wiring CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1717 of 4284

INSTALLATION - RHD

(1) Install the ICU on the mounting bracket (Fig.

5). Install the 3 bolts (Fig. 5) attaching the ICU to

the mounting bracket. Tighten the 3 mounting bolts

to a torque of 11 N´m (97 in. lbs.).

CAUTION: The ICU mounting bracket to front sus-

pension cradle mounting bolts have a unique corro-

sion protection coating and a special aluminum

washer. For this reason, only the original, or origi-

nal equipment Mopar replacement bolts can be

used to mount the ICU bracket to the front suspen-

sion crossmember.

(2) Install the ICU and its mounting bracket as an

assembly on the front suspension crossmember.

Install the 3 bolts attaching the ICU bracket to the

crossmember (Fig. 4). Tighten the 3 mounting bolts

to a torque of 28 N´m (250 in. lbs.).

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, and the brake

tubes between the HCU and the proportioning

valve, the brake tubes must be held in proper ori-

entation when tightened and torqued. These tubes

must not contact each other or other vehicle com-

ponents when installed. Also, after the brake tubes

are installed on the HCU, ensure all spacer clips are

reinstalled on the brake tubes.

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation. Refer to (Fig. 3) for the correct chassis brake

tube locations.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the ICU

mounting bracket.

(3) Install the 6 chassis brake tubes into their cor-

rect port locations on the HCU valve block as shown

in (Fig. 3). Tighten the tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: Before installing the 24-way connector in the

CAB be sure the seal is properly installed in the

connector.(4) Install the 24-way connector (Fig. 1) on the

CAB using the following procedure. Position the

24-way connector in the socket of the CAB and care-

fully push it down as far as possible. When connector

is fully seated by hand into the CAB socket, push in

the connector lock (Fig. 2). This will pull the connec-

tor into the socket of the CAB and lock it in the

installed position.

NOTE: The CAB wiring harness must be clipped to

the ICU mounting bracket. This will ensure the wir-

ing harness is properly routed and does not contact

the brake tubes or the body of the vehicle.

(5) Clip the cab wiring harness (Fig. 1) to the ICU

mounting bracket.

