window CHRYSLER VOYAGER 1996 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1759 of 1938

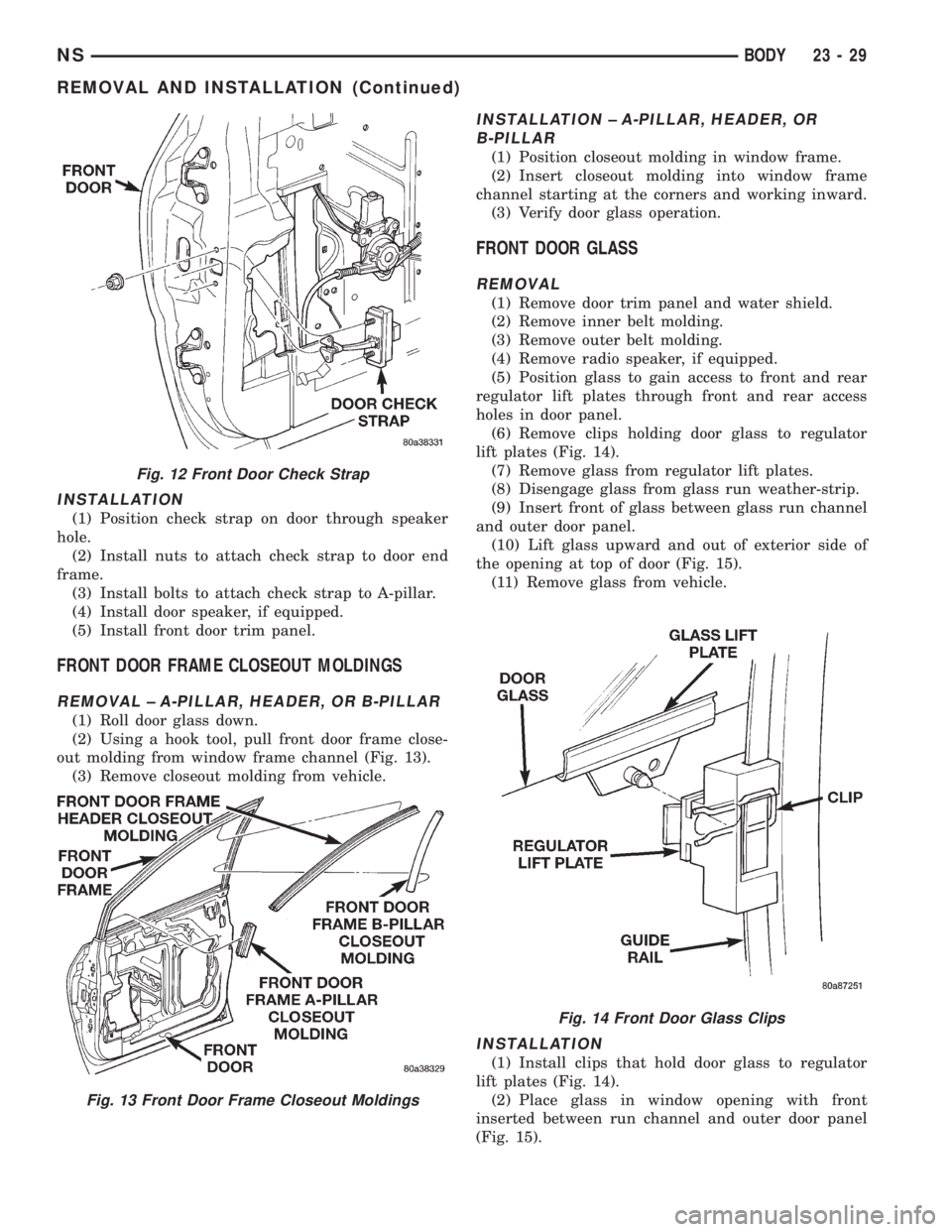

INSTALLATION

(1) Position check strap on door through speaker

hole.

(2) Install nuts to attach check strap to door end

frame.

(3) Install bolts to attach check strap to A-pillar.

(4) Install door speaker, if equipped.

(5) Install front door trim panel.

