service CHRYSLER VOYAGER 1996 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 88 of 1938

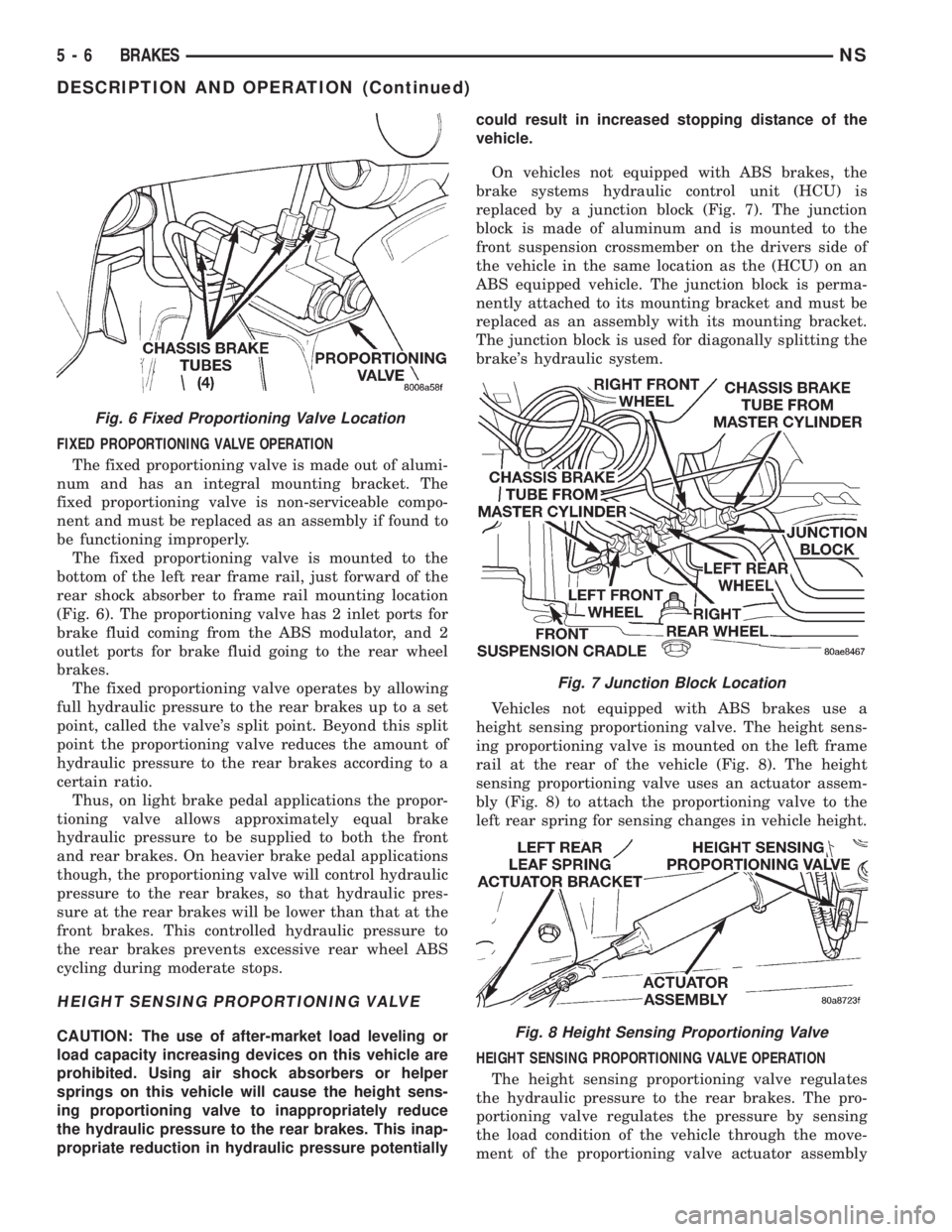

FIXED PROPORTIONING VALVE OPERATION

The fixed proportioning valve is made out of alumi-

num and has an integral mounting bracket. The

fixed proportioning valve is non-serviceable compo-

nent and must be replaced as an assembly if found to

be functioning improperly.

The fixed proportioning valve is mounted to the

bottom of the left rear frame rail, just forward of the

rear shock absorber to frame rail mounting location

(Fig. 6). The proportioning valve has 2 inlet ports for

brake fluid coming from the ABS modulator, and 2

outlet ports for brake fluid going to the rear wheel

brakes.

The fixed proportioning valve operates by allowing

full hydraulic pressure to the rear brakes up to a set

point, called the valve's split point. Beyond this split

point the proportioning valve reduces the amount of

hydraulic pressure to the rear brakes according to a

certain ratio.

Thus, on light brake pedal applications the propor-

tioning valve allows approximately equal brake

hydraulic pressure to be supplied to both the front

and rear brakes. On heavier brake pedal applications

though, the proportioning valve will control hydraulic

pressure to the rear brakes, so that hydraulic pres-

sure at the rear brakes will be lower than that at the

front brakes. This controlled hydraulic pressure to

the rear brakes prevents excessive rear wheel ABS

cycling during moderate stops.

HEIGHT SENSING PROPORTIONING VALVE

CAUTION: The use of after-market load leveling or

load capacity increasing devices on this vehicle are

prohibited. Using air shock absorbers or helper

springs on this vehicle will cause the height sens-

ing proportioning valve to inappropriately reduce

the hydraulic pressure to the rear brakes. This inap-

propriate reduction in hydraulic pressure potentiallycould result in increased stopping distance of the

vehicle.

On vehicles not equipped with ABS brakes, the

brake systems hydraulic control unit (HCU) is

replaced by a junction block (Fig. 7). The junction

block is made of aluminum and is mounted to the

front suspension crossmember on the drivers side of

the vehicle in the same location as the (HCU) on an

ABS equipped vehicle. The junction block is perma-

nently attached to its mounting bracket and must be

replaced as an assembly with its mounting bracket.

The junction block is used for diagonally splitting the

brake's hydraulic system.

Vehicles not equipped with ABS brakes use a

height sensing proportioning valve. The height sens-

ing proportioning valve is mounted on the left frame

rail at the rear of the vehicle (Fig. 8). The height

sensing proportioning valve uses an actuator assem-

bly (Fig. 8) to attach the proportioning valve to the

left rear spring for sensing changes in vehicle height.

HEIGHT SENSING PROPORTIONING VALVE OPERATION

The height sensing proportioning valve regulates

the hydraulic pressure to the rear brakes. The pro-

portioning valve regulates the pressure by sensing

the load condition of the vehicle through the move-

ment of the proportioning valve actuator assembly

Fig. 6 Fixed Proportioning Valve Location

Fig. 7 Junction Block Location

Fig. 8 Height Sensing Proportioning Valve

5 - 6 BRAKESNS

DESCRIPTION AND OPERATION (Continued)

Page 91 of 1938

normal. This may indicate:(1)Abnormal loss of

brake fluid in the master cylinder fluid reservoir

resulting from a leak in the hydraulic system.(2)

Brake shoe linings which have worn to a point

requiring replacement.

As the brake fluid drops below the minimum level,

the brake fluid level sensor closes to ground the

brake warning light circuit. This will turn on the red

brake warning light. At this time, master cylinder

fluid reservoir should be checked and filled to the full

mark with DOT 3 brake fluid.If brake fluid level

has dropped below the add line in the master

cylinder fluid reservoir, the entire brake

hydraulic system should be checked for evi-

dence of a leak.

STOP LAMP SWITCH

The stop lamp switch controls operation of the

vehicles stop lamps. Also, if the vehicle is equippedwith speed control, the stop lamp switch will deacti-

vate speed control when the brake pedal is

depressed.

The stop lamp switch controls operation of the

right and left tail, stop and turn signal lamp and

CHMSL lamp, by supplying battery current to these

lamps.

The stop lamp switch controls the lamp operation

by opening and closing the electrical circuit to the

stop lamps.

HUB/BEARING REAR WHEEL

The rear hub and bearing assembly used on this

vehicle is serviceable only as a complete assembly. No

attempt should be made to disassemble a rear hub

and bearing assembly in an effort to repair it.

The rear hub and bearing assembly is attached to

the rear axle using 4 mounting bolts that are remov-

able from the back of the rear hub/bearing.