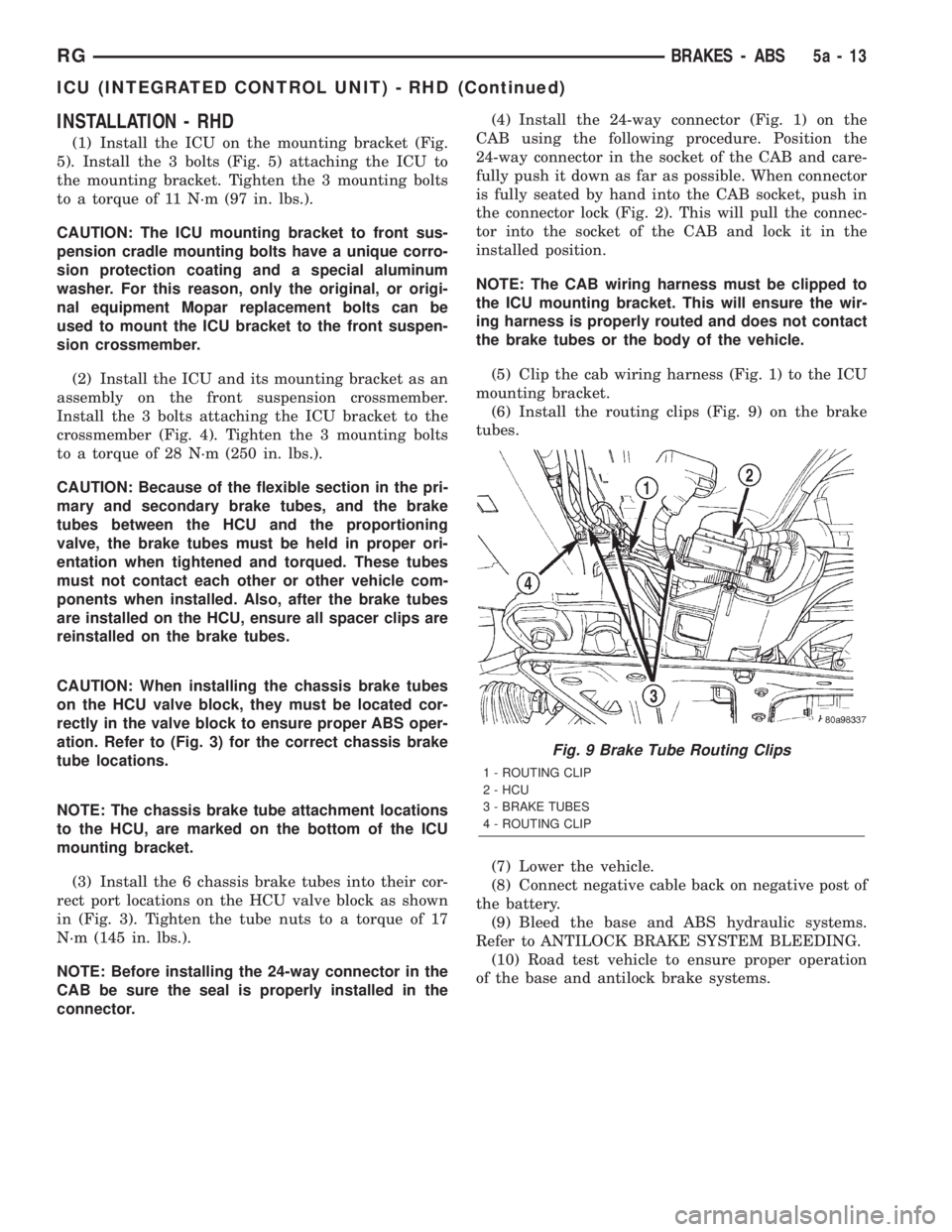

(6) Install the routing clips (Fig. 9) on the brake

tubes.

(7) Lower the vehicle.

(8) Connect negative cable back on negative post of

the battery.

(9) Bleed the base and ABS hydraulic systems.

Refer to ANTILOCK BRAKE SYSTEM BLEEDING.

(10) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

Fig. 9 Brake Tube Routing Clips

1 - ROUTING CLIP

2 - HCU

3 - BRAKE TUBES

4 - ROUTING CLIP

RGBRAKES - ABS5a-13

ICU (INTEGRATED CONTROL UNIT) - RHD (Continued)

Page 1751 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

COOLANT LEVEL CHANGES IN

COOLANT BOTTLE.

TEMPERATURE GAUGE IS IN

NORMAL RANGE.1. Level changes are to be

expected as coolant volume

fluctuates with engine temperature.

The coolant level will also drop as

the system removes air from a

recent filling.1. A normal condition. No repair is

necessary.

TEMPERATURE GAUGE INDICATION DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READING

IS INCONSISTENT (FLUCTUATES,

CYCLES OR IS ERRATIC).1. Normal reaction to fan and/or

thermostat cycle 1, Examples B

and C. During cold weather

operation with the heater blower in

the high position, the gauge reading

may drop slightly 1, Example D.

Fluctuation is also influenced by

outside temperature and heavy

loads 1, Example E.1. A normal condition. No correction

is necessary.

2. Gauge reading rises when

vehicle is brought to a stop after

heavy use (engine still running) 1,

Example F.2. A normal condition. No correction

is necessary. Gauge reading should

return to normal range 1, Example

A, after vehicle is driven.

3. Gauge reading high after

restarting a warmed-up (hot)

engine.3. A normal condition. No correction

is necessary. The gauge should

return to normal range 1, Example

A, after a few minutes of engine

operation.

4. Temperature gauge or engine

coolant temperature sensor

defective or shorted. Also, corroded

or loose wiring in the electrical

circuit.4. Check operation of gauge or

engine coolant temperature sensor

and repair, if necessary.

CLEANING

Drain cooling system and refill with clean water.

Refer to procedures in this section. Run engine with

radiator cap installed until upper radiator hose is

hot. Stop engine and drain water from system. If

water is dirty; fill, run, and drain system again, until

water runs clear.

INSPECTION

After performing a cleaning/flush procedure,

inspect all hoses, clamps and connections for deterio-

ration and leaks. Inspect radiator and heater core for

leaks.

COOLANT

DIAGNOSIS AND TESTING - COOLANT

CONCENTRATION

Coolant concentration should be checked when any

additional coolant was added to system or after a cool-

ant drain, flush and refill. The coolant mixture offers

optimum engine cooling and protection against corrosion

when mixed to a freeze point of -37ÉC (-34ÉF) to -59ÉC

(-50ÉF). The use of a hydrometer or a refractometer can

be used to test coolant concentration.

A hydrometer will test the amount of glycol in a

mixture by measuring the specific gravity of the mix-

ture. The higher the concentration of ethylene glycol,

the larger the number of balls that will float, and

higher the freeze protection (up to a maximum of

60% by volume glycol).

