spark plugs CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 320 of 1938

SPECIFICATIONS

IGNITION COIL

SPARK PLUG

TORQUE

DESCRIPTION......................TORQUE

2.4L Target Magnet Screw.......3N´m(30in.lbs.)

2.4L Camshaft Position Sensoe Screw . .9 N´m (80 in.

lbs.)

Ignition Switch...............2N´m(17in.lbs.)

Spark Plugs.................28N´m(60in.lbs.)

SPARK PLUG CABLE RESISTANCEÐ2.4L

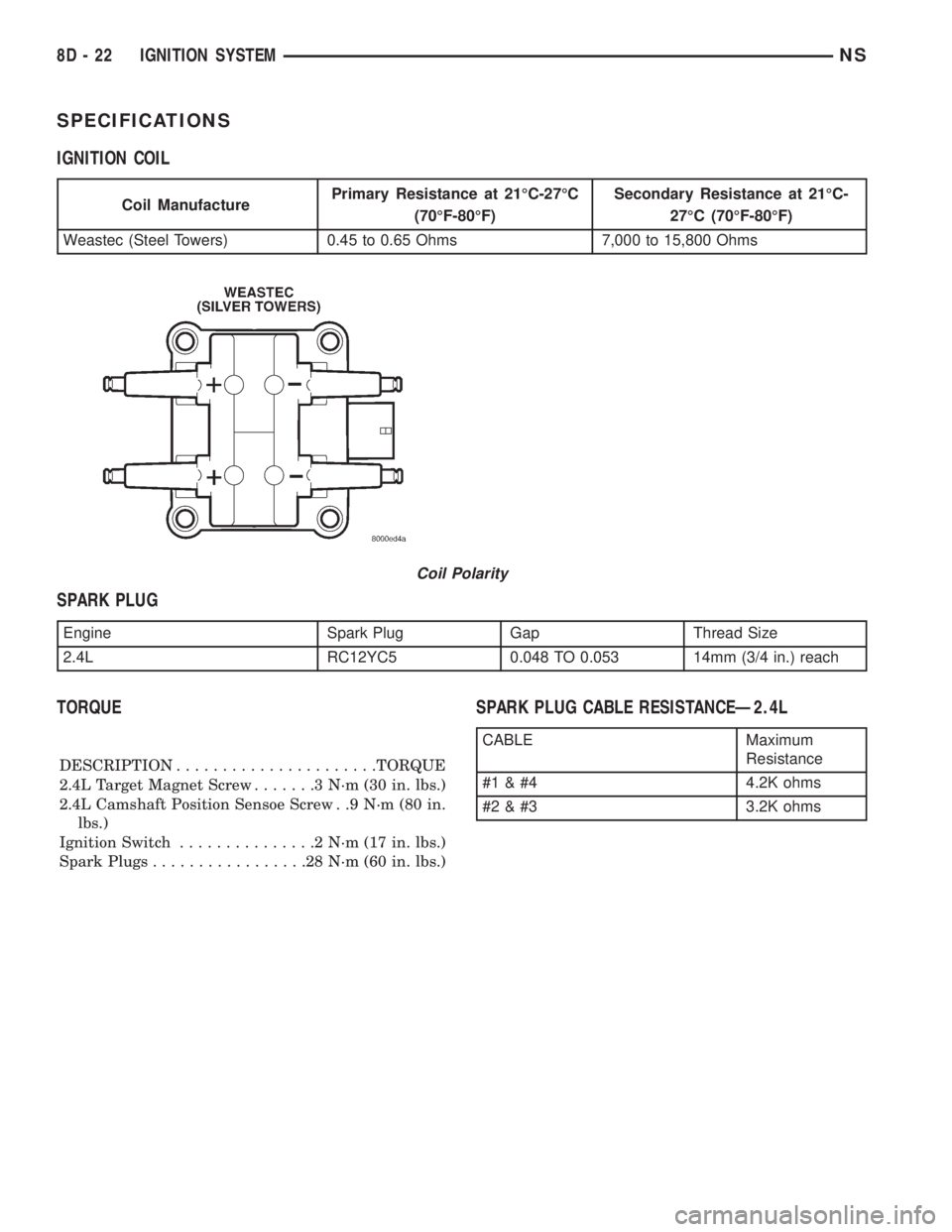

Coil ManufacturePrimary Resistance at 21ÉC-27ÉC

(70ÉF-80ÉF)Secondary Resistance at 21ÉC-

27ÉC (70ÉF-80ÉF)

Weastec (Steel Towers) 0.45 to 0.65 Ohms 7,000 to 15,800 Ohms

Coil Polarity

Engine Spark Plug Gap Thread Size

2.4L RC12YC5 0.048 TO 0.053 14mm (3/4 in.) reach

CABLE Maximum

Resistance

#1 & #4 4.2K ohms

#2 & #3 3.2K ohms

8D - 22 IGNITION SYSTEMNS

Page 322 of 1938

REMOVAL AND INSTALLATION

SPARK PLUG SERVICE

When replacing the spark plugs and spark plug

cables, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise, cross ignition of the spark plugs orshort cir-

cuit the cables to ground.