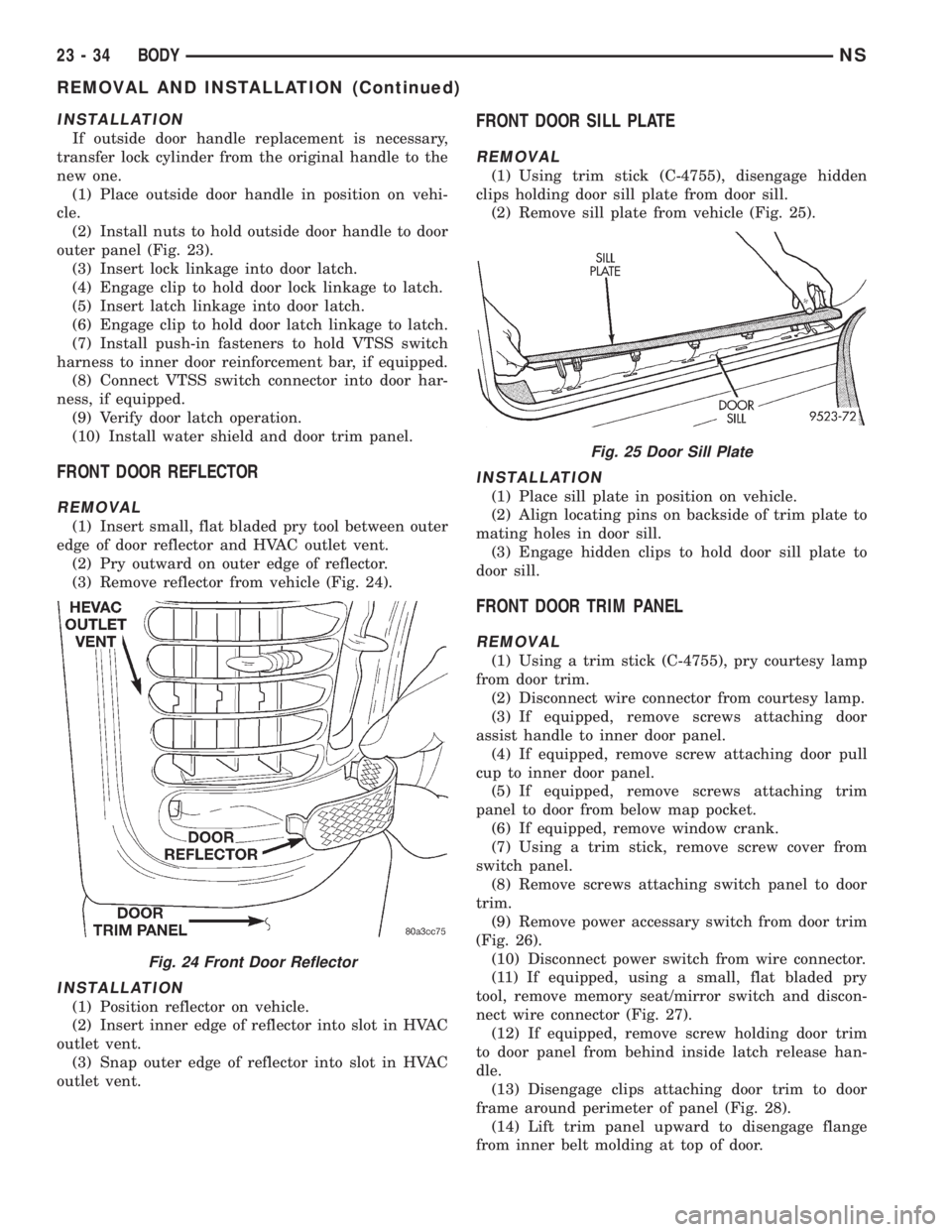

FRONT DOOR FRAME CLOSEOUT MOLDINGS

REMOVAL ± A-PILLAR, HEADER, OR B-PILLAR

(1) Roll door glass down.

(2) Using a hook tool, pull front door frame close-

out molding from window frame channel (Fig. 13).

(3) Remove closeout molding from vehicle.

INSTALLATION ± A-PILLAR, HEADER, OR

B-PILLAR

(1) Position closeout molding in window frame.

(2) Insert closeout molding into window frame

channel starting at the corners and working inward.

(3) Verify door glass operation.

FRONT DOOR GLASS

REMOVAL

(1) Remove door trim panel and water shield.

(2) Remove inner belt molding.

(3) Remove outer belt molding.

(4) Remove radio speaker, if equipped.

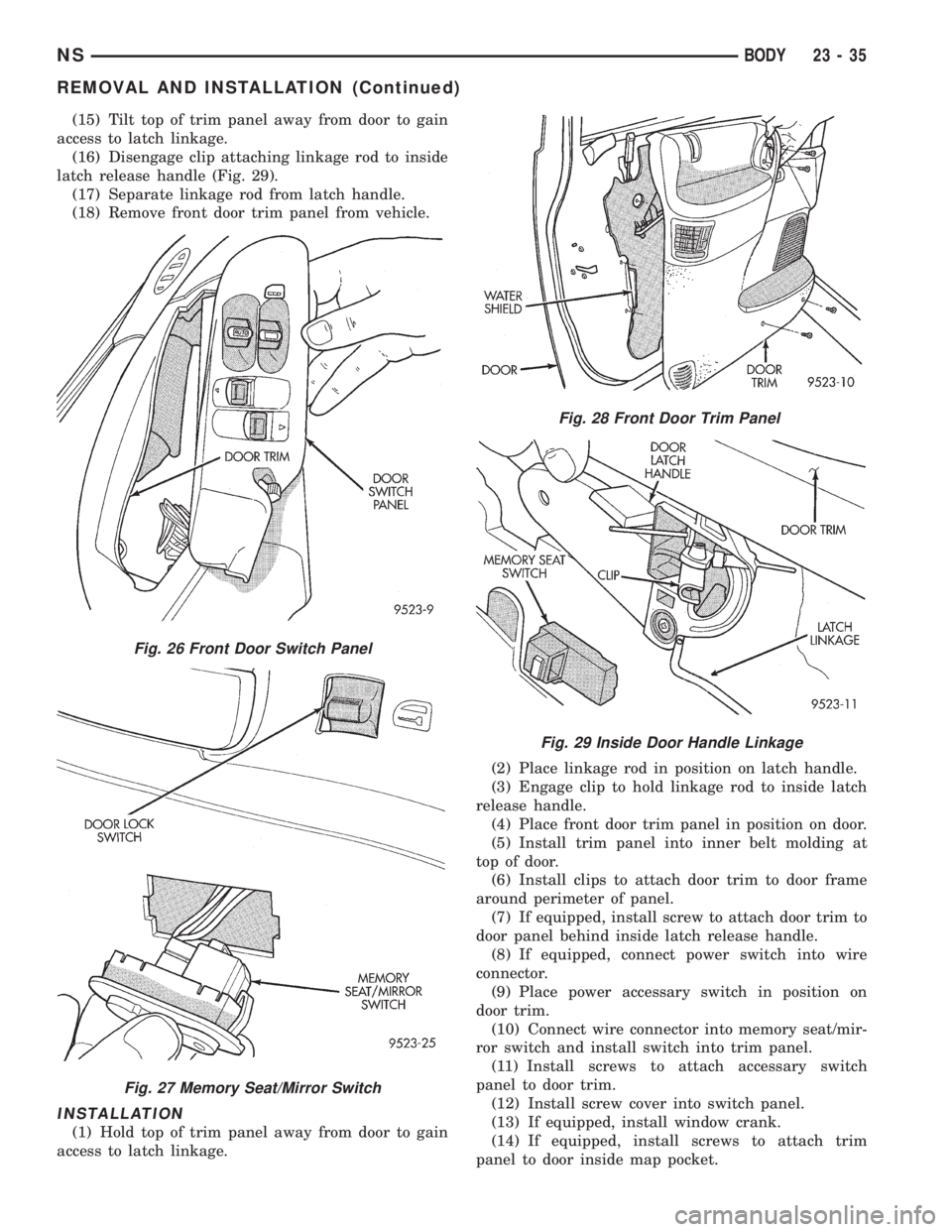

(5) Position glass to gain access to front and rear

regulator lift plates through front and rear access

holes in door panel.

(6) Remove clips holding door glass to regulator

lift plates (Fig. 14).

(7) Remove glass from regulator lift plates.

(8) Disengage glass from glass run weather-strip.

(9) Insert front of glass between glass run channel

and outer door panel.

(10) Lift glass upward and out of exterior side of

the opening at top of door (Fig. 15).

(11) Remove glass from vehicle.

INSTALLATION

(1) Install clips that hold door glass to regulator

lift plates (Fig. 14).

(2) Place glass in window opening with front

inserted between run channel and outer door panel

(Fig. 15).

Fig. 12 Front Door Check Strap

Fig. 13 Front Door Frame Closeout Moldings

Fig. 14 Front Door Glass Clips

NSBODY 23 - 29

REMOVAL AND INSTALLATION (Continued)

Page 1764 of 1938

INSTALLATION

If outside door handle replacement is necessary,

transfer lock cylinder from the original handle to the

new one.