RSENGINE7-17

ENGINE (Continued)

Page 1762 of 4284

OPERATION

RADIATOR FAN OPERATION CHART

COOLANT TEMPERATURE A/C PRESSURE TRANSAXLE OIL

TEMPERATURE

Fan

Operation

Speeds:Initial Max Initial Max Initial Max

Fan On: 104ÉC

(220ÉF)110ÉC

(230ÉF) Fan

Speed

Duty-Cycles

(Ramps-up)

from 30% to

99%1,724 Kpa

(250 psi)2,068 Kpa

(300 psi) Fan

Speed

Duty-Cycles

(Ramps-up)

from 30% to

99%96ÉC (204ÉF) 111ÉC (232ÉF)

Fan Speed

Duty Cycles

(Ramps-up)

from 30% to

99%

Fan Off: 101ÉC

(214ÉF)Fan Speed

Duty-Cycles

(Ramps-

down) from

99% to 30%1,710 Kpa

(248 psi)Fan Speed

Duty-Cycles

(Ramps-

down) from

99% to 30%89ÉC (192ÉF) Fan Speed

Duty Cycles

(Ramps-down)

from 99% to

30%

DIAGNOSIS AND TESTING - RADIATOR FAN

MOTOR

RADIATOR FAN DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY RADIATOR FAN 1. Fan blade loose. 1. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

2. Fan blade striking a surrounding

object.2. Locate point of fan blade contact

and repair as necessary.

3. Air obstructions at radiator or A/C

condenser.3. Remove obstructions and/or

clean debris.

4. Electric fan motor defective. 4. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

ELECTRIC FAN MOTOR DOES

NOT OPERATE1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor, or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Defective A/C pressure

transducer.2. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Check for low coolant level. 2. Add coolant as necessary.

3. Defective A/C pressure

transducer.3. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

7 - 28 ENGINERS

RADIATOR FAN (Continued)

