window CHRYSLER VOYAGER 1996 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 969 of 1938

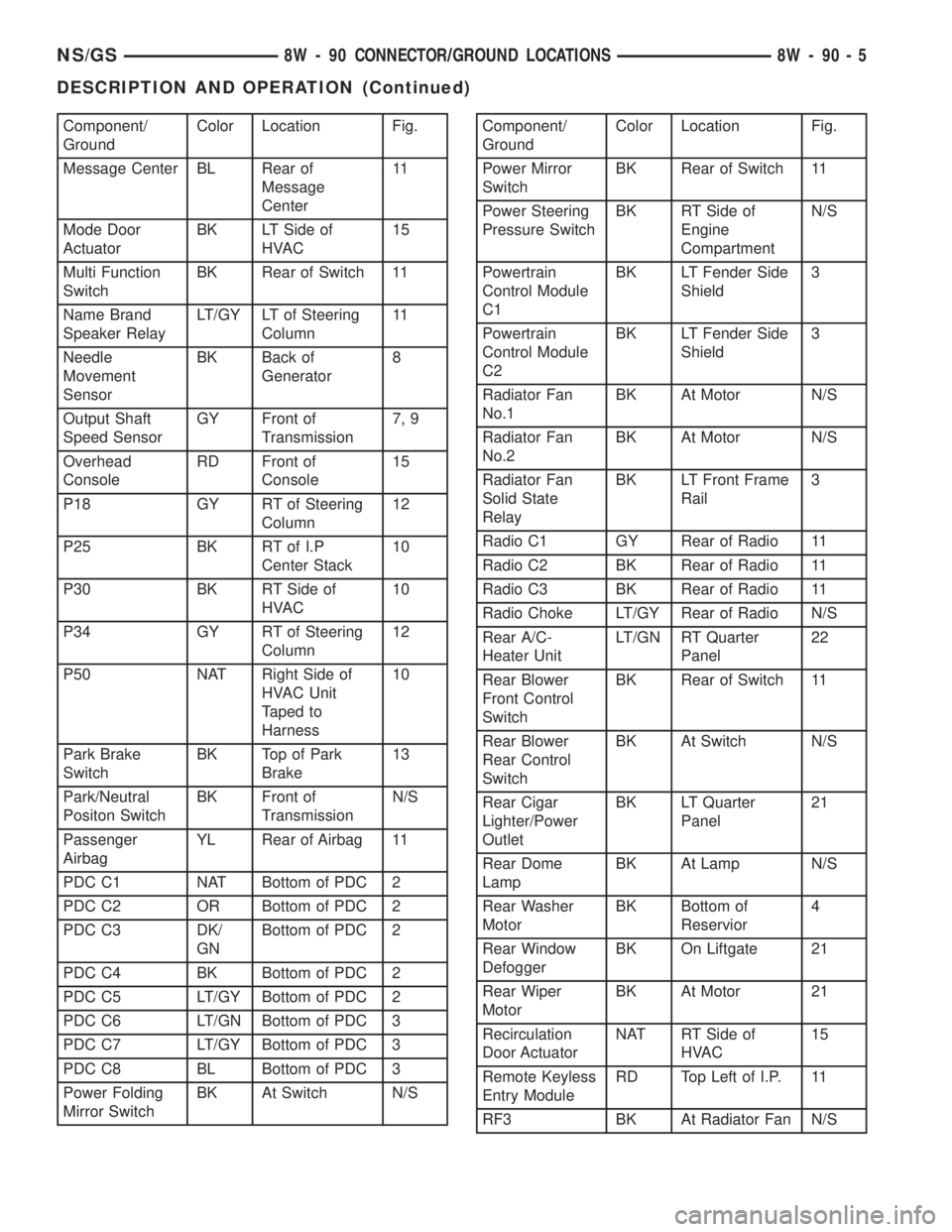

Component/

GroundColor Location Fig.

Message Center BL Rear of

Message

Center11

Mode Door

ActuatorBK LT Side of

HVAC15

Multi Function

SwitchBK Rear of Switch 11

Name Brand

Speaker RelayLT/GY LT of Steering

Column11

Needle

Movement

SensorBK Back of

Generator8

Output Shaft

Speed SensorGY Front of

Transmission7, 9

Overhead

ConsoleRD Front of

Console15

P18 GY RT of Steering

Column12

P25 BK RT of I.P

Center Stack10

P30 BK RT Side of

HVAC10

P34 GY RT of Steering

Column12

P50 NAT Right Side of

HVAC Unit

Taped to

Harness10

Park Brake

SwitchBK Top of Park

Brake13

Park/Neutral

Positon SwitchBK Front of

TransmissionN/S

Passenger

AirbagYL Rear of Airbag 11

PDC C1 NAT Bottom of PDC 2

PDC C2 OR Bottom of PDC 2

PDC C3 DK/

GNBottom of PDC 2

PDC C4 BK Bottom of PDC 2

PDC C5 LT/GY Bottom of PDC 2

PDC C6 LT/GN Bottom of PDC 3

PDC C7 LT/GY Bottom of PDC 3

PDC C8 BL Bottom of PDC 3

Power Folding

Mirror SwitchBK At Switch N/SComponent/

GroundColor Location Fig.

