check engine CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 306 of 1938

NOTE: Over or under tightening effects knock sen-

sor performance, possibly causing improper spark

control.

DIAGNOSIS AND TESTING

TESTING FOR SPARK AT COILÐ2.4/3.3/3.8L

ENGINES

WARNING: THE DIRECT IGNITION SYSTEMS GEN-

ERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

The coil pack contains independent coils. Each coil

must be checked individually.

CAUTION: Spark plug wire damage may occur if

the spark plug is moved more than 1/4 inch away

from the engine ground.

CAUTION: Do not leave any one spark plug cable

disconnected any longer than 30 seconds or possi-

ble heat damage to catalytic converter will occur.

CAUTION: Test must be performed at idle and in

park only with the parking brake on.

Use a new spark plug and spark plug cable

for the following test.

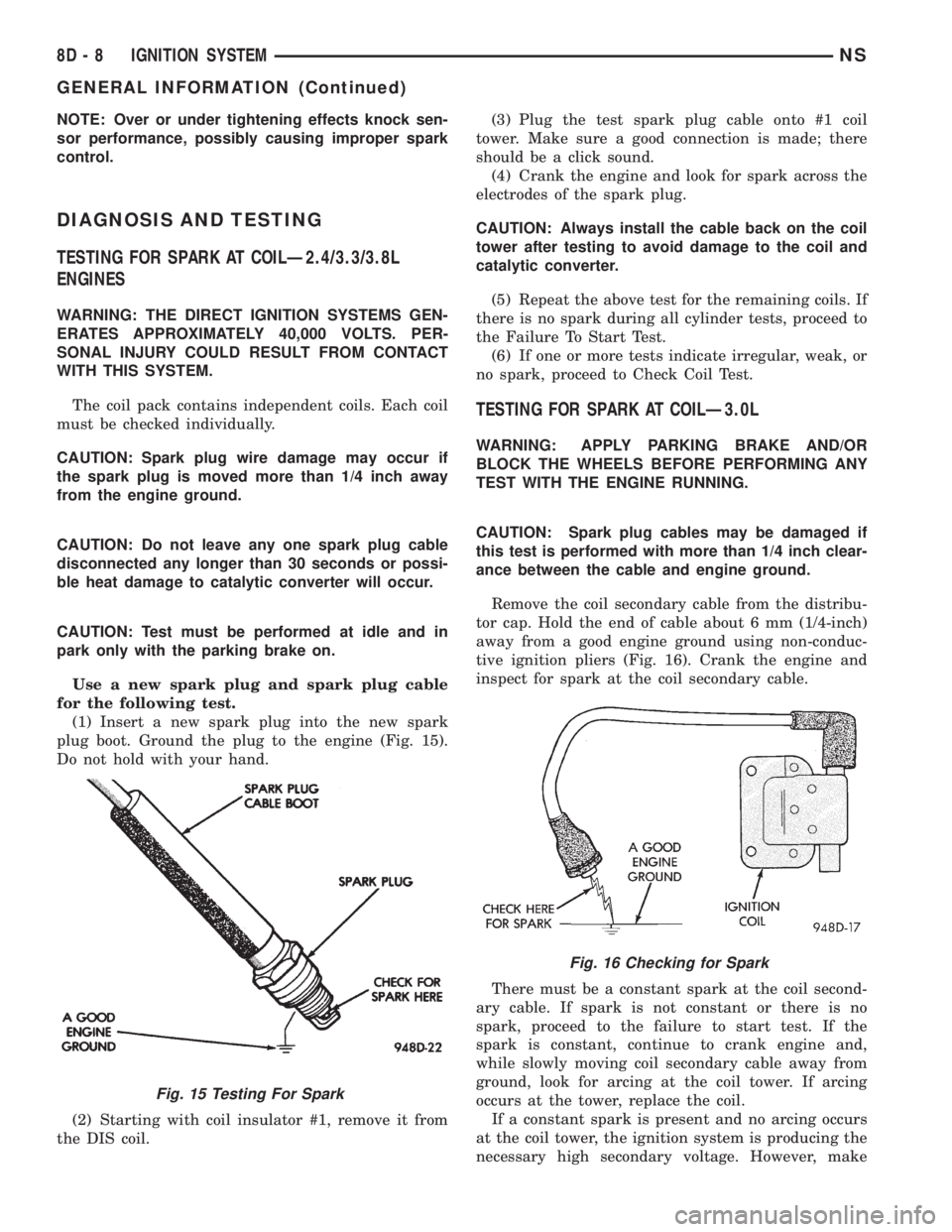

(1) Insert a new spark plug into the new spark

plug boot. Ground the plug to the engine (Fig. 15).

