CHRYSLER VOYAGER 1996 Service Manual

Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1701 of 1938

(3) Install the synchro springs into the synchro

struts.

(4) Line up stop ring tang over the struts in the

hub. Install stop rings. Center the struts by pushing

on both stop rings.

(5) Install the outer cones (dual-cone synchronizer)

into the synchronizer stop rings.

(6) Install the inner cones (dual-cone synchronizer)

into the outer cones.

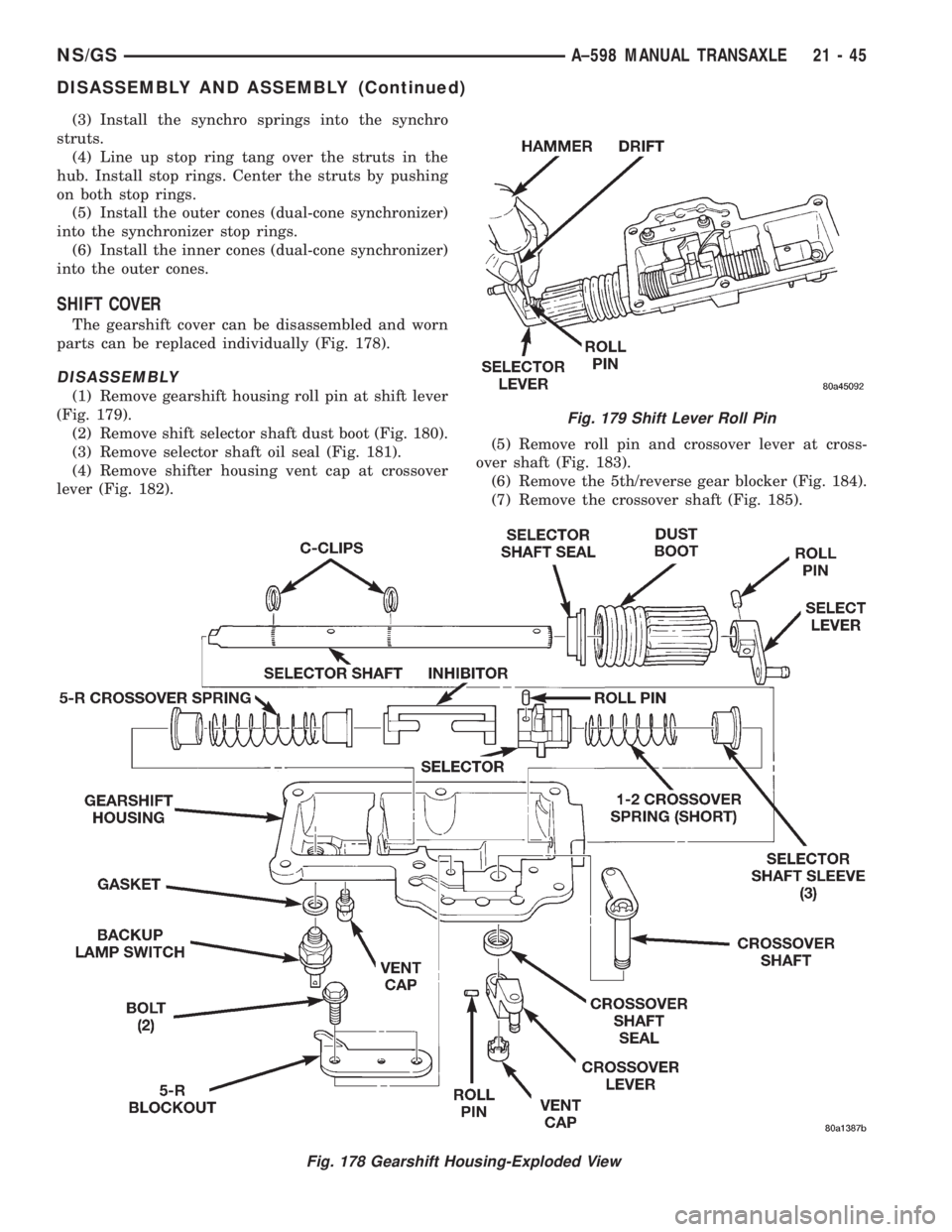

SHIFT COVER

The gearshift cover can be disassembled and worn

parts can be replaced individually (Fig. 178).

DISASSEMBLY

(1) Remove gearshift housing roll pin at shift lever

(Fig. 179).

(2) Remove shift selector shaft dust boot (Fig. 180).

(3) Remove selector shaft oil seal (Fig. 181).

(4) Remove shifter housing vent cap at crossover

lever (Fig. 182).(5) Remove roll pin and crossover lever at cross-

over shaft (Fig. 183).

(6) Remove the 5th/reverse gear blocker (Fig. 184).

(7) Remove the crossover shaft (Fig. 185).

