engine CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1430 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Remove the Starter Relay from the PDC.

WARNING: THE TRANSMISSION MUST BE IN NEUTRAL AND THE PARK

BRAKE MUST BE SET FOR THIS TEST.

WARNING: THE ENGINE MAY CRANK IN THE NEXT STEP. WHEN THE

ENGINE IS CRANKING, DO NOT STAND IN A DIRECT LINE WITH THE

FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN.

DO NOT WEAR LOOSE CLOTHING.

Momentarily jumper Starter Relay connector cavities 30 and 87 in the IPM

connector.

Did the engine crank?All

Ye s®Go To 4

No®Go To 11

4 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit while fully depressing the clutch pedal and turning the ignition switch

to the START position.

Does the test light illuminate with the ignition switch in the START position?All

Ye s®Go To 5

No®Go To 9

5 Turn the ignition off.

Remove the Starter Relay From the PDC.

Install a substitute relay in place of the Starter Relay.

Attempt to start the engine.

Does the engine crank?All

Ye s®Replace the Starter Relay.

Perform NO START VERIFICATION - VER-1.

No®Go To 6

6 Turn the ignition off.

Disconnect the ECM harness connectors.

Using a 12-volt test light connected to ground, probe ECM harness connector cavity

49 while fully depressing the clutch pedal and turning the ignition switch to the

START position.

Does the test light illuminate while the ignition is in the Start position.All

Ye s®Go To 7

No®Repair the Ignition Switch Start Output circuit to the ECM.

Perform NO START VERIFICATION - VER-1.

211

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1431 of 4284

TEST ACTION APPLICABILITY

7 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Remove the ECM/PCM Relay from the IPM.

Using a jumper wire, connect ECM/PCM relay connector cavities 30 and 87 in the

IPM.

Turn the ignition on.

Measure the voltage of the Starter Relay Control circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the Starter Relay Control circuit for a short to voltage.

Perform NO START VERIFICATION - VER-1.

No®Go To 8

8 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Turn the ignition on.

Measure the resistance of the Starter Relay Control circuit.

Is the resistance below 10.0 ohms?All

Ye s®Replace and program the ECM in accordance with the Service

Information.

Perform NO START VERIFICATION - VER-1.

No®Repair the Starter Relay Control circuit for an open.

Perform NO START VERIFICATION - VER-1.

9 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the Clutch Interlock Switch harness connector.

Connect a jumper wire across the Clutch Interlock Switch harness connector.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit at the Starter Relay connector in the PDC and turning the ignition

switch to the crank position.

Does the test light illuminate with the ignition switch in the crank position?All

Ye s®Replace the Clutch Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Go To 10

10 Turn the ignition off.

Disconnect the Clutch Interlock Switch harness connector.

Remove the Starter Relay from the PDC.

Measure the resistance of the Clutch Interlock Switch Output circuit between the

PDC and the Clutch Interlock Switch harness connector.

Is the resistance below 10.0 ohms?All

Ye s®Repair the Ignition Switch Start Output circuit to the Clutch

Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Repair the Clutch Interlock Switch Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

212

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1432 of 4284

TEST ACTION APPLICABILITY

11 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Fused B+ circuit.

Is the test light on?All

Ye s®Go To 12

No®Repair the Fused B(+) circuit for an open.

Perform NO START VERIFICATION - VER-1.

12 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the Starter Relay Output wire from the Starter Solenoid.

Connect the Starter Relay Output wire (at the Starter) to ground.

Using a 12-volt test light connected to 12-volts, check the Starter Relay Output

circuit at the Starter Relay connector in the IPM.

Does the test light illuminate brightly?All

Ye s®Go To 13

No®Repair the Starter Relay Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

13 Using the Service Information, check the battery cables for high resistance.

Did either battery cable have a voltage drop greater than 0.2 volts?All

Ye s®Replace the battery cable(s).