Do not hold with your hand.

(2) Starting with coil insulator #1, remove it from

the DIS coil.(3) Plug the test spark plug cable onto #1 coil

tower. Make sure a good connection is made; there

should be a click sound.

(4) Crank the engine and look for spark across the

electrodes of the spark plug.

CAUTION: Always install the cable back on the coil

tower after testing to avoid damage to the coil and

catalytic converter.

(5) Repeat the above test for the remaining coils. If

there is no spark during all cylinder tests, proceed to

the Failure To Start Test.

(6) If one or more tests indicate irregular, weak, or

no spark, proceed to Check Coil Test.

TESTING FOR SPARK AT COILÐ3.0L

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK THE WHEELS BEFORE PERFORMING ANY

TEST WITH THE ENGINE RUNNING.

CAUTION: Spark plug cables may be damaged if

this test is performed with more than 1/4 inch clear-

ance between the cable and engine ground.

Remove the coil secondary cable from the distribu-

tor cap. Hold the end of cable about 6 mm (1/4-inch)

away from a good engine ground using non-conduc-

tive ignition pliers (Fig. 16). Crank the engine and

inspect for spark at the coil secondary cable.

There must be a constant spark at the coil second-

ary cable. If spark is not constant or there is no

spark, proceed to the failure to start test. If the

spark is constant, continue to crank engine and,

while slowly moving coil secondary cable away from

ground, look for arcing at the coil tower. If arcing

occurs at the tower, replace the coil.

If a constant spark is present and no arcing occurs

at the coil tower, the ignition system is producing the

necessary high secondary voltage. However, make

Fig. 15 Testing For Spark

Fig. 16 Checking for Spark

8D - 8 IGNITION SYSTEMNS

GENERAL INFORMATION (Continued)

Page 307 of 1938

sure that the spark plugs are firing. Inspect the dis-

tributor rotor, cap, spark plug cables, and spark

plugs. If they are in proper working order, the igni-

tion system is not the reason why the engine will not

start. Inspect the fuel system and engine for proper

operation.

CHECK COIL TESTÐ2.4L

Coil one fires cylinders 1 and 4, coil two fires

cylinders 2 and 3. Each coil tower is labeled

with the number of the corresponding cylinder.

(1) Remove ignition cables and measure the resis-

tance of the cables. Resistance must be within the

range shown in the Cable Resistance Chart in Spec-

ifications. Replace any cable not within tolerance.

(2) Disconnect the electrical connector from the

coil pack.