(1) Place outside door handle in position on vehi-

cle.

(2) Install nuts to hold outside door handle to door

outer panel (Fig. 23).

(3) Insert lock linkage into door latch.

(4) Engage clip to hold door lock linkage to latch.

(5) Insert latch linkage into door latch.

(6) Engage clip to hold door latch linkage to latch.

(7) Install push-in fasteners to hold VTSS switch

harness to inner door reinforcement bar, if equipped.

(8) Connect VTSS switch connector into door har-

ness, if equipped.

(9) Verify door latch operation.

(10) Install water shield and door trim panel.

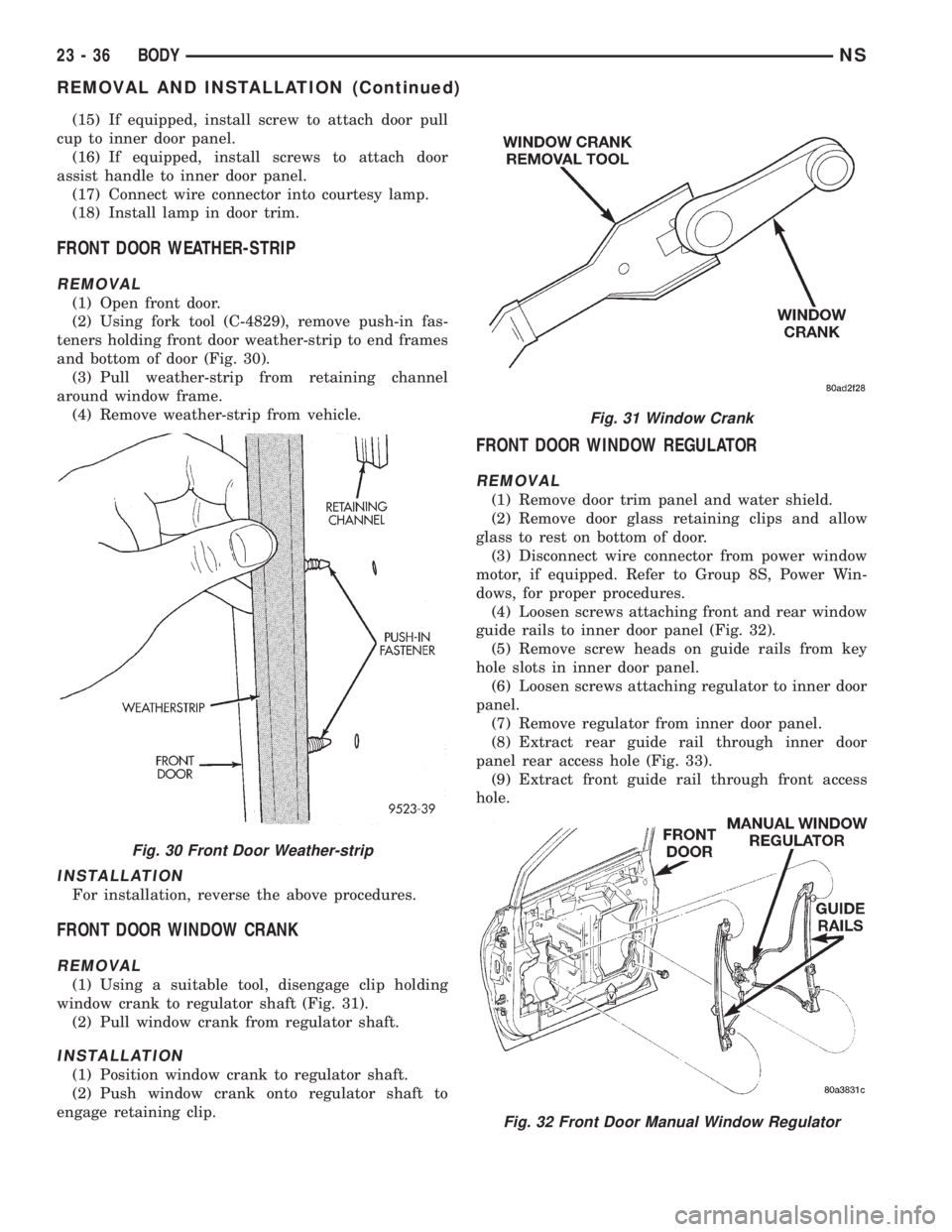

FRONT DOOR REFLECTOR

REMOVAL

(1) Insert small, flat bladed pry tool between outer

edge of door reflector and HVAC outlet vent.

(2) Pry outward on outer edge of reflector.

(3) Remove reflector from vehicle (Fig. 24).

INSTALLATION

(1) Position reflector on vehicle.

(2) Insert inner edge of reflector into slot in HVAC

outlet vent.

(3) Snap outer edge of reflector into slot in HVAC

outlet vent.

FRONT DOOR SILL PLATE

REMOVAL

(1) Using trim stick (C-4755), disengage hidden

clips holding door sill plate from door sill.

(2) Remove sill plate from vehicle (Fig. 25).

INSTALLATION

(1) Place sill plate in position on vehicle.

(2) Align locating pins on backside of trim plate to

mating holes in door sill.

(3) Engage hidden clips to hold door sill plate to

door sill.

FRONT DOOR TRIM PANEL

REMOVAL

(1) Using a trim stick (C-4755), pry courtesy lamp

from door trim.

(2) Disconnect wire connector from courtesy lamp.

(3) If equipped, remove screws attaching door

assist handle to inner door panel.

(4) If equipped, remove screw attaching door pull

cup to inner door panel.

(5) If equipped, remove screws attaching trim

panel to door from below map pocket.

(6) If equipped, remove window crank.

(7) Using a trim stick, remove screw cover from

switch panel.

(8) Remove screws attaching switch panel to door

trim.

(9) Remove power accessary switch from door trim

(Fig. 26).

(10) Disconnect power switch from wire connector.

(11) If equipped, using a small, flat bladed pry

tool, remove memory seat/mirror switch and discon-

nect wire connector (Fig. 27).

(12) If equipped, remove screw holding door trim

to door panel from behind inside latch release han-

dle.

(13) Disengage clips attaching door trim to door

frame around perimeter of panel (Fig. 28).

(14) Lift trim panel upward to disengage flange

from inner belt molding at top of door.

Fig. 24 Front Door Reflector

Fig. 25 Door Sill Plate

23 - 34 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1765 of 1938

(15) Tilt top of trim panel away from door to gain

access to latch linkage.

(16) Disengage clip attaching linkage rod to inside

latch release handle (Fig. 29).

(17) Separate linkage rod from latch handle.

(18) Remove front door trim panel from vehicle.

