spark plugs CHRYSLER VOYAGER 1996 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1263 of 1938

EXHAUST SYSTEM AND INTAKE MANIFOLD

CONTENTS

page page

GENERAL INFORMATION

CATALYTIC CONVERTERS................. 1

EXHAUST FLEX-JOINT COUPLING........... 2

EXHAUST GAS RECIRCULATION (EGR)....... 2

EXHAUST SYSTEM....................... 1

HEAT SHIELDS.......................... 2

DESCRIPTION AND OPERATION

INTAKE/EXHAUST MANIFOLDÐ2.4L ENGINE . . 3

INTAKE/EXHAUST MANIFOLDÐ3.0L ENGINE . . 3

INTAKE/EXHAUST MANIFOLDÐ3.3/3.8L

ENGINES............................. 3

DIAGNOSIS AND TESTING

EXHAUST SYSTEM....................... 3REMOVAL AND INSTALLATION

EXHAUST MANIFOLDÐ2.4L ENGINE........ 8

EXHAUST MANIFOLDÐ3.0L ENGINE....... 11

EXHAUST MANIFOLDSÐ3.3/3.8L ENGINE . . . 16

EXHAUST PIPES, MUFFLERS AND TAILPIPES . 4

INTAKE MANIFOLD LOWERÐ2.4L ENGINE.... 6

INTAKE MANIFOLDÐ3.0L ENGINE.......... 8

INTAKE MANIFOLDÐ3.3/3.8L ENGINE...... 12

UPPER INTAKE MANIFOLDÐ2.4L ENGINE.... 4

CLEANING AND INSPECTION

EXHAUST MANIFOLD.................... 17

INTAKE MANIFOLD...................... 17

SPECIFICATIONS

TORQUE CHART........................ 18

GENERAL INFORMATION

EXHAUST SYSTEM

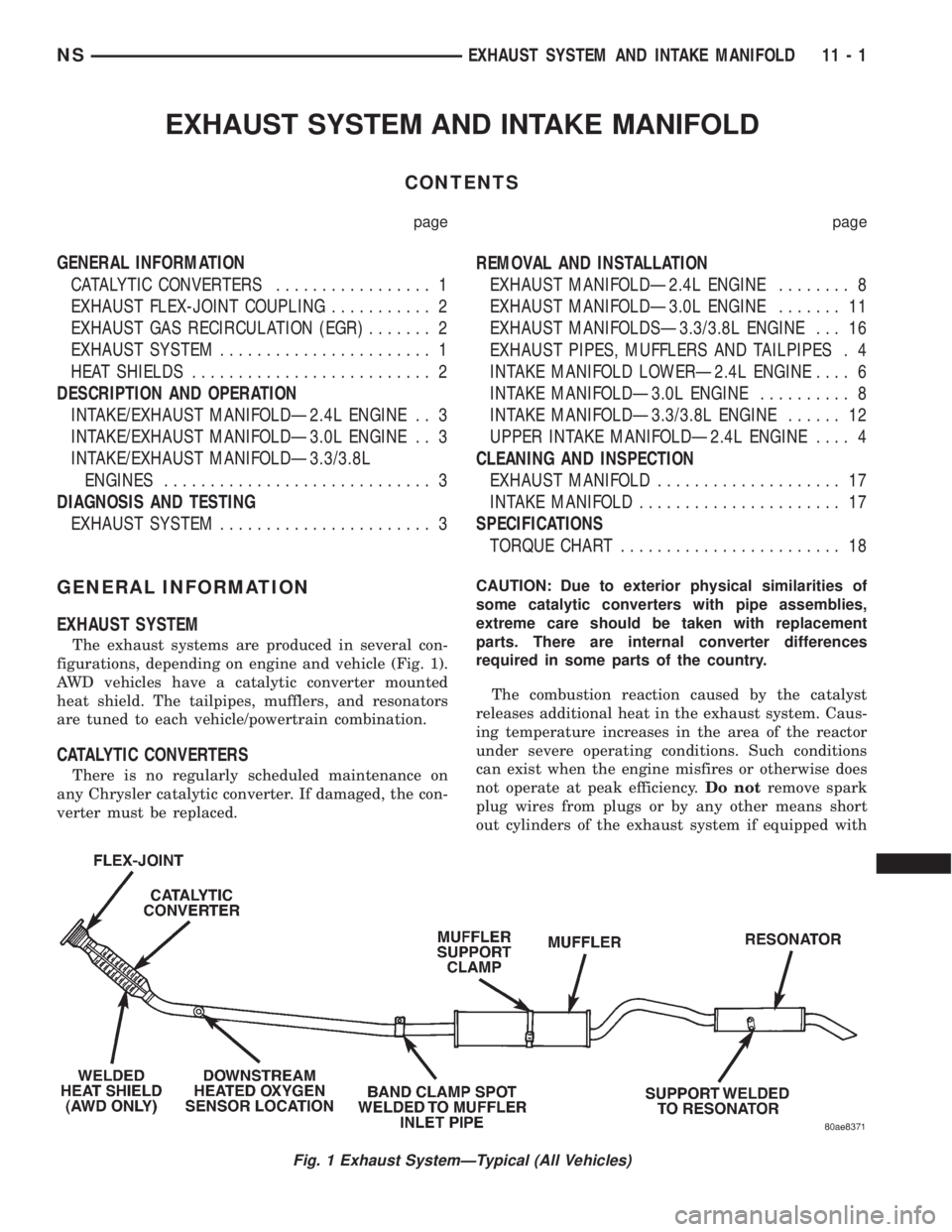

The exhaust systems are produced in several con-

figurations, depending on engine and vehicle (Fig. 1).