Power Mirror

SwitchBK Rear of Switch 11

Power Steering

Pressure SwitchBK RT Side of

Engine

CompartmentN/S

Powertrain

Control Module

C1BK LT Fender Side

Shield3

Powertrain

Control Module

C2BK LT Fender Side

Shield3

Radiator Fan

No.1BK At Motor N/S

Radiator Fan

No.2BK At Motor N/S

Radiator Fan

Solid State

RelayBK LT Front Frame

Rail3

Radio C1 GY Rear of Radio 11

Radio C2 BK Rear of Radio 11

Radio C3 BK Rear of Radio 11

Radio Choke LT/GY Rear of Radio N/S

Rear A/C-

Heater UnitLT/GN RT Quarter

Panel22

Rear Blower

Front Control

SwitchBK Rear of Switch 11

Rear Blower

Rear Control

SwitchBK At Switch N/S

Rear Cigar

Lighter/Power

OutletBK LT Quarter

Panel21

Rear Dome

LampBK At Lamp N/S

Rear Washer

MotorBK Bottom of

Reservior4

Rear Window

DefoggerBK On Liftgate 21

Rear Wiper

MotorBK At Motor 21

Recirculation

Door ActuatorNAT RT Side of

HVAC15

Remote Keyless

Entry ModuleRD Top Left of I.P. 11

RF3 BK At Radiator Fan N/S

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 5

DESCRIPTION AND OPERATION (Continued)

Page 970 of 1938

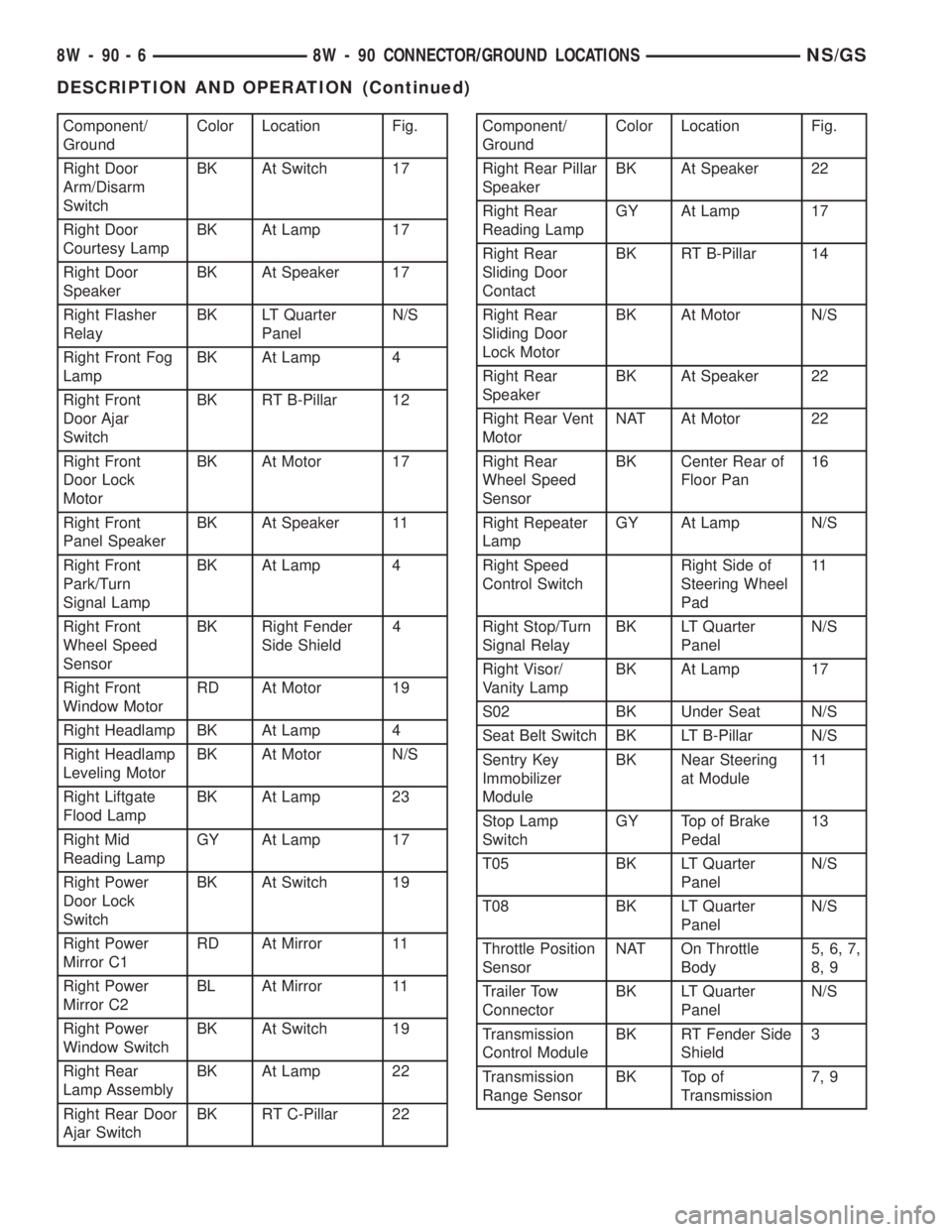

Component/

GroundColor Location Fig.