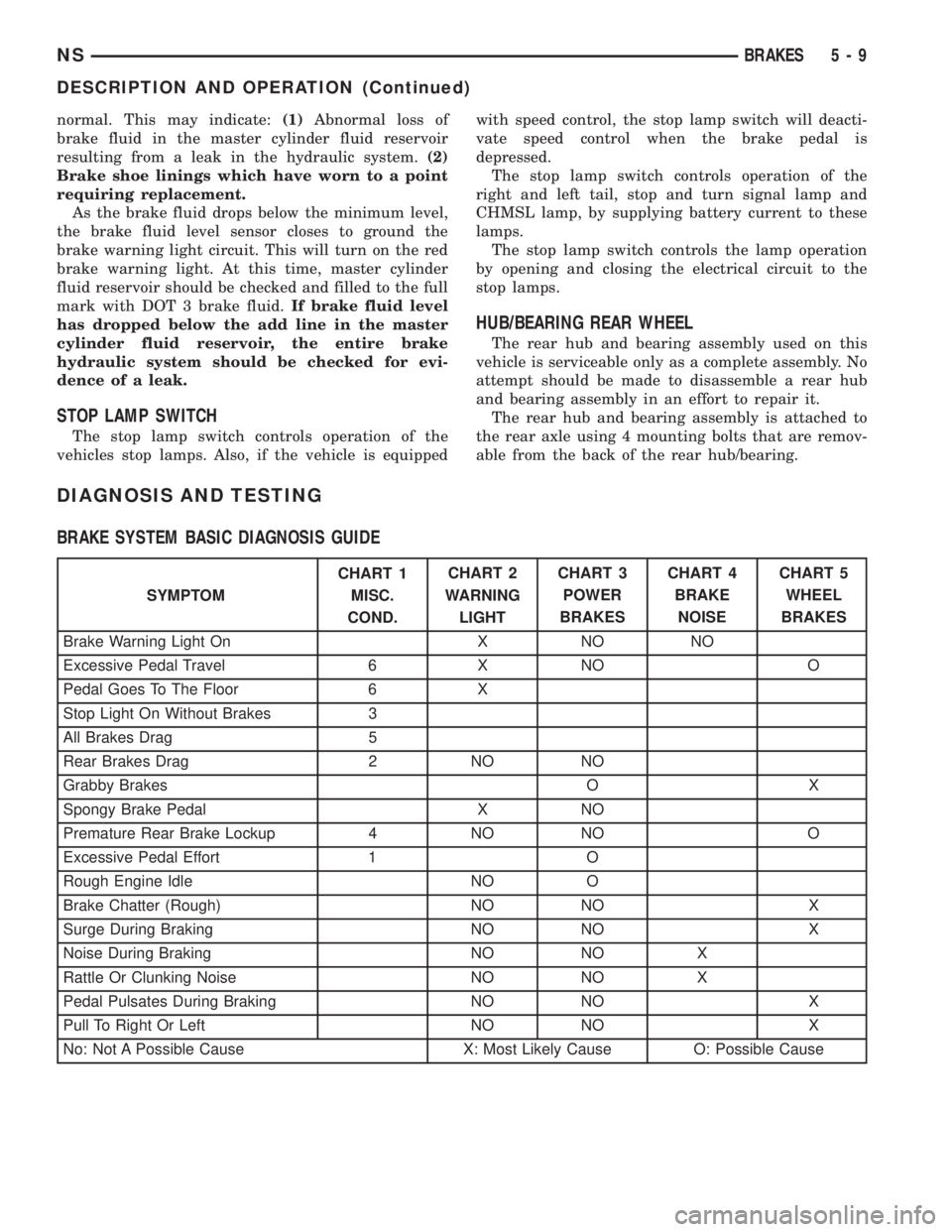

DIAGNOSIS AND TESTING

BRAKE SYSTEM BASIC DIAGNOSIS GUIDE

SYMPTOMCHART 1

MISC.

COND.CHART 2

WARNING

LIGHTCHART 3

POWER

BRAKESCHART 4

BRAKE

NOISECHART 5

WHEEL

BRAKES

Brake Warning Light On X NO NO

Excessive Pedal Travel 6 X NO O

Pedal Goes To The Floor 6 X

Stop Light On Without Brakes 3

All Brakes Drag 5

Rear Brakes Drag 2 NO NO

Grabby Brakes O X

Spongy Brake Pedal X NO

Premature Rear Brake Lockup 4 NO NO O

Excessive Pedal Effort 1 O

Rough Engine Idle NO O

Brake Chatter (Rough) NO NO X

Surge During Braking NO NO X

Noise During Braking NO NO X

Rattle Or Clunking Noise NO NO X

Pedal Pulsates During Braking NO NO X

Pull To Right Or Left NO NO X

No: Not A Possible Cause X: Most Likely Cause O: Possible Cause

NSBRAKES 5 - 9

DESCRIPTION AND OPERATION (Continued)

Page 96 of 1938

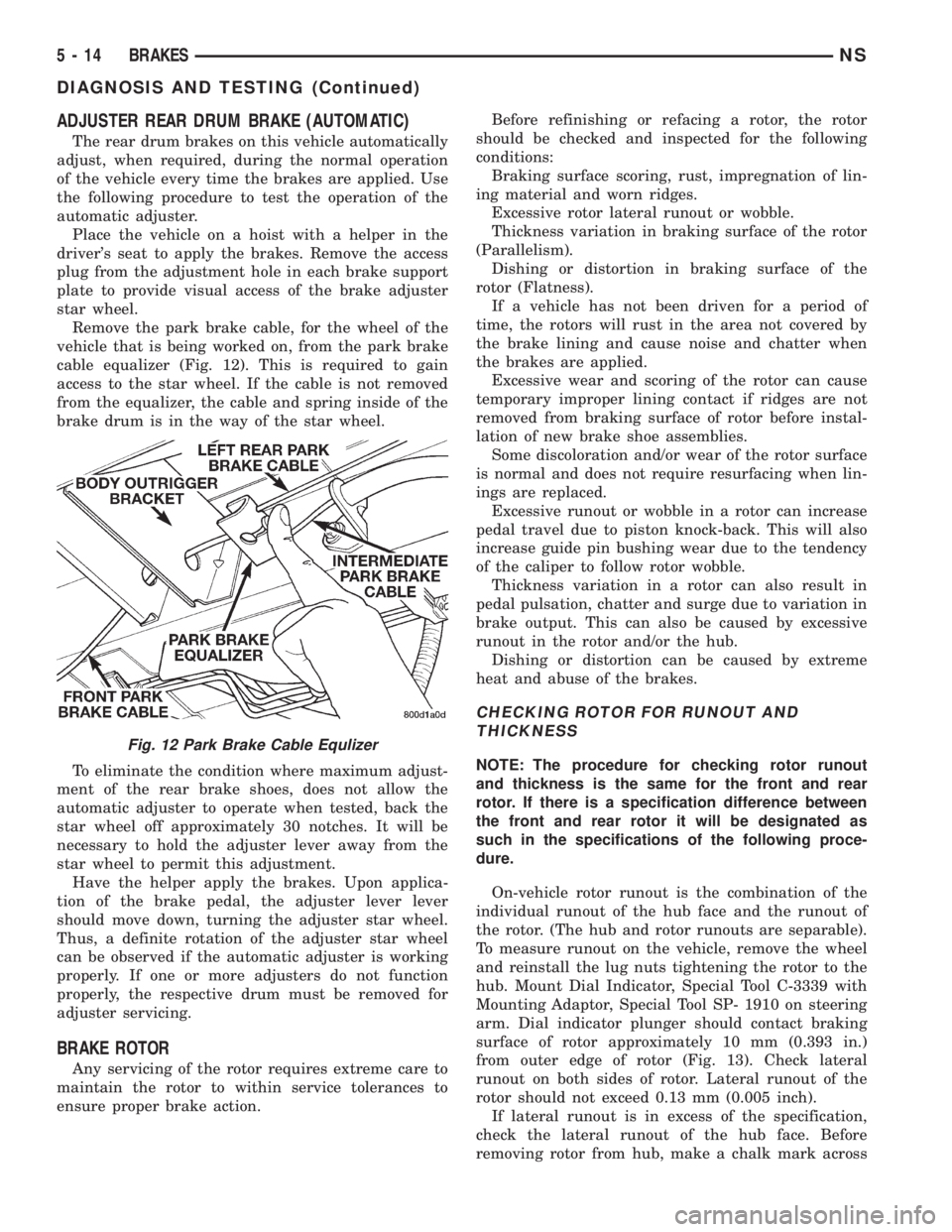

ADJUSTER REAR DRUM BRAKE (AUTOMATIC)

The rear drum brakes on this vehicle automatically

adjust, when required, during the normal operation

of the vehicle every time the brakes are applied. Use

the following procedure to test the operation of the

automatic adjuster.