Never Wire Brush Spark Plugs.The spark plug

insulator tip is harder than the bristles of wire

brushes. Bristles of wire brushes can leave a conduc-

tive, metallic film on the insulator which could lead

to conductive deposits. Conductive deposits can cause

spark plug failure and engine misfire. Use a jewelers

file to remove deposits from the electrode gap or use

a spark plug cleaning machine to clean spark plugs.

REMOVAL

Always remove cables by grasping at the boot,

rotating the boot 1/2 turn, and pulling straight back

in a steady motion.

(1) Prior to removing the spark plug, spray com-

pressed air around the spark plug hole and the area

around the spark plug.

(2) Remove the spark plug using a quality socket

with a foam insert.

(3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand.

(2) Tighten spark plugs to 28 N´m (20 ft. lbs.)

torque.

(3) Install spark plug cables over spark plugs. A

click will be heard and felt when the cable properly

attaches to the spark plug.

IGNITION COILÐ3.OL

The ignition coil is located at the back of the

intake manifold (Fig. 2).

REMOVAL

(1) Remove air cleaner assembly.

(2) Disconnect ignition cable from coil.

(3) Disconnect wiring harness connector from coil.

(4) Remove coil mounting screws.

INSTALLATION

(1) Loosely install ignition coil on intake manifold.

Tighten the intake manifold fastener to 13 N´m (115

in. lbs.) torque. Tighten ignition coil bracket fasten-

ers to 10 N´m (96 in. lbs.) torque.

(2) Connect the wiring harness connector.

(3) Connect the coil to distributor ignition cable.

(4) Install the air cleaner assembly. Tighten the

air cleaner fasteners to 25 N´m (225 in. lbs.) torque.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ3.0L

REMOVAL

(1) Remove vacuum hose and mounting screws

from manifold absolute pressure (MAP) sensor (Fig.

3).

(2) Disconnect electrical connector from sensor.

Remove sensor.

Fig. 1 Camshaft Position SensorÐ3.0L Engine

Fig. 2 Ignition CoilÐ3.0L Engine

8D - 24 IGNITION SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 325 of 1938

