service CHRYSLER VOYAGER 1996 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 147 of 1938

(30) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoe linings.

FRONT PARK BRAKE CABLE

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Manually lockout the automatic self adjusting

mechanism of the park brake pedal assembly. Refer

to Manual Lockout Of Auto Adjuster Mechanism in

this section of the service manual for the required

procedure.

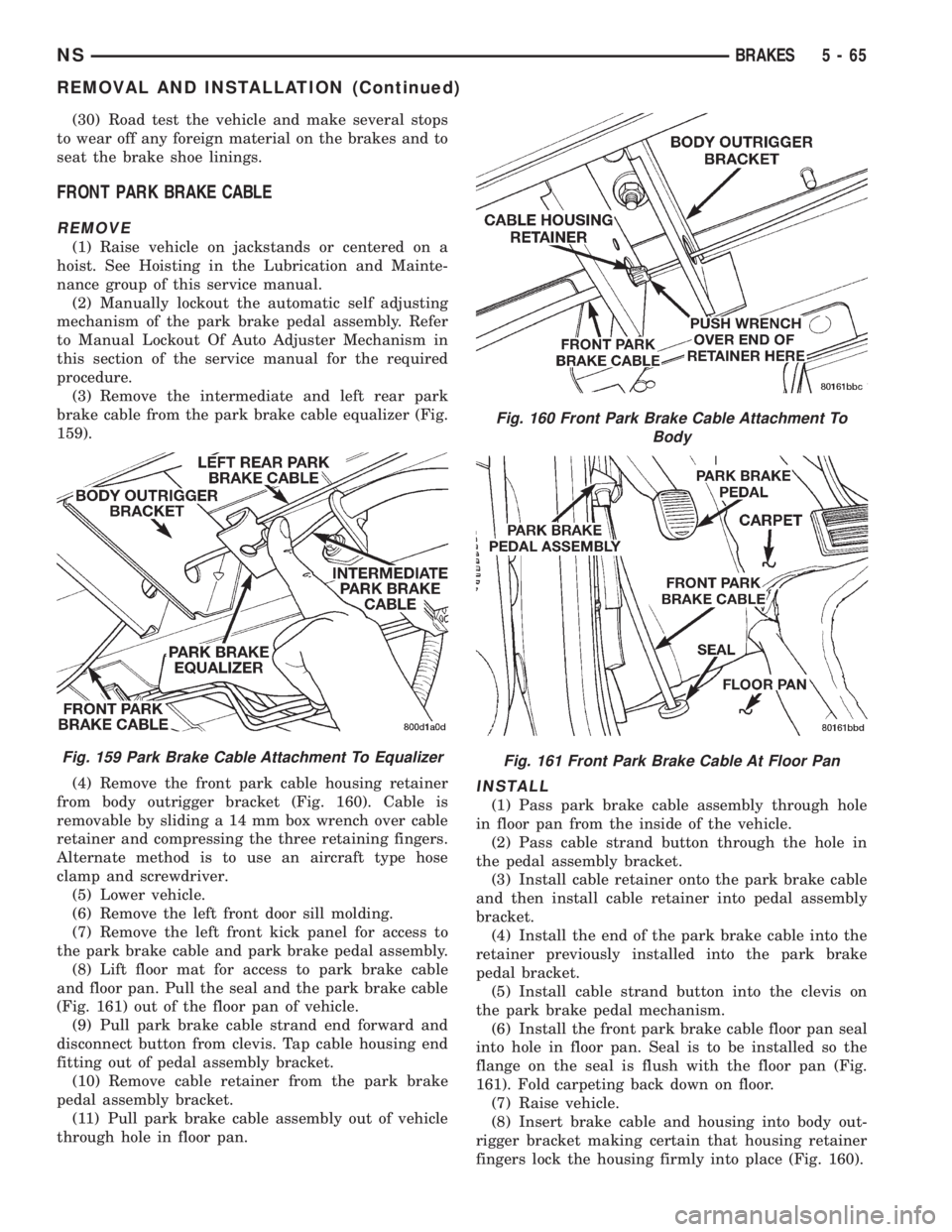

(3) Remove the intermediate and left rear park

brake cable from the park brake cable equalizer (Fig.

159).

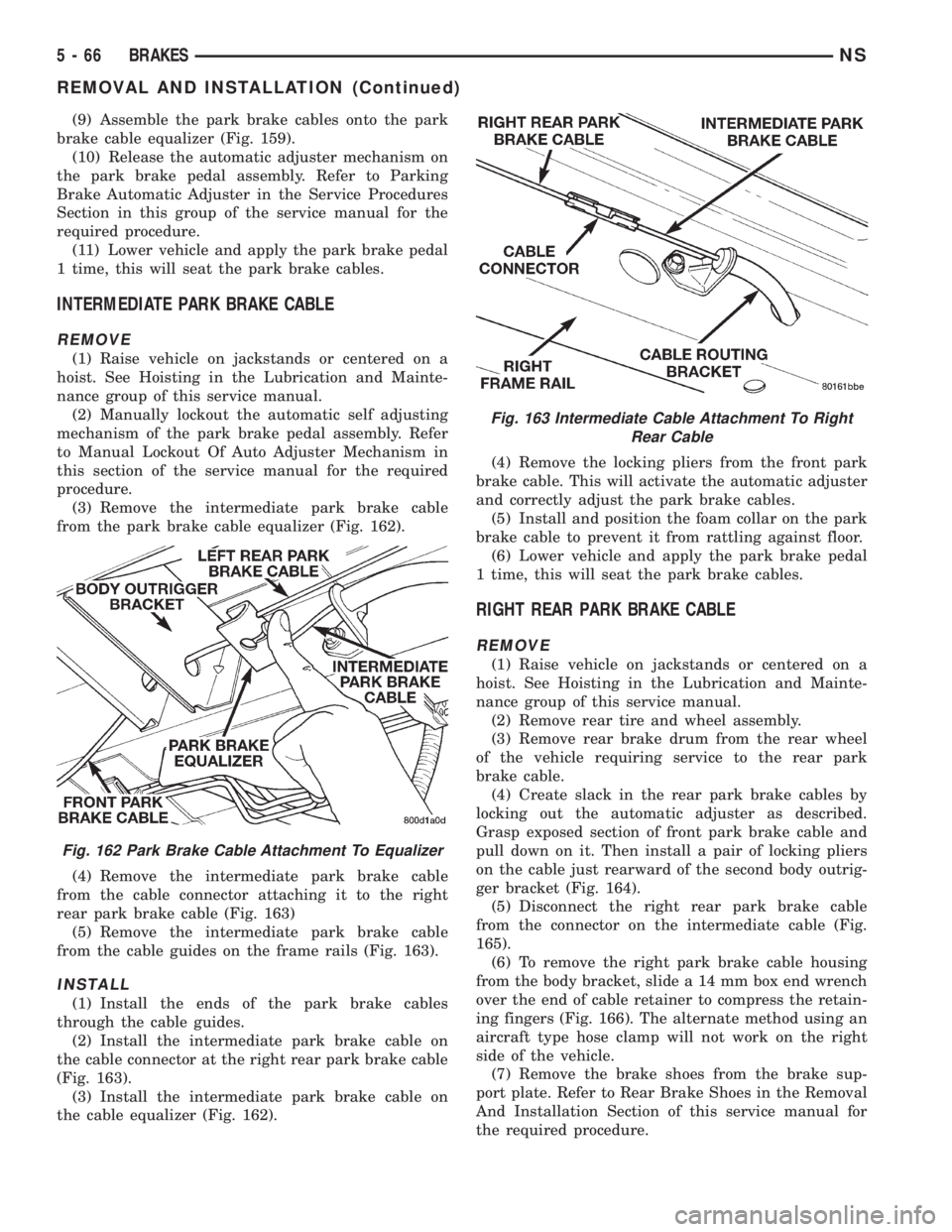

(4) Remove the front park cable housing retainer

from body outrigger bracket (Fig. 160). Cable is

removable by sliding a 14 mm box wrench over cable

retainer and compressing the three retaining fingers.