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the adjustment hole in each brake support

plate to provide visual access of the brake adjuster

star wheel.

Remove the park brake cable, for the wheel of the

vehicle that is being worked on, from the park brake

cable equalizer (Fig. 12). This is required to gain

access to the star wheel. If the cable is not removed

from the equalizer, the cable and spring inside of the

brake drum is in the way of the star wheel.

To eliminate the condition where maximum adjust-

ment of the rear brake shoes, does not allow the

automatic adjuster to operate when tested, back the

star wheel off approximately 30 notches. It will be

necessary to hold the adjuster lever away from the

star wheel to permit this adjustment.

Have the helper apply the brakes. Upon applica-

tion of the brake pedal, the adjuster lever lever

should move down, turning the adjuster star wheel.

Thus, a definite rotation of the adjuster star wheel

can be observed if the automatic adjuster is working

properly. If one or more adjusters do not function

properly, the respective drum must be removed for

adjuster servicing.

BRAKE ROTOR

Any servicing of the rotor requires extreme care to

maintain the rotor to within service tolerances to

ensure proper brake action.Before refinishing or refacing a rotor, the rotor

should be checked and inspected for the following

conditions:

Braking surface scoring, rust, impregnation of lin-

ing material and worn ridges.

Excessive rotor lateral runout or wobble.

Thickness variation in braking surface of the rotor

(Parallelism).

Dishing or distortion in braking surface of the

rotor (Flatness).

If a vehicle has not been driven for a period of

time, the rotors will rust in the area not covered by

the brake lining and cause noise and chatter when

the brakes are applied.

Excessive wear and scoring of the rotor can cause

temporary improper lining contact if ridges are not

removed from braking surface of rotor before instal-

lation of new brake shoe assemblies.

Some discoloration and/or wear of the rotor surface

is normal and does not require resurfacing when lin-

ings are replaced.

Excessive runout or wobble in a rotor can increase

pedal travel due to piston knock-back. This will also

increase guide pin bushing wear due to the tendency

of the caliper to follow rotor wobble.

Thickness variation in a rotor can also result in

pedal pulsation, chatter and surge due to variation in

brake output. This can also be caused by excessive

runout in the rotor and/or the hub.

Dishing or distortion can be caused by extreme

heat and abuse of the brakes.

CHECKING ROTOR FOR RUNOUT AND

THICKNESS

NOTE: The procedure for checking rotor runout

and thickness is the same for the front and rear

rotor. If there is a specification difference between

the front and rear rotor it will be designated as

such in the specifications of the following proce-

dure.

On-vehicle rotor runout is the combination of the

individual runout of the hub face and the runout of

the rotor. (The hub and rotor runouts are separable).

To measure runout on the vehicle, remove the wheel

and reinstall the lug nuts tightening the rotor to the

hub. Mount Dial Indicator, Special Tool C-3339 with

Mounting Adaptor, Special Tool SP- 1910 on steering

arm. Dial indicator plunger should contact braking

surface of rotor approximately 10 mm (0.393 in.)

from outer edge of rotor (Fig. 13). Check lateral

runout on both sides of rotor. Lateral runout of the

rotor should not exceed 0.13 mm (0.005 inch).

If lateral runout is in excess of the specification,

check the lateral runout of the hub face. Before

removing rotor from hub, make a chalk mark across

Fig. 12 Park Brake Cable Equlizer

5 - 14 BRAKESNS

DIAGNOSIS AND TESTING (Continued)

Page 100 of 1938

shoe assemblies meeting the OEM lining mate-

rial specification. The vehicles brake system is

not balanced for after market brake shoe

assembly lining material.

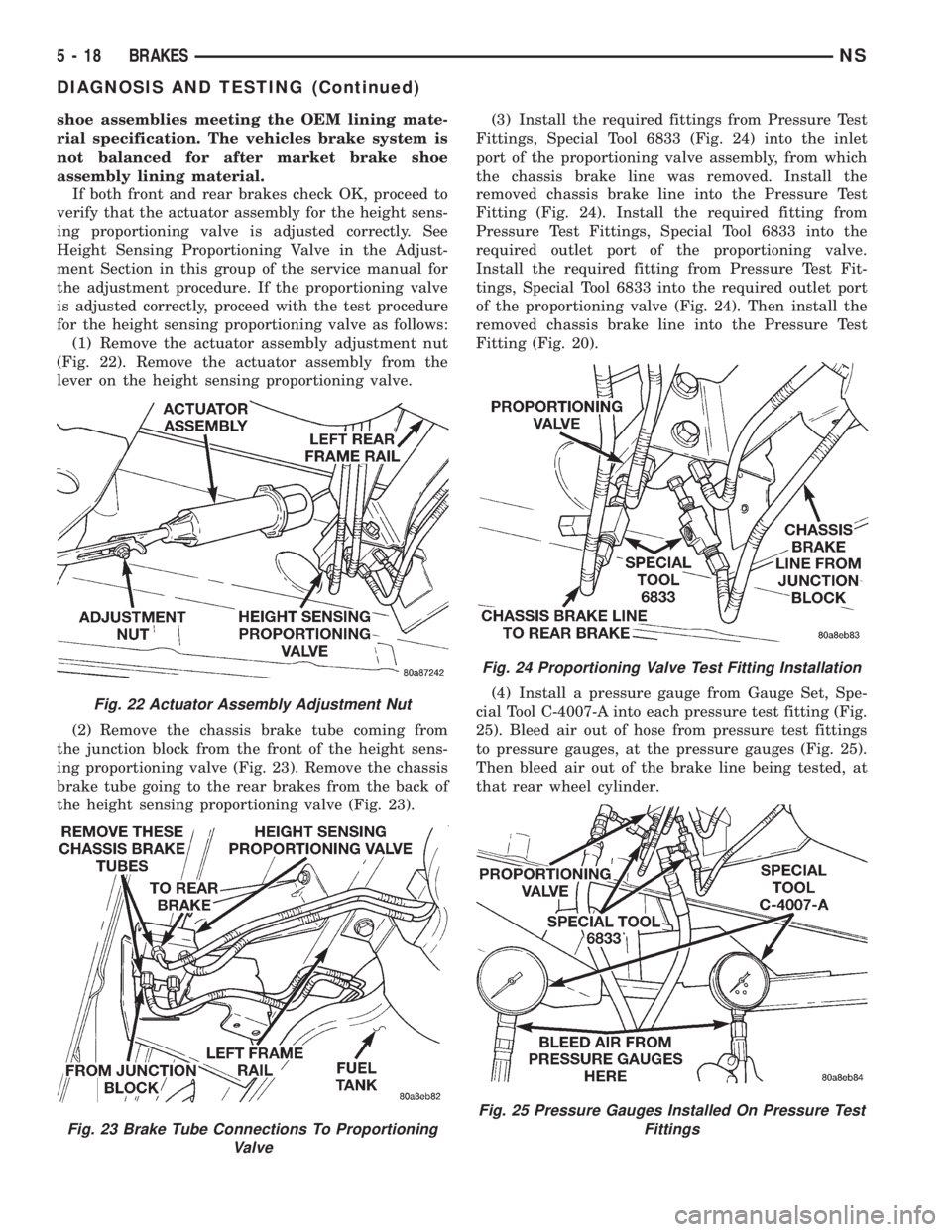

If both front and rear brakes check OK, proceed to

verify that the actuator assembly for the height sens-

ing proportioning valve is adjusted correctly. See

Height Sensing Proportioning Valve in the Adjust-

ment Section in this group of the service manual for

the adjustment procedure. If the proportioning valve

is adjusted correctly, proceed with the test procedure

for the height sensing proportioning valve as follows:

(1) Remove the actuator assembly adjustment nut

(Fig. 22). Remove the actuator assembly from the

lever on the height sensing proportioning valve.