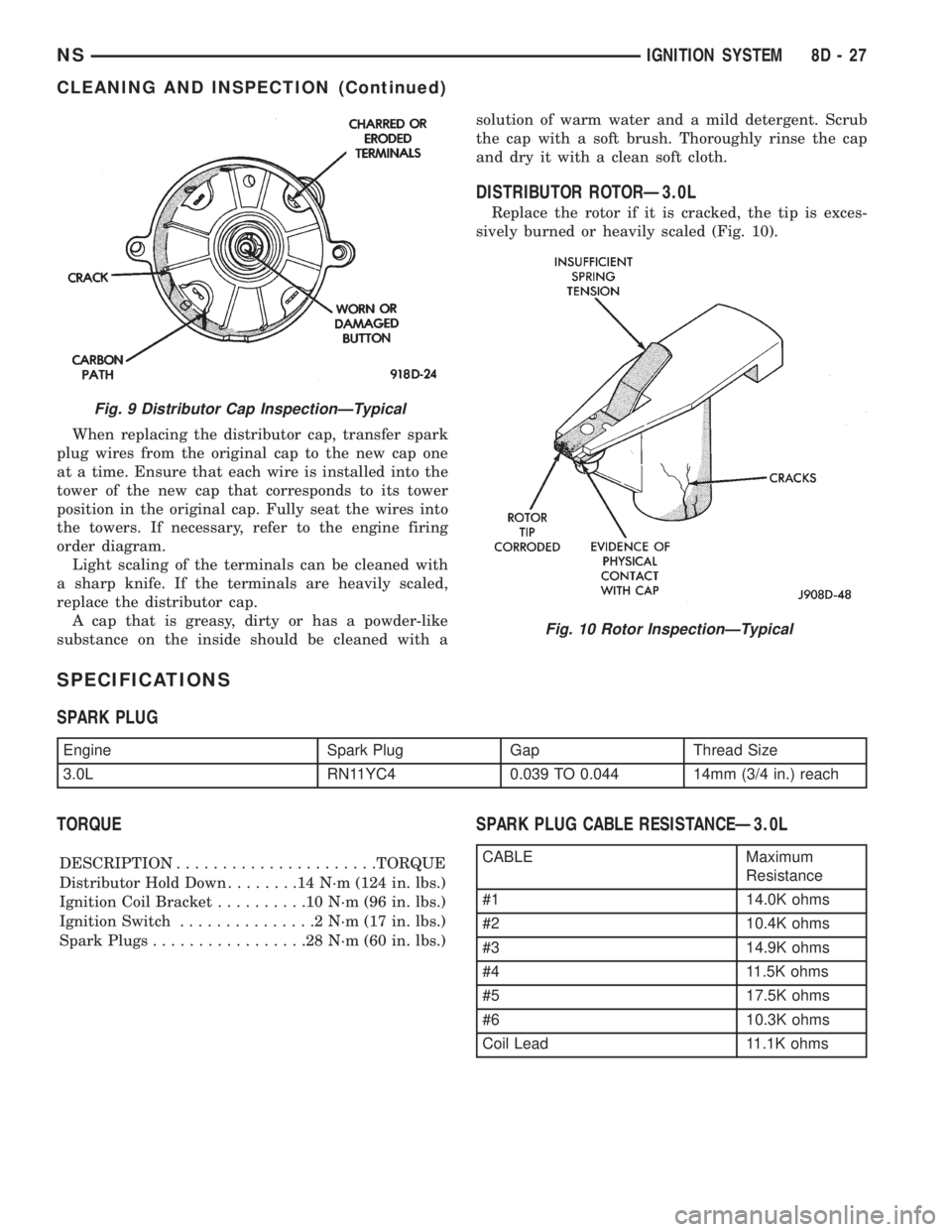

When replacing the distributor cap, transfer spark

plug wires from the original cap to the new cap one

at a time. Ensure that each wire is installed into the

tower of the new cap that corresponds to its tower

position in the original cap. Fully seat the wires into

the towers. If necessary, refer to the engine firing

order diagram.

Light scaling of the terminals can be cleaned with

a sharp knife. If the terminals are heavily scaled,

replace the distributor cap.

A cap that is greasy, dirty or has a powder-like

substance on the inside should be cleaned with asolution of warm water and a mild detergent. Scrub

the cap with a soft brush. Thoroughly rinse the cap

and dry it with a clean soft cloth.

DISTRIBUTOR ROTORÐ3.0L

Replace the rotor if it is cracked, the tip is exces-

sively burned or heavily scaled (Fig. 10).

SPECIFICATIONS

SPARK PLUG

TORQUE

DESCRIPTION......................TORQUE

Distributor Hold Down........14N´m(124 in. lbs.)

Ignition Coil Bracket..........10N´m(96in.lbs.)

Ignition Switch...............2N´m(17in.lbs.)

Spark Plugs.................28N´m(60in.lbs.)

SPARK PLUG CABLE RESISTANCEÐ3.0L

Fig. 9 Distributor Cap InspectionÐTypical

Fig. 10 Rotor InspectionÐTypical

Engine Spark Plug Gap Thread Size

3.0L RN11YC4 0.039 TO 0.044 14mm (3/4 in.) reach

CABLE Maximum

Resistance

#1 14.0K ohms

#2 10.4K ohms

#3 14.9K ohms

#4 11.5K ohms

#5 17.5K ohms

#6 10.3K ohms

Coil Lead 11.1K ohms

NSIGNITION SYSTEM 8D - 27

CLEANING AND INSPECTION (Continued)

Page 326 of 1938

3.3/3.8L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

FIRING ORDERÐ3.3/3.8L................. 28

REMOVAL AND INSTALLATION

CAMSHAFT POSITION SENSOR............ 31

CRANKSHAFT POSITION SENSOR.......... 30

ENGINE COOLANT TEMPERATURE SENSOR . . 32

IGNITION COIL......................... 30

KNOCK SENSORÐ3.3/3.8L................ 32

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR............................. 32SPARK PLUG CABLE SERVICEÐ3.3/3.8L

