service CHRYSLER VOYAGER 1996 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 123 of 1938

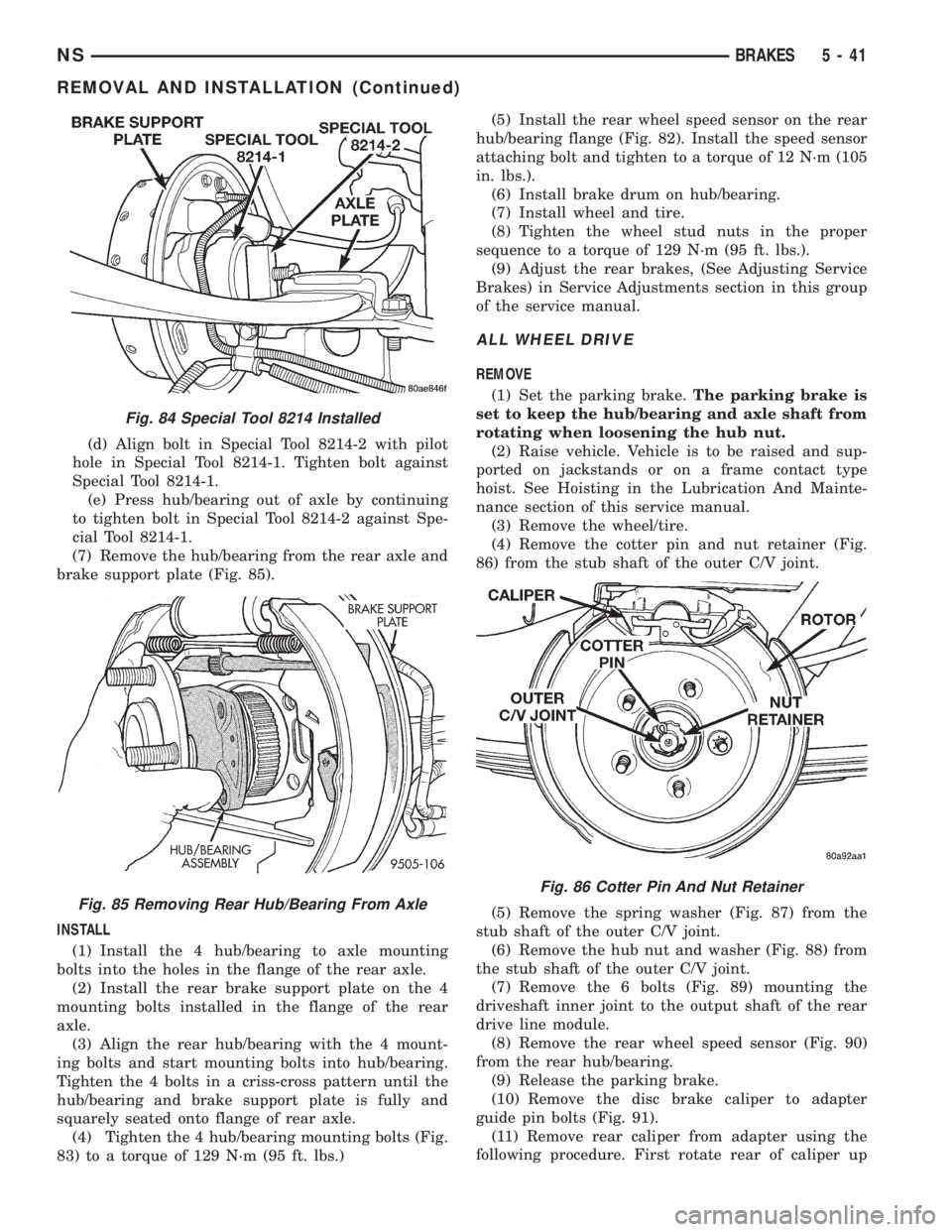

(d) Align bolt in Special Tool 8214-2 with pilot

hole in Special Tool 8214-1. Tighten bolt against

Special Tool 8214-1.

(e) Press hub/bearing out of axle by continuing

to tighten bolt in Special Tool 8214-2 against Spe-

cial Tool 8214-1.

(7) Remove the hub/bearing from the rear axle and

brake support plate (Fig. 85).

INSTALL

(1) Install the 4 hub/bearing to axle mounting

bolts into the holes in the flange of the rear axle.

(2) Install the rear brake support plate on the 4

mounting bolts installed in the flange of the rear

axle.

(3) Align the rear hub/bearing with the 4 mount-

ing bolts and start mounting bolts into hub/bearing.

Tighten the 4 bolts in a criss-cross pattern until the

hub/bearing and brake support plate is fully and

squarely seated onto flange of rear axle.

(4) Tighten the 4 hub/bearing mounting bolts (Fig.

83) to a torque of 129 N´m (95 ft. lbs.)(5) Install the rear wheel speed sensor on the rear

hub/bearing flange (Fig. 82). Install the speed sensor

attaching bolt and tighten to a torque of 12 N´m (105

in. lbs.).

(6) Install brake drum on hub/bearing.

(7) Install wheel and tire.

(8) Tighten the wheel stud nuts in the proper

sequence to a torque of 129 N´m (95 ft. lbs.).

(9) Adjust the rear brakes, (See Adjusting Service

Brakes) in Service Adjustments section in this group

of the service manual.

ALL WHEEL DRIVE

REMOVE

(1) Set the parking brake.The parking brake is

set to keep the hub/bearing and axle shaft from

rotating when loosening the hub nut.

(2) Raise vehicle. Vehicle is to be raised and sup-

ported on jackstands or on a frame contact type

hoist. See Hoisting in the Lubrication And Mainte-

nance section of this service manual.

(3) Remove the wheel/tire.

(4) Remove the cotter pin and nut retainer (Fig.

86) from the stub shaft of the outer C/V joint.

(5) Remove the spring washer (Fig. 87) from the

stub shaft of the outer C/V joint.

(6) Remove the hub nut and washer (Fig. 88) from

the stub shaft of the outer C/V joint.

(7) Remove the 6 bolts (Fig. 89) mounting the

driveshaft inner joint to the output shaft of the rear

drive line module.

(8) Remove the rear wheel speed sensor (Fig. 90)

from the rear hub/bearing.

(9) Release the parking brake.

(10) Remove the disc brake caliper to adapter

guide pin bolts (Fig. 91).

(11) Remove rear caliper from adapter using the

following procedure. First rotate rear of caliper up

Fig. 84 Special Tool 8214 Installed

Fig. 85 Removing Rear Hub/Bearing From Axle

Fig. 86 Cotter Pin And Nut Retainer

NSBRAKES 5 - 41

REMOVAL AND INSTALLATION (Continued)