Alternate method is to use an aircraft type hose

clamp and screwdriver.

(5) Lower vehicle.

(6) Remove the left front door sill molding.

(7) Remove the left front kick panel for access to

the park brake cable and park brake pedal assembly.

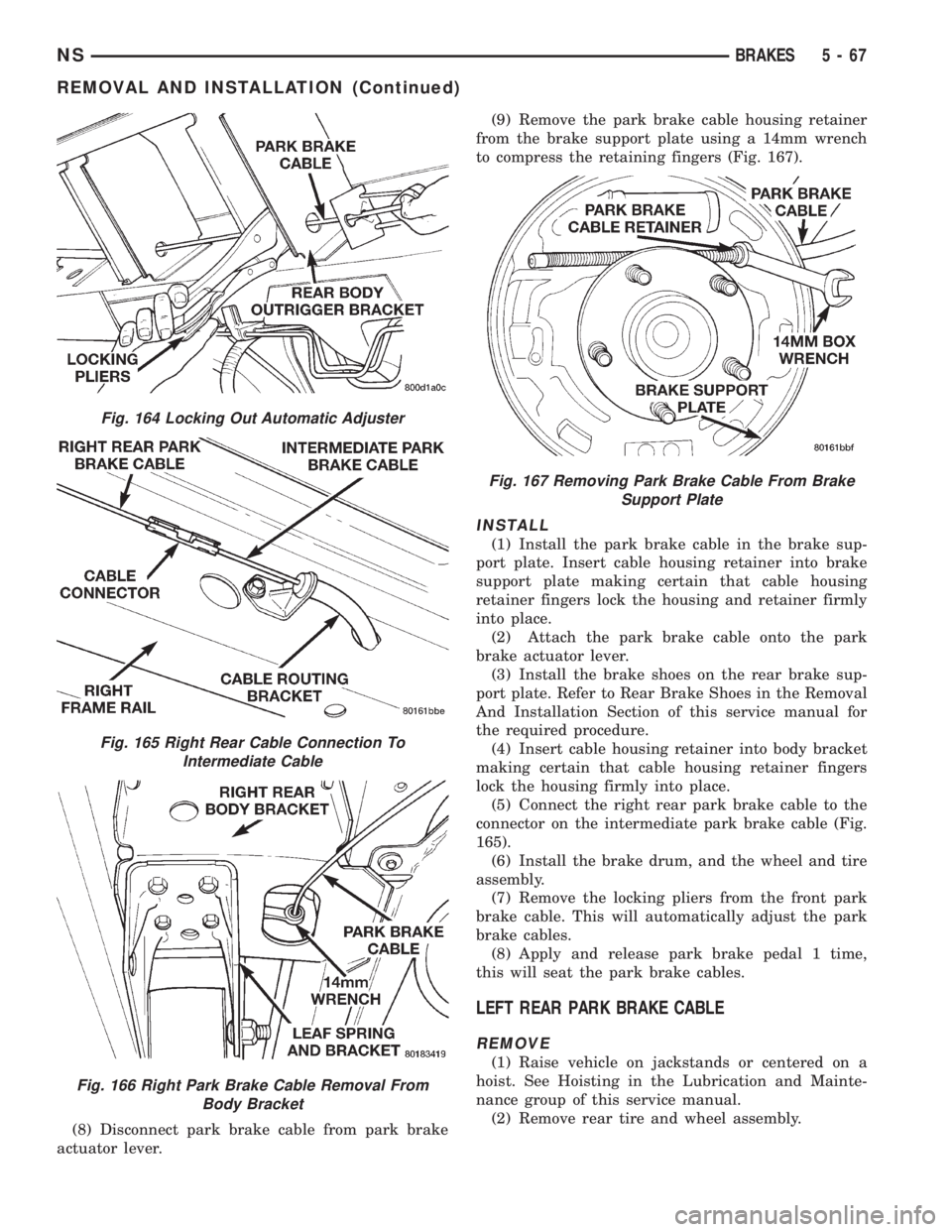

(8) Lift floor mat for access to park brake cable

and floor pan. Pull the seal and the park brake cable

(Fig. 161) out of the floor pan of vehicle.

(9) Pull park brake cable strand end forward and

disconnect button from clevis. Tap cable housing end

fitting out of pedal assembly bracket.

(10) Remove cable retainer from the park brake

pedal assembly bracket.

(11) Pull park brake cable assembly out of vehicle

through hole in floor pan.

INSTALL

(1) Pass park brake cable assembly through hole

in floor pan from the inside of the vehicle.

(2) Pass cable strand button through the hole in

the pedal assembly bracket.

(3) Install cable retainer onto the park brake cable

and then install cable retainer into pedal assembly

bracket.

(4) Install the end of the park brake cable into the

retainer previously installed into the park brake

pedal bracket.

(5) Install cable strand button into the clevis on

the park brake pedal mechanism.

(6) Install the front park brake cable floor pan seal

into hole in floor pan. Seal is to be installed so the

flange on the seal is flush with the floor pan (Fig.

161). Fold carpeting back down on floor.

(7) Raise vehicle.

(8) Insert brake cable and housing into body out-

rigger bracket making certain that housing retainer

fingers lock the housing firmly into place (Fig. 160).

Fig. 159 Park Brake Cable Attachment To Equalizer

Fig. 160 Front Park Brake Cable Attachment To

Body

Fig. 161 Front Park Brake Cable At Floor Pan

NSBRAKES 5 - 65

REMOVAL AND INSTALLATION (Continued)

Page 148 of 1938

(9) Assemble the park brake cables onto the park

brake cable equalizer (Fig. 159).

(10) Release the automatic adjuster mechanism on

the park brake pedal assembly. Refer to Parking

Brake Automatic Adjuster in the Service Procedures

Section in this group of the service manual for the

required procedure.

(11) Lower vehicle and apply the park brake pedal

1 time, this will seat the park brake cables.

INTERMEDIATE PARK BRAKE CABLE

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Manually lockout the automatic self adjusting

mechanism of the park brake pedal assembly. Refer

to Manual Lockout Of Auto Adjuster Mechanism in

this section of the service manual for the required

procedure.

