check engine CHRYSLER VOYAGER 1996 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 230 of 1938

at running operating temperature the high pressure

inlet tank runs full and the low pressure outlet tank

drops:

²Transmission oil will become hotter.

²High reading shown on the temperature gauge.

²Air in the coolant can cause loss of flow through

the heater.

²Exhaust gas leaks into the coolant also can

cause the same problems.

DEAERATION

Air can only be removed from the system by gath-

ering under the pressure cap. On the next heat up it

will be pushed past the pressure cap into the CRS

tank by thermal expansion of the coolant. It then

escapes to the atmosphere in the CRS tank and is

replaced with solid coolant on cool down.

TEMPERATURE GAUGE INDICATION

At idle with Air Conditioning off the temperature

gauge will rise slowly to about 5/8 gauge travel, the

fan will come on and the gauge will quickly drop to

about 1/2 gauge travel. This is normal.

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE

Do not remove radiator cap for routine cool-

ant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the radiator cap.With the engine cold

and not running,simply observe the level of the

coolant in the reserve tank (Fig. 3). The coolant level

should be between the minimum and maximum

marks.

COOLANTÐADDING ADDITIONAL

The radiator cap should not be removed.

When additional coolant is needed to maintain this

level, it should be added to the coolant reserve tank.

Use only 50/50 mix of ethylene glycol type antifreeze

and water.

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended.

COOLANT LEVEL SERVICE

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator.

When servicing requires a coolant level check in

the radiator, the engine must beoffandnotunder

pressure. Drain several ounces of coolant from the

radiator draincock while observing the CoolantRecovery System (CRS) Tank. Coolant level in the

CRS tank should drop slightly. Then remove the radi-

ator cap. The radiator should be full to the top. If

not, and the coolant level in the CRS tank is at the

MIN mark there is an air leak in the CRS system.

Check hose or hose connections to the CRS tank,

radiator filler neck or the pressure cap seal to the

radiator filler neck for leaks.

COOLING SYSTEMÐDRAINING

Without removing radiator pressure cap and

with system not under pressure,shut engine off

and open draincock. The coolant reserve tank should

empty first, then remove radiator pressure cap. (if

not, see Testing Cooling System for leaks). To vent

2.4L engine remove the coolant temperature sensor

located above water outlet housing (Fig. 15). The 3.0/

3.3/3.8L engines have an air bleed vent on the ther-

mostat.

Removal of a sensor is required because the ther-

mostat does not have an air vent. Sensor removal

allows an air bleed for coolant to drain from the

engine block.

COOLING SYSTEMÐREFILLING

First clean system to remove old coolant, see Cool-

ing System Cleaning.

Fill the system, using the correct antifreeze as

described in the Coolant Section. Fill the system to

50 percent of its capacity with 100 percent glycol.

Then complete filling system with water. The 2.4L

engine requires venting by removal of the coolant

sensor on top of the water outlet connector (Fig. 15).

When coolant reaches this hole:

²Install coolant sensor and tighten to 7 N´m (60

in. lbs.) for 2.4L Engines.

Fig. 15 Coolant Temperature SensorÐ2.4L Engine

Drain/Fill

7 - 16 COOLING SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 231 of 1938

Continue filling system until full, this provides bet-

ter heater performance.Be careful not to spill

coolant on drive belts or the generator.

Fill coolant reserve system to at least the MAX

mark with 50/50 solution. It may be necessary to add

coolant to the reserve tank after three or four warm

up/cool down cycles to maintain coolant level between

the MAX and MIN mark. This will allow trapped air

to be removed from the system.

REMOVAL AND INSTALLATION

WATER PUMPÐ2.4L ENGINE

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on a hoist. Remove right inner

splash shield.

(3) Remove accessory drive belts. Refer to Acces-

sory Drive Belt service in this section.

(4) Drain cooling system. Refer to Cooling System

Draining in this section.

(5) Support engine from the bottom and remove

right engine mount.

(6) Remove right engine mount bracket.

(7) Remove timing belt. Refer to Group 9, Engine

for procedure.

(8) Remove timing belt idler pulley.

(9) Hold camshaft sprocket with Special tool

C-4687 and adaptor C-4687-1 while removing bolt.

Remove both cam sprockets.

(10) Remove rear timing belt cover.