Right Door

Arm/Disarm

SwitchBK At Switch 17

Right Door

Courtesy LampBK At Lamp 17

Right Door

SpeakerBK At Speaker 17

Right Flasher

RelayBK LT Quarter

PanelN/S

Right Front Fog

LampBK At Lamp 4

Right Front

Door Ajar

SwitchBK RT B-Pillar 12

Right Front

Door Lock

MotorBK At Motor 17

Right Front

Panel SpeakerBK At Speaker 11

Right Front

Park/Turn

Signal LampBK At Lamp 4

Right Front

Wheel Speed

SensorBK Right Fender

Side Shield4

Right Front

Window MotorRD At Motor 19

Right Headlamp BK At Lamp 4

Right Headlamp

Leveling MotorBK At Motor N/S

Right Liftgate

Flood LampBK At Lamp 23

Right Mid

Reading LampGY At Lamp 17

Right Power

Door Lock

SwitchBK At Switch 19

Right Power

Mirror C1RD At Mirror 11

Right Power

Mirror C2BL At Mirror 11

Right Power

Window SwitchBK At Switch 19

Right Rear

Lamp AssemblyBK At Lamp 22

Right Rear Door

Ajar SwitchBK RT C-Pillar 22Component/

GroundColor Location Fig.

Right Rear Pillar

SpeakerBK At Speaker 22

Right Rear

Reading LampGY At Lamp 17

Right Rear

Sliding Door

ContactBK RT B-Pillar 14

Right Rear

Sliding Door

Lock MotorBK At Motor N/S

Right Rear

SpeakerBK At Speaker 22

Right Rear Vent

MotorNAT At Motor 22

Right Rear

Wheel Speed

SensorBK Center Rear of

Floor Pan16

Right Repeater

LampGY At Lamp N/S

Right Speed

Control SwitchRight Side of

Steering Wheel

Pad11

Right Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Right Visor/

Vanity LampBK At Lamp 17

S02 BK Under Seat N/S

Seat Belt Switch BK LT B-Pillar N/S

Sentry Key

Immobilizer

ModuleBK Near Steering

at Module11

Stop Lamp

SwitchGY Top of Brake

Pedal13

T05 BK LT Quarter

PanelN/S

T08 BK LT Quarter

PanelN/S

Throttle Position

SensorNAT On Throttle

Body5, 6, 7,

8, 9

Trailer Tow

ConnectorBK LT Quarter

PanelN/S

Transmission

Control ModuleBK RT Fender Side

Shield3

Transmission

Range SensorBK Top of

Transmission7, 9

8W - 90 - 6 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 997 of 1938

Component/

GroundColor Location Fig.

Headlamp

Switch C1NAT Rear of Switch 11

Headlamp

Switch C2BK Rear of Switch 11

Headlamp

Washer MotorBottom of

ReserviorN/S

High Note Horn BK LT Frame Rail 4

Hood Ajar

SwitchNAT LT Fender 2

Horn Switch Rear of Driver

Airbag11

Idle Air Control

MotorBK On Throttle

Body5, 6, 7,

8, 9

Ignition Coil

Pack 2.4LBK Top of Valve

Cover6, 7

Ignition Coil

Pack 3.3L, 3.8LBK RT Side of

Engine9

Ignition Switch

C1GY Rear of Switch 11

Ignition Switch

C2GN Rear of Switch 11

Ignition Switch

C3BK Rear of Switch 11

Instrument

ClusterRD Rear of Cluster 11

Intake Air Temp

SensorGY On Intake 6, 7

J01D BK RT Side of

HVAC15

J02A BK Top of Liftgate 23

JO3A BK Top of Liftgate 23

Junction Block

C1GY On Junction

Block12, 13

Junction Block

C2GY On Junction

Block12, 13

Junction Block

C3GY On Junction

Block12

Junction Block

C4GY On Junction

Block12

Key-In Halo

LampWT Rear of Lamp 11

Knock Sensor

2.4LGY Front of

Cylinder Block6, 7

Knock Sensor

3.3L, 3.8LGY Front of

Cylinder BlockN/S

L15 BK Top of Liftgate 23Component/

GroundColor Location Fig.

L16 BK Top of Liftgate 23

Left

Combination

RelayBK LT Rear

Quarter PanelN/S

Left Door Ajar

SwitchBK LT B-PIllar 12

Left Door

Arm/Disarm

SwitchBK At Switch 19

Left Door

Courtesy LampBK At Lamp 19

Left Door

SpeakerBK At Speaker 19

Left Fog Lamp GY At Lamp 4

Left Front Door

Lock MotorBK At Motor 19

Left Front Panel

SpeakerBK At Speaker 11

Left Front

Park/Turn

Signal LampBK At Lamp 4

Left Front

Wheel Speed

SensorBK LT Fender Side

Shield2

Left Front

Window MotorRD At Motor 19

Left Headlamp BK At Lamp 2

Left Headlamp

Leveling MotorBK At Motor N/S

Left Liftgate

Flood LampBK At Lamp 23

Left Mid

Reading LampGY At Lamp 17

Left Power Door

Lock SwitchBK At Switch 19

Left Power

Mirror C1RD At Mirror 11

Left Power

Mirror C2BL At Mirror 11

Left Power

Window SwitchOR At Switch 19

Left Rear Lamp

AssemblyBK At Lamp 21

Left Rear Door

Ajar SwitchBK LT C-Pillar 21

Left Rear Pillar

SpeakerBK At Speaker 21

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 33

DESCRIPTION AND OPERATION (Continued)

Page 999 of 1938

Component/

GroundColor Location Fig.

