check engine CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 30 of 1938

²Check glow plug operation.

²Replace drive belt.

²Check engine smoke.

²Replace engine coolant.

35 000 KM

²Change engine oil.

²Change engine oil filter.

²Change MTX Fluid

40 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Diesel engines onlyÐReplace fuel filter/water

separator element.

45 000 KM

²Change engine oil.

²Change engine oil filter.

50 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

55 000 KM

²Change engine oil.

²Change engine oil filter.

60 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Diesel engines onlyÐReplace fuel filter/water

separator element.

65 000 KM

²Change engine oil.

²Change engine oil filter.

70 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Change MTX fluid

75 000 KM

²Change engine oil.

²Change engine oil filter.

80 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check glow plug operation.

²Replace drive belt.

²Check engine smoke.

²Replace engine coolant.

85 000 KM

²Change engine oil.

²Change engine oil filter.

90 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

95 000 KM

²Change engine oil.

²Change engine oil filter.

100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Diesel engines onlyÐReplace fuel filter/water

separator element.

²Change MTX fluid

EVERY 5 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

EVERY 10 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

EVERY 20 000 KM AFTER 100 000 KM

²Diesel engines onlyÐReplace fuel filter/water

separator element.

EVERY 35 000 KM AFTER 100 000 KM

²Change MTX fluid

0 - 4 LUBRICATION AND MAINTENANCENS/GS

GENERAL INFORMATION (Continued)

Page 35 of 1938

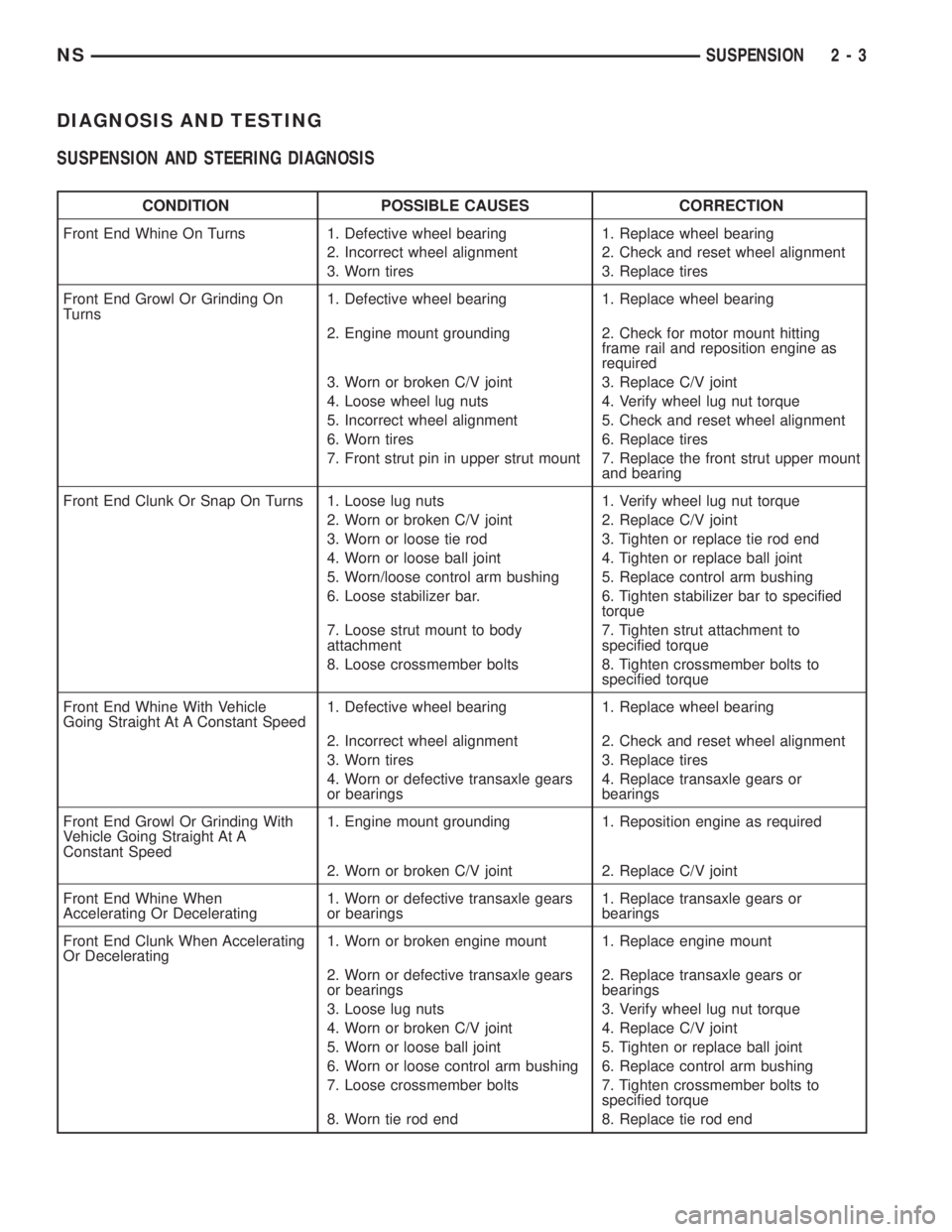

DIAGNOSIS AND TESTING

SUSPENSION AND STEERING DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

Front End Whine On Turns 1. Defective wheel bearing 1. Replace wheel bearing

2. Incorrect wheel alignment 2. Check and reset wheel alignment

3. Worn tires 3. Replace tires

Front End Growl Or Grinding On

Turns1. Defective wheel bearing 1. Replace wheel bearing

2. Engine mount grounding 2. Check for motor mount hitting

frame rail and reposition engine as

required

3. Worn or broken C/V joint 3. Replace C/V joint

4. Loose wheel lug nuts 4. Verify wheel lug nut torque

5. Incorrect wheel alignment 5. Check and reset wheel alignment

6. Worn tires 6. Replace tires

7. Front strut pin in upper strut mount 7. Replace the front strut upper mount

and bearing

Front End Clunk Or Snap On Turns 1. Loose lug nuts 1. Verify wheel lug nut torque

2. Worn or broken C/V joint 2. Replace C/V joint

3. Worn or loose tie rod 3. Tighten or replace tie rod end

4. Worn or loose ball joint 4. Tighten or replace ball joint

5. Worn/loose control arm bushing 5. Replace control arm bushing

6. Loose stabilizer bar. 6. Tighten stabilizer bar to specified

torque

7. Loose strut mount to body

attachment7. Tighten strut attachment to

specified torque

8. Loose crossmember bolts 8. Tighten crossmember bolts to

specified torque

Front End Whine With Vehicle

Going Straight At A Constant Speed1. Defective wheel bearing 1. Replace wheel bearing