INSTALLATION

(1) Hold top of trim panel away from door to gain

access to latch linkage.(2) Place linkage rod in position on latch handle.

(3) Engage clip to hold linkage rod to inside latch

release handle.

(4) Place front door trim panel in position on door.

(5) Install trim panel into inner belt molding at

top of door.

(6) Install clips to attach door trim to door frame

around perimeter of panel.

(7) If equipped, install screw to attach door trim to

door panel behind inside latch release handle.

(8) If equipped, connect power switch into wire

connector.

(9) Place power accessary switch in position on

door trim.

(10) Connect wire connector into memory seat/mir-

ror switch and install switch into trim panel.

(11) Install screws to attach accessary switch

panel to door trim.

(12) Install screw cover into switch panel.

(13) If equipped, install window crank.

(14) If equipped, install screws to attach trim

panel to door inside map pocket.

Fig. 26 Front Door Switch Panel

Fig. 27 Memory Seat/Mirror Switch

Fig. 28 Front Door Trim Panel

Fig. 29 Inside Door Handle Linkage

NSBODY 23 - 35

REMOVAL AND INSTALLATION (Continued)

Page 1766 of 1938

(15) If equipped, install screw to attach door pull

cup to inner door panel.

(16) If equipped, install screws to attach door

assist handle to inner door panel.

(17) Connect wire connector into courtesy lamp.

(18) Install lamp in door trim.

FRONT DOOR WEATHER-STRIP

REMOVAL

(1) Open front door.

(2) Using fork tool (C-4829), remove push-in fas-

teners holding front door weather-strip to end frames

and bottom of door (Fig. 30).

(3) Pull weather-strip from retaining channel

around window frame.

(4) Remove weather-strip from vehicle.

INSTALLATION

For installation, reverse the above procedures.

FRONT DOOR WINDOW CRANK

REMOVAL

(1) Using a suitable tool, disengage clip holding

window crank to regulator shaft (Fig. 31).

(2) Pull window crank from regulator shaft.

INSTALLATION

(1) Position window crank to regulator shaft.

(2) Push window crank onto regulator shaft to

engage retaining clip.

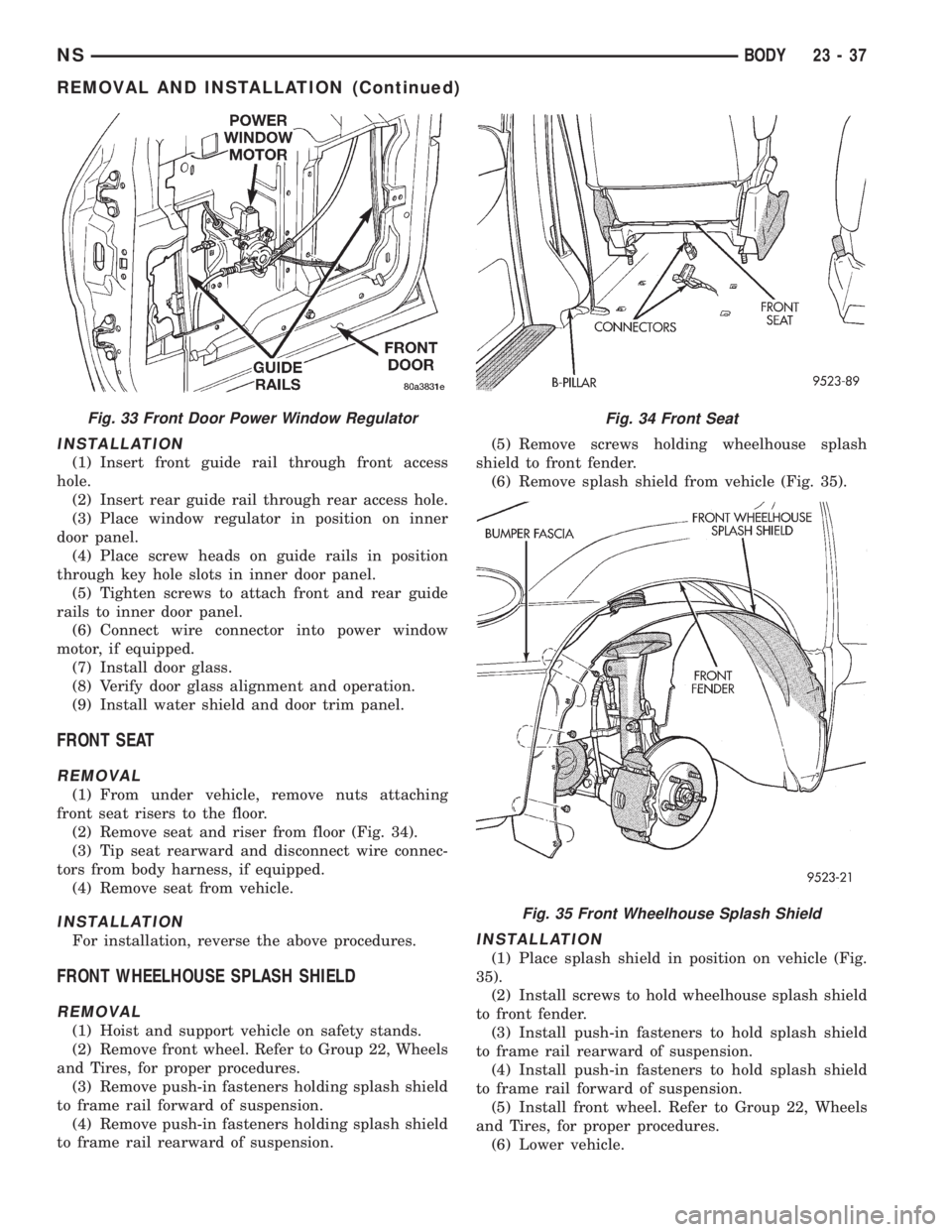

FRONT DOOR WINDOW REGULATOR

REMOVAL

(1) Remove door trim panel and water shield.

(2) Remove door glass retaining clips and allow

glass to rest on bottom of door.

(3) Disconnect wire connector from power window

motor, if equipped. Refer to Group 8S, Power Win-

dows, for proper procedures.

(4) Loosen screws attaching front and rear window

guide rails to inner door panel (Fig. 32).

(5) Remove screw heads on guide rails from key

hole slots in inner door panel.

(6) Loosen screws attaching regulator to inner door

panel.

(7) Remove regulator from inner door panel.

(8) Extract rear guide rail through inner door

panel rear access hole (Fig. 33).

(9) Extract front guide rail through front access

hole.

Fig. 30 Front Door Weather-strip

Fig. 31 Window Crank

Fig. 32 Front Door Manual Window Regulator

23 - 36 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1767 of 1938

INSTALLATION

(1) Insert front guide rail through front access

hole.