Perform NO START VERIFICATION - VER-1.

No®Go To 14

14 Turn the ignition off.

Attempt to manually rotate the crankshaft 360É.

Is the crankshaft able to rotate 360É?All

Ye s®Replace the Starter Motor.

Perform NO START VERIFICATION - VER-1.

No®Repair the engine mechanical problem.

Perform NO START VERIFICATION - VER-1.

213

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1438 of 4284

TEST ACTION APPLICABILITY

2NOTE: Ensure that a VIN has been programmed into the PCM. If a VIN is not

displayed, attempt to program the PCM with the correct vehicle VIN before

continuing.

Turn the ignition on.

With the DRBIIIt, select Engine system from the main menu.

Display and record the Vehicle Identification Number.

Does the VIN recorded from the PCM match the VIN of the vehicle?All

Ye s®Go To 3

No®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform SKIS VERIFICATION.

3 Turn the ignition off.

Replace and program the Sentry Key Immobilizer Module in accordance with the

Service Information.

Turn the ignition on.

With the DRBIIIt, display and clear all PCM and SKIM DTC's.

Perform 5 ignition key cycles leaving the ignition key on for 90 seconds per cycle.

With the DRBIIIt, check for SKIM DTC's.

Does the DRBIIItdisplay the same DTC?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform SKIS VERIFICATION.

No®Test Complete.

4 Turn the ignition off.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

Perform SKIS VERIFICATION.

No®Test Complete.

219

VEHICLE THEFT/SECURITY

ROLLING CODE FAILURE ÐContinued

Page 1442 of 4284

Verification Tests

CHARGING VERIFICATION - VER-3 APPLICABILITY

1. Inspect the vehicle to ensure that all engine components are properly installed and

connected. Reassemble and reconnect components as necessary.

2. If the PCM has been replaced, perform step 3. Otherwise, continue with step 4.

3. If the vehicle is equipped with a factory theft alarm, start the engine at least 20 times in

order to be able to activate the alarm system when desired.

4. With the DRB, erase all diagnostic trouble codes (DTCs).

5. Start the engine.

6. Raise the engine speed to 2000 RPM for at least 30 seconds.

7. Allow the engine to idle.

8. Turn the ignition off for 20 seconds.

9. Turn the ignition on.

10. With the DRB, read ECM and PCM DTCs.

11. If this DTC has reset, or another DTC has set, look for any Technical Service Bulletins

(TSBs) that may relate to this condition. Return to the Symptom List if necessary.

12. If the charging system is functioning correctly and there are no DTCs, the repair is now

complete.

Are any DTCs or symptoms remaining?All

Ye s®Repair is not complete, refer to appropriate symptom.

No®Repair is complete.

NO START VERIFICATION - VER-1 APPLICABILITY

1. NOTE: IMPORTANT! If the Engine Control Module, Sentry Key Immobilizer

Module or Powertrain Control Module have been replaced, ensure the programming

procedures for these modules have been performed in accordance with the Service

Information.

2. Inspect the vehicle to ensure that all engine components are properly installed and

connected. Reassemble and reconnect components as necessary.

3. Inspect the engine oil for contamination. If it is contaminated, change the oil and filter.

4. With the DRB, erase all diagnostic trouble codes (DTCs).

5. Turn the ignition off for at least 10 seconds.

6. Attempt to start the engine.

7. If the engine is unable to start, look for any Technical Service Bulletins (TSBs) that may

relate to this condition. Return to the Symptom List if necessary.

8. If the engine starts and continues to run, the repair is now complete.

Are any DTCs or symptoms remaining?All

Ye s®Repair is not complete, refer to appropriate symptom.

No®Repair is complete.

223

VERIFICATION TESTS

Page 1443 of 4284

ROAD TEST VERIFICATION - VER-2 APPLICABILITY

1. Inspect the vehicle to ensure that all engine components are properly installed and

connected. Reassemble and reconnect components as necessary.

