engine CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1367 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Install a substitute relay in place of the ECM/PCM Relay.

Perform several ignition key cycles, pausing for at least 10 seconds between each

cycle.

Turn the ignition on.

With the DRB, read ECM DTCs.

Did this DTC reset?All

Ye s®Go To 4

No®Replace the ECM/PCM Relay.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Remove the ECM/PCM Relay from the IPM.

Disconnect the ECM harness connectors.

Measure the resistance between ground and the ECM/PCM Relay Control circuit

while wiggling the wiring harness and connectors.

Was the resistance below 5.0 ohms at any time while wiggling the wiring harness and

connectors?All

Ye s®Repair the ECM/PCM Relay Control circuit for an intermittent

short to ground.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 5

5 Turn the ignition off.

Remove the ECM/PCM Relay from the IPM.

Turn the ignition on.

Measure the voltage of the ECM/PCM Relay Output circuit.

Is the voltage below 0.5 volt?All

Ye s®Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No®Repair the ECM/PCM Relay Output circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

6WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

148

DRIVEABILITY - DIESEL

P0685-ECM/PCM RELAY CONTROL CIRCUIT SHUTS OFF TOO LATE Ð

Continued

Page 1368 of 4284

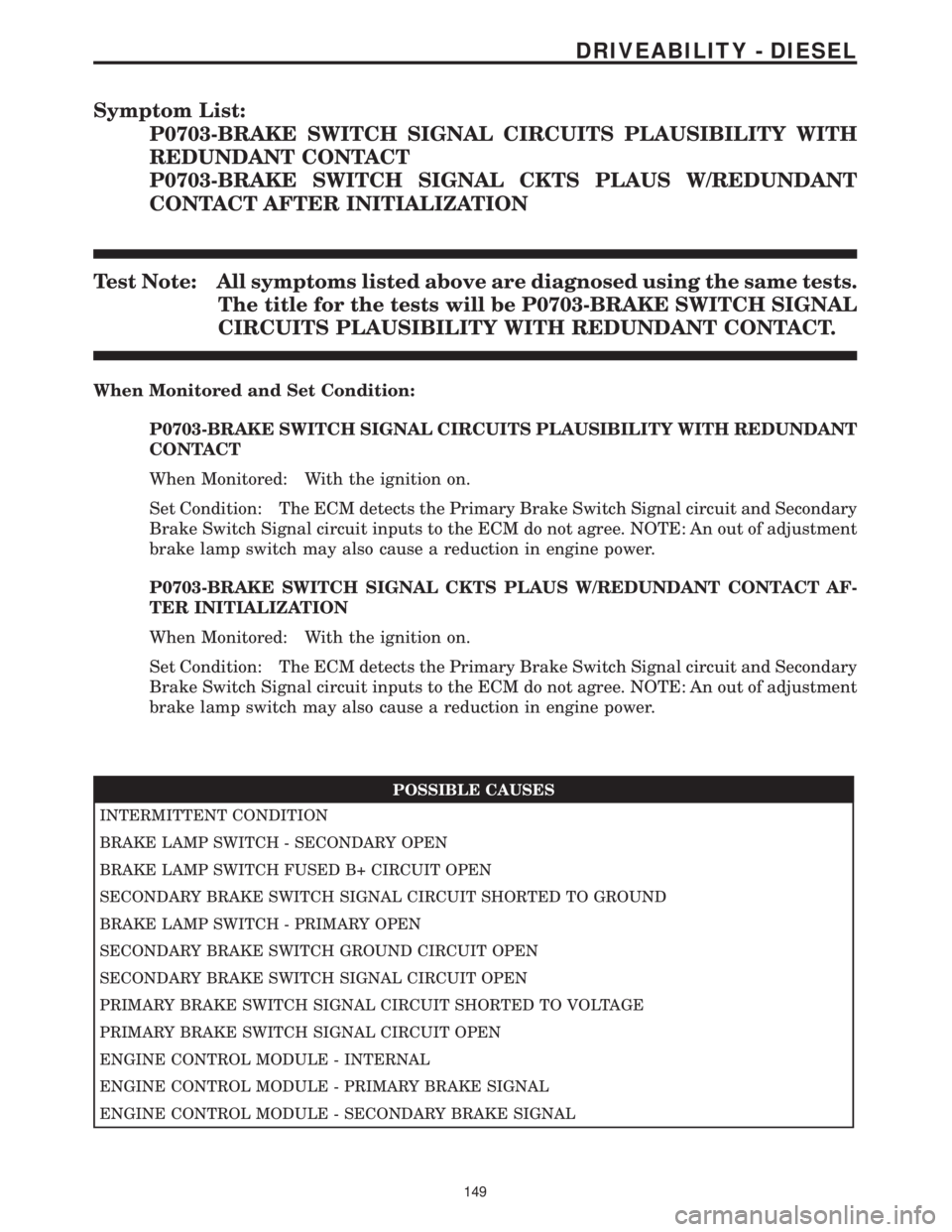

Symptom List:

P0703-BRAKE SWITCH SIGNAL CIRCUITS PLAUSIBILITY WITH

REDUNDANT CONTACT

P0703-BRAKE SWITCH SIGNAL CKTS PLAUS W/REDUNDANT

CONTACT AFTER INITIALIZATION

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0703-BRAKE SWITCH SIGNAL

CIRCUITS PLAUSIBILITY WITH REDUNDANT CONTACT.

When Monitored and Set Condition:

P0703-BRAKE SWITCH SIGNAL CIRCUITS PLAUSIBILITY WITH REDUNDANT

CONTACT

When Monitored: With the ignition on.

Set Condition: The ECM detects the Primary Brake Switch Signal circuit and Secondary

Brake Switch Signal circuit inputs to the ECM do not agree. NOTE: An out of adjustment

brake lamp switch may also cause a reduction in engine power.

P0703-BRAKE SWITCH SIGNAL CKTS PLAUS W/REDUNDANT CONTACT AF-

TER INITIALIZATION

When Monitored: With the ignition on.

Set Condition: The ECM detects the Primary Brake Switch Signal circuit and Secondary

Brake Switch Signal circuit inputs to the ECM do not agree. NOTE: An out of adjustment

brake lamp switch may also cause a reduction in engine power.

POSSIBLE CAUSES

INTERMITTENT CONDITION

BRAKE LAMP SWITCH - SECONDARY OPEN

BRAKE LAMP SWITCH FUSED B+ CIRCUIT OPEN

SECONDARY BRAKE SWITCH SIGNAL CIRCUIT SHORTED TO GROUND

BRAKE LAMP SWITCH - PRIMARY OPEN

SECONDARY BRAKE SWITCH GROUND CIRCUIT OPEN

SECONDARY BRAKE SWITCH SIGNAL CIRCUIT OPEN

PRIMARY BRAKE SWITCH SIGNAL CIRCUIT SHORTED TO VOLTAGE

PRIMARY BRAKE SWITCH SIGNAL CIRCUIT OPEN

ENGINE CONTROL MODULE - INTERNAL

ENGINE CONTROL MODULE - PRIMARY BRAKE SIGNAL

ENGINE CONTROL MODULE - SECONDARY BRAKE SIGNAL

149

DRIVEABILITY - DIESEL

Page 1369 of 4284

TEST ACTION APPLICABILITY

1 Turn the ignition on.

While observing the PRIM BRAKE SWITCH status on the DRB display, press and

release the brake pedal several times.

Does the DRB display PRIM BRAKE SWITCH: PRESSED and RELEASED for the

appropriate pedal position?All

Ye s®Go To 2

No®Go To 11

2 Turn the ignition on.

While observing the SEC BRAKE SWITCH status on the DRB display, press and

release the brake pedal several times.

Does the DRB display SEC BRAKE SWITCH: PRESSED and RELEASED for the

appropriate pedal position?All

Ye s®Go To 3

No®Go To 4

3WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No®Test Complete.

4 Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Turn the ignition on.

Measure the voltage between the Secondary Brake Switch Signal circuit and ground.

Is the voltage above 9.0 volts?All

Ye s®Go To 5

No®Go To 8

150

DRIVEABILITY - DIESEL

P0703-BRAKE SWITCH SIGNAL CIRCUITS PLAUSIBILITY WITH RE-

DUNDANT CONTACT Ð

Continued

Page 1370 of 4284

TEST ACTION APPLICABILITY

5 Disconnect the Brake Lamp Switch harness connector.

Turn the ignition on.

While monitoring the SEC BRAKE SWITCH status with the DRB, connect a jumper

wire between ground and the Secondary Brake Switch Signal circuit.

Does the DRB display change from PRESSED to RELEASED?All

Ye s®Adjust or replace the Brake Lamp Switch in accordance with the

Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 6

6 Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Measure the resistance between ground and the Secondary Brake Switch Ground

circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 7

No®Repair the Secondary Brake Switch Ground circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

7 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

8 Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between ground and the Secondary Brake Switch Signal

circuit.