2. Incorrect wheel alignment 2. Check and reset wheel alignment

3. Worn tires 3. Replace tires

4. Worn or defective transaxle gears

or bearings4. Replace transaxle gears or

bearings

Front End Growl Or Grinding With

Vehicle Going Straight At A

Constant Speed1. Engine mount grounding 1. Reposition engine as required

2. Worn or broken C/V joint 2. Replace C/V joint

Front End Whine When

Accelerating Or Decelerating1. Worn or defective transaxle gears

or bearings1. Replace transaxle gears or

bearings

Front End Clunk When Accelerating

Or Decelerating1. Worn or broken engine mount 1. Replace engine mount

2. Worn or defective transaxle gears

or bearings2. Replace transaxle gears or

bearings

3. Loose lug nuts 3. Verify wheel lug nut torque

4. Worn or broken C/V joint 4. Replace C/V joint

5. Worn or loose ball joint 5. Tighten or replace ball joint

6. Worn or loose control arm bushing 6. Replace control arm bushing

7. Loose crossmember bolts 7. Tighten crossmember bolts to

specified torque

8. Worn tie rod end 8. Replace tie rod end

NSSUSPENSION 2 - 3

Page 85 of 1938

BASE BRAKE SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

CHASSIS TUBES AND HOSES.............. 7

FRONT DISC BRAKE SYSTEM.............. 4

HUB/BEARING REAR WHEEL............... 9

MASTER CYLINDER...................... 7

PARKING BRAKE SYSTEM OPERATION....... 5

POWER BRAKE VACUUM BOOSTER

OPERATION........................... 8

PROPORTIONING VALVES................. 5

REAR DISC BRAKES...................... 5

REAR DRUM BRAKES..................... 5

RED BRAKE WARNING LAMP OPERATION..... 8

STOP LAMP SWITCH...................... 9

DIAGNOSIS AND TESTING

ADJUSTER REAR DRUM BRAKE

(AUTOMATIC)......................... 14

BRAKE FLUID CONTAMINATION............ 19

BRAKE ROTOR......................... 14

BRAKE SYSTEM BASIC DIAGNOSIS GUIDE.... 9

BRAKE SYSTEM DIAGNOSIS CHARTS....... 10

PROPORTIONING VALVES................ 16

RED BRAKE WARNING LAMP TEST......... 19

STOP LAMP SWITCH TEST PROCEDURE..... 19

TRACTION CONTROL LAMP TEST.......... 19

SERVICE PROCEDURES

BLEEDING BASE BRAKE

HYDRAULIC SYSTEM................... 20

BRAKE DRUM MACHINING................ 24

BRAKE TUBE REPAIR PROCEDURE......... 24

MASTER CYLINDER BLEEDING

PROCEDURE......................... 22

MASTER CYLINDER FLUID LEVEL CHECK.... 20

PARK BRAKE AUTO ADJUSTER

MECHANISM RELEASE................. 26

ROTOR MACHINING (FRONT/REAR)......... 22

REMOVAL AND INSTALLATION

BRAKE SUPPORT PLATE (REAR DRUM

BRAKES)............................ 37

FRONT DISC BRAKE CALIPER............. 27

FRONT DISC BRAKE PADS................ 30

FRONT PARK BRAKE CABLE.............. 65

HUB/BEARING.......................... 40

HYDRAULIC BRAKE TUBES AND HOSES..... 58

INTERMEDIATE PARK BRAKE CABLE....... 66

JUNCTION BLOCK....................... 55

LEFT REAR PARK BRAKE CABLE........... 67

MASTER CYLINDER..................... 44

PARK BRAKE PEDAL MECHANISM.......... 58PARK BRAKE SHOES (WITH REAR DISC

BRAKES)............................ 60

PROPORTIONING VALVE (W/ABS BRAKES) . . . 56

PROPORTIONING VALVE

(W/O ABS BRAKES).................... 57

REAR BRAKE DRUM..................... 33

REAR BRAKE WHEEL CYLINDER........... 39

REAR DISC BRAKE CALIPER.............. 28

REAR DISC BRAKE SHOES................ 31

REAR DRUM BRAKE SHOES............... 34

RIGHT REAR PARK BRAKE CABLE......... 66

STOP LAMP SWITCH..................... 69

VACUUM BOOSTER 2.4 LITER ENGINE...... 47

VACUUM BOOSTER 3.0 LITER ENGINE...... 49

VACUUM BOOSTER 3.3/3.8 LITER ENGINE.... 52

WHEEL AND TIRE INSTALLATION........... 27

DISASSEMBLY AND ASSEMBLY

FRONT DISC BRAKE CALIPER............. 71

MASTER CYLINDER BRAKE FLUID LEVEL

SWITCH............................. 71

MASTER CYLINDER FLUID RESERVOIR

FILL TUBE............................ 71

MASTER CYLINDER FLUID RESERVOIR...... 70

MASTER CYLINDER TO POWER BRAKE

BOOSTER VACUUM SEAL............... 69

WHEEL CYLINDER REAR DRUM BRAKE...... 76

CLEANING AND INSPECTION

BRAKE HOSE AND BRAKE LINES

INSPECTION.......................... 78

FRONT DISC BRAKE PAD LINING

INSPECTION.......................... 76

REAR DISC BRAKES..................... 76

REAR DRUM BRAKE SHOE LINING

INSPECTION.......................... 77

REAR DRUM BRAKE WHEEL CYLINDER...... 78

REAR WHEEL HUB AND BEARING

ASSEMBLY........................... 78

ADJUSTMENTS

PARK BRAKE CABLE ADJUSTMENT......... 81

PARK BRAKE SHOES (WITH REAR DISC

BRAKES)............................ 79

PROPORTIONING VALVE

(HEIGHT SENSING).................... 81

REAR DRUM BRAKE SHOE ADJUSTMENT.... 79

STOP LAMP SWITCH..................... 78

SPECIFICATIONS

BRAKE ACTUATION SYSTEM.............. 83

BRAKE FASTENER TORQUE

SPECIFICATIONS...................... 83

NSBRAKES 5 - 3

Page 90 of 1938

brakes. The secondary outlet port supplies hydraulic

pressure to the left front and right rear brakes.