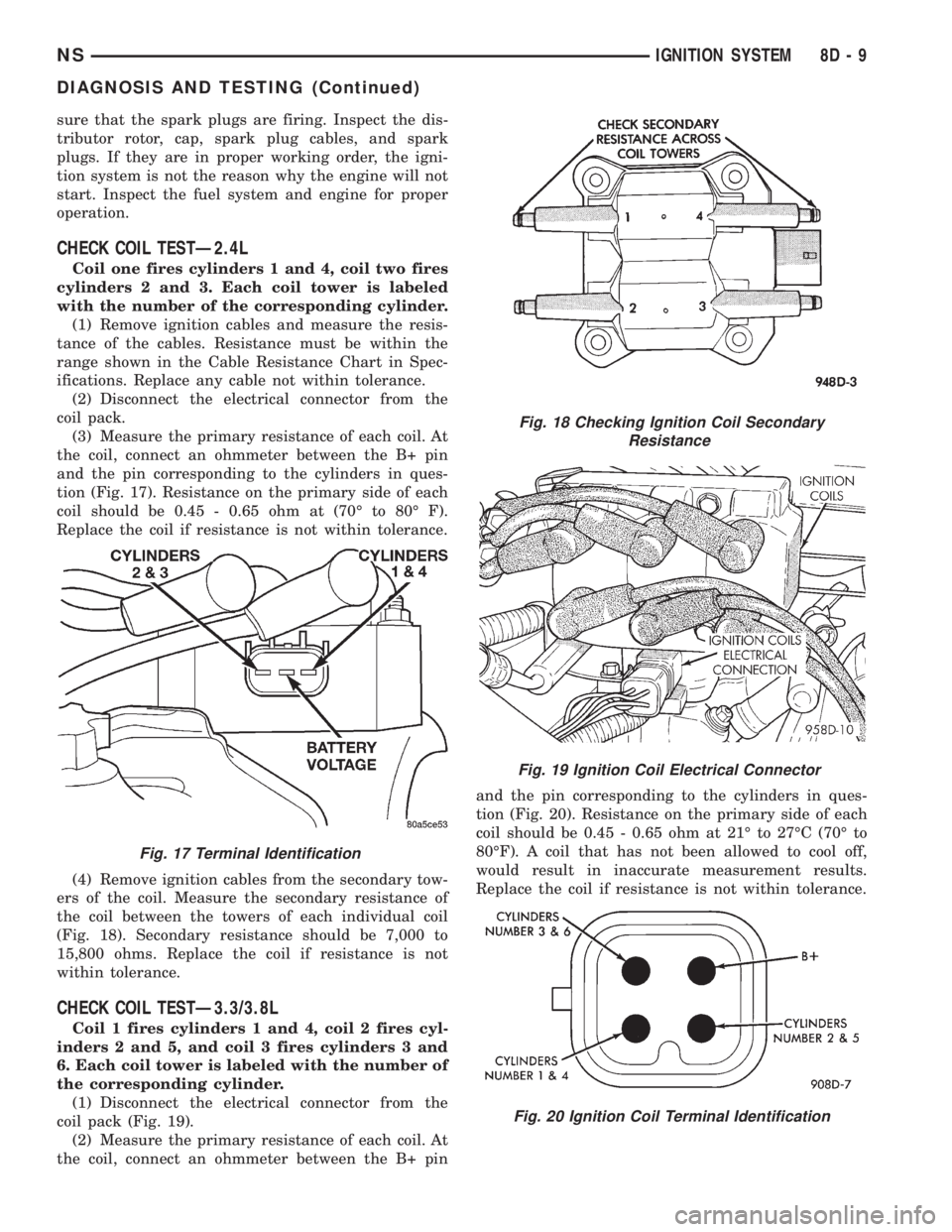

(3) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pin

and the pin corresponding to the cylinders in ques-

tion (Fig. 17). Resistance on the primary side of each

coil should be 0.45 - 0.65 ohm at (70É to 80É F).

Replace the coil if resistance is not within tolerance.

(4) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of

the coil between the towers of each individual coil

(Fig. 18). Secondary resistance should be 7,000 to

15,800 ohms. Replace the coil if resistance is not

within tolerance.

CHECK COIL TESTÐ3.3/3.8L

Coil 1 fires cylinders 1 and 4, coil 2 fires cyl-

inders 2 and 5, and coil 3 fires cylinders 3 and

6. Each coil tower is labeled with the number of

the corresponding cylinder.

(1) Disconnect the electrical connector from the

coil pack (Fig. 19).

(2) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pinand the pin corresponding to the cylinders in ques-

tion (Fig. 20). Resistance on the primary side of each

coil should be 0.45 - 0.65 ohm at 21É to 27ÉC (70É to

80ÉF). A coil that has not been allowed to cool off,

would result in inaccurate measurement results.

Replace the coil if resistance is not within tolerance.

Fig. 17 Terminal Identification

Fig. 18 Checking Ignition Coil Secondary

Resistance

Fig. 19 Ignition Coil Electrical Connector

Fig. 20 Ignition Coil Terminal Identification

NSIGNITION SYSTEM 8D - 9

DIAGNOSIS AND TESTING (Continued)

Page 308 of 1938

(3) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of

the coil between the towers of each individual coil

(Fig. 21). Secondary resistance should be 7,000 to

15,800 ohms. Replace the coil if resistance is not

within tolerance.