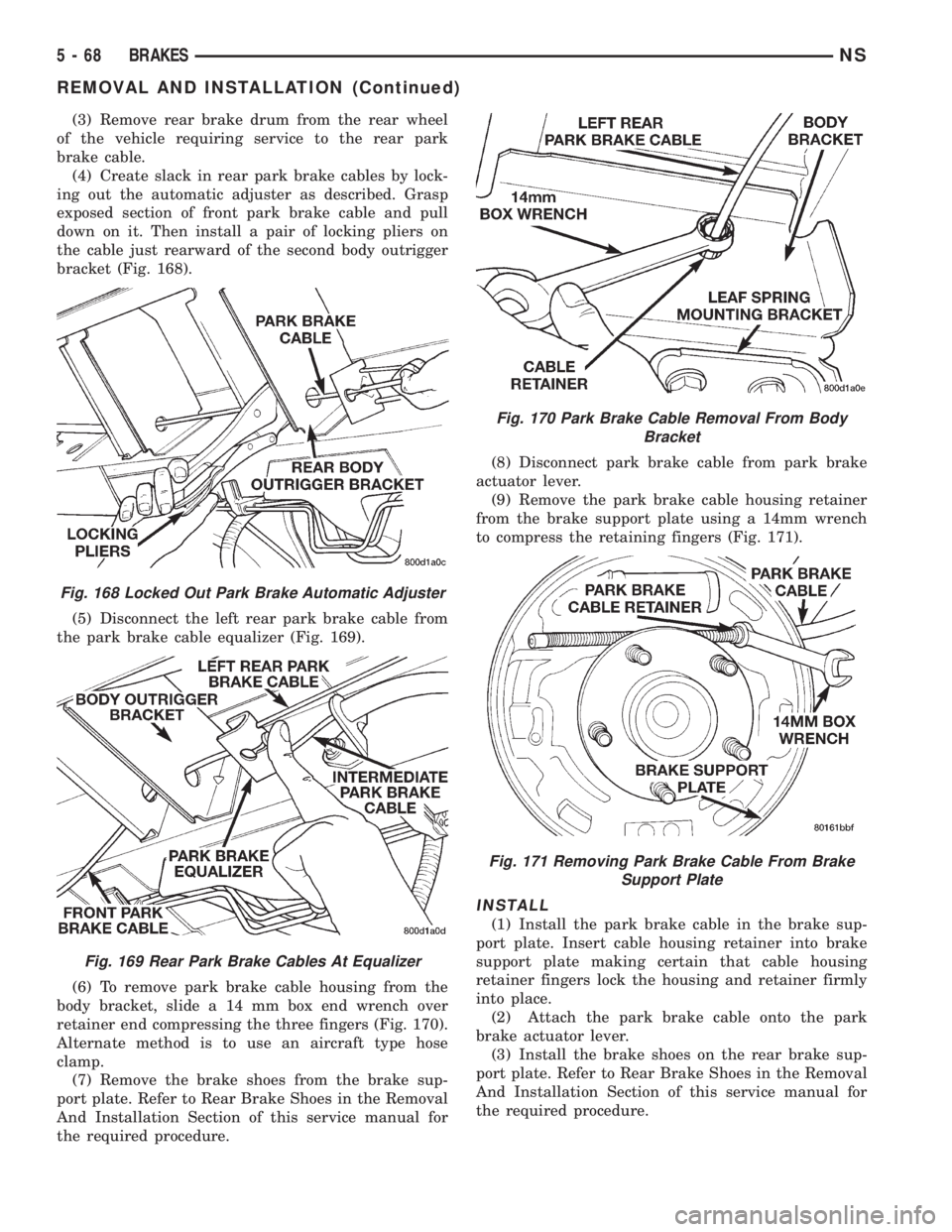

(3) Remove the intermediate park brake cable

from the park brake cable equalizer (Fig. 162).

(4) Remove the intermediate park brake cable

from the cable connector attaching it to the right

rear park brake cable (Fig. 163)

(5) Remove the intermediate park brake cable

from the cable guides on the frame rails (Fig. 163).

INSTALL

(1) Install the ends of the park brake cables

through the cable guides.

(2) Install the intermediate park brake cable on

the cable connector at the right rear park brake cable

(Fig. 163).

(3) Install the intermediate park brake cable on

the cable equalizer (Fig. 162).(4) Remove the locking pliers from the front park

brake cable. This will activate the automatic adjuster

and correctly adjust the park brake cables.

(5) Install and position the foam collar on the park

brake cable to prevent it from rattling against floor.

(6) Lower vehicle and apply the park brake pedal

1 time, this will seat the park brake cables.

RIGHT REAR PARK BRAKE CABLE

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Remove rear tire and wheel assembly.

(3) Remove rear brake drum from the rear wheel

of the vehicle requiring service to the rear park

brake cable.

(4) Create slack in the rear park brake cables by

locking out the automatic adjuster as described.

Grasp exposed section of front park brake cable and

pull down on it. Then install a pair of locking pliers

on the cable just rearward of the second body outrig-

ger bracket (Fig. 164).

(5) Disconnect the right rear park brake cable

from the connector on the intermediate cable (Fig.

165).

(6) To remove the right park brake cable housing

from the body bracket, slide a 14 mm box end wrench

over the end of cable retainer to compress the retain-

ing fingers (Fig. 166). The alternate method using an

aircraft type hose clamp will not work on the right

side of the vehicle.

(7) Remove the brake shoes from the brake sup-

port plate. Refer to Rear Brake Shoes in the Removal

And Installation Section of this service manual for

the required procedure.

Fig. 162 Park Brake Cable Attachment To Equalizer

Fig. 163 Intermediate Cable Attachment To Right

Rear Cable

5 - 66 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 149 of 1938

(8) Disconnect park brake cable from park brake

actuator lever.(9) Remove the park brake cable housing retainer

from the brake support plate using a 14mm wrench

to compress the retaining fingers (Fig. 167).

INSTALL

(1) Install the park brake cable in the brake sup-

port plate. Insert cable housing retainer into brake

support plate making certain that cable housing

retainer fingers lock the housing and retainer firmly

into place.

(2) Attach the park brake cable onto the park

brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. Refer to Rear Brake Shoes in the Removal

And Installation Section of this service manual for

the required procedure.

(4) Insert cable housing retainer into body bracket

making certain that cable housing retainer fingers

lock the housing firmly into place.

(5) Connect the right rear park brake cable to the

connector on the intermediate park brake cable (Fig.

165).

(6) Install the brake drum, and the wheel and tire

assembly.

(7) Remove the locking pliers from the front park

brake cable. This will automatically adjust the park

brake cables.

(8) Apply and release park brake pedal 1 time,

this will seat the park brake cables.

LEFT REAR PARK BRAKE CABLE

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Remove rear tire and wheel assembly.

Fig. 164 Locking Out Automatic Adjuster

Fig. 165 Right Rear Cable Connection To

Intermediate Cable

Fig. 166 Right Park Brake Cable Removal From

Body Bracket

Fig. 167 Removing Park Brake Cable From Brake

Support Plate

NSBRAKES 5 - 67

REMOVAL AND INSTALLATION (Continued)

Page 150 of 1938

(3) Remove rear brake drum from the rear wheel

of the vehicle requiring service to the rear park

brake cable.

(4) Create slack in rear park brake cables by lock-

ing out the automatic adjuster as described. Grasp

exposed section of front park brake cable and pull

down on it. Then install a pair of locking pliers on

the cable just rearward of the second body outrigger

bracket (Fig. 168).

(5) Disconnect the left rear park brake cable from

the park brake cable equalizer (Fig. 169).

(6) To remove park brake cable housing from the

body bracket, slide a 14 mm box end wrench over

retainer end compressing the three fingers (Fig. 170).

Alternate method is to use an aircraft type hose

clamp.

(7) Remove the brake shoes from the brake sup-

port plate. Refer to Rear Brake Shoes in the Removal

And Installation Section of this service manual for

the required procedure.(8) Disconnect park brake cable from park brake

actuator lever.

(9) Remove the park brake cable housing retainer

from the brake support plate using a 14mm wrench

to compress the retaining fingers (Fig. 171).

INSTALL

(1) Install the park brake cable in the brake sup-

port plate. Insert cable housing retainer into brake

support plate making certain that cable housing

retainer fingers lock the housing and retainer firmly

into place.

(2) Attach the park brake cable onto the park

brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. Refer to Rear Brake Shoes in the Removal

And Installation Section of this service manual for

the required procedure.