Page 130 of 1938

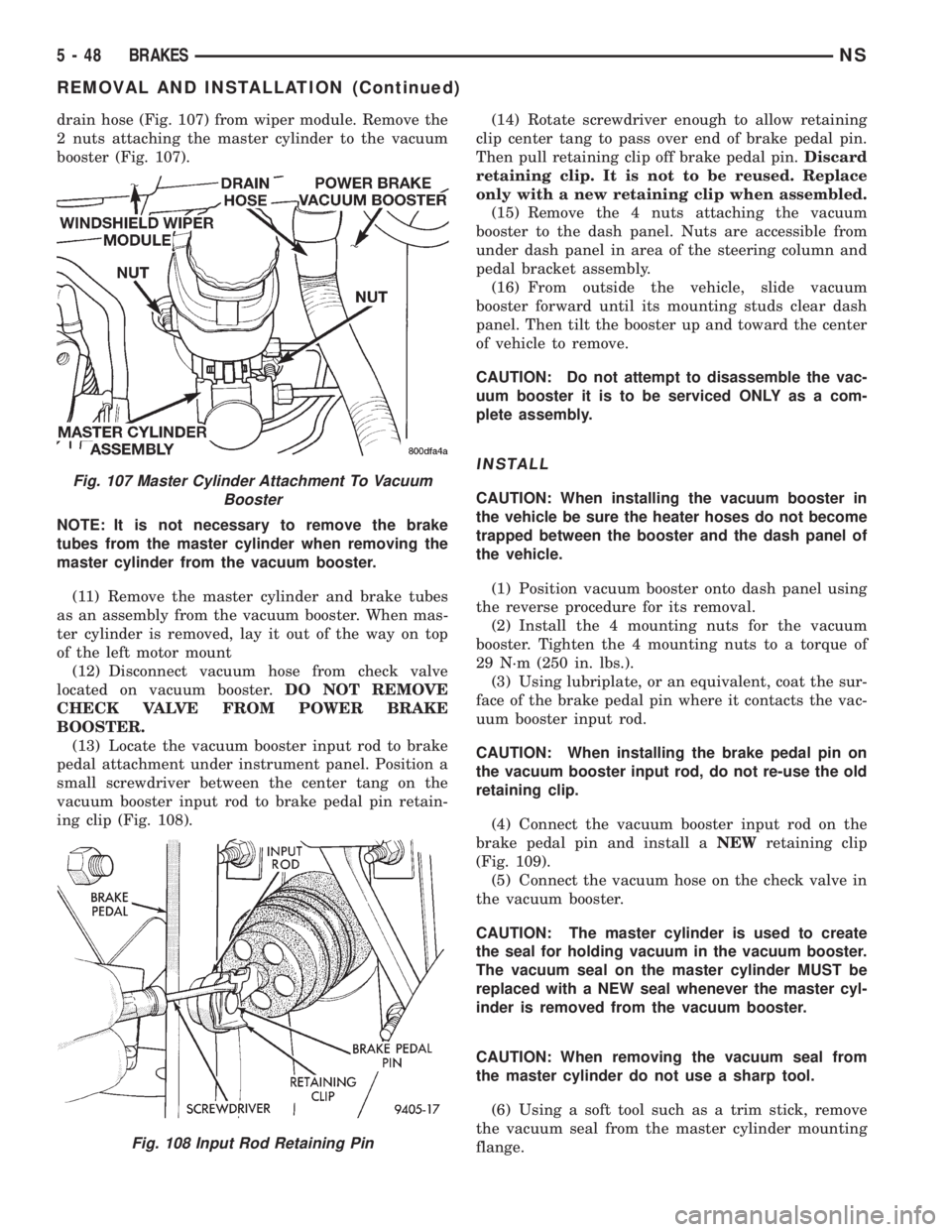

drain hose (Fig. 107) from wiper module. Remove the

2 nuts attaching the master cylinder to the vacuum

booster (Fig. 107).

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the vacuum booster.

(11) Remove the master cylinder and brake tubes

as an assembly from the vacuum booster. When mas-

ter cylinder is removed, lay it out of the way on top

of the left motor mount

(12) Disconnect vacuum hose from check valve

located on vacuum booster.DO NOT REMOVE

CHECK VALVE FROM POWER BRAKE

BOOSTER.

(13) Locate the vacuum booster input rod to brake

pedal attachment under instrument panel. Position a

small screwdriver between the center tang on the

vacuum booster input rod to brake pedal pin retain-

ing clip (Fig. 108).(14) Rotate screwdriver enough to allow retaining

clip center tang to pass over end of brake pedal pin.

Then pull retaining clip off brake pedal pin.Discard

retaining clip. It is not to be reused. Replace

only with a new retaining clip when assembled.

(15) Remove the 4 nuts attaching the vacuum

booster to the dash panel. Nuts are accessible from

under dash panel in area of the steering column and

pedal bracket assembly.

(16) From outside the vehicle, slide vacuum

booster forward until its mounting studs clear dash

panel. Then tilt the booster up and toward the center

of vehicle to remove.

CAUTION: Do not attempt to disassemble the vac-

uum booster it is to be serviced ONLY as a com-

plete assembly.

INSTALL

CAUTION: When installing the vacuum booster in

the vehicle be sure the heater hoses do not become

trapped between the booster and the dash panel of

the vehicle.

(1) Position vacuum booster onto dash panel using

the reverse procedure for its removal.

(2) Install the 4 mounting nuts for the vacuum

booster. Tighten the 4 mounting nuts to a torque of

29 N´m (250 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the vac-

uum booster input rod.

CAUTION: When installing the brake pedal pin on

the vacuum booster input rod, do not re-use the old

retaining clip.

(4) Connect the vacuum booster input rod on the

brake pedal pin and install aNEWretaining clip

(Fig. 109).

(5) Connect the vacuum hose on the check valve in

the vacuum booster.

CAUTION: The master cylinder is used to create

the seal for holding vacuum in the vacuum booster.

The vacuum seal on the master cylinder MUST be

replaced with a NEW seal whenever the master cyl-

inder is removed from the vacuum booster.

CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(6) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

Fig. 107 Master Cylinder Attachment To Vacuum

Booster

Fig. 108 Input Rod Retaining Pin

5 - 48 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 133 of 1938

clear dash panel. Then tilt the booster up and toward

the center of vehicle to remove.

CAUTION: Do not attempt to disassemble the

power brake vacuum booster it is to be serviced

ONLY as a complete assembly.

INSTALL

CAUTION: When installing the power brake vacuum

booster in the vehicle be sure the heater hoses do

not become trapped between the booster and the

dash panel of the vehicle.