FAILURE TO START TEST

This no-start test checks the camshaft position sen-

sor and crankshaft position sensor.

The Powertrain Control Module (PCM) supplies 8

volts to the camshaft position sensor and crankshaft

position sensor through one circuit. If the 8 volt sup-

ply circuit shorts to ground, neither sensor will pro-

duce a signal (output voltage to the PCM).

When the ignition key is turned and left in the On

position, the PCM automatically energizes the Auto

Shutdown (ASD) relay. However, the controller de-en-

ergizes the relay within one second because it has

not received a camshaft position sensor signal indi-

cating engine rotation.

During cranking, the ASD relay will not energize

until the PCM receives a camshaft position sensor

signal. Secondly, the ASD relay remains energized

only if the controller senses a crankshaft position

sensor signal immediately after detecting the cam-

shaft position sensor signal.

(1) Check battery voltage. Voltage should be

approximately 12.66 volts or higher to perform fail-

ure to start test.

(2) Disconnect the harness connector from the coil

pack.

(3) Connect a test light to the B+ (battery voltage)

terminal of the coil electrical connector and ground

as shown in (Fig. 22). The B+ wire for the DIS coil is

dark green with an orange tracer.Do not spread

the terminal with the test light probe.(4) Turn the ignition key to theON position.The

test light should flash On and then Off.Do not turn

the Key to off position, leave it in the On posi-

tion.

(a) If the test light flashes momentarily, the

PCM grounded the Auto Shutdown (ASD) relay.

Proceed to step 5.

(b) If the test light did not flash, the ASD relay

did not energize. The cause is either the relay or

one of the relay circuits. Use the DRB scan tool to

test the ASD relay and circuits. Refer to the appro-

priate Powertrain Diagnostics Procedure Manual.

Refer to the wiring diagrams section for circuit

information.

(5) Crank the engine. (If the key was placed in the

off position after step 4, place the key in the On posi-

tion before cranking. Wait for the test light to flash

once, then crank the engine.)

(6) If the test light momentarily flashes during

cranking, the PCM is not receiving a crankshaft posi-

tion sensor signal. Use the DRB scan tool to test the

crankshaft position sensor and sensor circuits. Refer

to the appropriate Powertrain Diagnostics Procedure

Manual. Refer to the wiring diagrams section for cir-

cuit information.

(7) If the test light did not flash during cranking,

unplug the crankshaft position sensor connector.

Turn the ignition key to the off position. Turn the

key to the On position, wait for the test light to

momentarily flash once, then crank the engine. If the

test light momentarily flashes, the crankshaft posi-

tion sensor is shorted and must be replaced. If the

light did not flash, the cause of the no-start is in

Fig. 21 Checking Ignition Coil Secondary

ResistanceFig. 22 Ignition Coil Engine Harness Connector

8D - 10 IGNITION SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 324 of 1938

DISASSEMBLY AND ASSEMBLY

DISTRIBUTORÐ3.0L

REMOVAL

(1) Disconnect distributor connector from distribu-

tor (Fig. 6).

(2) Loosen distributor cap retaining screws.

(3) Lift cap of off distributor.

(4) Rotate engine crankshaft until the distributor

rotor points to the intake manifold plenum. Scribe a

mark on the plenum in line with the rotor. The scribe

line indicates where to position the rotor when rein-

stalling the distributor.

(5) Remove distributor hold down nut (Fig. 7).

(6) Carefully lift the distributor from the engine.

INSTALLATION

(1) Position distributor in engine. Make certain

that the O-ring is properly seated on distributor. If

O-ring is cracked or nicked replace with new one.

(2) Carefully engage distributor drive with gear on

camshaft. When the distributor is installed properly,

the rotor will be in line with previously scribe line on

air intake plenum.If engine was cranked while

distributor was removed, it will be necessary to

establish proper relationship between the dis-

tributor shaft and Number 1 piston position as

follows:

(a) Rotate the crankshaft until number one pis-

ton is at top of compression stroke.