Fig. 168 Locked Out Park Brake Automatic Adjuster

Fig. 169 Rear Park Brake Cables At Equalizer

Fig. 170 Park Brake Cable Removal From Body

Bracket

Fig. 171 Removing Park Brake Cable From Brake

Support Plate

5 - 68 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 152 of 1938

(7) Road test vehicle to ensure proper operation of

the vehicle's power brake system.

MASTER CYLINDER FLUID RESERVOIR

(1) Clean master cylinder housing and brake fluid

reservoir. Use only a solvent such as Mopar Brake

Parts Cleaner or an equivalent.

(2) Remove the filler tube and brake fluid reser-

voir cap. Using a syringe or equivalent type tool

empty as much brake fluid as possible from the res-

ervoir.

CAUTION: When removing fluid reservoir from the

master cylinder, do not pry off using any type of

tool. This can damage the fluid reservoir or master

cylinder housing.

(3) Remove the master cylinder assembly from the

power brake vacuum booster. Refer to master cylin-

der, in the removal and installation section in this

group of the service manual for the required proce-

dure

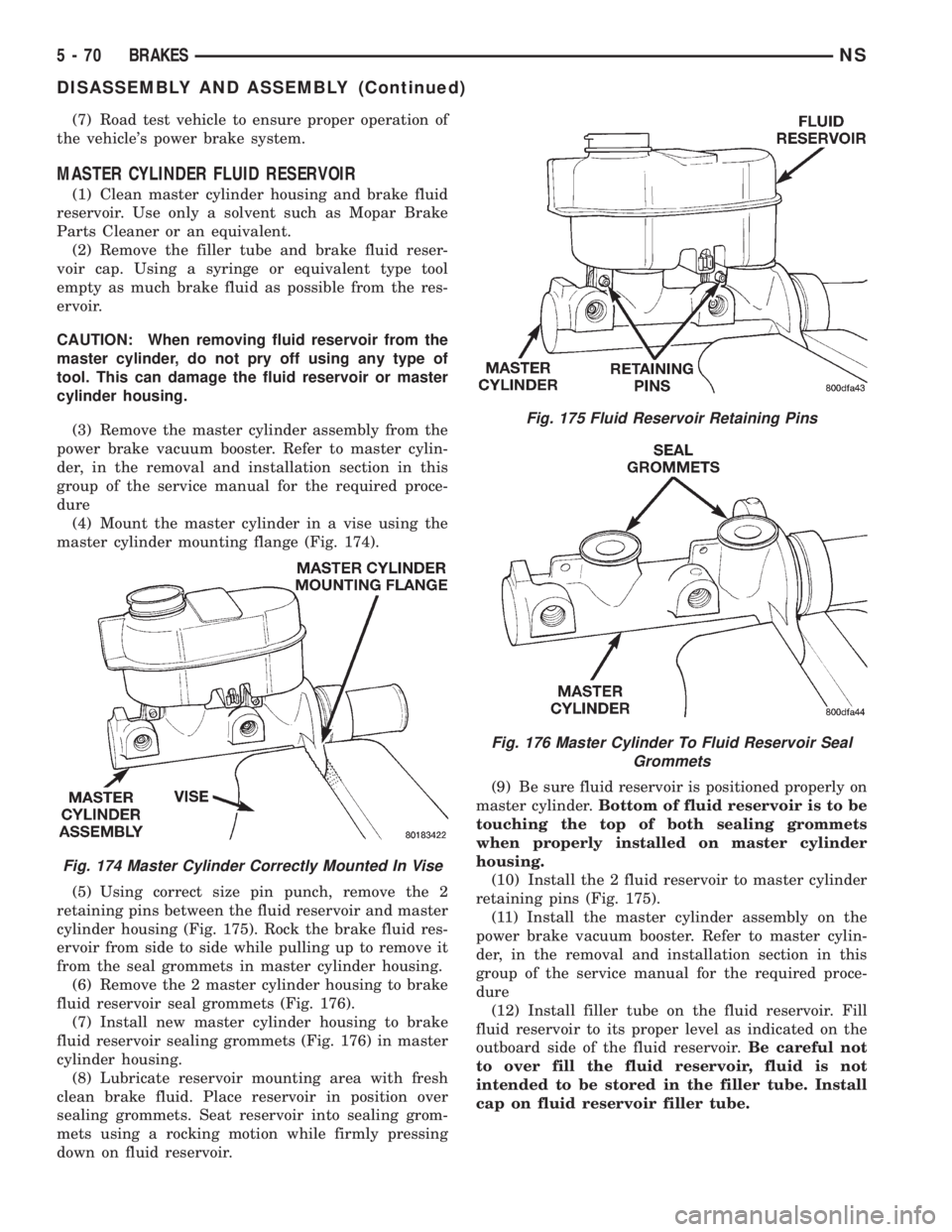

(4) Mount the master cylinder in a vise using the

master cylinder mounting flange (Fig. 174).