ENGINES............................ 28

SPARK PLUG SERVICEÐ3.3/3.8L ENGINES . . . 29

THROTTLE POSITION SENSOR............ 32

SPECIFICATIONS

IGNITION COIL......................... 33

SPARK PLUG CABLE RESISTANCEÐ3.3/3.8L . . 34

SPARK PLUG........................... 33

TORQUE.............................. 34

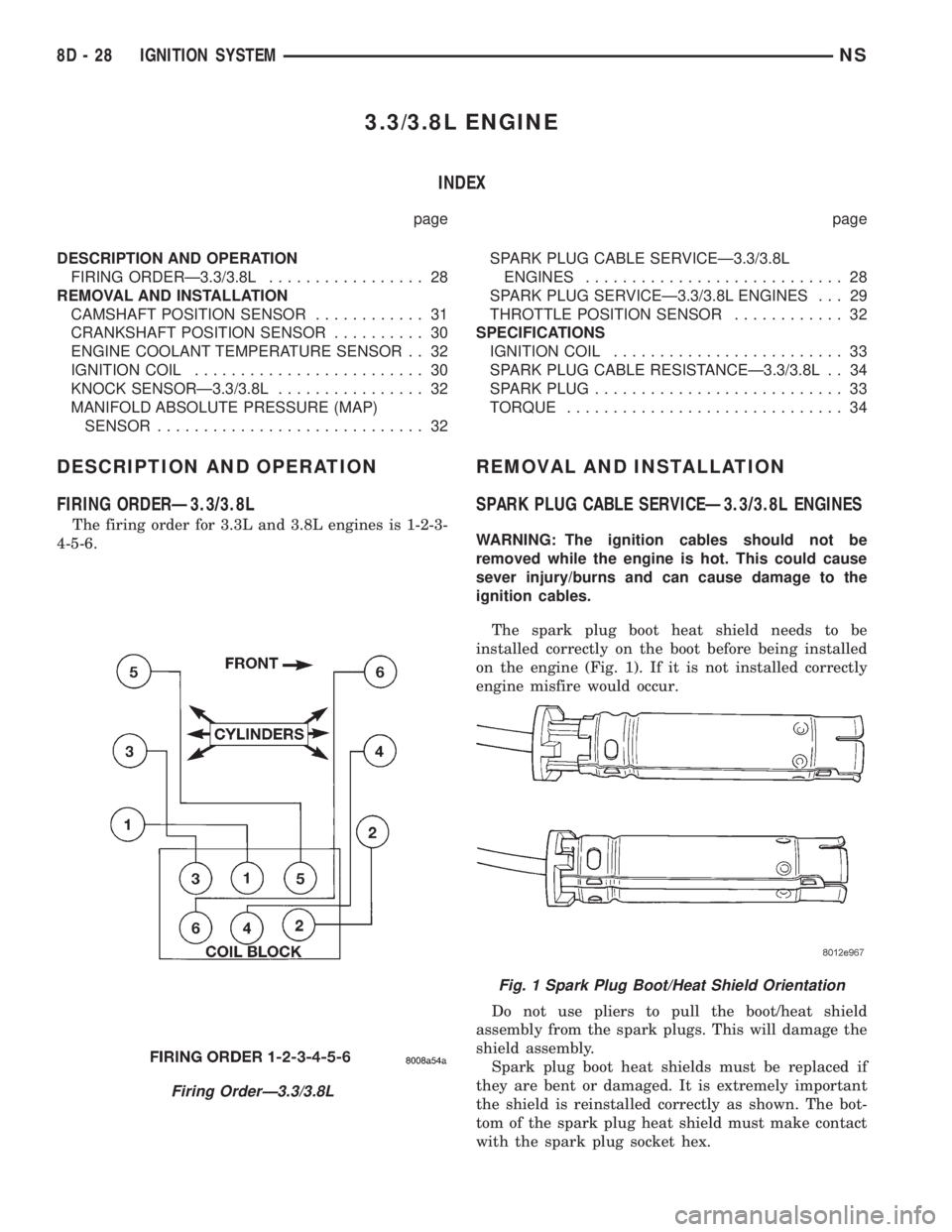

DESCRIPTION AND OPERATION

FIRING ORDERÐ3.3/3.8L

The firing order for 3.3L and 3.8L engines is 1-2-3-

4-5-6.

REMOVAL AND INSTALLATION

SPARK PLUG CABLE SERVICEÐ3.3/3.8L ENGINES

WARNING: The ignition cables should not be

removed while the engine is hot. This could cause

sever injury/burns and can cause damage to the

ignition cables.