(b) Rotate rotor to number one rotor terminal

(Fig. 8).

(c) Lower the distributor into the opening,

engaging distributor drive with drive on camshaft.

With distributor fully seated on engine, rotor

should be under the number 1 terminal.

(3) Install the distributor cap. Ensure sure all high

tension wires are firmly in the cap towers.

(4) Install hold-down nut and tighten (Fig. 7).

(5) Connect distributor electrical connector to dis-

tributor (Fig. 6).

CLEANING AND INSPECTION

DISTRIBUTOR CAP

Remove the distributor cap and inspect the inside

for flashover, cracking of carbon button, lack of

spring tension on carbon button, cracking of cap, and

burned, worn terminals (Fig. 9). Also check for bro-

ken distributor cap towers. If any of these conditions

are present the distributor cap and/or cables should

be replaced.

Fig. 6 Distributor Electrical ConnectorÐ3.0L Engine

Fig. 7 Distributor Hold-Down

Fig. 8 Distributor Cap Terminal Routing, View from

TopofCap

8D - 26 IGNITION SYSTEMNS

Page 341 of 1938

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT1. Erratic Message from

another Module.1. (a) Check the BCM using a scan tool If OK, go to

Step (b). If not OK, refer to the BCM section of the

service manual to repair the BCM.

(b) Check the PCM using a scan tool. If OK, go to Step

(c). If not OK, refer to the PCM section of the service

manual to repair the PCM.

(c) Check the speed signal input into the PCM. The

speed signal originates from one of the following

sources:

²A distance sensor for vehicles with 3 speed automatic

transmission. Check continuity from distance sensor to

PCM. If OK, replace distance sensor. If not OK, repair

wiring.

²The Electronic Transmission Control Module (TCM)

vehicles with the 4 speed electronic transmissions.

Check continuity from TCM to engine controller. If OK,

use a scan tool to check TCM. Refer to the electronic

section of the service manual to repair the TCM. If not

OK, repair wiring.

2. Internal Cluster Failure. 2. (a) Perform cluster self diagnostic test and check for

fault codes.

²If the pointer moves during test but still appears

erratic and fault codes 110 or 111 don't appear in the

odometer display, then go to Step (b).

²If fault code 110 is displayed in the odometer, go to

Step (e).

²If fault code 111 appears in the odometer display go

to Step (d).

²If fault codes 905, 920, or 940 are displayed in the

odometer display refer to the fault code chart to identify

which module is causing the fault and repair module.

(b) Replace cluster subdial assembly. To Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place. DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) Use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go to Step (e).

Replace main cluster pc board and use a scan tool to

calibrate cluster. If not OK, look at another possible

cause for the speedometer failure.

NSINSTRUMENT PANEL AND SYSTEMS 8E - 5

DIAGNOSIS AND TESTING (Continued)

Page 343 of 1938

TACHOMETER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT1. Internal Cluster Failure. 1. (a) Perform Cluster Self Diagnostic Test and check

for fault codes.

²If tachometer pointer moves to calibration points

during test and fault codes 110 or 111 don't appear in

the odometer display then failure is not in the cluster.

Look for another possible cause of failure.

²If the pointer doesn't move during test, go to Step

(b).

²If fault code 110 is displayed in the odometer, go to

Step (b).

²If fault code 111 is displayed in the odometer then go

to Step (f).

²If fault codes 920 or 940 are displayed in the

odometer display refer to the fault code chart to identify

which module is causing the fault an repair module.

(b) Replace main cluster pc board. Go to Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place. DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go to Step (e).

(e) Replace subdial assembly and use a scan tool to

calibrate cluster. If not OK, look at another possible

cause for the tachometer failure.

(f) Use a scan tool to calibrate tachometer and perform

Self Diagnostic Test. If OK, stop. If not OK, go to Step

(b).

2. No rpm CCD Bus

Message or Zero rpm

CCD Bus Message from

Engine Controller.2. Check the PCM using a scan tool. Refer to the PCM

section of the manual to properly diagnose and repair.