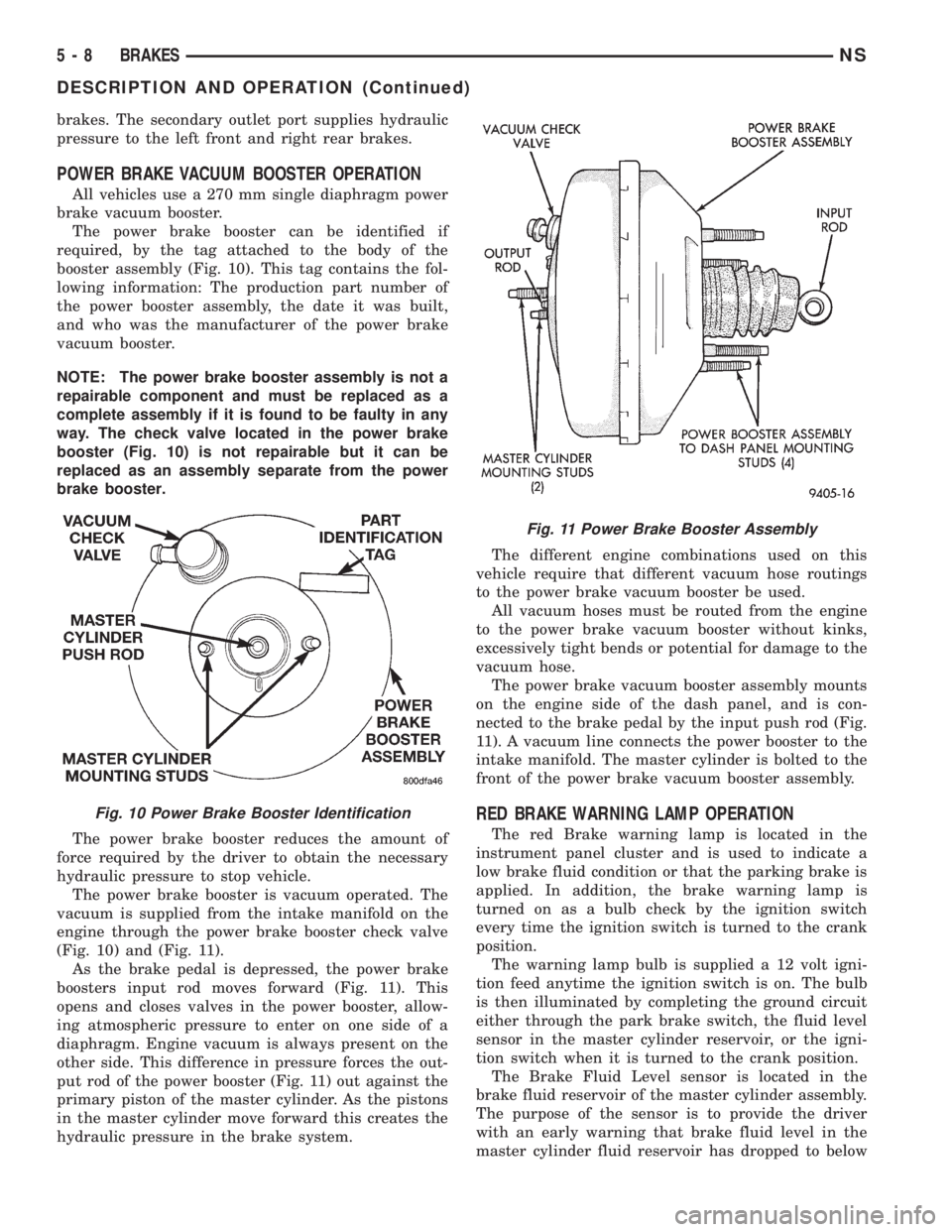

POWER BRAKE VACUUM BOOSTER OPERATION

All vehicles use a 270 mm single diaphragm power

brake vacuum booster.

The power brake booster can be identified if

required, by the tag attached to the body of the

booster assembly (Fig. 10). This tag contains the fol-

lowing information: The production part number of

the power booster assembly, the date it was built,

and who was the manufacturer of the power brake

vacuum booster.

NOTE: The power brake booster assembly is not a

repairable component and must be replaced as a

complete assembly if it is found to be faulty in any

way. The check valve located in the power brake

booster (Fig. 10) is not repairable but it can be

replaced as an assembly separate from the power

brake booster.

The power brake booster reduces the amount of

force required by the driver to obtain the necessary

hydraulic pressure to stop vehicle.

The power brake booster is vacuum operated. The

vacuum is supplied from the intake manifold on the

engine through the power brake booster check valve

(Fig. 10) and (Fig. 11).

As the brake pedal is depressed, the power brake

boosters input rod moves forward (Fig. 11). This

opens and closes valves in the power booster, allow-

ing atmospheric pressure to enter on one side of a

diaphragm. Engine vacuum is always present on the

other side. This difference in pressure forces the out-

put rod of the power booster (Fig. 11) out against the

primary piston of the master cylinder. As the pistons

in the master cylinder move forward this creates the

hydraulic pressure in the brake system.The different engine combinations used on this

vehicle require that different vacuum hose routings

to the power brake vacuum booster be used.

All vacuum hoses must be routed from the engine

to the power brake vacuum booster without kinks,

excessively tight bends or potential for damage to the

vacuum hose.

The power brake vacuum booster assembly mounts

on the engine side of the dash panel, and is con-

nected to the brake pedal by the input push rod (Fig.

11). A vacuum line connects the power booster to the

intake manifold. The master cylinder is bolted to the

front of the power brake vacuum booster assembly.

RED BRAKE WARNING LAMP OPERATION

The red Brake warning lamp is located in the

instrument panel cluster and is used to indicate a

low brake fluid condition or that the parking brake is

applied. In addition, the brake warning lamp is

turned on as a bulb check by the ignition switch

every time the ignition switch is turned to the crank

position.

The warning lamp bulb is supplied a 12 volt igni-

tion feed anytime the ignition switch is on. The bulb

is then illuminated by completing the ground circuit

either through the park brake switch, the fluid level

sensor in the master cylinder reservoir, or the igni-

tion switch when it is turned to the crank position.

The Brake Fluid Level sensor is located in the

brake fluid reservoir of the master cylinder assembly.

The purpose of the sensor is to provide the driver

with an early warning that brake fluid level in the

master cylinder fluid reservoir has dropped to below

Fig. 10 Power Brake Booster Identification

Fig. 11 Power Brake Booster Assembly

5 - 8 BRAKESNS

DESCRIPTION AND OPERATION (Continued)

Page 91 of 1938

normal. This may indicate:(1)Abnormal loss of

brake fluid in the master cylinder fluid reservoir

resulting from a leak in the hydraulic system.(2)

Brake shoe linings which have worn to a point

requiring replacement.