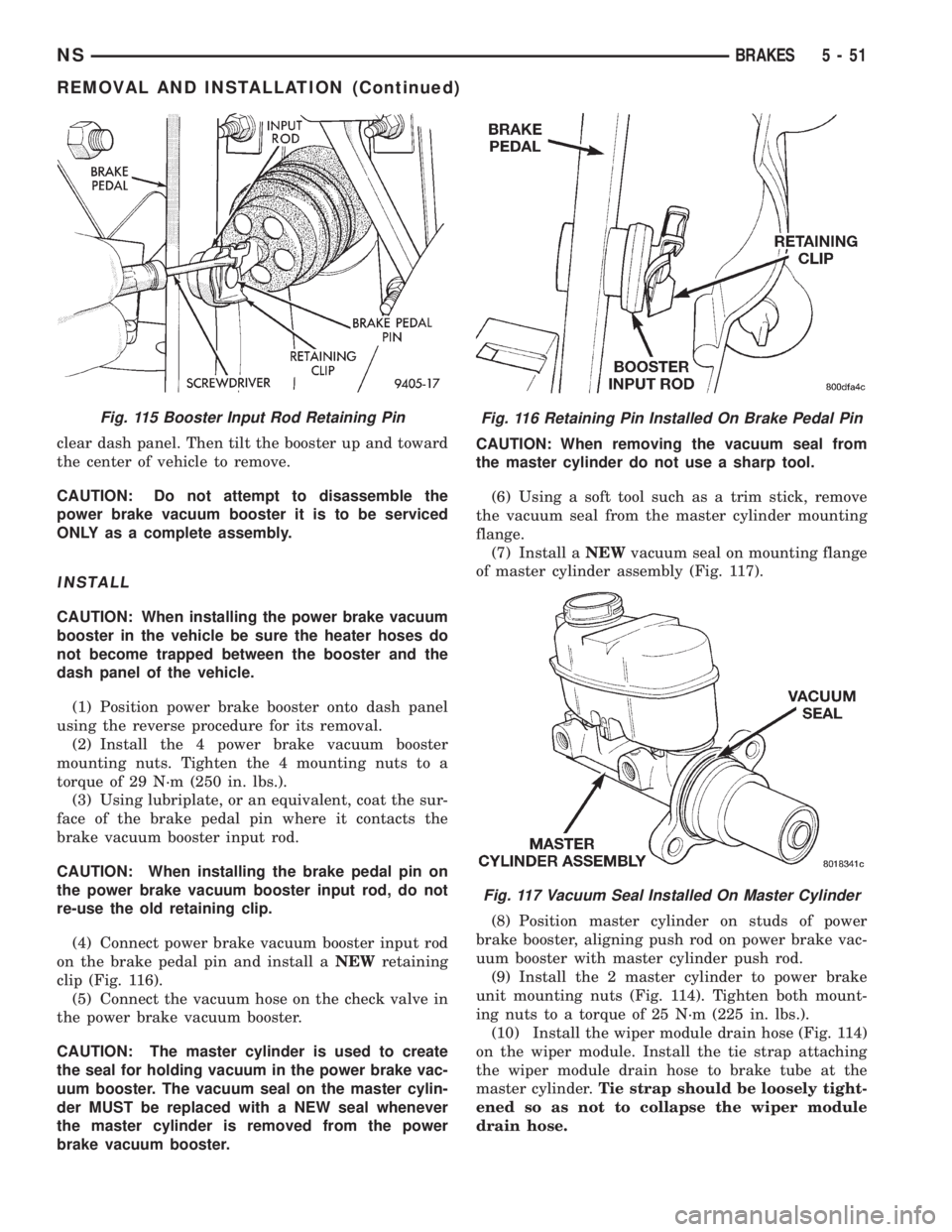

(1) Position power brake booster onto dash panel

using the reverse procedure for its removal.

(2) Install the 4 power brake vacuum booster

mounting nuts. Tighten the 4 mounting nuts to a

torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the

brake vacuum booster input rod.

CAUTION: When installing the brake pedal pin on

the power brake vacuum booster input rod, do not

re-use the old retaining clip.

(4) Connect power brake vacuum booster input rod

on the brake pedal pin and install aNEWretaining

clip (Fig. 116).

(5) Connect the vacuum hose on the check valve in

the power brake vacuum booster.

CAUTION: The master cylinder is used to create

the seal for holding vacuum in the power brake vac-

uum booster. The vacuum seal on the master cylin-

der MUST be replaced with a NEW seal whenever

the master cylinder is removed from the power

brake vacuum booster.CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(6) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(7) Install aNEWvacuum seal on mounting flange

of master cylinder assembly (Fig. 117).

(8) Position master cylinder on studs of power

brake booster, aligning push rod on power brake vac-

uum booster with master cylinder push rod.

(9) Install the 2 master cylinder to power brake

unit mounting nuts (Fig. 114). Tighten both mount-

ing nuts to a torque of 25 N´m (225 in. lbs.).

(10) Install the wiper module drain hose (Fig. 114)

on the wiper module. Install the tie strap attaching

the wiper module drain hose to brake tube at the

master cylinder.Tie strap should be loosely tight-

ened so as not to collapse the wiper module

drain hose.

Fig. 115 Booster Input Rod Retaining PinFig. 116 Retaining Pin Installed On Brake Pedal Pin

Fig. 117 Vacuum Seal Installed On Master Cylinder

NSBRAKES 5 - 51

REMOVAL AND INSTALLATION (Continued)

Page 136 of 1938

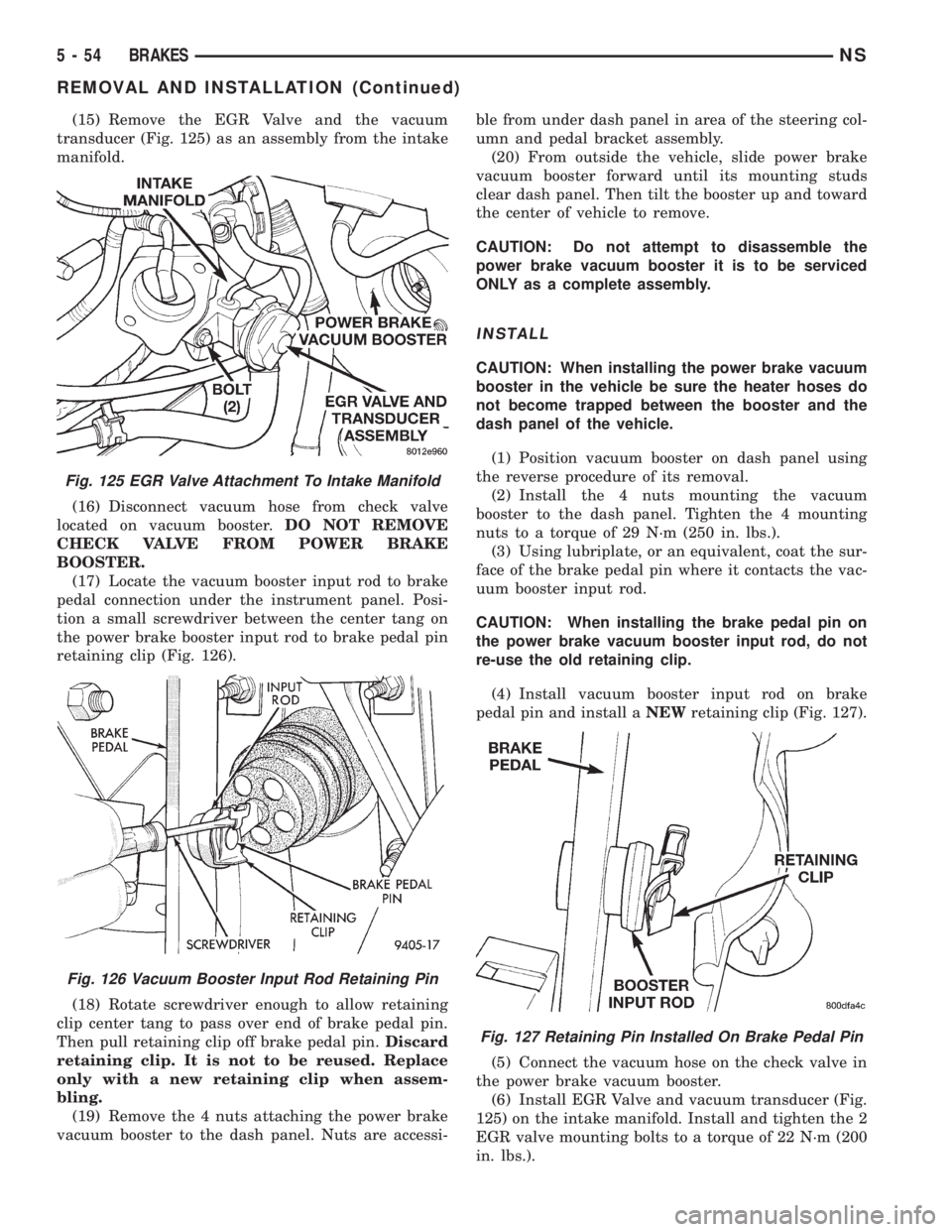

(15) Remove the EGR Valve and the vacuum

transducer (Fig. 125) as an assembly from the intake

manifold.