Fig. 178 Gearshift Housing-Exploded View

Fig. 179 Shift Lever Roll Pin

NS/GSA±598 MANUAL TRANSAXLE 21 - 45

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1702 of 1938

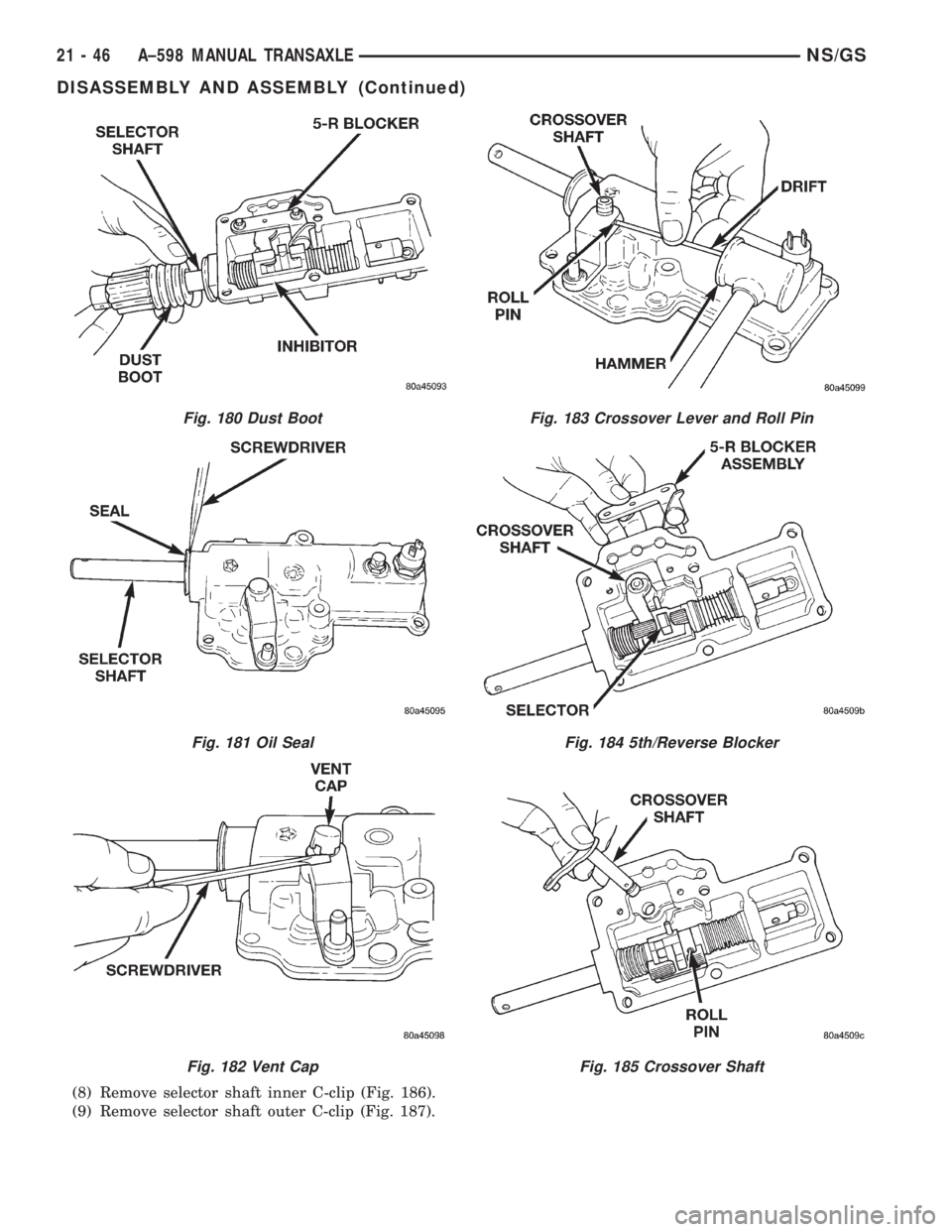

(8) Remove selector shaft inner C-clip (Fig. 186).

(9) Remove selector shaft outer C-clip (Fig. 187).

Fig. 180 Dust Boot

Fig. 181 Oil Seal

Fig. 182 Vent Cap

Fig. 183 Crossover Lever and Roll Pin

Fig. 184 5th/Reverse Blocker

Fig. 185 Crossover Shaft

21 - 46 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1703 of 1938

NOTE: Drive roll pin out far enough to clear the

selector shaft, but not through. The pin must

remain in the selector so not to break the housing.

(10) Remove selector shaft center roll pin (Fig.

188).

(11) Remove selector shaft from the shift housing

(Fig. 189) (Fig. 190).

ASSEMBLY

(1) Install selector shaft components and selector

shaft into shift housing.

(2) Install selector shaft roll pin flush with selec-

tor.

(3) Install outer selector shaft C-clip.

(4) Install inner selector shaft C-clip.

(5) Install crossover shaft.

NOTE: Proper torque of the 5-R blocker bolts is

very important.

(6) Install the 5th/reverse gear blocker bolts (Fig.

191).(7) Install roll pin and crossover lever at crossover

shaft

(8) Install vent cap.