2. If this verification procedure is being performed after a non-DTC test, perform steps 3 and

4.

3. Check to see if the initial symptom still exists. If there are no trouble codes and the symptom

no longer exists, the repair was successful and testing is now complete.

4. If the initial or another symptom exists, the repair is not complete. Check all pertinent

Technical Service Bulletins (TSBs) and return to the Symptom List if necessary.

5. For previously read DTCs that have not been dealt with, return to the Symptom List and

follow the diagnostic path for that DTC; otherwise, continue.

6. If the Engine Control Module (ECM) (diesel only) or Powertrain Control Module (PCM) has

not been changed, perform steps 7 and 8, otherwise, continue with step 9.

7. With the DRB, erase all diagnostic trouble codes (DTCs), then disconnect the DRB.

8. Turn the ignition off for at least 10 seconds.

9. Ensure no DTCs remain by performing steps 10 through 13.

10. Road test the vehicle. For some of the road test, go at least 64 km/h (40 MPH). If this test

is for an A/C Relay Control Circuit, drive the vehicle for at least 5 minutes with the A/C on.

11. At some point, stop the vehicle and turn the engine off for at least 10 seconds, then restart

the engine and continue.

12. Upon completion of the road test, turn the engine off and check for DTCs with the DRB.

13. If the repaired DTC has reset, the repair is not complete. Check for any pertinent Technical

Service Bulletins (TSBs) and return to the Symptom List. If there are no DTCs, the repair was

successful and is now complete.

Are any DTCs or symptoms remaining?All

Ye s®Repair is not complete, refer to appropriate symptom.

No®Repair is complete.

SKIS VERIFICATION APPLICABILITY

1. Reconnect all previously disconnected components and connectors.

2. Obtain the vehicle's unique Personal Identification Number (PIN) assigned to it's original

SKIM. This number can be obtained from the vehicle's invoice or Chrysler's Customer Center

(1-800-992-1997).

3. NOTE: When entering the PIN, care should be taken because the SKIM will only

allow 3 consecutive attempts to enter the correct PIN. If 3 consecutive incorrect

PINs are entered, the SKIM will Lock Out the DRB III for 1 hour.

4. To exit Lock Out mode, the ignition key must remain in the Run position continually for 1

hour. Turn off all accessories and connect a battery charger if necessary.

5. With the DRBIIIt, select Theft Alarm, SKIM and Miscellaneous. Then, select the desired

procedure and follow the steps that will be displayed.

6. If the SKIM has been replaced, ensure all of the vehicle ignition keys are programmed to the

new SKIM.

7. NOTE: Prior to returning vehicle to the customer, perform a module scan to be

sure that all DTCs are erased. Erase any DTCs that are found.

8. With the DRBIIIt, erase all DTCs. Perform 5 ignition key cycles leaving the key on for at

least 90 seconds per cycle.

9. With the DRBIIIt, read the SKIM DTCs.

Are there any SKIM DTCs?All

Ye s®Repair is not complete, refer to appropriate symptom.

No®Repair is complete.

224

VERIFICATION TESTS

Verification Tests ÐContinued

Page 1444 of 4284

SPEED CONTROL VERIFICATION - VER-4 APPLICABILITY

1. Inspect the vehicle to ensure that all engine components are properly installed and

connected. Reassemble and reconnect components as necessary.

2. If the ECM has been replaced, perform step 3. Otherwise, continue with step 4.

3. If the vehicle is equipped with a factory theft alarm, start the engine at least 20 times in

order to be able to activate the alarm system when desired.

4. With the DRB, erase all diagnostic trouble codes (DTCs).

5. Road test the vehicle at a speed above 58 km/h (35 MPH).

6. Turn the speed control ON/OFF switch on.

7. Depress and release the SET switch. If the speed control does not engage, the repair is not

complete, continue with step 15.