(16) Disconnect vacuum hose from check valve

located on vacuum booster.DO NOT REMOVE

CHECK VALVE FROM POWER BRAKE

BOOSTER.

(17) Locate the vacuum booster input rod to brake

pedal connection under the instrument panel. Posi-

tion a small screwdriver between the center tang on

the power brake booster input rod to brake pedal pin

retaining clip (Fig. 126).

(18) Rotate screwdriver enough to allow retaining

clip center tang to pass over end of brake pedal pin.

Then pull retaining clip off brake pedal pin.Discard

retaining clip. It is not to be reused. Replace

only with a new retaining clip when assem-

bling.

(19) Remove the 4 nuts attaching the power brake

vacuum booster to the dash panel. Nuts are accessi-ble from under dash panel in area of the steering col-

umn and pedal bracket assembly.

(20) From outside the vehicle, slide power brake

vacuum booster forward until its mounting studs

clear dash panel. Then tilt the booster up and toward

the center of vehicle to remove.

CAUTION: Do not attempt to disassemble the

power brake vacuum booster it is to be serviced

ONLY as a complete assembly.

INSTALL

CAUTION: When installing the power brake vacuum

booster in the vehicle be sure the heater hoses do

not become trapped between the booster and the

dash panel of the vehicle.

(1) Position vacuum booster on dash panel using

the reverse procedure of its removal.

(2) Install the 4 nuts mounting the vacuum

booster to the dash panel. Tighten the 4 mounting

nuts to a torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the vac-

uum booster input rod.

CAUTION: When installing the brake pedal pin on

the power brake vacuum booster input rod, do not

re-use the old retaining clip.

(4) Install vacuum booster input rod on brake

pedal pin and install aNEWretaining clip (Fig. 127).

(5) Connect the vacuum hose on the check valve in

the power brake vacuum booster.

(6) Install EGR Valve and vacuum transducer (Fig.

125) on the intake manifold. Install and tighten the 2

EGR valve mounting bolts to a torque of 22 N´m (200

in. lbs.).

Fig. 125 EGR Valve Attachment To Intake Manifold

Fig. 126 Vacuum Booster Input Rod Retaining Pin

Fig. 127 Retaining Pin Installed On Brake Pedal Pin

5 - 54 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 137 of 1938

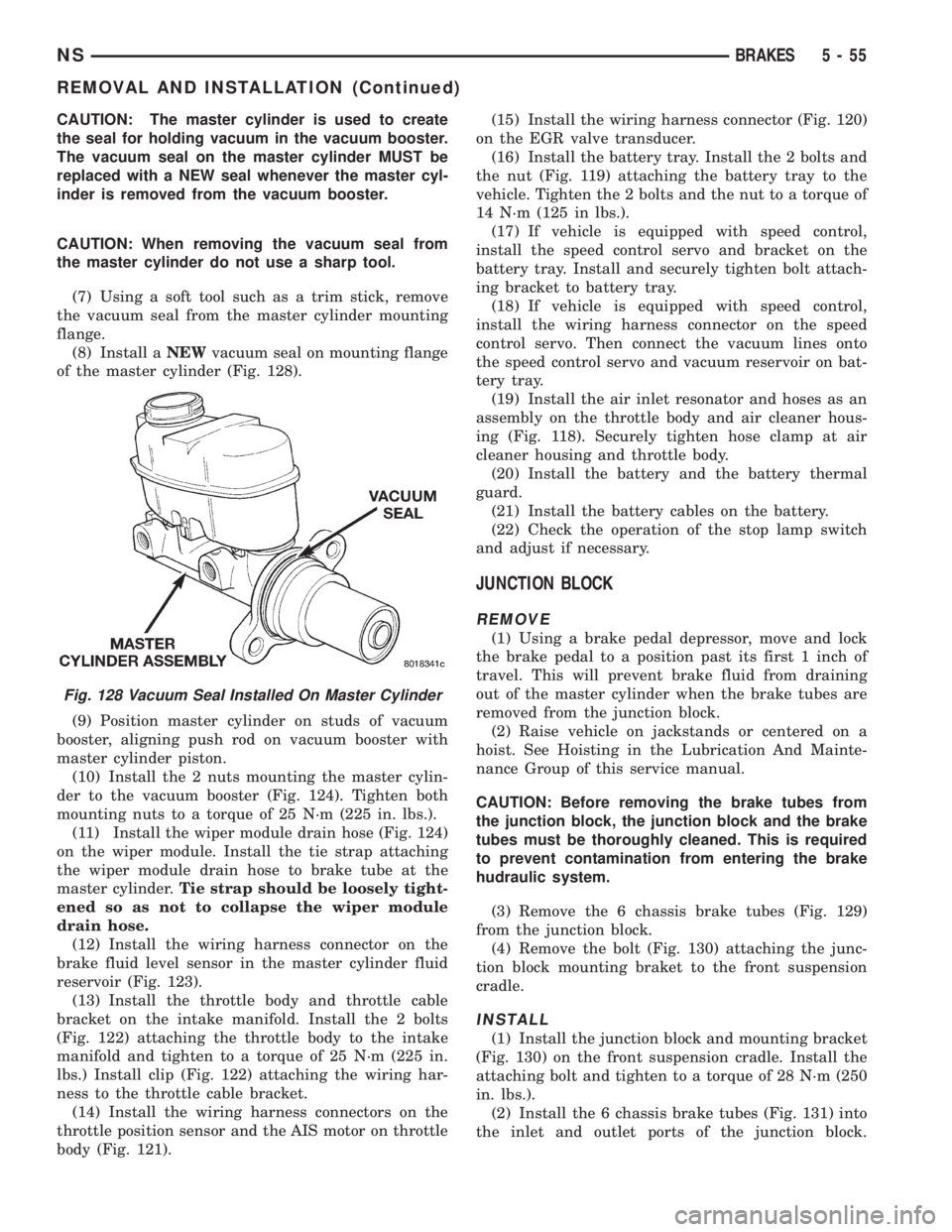

CAUTION: The master cylinder is used to create

the seal for holding vacuum in the vacuum booster.

The vacuum seal on the master cylinder MUST be

replaced with a NEW seal whenever the master cyl-

inder is removed from the vacuum booster.

CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(7) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(8) Install aNEWvacuum seal on mounting flange

of the master cylinder (Fig. 128).

(9) Position master cylinder on studs of vacuum

booster, aligning push rod on vacuum booster with

master cylinder piston.

(10) Install the 2 nuts mounting the master cylin-

der to the vacuum booster (Fig. 124). Tighten both

mounting nuts to a torque of 25 N´m (225 in. lbs.).

(11) Install the wiper module drain hose (Fig. 124)

on the wiper module. Install the tie strap attaching

the wiper module drain hose to brake tube at the

master cylinder.Tie strap should be loosely tight-

ened so as not to collapse the wiper module

drain hose.

(12) Install the wiring harness connector on the

brake fluid level sensor in the master cylinder fluid

reservoir (Fig. 123).

(13) Install the throttle body and throttle cable

bracket on the intake manifold. Install the 2 bolts

(Fig. 122) attaching the throttle body to the intake

manifold and tighten to a torque of 25 N´m (225 in.

lbs.) Install clip (Fig. 122) attaching the wiring har-

ness to the throttle cable bracket.