Fig. 186 Inner C-clip

Fig. 187 Outer C-clip

Fig. 188 Center Roll Pin

Fig. 189 Selector Shaft Removal

Fig. 190 Selector Shaft Components

NS/GSA±598 MANUAL TRANSAXLE 21 - 47

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1704 of 1938

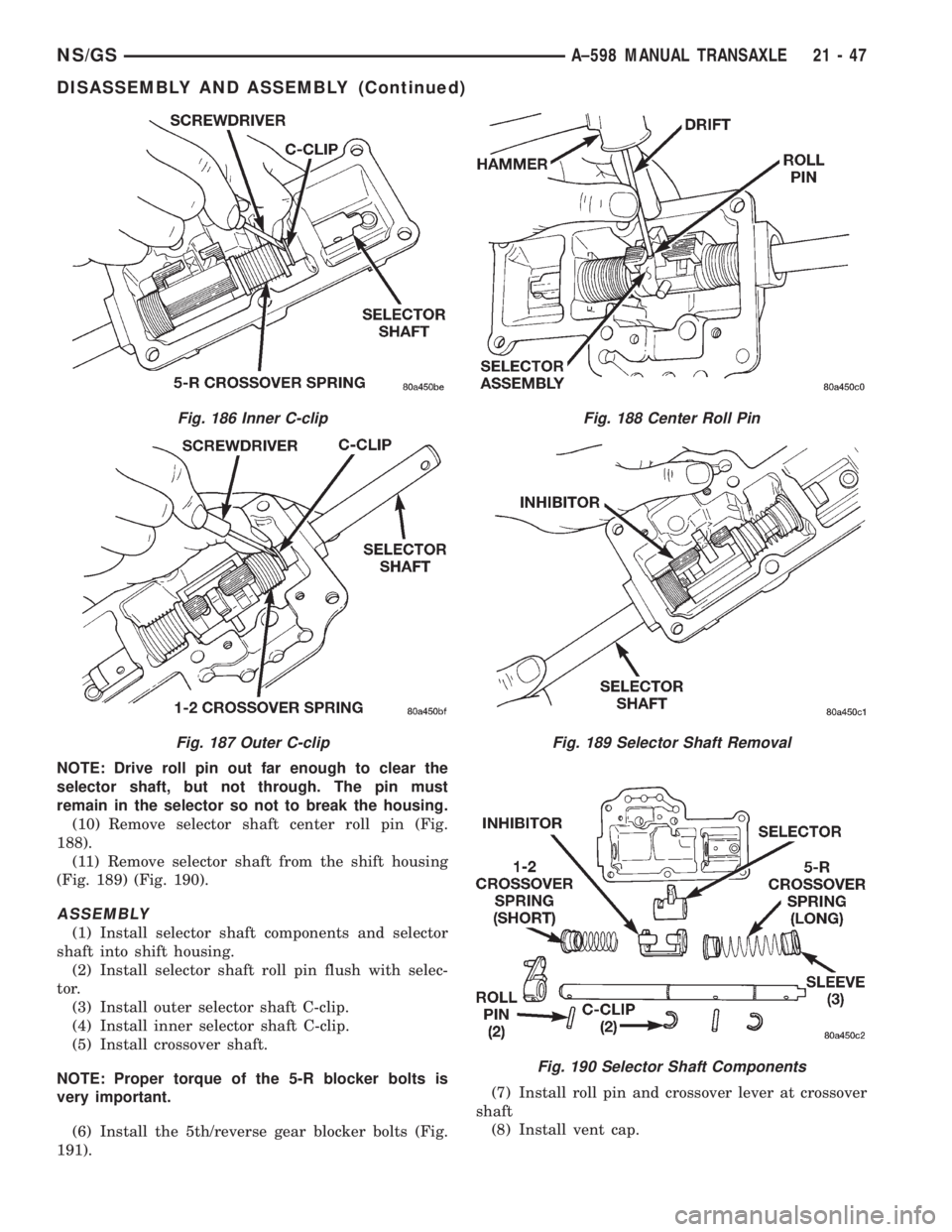

NOTE: The C-Clip grooves in the selector shaft will

damage the oil seal. Install oil seal after selector

shaft is installed. Always use a new oil seal when

selector shaft is removed.

(9) Install selector shaft oil seal (Fig. 192).

(10) Install selector shaft dust boot.

(11) Install selector shaft selector lever.

NOTE: Roll pin must be flush with top of lever.

TRANSAXLE CASE

INTERMEDIATE SHAFT FRONT BEARING CUP

REMOVAL

(1) Insert Special Tool 6787 into the intermediate

shaft front bearing cup (Fig. 193).

(2) Tighten the special tool so that the tool fingers

spread out and seat underneath the bearing cup.(3) Install Special Tool 3752 (Slide Hammer) onto

the Special Tool 6787.

(4) Remove the intermediate shaft front bearing

cup (Fig. 194).

(5) Remove the bearing oil feeder (if necessary).

INSTALLATION

(1) Insert the bearing oil feeder (if necessary) into

the transaxle case (Fig. 195).