AWD vehicles have a catalytic converter mounted

heat shield. The tailpipes, mufflers, and resonators

are tuned to each vehicle/powertrain combination.

CATALYTIC CONVERTERS

There is no regularly scheduled maintenance on

any Chrysler catalytic converter. If damaged, the con-

verter must be replaced.CAUTION: Due to exterior physical similarities of

some catalytic converters with pipe assemblies,

extreme care should be taken with replacement

parts. There are internal converter differences

required in some parts of the country.

The combustion reaction caused by the catalyst

releases additional heat in the exhaust system. Caus-

ing temperature increases in the area of the reactor

under severe operating conditions. Such conditions

can exist when the engine misfires or otherwise does

not operate at peak efficiency.Do notremove spark

plug wires from plugs or by any other means short

out cylinders of the exhaust system if equipped with

Fig. 1 Exhaust SystemÐTypical (All Vehicles)

NSEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 1

Page 1339 of 1938

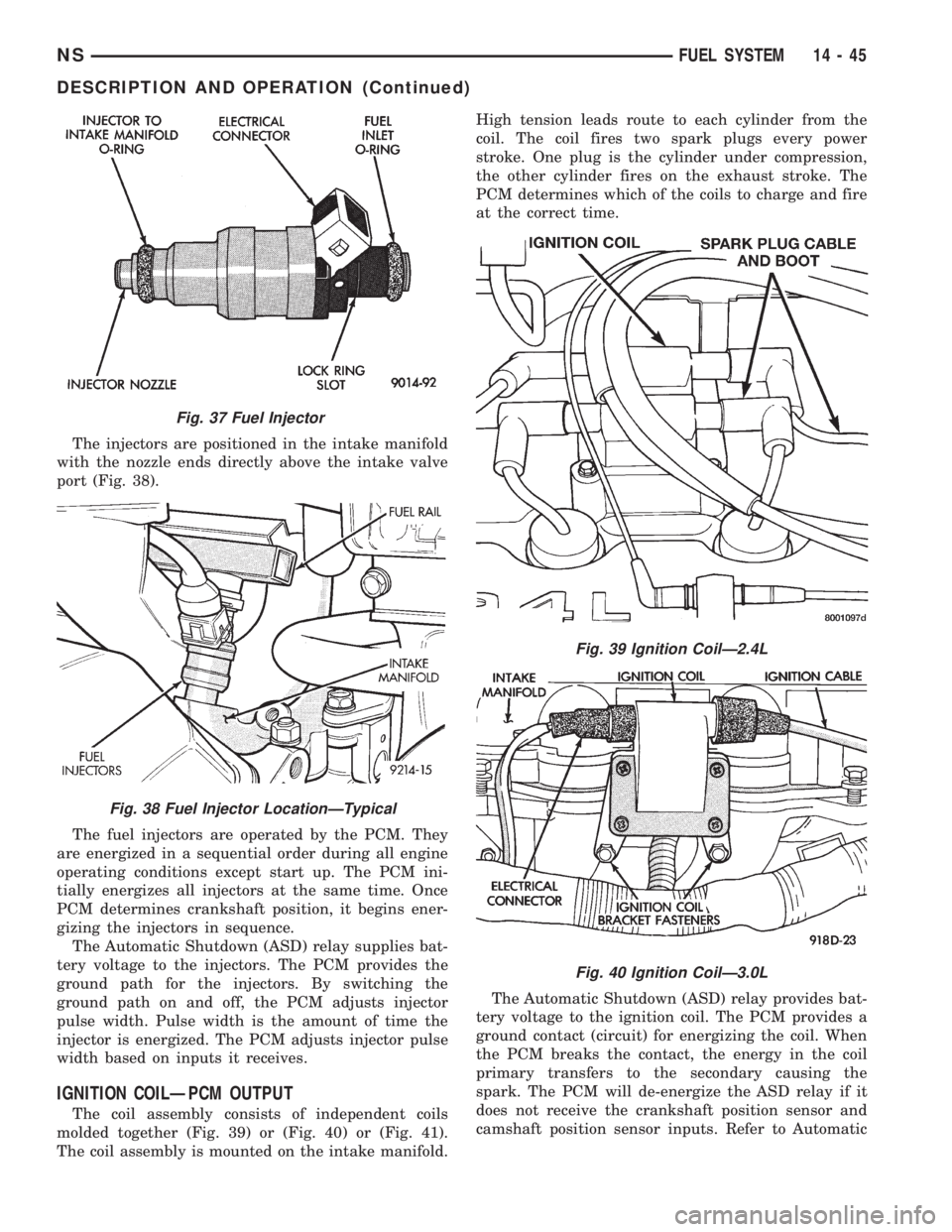

The injectors are positioned in the intake manifold

with the nozzle ends directly above the intake valve

port (Fig. 38).

The fuel injectors are operated by the PCM. They

are energized in a sequential order during all engine

operating conditions except start up. The PCM ini-

tially energizes all injectors at the same time. Once

PCM determines crankshaft position, it begins ener-

gizing the injectors in sequence.

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to the injectors. The PCM provides the

ground path for the injectors. By switching the

ground path on and off, the PCM adjusts injector

pulse width. Pulse width is the amount of time the

injector is energized. The PCM adjusts injector pulse

width based on inputs it receives.