NSINSTRUMENT PANEL AND SYSTEMS 8E - 7

DIAGNOSIS AND TESTING (Continued)

Page 344 of 1938

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. Bad CCD Bus

Message from Engine

Controller.1. Check the PCM using a scan tool. Refer to the PCM

section of the manual to properly diagnose and repair.

2. Internal Cluster Failure. 2. (a) Perform Cluster Self Diagnostic Test and check

for fault codes.

²If the pointer moves during test but still appears

erratic and fault codes 110 or 111 don't appear in the

odometer display, go to Step (b).

²If fault code 110 is displayed in the odometer, go to

Step (e).

²If fault code 111 appears in the odometer display go

to Step (d).

²If fault codes 920 or 940 are displayed in the

odometer display refer to the fault code chart to identify

which module is causing the fault and repair module.

(b) Replace cluster subdial assembly. Go to Step (c).

(c) Connect cluster into instrument panel wiring

harness. Place it back into the proper position in the

instrument panel. Put in the top two mounting screws to

hold the cluster in place DO NOT COMPLETELY

INSTALL CLUSTER TO INSTRUMENT PANEL UNTIL

UNIT IS CALIBRATED AND TESTED. Go to Step (d).

(d) Use a scan tool to calibrate cluster and perform Self

Diagnostic Test. If OK, continue installation. If not OK,

go to Step (e).

(e) Replace main cluster pc board and use a scan tool

to calibrate cluster. If not OK, look at another possible

cause for the tachometer failure.

TACHOMETER

INACCURATE.1. Tachometer out of

calibration.1. Calibrate tachometer using a scan tool.

8E - 8 INSTRUMENT PANEL AND SYSTEMSNS

DIAGNOSIS AND TESTING (Continued)

Page 404 of 1938

CD/3-band graphic equalizer (RBR sales code), or an

AM/FM/CD/cassette/3-band graphic equalizer (RAZ

sales code).

All factory-installed radio receivers are stereo Elec-

tronically Tuned Radios (ETR) and include an elec-

tronic digital clock function.

All factory-installed radio receivers, except the

RAS model, communicate on the Chrysler Collision

Detection (CCD) data bus network through a sepa-

rate two-way wire harness connector. The CCD data

bus network allows the sharing of sensor informa-

tion. This helps to reduce wire harness complexity,

internal controller hardware, and component sensor

current loads. At the same time, this system provides

increased reliability, enhanced diagnostics, and

allows the addition of many new feature capabilities.

In addition, radios connected to the CCD data bus

have several audio system functions that can be diag-

nosed using a DRB scan tool. Refer to the proper

Diagnostic Procedures manual for more information

on DRB testing of the audio systems.

The radio can only be serviced by an authorized

radio repair station. Refer to the latest Warranty Pol-

icies and Procedures manual for a current listing of

authorized radio repair stations.

For more information on radio features, setting

procedures, and control functions refer to the owner's

manual in the vehicle glove box.

RADIO IGNITION INTERFERENCE

If receiving ignition/engine interference noise on

the radio stations, check and clean all engine and

body ground connections. Tighten properly after

cleaning. Example (Fig. 1), (Fig. 2), (Fig. 3) and (Fig.

4).

Ensure all ground connections are without corro-

sion.

