check engine CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 202 of 1938

DESCRIPTION AND OPERATION

CLUTCH RELEASE SYSTEM

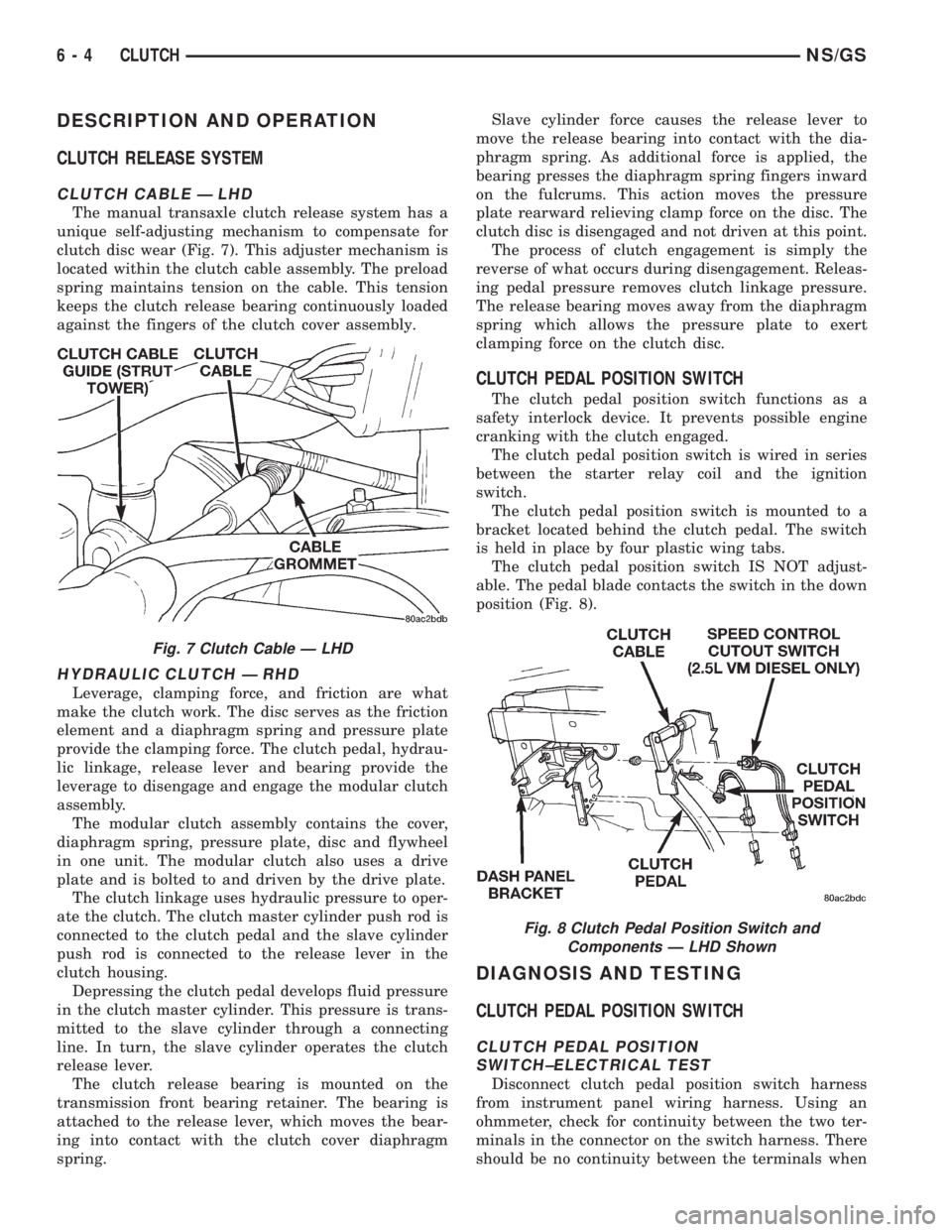

CLUTCH CABLE Ð LHD

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear (Fig. 7). This adjuster mechanism is

located within the clutch cable assembly. The preload

spring maintains tension on the cable. This tension

keeps the clutch release bearing continuously loaded

against the fingers of the clutch cover assembly.

HYDRAULIC CLUTCH Ð RHD

Leverage, clamping force, and friction are what

make the clutch work. The disc serves as the friction

element and a diaphragm spring and pressure plate

provide the clamping force. The clutch pedal, hydrau-

lic linkage, release lever and bearing provide the

leverage to disengage and engage the modular clutch

assembly.

The modular clutch assembly contains the cover,

diaphragm spring, pressure plate, disc and flywheel

in one unit. The modular clutch also uses a drive

plate and is bolted to and driven by the drive plate.

The clutch linkage uses hydraulic pressure to oper-

ate the clutch. The clutch master cylinder push rod is

connected to the clutch pedal and the slave cylinder

push rod is connected to the release lever in the

clutch housing.

Depressing the clutch pedal develops fluid pressure

in the clutch master cylinder. This pressure is trans-

mitted to the slave cylinder through a connecting

line. In turn, the slave cylinder operates the clutch

release lever.

The clutch release bearing is mounted on the

transmission front bearing retainer. The bearing is

attached to the release lever, which moves the bear-

ing into contact with the clutch cover diaphragm

spring.Slave cylinder force causes the release lever to

move the release bearing into contact with the dia-

phragm spring. As additional force is applied, the

bearing presses the diaphragm spring fingers inward

on the fulcrums. This action moves the pressure

plate rearward relieving clamp force on the disc. The

clutch disc is disengaged and not driven at this point.

The process of clutch engagement is simply the

reverse of what occurs during disengagement. Releas-

ing pedal pressure removes clutch linkage pressure.

The release bearing moves away from the diaphragm

spring which allows the pressure plate to exert

clamping force on the clutch disc.