Is the resistance above 1000 ohms?All

Ye s®Go To 9

No®Repair the Secondary Brake Switch Signal circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

9 Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Secondary Brake Switch Signal circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 10

No®Repair the Secondary Brake Switch Signal circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

10 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

151

DRIVEABILITY - DIESEL

P0703-BRAKE SWITCH SIGNAL CIRCUITS PLAUSIBILITY WITH RE-

DUNDANT CONTACT Ð

Continued

Page 1371 of 4284

TEST ACTION APPLICABILITY

11 Disconnect the Brake Lamp Switch harness connector.

Using a 12-volt test light connected to ground, check the Fused B+ circuit.

Does the test light illuminate brightly?All

Ye s®Go To 12

No®Repair the Brake Lamp Switch Fused B+ circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

12 Disconnect the Brake Lamp Switch harness connector.

Turn the ignition on.

While monitoring the PRIM BRAKE SWITCH status with the DRB, connect a

jumper wire between the Primary Brake Switch Signal circuit and the Fused B(+)

circuit.

Does the DRB display change from RELEASED to PRESSED?All

Ye s®Adjust or replace the Brake Lamp Switch in accordance with the

Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 13

13 Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Disconnect the ECM harness connectors.

Turn the ignition on.

Measure the voltage between the Primary Brake Switch Signal circuit and ground.

Is the voltage above 1.0 volt?All

Ye s®Repair the Primary Brake Switch Signal circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 14

14 Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Primary Brake Switch Signal circuit.

Is the resistance below 5.0 ohms?All

Ye s®Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No®Repair the Primary Brake Switch Signal circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

152

DRIVEABILITY - DIESEL

P0703-BRAKE SWITCH SIGNAL CIRCUITS PLAUSIBILITY WITH RE-

DUNDANT CONTACT Ð

Continued

Page 1372 of 4284

Symptom:

P0833-CLUTCH PEDAL PLAUSIBILITY

POSSIBLE CAUSES

CLUTCH PEDAL SWITCH

CLUTCH PEDAL SWITCH SENSE CIRCUIT OPEN

CLUTCH PEDAL SWITCH SENSE CIRCUIT SHORTED TO GROUND

ECM

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIItin Inputs/Outputs, read the Clutch switch states while pressing

and releasing the Clutch Pedal several times.

Did the DRB indicate the correct clutch pedal state when pressing and releasing the

Clutch Pedal?All

Ye s®Go To 2

No®Go To 3

2WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

No®Test Complete.

3 Turn the ignition off.

Disconnect the Clutch Pedal Switch harness connector.

Turn the ignition on.

With the DRBIIItin Inputs/Outputs, read the Clutch Switch state while using a

jumper wire to connect the Clutch Pedal Switch Sense circuit to ground at the Clutch

Pedal Switch harness connector.

NOTE: Leave jumper connected to ground for 5 seconds then disconnect

jumper and note DRB reading for both conditions.

Does the DRB display RELEASED and PRESSED?All

Ye s®Replace the Clutch Pedal Switch.

No®Go To 4

4 Turn the ignition off.

Disconnect the Clutch Pedal Switch harness connector.

Measure the resistance of the Clutch Pedal Switch Sense circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 5

No®Repair the Clutch Pedal Switch Sense circuit for an open.

153

DRIVEABILITY - DIESEL

Page 1374 of 4284

Symptom List:

P1130-FUEL RAIL PRESSURE MALFUNCTION LEAKAGE DE-

TECTED

P1130-FUEL RAIL PRESSURE MALFUNCTION PRESSURE TOO

HIGH-SHUT OFF

P1130-FUEL RAIL PRESSURE MALFUNCTION PRESSURE TOO

LOW

P1130-FUEL RAIL PRESSURE MALFUNCTION SOLENOID OPEN

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P1130-FUEL RAIL PRESSURE

MALFUNCTION LEAKAGE DETECTED.

When Monitored and Set Condition:

P1130-FUEL RAIL PRESSURE MALFUNCTION LEAKAGE DETECTED

When Monitored: With the engine running.

Set Condition: The ECM detects the desired flow of fuel at idle is greater than 5000

mm/sec.

P1130-FUEL RAIL PRESSURE MALFUNCTION PRESSURE TOO HIGH-SHUT

OFF

When Monitored: With the ignition on.

Set Condition: The fuel rail pressure sensor indicates fuel pressure above 21,000 PSI

with the engine off.

P1130-FUEL RAIL PRESSURE MALFUNCTION PRESSURE TOO LOW

When Monitored: With the engine running.

Set Condition: The ECM determines that the fuel rail pressure is too low for a given

engine speed.

P1130-FUEL RAIL PRESSURE MALFUNCTION SOLENOID OPEN

When Monitored: With the engine running.

Set Condition: The ECM detects a higher rate of fuel pressure than the target pressure.