(2) Insert rear guide rail through rear access hole.

(3) Place window regulator in position on inner

door panel.

(4) Place screw heads on guide rails in position

through key hole slots in inner door panel.

(5) Tighten screws to attach front and rear guide

rails to inner door panel.

(6) Connect wire connector into power window

motor, if equipped.

(7) Install door glass.

(8) Verify door glass alignment and operation.

(9) Install water shield and door trim panel.

FRONT SEAT

REMOVAL

(1) From under vehicle, remove nuts attaching

front seat risers to the floor.

(2) Remove seat and riser from floor (Fig. 34).

(3) Tip seat rearward and disconnect wire connec-

tors from body harness, if equipped.

(4) Remove seat from vehicle.

INSTALLATION

For installation, reverse the above procedures.

FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove front wheel. Refer to Group 22, Wheels

and Tires, for proper procedures.

(3) Remove push-in fasteners holding splash shield

to frame rail forward of suspension.

(4) Remove push-in fasteners holding splash shield

to frame rail rearward of suspension.(5) Remove screws holding wheelhouse splash

shield to front fender.

(6) Remove splash shield from vehicle (Fig. 35).

INSTALLATION

(1) Place splash shield in position on vehicle (Fig.

35).

(2) Install screws to hold wheelhouse splash shield

to front fender.

(3) Install push-in fasteners to hold splash shield

to frame rail rearward of suspension.

(4) Install push-in fasteners to hold splash shield

to frame rail forward of suspension.

(5) Install front wheel. Refer to Group 22, Wheels

and Tires, for proper procedures.

(6) Lower vehicle.

Fig. 33 Front Door Power Window RegulatorFig. 34 Front Seat

Fig. 35 Front Wheelhouse Splash Shield

NSBODY 23 - 37

REMOVAL AND INSTALLATION (Continued)

Page 1776 of 1938

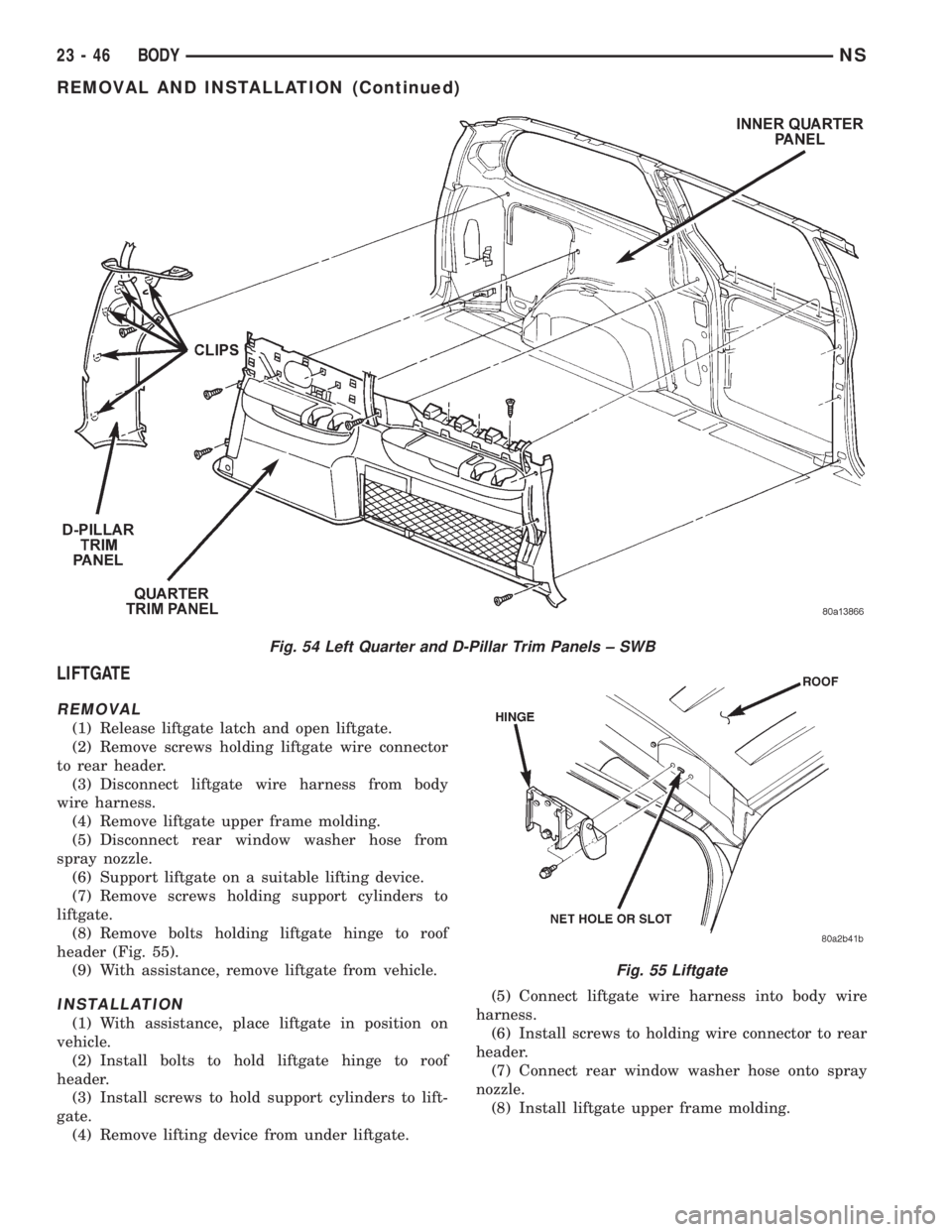

LIFTGATE

REMOVAL

(1) Release liftgate latch and open liftgate.

(2) Remove screws holding liftgate wire connector

to rear header.

(3) Disconnect liftgate wire harness from body

wire harness.

(4) Remove liftgate upper frame molding.

(5) Disconnect rear window washer hose from

spray nozzle.

(6) Support liftgate on a suitable lifting device.

(7) Remove screws holding support cylinders to

liftgate.

(8) Remove bolts holding liftgate hinge to roof

header (Fig. 55).

(9) With assistance, remove liftgate from vehicle.

INSTALLATION

(1) With assistance, place liftgate in position on

vehicle.

(2) Install bolts to hold liftgate hinge to roof

header.

(3) Install screws to hold support cylinders to lift-

gate.

(4) Remove lifting device from under liftgate.(5) Connect liftgate wire harness into body wire

harness.

(6) Install screws to holding wire connector to rear

header.

(7) Connect rear window washer hose onto spray

nozzle.

(8) Install liftgate upper frame molding.