IGNITION COILÐPCM OUTPUT

The coil assembly consists of independent coils

molded together (Fig. 39) or (Fig. 40) or (Fig. 41).

The coil assembly is mounted on the intake manifold.High tension leads route to each cylinder from the

coil. The coil fires two spark plugs every power

stroke. One plug is the cylinder under compression,

the other cylinder fires on the exhaust stroke. The

PCM determines which of the coils to charge and fire

at the correct time.

The Automatic Shutdown (ASD) relay provides bat-

tery voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Automatic

Fig. 37 Fuel Injector

Fig. 38 Fuel Injector LocationÐTypical

Fig. 39 Ignition CoilÐ2.4L

Fig. 40 Ignition CoilÐ3.0L

NSFUEL SYSTEM 14 - 45

DESCRIPTION AND OPERATION (Continued)

Page 1341 of 1938

ances the two solenoids to maintain the set speed.

Refer to Group 8H for speed control information.

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer through the CCD Bus. The CCD

Bus is a communications port. Various modules use

the CCD Bus to exchange information. Refer to

Group 8E for more information.

THROTTLE BODY

On all engine assemblies (2.4, 3.0, and 3.3/3.8L)

the throttle body's are located on the left side of the

intake manifold plenum. The throttle body houses

the throttle position sensor and the idle air control

motor. Air flow through the throttle body is con-

trolled by a cable operated throttle blade located in

the base of the throttle body (Fig. 43) or (Fig. 44) or

(Fig. 45).

DIAGNOSIS AND TESTING

VISUAL INSPECTIONÐ2.4L ENGINE

A visual inspection for loose, disconnected, or mis-

routed wires and hoses should be made before

attempting to diagnose or service the fuel injection

system. A visual check helps save unnecessary test

and diagnostic time. A thorough visual inspection will

include the following checks:

(1) Check ignition cable routing from the coil pack

to the spark plugs. Verify the cable are routed in the

correct order and are fully seated to the coil and

spark plug.

(2) Check direct ignition system (DIS) coil electri-

cal connection for damage and a complete connection

to the coil pack (Fig. 46).

Fig. 43 Throttle BodyÐ2.4L

Fig. 44 Throttle BodyÐ3.0L

NSFUEL SYSTEM 14 - 47

DESCRIPTION AND OPERATION (Continued)