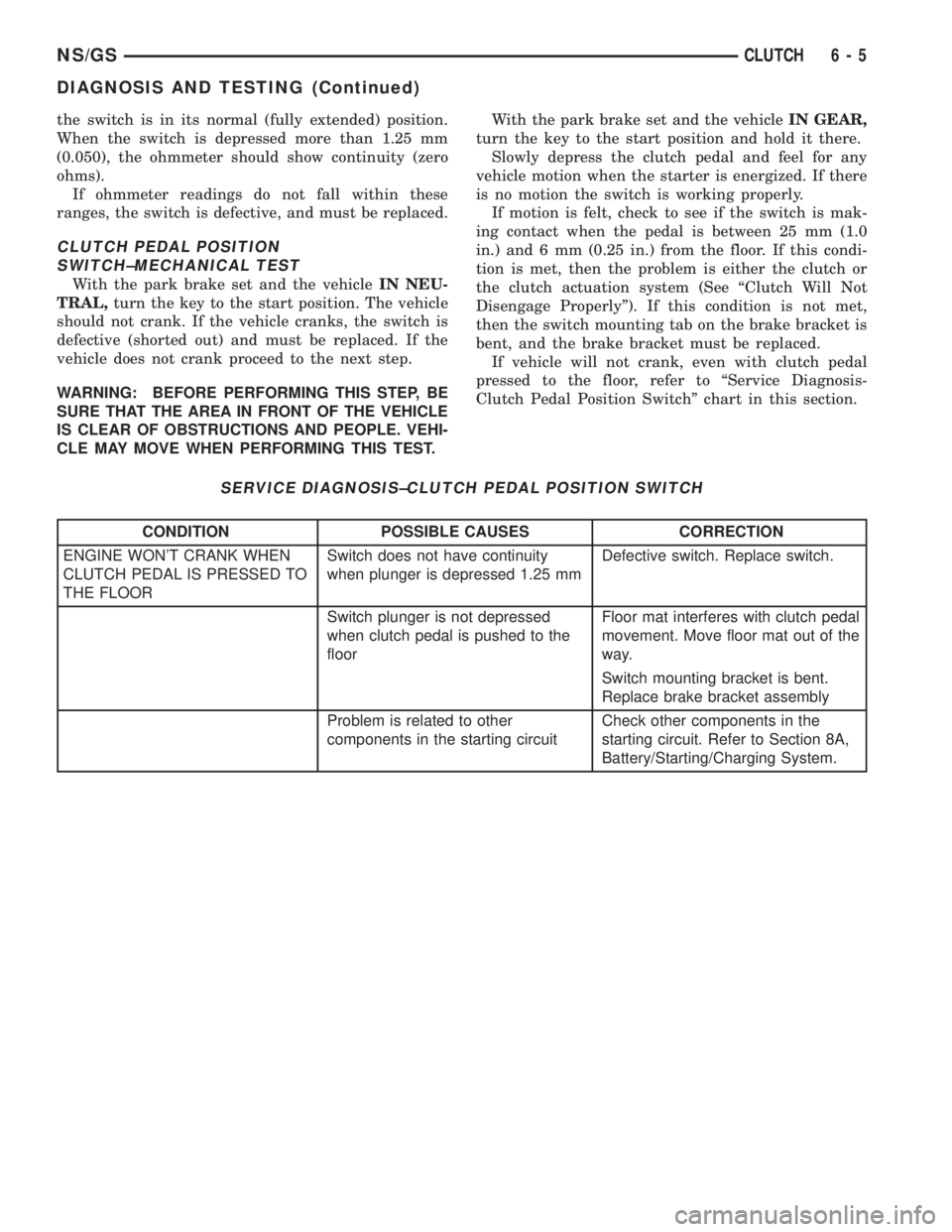

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch functions as a

safety interlock device. It prevents possible engine

cranking with the clutch engaged.

The clutch pedal position switch is wired in series

between the starter relay coil and the ignition

switch.

The clutch pedal position switch is mounted to a

bracket located behind the clutch pedal. The switch

is held in place by four plastic wing tabs.

The clutch pedal position switch IS NOT adjust-

able. The pedal blade contacts the switch in the down

position (Fig. 8).

DIAGNOSIS AND TESTING

CLUTCH PEDAL POSITION SWITCH

CLUTCH PEDAL POSITION

SWITCH±ELECTRICAL TEST

Disconnect clutch pedal position switch harness

from instrument panel wiring harness. Using an

ohmmeter, check for continuity between the two ter-

minals in the connector on the switch harness. There

should be no continuity between the terminals when

Fig. 7 Clutch Cable Ð LHD

Fig. 8 Clutch Pedal Position Switch and

Components Ð LHD Shown

6 - 4 CLUTCHNS/GS

Page 203 of 1938

the switch is in its normal (fully extended) position.

When the switch is depressed more than 1.25 mm

(0.050), the ohmmeter should show continuity (zero

ohms).

If ohmmeter readings do not fall within these

ranges, the switch is defective, and must be replaced.

CLUTCH PEDAL POSITION

SWITCH±MECHANICAL TEST

With the park brake set and the vehicleIN NEU-

TRAL,turn the key to the start position. The vehicle

should not crank. If the vehicle cranks, the switch is

defective (shorted out) and must be replaced. If the

vehicle does not crank proceed to the next step.

WARNING: BEFORE PERFORMING THIS STEP, BE

SURE THAT THE AREA IN FRONT OF THE VEHICLE

IS CLEAR OF OBSTRUCTIONS AND PEOPLE. VEHI-

CLE MAY MOVE WHEN PERFORMING THIS TEST.With the park brake set and the vehicleIN GEAR,

turn the key to the start position and hold it there.

Slowly depress the clutch pedal and feel for any

vehicle motion when the starter is energized. If there

is no motion the switch is working properly.

If motion is felt, check to see if the switch is mak-

ing contact when the pedal is between 25 mm (1.0

in.) and 6 mm (0.25 in.) from the floor. If this condi-

tion is met, then the problem is either the clutch or

the clutch actuation system (See ªClutch Will Not

Disengage Properlyº). If this condition is not met,

then the switch mounting tab on the brake bracket is

bent, and the brake bracket must be replaced.

If vehicle will not crank, even with clutch pedal

pressed to the floor, refer to ªService Diagnosis-

Clutch Pedal Position Switchº chart in this section.

SERVICE DIAGNOSIS±CLUTCH PEDAL POSITION SWITCH

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WON'T CRANK WHEN

CLUTCH PEDAL IS PRESSED TO

THE FLOORSwitch does not have continuity

when plunger is depressed 1.25 mmDefective switch. Replace switch.

Switch plunger is not depressed

when clutch pedal is pushed to the

floorFloor mat interferes with clutch pedal

movement. Move floor mat out of the

way.

Switch mounting bracket is bent.

Replace brake bracket assembly

Problem is related to other

components in the starting circuitCheck other components in the

starting circuit. Refer to Section 8A,

Battery/Starting/Charging System.

NS/GSCLUTCH 6 - 5

DIAGNOSIS AND TESTING (Continued)