Page 1763 of 4284

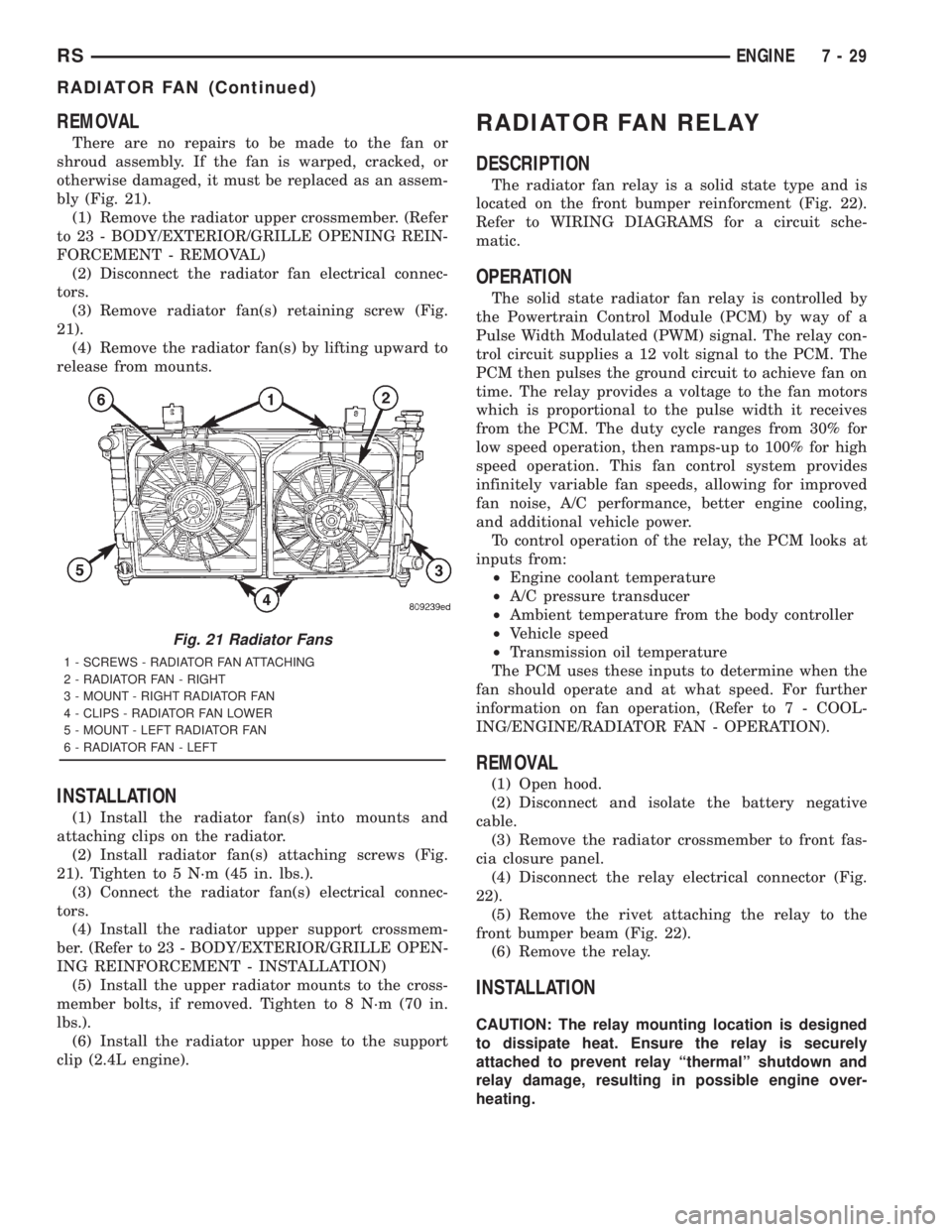

REMOVAL

There are no repairs to be made to the fan or

shroud assembly. If the fan is warped, cracked, or

otherwise damaged, it must be replaced as an assem-

bly (Fig. 21).

(1) Remove the radiator upper crossmember. (Refer

to 23 - BODY/EXTERIOR/GRILLE OPENING REIN-

FORCEMENT - REMOVAL)

(2) Disconnect the radiator fan electrical connec-

tors.

(3) Remove radiator fan(s) retaining screw (Fig.

21).

(4) Remove the radiator fan(s) by lifting upward to

release from mounts.

INSTALLATION

(1) Install the radiator fan(s) into mounts and

attaching clips on the radiator.

(2) Install radiator fan(s) attaching screws (Fig.

21). Tighten to 5 N´m (45 in. lbs.).

(3) Connect the radiator fan(s) electrical connec-

tors.

(4) Install the radiator upper support crossmem-

ber. (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION)

(5) Install the upper radiator mounts to the cross-

member bolts, if removed. Tighten to 8 N´m (70 in.

lbs.).

(6) Install the radiator upper hose to the support

clip (2.4L engine).

RADIATOR FAN RELAY

DESCRIPTION

The radiator fan relay is a solid state type and is

located on the front bumper reinforcment (Fig. 22).

Refer to WIRING DIAGRAMS for a circuit sche-

matic.

OPERATION

The solid state radiator fan relay is controlled by

the Powertrain Control Module (PCM) by way of a

Pulse Width Modulated (PWM) signal. The relay con-

trol circuit supplies a 12 volt signal to the PCM. The

PCM then pulses the ground circuit to achieve fan on

time. The relay provides a voltage to the fan motors

which is proportional to the pulse width it receives

from the PCM. The duty cycle ranges from 30% for

low speed operation, then ramps-up to 100% for high

speed operation. This fan control system provides

infinitely variable fan speeds, allowing for improved

fan noise, A/C performance, better engine cooling,

and additional vehicle power.

To control operation of the relay, the PCM looks at

inputs from:

²Engine coolant temperature

²A/C pressure transducer

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

The PCM uses these inputs to determine when the

fan should operate and at what speed. For further

information on fan operation, (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - OPERATION).

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the radiator crossmember to front fas-

cia closure panel.

(4) Disconnect the relay electrical connector (Fig.

22).

(5) Remove the rivet attaching the relay to the

front bumper beam (Fig. 22).

(6) Remove the relay.

INSTALLATION

CAUTION: The relay mounting location is designed

to dissipate heat. Ensure the relay is securely

attached to prevent relay ªthermalº shutdown and

relay damage, resulting in possible engine over-

heating.

Fig. 21 Radiator Fans

1 - SCREWS - RADIATOR FAN ATTACHING

2 - RADIATOR FAN - RIGHT

3 - MOUNT - RIGHT RADIATOR FAN

4 - CLIPS - RADIATOR FAN LOWER

5 - MOUNT - LEFT RADIATOR FAN

6 - RADIATOR FAN - LEFT

RSENGINE7-29

RADIATOR FAN (Continued)