(2) Remove the chassis brake tube coming from

the junction block from the front of the height sens-

ing proportioning valve (Fig. 23). Remove the chassis

brake tube going to the rear brakes from the back of

the height sensing proportioning valve (Fig. 23).(3) Install the required fittings from Pressure Test

Fittings, Special Tool 6833 (Fig. 24) into the inlet

port of the proportioning valve assembly, from which

the chassis brake line was removed. Install the

removed chassis brake line into the Pressure Test

Fitting (Fig. 24). Install the required fitting from

Pressure Test Fittings, Special Tool 6833 into the

required outlet port of the proportioning valve.

Install the required fitting from Pressure Test Fit-

tings, Special Tool 6833 into the required outlet port

of the proportioning valve (Fig. 24). Then install the

removed chassis brake line into the Pressure Test

Fitting (Fig. 20).

(4) Install a pressure gauge from Gauge Set, Spe-

cial Tool C-4007-A into each pressure test fitting (Fig.

25). Bleed air out of hose from pressure test fittings

to pressure gauges, at the pressure gauges (Fig. 25).

Then bleed air out of the brake line being tested, at

that rear wheel cylinder.

Fig. 22 Actuator Assembly Adjustment Nut

Fig. 23 Brake Tube Connections To Proportioning

Valve

Fig. 24 Proportioning Valve Test Fitting Installation

Fig. 25 Pressure Gauges Installed On Pressure Test

Fittings

5 - 18 BRAKESNS

DIAGNOSIS AND TESTING (Continued)

Page 101 of 1938

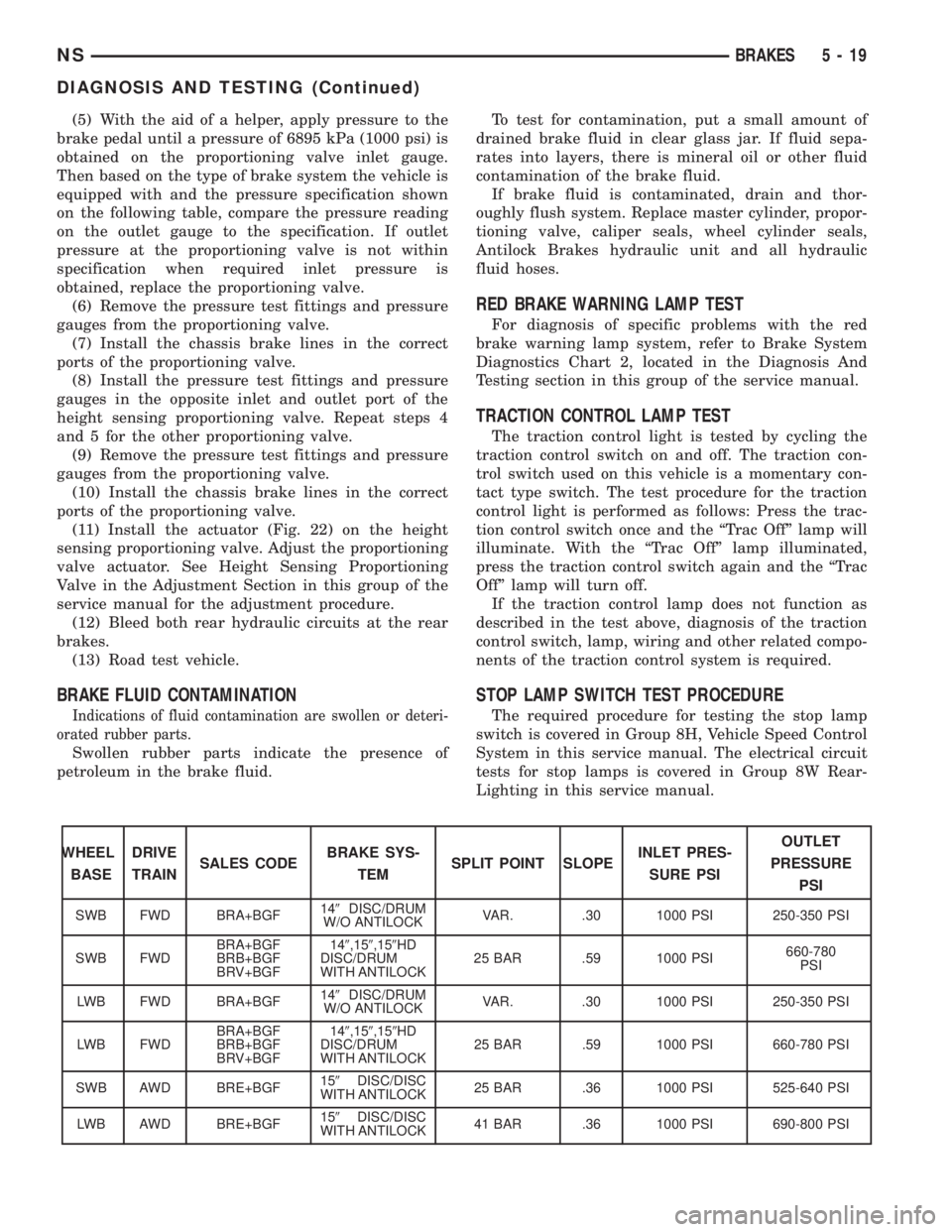

(5) With the aid of a helper, apply pressure to the

brake pedal until a pressure of 6895 kPa (1000 psi) is

obtained on the proportioning valve inlet gauge.

Then based on the type of brake system the vehicle is

equipped with and the pressure specification shown

on the following table, compare the pressure reading

on the outlet gauge to the specification. If outlet

pressure at the proportioning valve is not within

specification when required inlet pressure is

obtained, replace the proportioning valve.

(6) Remove the pressure test fittings and pressure

gauges from the proportioning valve.

(7) Install the chassis brake lines in the correct

ports of the proportioning valve.

(8) Install the pressure test fittings and pressure

gauges in the opposite inlet and outlet port of the

height sensing proportioning valve. Repeat steps 4

and 5 for the other proportioning valve.

(9) Remove the pressure test fittings and pressure

gauges from the proportioning valve.

(10) Install the chassis brake lines in the correct

ports of the proportioning valve.

(11) Install the actuator (Fig. 22) on the height

sensing proportioning valve. Adjust the proportioning

valve actuator. See Height Sensing Proportioning

Valve in the Adjustment Section in this group of the

service manual for the adjustment procedure.

(12) Bleed both rear hydraulic circuits at the rear

brakes.

(13) Road test vehicle.

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or deteri-

orated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

RED BRAKE WARNING LAMP TEST

For diagnosis of specific problems with the red

brake warning lamp system, refer to Brake System

Diagnostics Chart 2, located in the Diagnosis And

Testing section in this group of the service manual.

TRACTION CONTROL LAMP TEST

The traction control light is tested by cycling the

traction control switch on and off. The traction con-

trol switch used on this vehicle is a momentary con-

tact type switch. The test procedure for the traction

control light is performed as follows: Press the trac-

tion control switch once and the ªTrac Offº lamp will

illuminate. With the ªTrac Offº lamp illuminated,

press the traction control switch again and the ªTrac

Offº lamp will turn off.

If the traction control lamp does not function as

described in the test above, diagnosis of the traction

control switch, lamp, wiring and other related compo-

nents of the traction control system is required.

STOP LAMP SWITCH TEST PROCEDURE

The required procedure for testing the stop lamp

switch is covered in Group 8H, Vehicle Speed Control

System in this service manual. The electrical circuit

tests for stop lamps is covered in Group 8W Rear-

Lighting in this service manual.