Page 204 of 1938

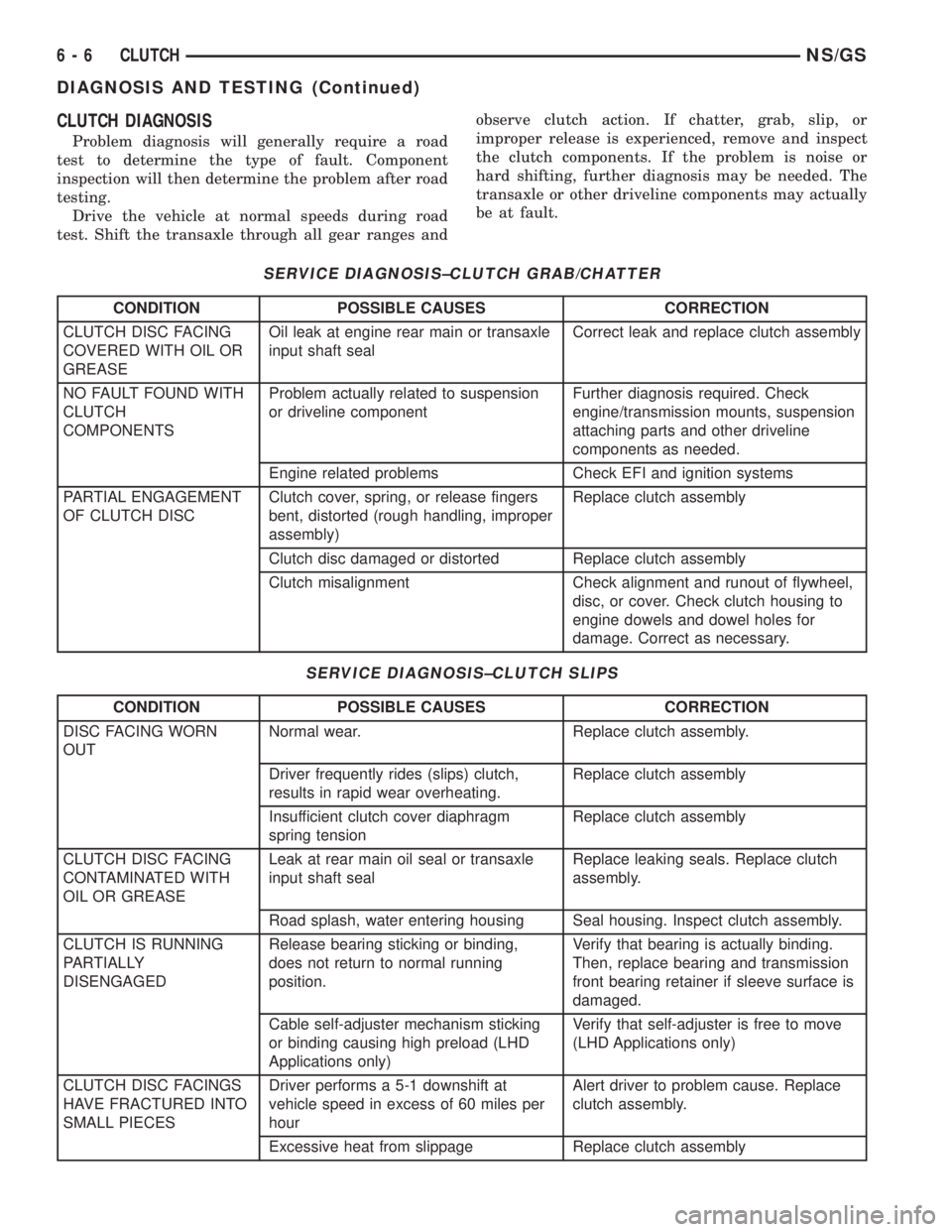

CLUTCH DIAGNOSIS

Problem diagnosis will generally require a road

test to determine the type of fault. Component

inspection will then determine the problem after road

testing.

Drive the vehicle at normal speeds during road

test. Shift the transaxle through all gear ranges andobserve clutch action. If chatter, grab, slip, or

improper release is experienced, remove and inspect

the clutch components. If the problem is noise or

hard shifting, further diagnosis may be needed. The

transaxle or other driveline components may actually

be at fault.

SERVICE DIAGNOSIS±CLUTCH GRAB/CHATTER

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC FACING

COVERED WITH OIL OR

GREASEOil leak at engine rear main or transaxle

input shaft sealCorrect leak and replace clutch assembly

NO FAULT FOUND WITH

CLUTCH

COMPONENTSProblem actually related to suspension

or driveline componentFurther diagnosis required. Check

engine/transmission mounts, suspension

attaching parts and other driveline

components as needed.

Engine related problems Check EFI and ignition systems

PARTIAL ENGAGEMENT

OF CLUTCH DISCClutch cover, spring, or release fingers

bent, distorted (rough handling, improper

assembly)Replace clutch assembly

Clutch disc damaged or distorted Replace clutch assembly

Clutch misalignment Check alignment and runout of flywheel,

disc, or cover. Check clutch housing to

engine dowels and dowel holes for

damage. Correct as necessary.

SERVICE DIAGNOSIS±CLUTCH SLIPS

CONDITION POSSIBLE CAUSES CORRECTION

DISC FACING WORN

OUTNormal wear. Replace clutch assembly.

Driver frequently rides (slips) clutch,

results in rapid wear overheating.Replace clutch assembly

Insufficient clutch cover diaphragm

spring tensionReplace clutch assembly

CLUTCH DISC FACING

CONTAMINATED WITH

OIL OR GREASELeak at rear main oil seal or transaxle

input shaft sealReplace leaking seals. Replace clutch

assembly.

Road splash, water entering housing Seal housing. Inspect clutch assembly.

CLUTCH IS RUNNING

PARTIALLY

DISENGAGEDRelease bearing sticking or binding,

does not return to normal running

position.Verify that bearing is actually binding.

Then, replace bearing and transmission

front bearing retainer if sleeve surface is

damaged.

Cable self-adjuster mechanism sticking

or binding causing high preload (LHD

Applications only)Verify that self-adjuster is free to move

(LHD Applications only)

CLUTCH DISC FACINGS

HAVE FRACTURED INTO

SMALL PIECESDriver performs a 5-1 downshift at

vehicle speed in excess of 60 miles per

hourAlert driver to problem cause. Replace

clutch assembly.

Excessive heat from slippage Replace clutch assembly

6 - 6 CLUTCHNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 206 of 1938

CLUTCH COVER AND DISC RUNOUT

Check condition of the clutch cover before installa-

tion. A warped cover or diaphragm spring will cause

grab and/or incomplete release or engagement. Use

care when handling the clutch assembly. Impact can

distort the cover, diaphragm spring, and release fin-

gers.

CLUTCH CHATTER COMPLAINTS

For all clutch chatter complaints, do the following:

(1) Check for loose, misaligned, or broken engine

and transmission mounts. If present, they should be

corrected at this time. Test vehicle for chatter. If

chatter is gone, there is no need to go any further. If

chatter persists:

(2) Check to see if clutch cable routing is correct

and operates smoothly (LHD applications).

(3) Check for loose connections in drivetrain. Cor-

rect any problems and determine if clutch chatter

complaints have been satisfied. If not:

(4) Remove transaxle. See Group 21, Manual Tran-

saxle for procedure.

(5) Check to see if the release bearing is sticky or

binding. Replace bearing, if needed.

(6) Check linkage for excessive wear on the pivot

shaft, fork, and bushings. Replace all worn parts.

(7) Check clutch assembly for contamination (dirt,

oil). Replace clutch assembly, if required.

(8) Check to see if the clutch disc hub splines are

damaged. Replace with new clutch assembly, if nec-

essary.

(9) Check input shaft splines for damage. Replace,

if necessary.

(10) Check for uneven wear on clutch fingers.

(11) Check for broken clutch cover diaphragm

spring fingers. Replace with new clutch assembly, if

necessary.

CLASH±INTO±REVERSE COMPLAINTS

(1) Depress clutch pedal to floor and hold. After

three seconds, shift to reverse. If clash is present,

clutch has excessive spin time.

NOTE: Verify that nothing is obstructing pedal

travel. Floormats or other articles located under-

neath the clutch pedal could prevent the clutch

from disengaging fully.

(2) Remove transaxle. See Group 21, Manual Tran-

saxle for procedure.

(3) Check the input shaft spline, clutch disc

splines, and release bearing for dry rust. If present,

clean rust off and apply a light coat of bearing grease

to the input shaft splines. Apply grease on the input

shaft splines only where the clutch disc slides. Verify

that the clutch disc slides freely along the input shaft

spline.(4) Check to see if the clutch disc hub splines are

damaged, and replace with new clutch assembly if

required.

(5) Check the input shaft for damaged splines.

Replace as necessary.

(6) Check for broken clutch cover diaphragm

spring fingers.

(7) Install clutch assembly and transaxle.