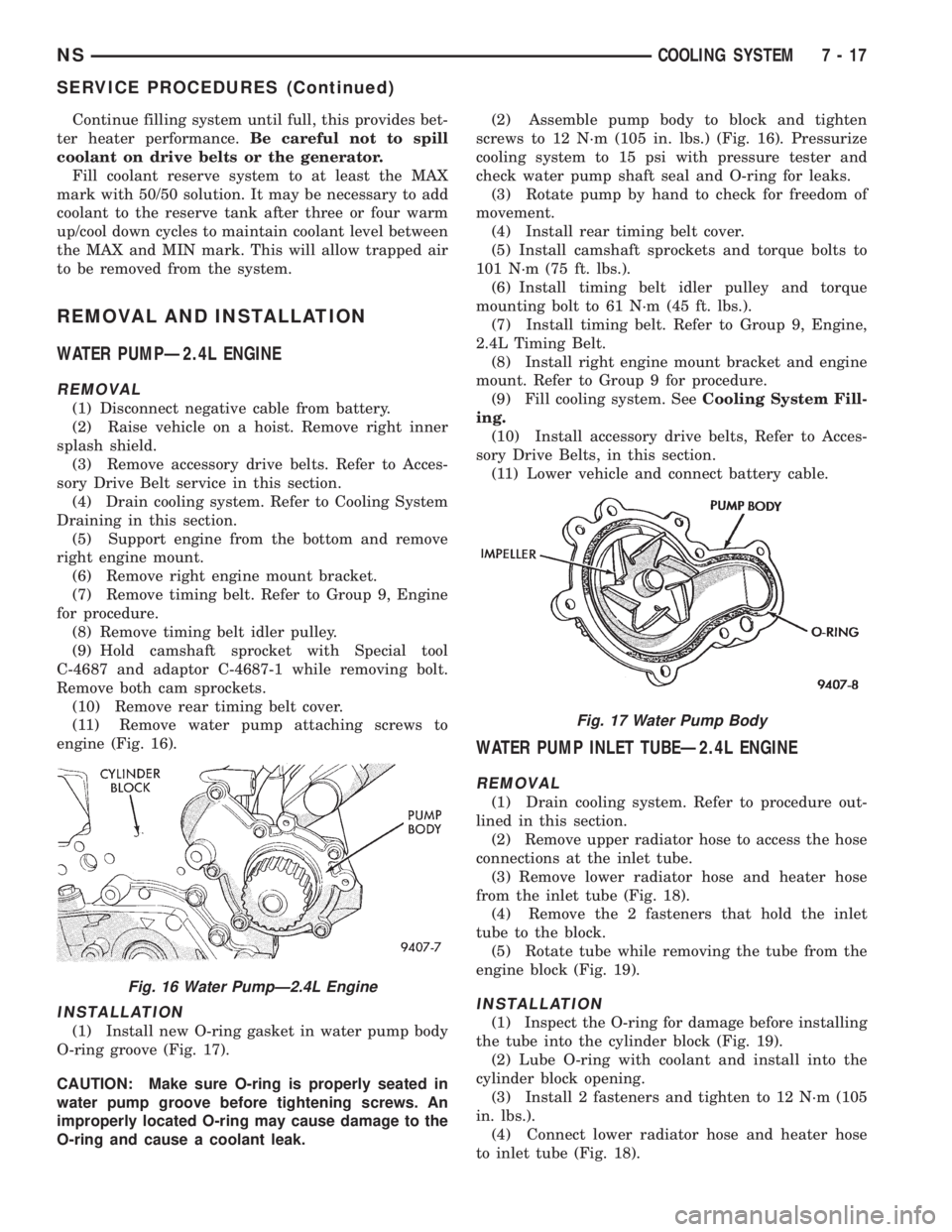

(11) Remove water pump attaching screws to

engine (Fig. 16).

INSTALLATION

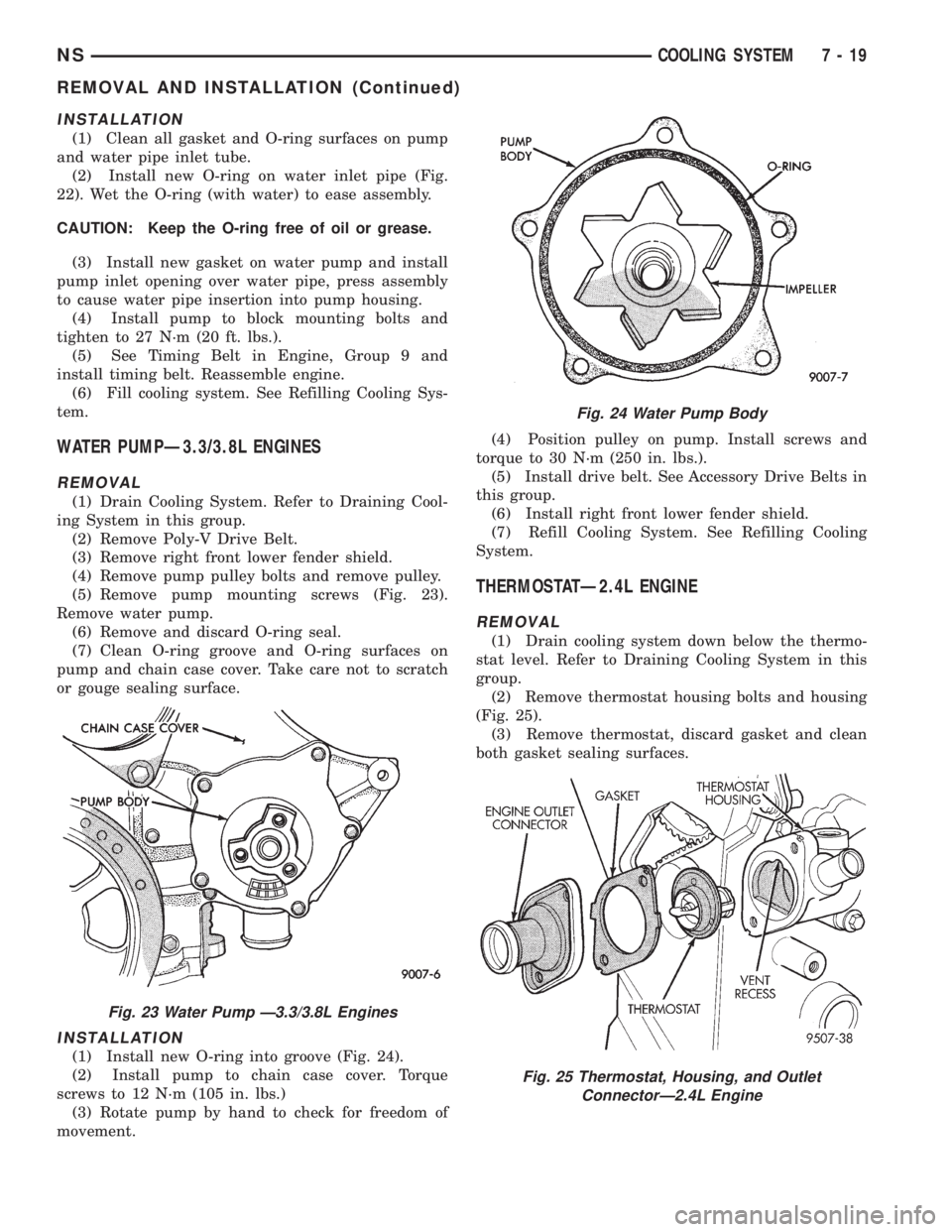

(1) Install new O-ring gasket in water pump body

O-ring groove (Fig. 17).

CAUTION: Make sure O-ring is properly seated in

water pump groove before tightening screws. An

improperly located O-ring may cause damage to the

O-ring and cause a coolant leak.(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.) (Fig. 16). Pressurize

cooling system to 15 psi with pressure tester and

check water pump shaft seal and O-ring for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install rear timing belt cover.

(5) Install camshaft sprockets and torque bolts to

101 N´m (75 ft. lbs.).

(6) Install timing belt idler pulley and torque

mounting bolt to 61 N´m (45 ft. lbs.).

(7) Install timing belt. Refer to Group 9, Engine,

2.4L Timing Belt.

(8) Install right engine mount bracket and engine

mount. Refer to Group 9 for procedure.

(9) Fill cooling system. SeeCooling System Fill-

ing.

(10) Install accessory drive belts, Refer to Acces-

sory Drive Belts, in this section.

(11) Lower vehicle and connect battery cable.

WATER PUMP INLET TUBEÐ2.4L ENGINE

REMOVAL

(1) Drain cooling system. Refer to procedure out-

lined in this section.

(2) Remove upper radiator hose to access the hose

connections at the inlet tube.

(3) Remove lower radiator hose and heater hose

from the inlet tube (Fig. 18).

(4) Remove the 2 fasteners that hold the inlet

tube to the block.

(5) Rotate tube while removing the tube from the

engine block (Fig. 19).

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 19).

(2) Lube O-ring with coolant and install into the

cylinder block opening.

(3) Install 2 fasteners and tighten to 12 N´m (105

in. lbs.).

(4) Connect lower radiator hose and heater hose

to inlet tube (Fig. 18).

Fig. 16 Water PumpÐ2.4L Engine

Fig. 17 Water Pump Body

NSCOOLING SYSTEM 7 - 17

SERVICE PROCEDURES (Continued)

Page 233 of 1938

INSTALLATION

(1) Clean all gasket and O-ring surfaces on pump

and water pipe inlet tube.