Fig. 54 Left Quarter and D-Pillar Trim Panels ± SWB

Fig. 55 Liftgate

23 - 46 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1782 of 1938

INSTALLATION

(1) Place crossbar in position on roof.

(2) Engage crossbar into notch in front riser.

(3) Slide crossbar rearward into desired position.

(4) Install luggage rack front riser covers.

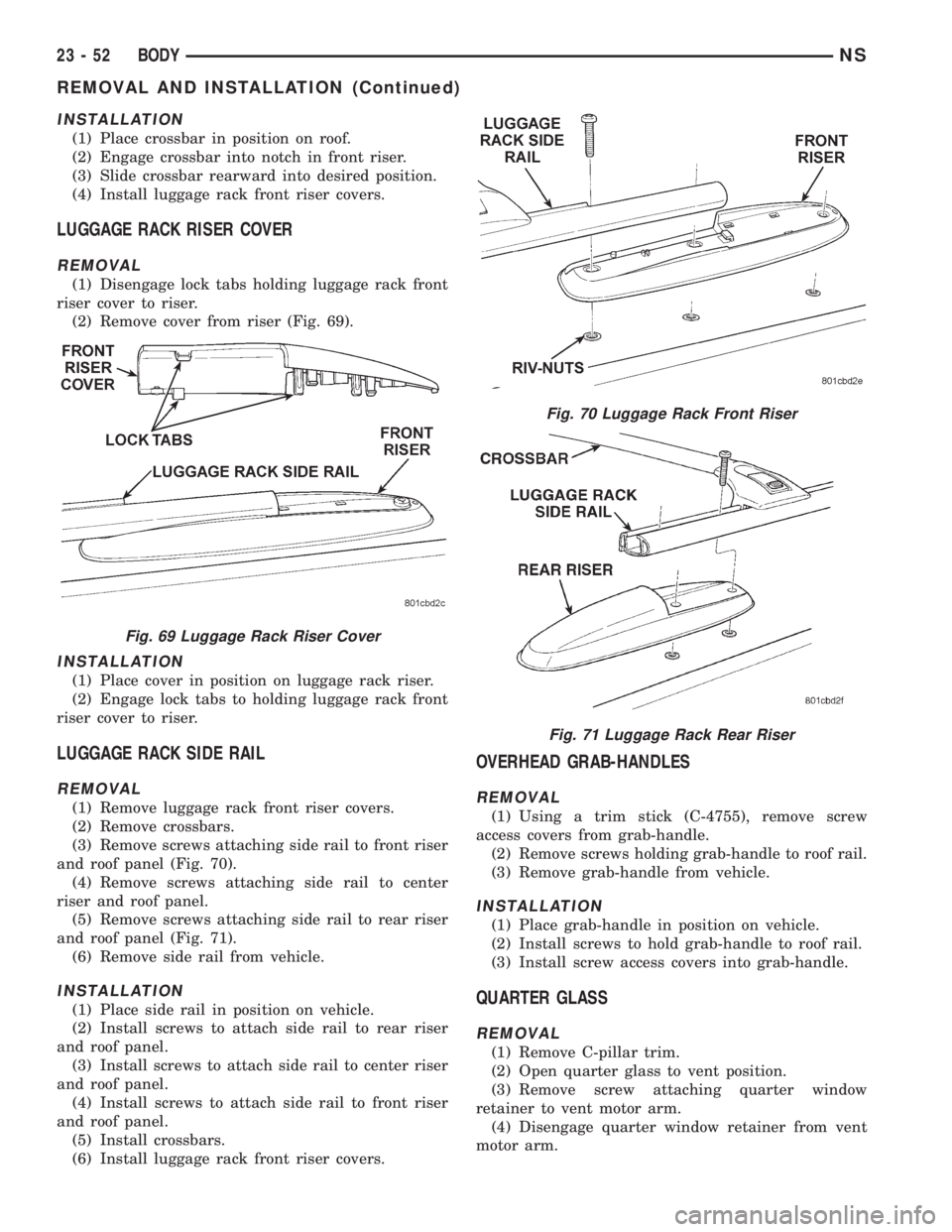

LUGGAGE RACK RISER COVER

REMOVAL

(1) Disengage lock tabs holding luggage rack front

riser cover to riser.

(2) Remove cover from riser (Fig. 69).

INSTALLATION

(1) Place cover in position on luggage rack riser.

(2) Engage lock tabs to holding luggage rack front

riser cover to riser.

LUGGAGE RACK SIDE RAIL

REMOVAL

(1) Remove luggage rack front riser covers.

(2) Remove crossbars.

(3) Remove screws attaching side rail to front riser

and roof panel (Fig. 70).

(4) Remove screws attaching side rail to center

riser and roof panel.

(5) Remove screws attaching side rail to rear riser

and roof panel (Fig. 71).

(6) Remove side rail from vehicle.

INSTALLATION

(1) Place side rail in position on vehicle.

(2) Install screws to attach side rail to rear riser

and roof panel.

(3) Install screws to attach side rail to center riser

and roof panel.

(4) Install screws to attach side rail to front riser

and roof panel.

(5) Install crossbars.

(6) Install luggage rack front riser covers.

OVERHEAD GRAB-HANDLES

REMOVAL

(1) Using a trim stick (C-4755), remove screw

access covers from grab-handle.

(2) Remove screws holding grab-handle to roof rail.

(3) Remove grab-handle from vehicle.

INSTALLATION

(1) Place grab-handle in position on vehicle.

(2) Install screws to hold grab-handle to roof rail.

(3) Install screw access covers into grab-handle.