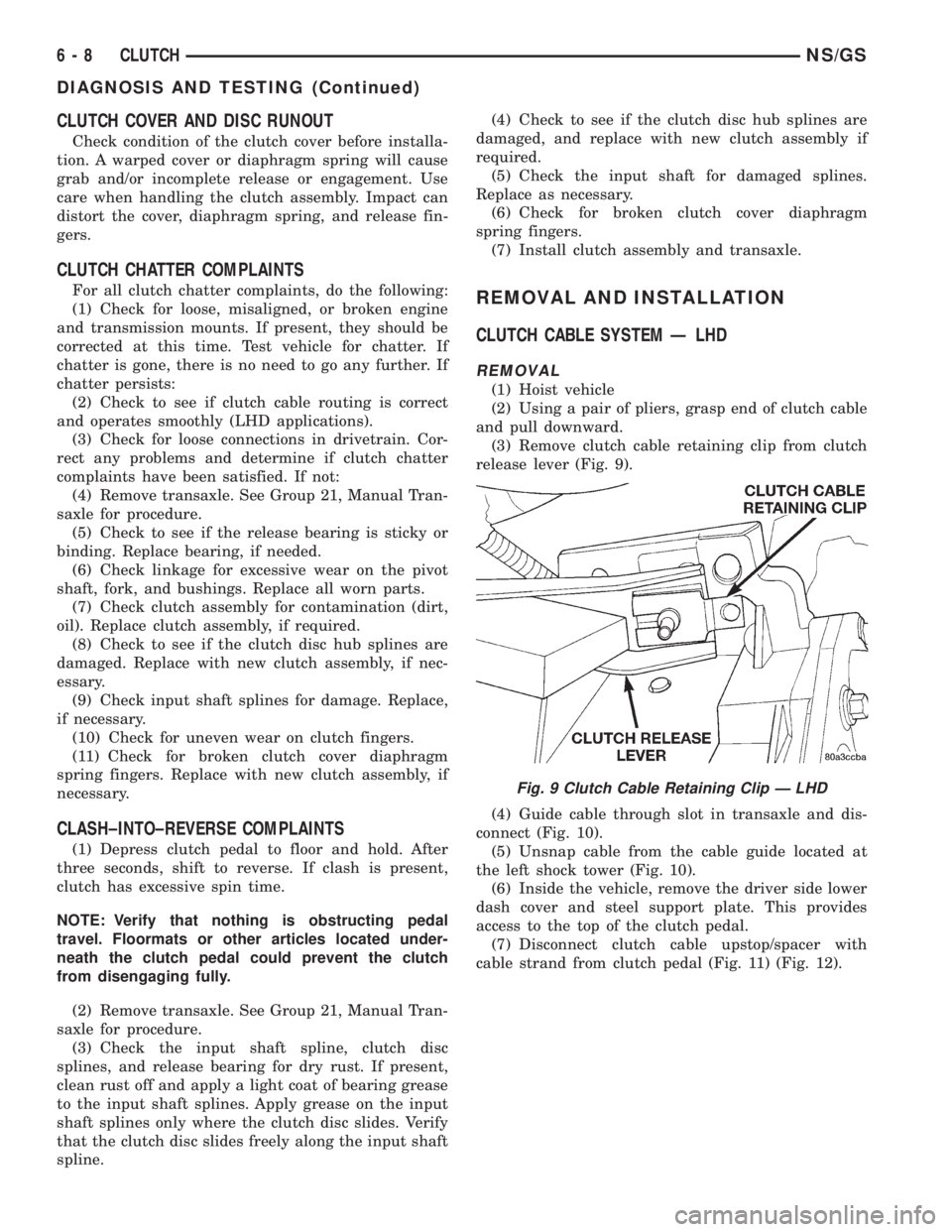

REMOVAL AND INSTALLATION

CLUTCH CABLE SYSTEM Ð LHD

REMOVAL

(1) Hoist vehicle

(2) Using a pair of pliers, grasp end of clutch cable

and pull downward.

(3) Remove clutch cable retaining clip from clutch

release lever (Fig. 9).

(4) Guide cable through slot in transaxle and dis-

connect (Fig. 10).

(5) Unsnap cable from the cable guide located at

the left shock tower (Fig. 10).

(6) Inside the vehicle, remove the driver side lower

dash cover and steel support plate. This provides

access to the top of the clutch pedal.

(7) Disconnect clutch cable upstop/spacer with

cable strand from clutch pedal (Fig. 11) (Fig. 12).

Fig. 9 Clutch Cable Retaining Clip Ð LHD

6 - 8 CLUTCHNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 211 of 1938

INSTALLATION

1. Position the slave cylinder assembly to the tran-

saxle deck and secure with the nut and washer

assemblies (2) and tighten to specifications (Fig. 14).

2. Make sure the slave cylinder pushrod is prop-

erly seated in the cup end of the clutch release lever.

3. Connect the quick connect coupling. Refer to the

ªQuick Connect Couplingº removal and installation

procedure in this section.