Page 1777 of 4284

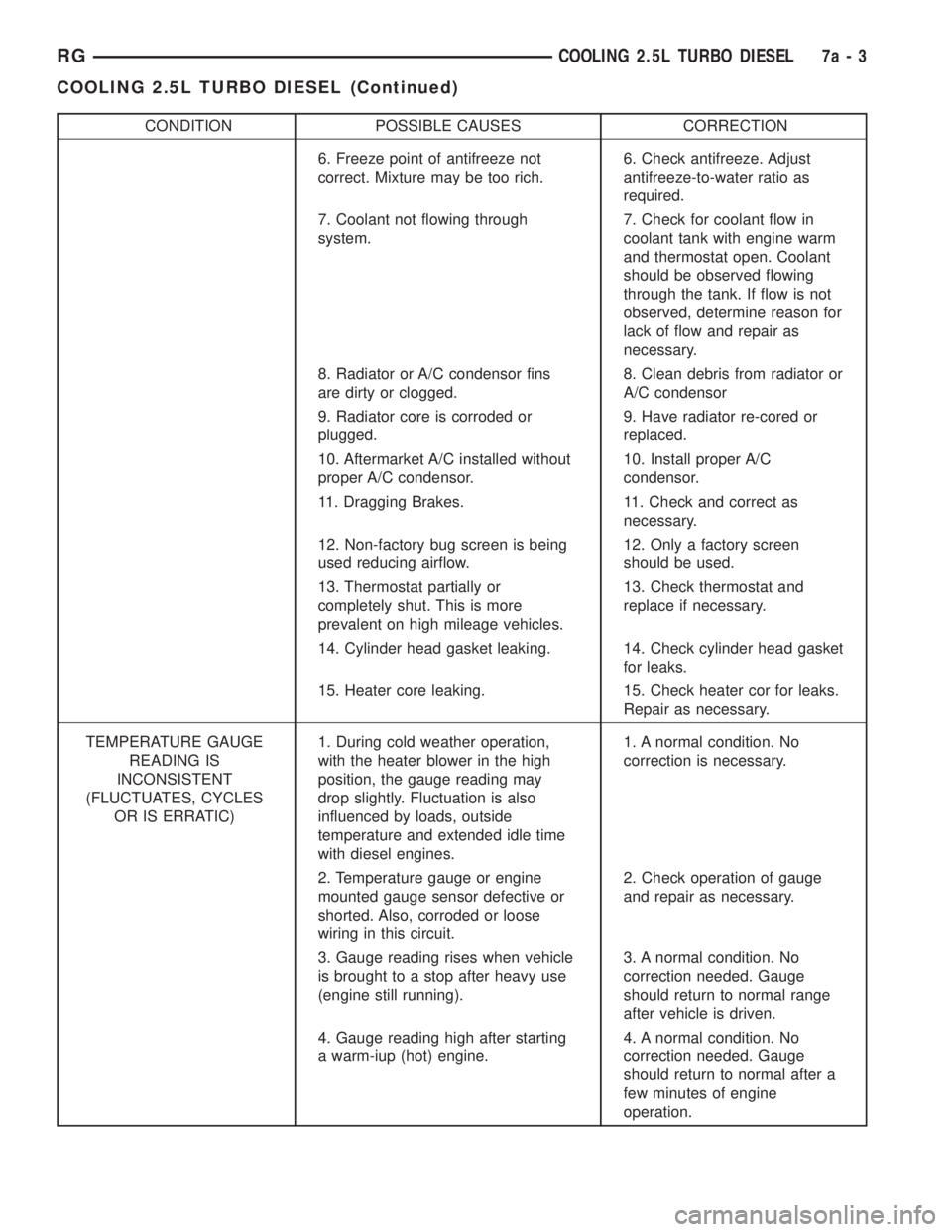

CONDITION POSSIBLE CAUSES CORRECTION

6. Freeze point of antifreeze not

correct. Mixture may be too rich.6. Check antifreeze. Adjust

antifreeze-to-water ratio as

required.

7. Coolant not flowing through

system.7. Check for coolant flow in

coolant tank with engine warm

and thermostat open. Coolant

should be observed flowing

through the tank. If flow is not

observed, determine reason for

lack of flow and repair as

necessary.

8. Radiator or A/C condensor fins

are dirty or clogged.8. Clean debris from radiator or

A/C condensor

9. Radiator core is corroded or

plugged.9. Have radiator re-cored or

replaced.

10. Aftermarket A/C installed without

proper A/C condensor.10. Install proper A/C

condensor.

11. Dragging Brakes. 11. Check and correct as

necessary.

12. Non-factory bug screen is being

used reducing airflow.12. Only a factory screen

should be used.

13. Thermostat partially or

completely shut. This is more

prevalent on high mileage vehicles.13. Check thermostat and

replace if necessary.

14. Cylinder head gasket leaking. 14. Check cylinder head gasket

for leaks.

15. Heater core leaking. 15. Check heater cor for leaks.

Repair as necessary.

TEMPERATURE GAUGE

READING IS

INCONSISTENT

(FLUCTUATES, CYCLES

OR IS ERRATIC)1. During cold weather operation,

with the heater blower in the high

position, the gauge reading may

drop slightly. Fluctuation is also

influenced by loads, outside

temperature and extended idle time

with diesel engines.1. A normal condition. No

correction is necessary.

2. Temperature gauge or engine

mounted gauge sensor defective or

shorted. Also, corroded or loose

wiring in this circuit.2. Check operation of gauge

and repair as necessary.

3. Gauge reading rises when vehicle

is brought to a stop after heavy use

(engine still running).3. A normal condition. No

correction needed. Gauge

should return to normal range

after vehicle is driven.