Powertrain

Control Module

C1BK LT Fender Side

Shield3

Powertrain

Control Module

C2BK LT Fender Side

Shield3

Radiator Fan

No.1BK At Motor N/S

Radiator Fan

No.2BK At Motor N/S

Radiator Fan

RelayBK LT Front Frame

Rail3

Radio C1 GY Rear of Radio 11

Radio C2 BK Rear of Radio 11

Radio C3 BK Rear of Radio 11

Radio Choke LT/GY Rear of Radio N/S

Rear A/C-

Heater UnitLT/GN RT Quarter

Panel22

Rear Blower

Front Control

SwitchBK Rear of Switch 11

Rear Blower

Rear Control

SwitchBK At Switch N/S

Rear Cigar

Lighter/Power

OutletBK LT Quarter

Panel21

Rear Dome

LampBK At Lamp N/S

Rear Washer

MotorBK Bottom of

Reservior4

Rear Window

DefoggerBK On Liftgate 23

Rear Wiper

MotorBK At Motor 23

Recirculation

Door ActuatorNAT RT Side of

HVAC15

Remote Keyless

Entry ModuleRD Top RT of I.P. 11

Right

Combination

RelayBK LT Quarter

PanelN/S

Right Door

Arm/Disarm

SwitchBK At Switch 19

Right Door

Courtesy LampBK At Lamp 19Component/

GroundColor Location Fig.

Right Door

SpeakerBK At Speaker 19

RF3 BK At Radiator Fan

ModuleN/S

Right Fog Lamp GY At Lamp 4

Right Front

Door Ajar

SwitchBK RT B-Pillar 12

Right Front

Door Lock

MotorBK At Motor 19

Right Front

Panel SpeakerBK At Speaker 11

Right Front

Park/Turn

Signal LampBK At Lamp 4

Right Front

Wheel Speed

SensorBK Right Fender

Side Shield4

Right Front

Window MotorRD At Motor 19

Right Headlamp BK At Lamp 4

Right Headlamp

Leveling MotorBK At Motor N/S

Right Liftgate

Flood LampBK At Lamp 23

Right Mid

Reading LampGY At Lamp 17

Right Power

Door Lock

SwitchBK At Switch 19

Right Power

Mirror C1RD At Mirror 11

Right Power

Mirror C2BL At Mirror 11

Right Power

Window SwitchBK At Switch 19

Right Rear

Lamp AssemblyBK At Lamp 22

Right Rear Door

Ajar SwitchBK RT C-Pillar N/S

Right Rear Pillar

SpeakerBK At Speaker 22

Right Rear

Reading LampGY At Lamp 17

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 35

DESCRIPTION AND OPERATION (Continued)

Page 1306 of 1938

(9) Momentarily touch the other end of this

jumper wire to the negative terminal of the battery

for no more than 4 seconds.

(10) Place a rag or towel below the fuel line at the

quick connect to the rail.

(11) Disconnect the quick connect fitting to the

rail. Refer to Quick-Connect Fittings in this section.

(12) Return the fuel pump relay to the PDC.

(13) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in the PCM memory due to the

fuel pump relay removal. The DRB scan tool must be

used to erase a DTC. Refer to group 25, On-Board

Diagnostics.