Fig. 191 5±R Blocker Bolts

Fig. 192 Selector Shaft Oil Seal

Fig. 193 Special Tool 6787 Installed in Bearing Cup

Fig. 194 Remove Intermediate Shaft Front Bearing

Cup

21 - 48 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1705 of 1938

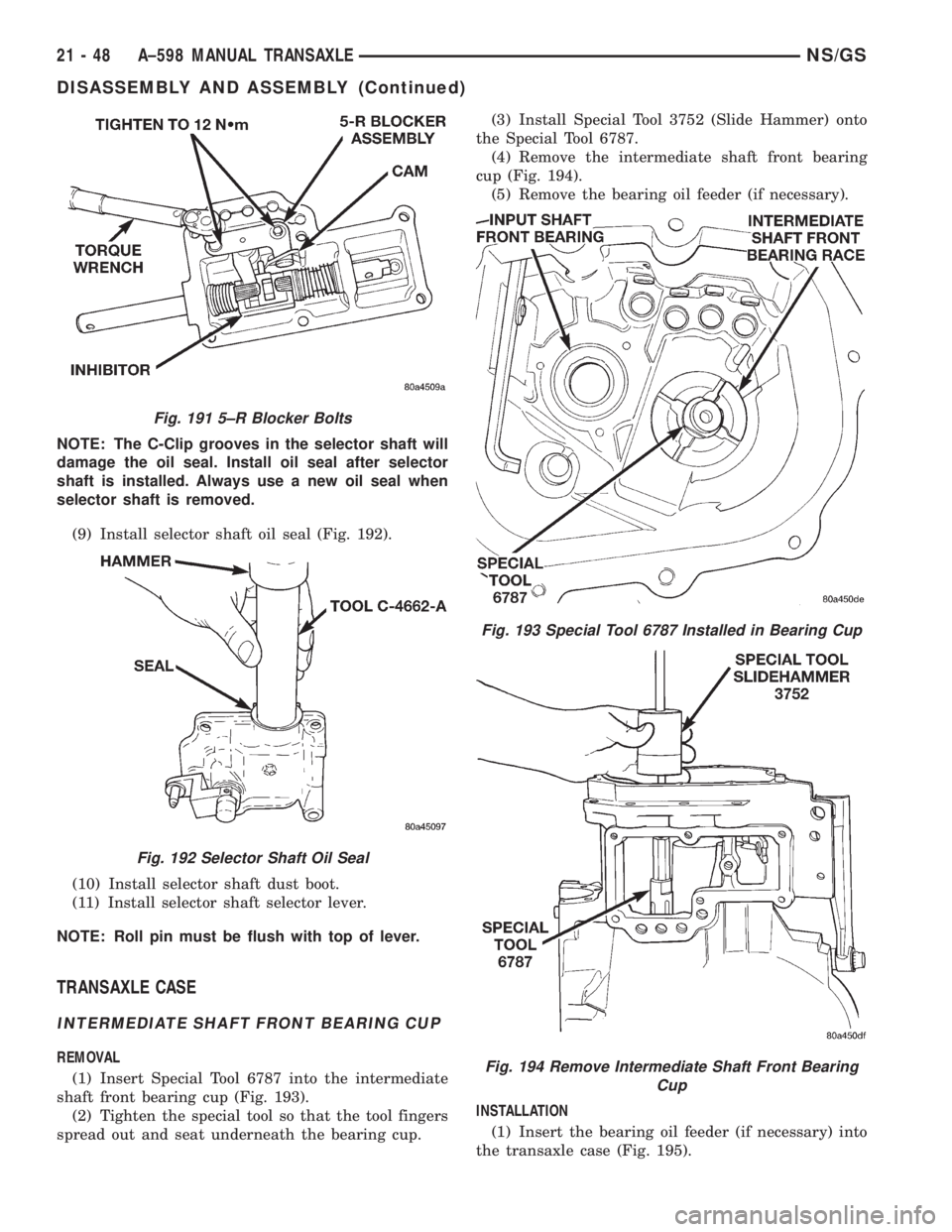

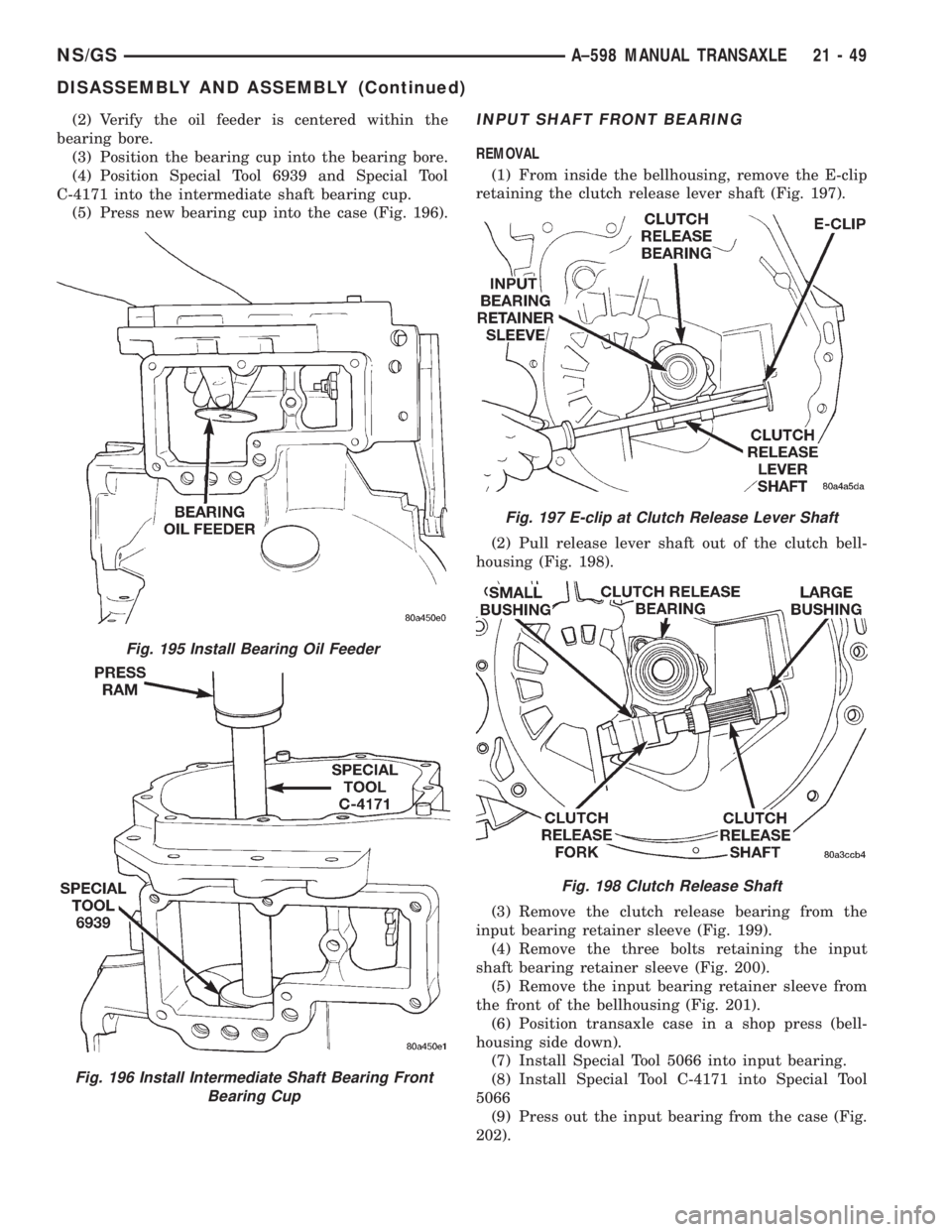

(2) Verify the oil feeder is centered within the

bearing bore.

(3) Position the bearing cup into the bearing bore.

(4) Position Special Tool 6939 and Special Tool

C-4171 into the intermediate shaft bearing cup.