(2) Install new O-ring on water inlet pipe (Fig.

22). Wet the O-ring (with water) to ease assembly.

CAUTION: Keep the O-ring free of oil or grease.

(3) Install new gasket on water pump and install

pump inlet opening over water pipe, press assembly

to cause water pipe insertion into pump housing.

(4) Install pump to block mounting bolts and

tighten to 27 N´m (20 ft. lbs.).

(5) See Timing Belt in Engine, Group 9 and

install timing belt. Reassemble engine.

(6) Fill cooling system. See Refilling Cooling Sys-

tem.

WATER PUMPÐ3.3/3.8L ENGINES

REMOVAL

(1) Drain Cooling System. Refer to Draining Cool-

ing System in this group.

(2) Remove Poly-V Drive Belt.

(3) Remove right front lower fender shield.

(4) Remove pump pulley bolts and remove pulley.

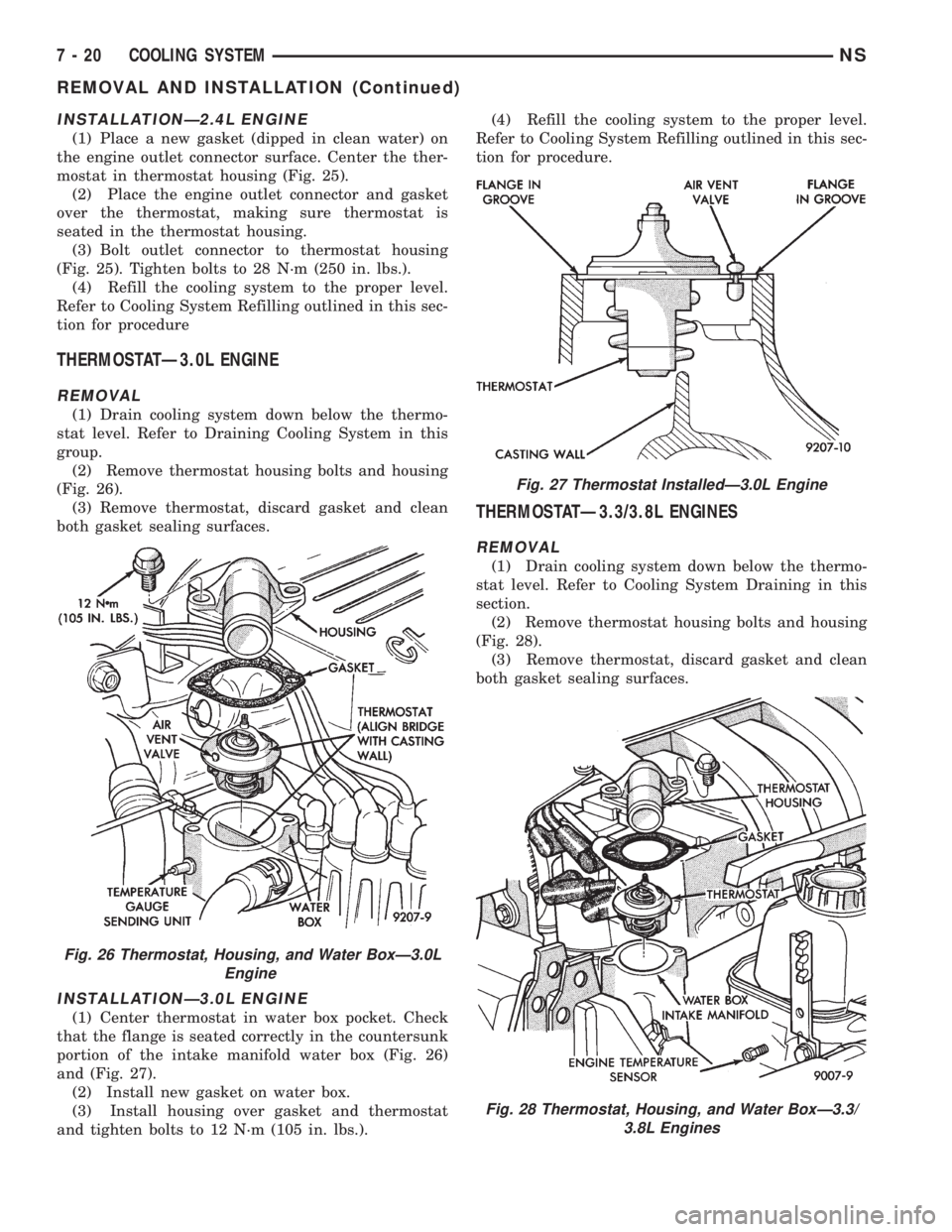

(5) Remove pump mounting screws (Fig. 23).

Remove water pump.

(6) Remove and discard O-ring seal.

(7) Clean O-ring groove and O-ring surfaces on

pump and chain case cover. Take care not to scratch

or gouge sealing surface.

INSTALLATION

(1) Install new O-ring into groove (Fig. 24).

(2) Install pump to chain case cover. Torque

screws to 12 N´m (105 in. lbs.)

(3) Rotate pump by hand to check for freedom of

movement.(4) Position pulley on pump. Install screws and

torque to 30 N´m (250 in. lbs.).

(5) Install drive belt. See Accessory Drive Belts in

this group.

(6) Install right front lower fender shield.

(7) Refill Cooling System. See Refilling Cooling

System.

THERMOSTATÐ2.4L ENGINE

REMOVAL

(1) Drain cooling system down below the thermo-

stat level. Refer to Draining Cooling System in this

group.

(2) Remove thermostat housing bolts and housing

(Fig. 25).

(3) Remove thermostat, discard gasket and clean

both gasket sealing surfaces.

Fig. 23 Water Pump Ð3.3/3.8L Engines

Fig. 24 Water Pump Body

Fig. 25 Thermostat, Housing, and Outlet

ConnectorÐ2.4L Engine

NSCOOLING SYSTEM 7 - 19

REMOVAL AND INSTALLATION (Continued)

Page 234 of 1938

INSTALLATIONÐ2.4L ENGINE

(1) Place a new gasket (dipped in clean water) on

the engine outlet connector surface. Center the ther-

mostat in thermostat housing (Fig. 25).

(2) Place the engine outlet connector and gasket

over the thermostat, making sure thermostat is

seated in the thermostat housing.

(3) Bolt outlet connector to thermostat housing

(Fig. 25). Tighten bolts to 28 N´m (250 in. lbs.).

(4) Refill the cooling system to the proper level.

Refer to Cooling System Refilling outlined in this sec-

tion for procedure

THERMOSTATÐ3.0L ENGINE

REMOVAL

(1) Drain cooling system down below the thermo-

stat level. Refer to Draining Cooling System in this

group.