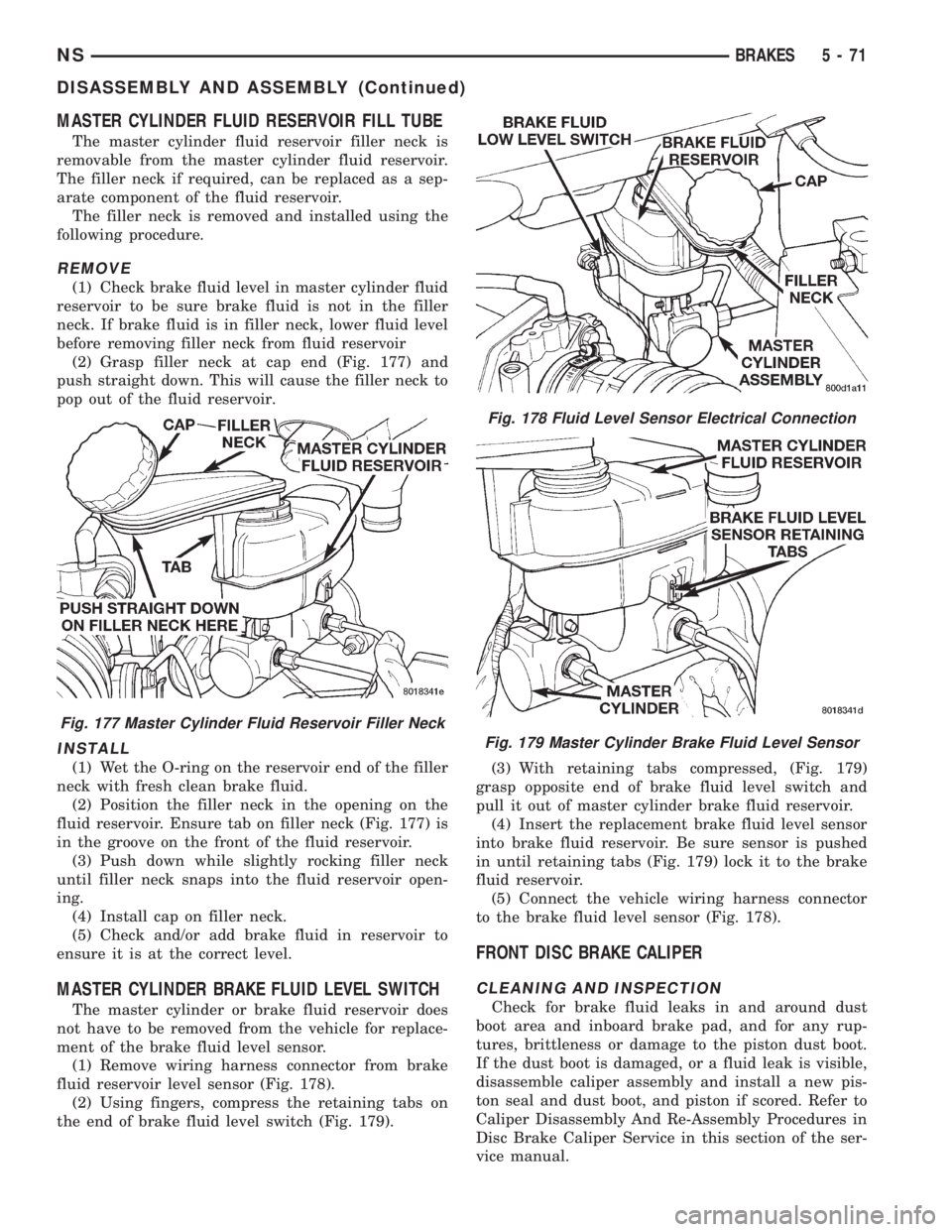

(5) Using correct size pin punch, remove the 2

retaining pins between the fluid reservoir and master

cylinder housing (Fig. 175). Rock the brake fluid res-

ervoir from side to side while pulling up to remove it

from the seal grommets in master cylinder housing.

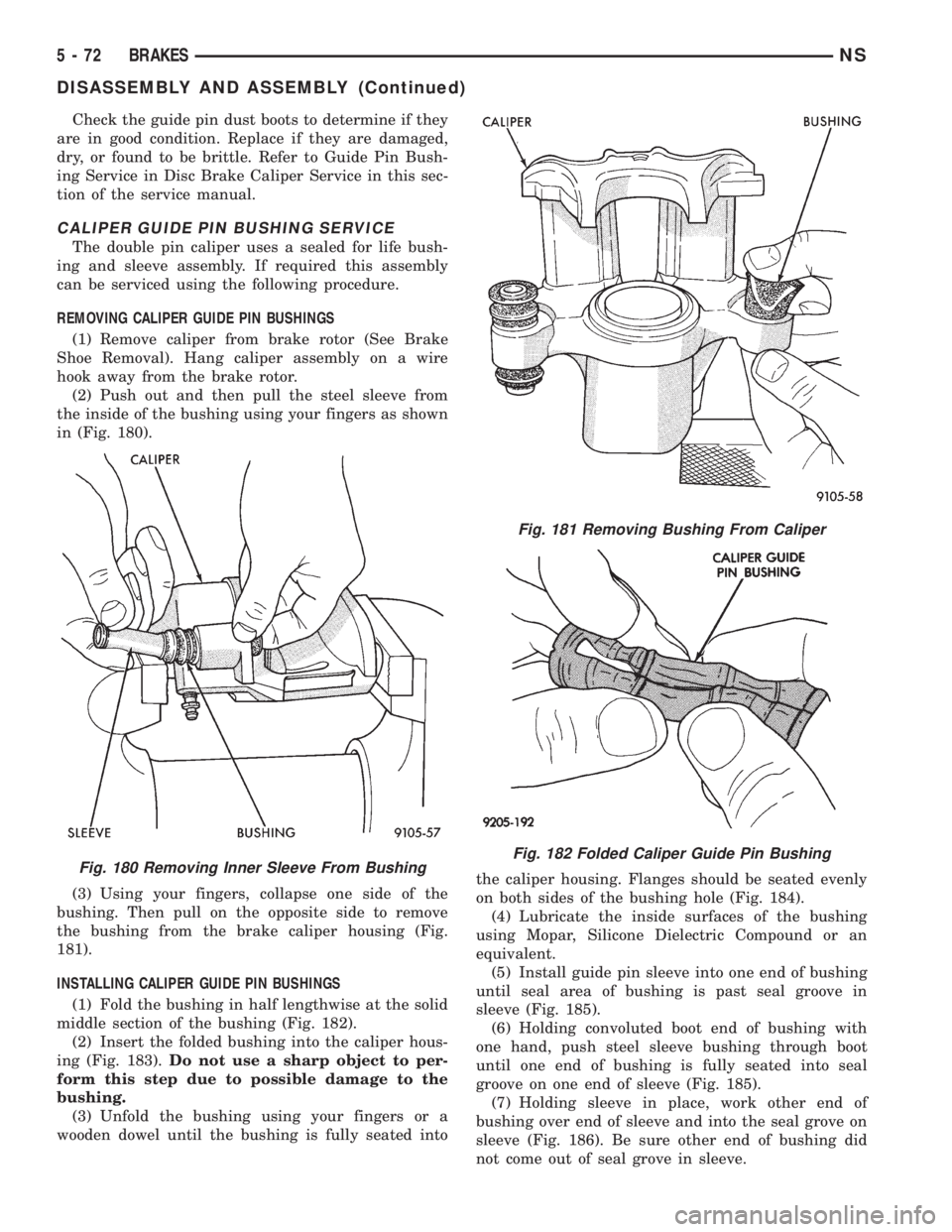

(6) Remove the 2 master cylinder housing to brake

fluid reservoir seal grommets (Fig. 176).

(7) Install new master cylinder housing to brake

fluid reservoir sealing grommets (Fig. 176) in master

cylinder housing.

(8) Lubricate reservoir mounting area with fresh

clean brake fluid. Place reservoir in position over

sealing grommets. Seat reservoir into sealing grom-

mets using a rocking motion while firmly pressing

down on fluid reservoir.(9) Be sure fluid reservoir is positioned properly on

master cylinder.Bottom of fluid reservoir is to be

touching the top of both sealing grommets

when properly installed on master cylinder

housing.

(10) Install the 2 fluid reservoir to master cylinder

retaining pins (Fig. 175).

(11) Install the master cylinder assembly on the

power brake vacuum booster. Refer to master cylin-

der, in the removal and installation section in this

group of the service manual for the required proce-

dure

(12) Install filler tube on the fluid reservoir. Fill

fluid reservoir to its proper level as indicated on the

outboard side of the fluid reservoir.Be careful not

to over fill the fluid reservoir, fluid is not

intended to be stored in the filler tube. Install

cap on fluid reservoir filler tube.

Fig. 174 Master Cylinder Correctly Mounted In Vise

Fig. 175 Fluid Reservoir Retaining Pins

Fig. 176 Master Cylinder To Fluid Reservoir Seal

Grommets

5 - 70 BRAKESNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 153 of 1938

MASTER CYLINDER FLUID RESERVOIR FILL TUBE

The master cylinder fluid reservoir filler neck is

removable from the master cylinder fluid reservoir.

The filler neck if required, can be replaced as a sep-

arate component of the fluid reservoir.

The filler neck is removed and installed using the

following procedure.

REMOVE

(1) Check brake fluid level in master cylinder fluid

reservoir to be sure brake fluid is not in the filler

neck. If brake fluid is in filler neck, lower fluid level

before removing filler neck from fluid reservoir

(2) Grasp filler neck at cap end (Fig. 177) and

push straight down. This will cause the filler neck to

pop out of the fluid reservoir.

INSTALL

(1) Wet the O-ring on the reservoir end of the filler

neck with fresh clean brake fluid.

(2) Position the filler neck in the opening on the

fluid reservoir. Ensure tab on filler neck (Fig. 177) is

in the groove on the front of the fluid reservoir.

(3) Push down while slightly rocking filler neck

until filler neck snaps into the fluid reservoir open-

ing.

(4) Install cap on filler neck.

(5) Check and/or add brake fluid in reservoir to

ensure it is at the correct level.