4. Gauge reading high after starting

a warm-iup (hot) engine.4. A normal condition. No

correction needed. Gauge

should return to normal after a

few minutes of engine

operation.

RGCOOLING 2.5L TURBO DIESEL7a-3

COOLING 2.5L TURBO DIESEL (Continued)

Page 1800 of 4284

INSPECTION

Hold the cap in your hand,top side up(Fig. 21).

The vent valve at the bottom of the cap should open.

If the rubber gasket has swollen, preventing the

valve from opening, replace the cap.

Hold the cleaned cap in your hand,upside down.

If any light can be seen between vent valve and the

rubber gasket, replace the cap.Do not use a

replacement cap that has a spring to hold the

vent shut.

A replacement cap must be of the type designed for

coolant reserve systems. This design ensures coolant

return to the radiator.

RADIATOR FAN

DESCRIPTION

The dual radiator fans are mounted to the back

side of the radiator (Fig. 22). The radiator fan consist

of the fan blade, electric motor and a support shroud

which are all serviced as an assembly.

OPERATION

RADIATOR FAN OPERATION CHART

COOLANT TEMPERATURE A/C PRESSURE

Fan Operation

Speeds:Initial Max Initial Max

Fan On: 104ÉC (220ÉF) 110ÉC (230ÉF) Fan

Speed Duty-Cycles

(Ramps-up) from

30% to 99%1,724 Kpa (250 psi) 2,068 Kpa (300 psi)

Fan Speed

Duty-Cycles

(Ramps-up) from

30% to 99%

Fan Off: 101ÉC (214ÉF) Fan Speed

Duty-Cycles

(Ramps-down) from

99% to 30%1,710 Kpa (248 psi) Fan Speed

Duty-Cycles

(Ramps-down) from

99% to 30%

DIAGNOSIS AND TESTING - RADIATOR FAN MOTOR

RADIATOR FAN DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY RADIATOR FAN 1. Fan blade loose. 1. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

2. Fan blade striking a surrounding

object.2. Locate point of fan blade contact

and repair as necessary.

3. Air obstructions at radiator or A/C

condenser.3. Remove obstructions and/or

clean debris.

4. Electric fan motor defective. 4. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

ELECTRIC FAN MOTOR DOES

NOT OPERATE1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor, or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Defective A/C pressure

transducer.2. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

7a - 26 ENGINERG

RADIATOR PRESSURE CAP (Continued)

Page 1801 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Check for low coolant level. 2. Add coolant as necessary.

3. Defective A/C pressure

transducer.3. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

REMOVAL

There are no repairs to be made to the fan or

shroud assembly. If the fan is warped, cracked, or

otherwise damaged, it must be replaced as an assem-

bly (Fig. 22).

(1) Remove the radiator upper crossmember. (Refer

to 23 - BODY/EXTERIOR/GRILLE OPENING REIN-

FORCEMENT - REMOVAL)

(2) Disconnect the radiator fan electrical connec-

tors.

(3) Remove radiator fan(s) retaining screw (Fig.

22).

(4) Remove the radiator fan(s) by lifting upward to

release from mounts.

INSTALLATION

(1) Install the radiator fan(s) into mounts and

attaching clips on the radiator.

(2) Install radiator fan(s) attaching screws (Fig.

22). Tighten to 5 N´m (45 in. lbs.).

(3) Connect the radiator fan(s) electrical connec-

tors.

(4) Install the radiator upper support crossmem-

ber. (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION).(5) Install the upper radiator mounts to the cross-

member bolts, if removed. Tighten to 8 N´m (70 in.

lbs.).

(6) Install the radiator upper hose to the support

clip (2.4L engine).

HOSE CLAMPS

DESCRIPTION - HOSE CLAMPS

The cooling system uses spring type hose clamps.

If a spring type clamp replacement is necessary,

replace with the original Mopartequipment spring

type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 23).

Fig. 22 Radiator Fans

1 - SCREWS - RADIATOR FAN ATTACHING

2 - RADIATOR FAN - RIGHT

3 - MOUNT - RIGHT RADIATOR FAN

4 - CLIPS - RADIATOR FAN LOWER

5 - MOUNT - LEFT RADIATOR FAN

6 - RADIATOR FAN - LEFT

Fig. 23 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

RGENGINE7a-27

RADIATOR FAN (Continued)