(2) Remove thermostat housing bolts and housing

(Fig. 26).

(3) Remove thermostat, discard gasket and clean

both gasket sealing surfaces.

INSTALLATIONÐ3.0L ENGINE

(1) Center thermostat in water box pocket. Check

that the flange is seated correctly in the countersunk

portion of the intake manifold water box (Fig. 26)

and (Fig. 27).

(2) Install new gasket on water box.

(3) Install housing over gasket and thermostat

and tighten bolts to 12 N´m (105 in. lbs.).(4) Refill the cooling system to the proper level.

Refer to Cooling System Refilling outlined in this sec-

tion for procedure.

THERMOSTATÐ3.3/3.8L ENGINES

REMOVAL

(1) Drain cooling system down below the thermo-

stat level. Refer to Cooling System Draining in this

section.

(2) Remove thermostat housing bolts and housing

(Fig. 28).

(3) Remove thermostat, discard gasket and clean

both gasket sealing surfaces.

Fig. 26 Thermostat, Housing, and Water BoxÐ3.0L

Engine

Fig. 27 Thermostat InstalledÐ3.0L Engine

Fig. 28 Thermostat, Housing, and Water BoxÐ3.3/

3.8L Engines

7 - 20 COOLING SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 241 of 1938

COOLING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

COOLANT PRESSURE BOTTLE............ 1

COOLING SYSTEM Ð 2.0L GASOLINE...... 1

COOLING SYSTEM Ð 2.5L VM DIESEL..... 1

LOW COOLANT LEVEL SENSOR........... 1

RADIATOR............................ 2

DESCRIPTION AND OPERATION

AUTOMATIC BELT TENSIONER............ 6

BELT TENSION......................... 5

COOLANT PERFORMANCE............... 5

PRESSURE/VENT CAP................... 4

THERMOSTAT OPERATION............... 4

THERMOSTAT......................... 6

WATER PUMP......................... 3

SERVICE PROCEDURES

ADDING ADDITIONAL COOLANT........... 7

DRAINING COOLING SYSTEM............. 7

REFILLING COOLING SYSTEM............ 7

REMOVAL AND INSTALLATION

ENGINE THERMOSTATÐ 2.0L GASOLINE . . . 9GENERATOR/POWER STEERING BELT Ð 2.5L

VM DIESEL......................... 10

RADIATOR Ð 2.5L VM DIESEL........... 9

THERMOSTAT Ð 2.5L VM DIESEL......... 9

WATER PUMP BELT Ð 2.5L VM DIESEL . . . 10

WATER PUMP Ð 2.0L GASOLINE......... 7

WATER PUMP Ð 2.5L VM DIESEL........ 8

CLEANING AND INSPECTION

WATER PUMP........................ 10

ADJUSTMENTS

BELT TENSION CHART................. 11

BELT TENSION GAUGE METHOD......... 11

SPECIFICATIONS

COOLING SYSTEM CAPACITY............ 12

TORQUE CHART...................... 12

SPECIAL TOOLS

COOLING............................ 12

GENERAL INFORMATION

COOLING SYSTEM Ð 2.0L GASOLINE

The 2.0L gasoline engine cooling system consists of

an engine cooling module, thermostat, coolant, a

water pump to circulate the coolant. The engine cool-

ing module may consist of a radiator, electric fan

motors, fan, shroud, coolant reserve system, hoses,

clamps, air condition condenser.

²When the Engine is cold: The thermostat is

closed; the cooling system has no flow through the

radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open;

the cooling system has flow through radiator, engine,

heater system and bypass.

COOLING SYSTEM Ð 2.5L VM DIESEL

The cooling system has a radiator, coolant, electric

fan motors, shroud, pressure cap, thermostat, coolant

pressure bottle, hoses, a water pump to circulate the

coolant, to complete the circuit. Coolant flow for the

VM diesel engine is shown in (Fig. 1).

COOLANT PRESSURE BOTTLE

2.5L VM DIESEL

This system works with the pressure cap to use

thermal expansion and contraction of the coolant to

keep the coolant free of trapped air. It provides some

reserve coolant to cover minor leaks and evaporation

or boiling losses. The coolant pressure bottle location

for 2.5L diesel is above the cylinder head cover (Fig.

2).

LOW COOLANT LEVEL SENSOR

The low coolant level sensor checks for low coolant

level in the coolant tank. A signal will be sent from

this sensor to the Body Control Module (BCM). When

the BCM determines low coolant level for 30 contin-

uous seconds, the instrument panel mounted low

coolant level warning lamp will be illuminated. The

sensor is located on the front side of the coolant tank

(Fig. 4). For information, refer to Group 8E, Instru-

ment Panel and Gauges.

If this lamp is illuminated, it indicates the need to

fill the coolant tank and check for leaks.

NS/GSCOOLING SYSTEM 7 - 1

Page 246 of 1938

Initial belt adjustment is done with a adjustable

tensioner pulley. After the initial adjustment is per-

formed, an automatic belt tensioner is used to main-

tain correct belt tension at all times. Do not attempt

to check belt tension with a belt tension gauge on

vehicles equipped with an automatic belt tensioner.

Refer to Automatic Belt Tensioner in this group.