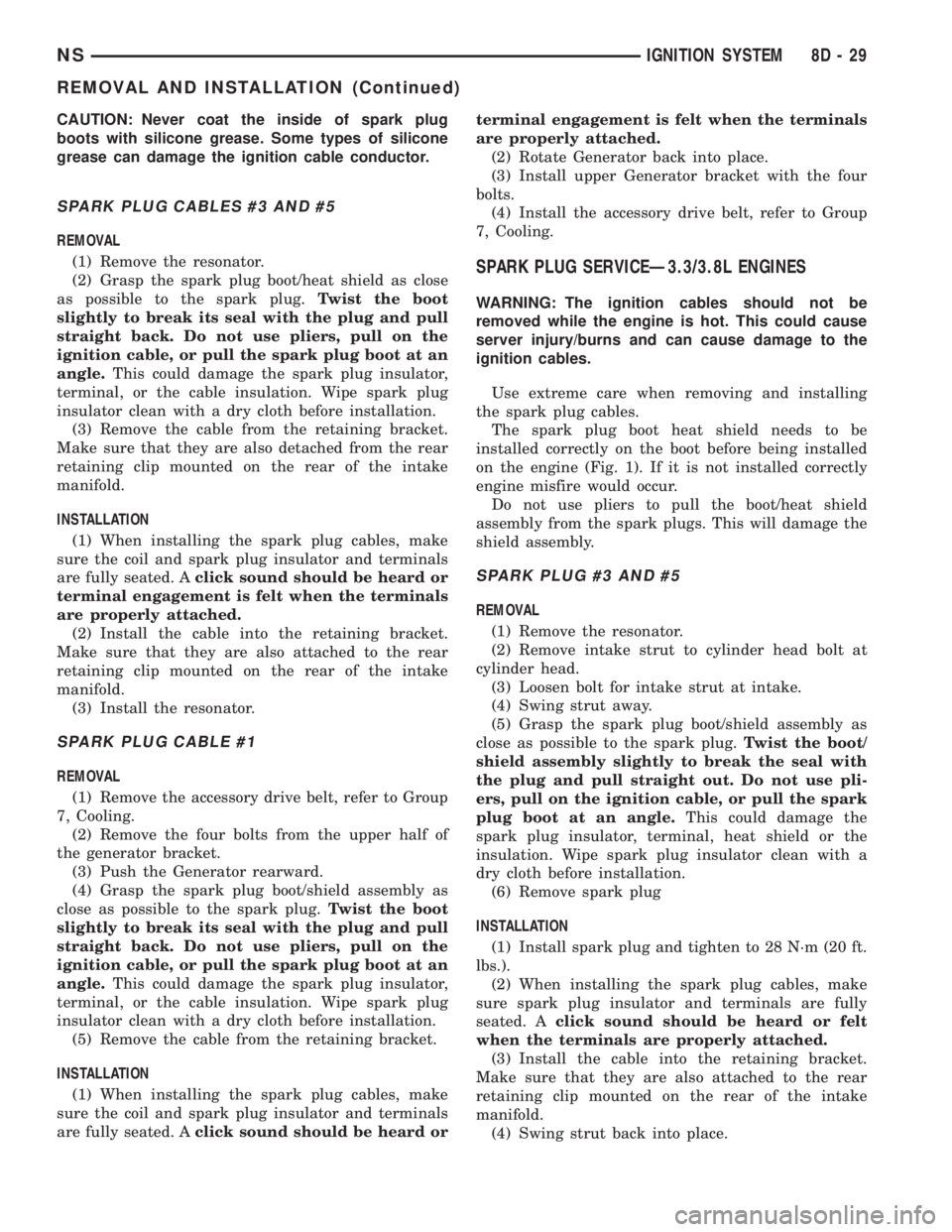

The spark plug boot heat shield needs to be

installed correctly on the boot before being installed

on the engine (Fig. 1). If it is not installed correctly

engine misfire would occur.

Do not use pliers to pull the boot/heat shield

assembly from the spark plugs. This will damage the

shield assembly.

Spark plug boot heat shields must be replaced if

they are bent or damaged. It is extremely important

the shield is reinstalled correctly as shown. The bot-

tom of the spark plug heat shield must make contact

with the spark plug socket hex.

Firing OrderÐ3.3/3.8L

Fig. 1 Spark Plug Boot/Heat Shield Orientation

8D - 28 IGNITION SYSTEMNS

Page 327 of 1938

CAUTION: Never coat the inside of spark plug

boots with silicone grease. Some types of silicone

grease can damage the ignition cable conductor.

SPARK PLUG CABLES #3 AND #5

REMOVAL

(1) Remove the resonator.

(2) Grasp the spark plug boot/heat shield as close

as possible to the spark plug.Twist the boot

slightly to break its seal with the plug and pull

straight back. Do not use pliers, pull on the

ignition cable, or pull the spark plug boot at an

angle.This could damage the spark plug insulator,

terminal, or the cable insulation. Wipe spark plug

insulator clean with a dry cloth before installation.

(3) Remove the cable from the retaining bracket.

Make sure that they are also detached from the rear

retaining clip mounted on the rear of the intake

manifold.

INSTALLATION

(1) When installing the spark plug cables, make

sure the coil and spark plug insulator and terminals

are fully seated. Aclick sound should be heard or

terminal engagement is felt when the terminals

are properly attached.

(2) Install the cable into the retaining bracket.

Make sure that they are also attached to the rear

retaining clip mounted on the rear of the intake

manifold.

(3) Install the resonator.

SPARK PLUG CABLE #1

REMOVAL

(1) Remove the accessory drive belt, refer to Group

7, Cooling.

(2) Remove the four bolts from the upper half of

the generator bracket.

(3) Push the Generator rearward.

(4) Grasp the spark plug boot/shield assembly as

close as possible to the spark plug.Twist the boot

slightly to break its seal with the plug and pull

straight back. Do not use pliers, pull on the

ignition cable, or pull the spark plug boot at an

angle.This could damage the spark plug insulator,

terminal, or the cable insulation. Wipe spark plug

insulator clean with a dry cloth before installation.

(5) Remove the cable from the retaining bracket.

INSTALLATION

(1) When installing the spark plug cables, make

sure the coil and spark plug insulator and terminals

are fully seated. Aclick sound should be heard orterminal engagement is felt when the terminals

are properly attached.

(2) Rotate Generator back into place.

(3) Install upper Generator bracket with the four

bolts.

(4) Install the accessory drive belt, refer to Group

7, Cooling.

SPARK PLUG SERVICEÐ3.3/3.8L ENGINES

WARNING: The ignition cables should not be

removed while the engine is hot. This could cause

server injury/burns and can cause damage to the

ignition cables.