As the brake fluid drops below the minimum level,

the brake fluid level sensor closes to ground the

brake warning light circuit. This will turn on the red

brake warning light. At this time, master cylinder

fluid reservoir should be checked and filled to the full

mark with DOT 3 brake fluid.If brake fluid level

has dropped below the add line in the master

cylinder fluid reservoir, the entire brake

hydraulic system should be checked for evi-

dence of a leak.

STOP LAMP SWITCH

The stop lamp switch controls operation of the

vehicles stop lamps. Also, if the vehicle is equippedwith speed control, the stop lamp switch will deacti-

vate speed control when the brake pedal is

depressed.

The stop lamp switch controls operation of the

right and left tail, stop and turn signal lamp and

CHMSL lamp, by supplying battery current to these

lamps.

The stop lamp switch controls the lamp operation

by opening and closing the electrical circuit to the

stop lamps.

HUB/BEARING REAR WHEEL

The rear hub and bearing assembly used on this

vehicle is serviceable only as a complete assembly. No

attempt should be made to disassemble a rear hub

and bearing assembly in an effort to repair it.

The rear hub and bearing assembly is attached to

the rear axle using 4 mounting bolts that are remov-

able from the back of the rear hub/bearing.

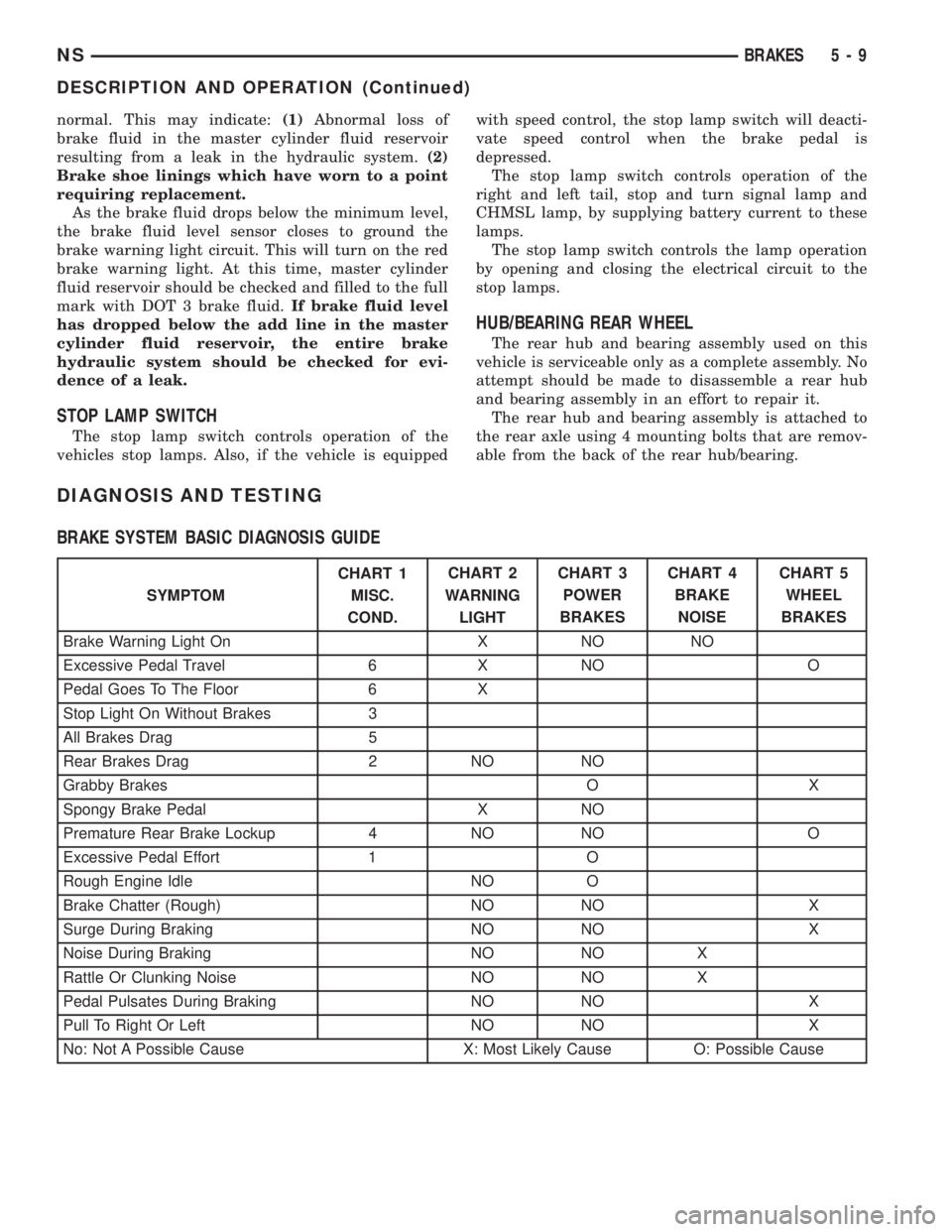

DIAGNOSIS AND TESTING

BRAKE SYSTEM BASIC DIAGNOSIS GUIDE

SYMPTOMCHART 1

MISC.

COND.CHART 2

WARNING

LIGHTCHART 3

POWER

BRAKESCHART 4

BRAKE

NOISECHART 5

WHEEL

BRAKES

Brake Warning Light On X NO NO

Excessive Pedal Travel 6 X NO O

Pedal Goes To The Floor 6 X

Stop Light On Without Brakes 3

All Brakes Drag 5

Rear Brakes Drag 2 NO NO

Grabby Brakes O X

Spongy Brake Pedal X NO

Premature Rear Brake Lockup 4 NO NO O

Excessive Pedal Effort 1 O

Rough Engine Idle NO O

Brake Chatter (Rough) NO NO X

Surge During Braking NO NO X

Noise During Braking NO NO X

Rattle Or Clunking Noise NO NO X

Pedal Pulsates During Braking NO NO X

Pull To Right Or Left NO NO X

No: Not A Possible Cause X: Most Likely Cause O: Possible Cause

NSBRAKES 5 - 9

DESCRIPTION AND OPERATION (Continued)