CHOKEÐINFINITY SPEAKERS

If the audio system is lacking bass response, check

for continuity across the choke connector. If no conti-

nuity Replace choke. The choke is located on the

Fig. 1 Motor Mount to Frame Rail Ground

Fig. 2 2.4L Engine Block Ground

Fig. 3 3.0L Engine Block Ground

Fig. 4 3.3/3.8L Engine Block Ground

8F - 2 AUDIO SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 406 of 1938

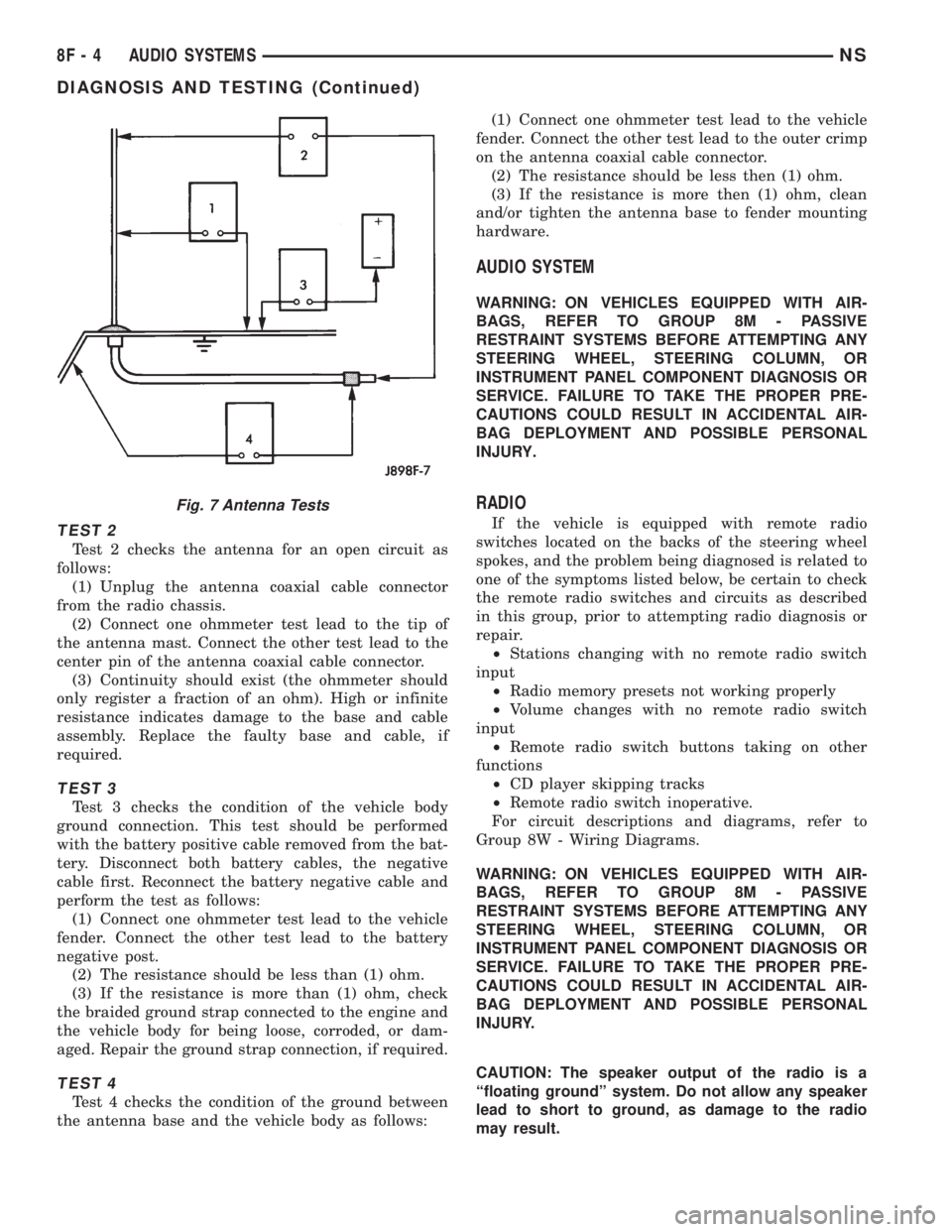

TEST 2

Test 2 checks the antenna for an open circuit as

follows:

(1) Unplug the antenna coaxial cable connector

from the radio chassis.

(2) Connect one ohmmeter test lead to the tip of

the antenna mast. Connect the other test lead to the

center pin of the antenna coaxial cable connector.

(3) Continuity should exist (the ohmmeter should

only register a fraction of an ohm). High or infinite

resistance indicates damage to the base and cable

assembly. Replace the faulty base and cable, if

required.

TEST 3

Test 3 checks the condition of the vehicle body

ground connection. This test should be performed

with the battery positive cable removed from the bat-

tery. Disconnect both battery cables, the negative

cable first. Reconnect the battery negative cable and

perform the test as follows:

(1) Connect one ohmmeter test lead to the vehicle

fender. Connect the other test lead to the battery

negative post.

(2) The resistance should be less than (1) ohm.