HOSES AND CLAMPS

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

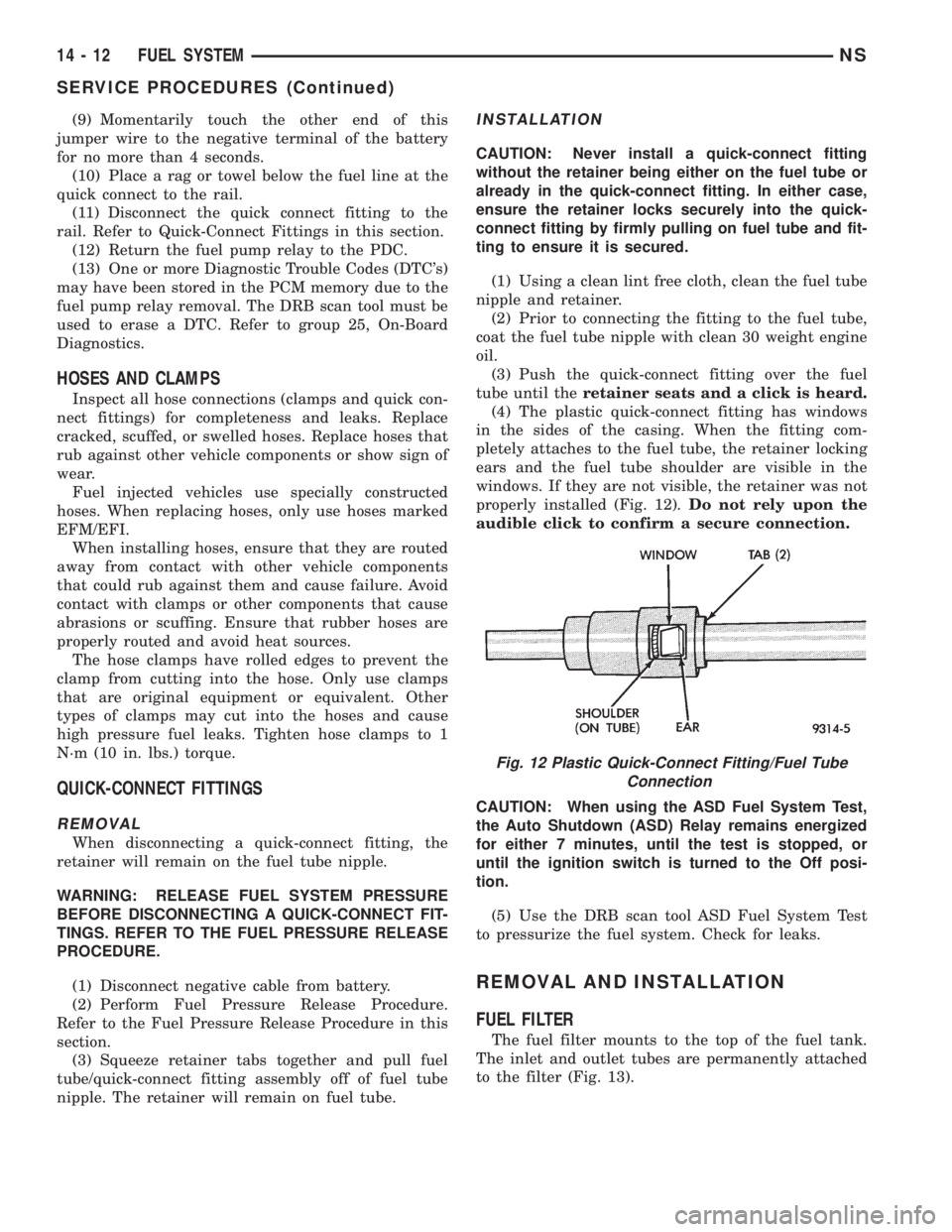

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 12).Do not rely upon the

audible click to confirm a secure connection.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(5) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

REMOVAL AND INSTALLATION

FUEL FILTER

The fuel filter mounts to the top of the fuel tank.

The inlet and outlet tubes are permanently attached

to the filter (Fig. 13).

Fig. 12 Plastic Quick-Connect Fitting/Fuel Tube

Connection

14 - 12 FUEL SYSTEMNS

SERVICE PROCEDURES (Continued)

Page 1734 of 1938

STATIONARY GLASS

INDEX

page page

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS................... 4

REMOVAL AND INSTALLATION

BODY SIDE/SLIDING DOOR STATIONARY

GLASS............................... 6REAR WINDOW.......................... 7

WINDSHIELD............................ 4

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, PVC (VINYL) PRIMER AND

PINCHWELD (FENCE) PRIMER PROVIDED BY THE

ADHESIVE MANUFACTURER. IF NOT, STRUCTURAL

INTEGRITY COULD BE COMPROMISED.

CHRYSLER DOES NOT RECOMMEND GLASS

ADHESIVE BY BRAND. TECHNICIANS SHOULD

REVIEW PRODUCT LABELS AND TECHNICAL DATA

SHEETS, AND USE ONLY ADHESIVES THAT THEIR

MANUFACTURES WARRANT WILL RESTORE A

VEHICLE TO THE REQUIREMENTS OF FMVSS 212.

TECHNICIANS SHOULD ALSO INSURE THAT PRIM-

ERS AND CLEANERS ARE COMPATIBLE WITH THE

PARTICULAR ADHESIVE USED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

It is difficult to salvage a windshield during the

removal operation. The windshield is part of the

structural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficult

to cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

REMOVAL AND INSTALLATION

WINDSHIELD

The urethane adhesive holding the windshield to

the opening pinch weld (fence) can be cut using a

sharp cold knife from the exterior of the vehicle.

Using the cold knife method is effective if the wind-

shield is already broken. If the glass must be sal-

vaged, cutting the urethane adhesive from the

interior of the vehicle using a reciprocating or oscil-

lating power knife is recommended.

WINDSHIELD REMOVAL ± EXTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove windshield wiper arms.

(3) Remove cowl cover.

(4) Remove A-pillar trim panels.

(5) Disconnect wire connectors to windshield

defroster grid.

(6) Place protective covers over instrument panel

and hood.

(7) Remove windshield molding (Fig. 1). Using pli-

ers, pull outward on molding at the bottom of A-pil-

lars.

(8) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 2). A power

cutting device can be used if available.

(9) Remove windshield from vehicle.

23 - 4 BODYNS

Page 1737 of 1938

NOTE: Tighten nuts to 3.4 N´m (30 in. lbs.) torque

in the sequence indicated. Do not over torque, or

glass breakage may result (Fig. 6).

(4) Install interior trim.

REAR WINDOW

Refer to the Safety Precautions in this section for

description of tools and adhesive systems that are

recommended for use in this procedure.