(14) Install the wiring harness connectors on the

throttle position sensor and the AIS motor on throttle

body (Fig. 121).(15) Install the wiring harness connector (Fig. 120)

on the EGR valve transducer.

(16) Install the battery tray. Install the 2 bolts and

the nut (Fig. 119) attaching the battery tray to the

vehicle. Tighten the 2 bolts and the nut to a torque of

14 N´m (125 in lbs.).

(17) If vehicle is equipped with speed control,

install the speed control servo and bracket on the

battery tray. Install and securely tighten bolt attach-

ing bracket to battery tray.

(18) If vehicle is equipped with speed control,

install the wiring harness connector on the speed

control servo. Then connect the vacuum lines onto

the speed control servo and vacuum reservoir on bat-

tery tray.

(19) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing (Fig. 118). Securely tighten hose clamp at air

cleaner housing and throttle body.

(20) Install the battery and the battery thermal

guard.

(21) Install the battery cables on the battery.

(22) Check the operation of the stop lamp switch

and adjust if necessary.

JUNCTION BLOCK

REMOVE

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block.

(2) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication And Mainte-

nance Group of this service manual.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hudraulic system.

(3) Remove the 6 chassis brake tubes (Fig. 129)

from the junction block.

(4) Remove the bolt (Fig. 130) attaching the junc-

tion block mounting braket to the front suspension

cradle.

INSTALL

(1) Install the junction block and mounting bracket

(Fig. 130) on the front suspension cradle. Install the

attaching bolt and tighten to a torque of 28 N´m (250

in. lbs.).

(2) Install the 6 chassis brake tubes (Fig. 131) into

the inlet and outlet ports of the junction block.

Fig. 128 Vacuum Seal Installed On Master Cylinder

NSBRAKES 5 - 55

REMOVAL AND INSTALLATION (Continued)

Page 138 of 1938

Tighten all 6 tube nuts to a torque of 16 N´m (145 in.

lbs.).

(3) Bleed the brake system thoroughly to ensure

that all air has been expelled from the hydraulic sys-tem. See Bleeding Brake System in the Service

Adjustments section in this group of the service man-

ual for the proper bleeding procedure.

(4) Lower the vehicle.

(5) Road test the vehicle to verify proper operation

of the vehicles brake system.

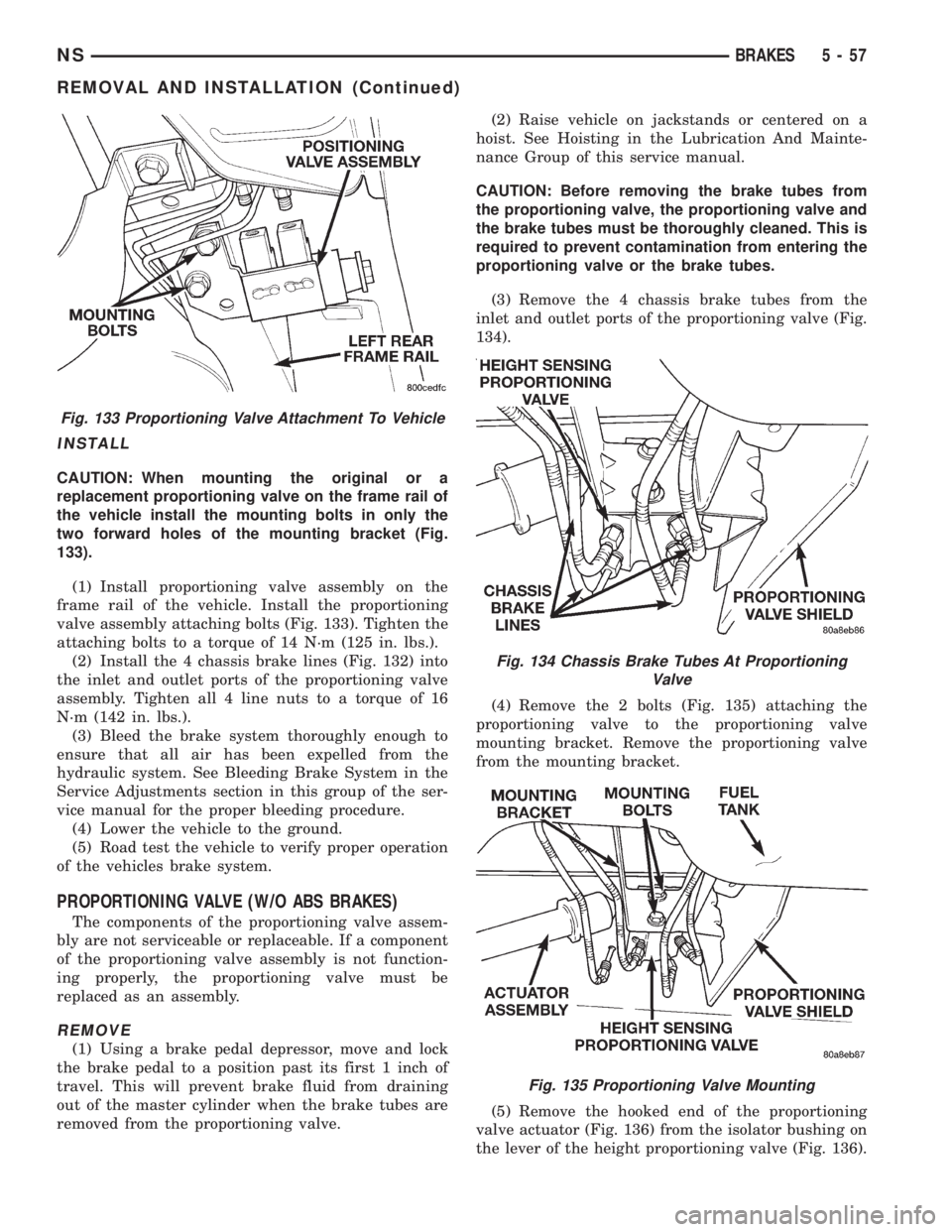

PROPORTIONING VALVE (W/ABS BRAKES)

The actual proportioning valves of the proportion-

ing valve assembly are not serviceable or replaceable.

If a proportioning valve of the proportioning valve

assembly is not functioning properly, the fixed pro-

portioning valve must be replaced as an assembly.

REMOVE

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the proportioning valve.

(2) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication And Mainte-

nance Group of this service manual.

CAUTION: Before removing the brake tubes from

the proportioning valve, the proportioning valve and

the brake tubes must be thoroughly cleaned. This is

required to prevent contamination from entering the

proportioning valve or the brake tubes.

(3) Remove the 4 chassis brake lines from the inlet

and outlet ports of the proportioning valve (Fig. 132).

(4) Remove the bolts (Fig. 133) attaching the pro-

portioning valve bracket to the frame rail of the vehi-

cle. Remove the fixed proportioning valve assembly

from the vehicle.

Fig. 129 Junction Block Brake Tubes

Fig. 130 Junction Block Mounting

Fig. 131 Brake Tube Connections To Junction Block

Fig. 132 Chassis Brake Tubes At Proportioning

Valve

5 - 56 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 139 of 1938

INSTALL

CAUTION: When mounting the original or a

replacement proportioning valve on the frame rail of

the vehicle install the mounting bolts in only the

two forward holes of the mounting bracket (Fig.

133).

(1) Install proportioning valve assembly on the

frame rail of the vehicle. Install the proportioning

valve assembly attaching bolts (Fig. 133). Tighten the

attaching bolts to a torque of 14 N´m (125 in. lbs.).