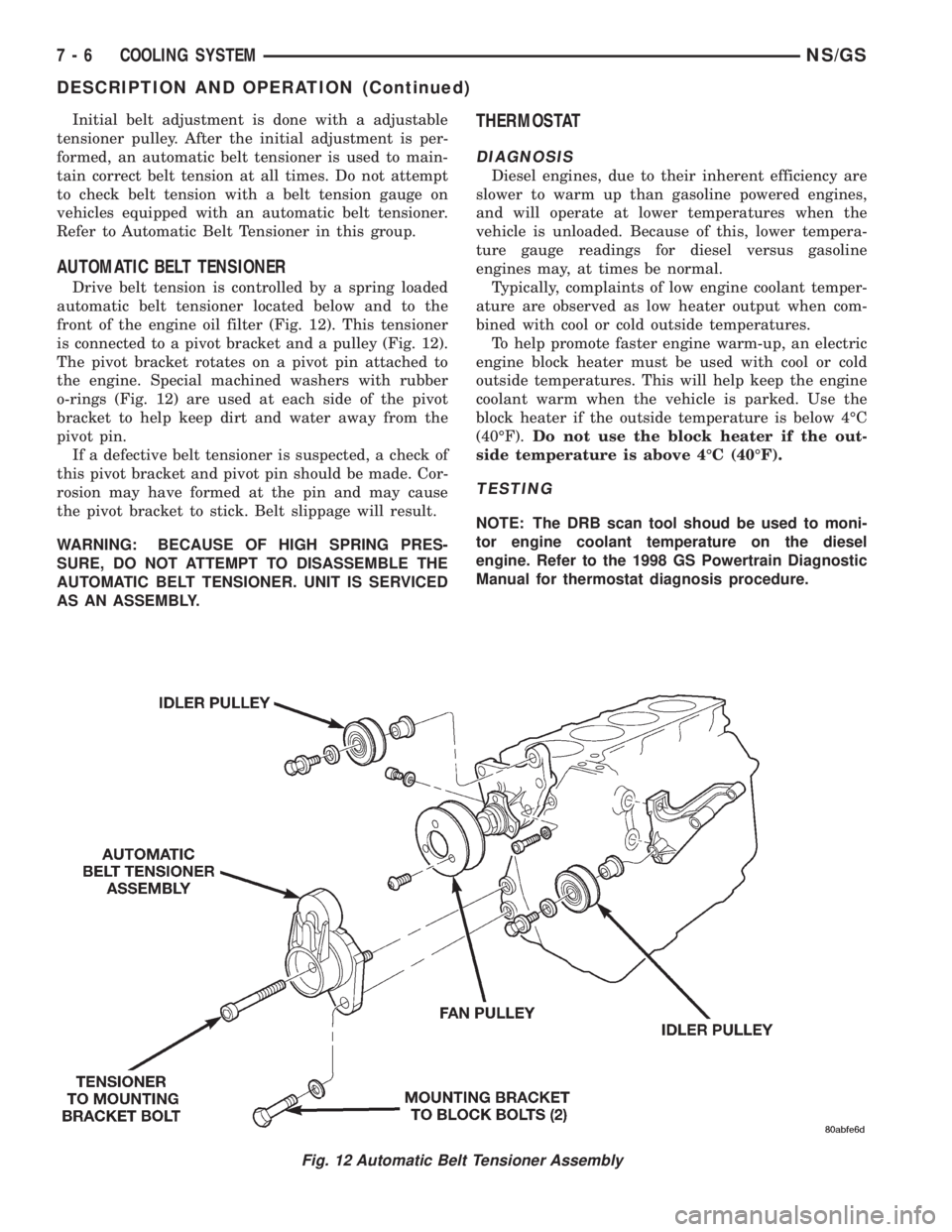

AUTOMATIC BELT TENSIONER

Drive belt tension is controlled by a spring loaded

automatic belt tensioner located below and to the

front of the engine oil filter (Fig. 12). This tensioner

is connected to a pivot bracket and a pulley (Fig. 12).

The pivot bracket rotates on a pivot pin attached to

the engine. Special machined washers with rubber

o-rings (Fig. 12) are used at each side of the pivot

bracket to help keep dirt and water away from the

pivot pin.

If a defective belt tensioner is suspected, a check of

this pivot bracket and pivot pin should be made. Cor-

rosion may have formed at the pin and may cause

the pivot bracket to stick. Belt slippage will result.

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE THE

AUTOMATIC BELT TENSIONER. UNIT IS SERVICED

AS AN ASSEMBLY.

THERMOSTAT

DIAGNOSIS

Diesel engines, due to their inherent efficiency are

slower to warm up than gasoline powered engines,

and will operate at lower temperatures when the

vehicle is unloaded. Because of this, lower tempera-

ture gauge readings for diesel versus gasoline

engines may, at times be normal.

Typically, complaints of low engine coolant temper-

ature are observed as low heater output when com-

bined with cool or cold outside temperatures.

To help promote faster engine warm-up, an electric

engine block heater must be used with cool or cold

outside temperatures. This will help keep the engine

coolant warm when the vehicle is parked. Use the

block heater if the outside temperature is below 4ÉC

(40ÉF).Do not use the block heater if the out-

side temperature is above 4ÉC (40ÉF).

TESTING

NOTE: The DRB scan tool shoud be used to moni-

tor engine coolant temperature on the diesel

engine. Refer to the 1998 GS Powertrain Diagnostic

Manual for thermostat diagnosis procedure.

Fig. 12 Automatic Belt Tensioner Assembly

7 - 6 COOLING SYSTEMNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 248 of 1938

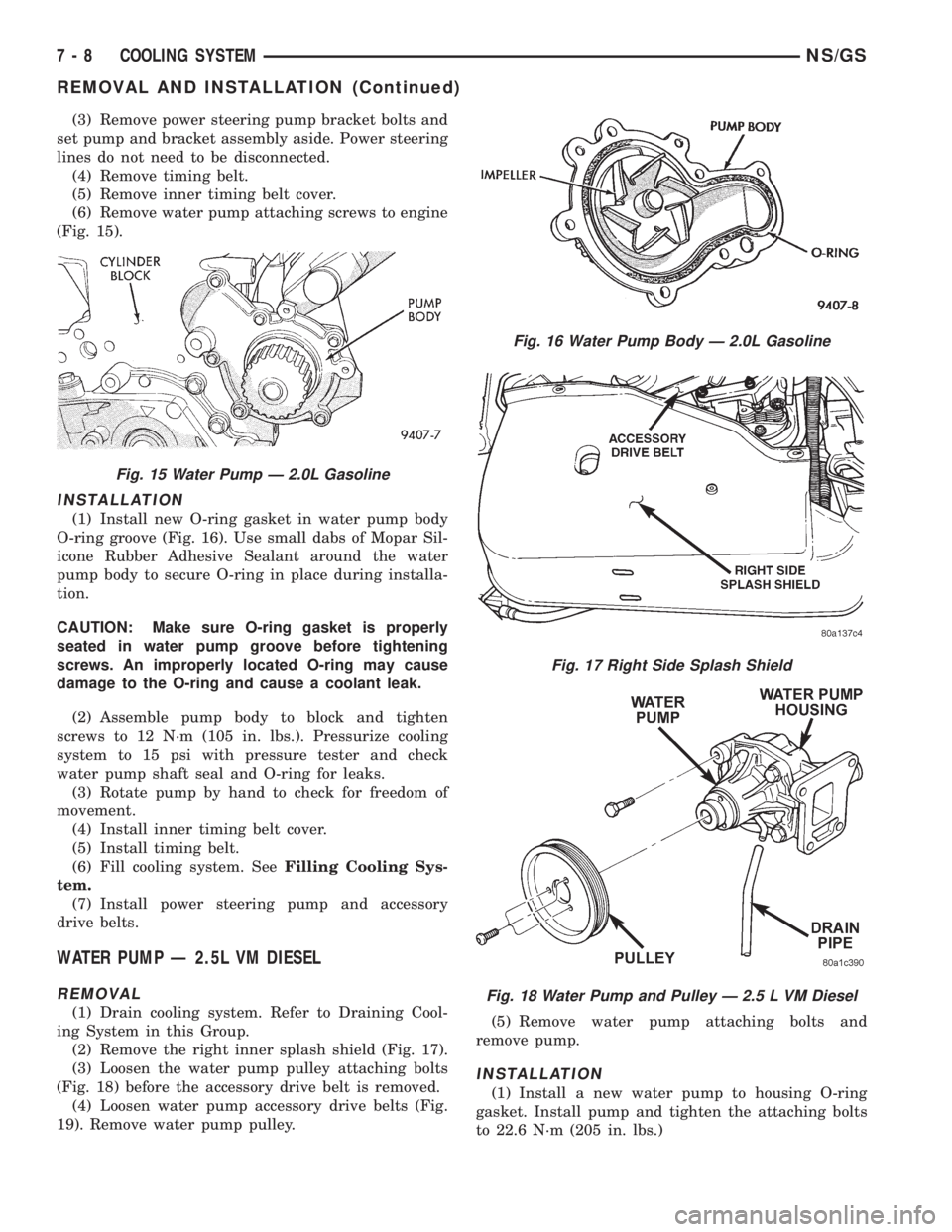

(3) Remove power steering pump bracket bolts and

set pump and bracket assembly aside. Power steering

lines do not need to be disconnected.