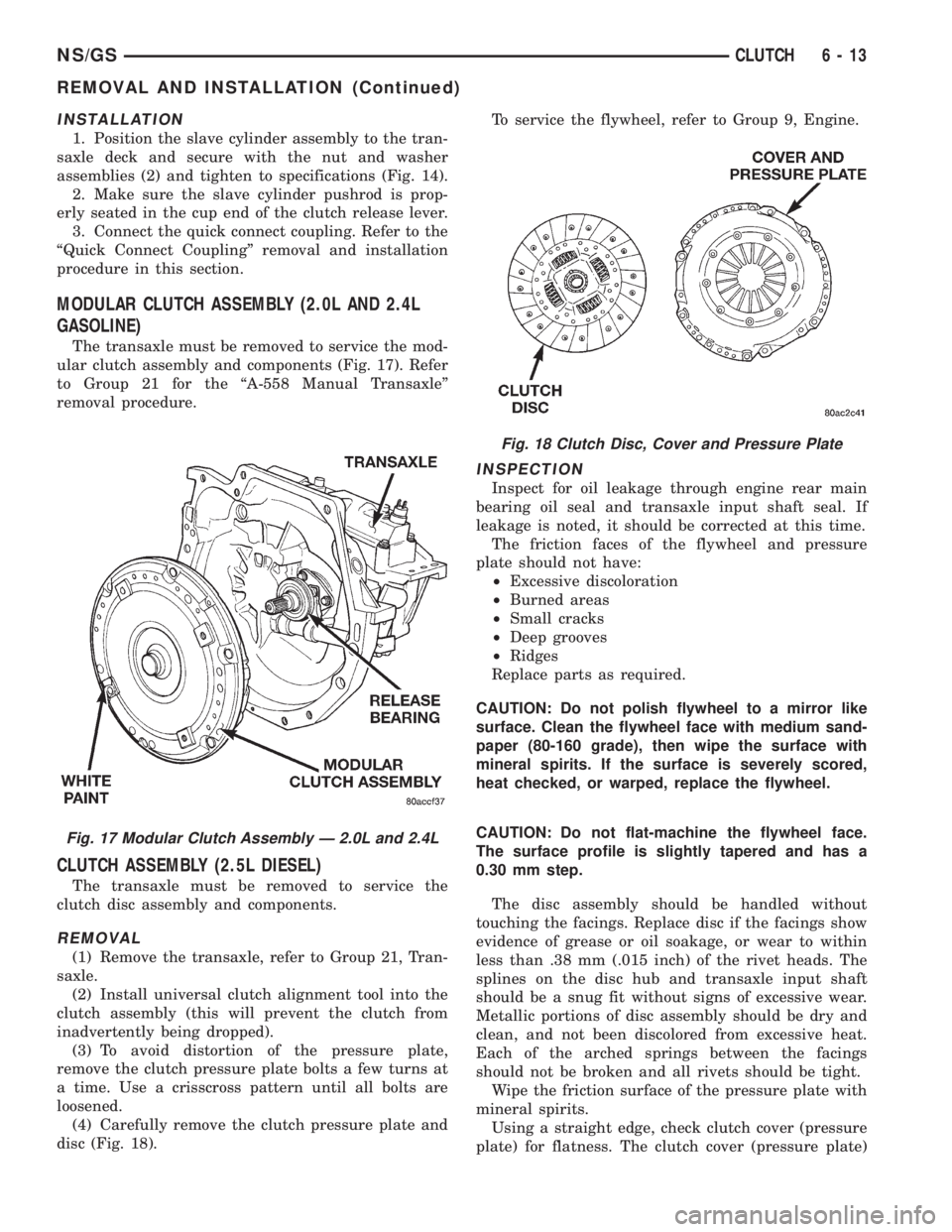

MODULAR CLUTCH ASSEMBLY (2.0L AND 2.4L

GASOLINE)

The transaxle must be removed to service the mod-

ular clutch assembly and components (Fig. 17). Refer

to Group 21 for the ªA-558 Manual Transaxleº

removal procedure.

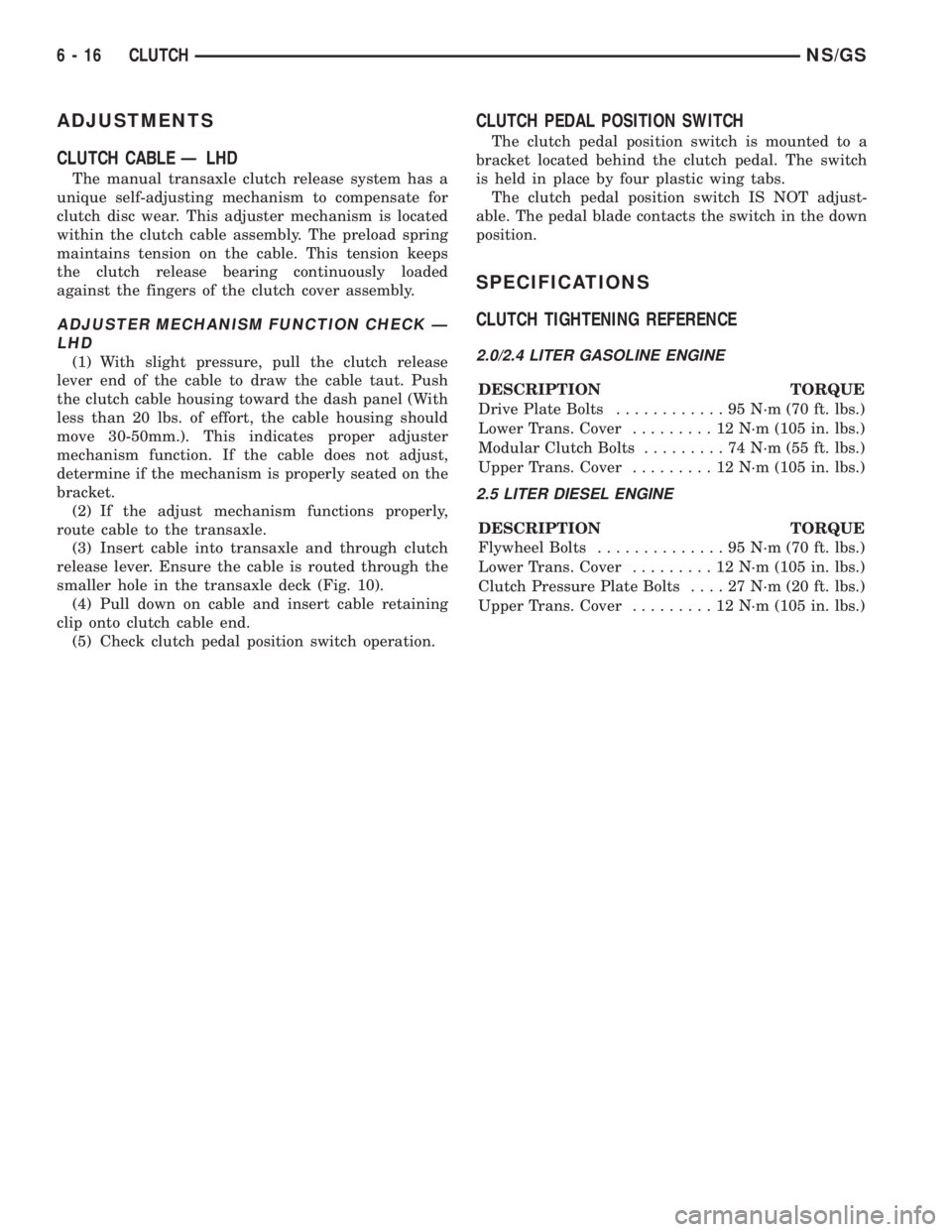

CLUTCH ASSEMBLY (2.5L DIESEL)

The transaxle must be removed to service the

clutch disc assembly and components.

REMOVAL

(1) Remove the transaxle, refer to Group 21, Tran-

saxle.

(2) Install universal clutch alignment tool into the

clutch assembly (this will prevent the clutch from

inadvertently being dropped).

(3) To avoid distortion of the pressure plate,

remove the clutch pressure plate bolts a few turns at

a time. Use a crisscross pattern until all bolts are

loosened.

(4) Carefully remove the clutch pressure plate and

disc (Fig. 18).To service the flywheel, refer to Group 9, Engine.

INSPECTION

Inspect for oil leakage through engine rear main

bearing oil seal and transaxle input shaft seal. If

leakage is noted, it should be corrected at this time.

The friction faces of the flywheel and pressure

plate should not have:

²Excessive discoloration

²Burned areas

²Small cracks

²Deep grooves

²Ridges

Replace parts as required.

CAUTION: Do not polish flywheel to a mirror like

surface. Clean the flywheel face with medium sand-

paper (80-160 grade), then wipe the surface with

mineral spirits. If the surface is severely scored,

heat checked, or warped, replace the flywheel.

CAUTION: Do not flat-machine the flywheel face.

The surface profile is slightly tapered and has a

0.30 mm step.

The disc assembly should be handled without

touching the facings. Replace disc if the facings show

evidence of grease or oil soakage, or wear to within

less than .38 mm (.015 inch) of the rivet heads. The

splines on the disc hub and transaxle input shaft

should be a snug fit without signs of excessive wear.

Metallic portions of disc assembly should be dry and

clean, and not been discolored from excessive heat.

Each of the arched springs between the facings

should not be broken and all rivets should be tight.

Wipe the friction surface of the pressure plate with

mineral spirits.