Page 1346 of 1938

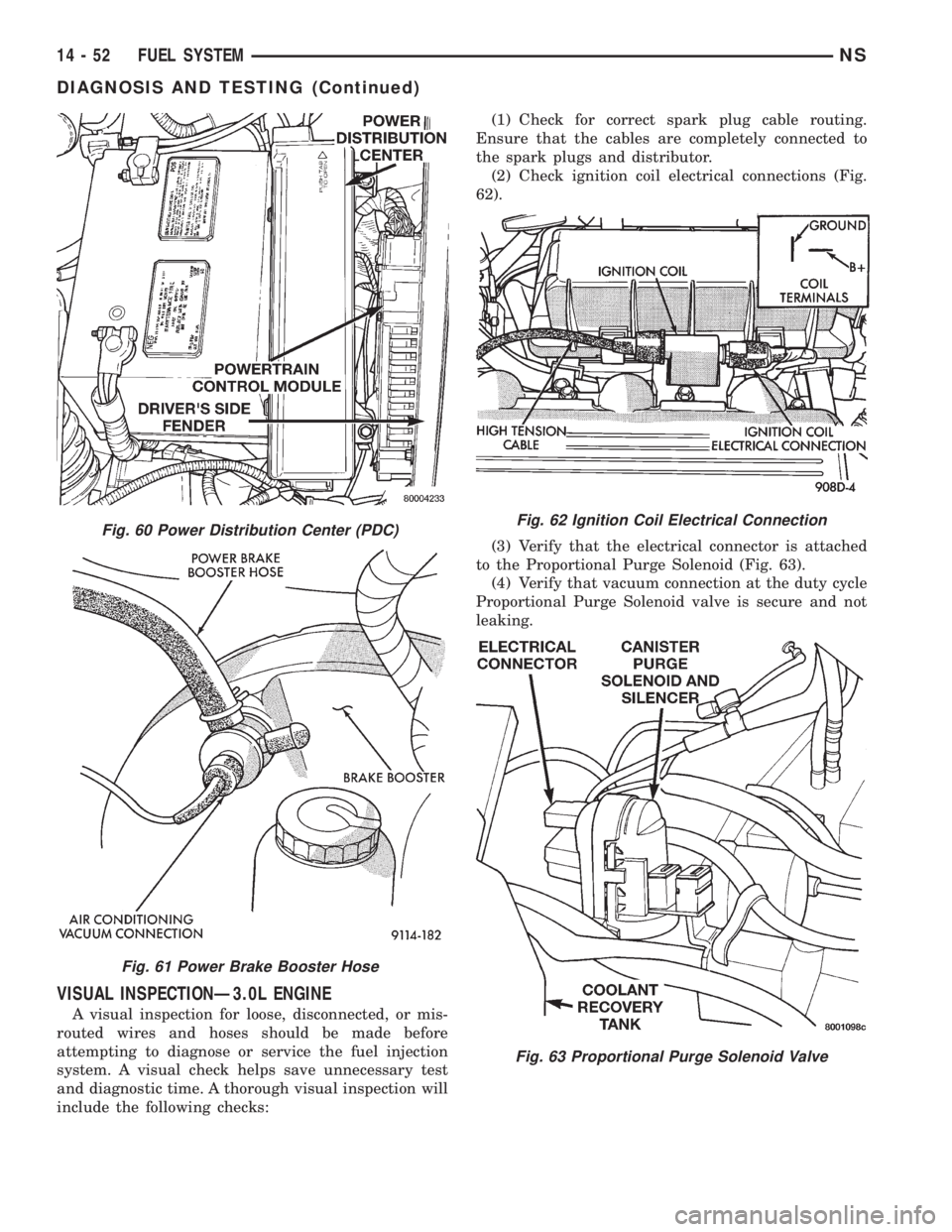

VISUAL INSPECTIONÐ3.0L ENGINE

A visual inspection for loose, disconnected, or mis-

routed wires and hoses should be made before

attempting to diagnose or service the fuel injection

system. A visual check helps save unnecessary test

and diagnostic time. A thorough visual inspection will

include the following checks:(1) Check for correct spark plug cable routing.

Ensure that the cables are completely connected to

the spark plugs and distributor.

(2) Check ignition coil electrical connections (Fig.

62).

(3) Verify that the electrical connector is attached

to the Proportional Purge Solenoid (Fig. 63).

(4) Verify that vacuum connection at the duty cycle

Proportional Purge Solenoid valve is secure and not

leaking.

Fig. 60 Power Distribution Center (PDC)

Fig. 61 Power Brake Booster Hose

Fig. 62 Ignition Coil Electrical Connection

Fig. 63 Proportional Purge Solenoid Valve

14 - 52 FUEL SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 1349 of 1938

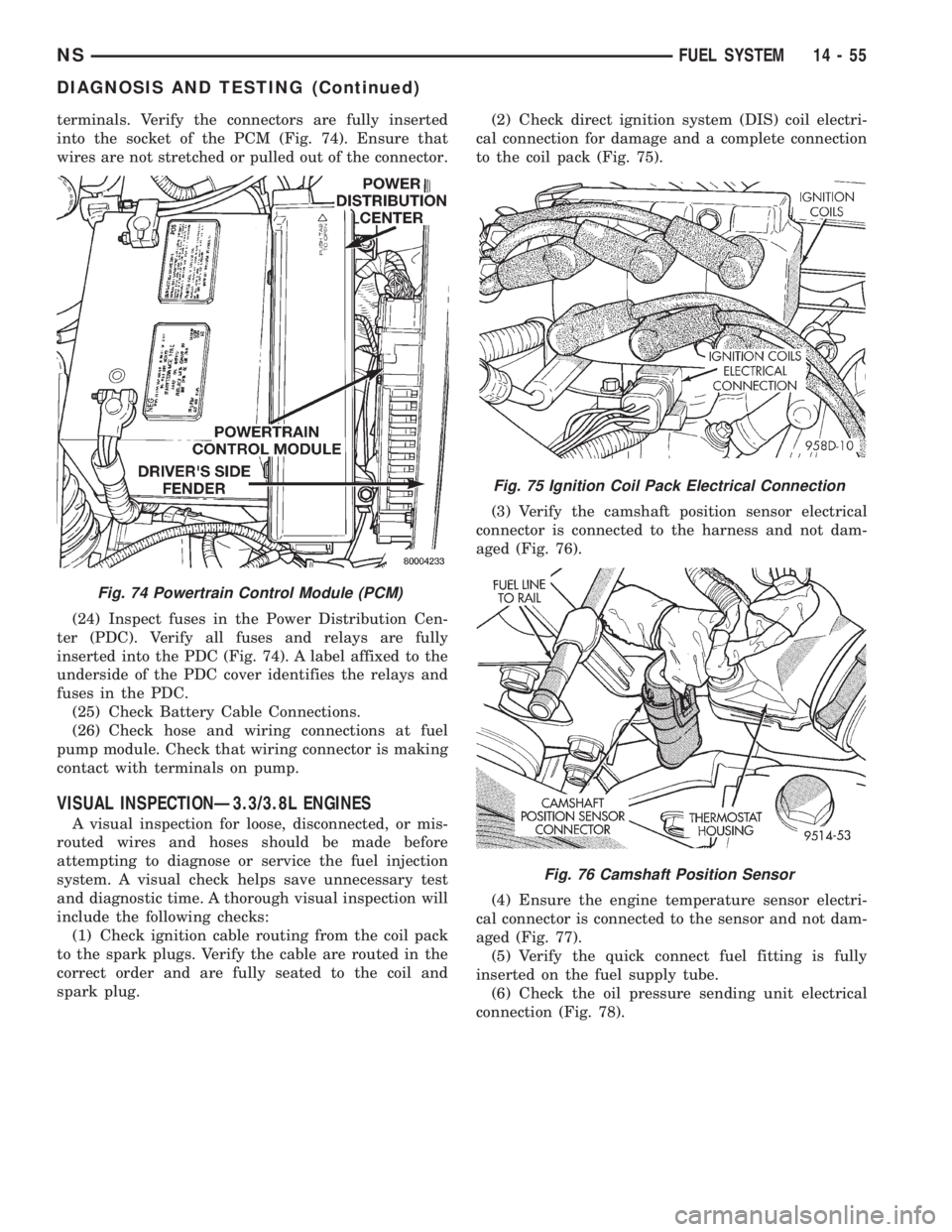

terminals. Verify the connectors are fully inserted

into the socket of the PCM (Fig. 74). Ensure that

wires are not stretched or pulled out of the connector.