8. Quickly depress and release the RESUME/ACCEL switch. If the vehicle speed does not

increase by 3 km/h (2 MPH), the repair is not complete, continue with step 15.

9. Using caution, depress and release the brake pedal. If the speed control does not disengage,

the repair is not complete, continue with step 15.

10. With the vehicle speed at least 56 km/h (35 MPH), depress the RESUME/ACCEL switch.

If the speed control does not resume at the previously set speed, the repair is not complete,

continue with step 15.

11. Hold down the COAST switch. If the vehicle does not decelerate, the repair is not complete,

continue with step 15.

12. While still holding down the COAST switch, ensure the vehicle speed is at least 56 km/h (35

MPH) and release the COAST switch. If the vehicle does not adjust and set a new vehicle speed,

the repair is not complete, continue with step 15.

13. With the speed control engaged, depress the ON/OFF switch. If the speed control does not

disengage, the repair is not complete, continue with step 15.

14. If the vehicle did not successfully perform all of the previous steps, check for Technical

Service Bulletins (TSBs) that pertain to this speed control problem and then, if necessary,

return to the Symptom List.

15. If the vehicle successfully performed all of the previous steps, the speed control system is

now functioning as designed. The repair is now complete.

Are any DTCs or symptoms remaining?All

Ye s®Repair is not complete, refer to appropriate symptom.

No®Repair is complete.