Using a straight edge, check clutch cover (pressure

plate) for flatness. The clutch cover (pressure plate)

Fig. 17 Modular Clutch Assembly Ð 2.0L and 2.4L

Fig. 18 Clutch Disc, Cover and Pressure Plate

NS/GSCLUTCH 6 - 13

REMOVAL AND INSTALLATION (Continued)

Page 214 of 1938

ADJUSTMENTS

CLUTCH CABLE Ð LHD

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch cable assembly. The preload spring

maintains tension on the cable. This tension keeps

the clutch release bearing continuously loaded

against the fingers of the clutch cover assembly.

ADJUSTER MECHANISM FUNCTION CHECK Ð

LHD

(1) With slight pressure, pull the clutch release

lever end of the cable to draw the cable taut. Push

the clutch cable housing toward the dash panel (With

less than 20 lbs. of effort, the cable housing should

move 30-50mm.). This indicates proper adjuster

mechanism function. If the cable does not adjust,

determine if the mechanism is properly seated on the

bracket.

(2) If the adjust mechanism functions properly,

route cable to the transaxle.

(3) Insert cable into transaxle and through clutch

release lever. Ensure the cable is routed through the

smaller hole in the transaxle deck (Fig. 10).

(4) Pull down on cable and insert cable retaining

clip onto clutch cable end.

(5) Check clutch pedal position switch operation.

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch is mounted to a

bracket located behind the clutch pedal. The switch

is held in place by four plastic wing tabs.

The clutch pedal position switch IS NOT adjust-

able. The pedal blade contacts the switch in the down

position.

SPECIFICATIONS

CLUTCH TIGHTENING REFERENCE

2.0/2.4 LITER GASOLINE ENGINE

DESCRIPTION TORQUE

Drive Plate Bolts............95N´m(70ft.lbs.)

Lower Trans. Cover.........12N´m(105 in. lbs.)

Modular Clutch Bolts.........74N´m(55ft.lbs.)

Upper Trans. Cover.........12N´m(105 in. lbs.)

2.5 LITER DIESEL ENGINE

DESCRIPTION TORQUE

Flywheel Bolts..............95N´m(70ft.lbs.)

Lower Trans. Cover.........12N´m(105 in. lbs.)

Clutch Pressure Plate Bolts....27N´m(20ft.lbs.)

Upper Trans. Cover.........12N´m(105 in. lbs.)

6 - 16 CLUTCHNS/GS

Page 215 of 1938

COOLING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

ACCESSORY DRIVE BELTS................ 1

AUTOMATIC TRANSMISSION OIL COOLERÐ

2.4L................................. 3

COOLANT RECOVERY SYSTEM (CRS)....... 3

COOLANT.............................. 3

COOLING SYSTEM....................... 2

ENGINE BLOCK HEATER.................. 5

ENGINE THERMOSTAT.................... 3

RADIATOR PRESSURE CAP................ 4

RADIATOR............................. 3

WATER PUMPS......................... 3

DESCRIPTION AND OPERATION

COOLANT PERFORMANCE................. 6

RADIATOR HOSES AND CLAMPS........... 6

WATER PIPESÐ3.0L ENGINE.............. 6

WATER PUMPÐ3.3/3.8L ENGINES.......... 7

WATER PUMPÐ2.4L ENGINE.............. 6

WATER PUMPÐ3.0L ENGINE.............. 6

DIAGNOSIS AND TESTING

ACCESSORY DRIVE BELT.................. 7

COOLING SYSTEM DIAGNOSIS............. 8

DEAERATION.......................... 16

ELECTRIC FAN MOTOR TEST.............. 14

LOW COOLANT LEVEL AERATION.......... 15

PRESSURE TESTING RADIATOR CAP....... 15

RADIATOR CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK.............. 15

RADIATOR COOLANT FLOW TEST.......... 14

RADIATOR FAN CONTROL................ 14

TEMPERATURE GAUGE INDICATION........ 16

TESTING COOLING SYSTEM FOR LEAKS.... 14

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE........ 16

COOLANT LEVEL SERVICE................ 16COOLANTÐADDING ADDITIONAL.......... 16

COOLING SYSTEMÐDRAINING............ 16

COOLING SYSTEMÐREFILLING........... 16

REMOVAL AND INSTALLATION

ACCESSORY DRIVE BELTSÐ2.4L.......... 23

ACCESSORY DRIVE BELTSÐ3.0L.......... 24

ACCESSORY DRIVE BELTÐ3.3/3.8L........ 24

ENGINE BLOCK HEATER................. 23

FAN MODULE.......................... 22

RADIATOR DRAINCOCK.................. 21

RADIATOR............................ 21

THERMOSTATÐ2.4L ENGINE............. 19

THERMOSTATÐ3.0L ENGINE............. 20

THERMOSTATÐ3.3/3.8L ENGINES......... 20

WATER PUMP INLET TUBEÐ2.4L ENGINE . . . 17

WATER PUMPÐ3.3/3.8L ENGINES......... 19

WATER PUMPÐ2.4L ENGINE............ 17

WATER PUMPÐ3.0L ENGINE............. 18

CLEANING AND INSPECTION

ACCESSORY DRIVE BELT................. 25

CHEMICAL CLEANING................... 25

COOLING SYSTEM CLEANING............. 25

RADIATOR PRESSURE CAP............... 25

REVERSE FLUSHING THE ENGINE......... 25

REVERSE FLUSHING THE RADIATOR....... 25

WATER PUMP......................... 24

ADJUSTMENTS

BELT TENSION CHART................... 26

BELT TENSION GAUGE METHOD........... 26

PROPER BELT TENSION................. 25

SPECIFICATIONS

COOLING SYSTEM CAPACITY............. 26

TORQUE CHART........................ 26

SPECIAL TOOLS

COOLING............................. 26

GENERAL INFORMATION

ACCESSORY DRIVE BELTS

The accessory drive system utilizes two different

style of drive belts. The conventional V-belt and the

Poly-V belt are used to drive the generator, air con-

ditioning compressor, power steering pump and waterpump. Satisfactory performance of these belts

depends on belt condition and proper belt tension.

Belt tensioning should be performed with the aid of a

Burroughs gauge Special Tool C-4162. Because of

space limitations in the engine compartment, the use

of the gauge may be restricted. Raise the vehicle on a

hoist and then remove the splash shield to gain

access to the drive belts.

