENCH SEAT BACK HINGE................. 9

BENCH SEAT RISER ± FIRST REAR......... 11

BENCH SEAT RISER ± SECOND REAR....... 11

BENCH SEAT TRACK ± SECOND REAR...... 11

BUCKET SEAT BACK ASSIST STRAP........ 12

BUCKET SEAT BACK..................... 12

BUCKET SEAT CUSHION PAN.............. 12

BUCKET SEAT CUSHION SIDE COVER....... 13

BUCKET SEAT RECLINER ± MANUAL........ 13

BUCKET SEAT RECLINER ± POWER......... 14

BUCKET SEAT RISER ± MANUAL TRACK..... 14

BUCKET SEAT TRACK FRONT COVER ±

POWER.............................. 15BUCKET SEAT TRACK REAR COVER ±

POWER.............................. 15

BUCKET SEAT TRACK ± MANUAL........... 14

BUCKET SEAT TRACK ± POWER........... 14

CHILD RESTRAINT SEAT MODULE.......... 16

HEAD RESTRAINT SLEEVE................ 18

HEAD RESTRAINT ± BENCH SEAT.......... 16

HEAD RESTRAINT ± BUCKET SEAT......... 17

HEATED SEAT HEATING ELEMENT.......... 18

HEATED SEAT MODULE.................. 18

HEATED SEAT SWITCH................... 19

MECHANICAL LUMBAR HANDLE ASSEMBLY . . 19

PLASTIC GROCERY BAG RETAINER......... 19

POWER SEAT SWITCH................... 20

RECLINER HANDLE ± MANUAL............. 20

UNDER SEAT STORAGE BIN GUIDE......... 21

UNDER SEAT STORAGE BIN LOCK/LATCH.... 21

UNDER SEAT STORAGE BIN............... 20

REMOVAL AND INSTALLATION

ARM REST

REMOVAL

(1) Using a screw driver, pry cap from side of arm

rest (Fig. 1).

(2) Remove bolt holding arm rest to seat back.

(3) Remove arm rest from seat.

INSTALLATION

(1) Place arm rest in position on seat.

(2) Install bolt to hold arm rest to seat back.

(3) Install cap into side of arm rest (Fig. 1).

BENCH SEAT BACK COVER

REMOVAL

(1) Remove plastic grocery bag retainer attaching

screws and remove retainer.

(2) Using a fork type prying tool (C4829), disen-

gage push-in fasteners holding bottom of seat back

cover to seat back frame (Fig. 2).

(3) Disengage hooks holding top of seat back cover

to seat back frame.

(4) Remove seat back cover from seat.

INSTALLATION

(1) Place seat back cover in position on seat.

(2) Engage hooks to hold top of seat back cover to

seat back frame.

(3) Install push-in fasteners to hold bottom of seat

back cover to seat back frame (Fig. 2).