POSSIBLE CAUSES

CHECKING FOR OTHER DTC'S

CHECKING THE FUEL PRESSURE

FUEL INJECTOR CONTROL CIRCUIT SHORTED TO GROUND

FUEL PRESSURE SENSOR

FUEL SYSTEM LEAK

155

DRIVEABILITY - DIESEL

Page 1376 of 4284

TEST ACTION APPLICABILITY

6 Refer to the appropriate Service Information and perform the Fuel Pressure Test.

NOTE: The following is a list of problems that can cause the fuel pressure to

become out of specification: restricted fuel filter or fuel lines, failed fuel

pressure solenoid, air in fuel system, failed fuel sending unit, gelled fuel,

faulty injector.

Is the fuel pressure within specification?All

Ye s®Replace the Fuel Pressure Sensor in accordance with the Service

Information.

No®Repair as necessary in accordance with the Service Information.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running and at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary.

No®Test Complete.

157

DRIVEABILITY - DIESEL

P1130-FUEL RAIL PRESSURE MALFUNCTION LEAKAGE DETECTED Ð

Continued

Page 1377 of 4284

Symptom List:

P1131-FUEL PRESSURE SOLENOID OPEN CIRCUIT

P1131-FUEL PRESSURE SOLENOID PLAUSIBILITY IN AFTER-

RUN

P1131-FUEL PRESSURE SOLENOID SHORT CIRCUIT

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P1131-FUEL PRESSURE SOLE-

NOID OPEN CIRCUIT.

When Monitored and Set Condition:

P1131-FUEL PRESSURE SOLENOID OPEN CIRCUIT

When Monitored: With the ignition on.

Set Condition: The ECM detects an open or short to ground on the Fuel Pressure Solenoid

Control circuit.

P1131-FUEL PRESSURE SOLENOID PLAUSIBILITY IN AFTER-RUN

When Monitored: When the ignition is turned off.

Set Condition: The ECM detects engine speed does not fall below 650 RPM within 0.5

second after ignition off.

P1131-FUEL PRESSURE SOLENOID SHORT CIRCUIT

When Monitored: With the ignition on.

Set Condition: The ECM detects a short to voltage on the Fuel Pressure Solenoid Control

circuit.

POSSIBLE CAUSES

INTERMITTENT CONDITION

ECM/PCM RELAY OUTPUT CIRCUIT OPEN

FUEL PRESSURE SOLENOID CONTROL SHORTED TO VOLTAGE

FUEL PRESSURE SOLENOID CONTROL CIRCUIT SHORTED TO GROUND

FUEL PRESSURE SOLENOID CONTROL CIRCUIT OPEN

FUEL PRESSURE SOLENOID

ENGINE CONTROL MODULE

158

DRIVEABILITY - DIESEL

Page 1378 of 4284

TEST ACTION APPLICABILITY

1WARNING: THE FUEL INJECTION PUMP SUPPLIES HIGH PRESSURE

FUEL TO EACH INDIVIDUAL INJECTOR THROUGH HIGH-PRESSURE

FUEL LINES. FUEL UNDER HIGH PRESSURE CAN PENETRATE SKIN

AND CAUSE PERSONAL INJURY. WEAR SAFETY GOGGLES AND ADE-

QUATE PROTECTIVE CLOTHING.

Turn the ignition on.

With the DRB, erase ECM DTCs.

Start the engine several times, turning the ignition off for at least 30 seconds

between each run cycle.

Monitor the DRB for ECM DTCs.

Did this DTC reset?All

Ye s®Go To 2

No®Go To 8

2 Turn the ignition off.

Disconnect the Fuel Pressure Solenoid harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the ECM/PCM Relay Output

circuit.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the ECM/PCM Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the Fuel Pressure Solenoid harness connector.

Disconnect the ECM harness connectors.

Remove the ECM/PCM Relay from the PDC.

Connect a jumper wire between cavity 30 and cavity 87 of the ECM/PCM Relay

connector.

Turn the ignition on.

Measure the voltage of the Fuel Pressure Solenoid Control circuit.

Is the voltage below 1.0 volt?All

Ye s®Go To 4

No®Repair the Fuel Pressure Solenoid Control circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Disconnect the Fuel Pressure Solenoid harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between ground and the Fuel Pressure Solenoid Control

circuit.

NOTE: The Fuel Pressure Solenoid Control circuit is duplicated at ECM

cavities C2-80 and C2-81.

Is the resistance above 100k ohms?All

Ye s®Go To 5

No®Repair the Fuel Pressure Solenoid Control circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

159

DRIVEABILITY - DIESEL

P1131-FUEL PRESSURE SOLENOID OPEN CIRCUIT ÐContinued