(4) Remove timing belt.

(5) Remove inner timing belt cover.

(6) Remove water pump attaching screws to engine

(Fig. 15).

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring groove (Fig. 16). Use small dabs of Mopar Sil-

icone Rubber Adhesive Sealant around the water

pump body to secure O-ring in place during installa-

tion.

CAUTION: Make sure O-ring gasket is properly

seated in water pump groove before tightening

screws. An improperly located O-ring may cause

damage to the O-ring and cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.). Pressurize cooling

system to 15 psi with pressure tester and check

water pump shaft seal and O-ring for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install inner timing belt cover.

(5) Install timing belt.

(6) Fill cooling system. SeeFilling Cooling Sys-

tem.

(7) Install power steering pump and accessory

drive belts.

WATER PUMP Ð 2.5L VM DIESEL

REMOVAL

(1) Drain cooling system. Refer to Draining Cool-

ing System in this Group.

(2) Remove the right inner splash shield (Fig. 17).

(3) Loosen the water pump pulley attaching bolts

(Fig. 18) before the accessory drive belt is removed.

(4) Loosen water pump accessory drive belts (Fig.

19). Remove water pump pulley.(5) Remove water pump attaching bolts and

remove pump.

INSTALLATION

(1) Install a new water pump to housing O-ring

gasket. Install pump and tighten the attaching bolts

to 22.6 N´m (205 in. lbs.)

Fig. 15 Water Pump Ð 2.0L Gasoline

Fig. 16 Water Pump Body Ð 2.0L Gasoline

Fig. 17 Right Side Splash Shield

Fig. 18 Water Pump and Pulley Ð 2.5 L VM Diesel

7 - 8 COOLING SYSTEMNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 255 of 1938

use. Refer to Causes of Battery Discharging in this

Group for more information.

NOTE: CLEAR COLOR = Replace Battery

WARNING: DO NOT CHARGE, ASSIST BOOST,

LOAD TEST, OR ADD WATER TO THE BATTERY

WHEN CLEAR COLOR DOT IS VISIBLE. PERSONAL

INJURY MAY OCCUR.

A clear color dot shows electrolyte level in battery

is below the test indicator (Fig. 1). Water cannot be

added to a maintenance free battery. The battery

must be replaced. A low electrolyte level may be

caused by an over charging condition. Refer to Gen-

erator Test Procedures on Vehicle.

CAUSES OF BATTERY DISCHARGING

It is normal to have a small 5 to 25 milliamperes

continuous electrical draw from the battery. This

draw will take place with the ignition in the OFF

position, and the courtesy, dome, storage compart-

ments, and engine compartment lights OFF. The con-

tinuous draw is due to various electronic features or

accessories that require electrical current with the

ignition OFF to function properly. When a vehicle is

not used over an extended period of approximately 20

days the IOD fuse should be pulled. The fuse is

located in the power distribution center. Disconnec-

tion of this fuse will reduce the level of battery dis-

charge. Refer to Battery Diagnosis and Testing table

and to the proper procedures.

ABNORMAL BATTERY DISCHARGING

²Corroded battery posts, cables or terminals.

²Loose or worn generator drive belt.

²Electrical loads that exceed the output of the

charging system due to equipment or accessories

installed after delivery.

²Slow driving speeds in heavy traffic conditions

or prolonged idling with high-amperage electrical

systems in use.²Defective electrical circuit or component causing

excess Ignition Off Draw (IOD). Refer to Battery

Ignition Off Draw (IOD).

²Defective charging system.

²Defective battery.

BATTERY IGNITION OFF DRAW (IOD)

High current draw on the battery with the ignition

OFF will discharge a battery. After a dead battery is

serviced the vehicle Ignition Off Draw (IOD) should

be checked. Determine if a high current draw condi-

tion exists first check the vehicle with a test lamp.

(1) Verify that all electrical accessories are OFF.

²Remove key from ignition switch

²Turn off all lights

²Liftgate and glove box door is closed

²Sun visor vanity lights are OFF

²All doors are closed

²Allow the Illuminated Entry System to time out

in approximately 30 seconds, if equipped.

²During Transmission Control Module (TCM)

power down there will be 500 milliamperes present

for 20 minutes. Afterwards less than 1.0 milliampere.

(2) Disconnect battery negative cable (Fig. 4).

CAUTION: Always disconnect the meter before

opening a door.

(3) Using an multimeter, that has least a milliam-

pere range of 200 mA. Set meter to the highest mA

range. Install meter between the battery negative

cable and battery negative post (Fig. 5). Carefully

remove the test lamp without disconnecting the

meter. After all modules time-out the total vehicle

IOD should be less than 25 milliamperes. If ignition

off draw is more than 25 milliamperes go to Step 4.

(4) Each time the test lamp or milliampere meter

is disconnected and connected, all electronic timer

functions will be activated for approximately one

minute. The Body Control Module (BCM) ignition off

draw can reach 90 milliamperes.

(5) Remove the PDC fuses:

²Interior lamps

²Brake lamp

²IOD

(6) If there is any reading, with fuses removed

there is a short circuit in the wiring. Refer to Group

8W, wiring diagrams. If reading is less than 25 mA

go to Step 8.

(7) Install all fuses. After installing fuse, the cur-

rent can reach 90 mA. After time-out the reading

should not exceed 25 mA. If OK go to. If not, discon-

nect:

²Radio

²Body Control Module

²Remote Keyless Entry Module

Fig. 3 Test Indicator

NSBATTERY 8A - 3

DIAGNOSIS AND TESTING (Continued)

Page 256 of 1938

(8) Disconnect one component at time, to see if any

component is at fault. If the high reading is not elim-

inated there is a short circuit in the wiring. Refer to

Group 8W, wiring diagrams.

(9) Remove interior and brake lamp fuses. Install

the fuses. The milliampere reading should be 2-4 mA.