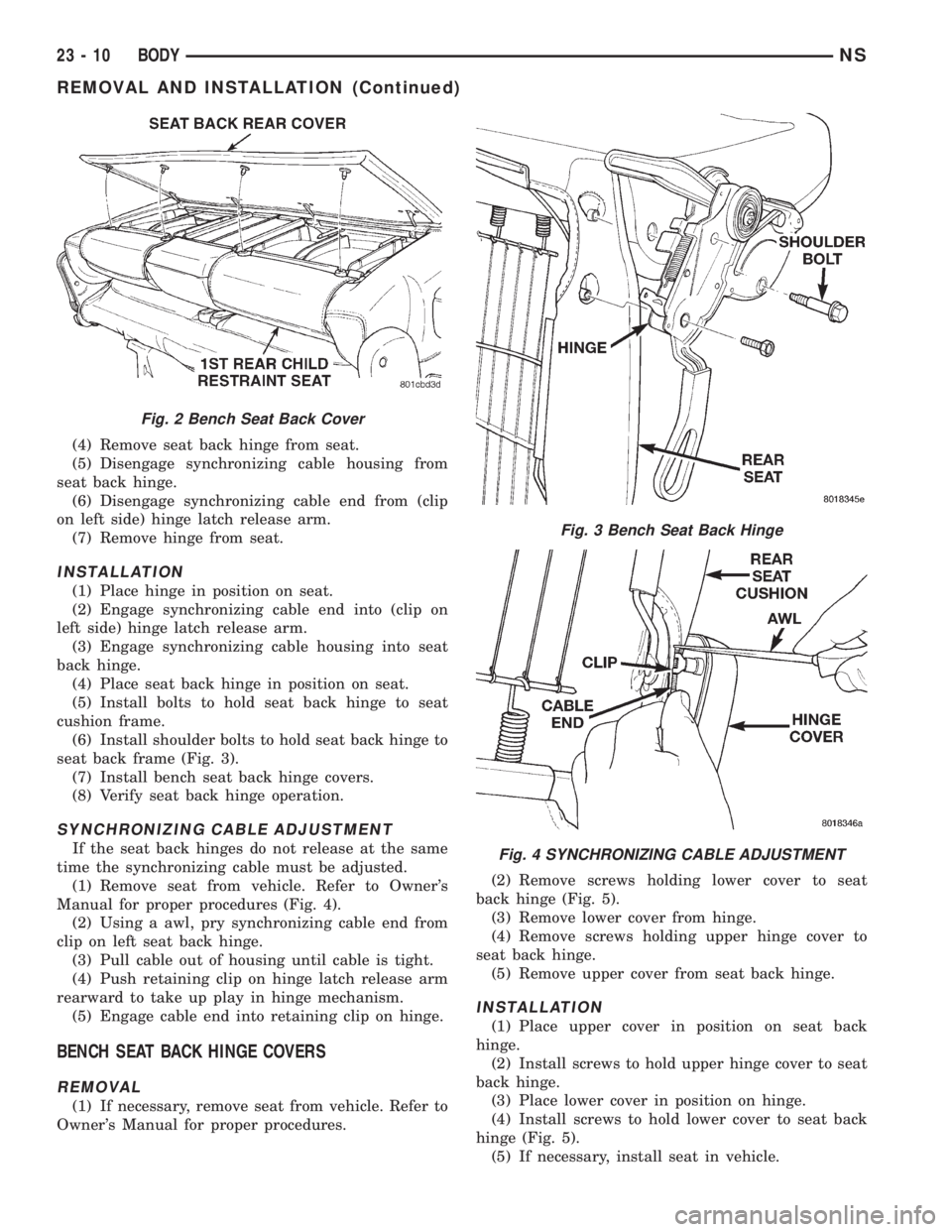

BENCH SEAT BACK HINGE

Bench seats equipped with child restraint seats

have an interlock feature that will not allow the seat

back to fold forward with the child seat open.

REMOVAL

(1) Remove bench seat back hinge covers.

(2) Remove shoulder bolts holding seat back hinge

to seat back frame (Fig. 3).

(3) Remove bolts holding seat back hinge to seat

cushion frame.

Fig. 1 Arm Rest

NSBODY 23 - 9

Page 1740 of 1938

(4) Remove seat back hinge from seat.

(5) Disengage synchronizing cable housing from

seat back hinge.

(6) Disengage synchronizing cable end from (clip

on left side) hinge latch release arm.

(7) Remove hinge from seat.

INSTALLATION

(1) Place hinge in position on seat.

(2) Engage synchronizing cable end into (clip on

left side) hinge latch release arm.

(3) Engage synchronizing cable housing into seat

back hinge.

(4) Place seat back hinge in position on seat.

(5) Install bolts to hold seat back hinge to seat

cushion frame.

(6) Install shoulder bolts to hold seat back hinge to

seat back frame (Fig. 3).

(7) Install bench seat back hinge covers.

(8) Verify seat back hinge operation.

SYNCHRONIZING CABLE ADJUSTMENT

If the seat back hinges do not release at the same

time the synchronizing cable must be adjusted.

(1) Remove seat from vehicle. Refer to Owner's

Manual for proper procedures (Fig. 4).

(2) Using a awl, pry synchronizing cable end from

clip on left seat back hinge.

(3) Pull cable out of housing until cable is tight.

(4) Push retaining clip on hinge latch release arm

rearward to take up play in hinge mechanism.

(5) Engage cable end into retaining clip on hinge.

BENCH SEAT BACK HINGE COVERS

REMOVAL

(1) If necessary, remove seat from vehicle. Refer to

Owner's Manual for proper procedures.(2) Remove screws holding lower cover to seat

back hinge (Fig. 5).

(3) Remove lower cover from hinge.

(4) Remove screws holding upper hinge cover to

seat back hinge.

(5) Remove upper cover from seat back hinge.

INSTALLATION

(1) Place upper cover in position on seat back

hinge.

(2) Install screws to hold upper hinge cover to seat

back hinge.

(3) Place lower cover in position on hinge.

(4) Install screws to hold lower cover to seat back

hinge (Fig. 5).

(5) If necessary, install seat in vehicle.

Fig. 2 Bench Seat Back Cover

Fig. 3 Bench Seat Back Hinge

Fig. 4 SYNCHRONIZING CABLE ADJUSTMENT

23 - 10 BODYNS

REMOVAL AND INSTALLATION (Continued)