Page 102 of 1938

SERVICE PROCEDURES

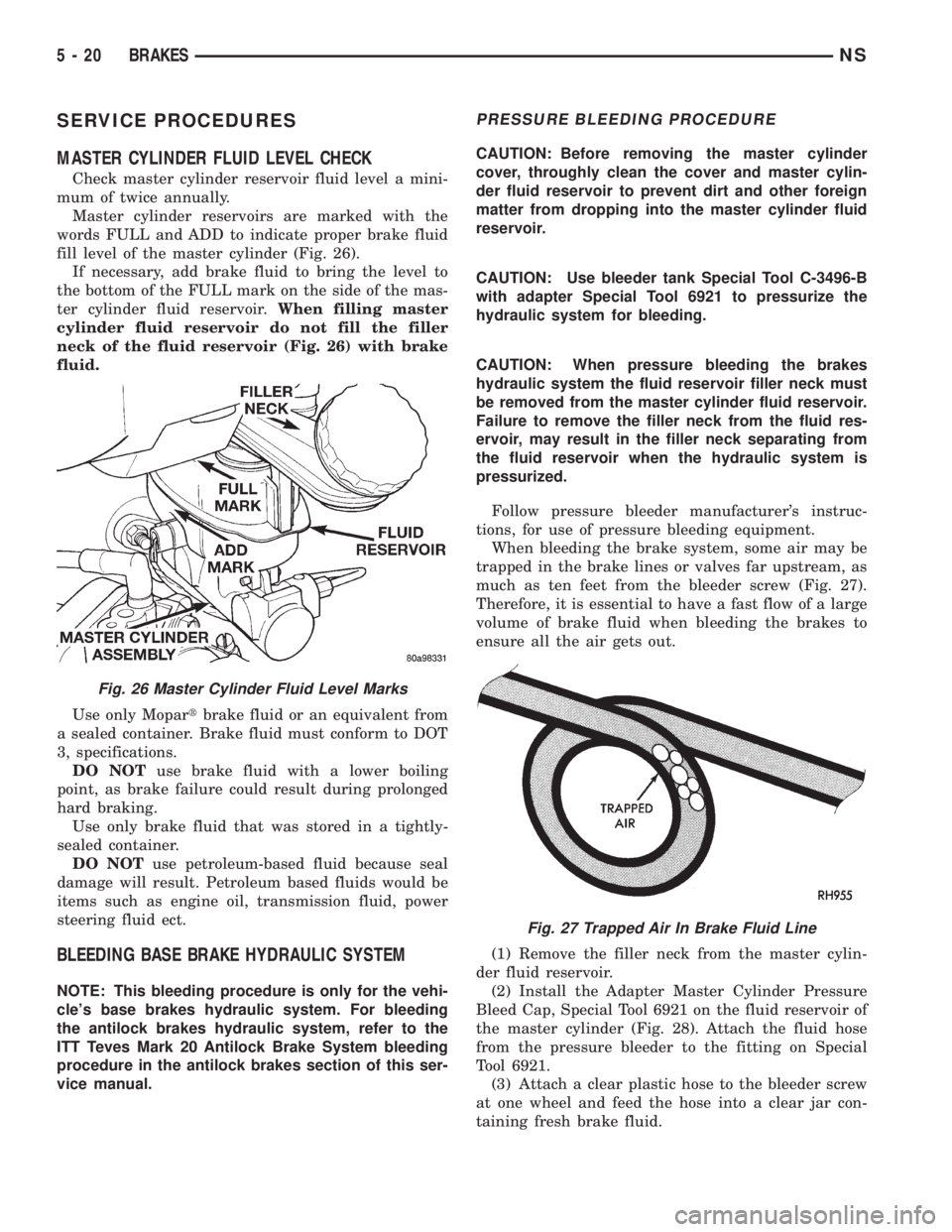

MASTER CYLINDER FLUID LEVEL CHECK

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

Master cylinder reservoirs are marked with the

words FULL and ADD to indicate proper brake fluid

fill level of the master cylinder (Fig. 26).

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.When filling master

cylinder fluid reservoir do not fill the filler

neck of the fluid reservoir (Fig. 26) with brake

fluid.

Use only Mopartbrake fluid or an equivalent from

a sealed container. Brake fluid must conform to DOT

3, specifications.

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid ect.

BLEEDING BASE BRAKE HYDRAULIC SYSTEM

NOTE: This bleeding procedure is only for the vehi-

cle's base brakes hydraulic system. For bleeding

the antilock brakes hydraulic system, refer to the

ITT Teves Mark 20 Antilock Brake System bleeding

procedure in the antilock brakes section of this ser-

vice manual.

PRESSURE BLEEDING PROCEDURE

CAUTION: Before removing the master cylinder

cover, throughly clean the cover and master cylin-

der fluid reservoir to prevent dirt and other foreign

matter from dropping into the master cylinder fluid

reservoir.

CAUTION: Use bleeder tank Special Tool C-3496-B

with adapter Special Tool 6921 to pressurize the

hydraulic system for bleeding.

CAUTION: When pressure bleeding the brakes

hydraulic system the fluid reservoir filler neck must

be removed from the master cylinder fluid reservoir.

Failure to remove the filler neck from the fluid res-

ervoir, may result in the filler neck separating from

the fluid reservoir when the hydraulic system is

pressurized.

Follow pressure bleeder manufacturer's instruc-

tions, for use of pressure bleeding equipment.

When bleeding the brake system, some air may be

trapped in the brake lines or valves far upstream, as

much as ten feet from the bleeder screw (Fig. 27).

Therefore, it is essential to have a fast flow of a large

volume of brake fluid when bleeding the brakes to

ensure all the air gets out.

(1) Remove the filler neck from the master cylin-

der fluid reservoir.

(2) Install the Adapter Master Cylinder Pressure

Bleed Cap, Special Tool 6921 on the fluid reservoir of

the master cylinder (Fig. 28). Attach the fluid hose

from the pressure bleeder to the fitting on Special

Tool 6921.

(3) Attach a clear plastic hose to the bleeder screw

at one wheel and feed the hose into a clear jar con-

taining fresh brake fluid.

Fig. 26 Master Cylinder Fluid Level Marks

Fig. 27 Trapped Air In Brake Fluid Line

5 - 20 BRAKESNS

Page 131 of 1938

(7) Install aNEWvacuum seal on mounting flange

of master cylinder (Fig. 110).

(8) Position master cylinder on studs of vacuum

booster aligning push rod on vacuum booster with

master cylinder piston.

(9) Install the 2 nuts (Fig. 107) mounting the mas-

ter cylinder to the vacuum booster. Tighten the

mounting nuts to a torque of 25 N´m (225 in. lbs.).

(10) Install the wiper module drain hose (Fig. 107)

on the wiper module. Install the tie strap attaching

the wiper module drain hose to the brake tube at the

master cylinder.Tie strap should be loosely tight-

ened so as not to collapse the wiper module

drain hose.