NSCOOLING SYSTEM 7 - 1

Page 217 of 1938

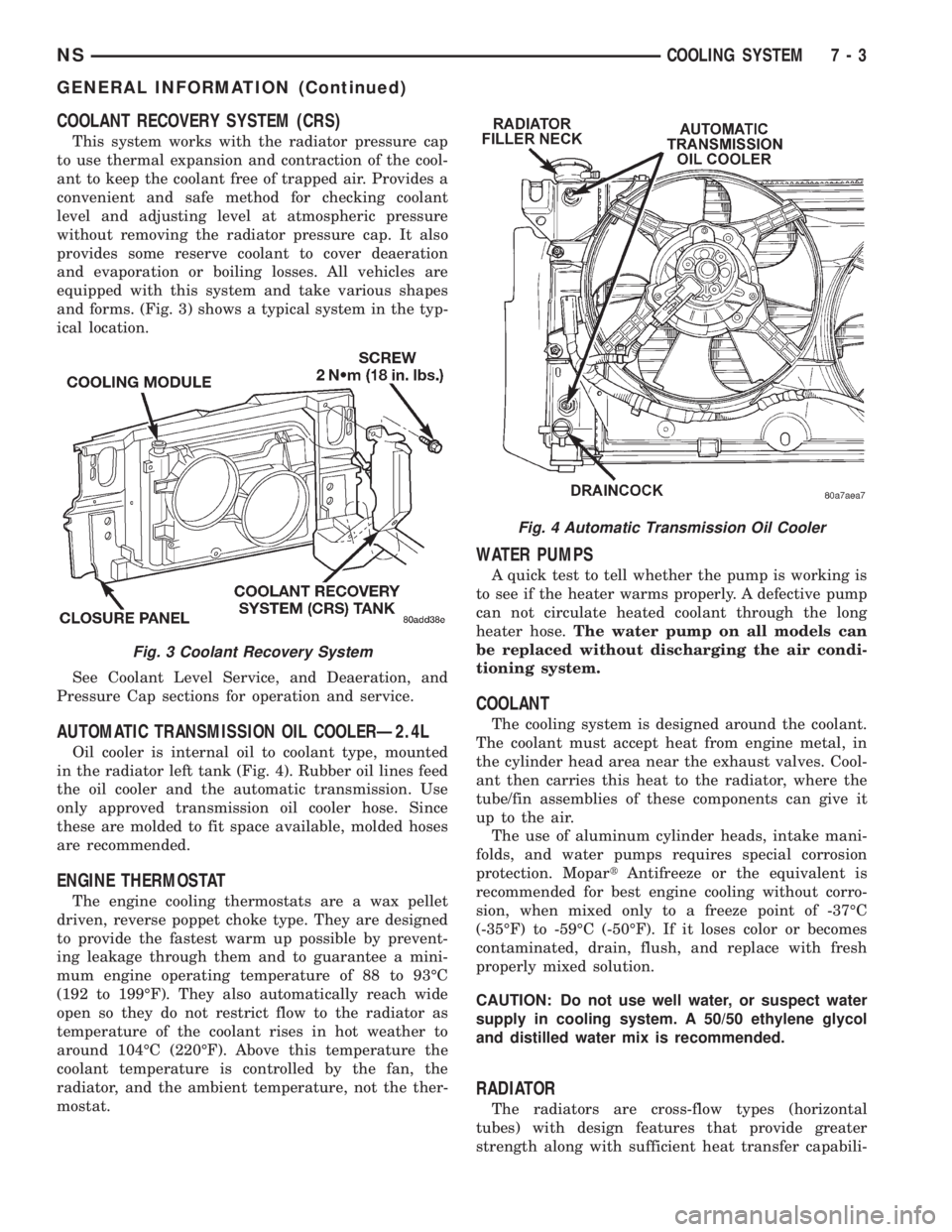

COOLANT RECOVERY SYSTEM (CRS)

This system works with the radiator pressure cap

to use thermal expansion and contraction of the cool-

ant to keep the coolant free of trapped air. Provides a

convenient and safe method for checking coolant

level and adjusting level at atmospheric pressure

without removing the radiator pressure cap. It also

provides some reserve coolant to cover deaeration

and evaporation or boiling losses. All vehicles are

equipped with this system and take various shapes

and forms. (Fig. 3) shows a typical system in the typ-

ical location.

See Coolant Level Service, and Deaeration, and

Pressure Cap sections for operation and service.

AUTOMATIC TRANSMISSION OIL COOLERÐ2.4L

Oil cooler is internal oil to coolant type, mounted

in the radiator left tank (Fig. 4). Rubber oil lines feed

the oil cooler and the automatic transmission. Use

only approved transmission oil cooler hose. Since

these are molded to fit space available, molded hoses

are recommended.

ENGINE THERMOSTAT

The engine cooling thermostats are a wax pellet

driven, reverse poppet choke type. They are designed

to provide the fastest warm up possible by prevent-

ing leakage through them and to guarantee a mini-

mum engine operating temperature of 88 to 93ÉC

(192 to 199ÉF). They also automatically reach wide

open so they do not restrict flow to the radiator as

temperature of the coolant rises in hot weather to

around 104ÉC (220ÉF). Above this temperature the

coolant temperature is controlled by the fan, the

radiator, and the ambient temperature, not the ther-

mostat.

WATER PUMPS

A quick test to tell whether the pump is working is

to see if the heater warms properly. A defective pump

can not circulate heated coolant through the long

heater hose.The water pump on all models can

be replaced without discharging the air condi-

tioning system.

COOLANT

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves. Cool-

ant then carries this heat to the radiator, where the

tube/fin assemblies of these components can give it

up to the air.

The use of aluminum cylinder heads, intake mani-

folds, and water pumps requires special corrosion

protection. MopartAntifreeze or the equivalent is

recommended for best engine cooling without corro-

sion, when mixed only to a freeze point of -37ÉC

(-35ÉF) to -59ÉC (-50ÉF). If it loses color or becomes

contaminated, drain, flush, and replace with fresh

properly mixed solution.

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended.

RADIATOR

The radiators are cross-flow types (horizontal

tubes) with design features that provide greater

strength along with sufficient heat transfer capabili-

Fig. 3 Coolant Recovery System

Fig. 4 Automatic Transmission Oil Cooler

NSCOOLING SYSTEM 7 - 3

GENERAL INFORMATION (Continued)

Page 227 of 1938

CONDITION - AND CHECKS DIAGNOSIS

Inadequate Air Conditioning Performance - Cooling System Suspected

(1) Check for plugged air side of condenser and

radiator front and rear.(1) Wash out with low-velocity water.

(2) Assure fan runs whenever A/C head pressure

exceeds 1724 kPa (250 psi).(2) Repair as necessary.

(3) Check for missing air seals-recirculating air path.

(4) Assure correct cooling system parts.

Battery Dead - Suspect Fan Current Draw as Cause

(1) With a good, fully charged battery. (1) a - Assure fan control is operating properly.

(1) b - See charging system in Electrical, Group 8B.

Hot Smell - Suspect Cooling System

(1) Was temperature gauge high? (1) a - Yes, See9Gauge Reads High9

(1) b - No. See 2, 3, 4, and 5.

(2) Heat shields all in place? (2) a - Yes, See 3, 4, and 5.

(2) b - Repair or replace heat shields.

(3) Fan control operating properly? (3) a - Yes, See 4 and 5.

(3) b - No, See Radiator Fan Control this section.

(4) Heat exchanger air side plugged? (4) Clean as required.

(5) Engine missing or running rich? (5) Repair as required.

Poor Driveability - Suspect Failed Open Thermostat.

(1) Check diagnostics - is code 17 set? (Engine too

cold for too long)(1) If yes, change thermostat.

Poor Heater Performance - Suspect Failed Open Thermostat

(1) Does gauge read low? (1) See 3

(2) Check coolant level. (2) See 3

(3) Check diagnostics - is code 17 set? (Engine too

cold for too long)(3) If yes, change thermostat. If no, check heater

bypass valve, which should be closed except in Max

A/C or off mode; if not, see Heater and Air Conditioning

Group, 24.

Steaming, Observe Water Vapor Through Grill or Head Gap at Standstill at Idle - In Wet Weather

(1) This is normal. It is moisture, snow, or water on the

outside of the radiator that evaporates when the

thermostat opens to put hot coolant into the radiator.