Use extreme care when removing and installing

the spark plug cables.

The spark plug boot heat shield needs to be

installed correctly on the boot before being installed

on the engine (Fig. 1). If it is not installed correctly

engine misfire would occur.

Do not use pliers to pull the boot/heat shield

assembly from the spark plugs. This will damage the

shield assembly.

SPARK PLUG #3 AND #5

REMOVAL

(1) Remove the resonator.

(2) Remove intake strut to cylinder head bolt at

cylinder head.

(3) Loosen bolt for intake strut at intake.

(4) Swing strut away.

(5) Grasp the spark plug boot/shield assembly as

close as possible to the spark plug.Twist the boot/

shield assembly slightly to break the seal with

the plug and pull straight out. Do not use pli-

ers, pull on the ignition cable, or pull the spark

plug boot at an angle.This could damage the

spark plug insulator, terminal, heat shield or the

insulation. Wipe spark plug insulator clean with a

dry cloth before installation.

(6) Remove spark plug

INSTALLATION

(1) Install spark plug and tighten to 28 N´m (20 ft.

lbs.).

(2) When installing the spark plug cables, make

sure spark plug insulator and terminals are fully

seated. Aclick sound should be heard or felt

when the terminals are properly attached.

(3) Install the cable into the retaining bracket.

Make sure that they are also attached to the rear

retaining clip mounted on the rear of the intake

manifold.

(4) Swing strut back into place.

NSIGNITION SYSTEM 8D - 29

REMOVAL AND INSTALLATION (Continued)

Page 332 of 1938

SPARK PLUG

* New Spark Plug Gap

TORQUE

DESCRIPTION......................TORQUE

3.3L Camshaft Position

Sensor Screw.............12N´m(105 in. lbs.)

3.3L Engine Coolant Sensor......7N´m(60in.lbs.)

3.3L Crankshaft Position

Sensor Screw.............12N´m(105 in. lbs.)

3.3/3.8L Ignition Coil.........12N´m(105 in. lbs.)

Ignition Switch...............2N´m(17in.lbs.)

Spark Plugs.................28N´m(20ft.lbs.)

SPARK PLUG CABLE RESISTANCEÐ3.3/3.8L

Engine Spark Plug Gap * Thread Size

3.3L RN14PMP5 0.048 TO 0.053 14mm (3/4 in.) reach

3.8L RN14PMP5 0.048 TO 0.053 14mm (3/4 in. ) reach

CABLE Maximum

Resistance

#1 18.5K ohms

#2 15.5K ohms

#3 20.4K ohms

#4 21.2K ohms

#5 27.7K ohms

#6 26.7K ohms

8D - 34 IGNITION SYSTEMNS

SPECIFICATIONS (Continued)

Page 1052 of 1938

made to seal the area between the bedplate and cyl-

inder block without disturbing the bearing clearance

or alignment of these components.

GASKET DISASSEMBLY

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some

instances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper

may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

SURFACE PREPARATION

Scrape clean or wire brush all gasket surfaces to

remove all loose material. Inspect stamped parts to

ensure gasket rails are flat. Gasket surfaces must be

free of oil and dirt. Make sure old gasket material is

removed from blind attaching holes.

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing the material off location.

TheMopartSilicone Rubber Adhesive Sealant

gasket material or equivalent should be applied in a

continuous bead approximately 3 mm (0.120 in.) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 in.) drop

is placed in the center of the gasket contact area.

Uncured sealant may be removed with a shop towels.

Components should be torqued in place while the

sealant is still wet to the touch (within 10 minutes).