(24) Inspect fuses in the Power Distribution Cen-

ter (PDC). Verify all fuses and relays are fully

inserted into the PDC (Fig. 74). A label affixed to the

underside of the PDC cover identifies the relays and

fuses in the PDC.

(25) Check Battery Cable Connections.

(26) Check hose and wiring connections at fuel

pump module. Check that wiring connector is making

contact with terminals on pump.

VISUAL INSPECTIONÐ3.3/3.8L ENGINES

A visual inspection for loose, disconnected, or mis-

routed wires and hoses should be made before

attempting to diagnose or service the fuel injection

system. A visual check helps save unnecessary test

and diagnostic time. A thorough visual inspection will

include the following checks:

(1) Check ignition cable routing from the coil pack

to the spark plugs. Verify the cable are routed in the

correct order and are fully seated to the coil and

spark plug.(2) Check direct ignition system (DIS) coil electri-

cal connection for damage and a complete connection

to the coil pack (Fig. 75).

(3) Verify the camshaft position sensor electrical

connector is connected to the harness and not dam-

aged (Fig. 76).

(4) Ensure the engine temperature sensor electri-

cal connector is connected to the sensor and not dam-

aged (Fig. 77).

(5) Verify the quick connect fuel fitting is fully

inserted on the fuel supply tube.

(6) Check the oil pressure sending unit electrical

connection (Fig. 78).

Fig. 74 Powertrain Control Module (PCM)

Fig. 75 Ignition Coil Pack Electrical Connection

Fig. 76 Camshaft Position Sensor

NSFUEL SYSTEM 14 - 55

DIAGNOSIS AND TESTING (Continued)

Page 1381 of 1938

A defective fuel injection pump, defective fuel tim-

ing solenoid or misadjusted mechanical pump timing

can cause starting problems or prevent the engine

from revving up. It can also cause:

²Engine surge at idle

²Rough idle (warm engine)

²Low power

²Excessive fuel consumption

²Poor performance

²Low power

²Black smoke from the exhaust

²Blue or white fog like exhaust

²Incorrect idle or maximum speed

The electronically controlled fuel pump has no

mechanical governor like older mechanically con-

trolled fuel pumps. Do not remove the top cover of

the fuel pump, or the screws fastening the wiring

pigtail to the side of the pump.The warranty of

the injection pump and the engine may be void

if those seals have been removed or tampered

with.

FUEL SUPPLY RESTRICTIONS

LOW±PRESSURE LINES

Restricted or Plugged supply lines or fuel filter can

cause a timing fault that will cause the PCM to oper-

ate the engine in a ªLimp Homeº mode. See the

introduction of the Fuel Injection System in this

group for more information on the Limp Home mode.

Fuel supply line restrictions can cause starting prob-

lems and prevent the engine from revving up. The

starting problems include; low power and blue or

white fog like exhaust. Test all fuel supply lines for

restrictions or blockage. Flush or replace as neces-

sary. Bleed the fuel system of air once a fuel supply

line has been replaced. Refer to the Air Bleed Proce-

dure section of this group for procedures.

HIGH±PRESSURE LINES

Restricted (kinked or bent) high±pressure lines can

cause starting problems, poor engine performance

and black smoke from exhaust.

Examine all high±pressure lines for any damage.

Each radius on each high±pressure line must be

smooth and free of any bends or kinks.

Replace damaged, restricted or leaking high±pres-

sure fuel lines with the correct replacement line.

CAUTION: The high±pressure fuel lines must be

clamped securely in place in the holders. The lines

cannot contact each other or other components. Do

not attempt to weld high±pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high±pressure

fuel line is necessary.