If reading is higher than 4 mA:

(a) Disconnect PCM.

(b) If reading is OK, replace PCM.(c) If reading does not change, disconnect the

TCM.

(d) If reading is OK, replace TCM.

(e) If reading stays, there is a short circuit to

one of the modules. Refer to Group 8W, Wiring

Diagrams.

BATTERY LOAD TEST

A fully charged battery must have cranking capac-

ity, to provide the starter motor and ignition system

enough power to start the engine over a broad range

of ambient temperatures. A battery load test will ver-

ify the actual cranking capability of the battery.

WARNING: IF BATTERY SHOWS SIGNS OF FREEZ-

ING, LEAKING, LOOSE POSTS, OR EXCESSIVELY

LOW ELECTROLYTE LEVEL, DO NOT TEST. ACID

BURNS OR AN EXPLOSIVE CONDITION MAY

RESULT.

(1) Remove both battery cables, negative cable

first. The battery top, cables and posts should be

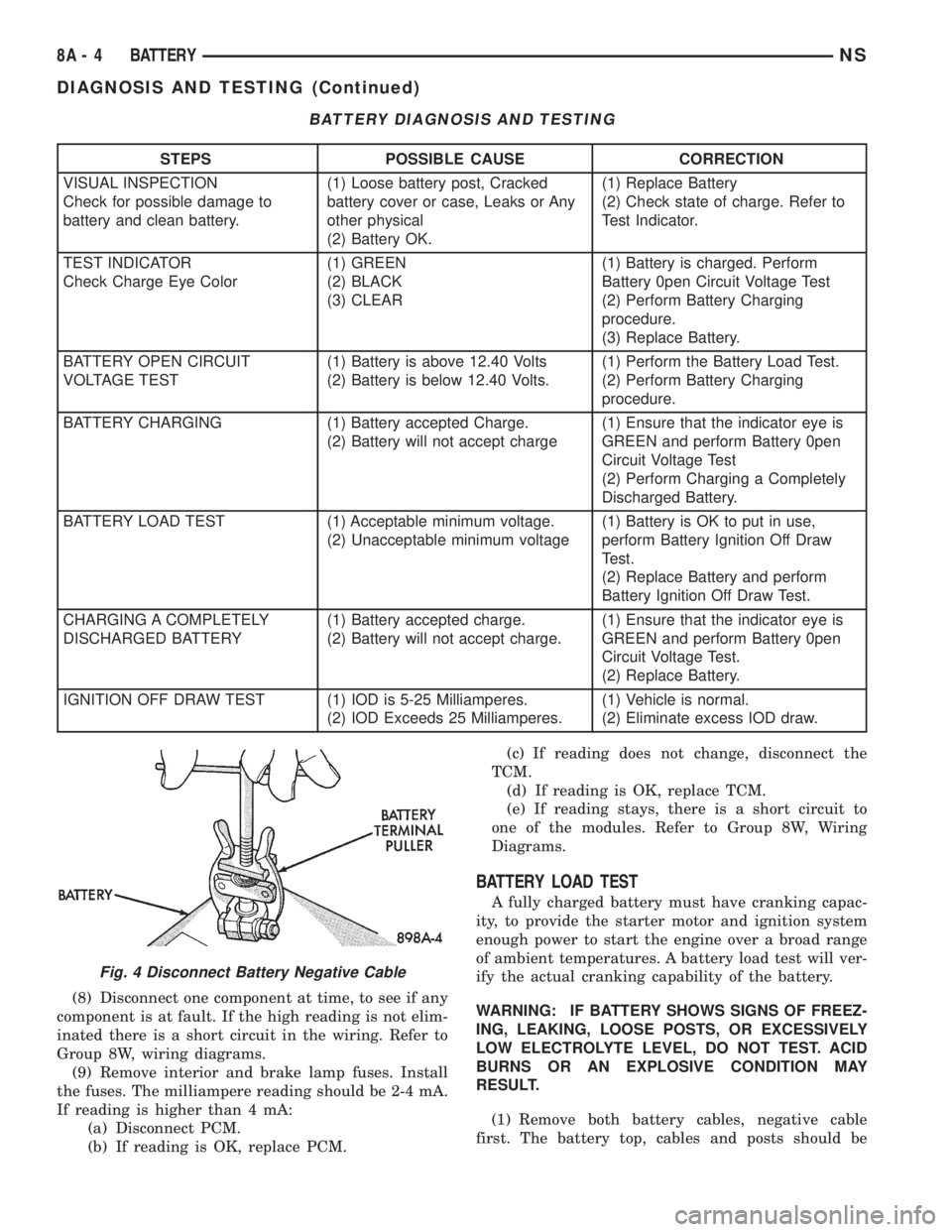

BATTERY DIAGNOSIS AND TESTING

STEPS POSSIBLE CAUSE CORRECTION

VISUAL INSPECTION

Check for possible damage to

battery and clean battery.(1) Loose battery post, Cracked

battery cover or case, Leaks or Any

other physical

(2) Battery OK.(1) Replace Battery

(2) Check state of charge. Refer to

Test Indicator.

TEST INDICATOR

Check Charge Eye Color(1) GREEN

(2) BLACK

(3) CLEAR(1) Battery is charged. Perform

Battery 0pen Circuit Voltage Test

(2) Perform Battery Charging

procedure.

(3) Replace Battery.

BATTERY OPEN CIRCUIT

VOLTAGE TEST(1) Battery is above 12.40 Volts

(2) Battery is below 12.40 Volts.(1) Perform the Battery Load Test.

(2) Perform Battery Charging

procedure.

BATTERY CHARGING (1) Battery accepted Charge.

(2) Battery will not accept charge(1) Ensure that the indicator eye is

GREEN and perform Battery 0pen

Circuit Voltage Test

(2) Perform Charging a Completely

Discharged Battery.

BATTERY LOAD TEST (1) Acceptable minimum voltage.

(2) Unacceptable minimum voltage(1) Battery is OK to put in use,

perform Battery Ignition Off Draw

Test.

(2) Replace Battery and perform

Battery Ignition Off Draw Test.

CHARGING A COMPLETELY

DISCHARGED BATTERY(1) Battery accepted charge.

(2) Battery will not accept charge.(1) Ensure that the indicator eye is

GREEN and perform Battery 0pen

Circuit Voltage Test.

(2) Replace Battery.

IGNITION OFF DRAW TEST (1) IOD is 5-25 Milliamperes.

(2) IOD Exceeds 25 Milliamperes.(1) Vehicle is normal.

(2) Eliminate excess IOD draw.