(5) Press new bearing cup into the case (Fig. 196).INPUT SHAFT FRONT BEARING

REMOVAL

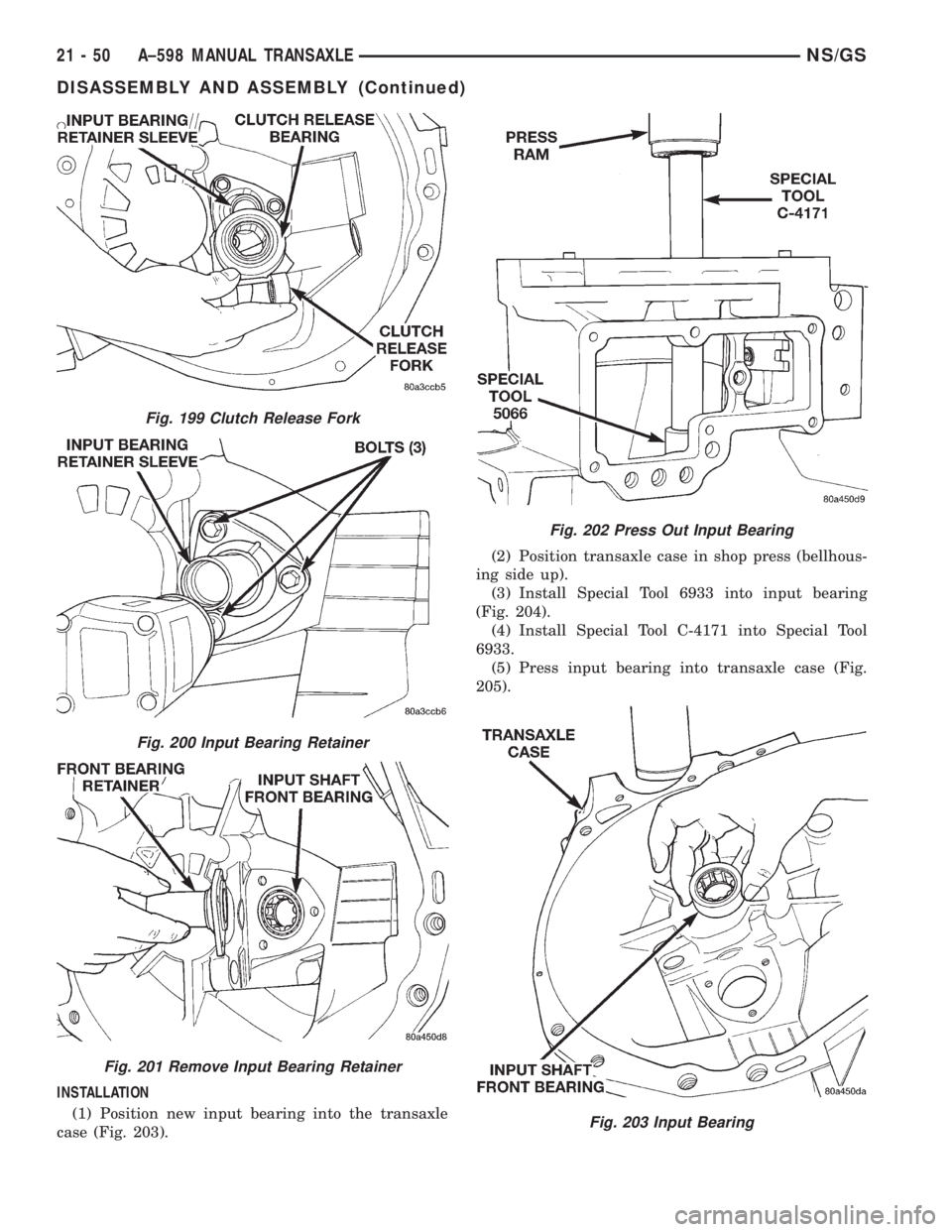

(1) From inside the bellhousing, remove the E-clip

retaining the clutch release lever shaft (Fig. 197).

(2) Pull release lever shaft out of the clutch bell-

housing (Fig. 198).

(3) Remove the clutch release bearing from the

input bearing retainer sleeve (Fig. 199).

(4) Remove the three bolts retaining the input

shaft bearing retainer sleeve (Fig. 200).

(5) Remove the input bearing retainer sleeve from

the front of the bellhousing (Fig. 201).

(6) Position transaxle case in a shop press (bell-

housing side down).

(7) Install Special Tool 5066 into input bearing.

(8) Install Special Tool C-4171 into Special Tool

5066

(9) Press out the input bearing from the case (Fig.

202).