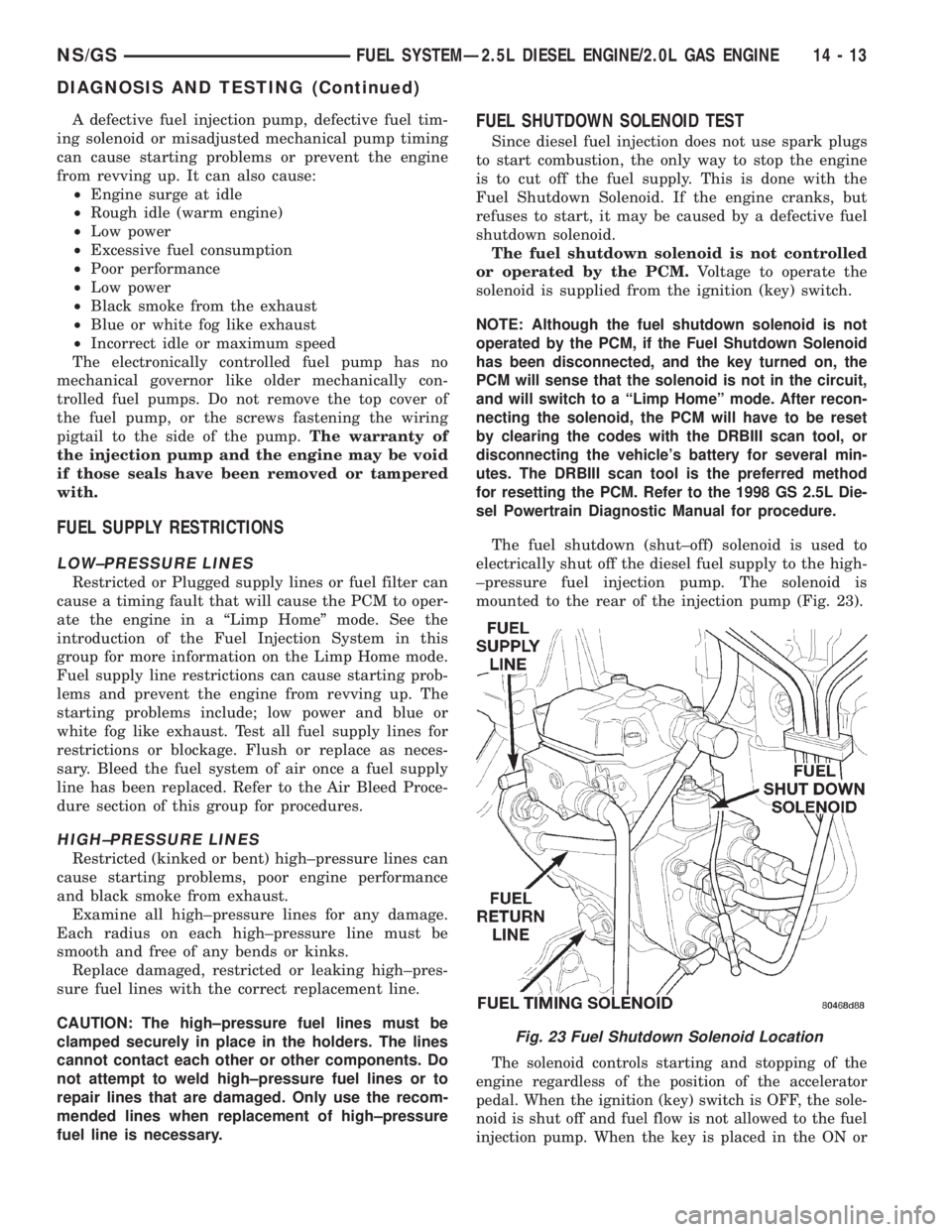

FUEL SHUTDOWN SOLENOID TEST

Since diesel fuel injection does not use spark plugs

to start combustion, the only way to stop the engine

is to cut off the fuel supply. This is done with the

Fuel Shutdown Solenoid. If the engine cranks, but

refuses to start, it may be caused by a defective fuel

shutdown solenoid.

The fuel shutdown solenoid is not controlled

or operated by the PCM.Voltage to operate the

solenoid is supplied from the ignition (key) switch.

NOTE: Although the fuel shutdown solenoid is not

operated by the PCM, if the Fuel Shutdown Solenoid

has been disconnected, and the key turned on, the

PCM will sense that the solenoid is not in the circuit,

and will switch to a ªLimp Homeº mode. After recon-

necting the solenoid, the PCM will have to be reset

by clearing the codes with the DRBIII scan tool, or

disconnecting the vehicle's battery for several min-

utes. The DRBIII scan tool is the preferred method

for resetting the PCM. Refer to the 1998 GS 2.5L Die-

sel Powertrain Diagnostic Manual for procedure.

The fuel shutdown (shut±off) solenoid is used to

electrically shut off the diesel fuel supply to the high-

±pressure fuel injection pump. The solenoid is

mounted to the rear of the injection pump (Fig. 23).

The solenoid controls starting and stopping of the

engine regardless of the position of the accelerator

pedal. When the ignition (key) switch is OFF, the sole-

noid is shut off and fuel flow is not allowed to the fuel

injection pump. When the key is placed in the ON or

Fig. 23 Fuel Shutdown Solenoid Location

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 13

DIAGNOSIS AND TESTING (Continued)