MASTER CYLINDER BRAKE FLUID LEVEL SWITCH

The master cylinder or brake fluid reservoir does

not have to be removed from the vehicle for replace-

ment of the brake fluid level sensor.

(1) Remove wiring harness connector from brake

fluid reservoir level sensor (Fig. 178).

(2) Using fingers, compress the retaining tabs on

the end of brake fluid level switch (Fig. 179).(3) With retaining tabs compressed, (Fig. 179)

grasp opposite end of brake fluid level switch and

pull it out of master cylinder brake fluid reservoir.

(4) Insert the replacement brake fluid level sensor

into brake fluid reservoir. Be sure sensor is pushed

in until retaining tabs (Fig. 179) lock it to the brake

fluid reservoir.

(5) Connect the vehicle wiring harness connector

to the brake fluid level sensor (Fig. 178).

FRONT DISC BRAKE CALIPER

CLEANING AND INSPECTION

Check for brake fluid leaks in and around dust

boot area and inboard brake pad, and for any rup-

tures, brittleness or damage to the piston dust boot.

If the dust boot is damaged, or a fluid leak is visible,

disassemble caliper assembly and install a new pis-

ton seal and dust boot, and piston if scored. Refer to

Caliper Disassembly And Re-Assembly Procedures in

Disc Brake Caliper Service in this section of the ser-

vice manual.

Fig. 177 Master Cylinder Fluid Reservoir Filler Neck

Fig. 178 Fluid Level Sensor Electrical Connection

Fig. 179 Master Cylinder Brake Fluid Level Sensor

NSBRAKES 5 - 71

DISASSEMBLY AND ASSEMBLY (Continued)

Page 154 of 1938

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to Guide Pin Bush-

ing Service in Disc Brake Caliper Service in this sec-

tion of the service manual.

CALIPER GUIDE PIN BUSHING SERVICE

The double pin caliper uses a sealed for life bush-

ing and sleeve assembly. If required this assembly

can be serviced using the following procedure.

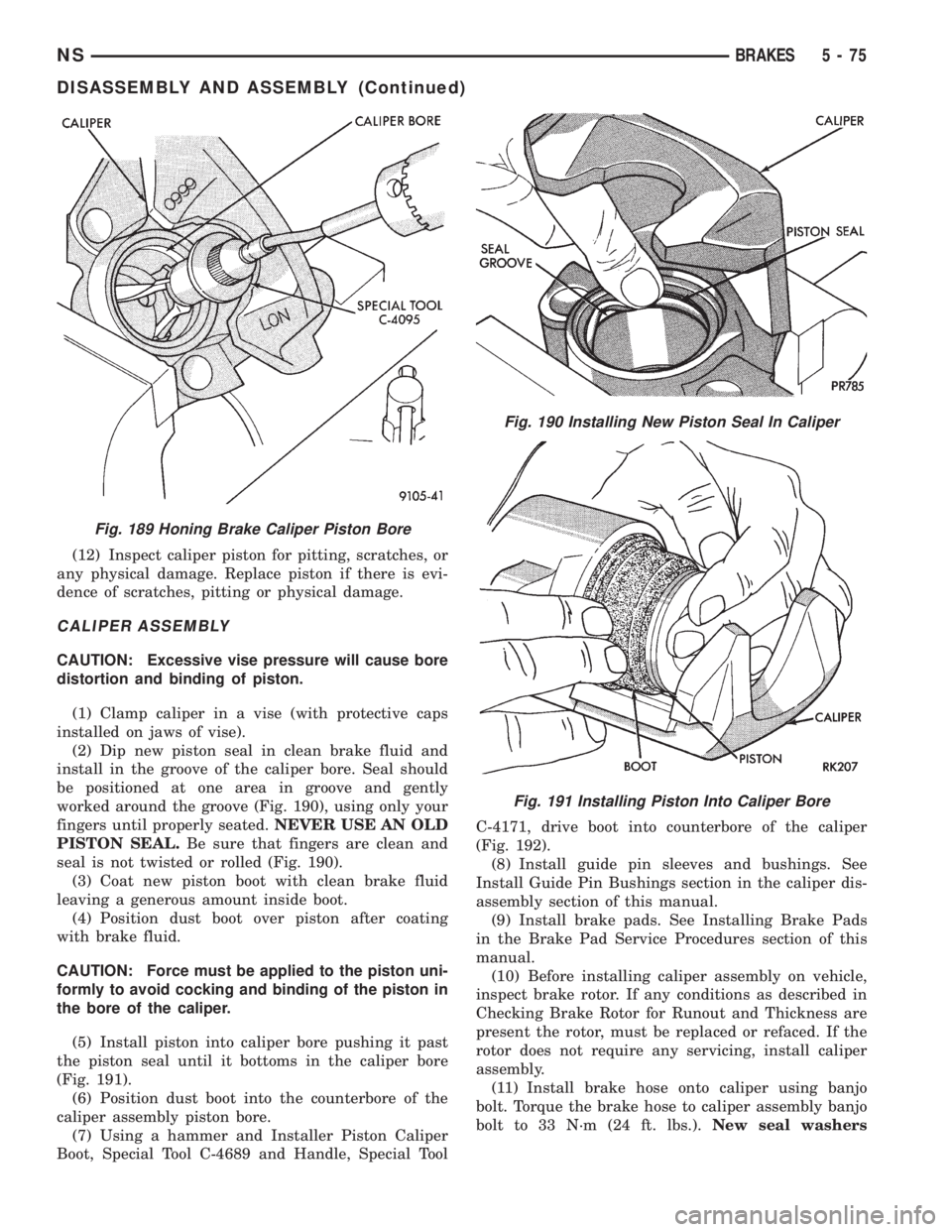

REMOVING CALIPER GUIDE PIN BUSHINGS

(1) Remove caliper from brake rotor (See Brake

Shoe Removal). Hang caliper assembly on a wire

hook away from the brake rotor.

(2) Push out and then pull the steel sleeve from

the inside of the bushing using your fingers as shown

in (Fig. 180).

(3) Using your fingers, collapse one side of the

bushing. Then pull on the opposite side to remove

the bushing from the brake caliper housing (Fig.

181).

INSTALLING CALIPER GUIDE PIN BUSHINGS

(1) Fold the bushing in half lengthwise at the solid

middle section of the bushing (Fig. 182).

(2) Insert the folded bushing into the caliper hous-

ing (Fig. 183).Do not use a sharp object to per-

form this step due to possible damage to the

bushing.

(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated intothe caliper housing. Flanges should be seated evenly

on both sides of the bushing hole (Fig. 184).

(4) Lubricate the inside surfaces of the bushing

using Mopar, Silicone Dielectric Compound or an

equivalent.

(5) Install guide pin sleeve into one end of bushing

until seal area of bushing is past seal groove in

sleeve (Fig. 185).

(6) Holding convoluted boot end of bushing with

one hand, push steel sleeve bushing through boot

until one end of bushing is fully seated into seal

groove on one end of sleeve (Fig. 185).

(7) Holding sleeve in place, work other end of

bushing over end of sleeve and into the seal grove on

sleeve (Fig. 186). Be sure other end of bushing did

not come out of seal grove in sleeve.

Fig. 180 Removing Inner Sleeve From Bushing

Fig. 181 Removing Bushing From Caliper

Fig. 182 Folded Caliper Guide Pin Bushing

5 - 72 BRAKESNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 157 of 1938

(12) Inspect caliper piston for pitting, scratches, or

any physical damage. Replace piston if there is evi-

dence of scratches, pitting or physical damage.