Fig. 196 Install Intermediate Shaft Bearing Front

Bearing Cup

Fig. 195 Install Bearing Oil Feeder

Fig. 197 E-clip at Clutch Release Lever Shaft

Fig. 198 Clutch Release Shaft

NS/GSA±598 MANUAL TRANSAXLE 21 - 49

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1706 of 1938

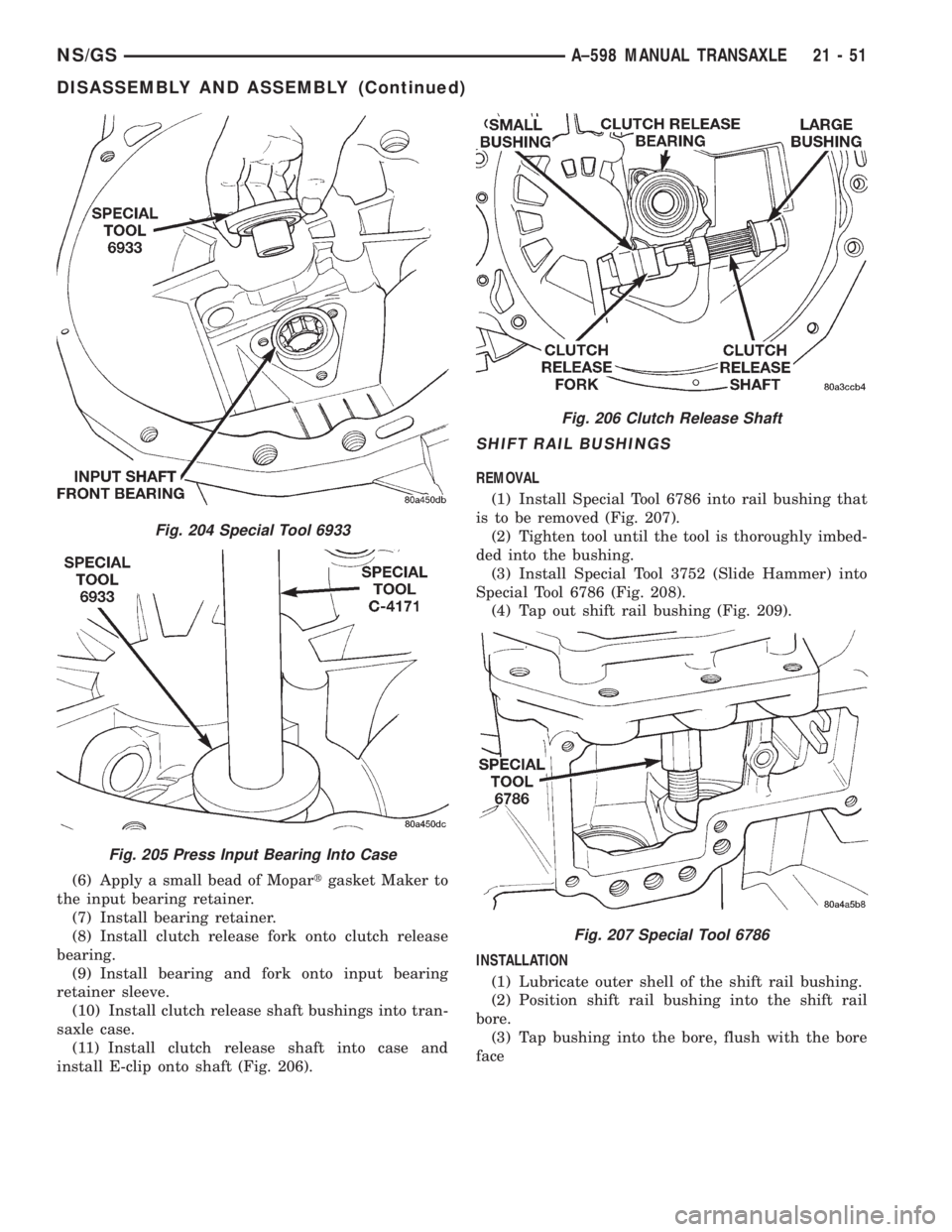

INSTALLATION

(1) Position new input bearing into the transaxle

case (Fig. 203).(2) Position transaxle case in shop press (bellhous-

ing side up).

(3) Install Special Tool 6933 into input bearing

(Fig. 204).

(4) Install Special Tool C-4171 into Special Tool

6933.

(5) Press input bearing into transaxle case (Fig.

205).

Fig. 199 Clutch Release Fork

Fig. 200 Input Bearing Retainer

Fig. 201 Remove Input Bearing Retainer

Fig. 202 Press Out Input Bearing

Fig. 203 Input Bearing

21 - 50 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1707 of 1938

(6) Apply a small bead of Mopartgasket Maker to

the input bearing retainer.

(7) Install bearing retainer.

(8) Install clutch release fork onto clutch release

bearing.

(9) Install bearing and fork onto input bearing

retainer sleeve.

(10) Install clutch release shaft bushings into tran-

saxle case.

(11) Install clutch release shaft into case and

install E-clip onto shaft (Fig. 206).

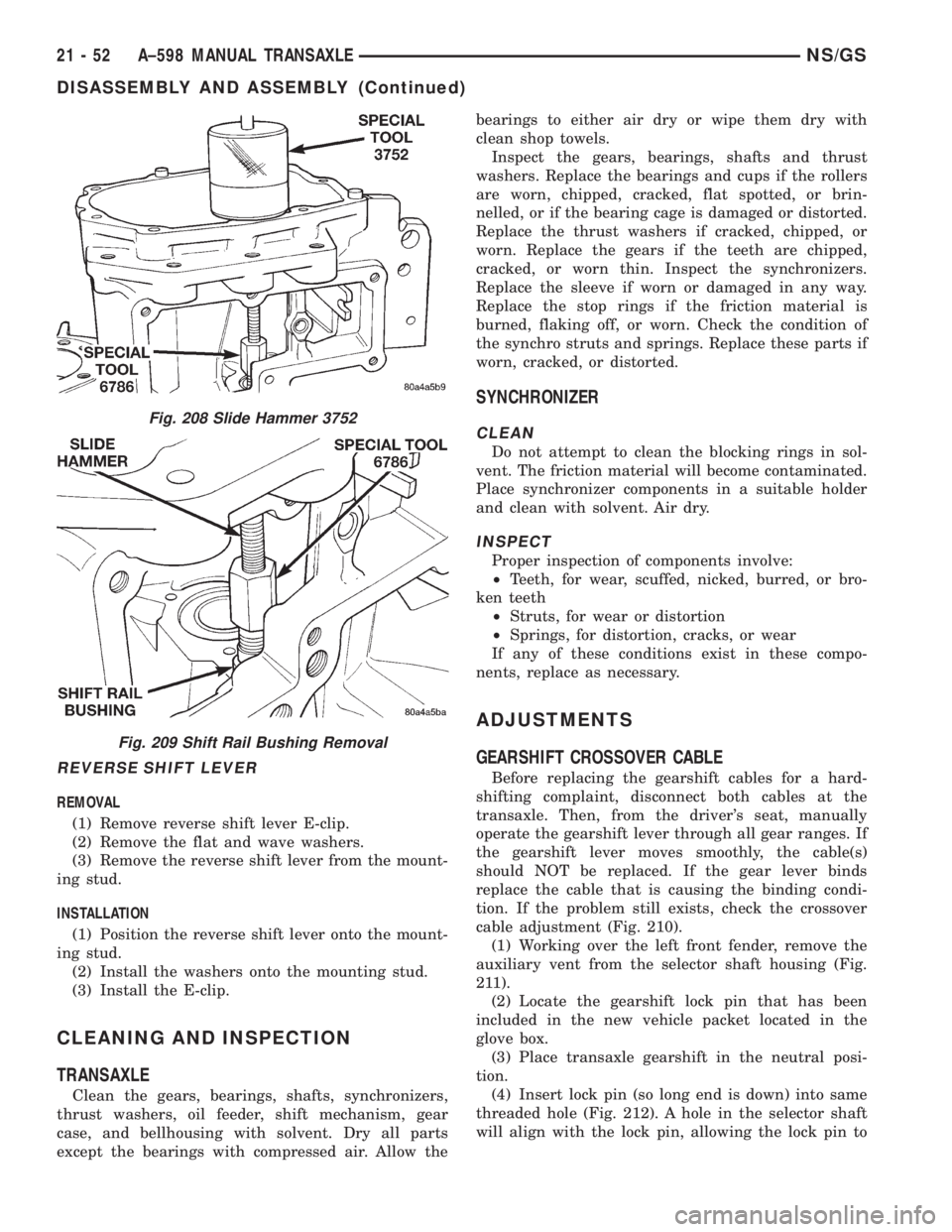

SHIFT RAIL BUSHINGS

REMOVAL

(1) Install Special Tool 6786 into rail bushing that

is to be removed (Fig. 207).

(2) Tighten tool until the tool is thoroughly imbed-

ded into the bushing.

(3) Install Special Tool 3752 (Slide Hammer) into

Special Tool 6786 (Fig. 208).

(4) Tap out shift rail bushing (Fig. 209).