Page 1404 of 1938

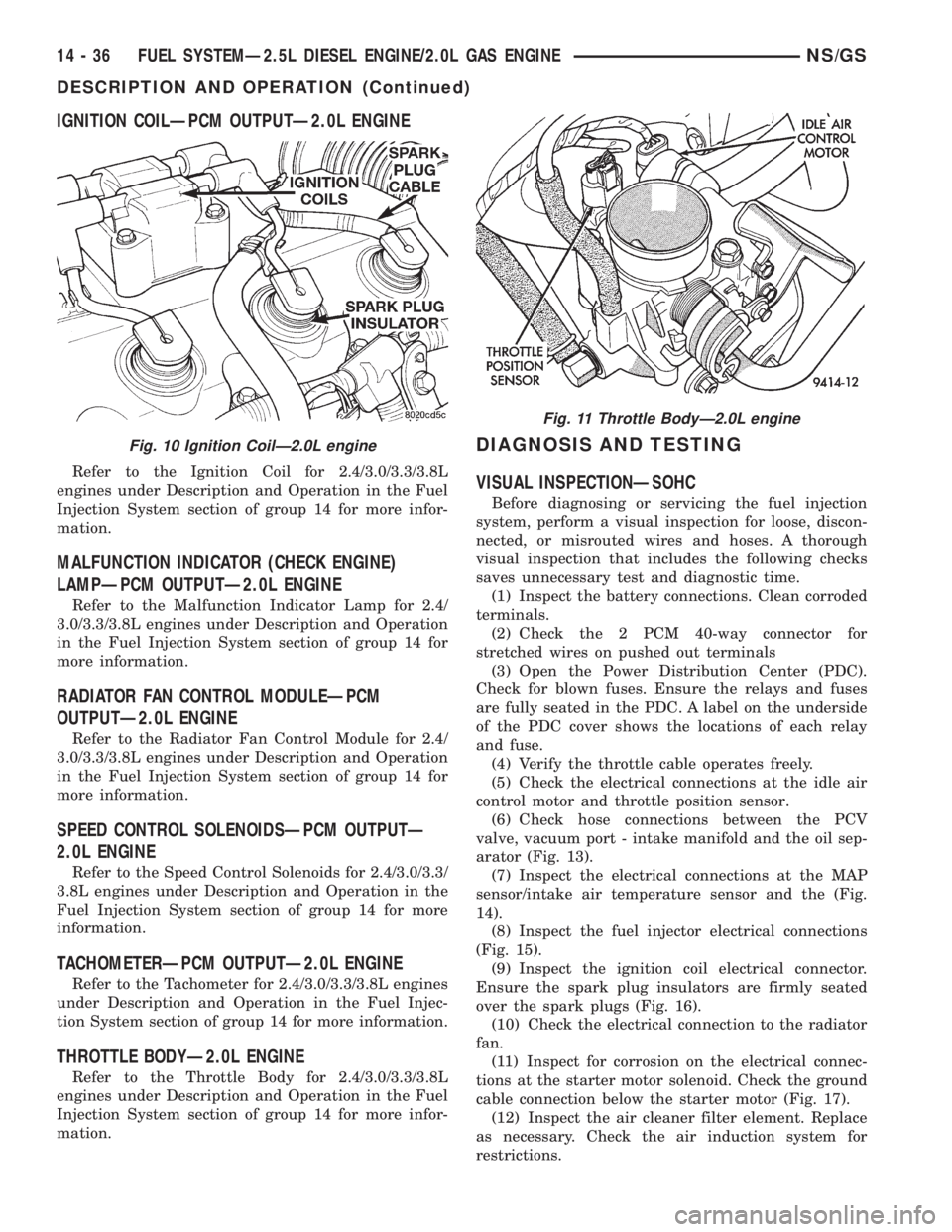

IGNITION COILÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Ignition Coil for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Malfunction Indicator Lamp for 2.4/

3.0/3.3/3.8L engines under Description and Operation

in the Fuel Injection System section of group 14 for

more information.

RADIATOR FAN CONTROL MODULEÐPCM

OUTPUTÐ2.0L ENGINE

Refer to the Radiator Fan Control Module for 2.4/

3.0/3.3/3.8L engines under Description and Operation

in the Fuel Injection System section of group 14 for

more information.

SPEED CONTROL SOLENOIDSÐPCM OUTPUTÐ

2.0L ENGINE

Refer to the Speed Control Solenoids for 2.4/3.0/3.3/

3.8L engines under Description and Operation in the

Fuel Injection System section of group 14 for more

information.

TACHOMETERÐPCM OUTPUTÐ2.0L ENGINE

Refer to the Tachometer for 2.4/3.0/3.3/3.8L engines

under Description and Operation in the Fuel Injec-

tion System section of group 14 for more information.

THROTTLE BODYÐ2.0L ENGINE

Refer to the Throttle Body for 2.4/3.0/3.3/3.8L

engines under Description and Operation in the Fuel

Injection System section of group 14 for more infor-

mation.

DIAGNOSIS AND TESTING

VISUAL INSPECTIONÐSOHC

Before diagnosing or servicing the fuel injection

system, perform a visual inspection for loose, discon-

nected, or misrouted wires and hoses. A thorough

visual inspection that includes the following checks

saves unnecessary test and diagnostic time.

(1) Inspect the battery connections. Clean corroded

terminals.

(2) Check the 2 PCM 40-way connector for

stretched wires on pushed out terminals

(3) Open the Power Distribution Center (PDC).

Check for blown fuses. Ensure the relays and fuses

are fully seated in the PDC. A label on the underside

of the PDC cover shows the locations of each relay

and fuse.

(4) Verify the throttle cable operates freely.

(5) Check the electrical connections at the idle air

control motor and throttle position sensor.

(6) Check hose connections between the PCV

valve, vacuum port - intake manifold and the oil sep-

arator (Fig. 13).

(7) Inspect the electrical connections at the MAP

sensor/intake air temperature sensor and the (Fig.

14).

(8) Inspect the fuel injector electrical connections

(Fig. 15).

(9) Inspect the ignition coil electrical connector.

Ensure the spark plug insulators are firmly seated

over the spark plugs (Fig. 16).

(10) Check the electrical connection to the radiator

fan.

(11) Inspect for corrosion on the electrical connec-

tions at the starter motor solenoid. Check the ground

cable connection below the starter motor (Fig. 17).

(12) Inspect the air cleaner filter element. Replace

as necessary. Check the air induction system for

restrictions.