CALIPER ASSEMBLY

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston.

(1) Clamp caliper in a vise (with protective caps

installed on jaws of vise).

(2) Dip new piston seal in clean brake fluid and

install in the groove of the caliper bore. Seal should

be positioned at one area in groove and gently

worked around the groove (Fig. 190), using only your

fingers until properly seated.NEVER USE AN OLD

PISTON SEAL.Be sure that fingers are clean and

seal is not twisted or rolled (Fig. 190).

(3) Coat new piston boot with clean brake fluid

leaving a generous amount inside boot.

(4) Position dust boot over piston after coating

with brake fluid.

CAUTION: Force must be applied to the piston uni-

formly to avoid cocking and binding of the piston in

the bore of the caliper.

(5) Install piston into caliper bore pushing it past

the piston seal until it bottoms in the caliper bore

(Fig. 191).

(6) Position dust boot into the counterbore of the

caliper assembly piston bore.

(7) Using a hammer and Installer Piston Caliper

Boot, Special Tool C-4689 and Handle, Special ToolC-4171, drive boot into counterbore of the caliper

(Fig. 192).

(8) Install guide pin sleeves and bushings. See

Install Guide Pin Bushings section in the caliper dis-

assembly section of this manual.

(9) Install brake pads. See Installing Brake Pads

in the Brake Pad Service Procedures section of this

manual.

(10) Before installing caliper assembly on vehicle,

inspect brake rotor. If any conditions as described in

Checking Brake Rotor for Runout and Thickness are

present the rotor, must be replaced or refaced. If the

rotor does not require any servicing, install caliper

assembly.

(11) Install brake hose onto caliper using banjo

bolt. Torque the brake hose to caliper assembly banjo

bolt to 33 N´m (24 ft. lbs.).New seal washers

Fig. 189 Honing Brake Caliper Piston Bore

Fig. 190 Installing New Piston Seal In Caliper

Fig. 191 Installing Piston Into Caliper Bore

NSBRAKES 5 - 75

DISASSEMBLY AND ASSEMBLY (Continued)

Page 159 of 1938

lation section in this group of the service manual for

the required procedure.

The combined brake shoe and lining material

thickness should be measured at the thinnest part of

the assembly.

When a set of brake shoes are worn to a total

thickness of approximately 7.0 mm (9/32 inch) they

should be replaced.

Replacebothbrake shoe assemblies (inboard and

outboard). It is necessary thatbothrear wheel sets

be replaced whenever brake shoe assemblies on

either side are replaced.

If the brake shoe assemblies do not require

replacement, reinstall, the assemblies making sure

each brake shoe is returned to the original position.

Refer to Rear Disc Brake Shoe Installation in the

Removal And Installation section in this group of the

service manual for the required procedure.

CALIPER INSPECTION

Check for brake fluid leaks in and around boot

area and inboard lining, and for any ruptures, brit-

tleness or damage to the piston dust boot. If the boot

is damaged, or a fluid leak is visible, disassemble cal-

iper assembly and install a new seal and boot, and

piston if scored. Refer to Rear Disc Brake Caliper in

the Disassembly And Assembly Section in this group

of the service manual.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to Rear Disc Brake

Caliper in the Disassembly And Assembly Section in

this group of the service manual.