(2) Install the 4 chassis brake lines (Fig. 132) into

the inlet and outlet ports of the proportioning valve

assembly. Tighten all 4 line nuts to a torque of 16

N´m (142 in. lbs.).

(3) Bleed the brake system thoroughly enough to

ensure that all air has been expelled from the

hydraulic system. See Bleeding Brake System in the

Service Adjustments section in this group of the ser-

vice manual for the proper bleeding procedure.

(4) Lower the vehicle to the ground.

(5) Road test the vehicle to verify proper operation

of the vehicles brake system.

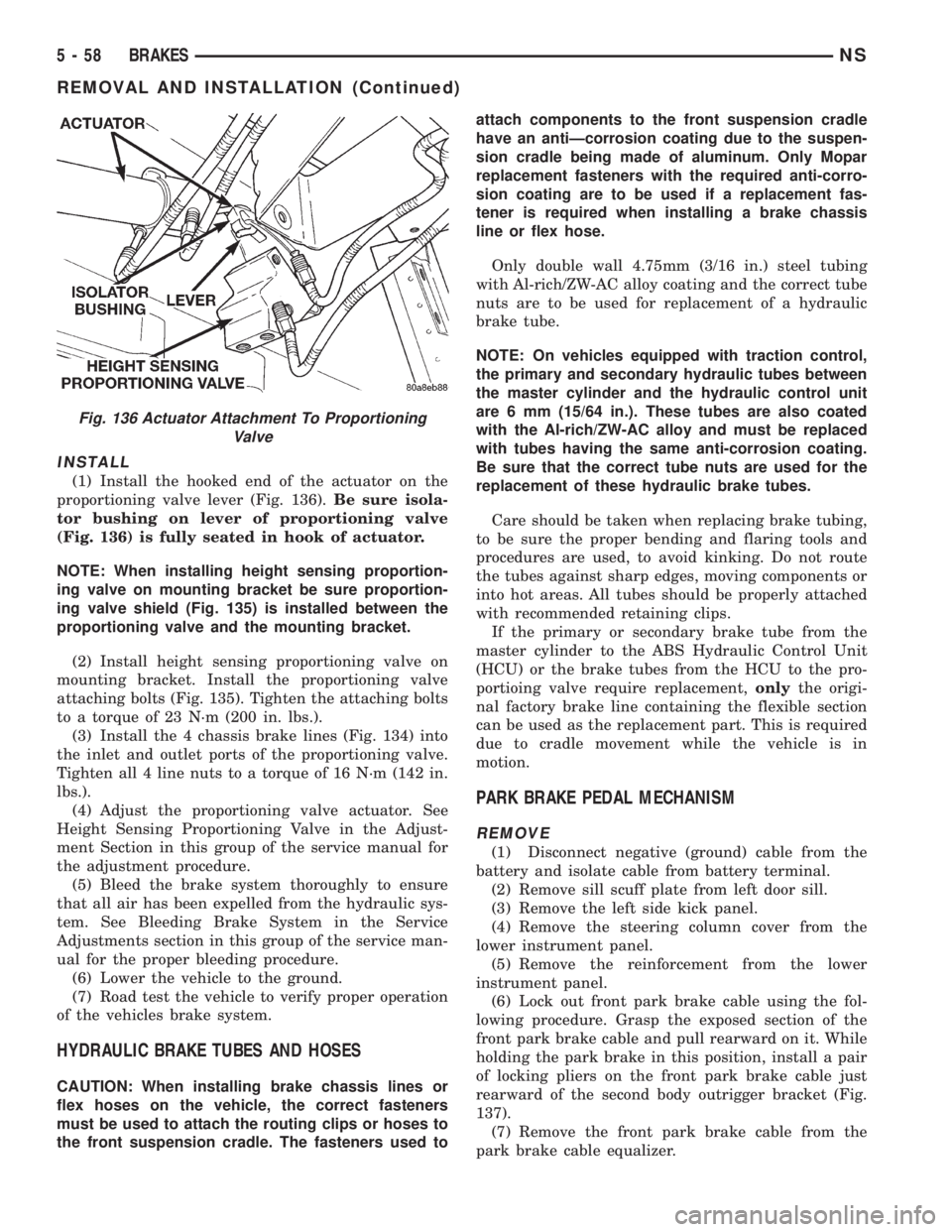

PROPORTIONING VALVE (W/O ABS BRAKES)

The components of the proportioning valve assem-

bly are not serviceable or replaceable. If a component

of the proportioning valve assembly is not function-

ing properly, the proportioning valve must be

replaced as an assembly.

REMOVE

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the proportioning valve.(2) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication And Mainte-

nance Group of this service manual.

CAUTION: Before removing the brake tubes from

the proportioning valve, the proportioning valve and

the brake tubes must be thoroughly cleaned. This is

required to prevent contamination from entering the

proportioning valve or the brake tubes.

(3) Remove the 4 chassis brake tubes from the

inlet and outlet ports of the proportioning valve (Fig.

134).

(4) Remove the 2 bolts (Fig. 135) attaching the

proportioning valve to the proportioning valve

mounting bracket. Remove the proportioning valve

from the mounting bracket.

(5) Remove the hooked end of the proportioning

valve actuator (Fig. 136) from the isolator bushing on

the lever of the height proportioning valve (Fig. 136).

Fig. 133 Proportioning Valve Attachment To Vehicle

Fig. 134 Chassis Brake Tubes At Proportioning

Valve

Fig. 135 Proportioning Valve Mounting

NSBRAKES 5 - 57

REMOVAL AND INSTALLATION (Continued)

Page 140 of 1938

INSTALL

(1) Install the hooked end of the actuator on the

proportioning valve lever (Fig. 136).Be sure isola-

tor bushing on lever of proportioning valve

(Fig. 136) is fully seated in hook of actuator.

NOTE: When installing height sensing proportion-

ing valve on mounting bracket be sure proportion-

ing valve shield (Fig. 135) is installed between the

proportioning valve and the mounting bracket.

(2) Install height sensing proportioning valve on

mounting bracket. Install the proportioning valve

attaching bolts (Fig. 135). Tighten the attaching bolts

to a torque of 23 N´m (200 in. lbs.).

(3) Install the 4 chassis brake lines (Fig. 134) into

the inlet and outlet ports of the proportioning valve.

Tighten all 4 line nuts to a torque of 16 N´m (142 in.

lbs.).

(4) Adjust the proportioning valve actuator. See

Height Sensing Proportioning Valve in the Adjust-

ment Section in this group of the service manual for

the adjustment procedure.

(5) Bleed the brake system thoroughly to ensure

that all air has been expelled from the hydraulic sys-

tem. See Bleeding Brake System in the Service

Adjustments section in this group of the service man-

ual for the proper bleeding procedure.

(6) Lower the vehicle to the ground.

(7) Road test the vehicle to verify proper operation

of the vehicles brake system.

HYDRAULIC BRAKE TUBES AND HOSES

CAUTION: When installing brake chassis lines or

flex hoses on the vehicle, the correct fasteners

must be used to attach the routing clips or hoses to

the front suspension cradle. The fasteners used toattach components to the front suspension cradle

have an antiÐcorrosion coating due to the suspen-

sion cradle being made of aluminum. Only Mopar

replacement fasteners with the required anti-corro-

sion coating are to be used if a replacement fas-

tener is required when installing a brake chassis

line or flex hose.