INSTALLATION

(1) Lubricate outer shell of the shift rail bushing.

(2) Position shift rail bushing into the shift rail

bore.

(3) Tap bushing into the bore, flush with the bore

face

Fig. 204 Special Tool 6933

Fig. 205 Press Input Bearing Into Case

Fig. 206 Clutch Release Shaft

Fig. 207 Special Tool 6786

NS/GSA±598 MANUAL TRANSAXLE 21 - 51

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1708 of 1938

REVERSE SHIFT LEVER

REMOVAL

(1) Remove reverse shift lever E-clip.

(2) Remove the flat and wave washers.

(3) Remove the reverse shift lever from the mount-

ing stud.

INSTALLATION

(1) Position the reverse shift lever onto the mount-

ing stud.

(2) Install the washers onto the mounting stud.

(3) Install the E-clip.

CLEANING AND INSPECTION

TRANSAXLE

Clean the gears, bearings, shafts, synchronizers,

thrust washers, oil feeder, shift mechanism, gear

case, and bellhousing with solvent. Dry all parts

except the bearings with compressed air. Allow thebearings to either air dry or wipe them dry with

clean shop towels.

Inspect the gears, bearings, shafts and thrust

washers. Replace the bearings and cups if the rollers

are worn, chipped, cracked, flat spotted, or brin-

nelled, or if the bearing cage is damaged or distorted.

Replace the thrust washers if cracked, chipped, or

worn. Replace the gears if the teeth are chipped,

cracked, or worn thin. Inspect the synchronizers.

Replace the sleeve if worn or damaged in any way.

Replace the stop rings if the friction material is

burned, flaking off, or worn. Check the condition of

the synchro struts and springs. Replace these parts if

worn, cracked, or distorted.

SYNCHRONIZER

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECT

Proper inspection of components involve:

²Teeth, for wear, scuffed, nicked, burred, or bro-

ken teeth

²Struts, for wear or distortion

²Springs, for distortion, cracks, or wear

If any of these conditions exist in these compo-

nents, replace as necessary.

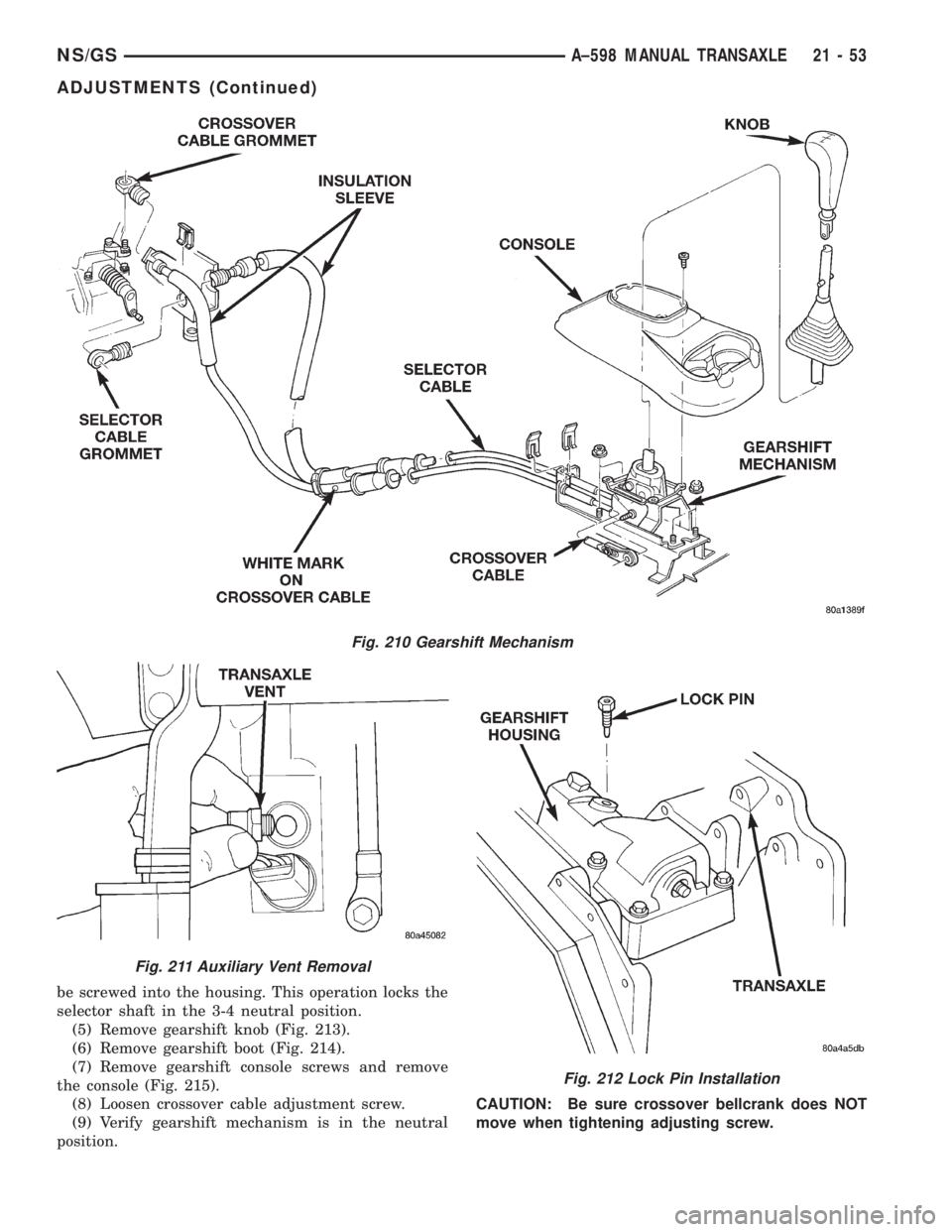

ADJUSTMENTS

GEARSHIFT CROSSOVER CABLE

Before replacing the gearshift cables for a hard-

shifting complaint, disconnect both cables at the

transaxle. Then, from the driver's seat, manually

operate the gearshift lever through all gear ranges. If

the gearshift lever moves smoothly, the cable(s)

should NOT be replaced. If the gear lever binds

replace the cable that is causing the binding condi-

tion. If the problem still exists, check the crossover

cable adjustment (Fig. 210).