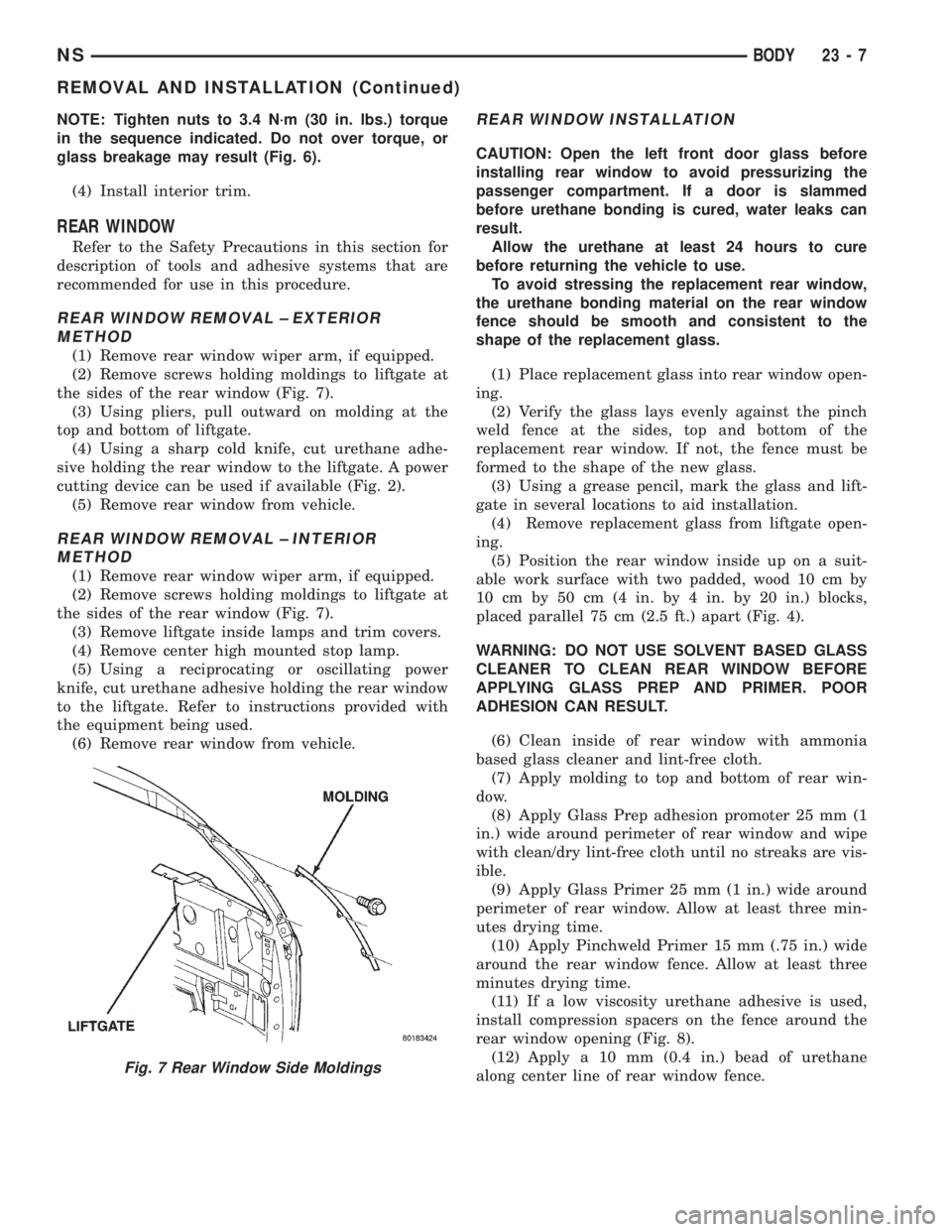

REAR WINDOW REMOVAL ± EXTERIOR

METHOD

(1) Remove rear window wiper arm, if equipped.

(2) Remove screws holding moldings to liftgate at

the sides of the rear window (Fig. 7).

(3) Using pliers, pull outward on molding at the

top and bottom of liftgate.

(4) Using a sharp cold knife, cut urethane adhe-

sive holding the rear window to the liftgate. A power

cutting device can be used if available (Fig. 2).

(5) Remove rear window from vehicle.

REAR WINDOW REMOVAL ± INTERIOR

METHOD

(1) Remove rear window wiper arm, if equipped.

(2) Remove screws holding moldings to liftgate at

the sides of the rear window (Fig. 7).

(3) Remove liftgate inside lamps and trim covers.

(4) Remove center high mounted stop lamp.

(5) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the rear window

to the liftgate. Refer to instructions provided with

the equipment being used.

(6) Remove rear window from vehicle.

REAR WINDOW INSTALLATION

CAUTION: Open the left front door glass before

installing rear window to avoid pressurizing the

passenger compartment. If a door is slammed

before urethane bonding is cured, water leaks can

result.

Allow the urethane at least 24 hours to cure

before returning the vehicle to use.

To avoid stressing the replacement rear window,

the urethane bonding material on the rear window

fence should be smooth and consistent to the

shape of the replacement glass.

(1) Place replacement glass into rear window open-

ing.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement rear window. If not, the fence must be

formed to the shape of the new glass.

(3) Using a grease pencil, mark the glass and lift-

gate in several locations to aid installation.

(4) Remove replacement glass from liftgate open-

ing.

(5) Position the rear window inside up on a suit-

able work surface with two padded, wood 10 cm by

10 cm by 50 cm (4 in. by 4 in. by 20 in.) blocks,

placed parallel 75 cm (2.5 ft.) apart (Fig. 4).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN REAR WINDOW BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(6) Clean inside of rear window with ammonia

based glass cleaner and lint-free cloth.

(7) Apply molding to top and bottom of rear win-

dow.

(8) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of rear window and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(9) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of rear window. Allow at least three min-

utes drying time.

(10) Apply Pinchweld Primer 15 mm (.75 in.) wide

around the rear window fence. Allow at least three

minutes drying time.

(11) If a low viscosity urethane adhesive is used,

install compression spacers on the fence around the

rear window opening (Fig. 8).

(12) Apply a 10 mm (0.4 in.) bead of urethane

along center line of rear window fence.