The usage of a locating dowel is recommended during

assembly to prevent smearing of material off loca-

tion.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

ENGINE CORE PLUGS

REMOVAL

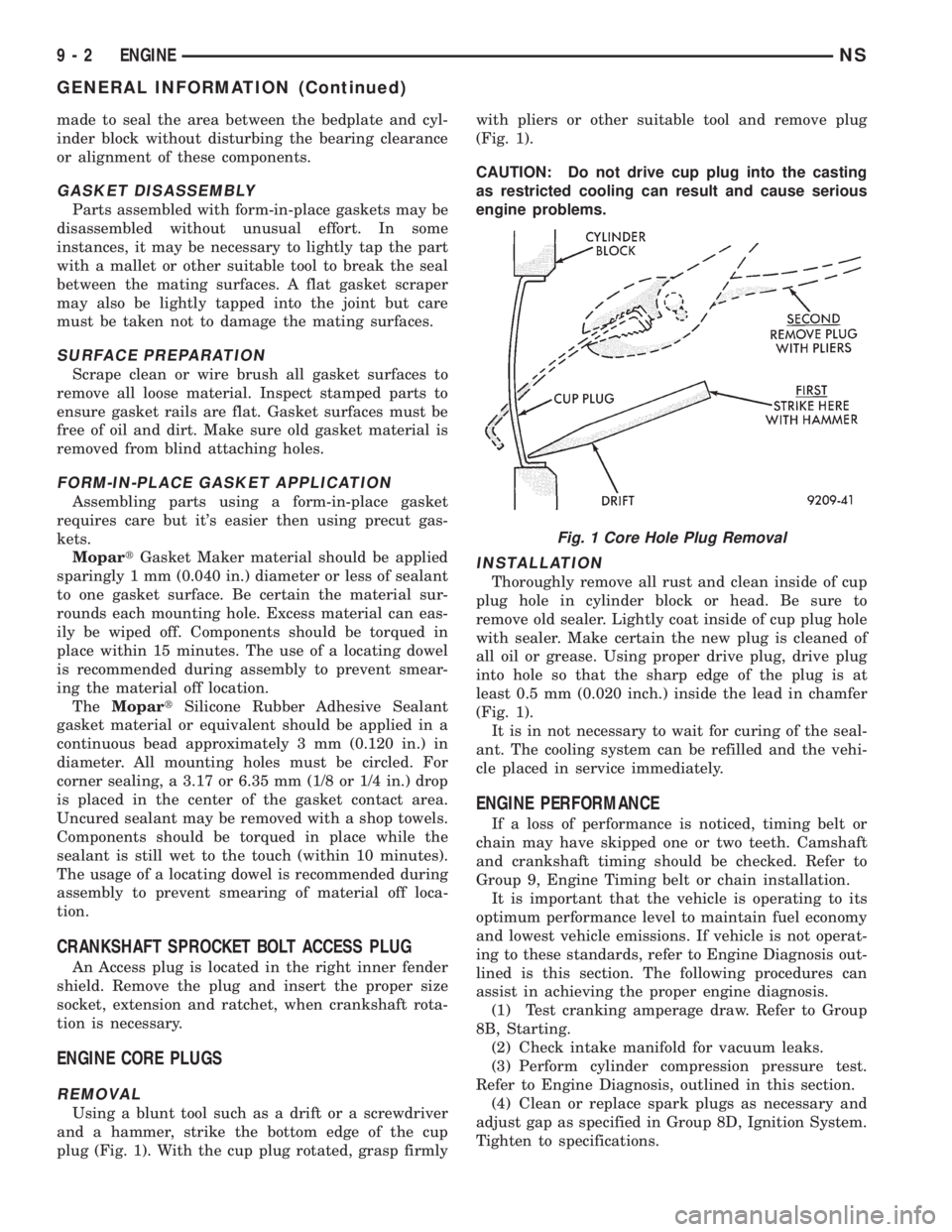

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 1). With the cup plug rotated, grasp firmlywith pliers or other suitable tool and remove plug

(Fig. 1).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly remove all rust and clean inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with sealer. Make certain the new plug is cleaned of

all oil or grease. Using proper drive plug, drive plug

into hole so that the sharp edge of the plug is at

least 0.5 mm (0.020 inch.) inside the lead in chamfer

(Fig. 1).

It is in not necessary to wait for curing of the seal-

ant. The cooling system can be refilled and the vehi-

cle placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-

ing to these standards, refer to Engine Diagnosis out-

lined is this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis, outlined in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

Fig. 1 Core Hole Plug Removal

9 - 2 ENGINENS

GENERAL INFORMATION (Continued)

Page 1055 of 1938

CAUTION: Be sure that the tapped holes maintain

the original centerline.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HYDROSTATIC LOCKED ENGINE

When an engine is suspected to be hydrostatically

locked, regardless of what caused the problem, these

steps should be used.

CAUTION: Do Not Use Starter Motor To Rotate

Engine, severe damage may occur.

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., Connecting

Rods, Pistons, Valves etc.)

(7) Repair engine or components as necessary to

prevent this problem from occurring again.

CAUTION: Squirt approximately 1 teaspoon of oil

into cylinders, rotate engine to lubricate the cylin-

der walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Fill engine with specified amount of approved

oil and install new oil filter.

(11) Connect negative battery cable.

(12) Start engine and check for any leaks.