(11) Install the wiring harness connector on the

brake fluid level sensor in the master cylinder fluid

reservoir (Fig. 106).

(12) Install the battery tray in the vehicle. Install

the 2 bolts and the nut (Fig. 105) attaching the bat-

tery tray. Tighten the 2 bolts and the nut to a torque

of 14 N´m (125 in lbs.).(13) If vehicle is equipped with speed control,

install the speed control servo and bracket on the

battery tray. Install and securely tighten bolt attach-

ing bracket to battery tray.

(14) If vehicle is equipped with speed control,

install the wiring harness connector on the speed

control servo. Then connect the vacuum lines onto

the speed control servo and vacuum reservoir on bat-

tery tray.

(15) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing (Fig. 104). Securely tighten the hose clamp at the

air cleaner housing and throttle body.

(16) Install the battery and the battery thermal

guard.

(17) Install the battery cables on the battery.

(18) Check the operation of the stop lamp switch

and adjust if necessary.

VACUUM BOOSTER 3.0 LITER ENGINE

REMOVE

CAUTION: Stored vacuum in the vacuum booster

must be pumped down (removed) before removing

master cylinder from power brake booster. This is

necessary to prevent the power brake booster from

sucking in any contamination as the master cylin-

der is removed. This can be done simply by pump-

ing the brake pedal, with the vehicle's engine not

running, until a firm feeling brake pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes).

(2) Remove both battery cables from battery.

(3) Remove the battery thermal guard and the bat-

tery from the battery tray.

(4) Remove the air inlet resonator and hoses as an

assembly from the throttle body and air cleaner

housing (Fig. 111)

(5) If vehicle is equipped with speed control,

unplug wiring harness connector from the speed con-

trol servo. Then disconnect vacuum lines from the

speed control servo and vacuum reservoir on battery

tray.

(6) Remove bolt attaching the speed control servo

bracket to the battery tray. Slide the bracket forward

to unhook it from the battery tray and remove.

(7) Remove the 2 bolts and the nut (Fig. 112)

attaching the battery tray to the body of the vehicle.

(8) Remove wiring harness connector from brake

fluid level sensor in master cylinder fluid reservoir

(Fig. 113).

(9) Clean the area where the master cylinder

assembly attaches to the power brake booster. Use

only a solvent such as Mopar Brake Parts Cleaner or

an equivalent.

Fig. 109 Retaining Clip Installed On Brake Pedal Pin

Fig. 110 Vacuum Seal Installed On Master Cylinder

NSBRAKES 5 - 49

REMOVAL AND INSTALLATION (Continued)

Page 134 of 1938

(11) Install the wiring harness connector on the

brake fluid level sensor in the master cylinder fluid

reservoir (Fig. 113).

(12) Install the battery tray in the vehicle. Install

the 2 bolts and the nut (Fig. 112) attaching the bat-

tery tray to the vehicle. Tighten the 2 bolts and the

nut to a torque of 14 N´m (125 in lbs.).

(13) If vehicle is equipped with speed control,

install the speed control servo and bracket on the

battery tray. Install and securely tighten bolt attach-

ing bracket to battery tray.

(14) If vehicle is equipped with speed control,

install the wiring harness connector on the speed

control servo. Then connect the vacuum lines onto

the speed control servo and vacuum reservoir on bat-

tery tray.

(15) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing (Fig. 111). Securely tighten the hose clamp at the

air cleaner housing and throttle body.

(16) Install the battery and the battery thermal

guard.

(17) Install the battery cables on the battery.

(18) Check the operation of the stop lamp switch

and adjust if necessary.

VACUUM BOOSTER 3.3/3.8 LITER ENGINE

REMOVE

CAUTION: Reserve vacuum in the vacuum booster

must be pumped down (removed) before removing

master cylinder from vacuum booster. This is nec-

essary to prevent the vacuum booster from sucking

in any contamination as the master cylinder is

removed. This can be done simply by pumping the

brake pedal, with the vehicle's engine not running,

until a firm feeling brake pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes).

(2) Remove both battery cables from battery.

(3) Remove the battery thermal guard and the bat-

tery from the battery tray.

(4) Remove the air inlet resonator and hoses as an

assembly from the throttle body and air cleaner

housing (Fig. 118)

(5) If vehicle is equipped with speed control,

unplug wiring harness connector from the speed con-

trol servo. Then disconnect vacuum lines from the

speed control servo and vacuum reservoir on battery

tray.

(6) Remove bolt attaching the speed control servo

bracket to the battery tray. Slide the bracket forward

to unhook it from the battery tray and remove.

(7) Remove the 2 bolts and the nut (Fig. 119)

attaching the battery tray to the body of the vehicle.(8) Remove the wiring harness connector (Fig. 120)

from the EGR valve transducer.

(9) Remove wiring harness connectors from throt-

tle position sensor and AIS motor on throttle body

(Fig. 121).

(10) Remove the 2 bolts (Fig. 122) attaching the

throttle body to the intake manifold and the clip (Fig.

122) attaching the wiring harness to the throttle

cable bracket. Then remove the throttle body and

throttle cable bracket as an assembly from the intake

manifold.

(11) Remove wiring harness connector from brake

fluid level sensor in master cylinder fluid reservoir

(Fig. 123).

(12) Clean the area where the master cylinder

assembly attaches to the power brake booster. Use

Fig. 118 Air Inlet Resonator

Fig. 119 Battery Tray Mounting Locations

5 - 52 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 160 of 1938

REAR DRUM BRAKE WHEEL CYLINDER

With brake drums removed, inspect the wheel cyl-

inder boots for evidence of a brake fluid leak. Visu-

ally check the boots for cuts, tears, or heat cracks. If

any of these conditions exist, the wheel cylinders

should be completely cleaned, inspected and new

parts installed.

If a wheel cylinder is leaking and the brake lining

material is saturated with brake fluid, the brake

shoes must be replaced.

BRAKE HOSE AND BRAKE LINES INSPECTION

Flexible rubber hose is used at both front brakes

and at the rear axle. Inspection of brake hoses

should be performed whenever the brake system is

serviced and every 7,500 miles or 12 months, which-

ever comes first (every engine oil change). Inspect

hydraulic brake hoses for surface cracking, scuffing,

or worn spots. If the fabric casing of the rubber hose

becomes exposed due to cracks or abrasions in the

rubber hose cover, the hose should be replaced imme-

diately. Eventual deterioration of the hose can take

place with possible burst failure. Faulty installation

can cause twisting, resulting in wheel, tire, or chassis

interference.