This usually occurs in cold weather with no fan or air

flow to blow it away.(1) Normal condition - no service required.

NSCOOLING SYSTEM 7 - 13

DIAGNOSIS AND TESTING (Continued)

Page 229 of 1938

WARNING: WITH TOOL IN PLACE, PRESSURE

WILL BUILD UP FAST. EXCESSIVE PRESSURE

BUILT UP, BY CONTINUOUS ENGINE OPERATION,

MUST BE RELEASED TO A SAFE PRESSURE

POINT. NEVER PERMIT PRESSURE TO EXCEED 138

kPa (20 psi).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam emits from the tail pipe, it may

indicate a coolant leak caused by a faulty head gas-

ket, cracked engine block, or cracked cylinder head.

There may be internal leaks that can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil it will indicate an

internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

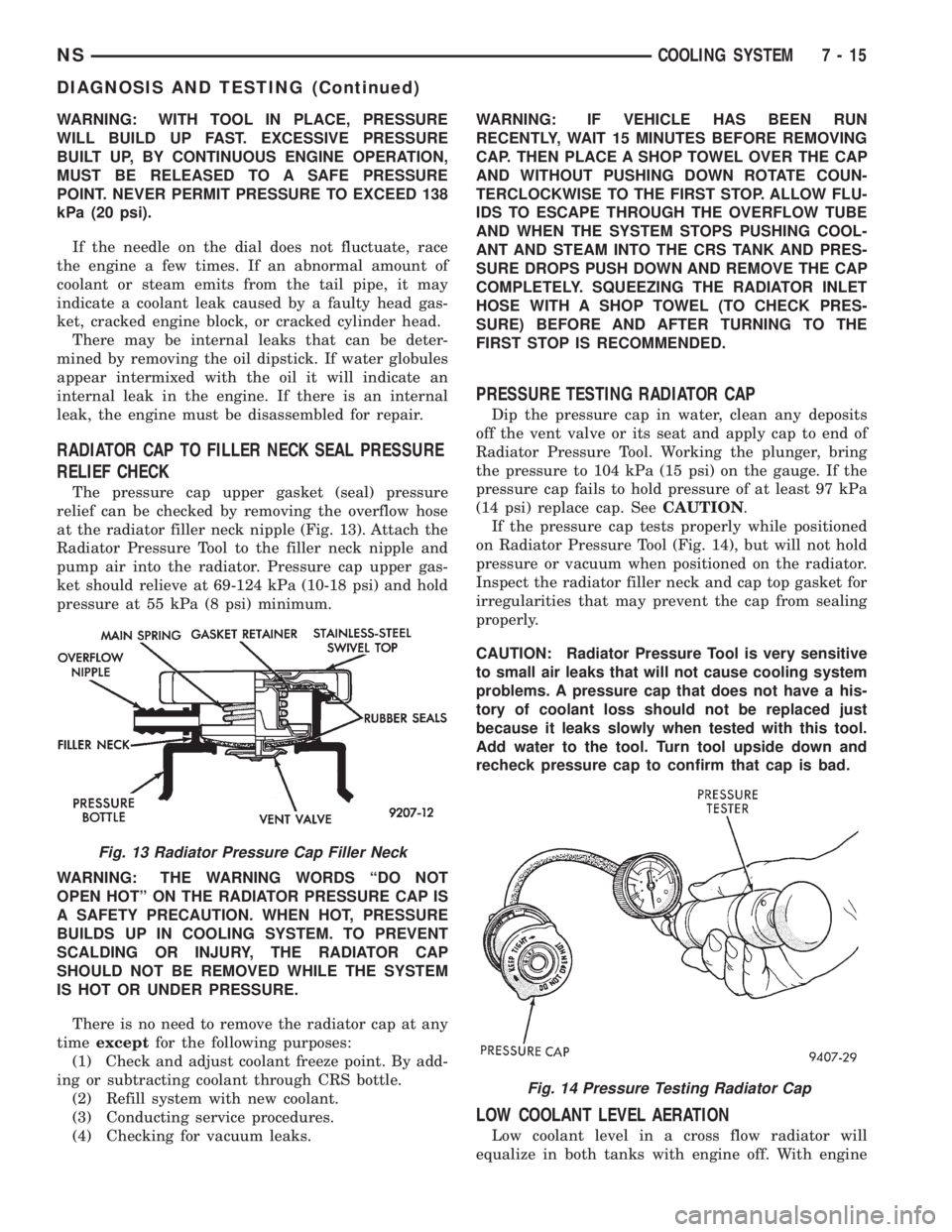

RADIATOR CAP TO FILLER NECK SEAL PRESSURE

RELIEF CHECK

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 13). Attach the

Radiator Pressure Tool to the filler neck nipple and

pump air into the radiator. Pressure cap upper gas-

ket should relieve at 69-124 kPa (10-18 psi) and hold

pressure at 55 kPa (8 psi) minimum.

WARNING: THE WARNING WORDS ªDO NOT

OPEN HOTº ON THE RADIATOR PRESSURE CAP IS

A SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

timeexceptfor the following purposes:

(1) Check and adjust coolant freeze point. By add-

ing or subtracting coolant through CRS bottle.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE REMOVING

CAP. THEN PLACE A SHOP TOWEL OVER THE CAP

AND WITHOUT PUSHING DOWN ROTATE COUN-

TERCLOCKWISE TO THE FIRST STOP. ALLOW FLU-

IDS TO ESCAPE THROUGH THE OVERFLOW TUBE

AND WHEN THE SYSTEM STOPS PUSHING COOL-

ANT AND STEAM INTO THE CRS TANK AND PRES-

SURE DROPS PUSH DOWN AND REMOVE THE CAP

COMPLETELY. SQUEEZING THE RADIATOR INLET

HOSE WITH A SHOP TOWEL (TO CHECK PRES-

SURE) BEFORE AND AFTER TURNING TO THE

FIRST STOP IS RECOMMENDED.

PRESSURE TESTING RADIATOR CAP

Dip the pressure cap in water, clean any deposits

off the vent valve or its seat and apply cap to end of

Radiator Pressure Tool. Working the plunger, bring

the pressure to 104 kPa (15 psi) on the gauge. If the

pressure cap fails to hold pressure of at least 97 kPa

(14 psi) replace cap. SeeCAUTION.

If the pressure cap tests properly while positioned

on Radiator Pressure Tool (Fig. 14), but will not hold

pressure or vacuum when positioned on the radiator.

Inspect the radiator filler neck and cap top gasket for

irregularities that may prevent the cap from sealing

properly.

CAUTION: Radiator Pressure Tool is very sensitive

to small air leaks that will not cause cooling system

problems. A pressure cap that does not have a his-

tory of coolant loss should not be replaced just

because it leaks slowly when tested with this tool.

Add water to the tool. Turn tool upside down and

recheck pressure cap to confirm that cap is bad.

LOW COOLANT LEVEL AERATION

Low coolant level in a cross flow radiator will

equalize in both tanks with engine off. With engine

Fig. 13 Radiator Pressure Cap Filler Neck

Fig. 14 Pressure Testing Radiator Cap

NSCOOLING SYSTEM 7 - 15

DIAGNOSIS AND TESTING (Continued)