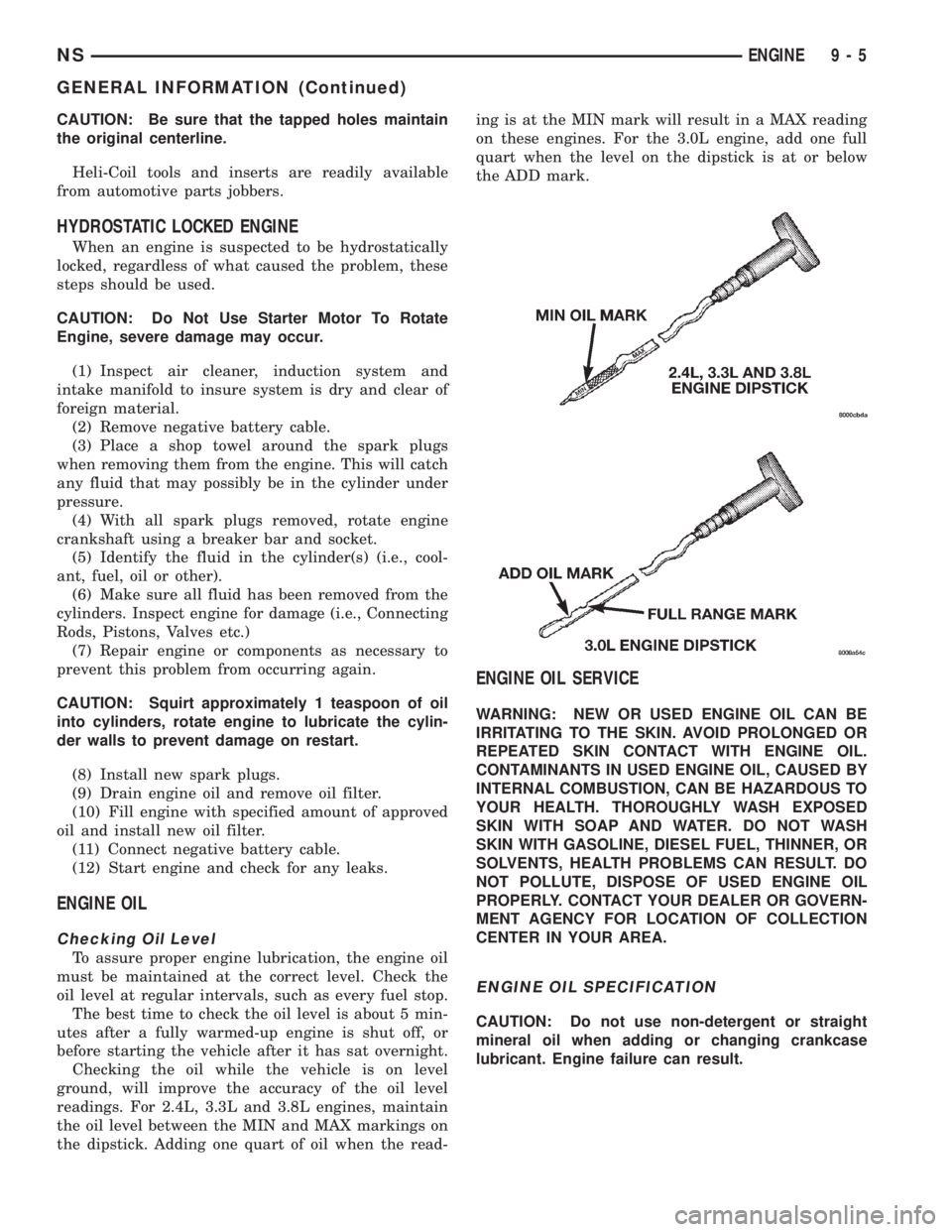

ENGINE OIL

Checking Oil Level

To assure proper engine lubrication, the engine oil

must be maintained at the correct level. Check the

oil level at regular intervals, such as every fuel stop.

The best time to check the oil level is about 5 min-

utes after a fully warmed-up engine is shut off, or

before starting the vehicle after it has sat overnight.

Checking the oil while the vehicle is on level

ground, will improve the accuracy of the oil level

readings. For 2.4L, 3.3L and 3.8L engines, maintain

the oil level between the MIN and MAX markings on

the dipstick. Adding one quart of oil when the read-ing is at the MIN mark will result in a MAX reading

on these engines. For the 3.0L engine, add one full

quart when the level on the dipstick is at or below

the ADD mark.

ENGINE OIL SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

NSENGINE 9 - 5

GENERAL INFORMATION (Continued)

Page 1057 of 1938

ENGINE DIAGNOSIS

INDEX

page page

DIAGNOSIS AND TESTING

CYLINDER COMBUSTION

PRESSURE LEAKAGE TEST.............. 8

CYLINDER COMPRESSION PRESSURE TEST . . 7

ENGINE DIAGNOSISÐMECHANICAL......... 12

ENGINE DIAGNOSISÐPERFORMANCE...... 10GENERAL INFORMATION.................. 7

INSPECTION

(ENGINE OIL LEAKS IN GENERAL)......... 8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS..... 7

LASH ADJUSTER (TAPPET)

NOISE DIAGNOSIS...................... 8

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If a change in RPM'S, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

NSENGINE 9 - 7

Page 1058 of 1938

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary

and adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance,.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and disassem-

bleDo not reuse retainer caps. Do not inter-

change parts and make sure that care and

cleanliness is exercised in the handling of parts.

c. Clean out dirt and varnish with solvent.

d. Reassemble with engine oil.

e. Check for sponginess.

f. If still spongy, replace with new adjuster.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

9 - 8 ENGINENS

DIAGNOSIS AND TESTING (Continued)