(1) Working over the left front fender, remove the

auxiliary vent from the selector shaft housing (Fig.

211).

(2) Locate the gearshift lock pin that has been

included in the new vehicle packet located in the

glove box.

(3) Place transaxle gearshift in the neutral posi-

tion.

(4) Insert lock pin (so long end is down) into same

threaded hole (Fig. 212). A hole in the selector shaft

will align with the lock pin, allowing the lock pin to

Fig. 208 Slide Hammer 3752

Fig. 209 Shift Rail Bushing Removal

21 - 52 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1709 of 1938

be screwed into the housing. This operation locks the

selector shaft in the 3-4 neutral position.

(5) Remove gearshift knob (Fig. 213).

(6) Remove gearshift boot (Fig. 214).

(7) Remove gearshift console screws and remove

the console (Fig. 215).

(8) Loosen crossover cable adjustment screw.

(9) Verify gearshift mechanism is in the neutral

position.CAUTION: Be sure crossover bellcrank does NOT

move when tightening adjusting screw.

Fig. 210 Gearshift Mechanism

Fig. 211 Auxiliary Vent Removal

Fig. 212 Lock Pin Installation

NS/GSA±598 MANUAL TRANSAXLE 21 - 53

ADJUSTMENTS (Continued)

Page 1710 of 1938

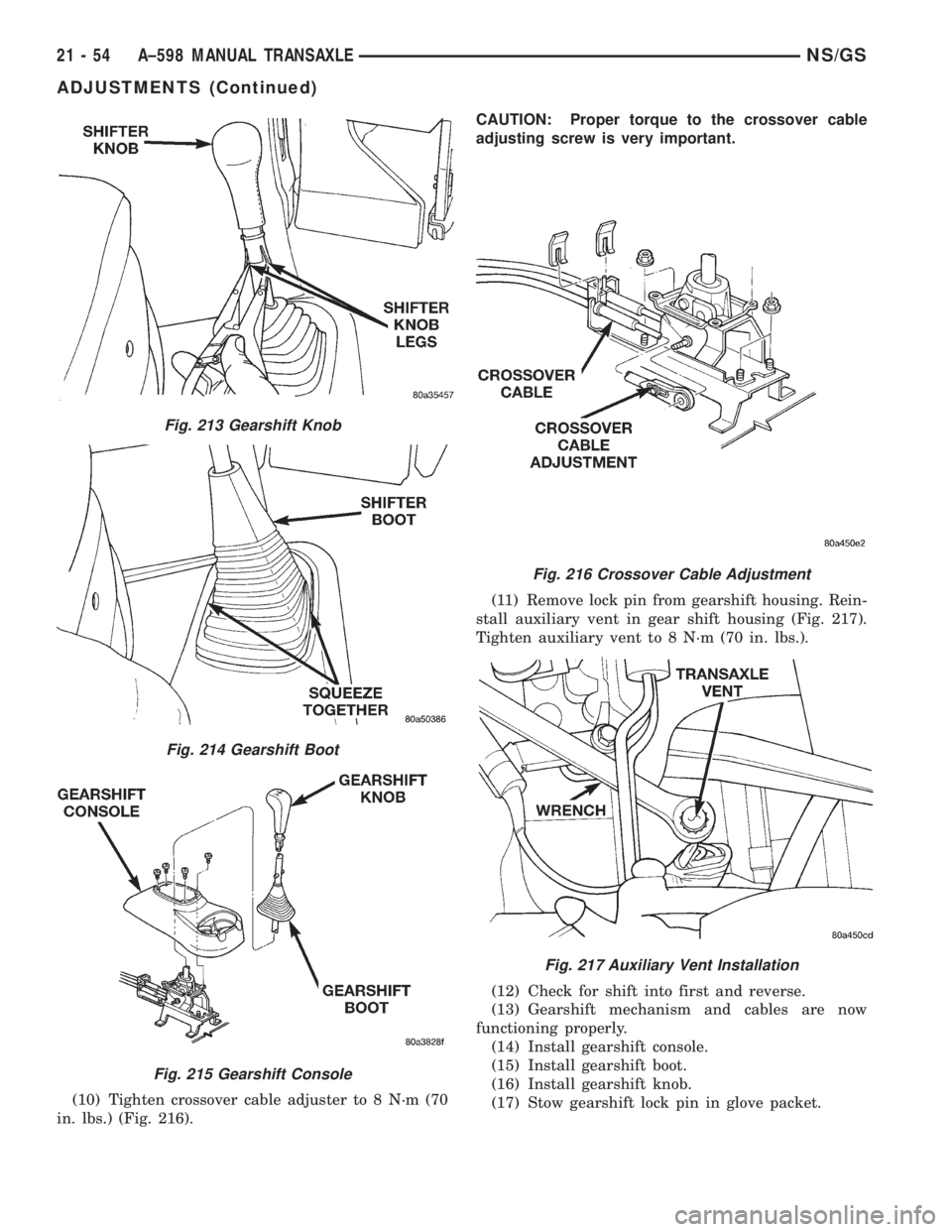

(10) Tighten crossover cable adjuster to 8 N´m (70

in. lbs.) (Fig. 216).CAUTION: Proper torque to the crossover cable

adjusting screw is very important.

(11) Remove lock pin from gearshift housing. Rein-

stall auxiliary vent in gear shift housing (Fig. 217).

Tighten auxiliary vent to 8 N´m (70 in. lbs.).

(12) Check for shift into first and reverse.

(13) Gearshift mechanism and cables are now

functioning properly.

(14) Install gearshift console.

(15) Install gearshift boot.

(16) Install gearshift knob.

(17) Stow gearshift lock pin in glove packet.

Fig. 213 Gearshift Knob

Fig. 214 Gearshift Boot

Fig. 215 Gearshift Console

Fig. 216 Crossover Cable Adjustment

Fig. 217 Auxiliary Vent Installation

21 - 54 A±598 MANUAL TRANSAXLENS/GS

ADJUSTMENTS (Continued)