WHEEL

BASEDRIVE

TRAINSALES CODEBRAKE SYS-

TEMSPLIT POINT SLOPEINLET PRES-

SURE PSIOUTLET

PRESSURE

PSI

SWB FWD BRA+BGF149DISC/DRUM

W/O ANTILOCKVAR. .30 1000 PSI 250-350 PSI

SWB FWDBRA+BGF

BRB+BGF

BRV+BGF149,159,159HD

DISC/DRUM

WITH ANTILOCK25 BAR .59 1000 PSI660-780

PSI

LWB FWD BRA+BGF149DISC/DRUM

W/O ANTILOCKVAR. .30 1000 PSI 250-350 PSI

LWB FWDBRA+BGF

BRB+BGF

BRV+BGF149,159,159HD

DISC/DRUM

WITH ANTILOCK25 BAR .59 1000 PSI 660-780 PSI

SWB AWD BRE+BGF159DISC/DISC

WITH ANTILOCK25 BAR .36 1000 PSI 525-640 PSI

LWB AWD BRE+BGF159DISC/DISC

WITH ANTILOCK41 BAR .36 1000 PSI 690-800 PSI

NSBRAKES 5 - 19

DIAGNOSIS AND TESTING (Continued)

Page 102 of 1938

SERVICE PROCEDURES

MASTER CYLINDER FLUID LEVEL CHECK

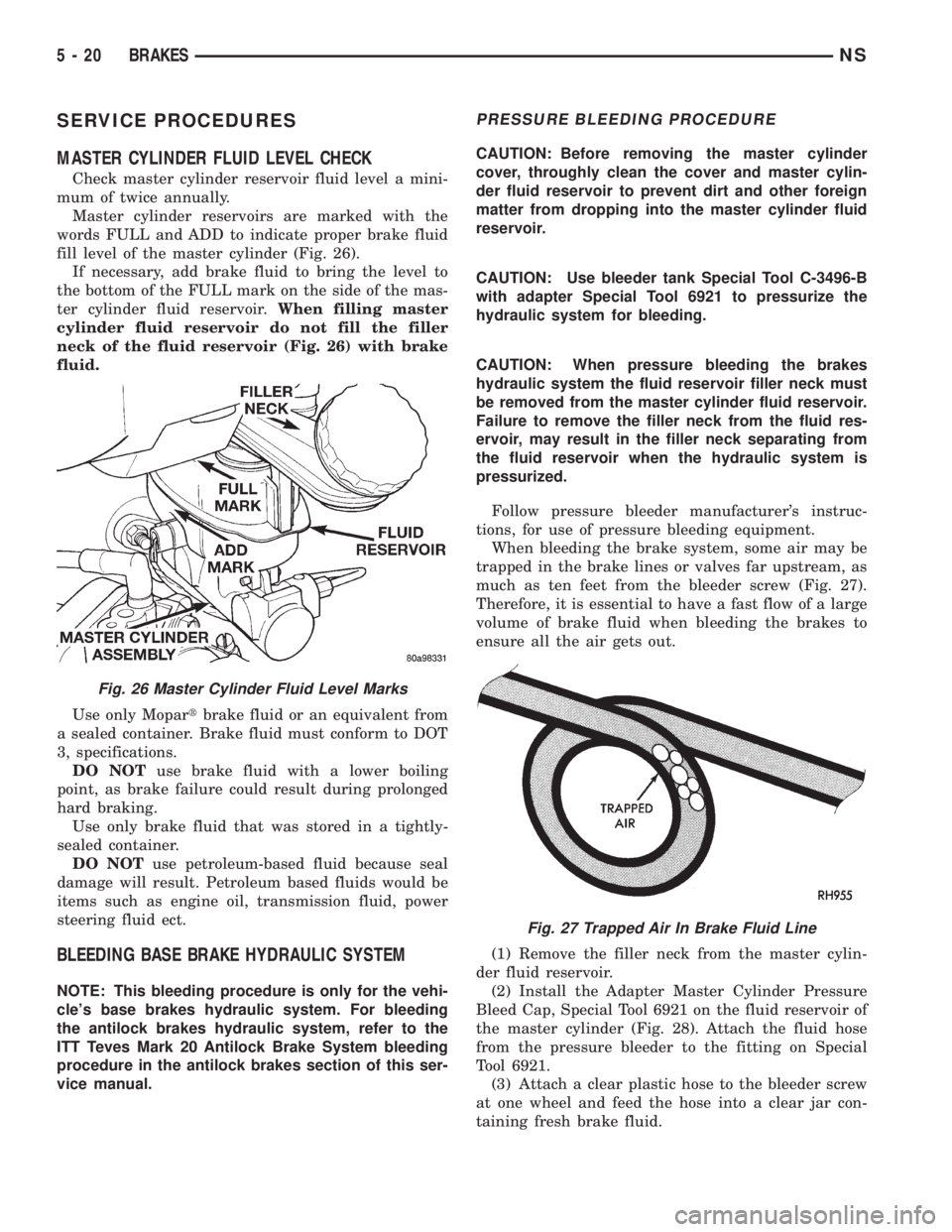

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

Master cylinder reservoirs are marked with the

words FULL and ADD to indicate proper brake fluid

fill level of the master cylinder (Fig. 26).

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.When filling master

cylinder fluid reservoir do not fill the filler

neck of the fluid reservoir (Fig. 26) with brake

fluid.

Use only Mopartbrake fluid or an equivalent from

a sealed container. Brake fluid must conform to DOT

3, specifications.

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid ect.

BLEEDING BASE BRAKE HYDRAULIC SYSTEM

NOTE: This bleeding procedure is only for the vehi-

cle's base brakes hydraulic system. For bleeding

the antilock brakes hydraulic system, refer to the

ITT Teves Mark 20 Antilock Brake System bleeding

procedure in the antilock brakes section of this ser-

vice manual.

PRESSURE BLEEDING PROCEDURE

CAUTION: Before removing the master cylinder

cover, throughly clean the cover and master cylin-

der fluid reservoir to prevent dirt and other foreign

matter from dropping into the master cylinder fluid

reservoir.

CAUTION: Use bleeder tank Special Tool C-3496-B

with adapter Special Tool 6921 to pressurize the

hydraulic system for bleeding.

CAUTION: When pressure bleeding the brakes

hydraulic system the fluid reservoir filler neck must

be removed from the master cylinder fluid reservoir.

Failure to remove the filler neck from the fluid res-

ervoir, may result in the filler neck separating from

the fluid reservoir when the hydraulic system is

pressurized.

Follow pressure bleeder manufacturer's instruc-

tions, for use of pressure bleeding equipment.