(3) If the resistance is more than (1) ohm, check

the braided ground strap connected to the engine and

the vehicle body for being loose, corroded, or dam-

aged. Repair the ground strap connection, if required.

TEST 4

Test 4 checks the condition of the ground between

the antenna base and the vehicle body as follows:(1) Connect one ohmmeter test lead to the vehicle

fender. Connect the other test lead to the outer crimp

on the antenna coaxial cable connector.

(2) The resistance should be less then (1) ohm.

(3) If the resistance is more then (1) ohm, clean

and/or tighten the antenna base to fender mounting

hardware.

AUDIO SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

RADIO

If the vehicle is equipped with remote radio

switches located on the backs of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

For circuit descriptions and diagrams, refer to

Group 8W - Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

Fig. 7 Antenna Tests

8F - 4 AUDIO SYSTEMSNS

DIAGNOSIS AND TESTING (Continued)

Page 419 of 1938

STEP IS NOT DONE A DIAGONSTIC TROUBLE

CODE (DTC) MAY BE SET.

VACUUM RESERVOIR

The reservoir contains a one-way check valve to

trap engine vacuum in the reservoir. When engine

vacuum drops, as in climbing a grade while driving,

the reservoir supplies the vacuum needed to main-

tain proper speed control operation. The vacuum res-

ervoir cannot be repaired and must be replaced if

faulty.

VEHICLE SPEED AND DISTANCE

The 4 speed automatic Transmission Control Mod-

ule (TCM) supplies the speed input to the PCM. The

PCM determines acceleration rates. The speed con-

trol software in the PCM uses vehicle speed and

acceleration to control to the set speed.

Vehicles with a 3 speed automatic or manual trans-

mission have a vehicle speed sensor (VSS) mounted

to an adapter near the transmission output shaft.

The sensor is driven through the adapter by a speed-

ometer pinion gear. The VSS pulse signal is moni-

tored by the PCM to determine vehicle speed and to

maintain speed control set speed. Refer to the appro-

priate Powertrain Diagnostic Procedures manual for

diagnosis and testing of this component. Refer to

group 14, Fuel System for Removal/Installation

DIAGNOSIS AND TESTING

ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road test

should include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8E,

Instrument Panel and Gauges for speedometer diag-

nosis.

If a road test verifies a surge following a set and

the speedometer operates properly see ªOvershoot/

Undershoot on speed control setº.

If a road test verifies an inoperative system, and

the speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose or corroded electrical connections at the

servo. Corrosion should be removed from electricalterminals and a light coating of Mopar Multipurpose

Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment at both ends of the speed

control servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Conduct electrical test at PCM.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

OVERSHOOT/UNDERSHOOT FOLLOWING SPEED

CONTROL SET

If the operator repeatedly presses and releases the

set button with their foot off of the accelerator (a ªlift

foot setº to begin speed control operation), the vehicle

may accelerate and exceed the desired set speed by

up to 5 MPH (8 km/h) and then decelerate to less

than the desired set speed before finally achieving

the desired set speed.

The Speed Control has an adaptive strategy that

compensates for vehicle-to-vehicle variations in speed

control cable lengths. When the speed control is set

with the vehicle operators foot off of the accelerator

pedal, the speed control thinks there is excessive

speed control cable slack and adapts. If the lift foot

sets are continually used, the speed control over-

shoot/undershoot condition will develop.

To ªunlearnº the overshoot/undershoot condition,

the vehicle operator has to press and release the set

button while maintaining the desired set speed with

the accelerator pedal (not decelerating or accelerat-

ing), and then turn the cruise control switch to the

OFF position (or press the CANCEL button if

equipped) after waiting 10 seconds. This procedure

must be performed approximately 10±15 times to

completely unlearn the overshoot/undershoot condi-

tion.

CHECKING FOR DIAGNOSTIC CODES

When trying to verify a speed control system elec-

tronic malfunction: Connect a DRB scan tool if avail-

able to the data link connector. The connector is

located at left side of the steering column, and at

lower edge of the panel.

(1) A speed control malfunction may occur without

a diagnostic code being indicated.

NSVEHICLE SPEED CONTROL SYSTEM 8H - 3

DESCRIPTION AND OPERATION (Continued)