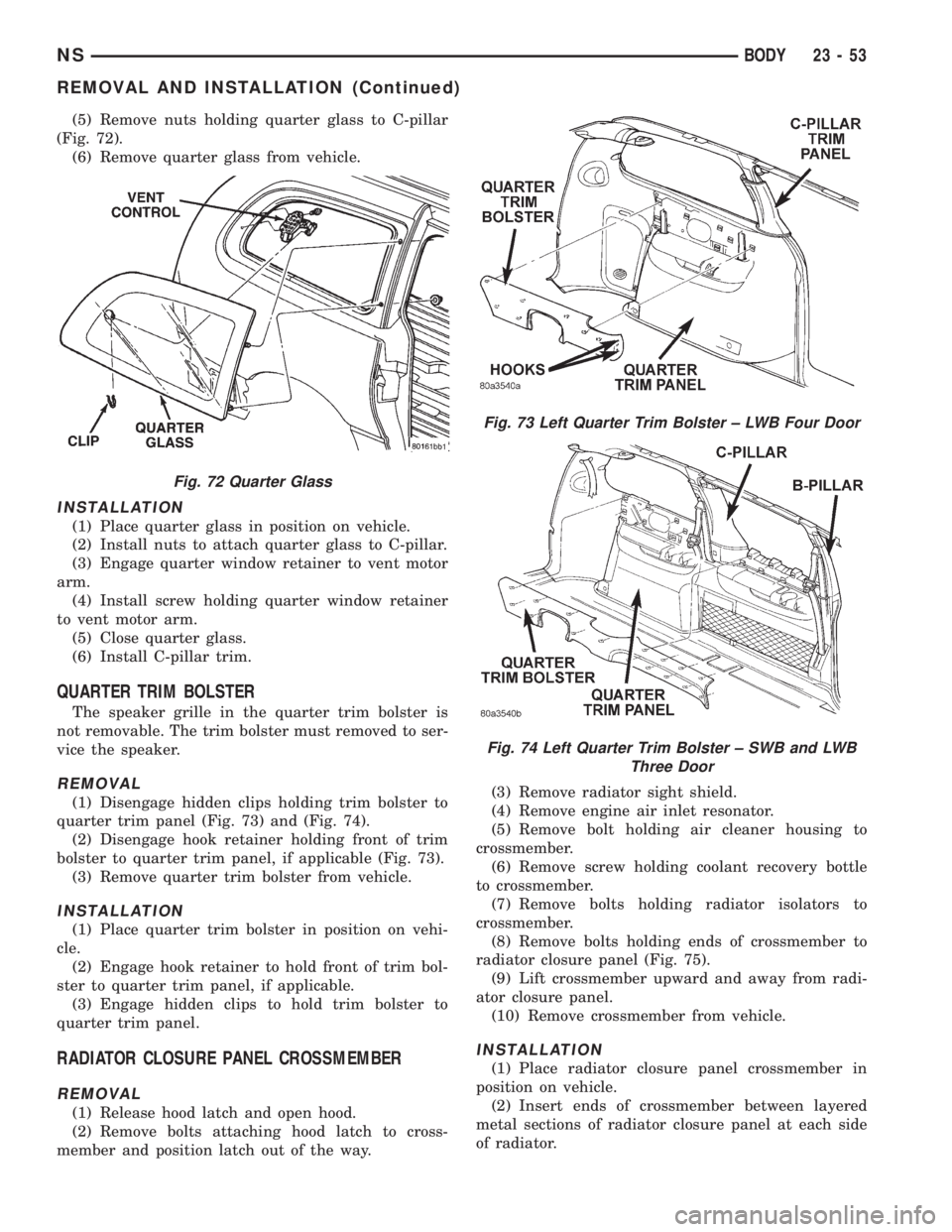

QUARTER GLASS

REMOVAL

(1) Remove C-pillar trim.

(2) Open quarter glass to vent position.

(3) Remove screw attaching quarter window

retainer to vent motor arm.

(4) Disengage quarter window retainer from vent

motor arm.

Fig. 69 Luggage Rack Riser Cover

Fig. 70 Luggage Rack Front Riser

Fig. 71 Luggage Rack Rear Riser

23 - 52 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1783 of 1938

(5) Remove nuts holding quarter glass to C-pillar

(Fig. 72).

(6) Remove quarter glass from vehicle.

INSTALLATION

(1) Place quarter glass in position on vehicle.

(2) Install nuts to attach quarter glass to C-pillar.

(3) Engage quarter window retainer to vent motor

arm.

(4) Install screw holding quarter window retainer

to vent motor arm.

(5) Close quarter glass.

(6) Install C-pillar trim.

QUARTER TRIM BOLSTER

The speaker grille in the quarter trim bolster is

not removable. The trim bolster must removed to ser-

vice the speaker.

REMOVAL

(1) Disengage hidden clips holding trim bolster to

quarter trim panel (Fig. 73) and (Fig. 74).

(2) Disengage hook retainer holding front of trim

bolster to quarter trim panel, if applicable (Fig. 73).

(3) Remove quarter trim bolster from vehicle.

INSTALLATION

(1) Place quarter trim bolster in position on vehi-

cle.

(2) Engage hook retainer to hold front of trim bol-

ster to quarter trim panel, if applicable.

(3) Engage hidden clips to hold trim bolster to

quarter trim panel.

RADIATOR CLOSURE PANEL CROSSMEMBER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to cross-

member and position latch out of the way.(3) Remove radiator sight shield.

(4) Remove engine air inlet resonator.

(5) Remove bolt holding air cleaner housing to

crossmember.

(6) Remove screw holding coolant recovery bottle

to crossmember.

(7) Remove bolts holding radiator isolators to

crossmember.

(8) Remove bolts holding ends of crossmember to

radiator closure panel (Fig. 75).

(9) Lift crossmember upward and away from radi-

ator closure panel.

(10) Remove crossmember from vehicle.

INSTALLATION

(1) Place radiator closure panel crossmember in

position on vehicle.

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

Fig. 72 Quarter Glass

Fig. 73 Left Quarter Trim Bolster ± LWB Four Door

Fig. 74 Left Quarter Trim Bolster ± SWB and LWB

Three Door

NSBODY 23 - 53

REMOVAL AND INSTALLATION (Continued)

Page 1817 of 1938

HEATING AND AIR CONDITIONING

CONTENTS

page page

FRONT HEATING AND AIR CONDITIONING

SYSTEM............................... 1REAR HEATING AND AIR CONDITIONING

SYSTEM.............................. 41

FRONT HEATING AND AIR CONDITIONING SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 2