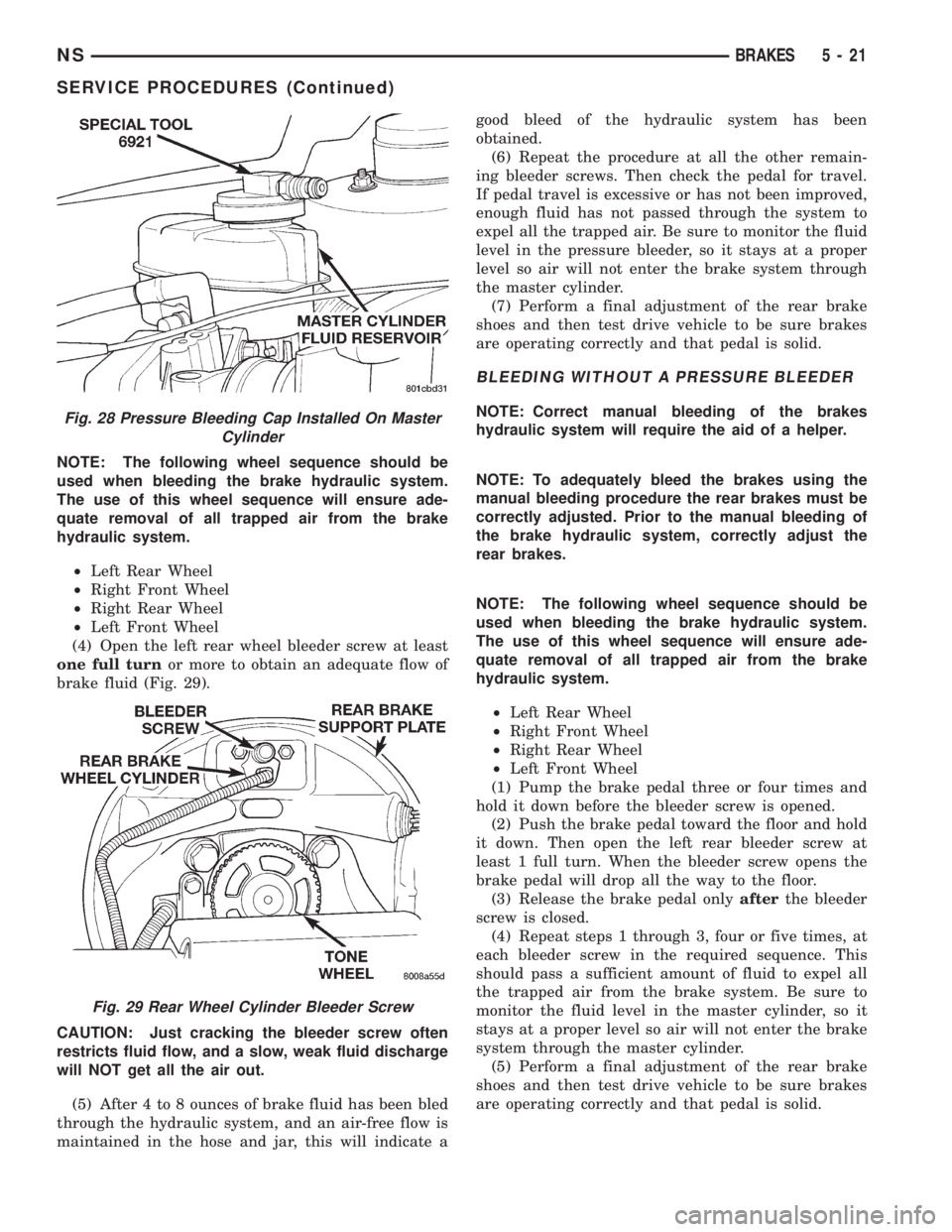

When bleeding the brake system, some air may be

trapped in the brake lines or valves far upstream, as

much as ten feet from the bleeder screw (Fig. 27).

Therefore, it is essential to have a fast flow of a large

volume of brake fluid when bleeding the brakes to

ensure all the air gets out.

(1) Remove the filler neck from the master cylin-

der fluid reservoir.

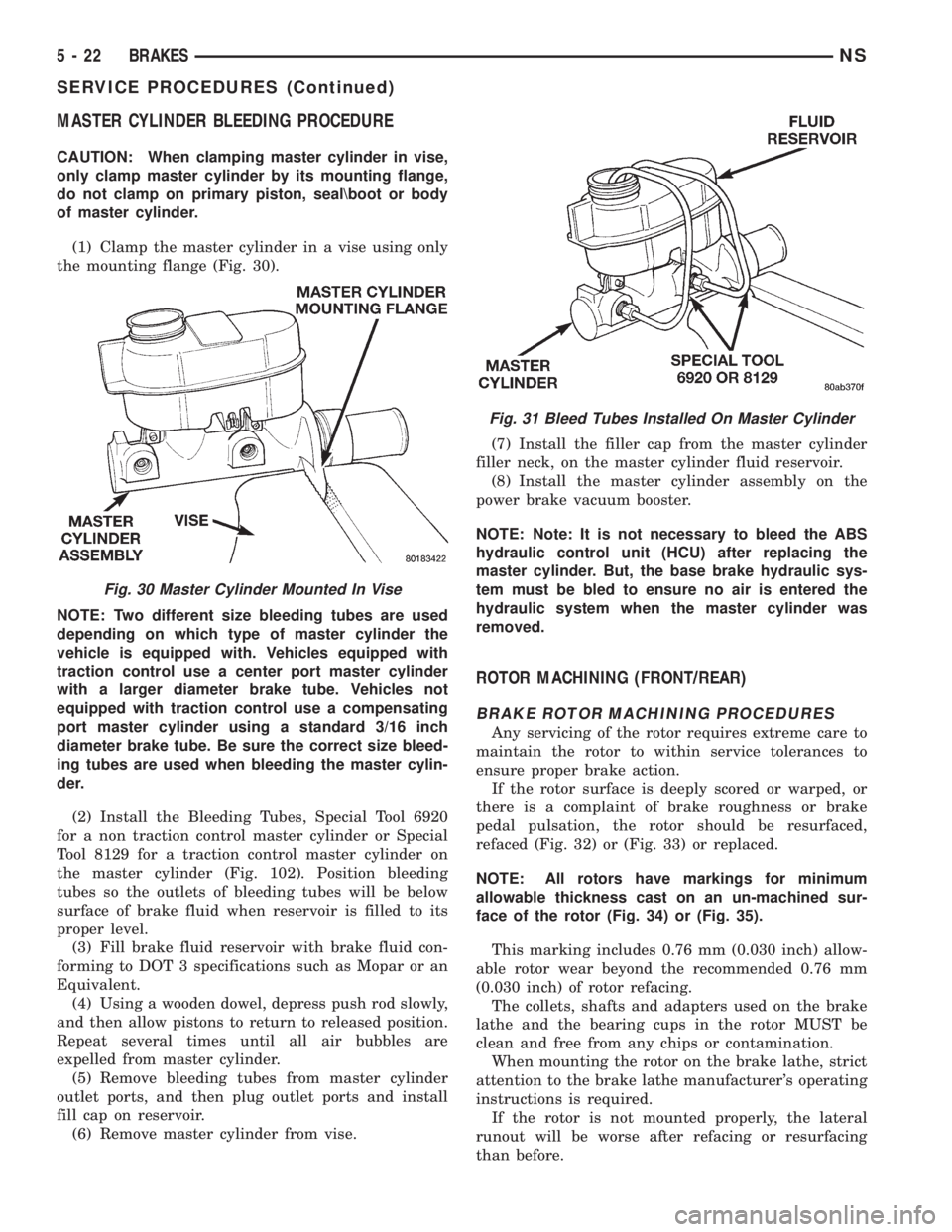

(2) Install the Adapter Master Cylinder Pressure

Bleed Cap, Special Tool 6921 on the fluid reservoir of

the master cylinder (Fig. 28). Attach the fluid hose

from the pressure bleeder to the fitting on Special

Tool 6921.

(3) Attach a clear plastic hose to the bleeder screw

at one wheel and feed the hose into a clear jar con-

taining fresh brake fluid.

Fig. 26 Master Cylinder Fluid Level Marks

Fig. 27 Trapped Air In Brake Fluid Line

5 - 20 BRAKESNS

Page 103 of 1938

NOTE: The following wheel sequence should be

used when bleeding the brake hydraulic system.

The use of this wheel sequence will ensure ade-

quate removal of all trapped air from the brake

hydraulic system.

²Left Rear Wheel

²Right Front Wheel

²Right Rear Wheel

²Left Front Wheel

(4) Open the left rear wheel bleeder screw at least

one full turnor more to obtain an adequate flow of

brake fluid (Fig. 29).

CAUTION: Just cracking the bleeder screw often

restricts fluid flow, and a slow, weak fluid discharge

will NOT get all the air out.

(5) After 4 to 8 ounces of brake fluid has been bled

through the hydraulic system, and an air-free flow is

maintained in the hose and jar, this will indicate agood bleed of the hydraulic system has been

obtained.

(6) Repeat the procedure at all the other remain-

ing bleeder screws. Then check the pedal for travel.

If pedal travel is excessive or has not been improved,

enough fluid has not passed through the system to

expel all the trapped air. Be sure to monitor the fluid

level in the pressure bleeder, so it stays at a proper

level so air will not enter the brake system through

the master cylinder.

(7) Perform a final adjustment of the rear brake

shoes and then test drive vehicle to be sure brakes

are operating correctly and that pedal is solid.

BLEEDING WITHOUT A PRESSURE BLEEDER

NOTE: Correct manual bleeding of the brakes

hydraulic system will require the aid of a helper.

NOTE: To adequately bleed the brakes using the

manual bleeding procedure the rear brakes must be

correctly adjusted. Prior to the manual bleeding of

the brake hydraulic system, correctly adjust the

rear brakes.

NOTE: The following wheel sequence should be

used when bleeding the brake hydraulic system.

The use of this wheel sequence will ensure ade-

quate removal of all trapped air from the brake

hydraulic system.

²Left Rear Wheel

²Right Front Wheel

²Right Rear Wheel

²Left Front Wheel

(1) Pump the brake pedal three or four times and

hold it down before the bleeder screw is opened.