Fig. 7 Rear Window Side Moldings

NSBODY 23 - 7

REMOVAL AND INSTALLATION (Continued)

Page 1738 of 1938

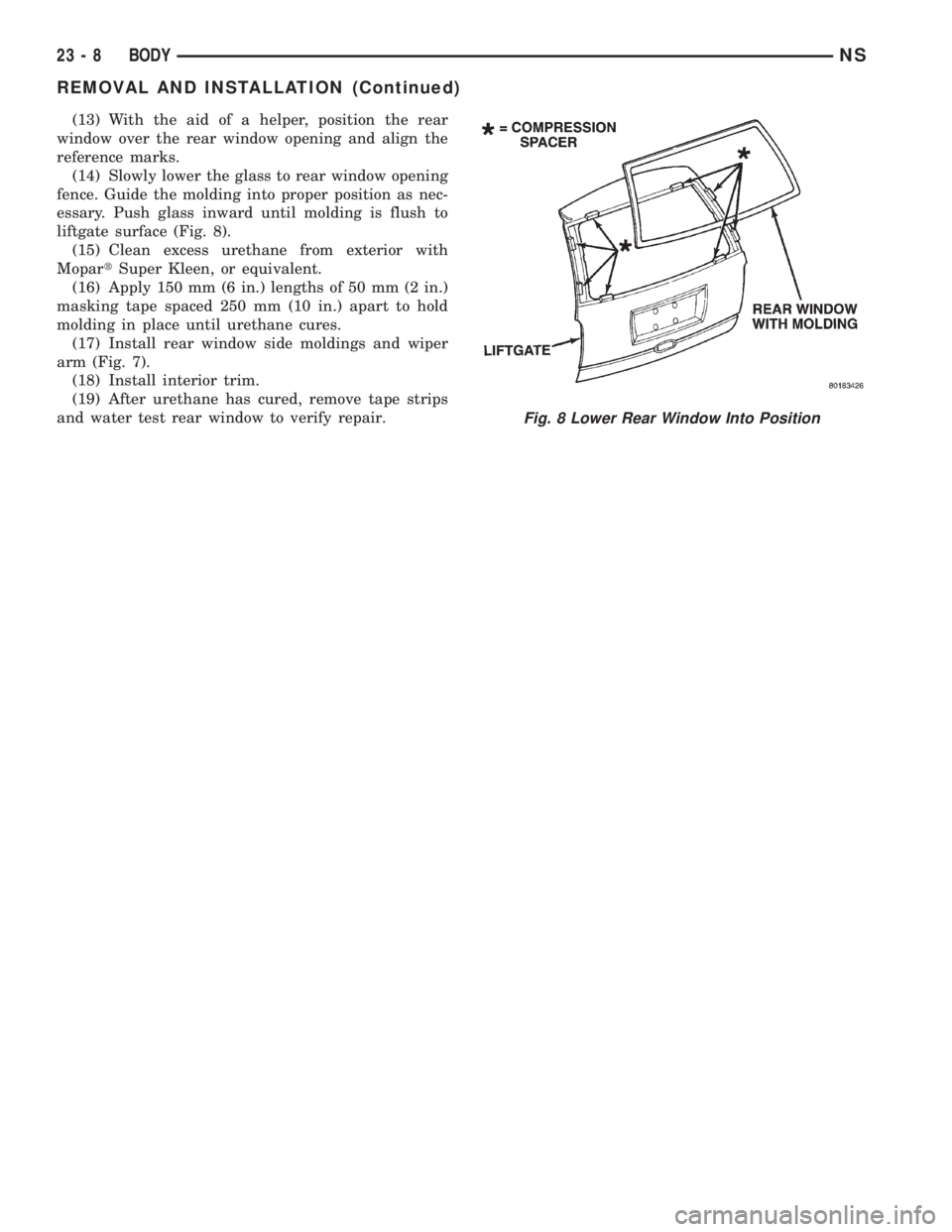

(13) With the aid of a helper, position the rear

window over the rear window opening and align the

reference marks.

(14) Slowly lower the glass to rear window opening

fence. Guide the molding into proper position as nec-

essary. Push glass inward until molding is flush to

liftgate surface (Fig. 8).

(15) Clean excess urethane from exterior with

MopartSuper Kleen, or equivalent.

(16) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(17) Install rear window side moldings and wiper

arm (Fig. 7).

(18) Install interior trim.

(19) After urethane has cured, remove tape strips

and water test rear window to verify repair.