Page 1806 of 4284

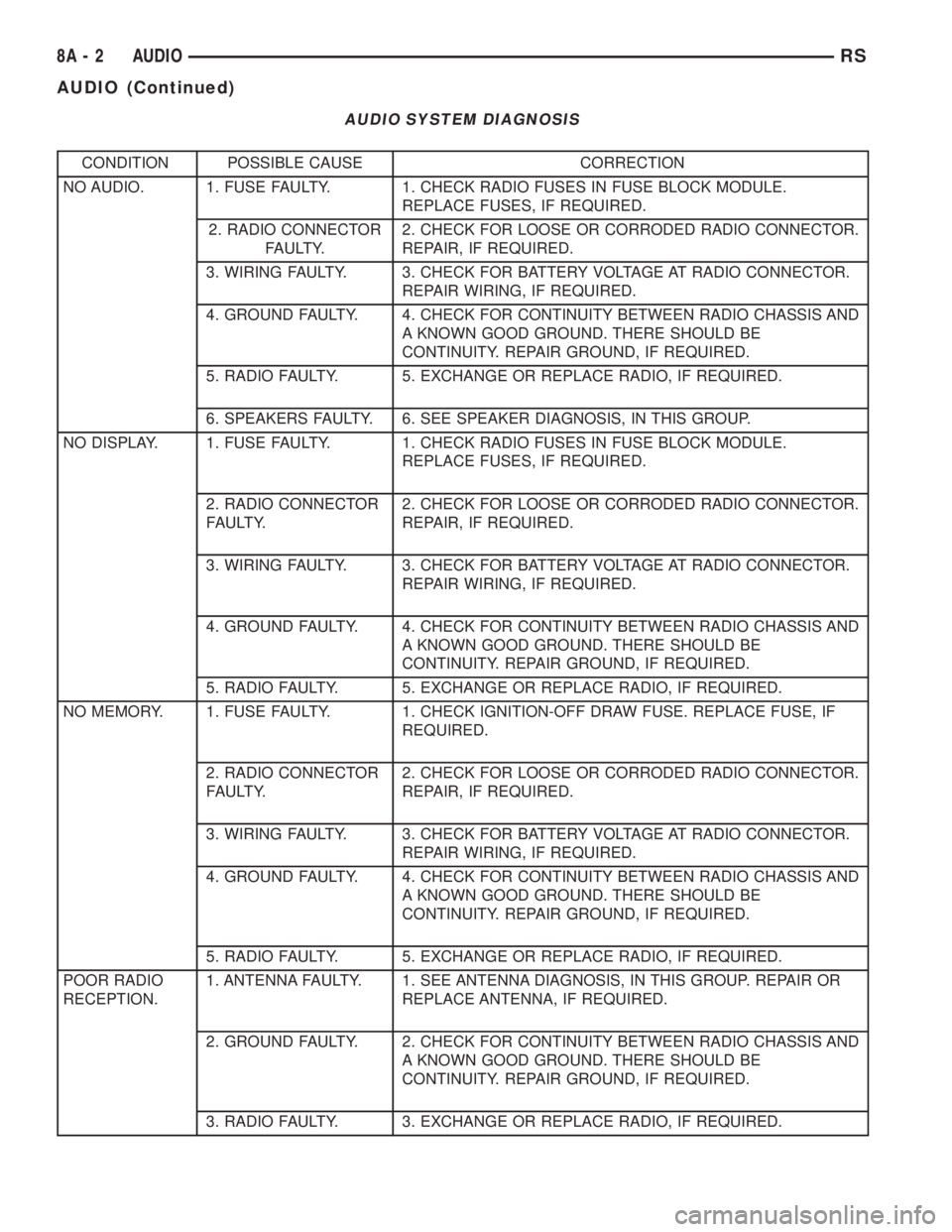

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

6. SPEAKERS FAULTY. 6. SEE SPEAKER DIAGNOSIS, IN THIS GROUP.

NO DISPLAY. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

NO MEMORY. 1. FUSE FAULTY. 1. CHECK IGNITION-OFF DRAW FUSE. REPLACE FUSE, IF

REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

POOR RADIO

RECEPTION.1. ANTENNA FAULTY. 1. SEE ANTENNA DIAGNOSIS, IN THIS GROUP. REPAIR OR

REPLACE ANTENNA, IF REQUIRED.

2. GROUND FAULTY. 2. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

3. RADIO FAULTY. 3. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

8A - 2 AUDIORS

AUDIO (Continued)

Page 1812 of 4284

(4) Connect battery negative cable.