(2) Push the brake pedal toward the floor and hold

it down. Then open the left rear bleeder screw at

least 1 full turn. When the bleeder screw opens the

brake pedal will drop all the way to the floor.

(3) Release the brake pedal onlyafterthe bleeder

screw is closed.

(4) Repeat steps 1 through 3, four or five times, at

each bleeder screw in the required sequence. This

should pass a sufficient amount of fluid to expel all

the trapped air from the brake system. Be sure to

monitor the fluid level in the master cylinder, so it

stays at a proper level so air will not enter the brake

system through the master cylinder.

(5) Perform a final adjustment of the rear brake

shoes and then test drive vehicle to be sure brakes

are operating correctly and that pedal is solid.Fig. 28 Pressure Bleeding Cap Installed On Master

Cylinder

Fig. 29 Rear Wheel Cylinder Bleeder Screw

NSBRAKES 5 - 21

SERVICE PROCEDURES (Continued)

Page 104 of 1938

MASTER CYLINDER BLEEDING PROCEDURE

CAUTION: When clamping master cylinder in vise,

only clamp master cylinder by its mounting flange,

do not clamp on primary piston, seal\boot or body

of master cylinder.

(1) Clamp the master cylinder in a vise using only

the mounting flange (Fig. 30).

NOTE: Two different size bleeding tubes are used

depending on which type of master cylinder the

vehicle is equipped with. Vehicles equipped with

traction control use a center port master cylinder

with a larger diameter brake tube. Vehicles not

equipped with traction control use a compensating

port master cylinder using a standard 3/16 inch

diameter brake tube. Be sure the correct size bleed-

ing tubes are used when bleeding the master cylin-

der.

(2) Install the Bleeding Tubes, Special Tool 6920

for a non traction control master cylinder or Special

Tool 8129 for a traction control master cylinder on

the master cylinder (Fig. 102). Position bleeding

tubes so the outlets of bleeding tubes will be below

surface of brake fluid when reservoir is filled to its

proper level.

(3) Fill brake fluid reservoir with brake fluid con-

forming to DOT 3 specifications such as Mopar or an

Equivalent.

(4) Using a wooden dowel, depress push rod slowly,

and then allow pistons to return to released position.

Repeat several times until all air bubbles are

expelled from master cylinder.

(5) Remove bleeding tubes from master cylinder

outlet ports, and then plug outlet ports and install

fill cap on reservoir.

(6) Remove master cylinder from vise.(7) Install the filler cap from the master cylinder

filler neck, on the master cylinder fluid reservoir.

(8) Install the master cylinder assembly on the

power brake vacuum booster.

NOTE: Note: It is not necessary to bleed the ABS

hydraulic control unit (HCU) after replacing the

master cylinder. But, the base brake hydraulic sys-

tem must be bled to ensure no air is entered the

hydraulic system when the master cylinder was

removed.

ROTOR MACHINING (FRONT/REAR)

BRAKE ROTOR MACHINING PROCEDURES

Any servicing of the rotor requires extreme care to

maintain the rotor to within service tolerances to

ensure proper brake action.

If the rotor surface is deeply scored or warped, or

there is a complaint of brake roughness or brake

pedal pulsation, the rotor should be resurfaced,

refaced (Fig. 32) or (Fig. 33) or replaced.

NOTE: All rotors have markings for minimum

allowable thickness cast on an un-machined sur-

face of the rotor (Fig. 34) or (Fig. 35).

This marking includes 0.76 mm (0.030 inch) allow-

able rotor wear beyond the recommended 0.76 mm

(0.030 inch) of rotor refacing.

The collets, shafts and adapters used on the brake

lathe and the bearing cups in the rotor MUST be

clean and free from any chips or contamination.

When mounting the rotor on the brake lathe, strict

attention to the brake lathe manufacturer's operating

instructions is required.

If the rotor is not mounted properly, the lateral

runout will be worse after refacing or resurfacing

than before.

Fig. 30 Master Cylinder Mounted In Vise

Fig. 31 Bleed Tubes Installed On Master Cylinder

5 - 22 BRAKESNS

SERVICE PROCEDURES (Continued)

Page 105 of 1938

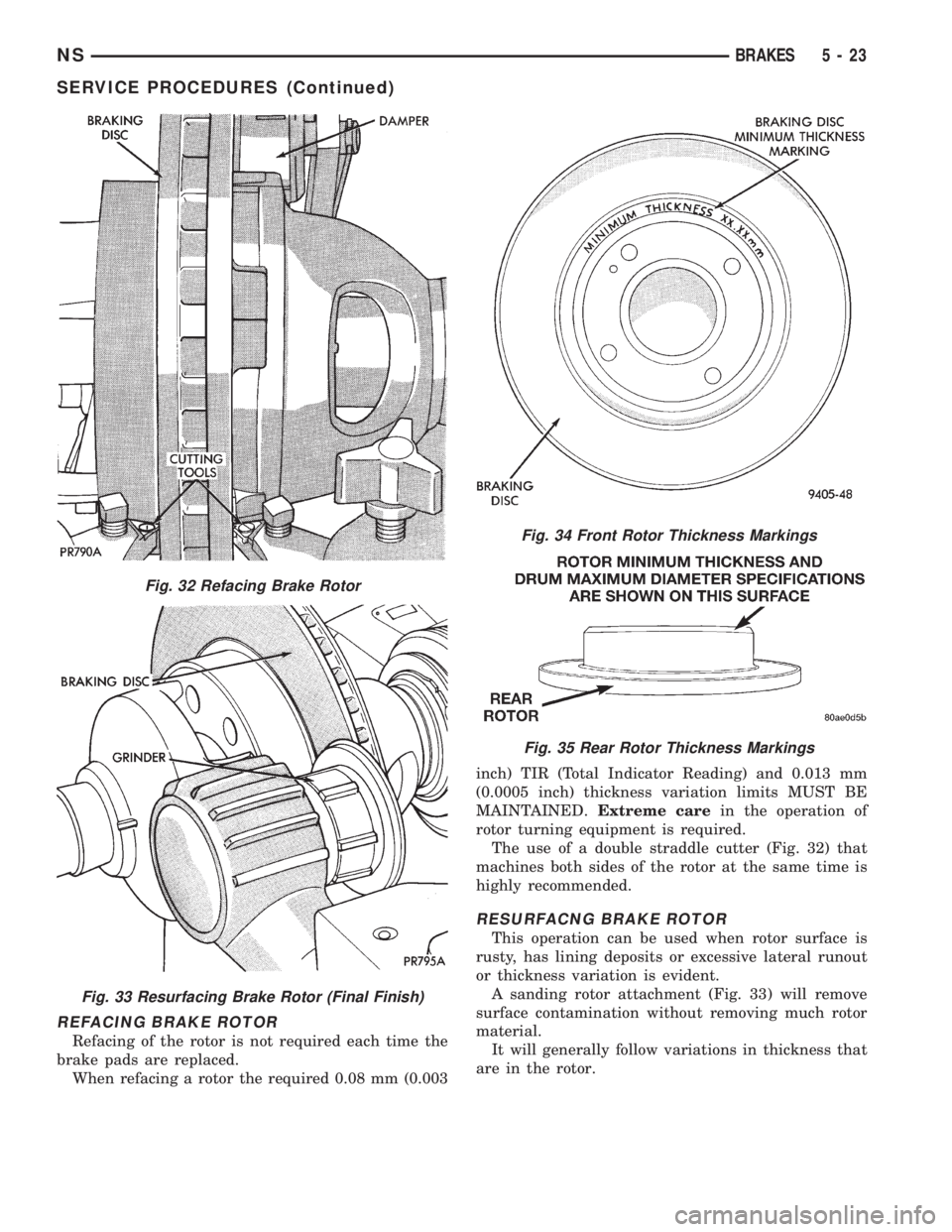

REFACING BRAKE ROTOR

Refacing of the rotor is not required each time the

brake pads are replaced.

When refacing a rotor the required 0.08 mm (0.003inch) TIR (Total Indicator Reading) and 0.013 mm

(0.0005 inch) thickness variation limits MUST BE

MAINTAINED.Extreme carein the operation of

rotor turning equipment is required.