The steel brake tubing should be inspected period-

ically for evidence of physical damage or contact with

moving or hot components.

The flexible brake tube sections used on this vehi-

cle in the primary and secondary tubes from the

master cylinder to the ABS hydraulic control unit

connections and the chassis brake tubes between the

hydraulic control unit and the proportioning valve

must also be inspected. This flexible tubing must be

inspected for kinks, fraying and its contact with

other components of the vehicle or contact with the

body of the vehicle.

REAR WHEEL HUB AND BEARING ASSEMBLY

The rear hub and bearing assembly is designed for

the life of the vehicle and should require no mainte-

nance. The following procedure may be used for eval-

uation of bearing condition.

With wheel and brake drum removed, rotate

flanged outer ring of hub. Excessive roughness, lat-

eral play or resistance to rotation may indicate dirt

intrusion or bearing failure. If the rear wheel bear-

ings exhibit these conditions during inspection, the

hub and bearing assembly should be replaced.

Damaged bearing seals and resulting excessive

grease loss may also require bearing replacement.

Moderate grease loss from bearing is considered nor-

mal and should not require replacement of the hub

and bearing assembly.

ADJUSTMENTS

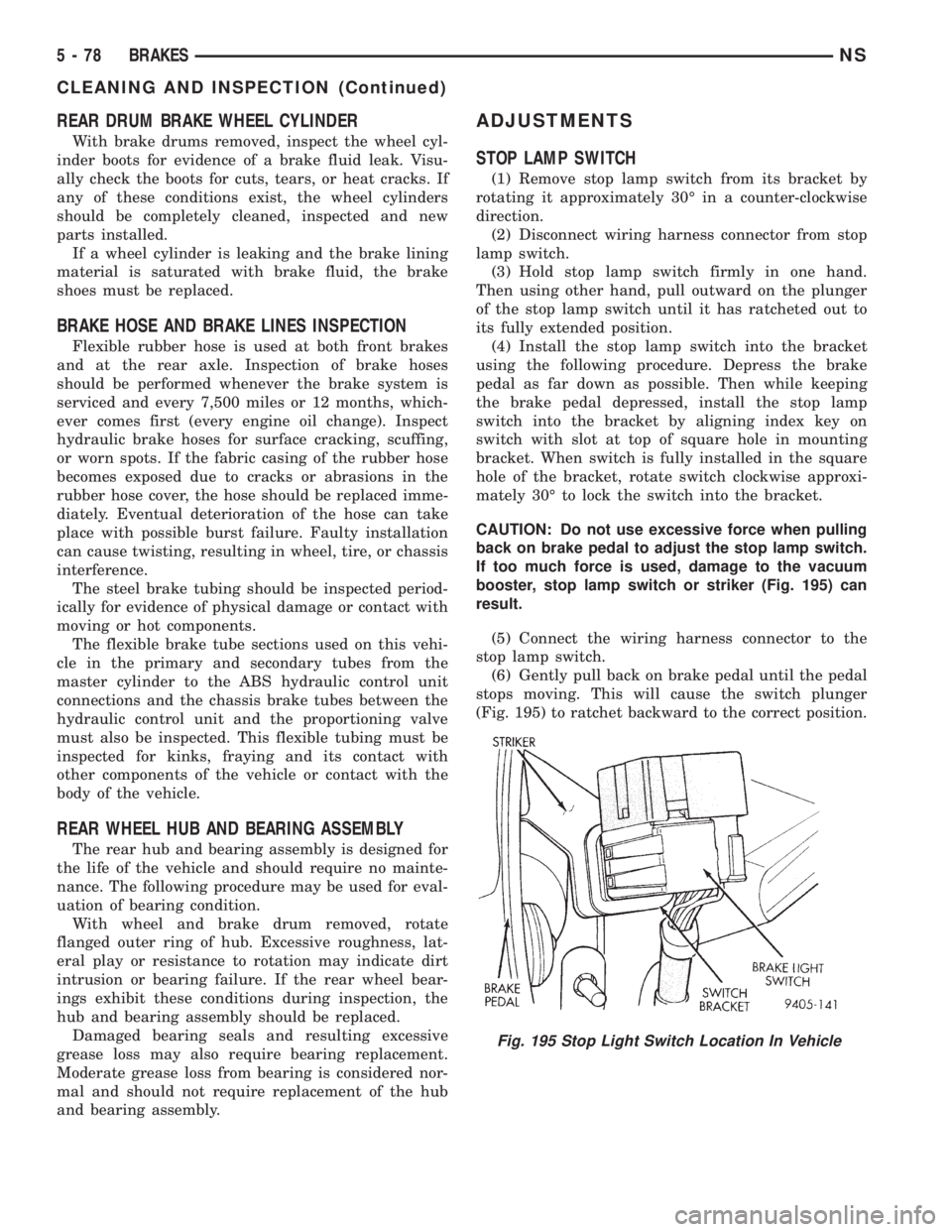

STOP LAMP SWITCH

(1) Remove stop lamp switch from its bracket by

rotating it approximately 30É in a counter-clockwise

direction.

(2) Disconnect wiring harness connector from stop

lamp switch.

(3) Hold stop lamp switch firmly in one hand.

Then using other hand, pull outward on the plunger

of the stop lamp switch until it has ratcheted out to

its fully extended position.

(4) Install the stop lamp switch into the bracket

using the following procedure. Depress the brake

pedal as far down as possible. Then while keeping

the brake pedal depressed, install the stop lamp

switch into the bracket by aligning index key on

switch with slot at top of square hole in mounting

bracket. When switch is fully installed in the square

hole of the bracket, rotate switch clockwise approxi-

mately 30É to lock the switch into the bracket.

CAUTION: Do not use excessive force when pulling

back on brake pedal to adjust the stop lamp switch.

If too much force is used, damage to the vacuum

booster, stop lamp switch or striker (Fig. 195) can

result.

(5) Connect the wiring harness connector to the

stop lamp switch.

(6) Gently pull back on brake pedal until the pedal

stops moving. This will cause the switch plunger

(Fig. 195) to ratchet backward to the correct position.

Fig. 195 Stop Light Switch Location In Vehicle

5 - 78 BRAKESNS

CLEANING AND INSPECTION (Continued)

Page 171 of 1938

fluid accumulators temporarily store brake fluid that

is decayed from the wheel brakes during an ABS

cycle. This stored brake fluid is then used by the

pump in the HCU to provide build pressure for the

brake hydraulic system.

Additionally on vehicles that are equipped with

only ABS (non-traction control vehicles) there is a

mini brake fluid accumulator on the secondary

hydraulic circuit which protects the master cylinder's

seals during an ABS stop. There is also a noise

damping chamber on the primary hydraulic circuit.