Fig. 10 Ignition CoilÐ2.0L engine

Fig. 11 Throttle BodyÐ2.0L engine

14 - 36 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1405 of 1938

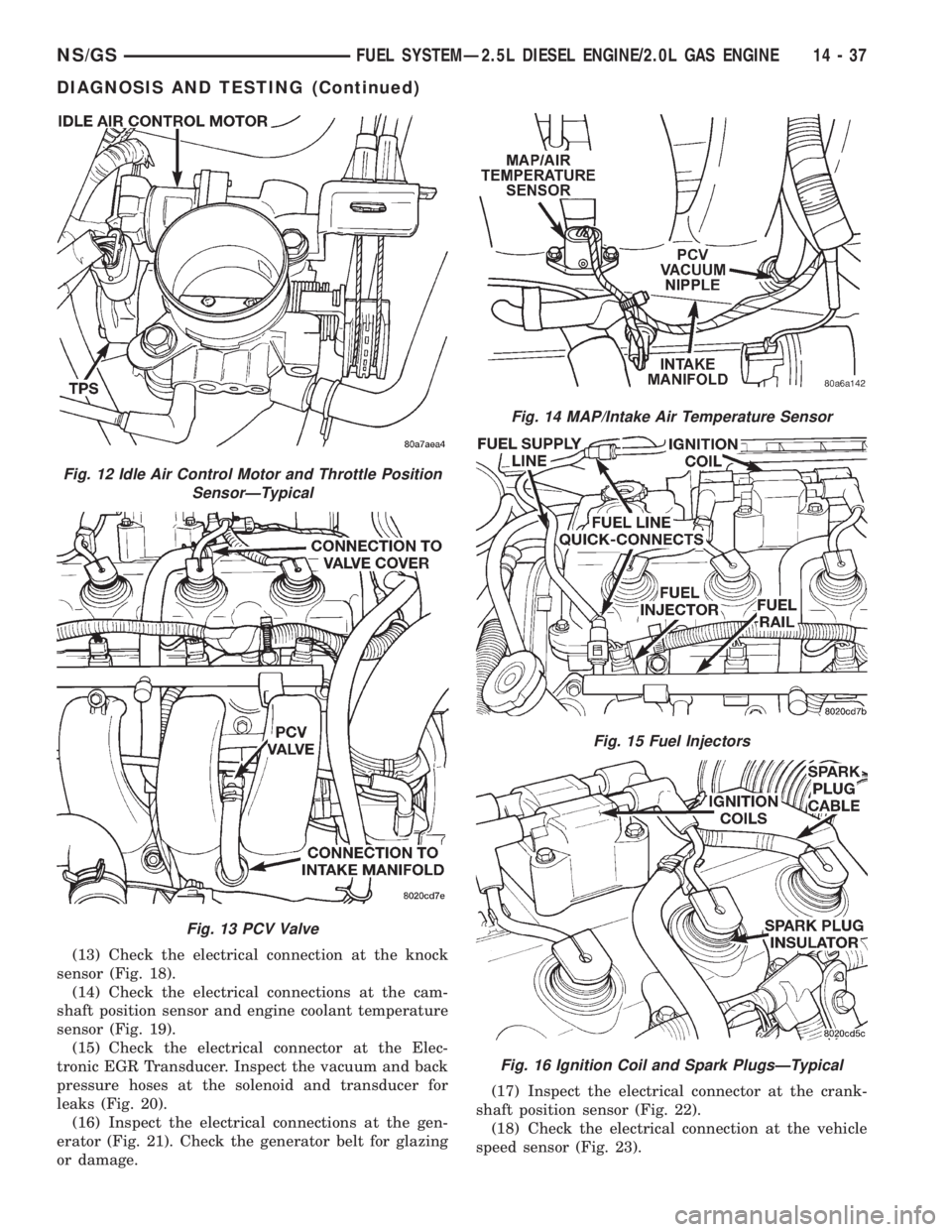

(13) Check the electrical connection at the knock

sensor (Fig. 18).

(14) Check the electrical connections at the cam-

shaft position sensor and engine coolant temperature

sensor (Fig. 19).

(15) Check the electrical connector at the Elec-

tronic EGR Transducer. Inspect the vacuum and back

pressure hoses at the solenoid and transducer for

leaks (Fig. 20).

(16) Inspect the electrical connections at the gen-

erator (Fig. 21). Check the generator belt for glazing

or damage.(17) Inspect the electrical connector at the crank-

shaft position sensor (Fig. 22).

(18) Check the electrical connection at the vehicle

speed sensor (Fig. 23).

Fig. 12 Idle Air Control Motor and Throttle Position

SensorÐTypical

Fig. 13 PCV Valve

Fig. 14 MAP/Intake Air Temperature Sensor

Fig. 15 Fuel Injectors

Fig. 16 Ignition Coil and Spark PlugsÐTypical

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 37

DIAGNOSIS AND TESTING (Continued)

Page 1915 of 1938

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum

and 1600 rpm.

Any component that has an associated limp in will

set a fault after 1 trip with the malfunction present.

Refer to the Diagnostic Trouble Codes Description

Charts in this section and the appropriate Power-

train Diagnostic Procedure Manual for diagnostic

procedures.

NON-MONITORED CIRCUITS

The PCM does not monitor all circuits, systems

and conditions that could have malfunctions causing

driveability problems. However, problems with these

systems may cause the PCM to store diagnostic trou-

ble codes for other systems or components. For exam-

ple, a fuel pressure problem will not register a fault

directly, but could cause a rich/lean condition or mis-

fire. This could cause the PCM to store an oxygen

sensor or misfire diagnostic trouble code.

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR or Fuel

system fault or O2S.

FUEL INJECTOR MECHANICAL

MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for

the device. If the input voltage is not within limits

and other criteria are met, the PCM stores a diagnos-

tic trouble code in memory. Other diagnostic trouble

code criteria might include engine RPM limits or

input voltages from other sensors or switches that

must be present before verifying a diagnostic trouble

code condition.

NSEMISSION CONTROL SYSTEMS 25 - 11

DESCRIPTION AND OPERATION (Continued)