The use of a double straddle cutter (Fig. 32) that

machines both sides of the rotor at the same time is

highly recommended.

RESURFACNG BRAKE ROTOR

This operation can be used when rotor surface is

rusty, has lining deposits or excessive lateral runout

or thickness variation is evident.

A sanding rotor attachment (Fig. 33) will remove

surface contamination without removing much rotor

material.

It will generally follow variations in thickness that

are in the rotor.

Fig. 32 Refacing Brake Rotor

Fig. 33 Resurfacing Brake Rotor (Final Finish)

Fig. 34 Front Rotor Thickness Markings

Fig. 35 Rear Rotor Thickness Markings

NSBRAKES 5 - 23

SERVICE PROCEDURES (Continued)

Page 106 of 1938

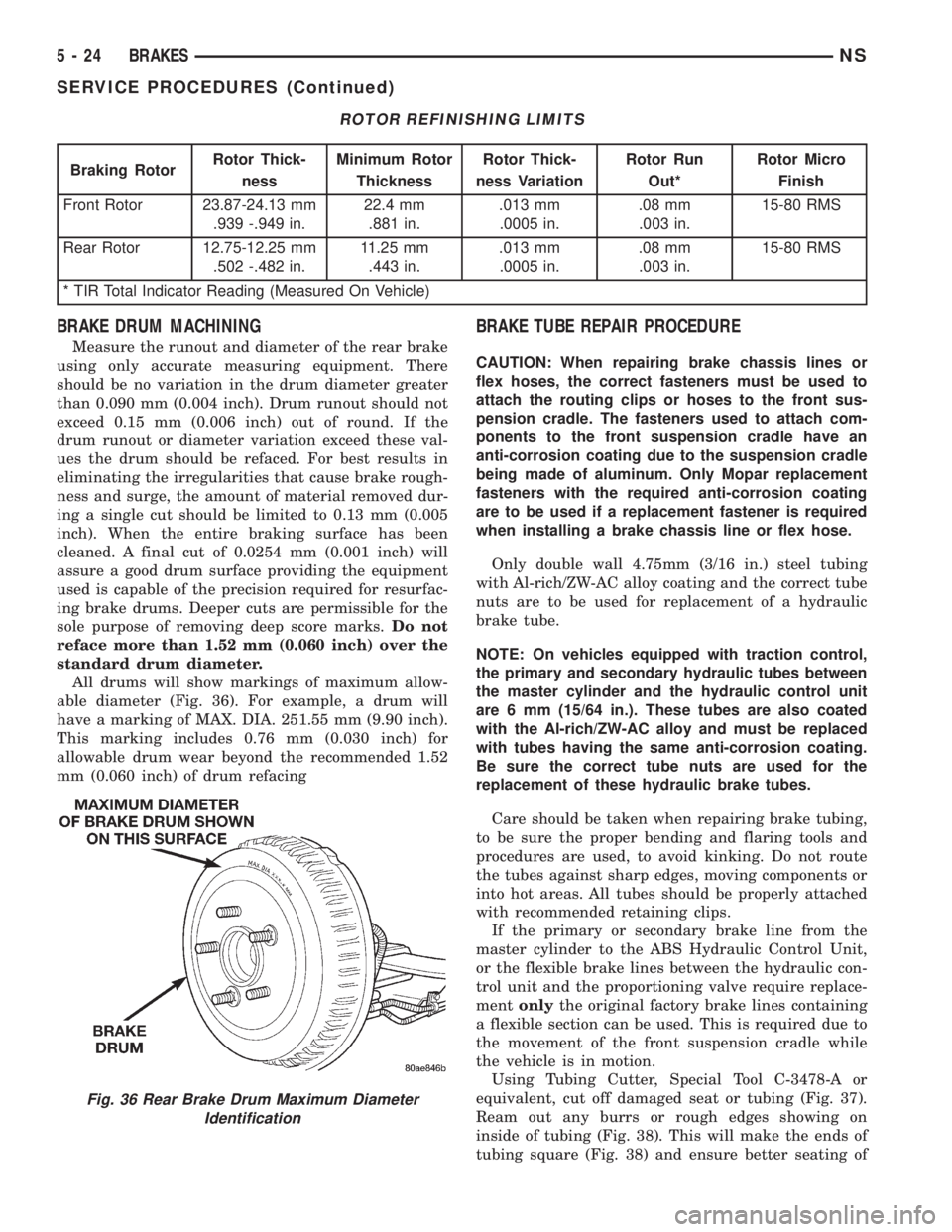

BRAKE DRUM MACHINING

Measure the runout and diameter of the rear brake

using only accurate measuring equipment. There

should be no variation in the drum diameter greater

than 0.090 mm (0.004 inch). Drum runout should not

exceed 0.15 mm (0.006 inch) out of round. If the

drum runout or diameter variation exceed these val-

ues the drum should be refaced. For best results in

eliminating the irregularities that cause brake rough-

ness and surge, the amount of material removed dur-

ing a single cut should be limited to 0.13 mm (0.005

inch). When the entire braking surface has been

cleaned. A final cut of 0.0254 mm (0.001 inch) will

assure a good drum surface providing the equipment

used is capable of the precision required for resurfac-

ing brake drums. Deeper cuts are permissible for the

sole purpose of removing deep score marks.Do not

reface more than 1.52 mm (0.060 inch) over the

standard drum diameter.

All drums will show markings of maximum allow-

able diameter (Fig. 36). For example, a drum will

have a marking of MAX. DIA. 251.55 mm (9.90 inch).

This marking includes 0.76 mm (0.030 inch) for

allowable drum wear beyond the recommended 1.52

mm (0.060 inch) of drum refacing

BRAKE TUBE REPAIR PROCEDURE

CAUTION: When repairing brake chassis lines or

flex hoses, the correct fasteners must be used to

attach the routing clips or hoses to the front sus-

pension cradle. The fasteners used to attach com-

ponents to the front suspension cradle have an

anti-corrosion coating due to the suspension cradle

being made of aluminum. Only Mopar replacement

fasteners with the required anti-corrosion coating

are to be used if a replacement fastener is required

when installing a brake chassis line or flex hose.

Only double wall 4.75mm (3/16 in.) steel tubing

with Al-rich/ZW-AC alloy coating and the correct tube

nuts are to be used for replacement of a hydraulic

brake tube.

NOTE: On vehicles equipped with traction control,

the primary and secondary hydraulic tubes between

the master cylinder and the hydraulic control unit

are 6 mm (15/64 in.). These tubes are also coated

with the Al-rich/ZW-AC alloy and must be replaced

with tubes having the same anti-corrosion coating.

Be sure the correct tube nuts are used for the

replacement of these hydraulic brake tubes.

Care should be taken when repairing brake tubing,

to be sure the proper bending and flaring tools and

procedures are used, to avoid kinking. Do not route

the tubes against sharp edges, moving components or

into hot areas. All tubes should be properly attached

with recommended retaining clips.

If the primary or secondary brake line from the

master cylinder to the ABS Hydraulic Control Unit,

or the flexible brake lines between the hydraulic con-

trol unit and the proportioning valve require replace-

mentonlythe original factory brake lines containing

a flexible section can be used. This is required due to

the movement of the front suspension cradle while

the vehicle is in motion.

Using Tubing Cutter, Special Tool C-3478-A or

equivalent, cut off damaged seat or tubing (Fig. 37).

Ream out any burrs or rough edges showing on

inside of tubing (Fig. 38). This will make the ends of

tubing square (Fig. 38) and ensure better seating of

ROTOR REFINISHING LIMITS

Braking RotorRotor Thick-

nessMinimum Rotor

ThicknessRotor Thick-

ness VariationRotor Run

Out*Rotor Micro

Finish

Front Rotor 23.87-24.13 mm

.939 -.949 in.22.4 mm

.881 in..013 mm

.0005 in..08 mm

.003 in.15-80 RMS

Rear Rotor 12.75-12.25 mm

.502 -.482 in.11.25 mm

.443 in..013 mm

.0005 in..08 mm

.003 in.15-80 RMS

* TIR Total Indicator Reading (Measured On Vehicle)

Fig. 36 Rear Brake Drum Maximum Diameter

Identification

5 - 24 BRAKESNS

SERVICE PROCEDURES (Continued)