225

VERIFICATION TESTS

Verification Tests ÐContinued

Page 1453 of 4284

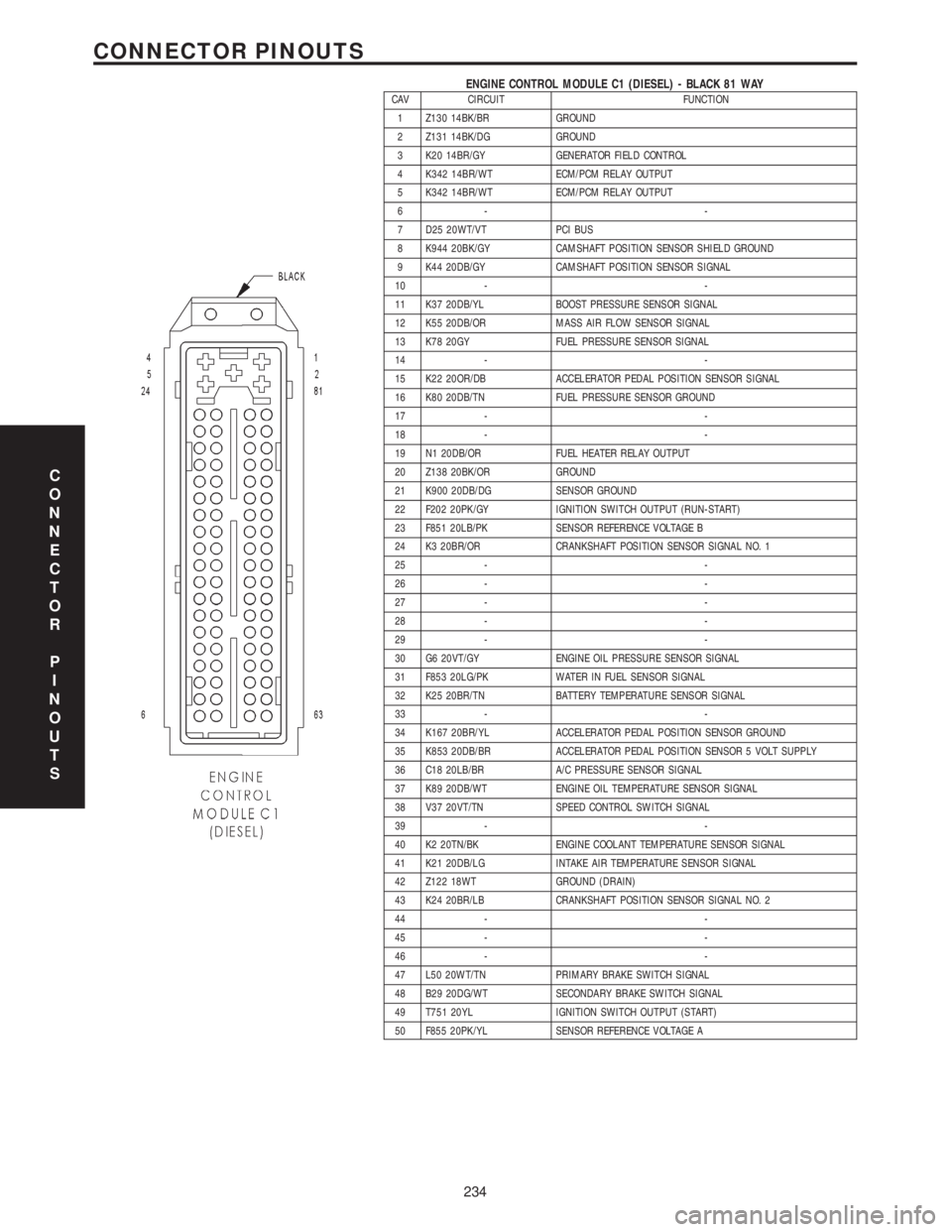

ENGINE CONTROL MODULE C1 (DIESEL) - BLACK 81 WAYCAV CIRCUIT FUNCTION

1 Z130 14BK/BR GROUND

2 Z131 14BK/DG GROUND

3 K20 14BR/GY GENERATOR FIELD CONTROL

4 K342 14BR/WT ECM/PCM RELAY OUTPUT

5 K342 14BR/WT ECM/PCM RELAY OUTPUT

6- -

7 D25 20WT/VT PCI BUS

8 K944 20BK/GY CAMSHAFT POSITION SENSOR SHIELD GROUND

9 K44 20DB/GY CAMSHAFT POSITION SENSOR SIGNAL

10 - -

11 K37 20DB/YL BOOST PRESSURE SENSOR SIGNAL

12 K55 20DB/OR MASS AIR FLOW SENSOR SIGNAL

13 K78 20GY FUEL PRESSURE SENSOR SIGNAL

14 - -

15 K22 20OR/DB ACCELERATOR PEDAL POSITION SENSOR SIGNAL

16 K80 20DB/TN FUEL PRESSURE SENSOR GROUND

17 - -

18 - -

19 N1 20DB/OR FUEL HEATER RELAY OUTPUT

20 Z138 20BK/OR GROUND

21 K900 20DB/DG SENSOR GROUND

22 F202 20PK/GY IGNITION SWITCH OUTPUT (RUN-START)

23 F851 20LB/PK SENSOR REFERENCE VOLTAGE B

24 K3 20BR/OR CRANKSHAFT POSITION SENSOR SIGNAL NO. 1

25 - -

26 - -

27 - -

28 - -

29 - -

30 G6 20VT/GY ENGINE OIL PRESSURE SENSOR SIGNAL

31 F853 20LG/PK WATER IN FUEL SENSOR SIGNAL

32 K25 20BR/TN BATTERY TEMPERATURE SENSOR SIGNAL

33 - -

34 K167 20BR/YL ACCELERATOR PEDAL POSITION SENSOR GROUND

35 K853 20DB/BR ACCELERATOR PEDAL POSITION SENSOR 5 VOLT SUPPLY

36 C18 20LB/BR A/C PRESSURE SENSOR SIGNAL

37 K89 20DB/WT ENGINE OIL TEMPERATURE SENSOR SIGNAL

38 V37 20VT/TN SPEED CONTROL SWITCH SIGNAL

39 - -

40 K2 20TN/BK ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

41 K21 20DB/LG INTAKE AIR TEMPERATURE SENSOR SIGNAL

42 Z122 18WT GROUND (DRAIN)

43 K24 20BR/LB CRANKSHAFT POSITION SENSOR SIGNAL NO. 2

44 - -

45 - -

46 - -

47 L50 20WT/TN PRIMARY BRAKE SWITCH SIGNAL

48 B29 20DG/WT SECONDARY BRAKE SWITCH SIGNAL

49 T751 20YL IGNITION SWITCH OUTPUT (START)

50 F855 20PK/YL SENSOR REFERENCE VOLTAGE A

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

234

CONNECTOR PINOUTS

Page 1454 of 4284

ENGINE CONTROL MODULE C1 (DIESEL) - BLACK 81 WAYCAV CIRCUIT FUNCTION