Fig. 4 Disconnect Battery Negative Cable

8A - 4 BATTERYNS

DIAGNOSIS AND TESTING (Continued)

Page 265 of 1938

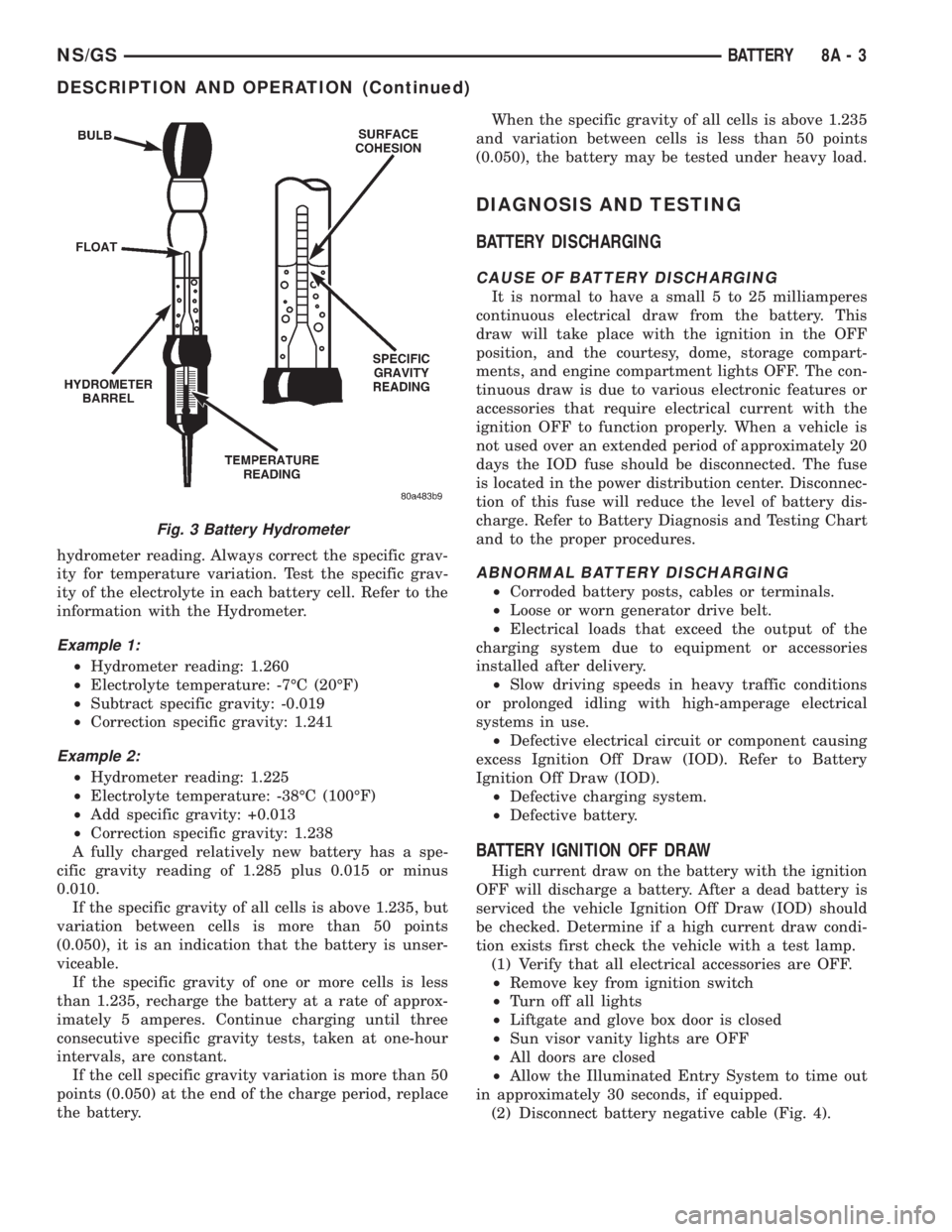

hydrometer reading. Always correct the specific grav-

ity for temperature variation. Test the specific grav-

ity of the electrolyte in each battery cell. Refer to the

information with the Hydrometer.

Example 1:

²Hydrometer reading: 1.260

²Electrolyte temperature: -7ÉC (20ÉF)

²Subtract specific gravity: -0.019

²Correction specific gravity: 1.241

Example 2:

²Hydrometer reading: 1.225

²Electrolyte temperature: -38ÉC (100ÉF)

²Add specific gravity: +0.013

²Correction specific gravity: 1.238

A fully charged relatively new battery has a spe-

cific gravity reading of 1.285 plus 0.015 or minus

0.010.

If the specific gravity of all cells is above 1.235, but

variation between cells is more than 50 points

(0.050), it is an indication that the battery is unser-

viceable.

If the specific gravity of one or more cells is less

than 1.235, recharge the battery at a rate of approx-

imately 5 amperes. Continue charging until three

consecutive specific gravity tests, taken at one-hour

intervals, are constant.

If the cell specific gravity variation is more than 50

points (0.050) at the end of the charge period, replace

the battery.When the specific gravity of all cells is above 1.235

and variation between cells is less than 50 points

(0.050), the battery may be tested under heavy load.

DIAGNOSIS AND TESTING

BATTERY DISCHARGING

CAUSE OF BATTERY DISCHARGING

It is normal to have a small 5 to 25 milliamperes

continuous electrical draw from the battery. This

draw will take place with the ignition in the OFF

position, and the courtesy, dome, storage compart-

ments, and engine compartment lights OFF. The con-

tinuous draw is due to various electronic features or

accessories that require electrical current with the

ignition OFF to function properly. When a vehicle is

not used over an extended period of approximately 20

days the IOD fuse should be disconnected. The fuse

is located in the power distribution center. Disconnec-

tion of this fuse will reduce the level of battery dis-

charge. Refer to Battery Diagnosis and Testing Chart

and to the proper procedures.

ABNORMAL BATTERY DISCHARGING

²Corroded battery posts, cables or terminals.

²Loose or worn generator drive belt.

²Electrical loads that exceed the output of the

charging system due to equipment or accessories

installed after delivery.

²Slow driving speeds in heavy traffic conditions

or prolonged idling with high-amperage electrical

systems in use.

²Defective electrical circuit or component causing

excess Ignition Off Draw (IOD). Refer to Battery

Ignition Off Draw (IOD).

²Defective charging system.

²Defective battery.

BATTERY IGNITION OFF DRAW

High current draw on the battery with the ignition

OFF will discharge a battery. After a dead battery is

serviced the vehicle Ignition Off Draw (IOD) should

be checked. Determine if a high current draw condi-

tion exists first check the vehicle with a test lamp.

(1) Verify that all electrical accessories are OFF.

²Remove key from ignition switch

²Turn off all lights

²Liftgate and glove box door is closed

²Sun visor vanity lights are OFF

²All doors are closed

²Allow the Illuminated Entry System to time out

in approximately 30 seconds, if equipped.

(2) Disconnect battery negative cable (Fig. 4).

Fig. 3 Battery Hydrometer

NS/GSBATTERY 8A - 3

DESCRIPTION AND OPERATION (Continued)