SAFETY PRECAUTIONS AND WARNINGS...... 2

DESCRIPTION AND OPERATION

A/C PRESSURE TRANSDUCER.............. 2

A/C SERVICE PORTS..................... 2

AIR DISTRIBUTION DUCTS................. 2

COMPRESSOR HIGH-PRESSURE RELIEF

VALVE................................ 3

CONDENSATE DRAIN..................... 3

ENGINE COOLING SYSTEM REQUIREMENTS . . 3

EVAPORATOR PROBE..................... 3

HANDLING TUBING AND FITTINGS........... 3

HVAC CONTROL MODULE................. 4

REAR BLOWER SPEED SWITCH............ 3

SIDE DOOR HEATER A/C OUTLETS.......... 4

SIDE WINDOW DEMISTER................. 4

SYSTEM AIRFLOW....................... 4

SYSTEM OIL LEVEL...................... 5

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST................ 12

A/C PRESSURE TRANSDUCER............. 12

ACTUATOR CALIBRATION/DIAGNOSTICS AND

COOLDOWN TEST...................... 6

BLOWER MOTOR AND WHEEL ASSEMBLY.... 13

COMPRESSOR CLUTCH/COIL.............. 13

COMPRESSOR NOISE DIAGNOSIS.......... 13

EXPANSION VALVE...................... 13

HEATER PERFORMANCE TEST............ 15

HVAC CONTROL DIAGNOSTIC CONDITIONS . . . 9

SYSTEM CHARGE LEVEL TEST............ 16SERVICE PROCEDURES

CHARGING REFRIGERANT SYSTEM........ 17

EVACUATING REFRIGERANT SYSTEM....... 18

R-134a REFRIGERANT................... 16

STICKING HVAC CONTROL MODULE PUSH

BUTTONS............................ 19

SYSTEM LEAK CHECKING................ 19

THERMOCOUPLE PROBE................. 19

REMOVAL AND INSTALLATION

A/C PRESSURE TRANSDUCER............. 20

A/C SERVICE PORTS.................... 20

BLEND-AIR DOOR ACTUATOR............. 20

BLOWER MOTOR AND WHEEL ASSEMBLY.... 21

BLOWER MOTOR RESISTOR BLOCK........ 21

BLOWER MOTOR WHEEL................. 22

COMPRESSOR CLUTCH/COIL.............. 23

COMPRESSOR......................... 23

CONDENSER ASSEMBLY................. 25

DISCHARGE LINE....................... 26

EVAPORATOR PROBE.................... 27

EXPANSION VALVE...................... 28

FILTER-DRIER ASSEMBLY................. 28

HEATER A/C UNIT HOUSING............... 29

HEATER CORE......................... 30

HEATER HOSES........................ 31

LIQUID LINE........................... 32

MODE DOOR ACTUATOR................. 32

RECIRC DOOR ACTUATOR................ 34

SIDE WINDOW DEMISTER DUCTS.......... 33

SUCTION LINE.......................... 33

DISASSEMBLY AND ASSEMBLY

HEATER A/C UNIT RECONDITION........... 34

NSHEATING AND AIR CONDITIONING 24 - 1

Page 1818 of 1938

GENERAL INFORMATION

INTRODUCTION

Both the heater and the heater/air conditioning

systems share many of the same components. This

group will deal with both systems together when

component function is common, and separately when

they are not.

For proper operation of the instrument panel con-

trols, refer to the Owner's Manual provided with the

vehicle.

All vehicles are equipped with a common A/C-

heater unit housing assembly. When the vehicle has

only a heater system, the evaporator and recirculat-

ing air door are omitted.

An optional zone control HVAC unit is available.

This unit has dual blend-air doors that can be regu-

lated independently of each other. The temperature

setting can be different from driver's side to passen-

ger side. There is also a rear (aux.) heating and A/C

system available when the vehicle is equipped with

zone control.

SAFETY PRECAUTIONS AND WARNINGS

WARNING: WEAR EYE PROTECTION WHEN SER-

VICING THE AIR CONDITIONING REFRIGERANT

SYSTEM. SERIOUS EYE INJURY CAN RESULT

FROM EYE CONTACT WITH REFRIGERANT. IF EYE

CONTACT IS MADE, SEEK MEDICAL ATTENTION

IMMEDIATELY.

DO NOT EXPOSE REFRIGERANT TO OPEN

FLAME. POISONOUS GAS IS CREATED WHEN

REFRIGERANT IS BURNED. AN ELECTRONIC TYPE

LEAK DETECTOR IS RECOMMENDED.

LARGE AMOUNTS OF REFRIGERANT RELEASED

IN A CLOSED WORK AREA WILL DISPLACE THE

OXYGEN AND CAUSE SUFFOCATION.

THE EVAPORATION RATE OF REFRIGERANT AT

AVERAGE TEMPERATURE AND ALTITUDE IS

EXTREMELY HIGH. AS A RESULT, ANYTHING THAT

COMES IN CONTACT WITH THE REFRIGERANT

WILL FREEZE. ALWAYS PROTECT SKIN OR DELI-

CATE OBJECTS FROM DIRECT CONTACT WITH

REFRIGERANT. R-134a SERVICE EQUIPMENT OR

VEHICLE A/C SYSTEM SHOULD NOT BE PRES-

SURE TESTED OR LEAK TESTED WITH COM-

PRESSED AIR.

SOME MIXTURES OF AIR and R-134a HAVE BEEN

SHOWN TO BE COMBUSTIBLE AT ELEVATED

PRESSURES. THESE MIXTURES ARE POTENTIALLY

DANGEROUS AND MAY RESULT IN FIRE OR

EXPLOSION CAUSING INJURY OR PROPERTY

DAMAGE.

ANTIFREEZE IS AN ETHYLENE GLYCOL BASE

COOLANT AND IS HARMFUL IF SWALLOWED ORINHALED. SEEK MEDICAL ATTENTION IMMEDI-

ATELY IF SWALLOWED OR INHALED. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN AND PETS.

DO NOT OPEN A COOLING SYSTEM WHEN THE

ENGINE IS AT RUNNING TEMPERATURE. PER-

SONAL INJURY CAN RESULT.

CAUTION: The engine cooling system is designed

to develop internal pressure of 97 to 123 kPa (14 to

18 psi). Allow the vehicle to cool a minimum of 15

minutes before opening the cooling system. Refer

to Group 7, Cooling System.

DESCRIPTION AND OPERATION

AIR DISTRIBUTION DUCTS

The air distribution ducts for the A/C, Heater,

Defroster, and Second Seating Air Distribution are

not serviceable in vehicle. The procedures for service

of these ducts are covered in Group 8E, Instrument

Panel and Gauges.

The only ducts that are serviceable in the vehicle

are the side window demister ducts and the ducts

that feed the front door outlets for the first rear pas-

senger(s) seating. To service the door ducts refer to

Group 23, Body.

A/C PRESSURE TRANSDUCER

The A/C Pressure Transducer (Fig. 1) monitors the

refrigerant gas pressure on the high side of the sys-

tem. The transducer is located on the liquid line. The

pressure transducer turns off the voltage to the com-

pressor clutch coil when refrigerant gas pressure

drops to levels that could damage the compressor.

The transducer also is used to adjust condenser fan

speeds and will turn off compressor at high refriger-

ant pressures. The pressure transducer is a sealed

factory calibrated unit. It must be replaced if defec-

tive. O-ring replacement is required whenever the

pressure transducer is serviced. Be sure to use the

O-ring specified for the transducer.

A/C SERVICE PORTS

The A/C service port valve cores are located within

the A/C lines (Fig. 2). The High Side (Discharge)

valve service port is located on the liquid line near

the right frame rail. The Low Side (Suction) valve

service port is located on the suction line near the

compressor.

24 - 2 HEATING AND AIR CONDITIONINGNS