Fig. 8 Lower Rear Window Into Position

23 - 8 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1752 of 1938

BODY COMPONENT SERVICE

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 23

WIND NOISE........................... 24

SERVICE PROCEDURES

HEAT STAKING......................... 24

REMOVAL AND INSTALLATION

A-PILLAR LOWER EXTENSION TRIM........ 25

A-PILLAR TRIM PANEL................... 25

COWL COVER.......................... 25

COWL TRIM............................ 25

FLOOR CARPET........................ 26

FRONT DOOR APPLIQUE................. 28

FRONT DOOR CHECK STRAP.............. 28

FRONT DOOR FRAME CLOSEOUT MOLDINGS . 29

FRONT DOOR GLASS RUN WEATHER-STRIP . . 30

FRONT DOOR GLASS.................... 29

FRONT DOOR HINGE.................... 30

FRONT DOOR INNER BELT MOLDING....... 31

FRONT DOOR LATCH STRIKER............ 32

FRONT DOOR LATCH.................... 31

FRONT DOOR LOCK CYLINDER............ 32

FRONT DOOR OUTER BELT MOLDING....... 33

FRONT DOOR OUTSIDE HANDLE........... 33

FRONT DOOR REFLECTOR............... 34

FRONT DOOR SILL PLATE................ 34

FRONT DOOR TRIM PANEL................ 34

FRONT DOOR WEATHER-STRIP............ 36

FRONT DOOR WINDOW CRANK............ 36

FRONT DOOR WINDOW REGULATOR....... 36

FRONT DOOR.......................... 27

FRONT SEAT........................... 37

FRONT WHEELHOUSE SPLASH SHIELD..... 37

FUEL FILL DOOR BLOCKER LATCH STRIKER . . 38

FUEL FILL DOOR BLOCKER LATCH......... 38

FUEL FILL DOOR BLOCKER LOCKOUT LINK . . 38

FUEL FILLER HOUSING ± WITH BLOCKER

LATCH .............................. 39

GRILLE............................... 39

HEADLINING........................... 39

HOOD HINGE.......................... 41

HOOD LATCH STRIKER................... 42

HOOD LATCH.......................... 41

HOOD RELEASE CABLE.................. 42

HOOD RELEASE HANDLE................. 42

HOOD................................ 40

JACK STORAGE COVER.................. 43

LEFT D-PILLAR TRIM PANEL............... 43

LEFT QUARTER TRIM PANEL.............. 44

LIFTGATE CHMSL ACCESS PANEL.......... 47

LIFTGATE HINGE........................ 47LIFTGATE LATCH STRIKER................ 47

LIFTGATE LATCH........................ 47

LIFTGATE LOCK CYLINDER............... 48

LIFTGATE OUTSIDE HANDLE.............. 48

LIFTGATE PROP ASSEMBLY............... 49

LIFTGATE SILL PLATE.................... 49

LIFTGATE STABILIZER WEDGE STRIKER..... 49

LIFTGATE STABILIZER WEDGE............. 49

LIFTGATE TRIM PANEL................... 50

LIFTGATE UPPER FRAME MOLDING........ 50

LIFTGATE UPPER FRAME SIDE MOLDINGS . . . 51

LIFTGATE............................. 46

LOWER B-PILLAR TRIM COVER............ 51

LUGGAGE RACK CROSSBAR.............. 51

LUGGAGE RACK RISER COVER............ 52

LUGGAGE RACK SIDE RAIL............... 52

OVERHEAD GRAB-HANDLES.............. 52

QUARTER GLASS....................... 52

QUARTER TRIM BOLSTER................ 53

RADIATOR CLOSURE PANEL CROSSMEMBER . 53

RAIL LAMP MODULE..................... 54

REAR HEADER TRIM..................... 55

REAR HVAC LOUVER AND BEZEL.......... 55

RIGHT D-PILLAR TRIM PANEL.............. 55

RIGHT QUARTER TRIM PANEL............. 56

ROOF APERTURE (RAP) MOLDING.......... 57

SEAT BELT BUCKLE FIRST REAR QUAD

BUCKET............................. 58

SEAT BELT BUCKLE FIRST REAR ± TWO

PASSENGER BENCH................... 58

SEAT BELT BUCKLE SECOND REAR ± THREE

PASSENGER BENCH................... 59

SEAT BELT BUCKLE ± FRONT INBOARD..... 57

SEAT BELT FIRST REAR ANCHOR BRACKET ±

LWB ................................ 59

SEAT BELT FIRST REAR OUTBOARD ± LWB

FOUR DOOR.......................... 60

SEAT BELT FIRST REAR OUTBOARD ± SWB

FOUR DOOR.......................... 60

SEAT BELT LEFT FIRST REAR OUTBOARD ±

LWB THREE DOOR..................... 61

SEAT BELT LEFT FIRST REAR OUTBOARD ±

SWB THREE DOOR.................... 61

SEAT BELT SECOND REAR OUTBOARD ±

SWB ................................ 61

SEAT BELT SECOND RIGHT REAR OUTBOARD

±LWB ............................... 62

SEAT BELT ± OUTBOARD FRONT........... 59

SECOND RIGHT REAR OUTBOARD SEAT BELT

± LWB W/REAR HVAC................... 62

23 - 22 BODYNS

Page 1754 of 1938

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during highcrosswinds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

Wind noise can also be caused by improperly fitted

exterior moldings or body ornamentation. Loose

moldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create a

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If component

alignment or sealing is necessary, refer to the appro-

priate section of this group for proper procedures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

SERVICE PROCEDURES

HEAT STAKING

(1) Remove trim panel.

(2) Bend or move the trim panel components at

the heat staked joints. Observe the heat staked loca-

tions and/or component seams for looseness.

(3) Heat stake the components.

(a) If the heat staked or component seam loca-

tion is loose, hold the two components tightly

together and using a soldering gun with a flat tip,

melt the material securing the components

together. Do not over heat the affected area, dam-

age to the exterior of the trim panel may occur.

(b) If the heat staked material is broken or miss-

ing, use a hot glue gun to apply new material to

the area to be repaired. The panels that are being

heat staked must be held together while the apply-

ing the glue. Once the new material is in place, it

23 - 24 BODYNS

DIAGNOSIS AND TESTING (Continued)