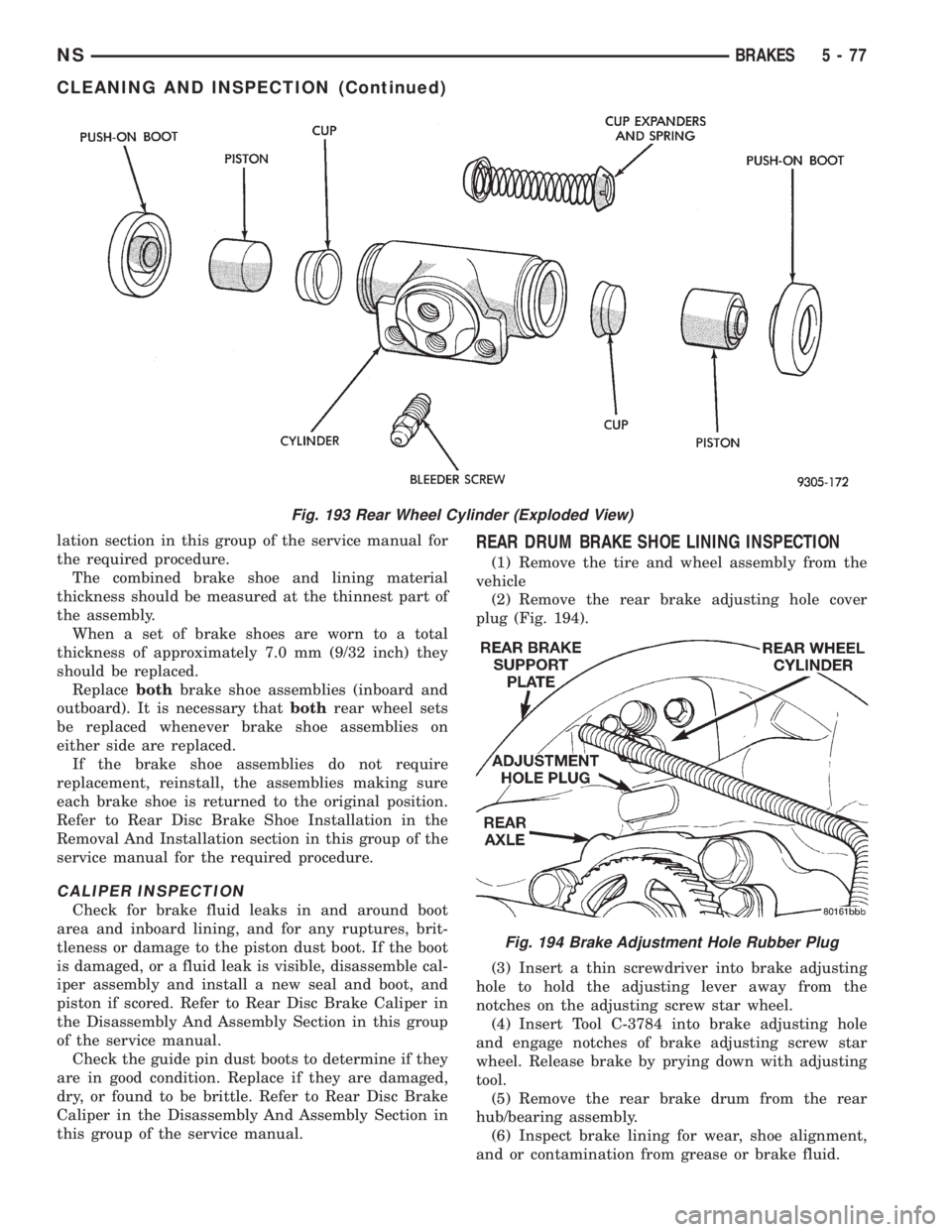

REAR DRUM BRAKE SHOE LINING INSPECTION

(1) Remove the tire and wheel assembly from the

vehicle

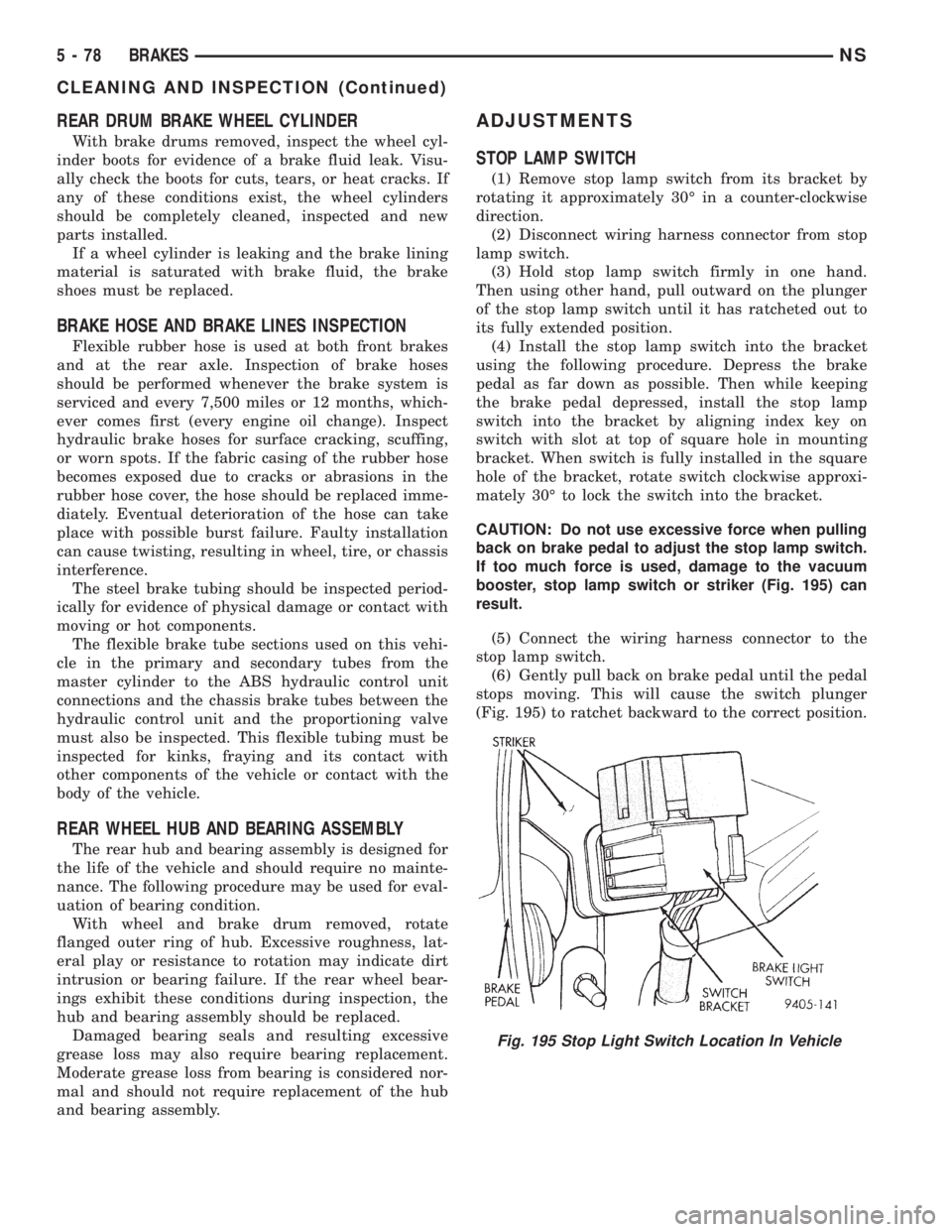

(2) Remove the rear brake adjusting hole cover

plug (Fig. 194).

(3) Insert a thin screwdriver into brake adjusting

hole to hold the adjusting lever away from the

notches on the adjusting screw star wheel.

(4) Insert Tool C-3784 into brake adjusting hole

and engage notches of brake adjusting screw star

wheel. Release brake by prying down with adjusting

tool.

(5) Remove the rear brake drum from the rear

hub/bearing assembly.

(6) Inspect brake lining for wear, shoe alignment,

and or contamination from grease or brake fluid.

Fig. 193 Rear Wheel Cylinder (Exploded View)

Fig. 194 Brake Adjustment Hole Rubber Plug

NSBRAKES 5 - 77

CLEANING AND INSPECTION (Continued)

Page 160 of 1938

REAR DRUM BRAKE WHEEL CYLINDER

With brake drums removed, inspect the wheel cyl-

inder boots for evidence of a brake fluid leak. Visu-

ally check the boots for cuts, tears, or heat cracks. If

any of these conditions exist, the wheel cylinders

should be completely cleaned, inspected and new

parts installed.

If a wheel cylinder is leaking and the brake lining

material is saturated with brake fluid, the brake

shoes must be replaced.

BRAKE HOSE AND BRAKE LINES INSPECTION

Flexible rubber hose is used at both front brakes

and at the rear axle. Inspection of brake hoses

should be performed whenever the brake system is

serviced and every 7,500 miles or 12 months, which-

ever comes first (every engine oil change). Inspect

hydraulic brake hoses for surface cracking, scuffing,

or worn spots. If the fabric casing of the rubber hose

becomes exposed due to cracks or abrasions in the

rubber hose cover, the hose should be replaced imme-

diately. Eventual deterioration of the hose can take

place with possible burst failure. Faulty installation

can cause twisting, resulting in wheel, tire, or chassis

interference.

The steel brake tubing should be inspected period-

ically for evidence of physical damage or contact with

moving or hot components.

The flexible brake tube sections used on this vehi-

cle in the primary and secondary tubes from the

master cylinder to the ABS hydraulic control unit

connections and the chassis brake tubes between the

hydraulic control unit and the proportioning valve

must also be inspected. This flexible tubing must be

inspected for kinks, fraying and its contact with

other components of the vehicle or contact with the

body of the vehicle.

REAR WHEEL HUB AND BEARING ASSEMBLY

The rear hub and bearing assembly is designed for

the life of the vehicle and should require no mainte-

nance. The following procedure may be used for eval-

uation of bearing condition.

With wheel and brake drum removed, rotate

flanged outer ring of hub. Excessive roughness, lat-

eral play or resistance to rotation may indicate dirt

intrusion or bearing failure. If the rear wheel bear-

ings exhibit these conditions during inspection, the

hub and bearing assembly should be replaced.

Damaged bearing seals and resulting excessive

grease loss may also require bearing replacement.

Moderate grease loss from bearing is considered nor-

mal and should not require replacement of the hub

and bearing assembly.

ADJUSTMENTS

STOP LAMP SWITCH

(1) Remove stop lamp switch from its bracket by

rotating it approximately 30É in a counter-clockwise

direction.

(2) Disconnect wiring harness connector from stop

lamp switch.

(3) Hold stop lamp switch firmly in one hand.

Then using other hand, pull outward on the plunger

of the stop lamp switch until it has ratcheted out to

its fully extended position.

(4) Install the stop lamp switch into the bracket

using the following procedure. Depress the brake

pedal as far down as possible. Then while keeping

the brake pedal depressed, install the stop lamp

switch into the bracket by aligning index key on

switch with slot at top of square hole in mounting

bracket. When switch is fully installed in the square

hole of the bracket, rotate switch clockwise approxi-

mately 30É to lock the switch into the bracket.

CAUTION: Do not use excessive force when pulling

back on brake pedal to adjust the stop lamp switch.

If too much force is used, damage to the vacuum

booster, stop lamp switch or striker (Fig. 195) can

result.

(5) Connect the wiring harness connector to the

stop lamp switch.

(6) Gently pull back on brake pedal until the pedal

stops moving. This will cause the switch plunger

(Fig. 195) to ratchet backward to the correct position.

Fig. 195 Stop Light Switch Location In Vehicle

5 - 78 BRAKESNS

CLEANING AND INSPECTION (Continued)