Only double wall 4.75mm (3/16 in.) steel tubing

with Al-rich/ZW-AC alloy coating and the correct tube

nuts are to be used for replacement of a hydraulic

brake tube.

NOTE: On vehicles equipped with traction control,

the primary and secondary hydraulic tubes between

the master cylinder and the hydraulic control unit

are 6 mm (15/64 in.). These tubes are also coated

with the Al-rich/ZW-AC alloy and must be replaced

with tubes having the same anti-corrosion coating.

Be sure that the correct tube nuts are used for the

replacement of these hydraulic brake tubes.

Care should be taken when replacing brake tubing,

to be sure the proper bending and flaring tools and

procedures are used, to avoid kinking. Do not route

the tubes against sharp edges, moving components or

into hot areas. All tubes should be properly attached

with recommended retaining clips.

If the primary or secondary brake tube from the

master cylinder to the ABS Hydraulic Control Unit

(HCU) or the brake tubes from the HCU to the pro-

portioing valve require replacement,onlythe origi-

nal factory brake line containing the flexible section

can be used as the replacement part. This is required

due to cradle movement while the vehicle is in

motion.

PARK BRAKE PEDAL MECHANISM

REMOVE

(1) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

(2) Remove sill scuff plate from left door sill.

(3) Remove the left side kick panel.

(4) Remove the steering column cover from the

lower instrument panel.

(5) Remove the reinforcement from the lower

instrument panel.

(6) Lock out front park brake cable using the fol-

lowing procedure. Grasp the exposed section of the

front park brake cable and pull rearward on it. While

holding the park brake in this position, install a pair

of locking pliers on the front park brake cable just

rearward of the second body outrigger bracket (Fig.

137).

(7) Remove the front park brake cable from the

park brake cable equalizer.

Fig. 136 Actuator Attachment To Proportioning

Valve

5 - 58 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 142 of 1938

(23) Install the negative (ground) cable on the bat-

tery.

(24) Cycle the park brake pedal one time. This will

seat the park brake cables and will allow the auto-

matic self adjuster to properly tension the park brake

cables.

PARK BRAKE SHOES (WITH REAR DISC BRAKES)

On this vehicle, the park brake shoes are removed

from the disc brake adapter with the disc brake

adapter removed from the vehicle.

REMOVE

(1) Set the parking brake.The parking brake is

set to keep the hub/bearing and axle shaft from

rotating when loosening the hub nut.

(2) Raise vehicle. Vehicle is to be raised and sup-

ported on jackstands or on a frame contact type

hoist. See Hoisting in the Lubrication And Mainte-

nance section of this service manual.

(3) Remove the wheel/tire.

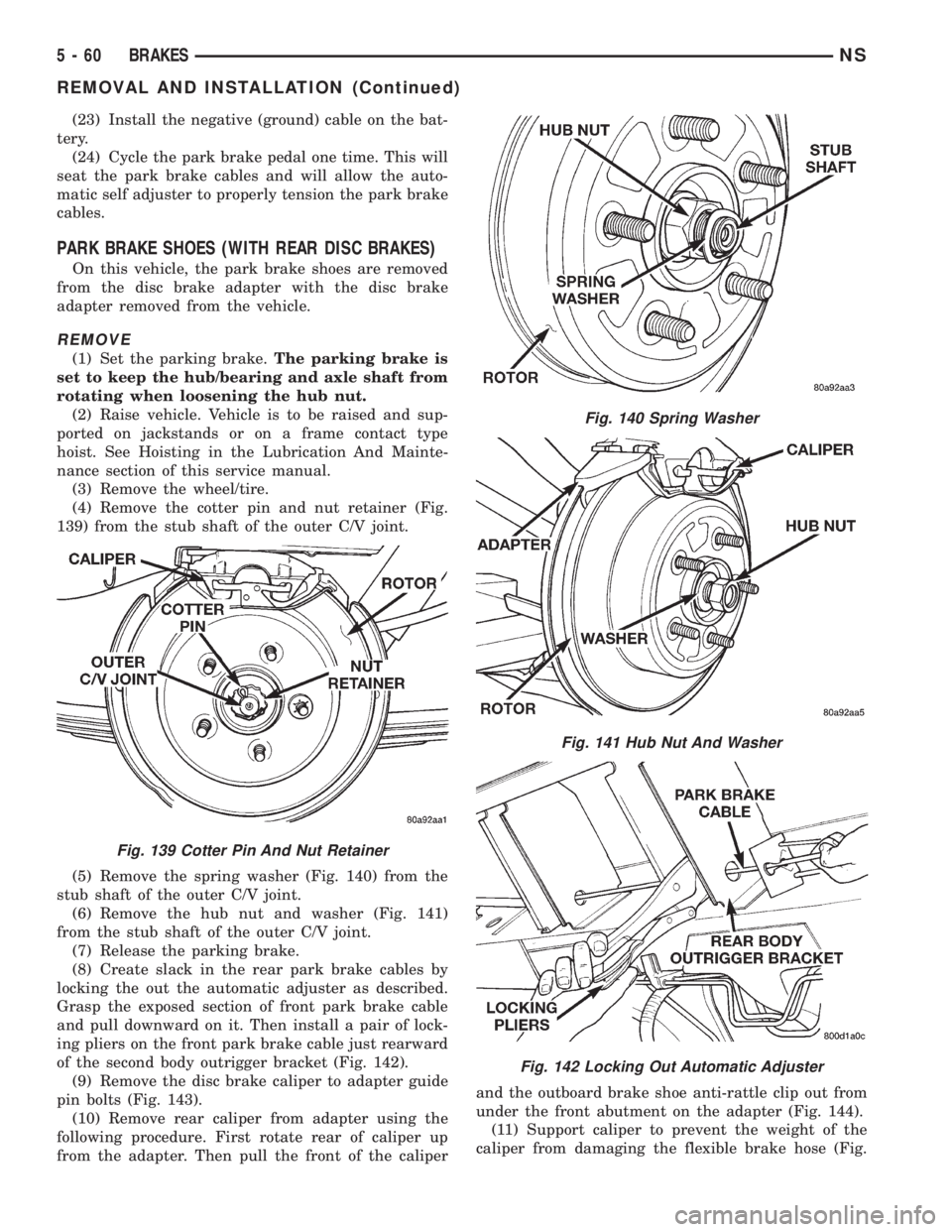

(4) Remove the cotter pin and nut retainer (Fig.

139) from the stub shaft of the outer C/V joint.

(5) Remove the spring washer (Fig. 140) from the

stub shaft of the outer C/V joint.

(6) Remove the hub nut and washer (Fig. 141)

from the stub shaft of the outer C/V joint.

(7) Release the parking brake.

(8) Create slack in the rear park brake cables by

locking the out the automatic adjuster as described.

Grasp the exposed section of front park brake cable

and pull downward on it. Then install a pair of lock-

ing pliers on the front park brake cable just rearward

of the second body outrigger bracket (Fig. 142).

(9) Remove the disc brake caliper to adapter guide

pin bolts (Fig. 143).

(10) Remove rear caliper from adapter using the

following procedure. First rotate rear of caliper up

from the adapter. Then pull the front of the caliperand the outboard brake shoe anti-rattle clip out from

under the front abutment on the adapter (Fig. 144).

(11) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

Fig. 139 Cotter Pin And Nut Retainer

Fig. 140 Spring Washer

Fig. 141 Hub Nut And Washer

Fig. 142 Locking Out Automatic Adjuster

5 - 60 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 146 of 1938

NOTE: When the hold down pin is installed, the

long part of the hold down pin is to be positioned

strait up and down. This will ensure that the hold

down pin is correctly engaged with the adapter.