On ABS equipped vehicles with traction control, in

addition to the brake fluid accumulators there are

also two noise damping chambers in the HCU.

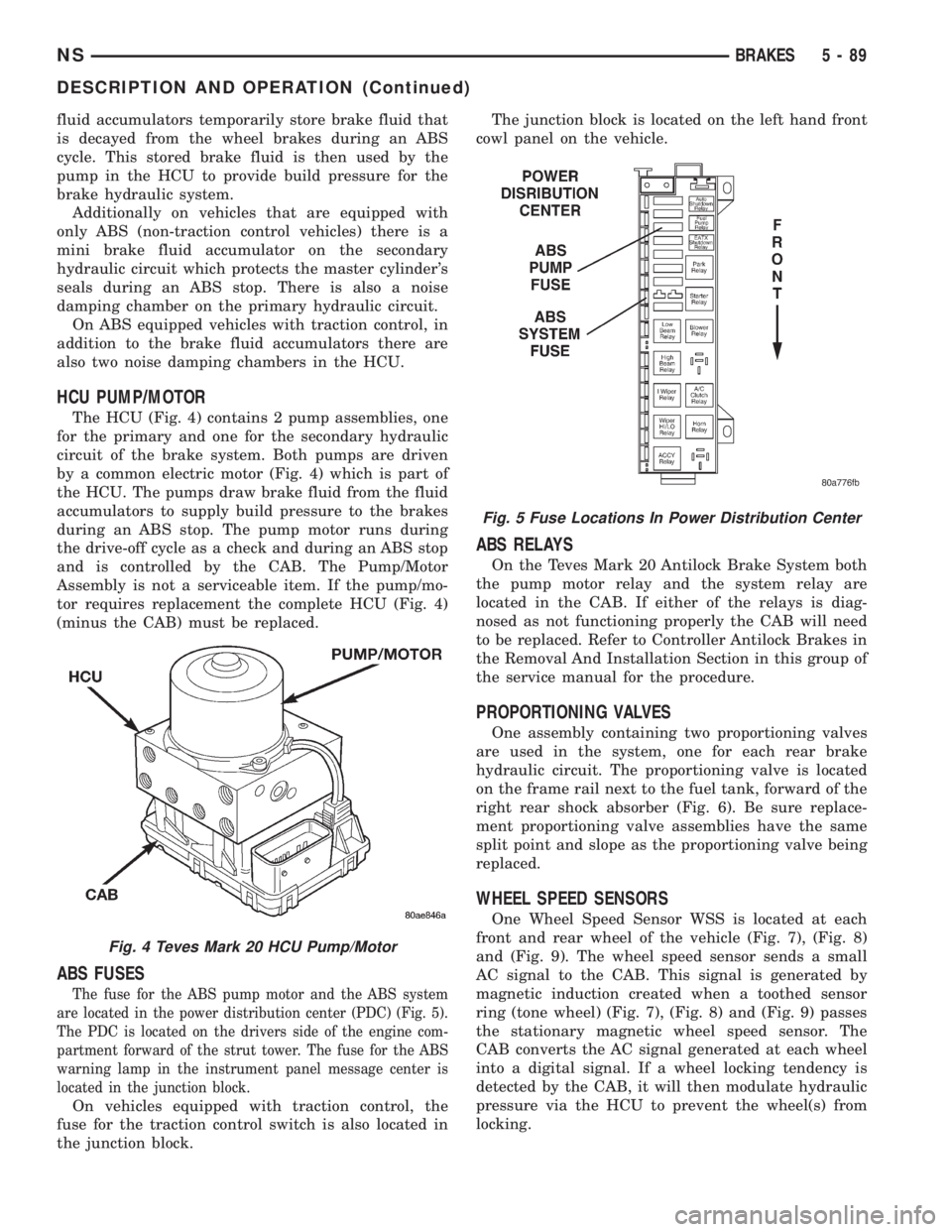

HCU PUMP/MOTOR

The HCU (Fig. 4) contains 2 pump assemblies, one

for the primary and one for the secondary hydraulic

circuit of the brake system. Both pumps are driven

by a common electric motor (Fig. 4) which is part of

the HCU. The pumps draw brake fluid from the fluid

accumulators to supply build pressure to the brakes

during an ABS stop. The pump motor runs during

the drive-off cycle as a check and during an ABS stop

and is controlled by the CAB. The Pump/Motor

Assembly is not a serviceable item. If the pump/mo-

tor requires replacement the complete HCU (Fig. 4)

(minus the CAB) must be replaced.

ABS FUSES

The fuse for the ABS pump motor and the ABS system

are located in the power distribution center (PDC) (Fig. 5).

The PDC is located on the drivers side of the engine com-

partment forward of the strut tower. The fuse for the ABS

warning lamp in the instrument panel message center is

located in the junction block.

On vehicles equipped with traction control, the

fuse for the traction control switch is also located in

the junction block.The junction block is located on the left hand front

cowl panel on the vehicle.

ABS RELAYS

On the Teves Mark 20 Antilock Brake System both

the pump motor relay and the system relay are

located in the CAB. If either of the relays is diag-

nosed as not functioning properly the CAB will need

to be replaced. Refer to Controller Antilock Brakes in

the Removal And Installation Section in this group of

the service manual for the procedure.

PROPORTIONING VALVES

One assembly containing two proportioning valves

are used in the system, one for each rear brake

hydraulic circuit. The proportioning valve is located

on the frame rail next to the fuel tank, forward of the

right rear shock absorber (Fig. 6). Be sure replace-

ment proportioning valve assemblies have the same

split point and slope as the proportioning valve being

replaced.

WHEEL SPEED SENSORS

One Wheel Speed Sensor WSS is located at each

front and rear wheel of the vehicle (Fig. 7), (Fig. 8)

and (Fig. 9). The wheel speed sensor sends a small

AC signal to the CAB. This signal is generated by

magnetic induction created when a toothed sensor

ring (tone wheel) (Fig. 7), (Fig. 8) and (Fig. 9) passes

the stationary magnetic wheel speed sensor. The

CAB converts the AC signal generated at each wheel

into a digital signal. If a wheel locking tendency is

detected by the CAB, it will then modulate hydraulic

pressure via the HCU to prevent the wheel(s) from

locking.

Fig. 4 Teves Mark 20 HCU Pump/Motor

Fig. 5 Fuse Locations In Power Distribution Center

NSBRAKES 5 - 89

DESCRIPTION AND OPERATION (Continued)