51 - -

52 K121 20DB BOOST PRESSURE SENSOR GROUND

53 - -

54 K957 20BK/OR MASS AIR FLOW SENSOR GROUND

55 N7 20DB/OR VEHICLE SPEED SENSOR SIGNAL

56 C918 20BK/LB A/C PRESSURE SENSOR GROUND

57 - -

58 K4 20BK/LB LOW IDLE POSITION SWITCH GROUND

59 - -

60 K9 20LB FUEL PRESSURE SENSOR 5 VOLT SUPPLY

61 K51 20BR/WT ECM/PCM RELAY CONTROL

62 - -

63 D21 20WT/BR SCI TRANSMIT

64 K151 20WT LOW IDLE POSITION SWITCH SENSE

65 - -

66 K936 20BR/YL ENGINE OIL PRESSURE SENSOR GROUND

67 - -

68 - -

69 C13 20LB/OR A/C COMPRESSOR CLUTCH RELAY CONTROL

70 N210 20DB/DG LOW SPEED RADIATOR FAN RELAY CONTROL

71 - -

72 N21 20DB/TN LIFT PUMP RELAY CONTROL

73 - -

74 T752 20DG/OR ENGINE STARTER MOTOR RELAY CONTROL

75 - -

76 - -

77 K152 20DB/WT GLOW PLUG RELAY CONTROL

78 N122 20DB/YL HIGH SPEED RADIATOR FAN DUAL RELAY CONTROL

79 - -

80 K87 20BR FUEL PRESSURE SOLENOID CONTROL

81 K87 20BR FUEL PRESSURE SOLENOID CONTROL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

235

CONNECTOR PINOUTS

Page 1455 of 4284

ENGINE CONTROL MODULE C2 (DIESEL) - BLACK 40 WAYCAV CIRCUIT FUNCTION

82 - -

83 - -

84 - -

85 - -

86 T753 20DG/YL IGNITION SWITCH OUTPUT (START)

87 - -

88 K35 20GY/YL EGR SOLENOID CONTROL

89 K35 20GY/YL EGR SOLENOID CONTROL

90 - -

91 - -

92 - -

93 - -

94 - -

95 - -

96 - -

97 - -

98 - -

99 - -

100 - -

101 - -

102 - -

103 - -

104 - -

105 - -

106 - -

107 - -

108 - -

109 - -

110 - -

111 - -

112 K119 20DB/LG CLUTCH PEDAL UPSTOP SWITCH SENSE

113 - -

114 - -

115 K14 14LB/BR FUEL INJECTOR NO. 4 CONTROL

116 K111 14DB/LB COMMON INJECTOR DRIVER

117 - -

118 K11 14WT/DB FUEL INJECTOR NO. 1 CONTROL

119 K12 14TN FUEL INJECTOR NO. 2 CONTROL

120 K13 14BR/LB FUEL INJECTOR NO. 3 CONTROL

121 - -

ENGINE COOLANT TEMP SENSOR (DIESEL) - BLUE 2 WAYCAV CIRCUIT FUNCTION

1 K2 20TN/BK ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

2 K900 20DB/DG SENSOR GROUND

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

236

CONNECTOR PINOUTS