(6) Install the hold down spring and pin (Fig. 153)

on the leading park brake shoe.

(7) Install the lower return spring (Fig. 152) on

the leading and trailing park brake shoes.When

installing the hold down spring it is to be

installed behind the park brake shoes (Fig.

152).

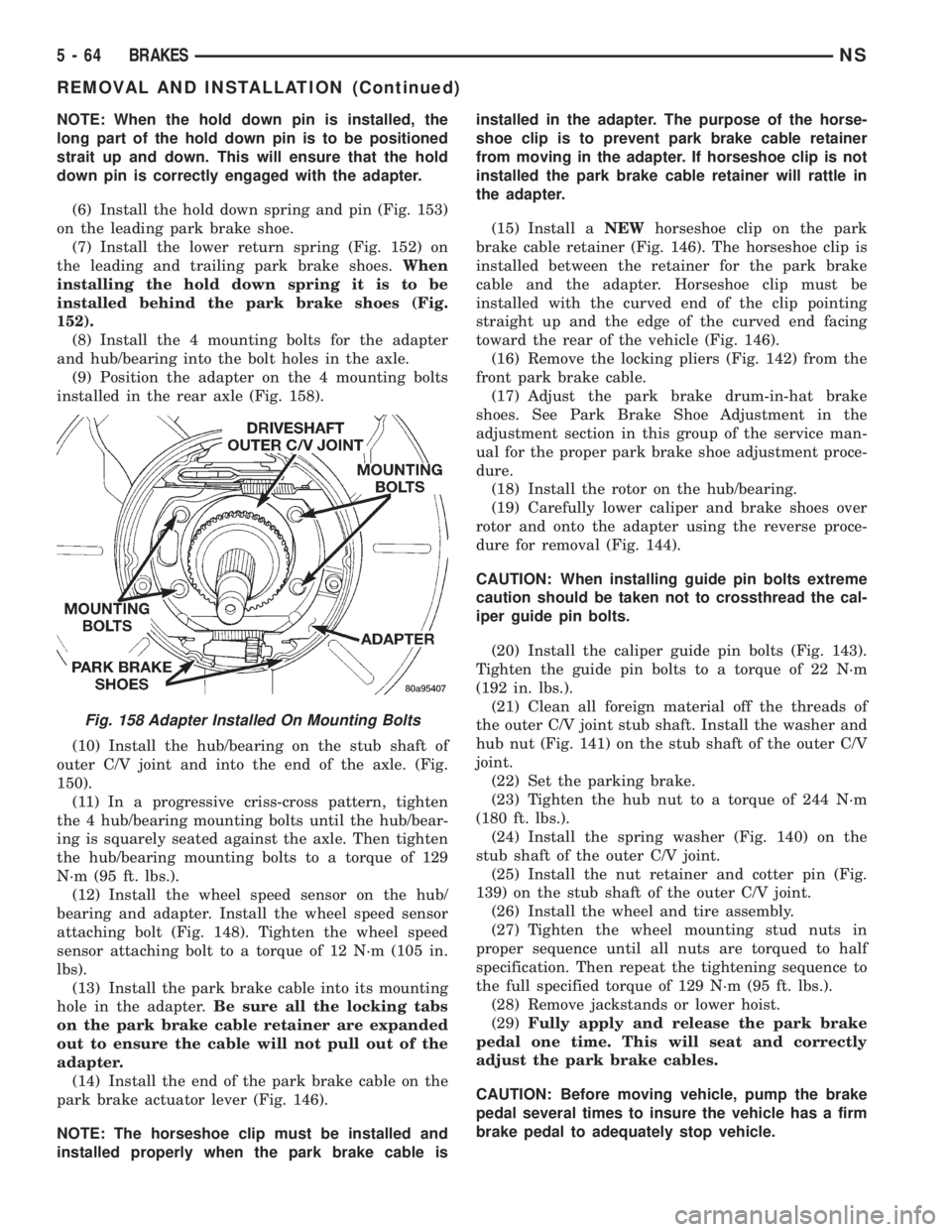

(8) Install the 4 mounting bolts for the adapter

and hub/bearing into the bolt holes in the axle.

(9) Position the adapter on the 4 mounting bolts

installed in the rear axle (Fig. 158).

(10) Install the hub/bearing on the stub shaft of

outer C/V joint and into the end of the axle. (Fig.

150).

(11) In a progressive criss-cross pattern, tighten

the 4 hub/bearing mounting bolts until the hub/bear-

ing is squarely seated against the axle. Then tighten

the hub/bearing mounting bolts to a torque of 129

N´m (95 ft. lbs.).

(12) Install the wheel speed sensor on the hub/

bearing and adapter. Install the wheel speed sensor

attaching bolt (Fig. 148). Tighten the wheel speed

sensor attaching bolt to a torque of 12 N´m (105 in.

lbs).

(13) Install the park brake cable into its mounting

hole in the adapter.Be sure all the locking tabs

on the park brake cable retainer are expanded

out to ensure the cable will not pull out of the

adapter.

(14) Install the end of the park brake cable on the

park brake actuator lever (Fig. 146).

NOTE: The horseshoe clip must be installed and

installed properly when the park brake cable isinstalled in the adapter. The purpose of the horse-

shoe clip is to prevent park brake cable retainer

from moving in the adapter. If horseshoe clip is not

installed the park brake cable retainer will rattle in

the adapter.

(15) Install aNEWhorseshoe clip on the park

brake cable retainer (Fig. 146). The horseshoe clip is

installed between the retainer for the park brake

cable and the adapter. Horseshoe clip must be

installed with the curved end of the clip pointing

straight up and the edge of the curved end facing

toward the rear of the vehicle (Fig. 146).

(16) Remove the locking pliers (Fig. 142) from the

front park brake cable.

(17) Adjust the park brake drum-in-hat brake

shoes. See Park Brake Shoe Adjustment in the

adjustment section in this group of the service man-

ual for the proper park brake shoe adjustment proce-

dure.

(18) Install the rotor on the hub/bearing.

(19) Carefully lower caliper and brake shoes over

rotor and onto the adapter using the reverse proce-

dure for removal (Fig. 144).

CAUTION: When installing guide pin bolts extreme

caution should be taken not to crossthread the cal-

iper guide pin bolts.

(20) Install the caliper guide pin bolts (Fig. 143).

Tighten the guide pin bolts to a torque of 22 N´m

(192 in. lbs.).

(21) Clean all foreign material off the threads of

the outer C/V joint stub shaft. Install the washer and

hub nut (Fig. 141) on the stub shaft of the outer C/V

joint.

(22) Set the parking brake.

(23) Tighten the hub nut to a torque of 244 N´m

(180 ft. lbs.).

(24) Install the spring washer (Fig. 140) on the

stub shaft of the outer C/V joint.

(25) Install the nut retainer and cotter pin (Fig.

139) on the stub shaft of the outer C/V joint.

(26) Install the wheel and tire assembly.

(27) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 129 N´m (95 ft. lbs.).

(28) Remove jackstands or lower hoist.

(29)Fully apply and release the park brake

pedal one time. This will seat and correctly

adjust the park brake cables.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop vehicle.

Fig. 158 Adapter Installed On Mounting Bolts

5 - 64 BRAKESNS

REMOVAL AND INSTALLATION (Continued)