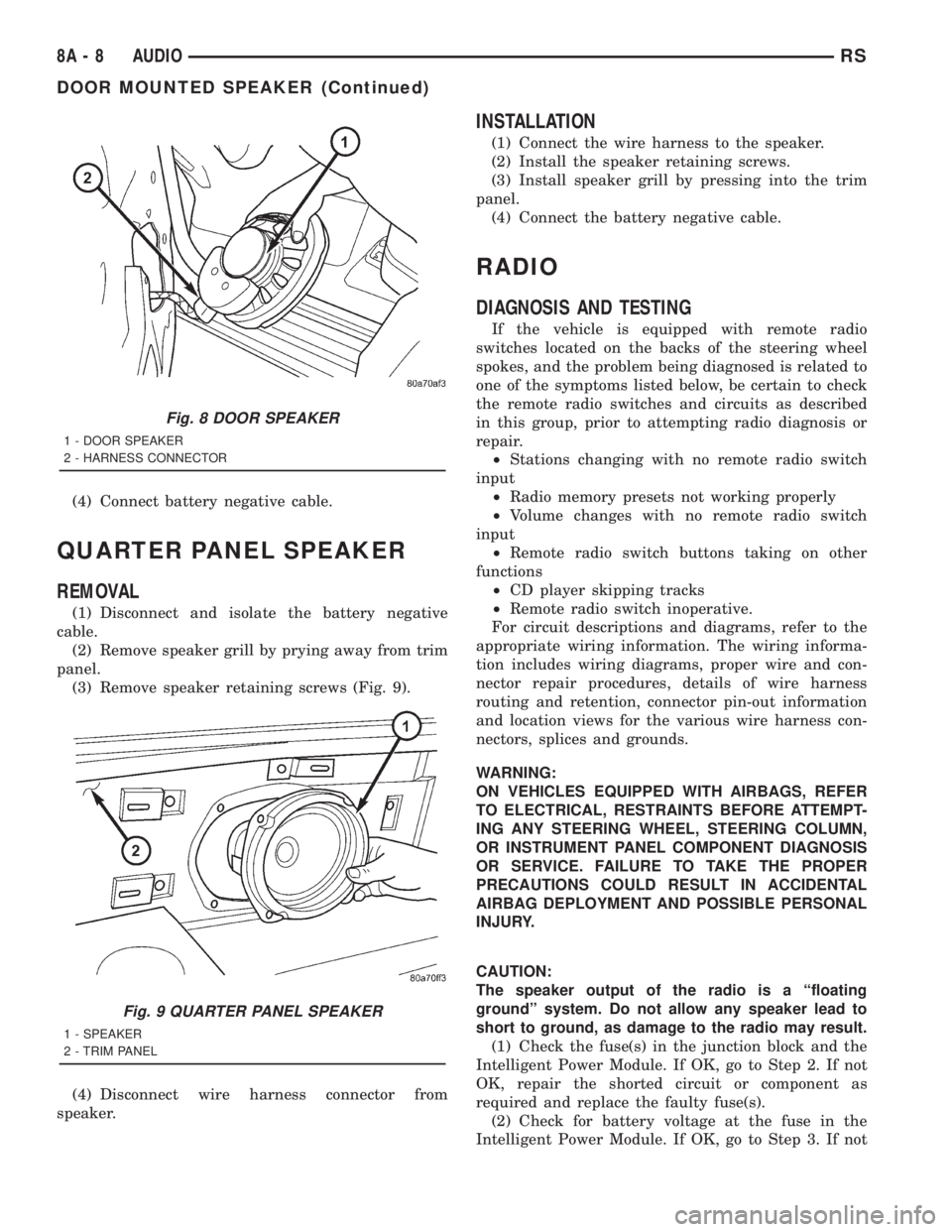

QUARTER PANEL SPEAKER

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove speaker grill by prying away from trim

panel.

(3) Remove speaker retaining screws (Fig. 9).

(4) Disconnect wire harness connector from

speaker.

INSTALLATION

(1) Connect the wire harness to the speaker.

(2) Install the speaker retaining screws.

(3) Install speaker grill by pressing into the trim

panel.

(4) Connect the battery negative cable.

RADIO

DIAGNOSIS AND TESTING

If the vehicle is equipped with remote radio

switches located on the backs of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

WARNING:

ON VEHICLES EQUIPPED WITH AIRBAGS, REFER

TO ELECTRICAL, RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION:

The speaker output of the radio is a ªfloating

groundº system. Do not allow any speaker lead to

short to ground, as damage to the radio may result.

(1) Check the fuse(s) in the junction block and the

Intelligent Power Module. If OK, go to Step 2. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(2) Check for battery voltage at the fuse in the

Intelligent Power Module. If OK, go to Step 3. If not

Fig. 8 DOOR SPEAKER

1 - DOOR SPEAKER

2 - HARNESS CONNECTOR

Fig. 9 QUARTER PANEL SPEAKER

1 - SPEAKER

2 - TRIM PANEL

8A - 8 AUDIORS

DOOR MOUNTED SPEAKER (Continued)

Page 1817 of 4284

AUDIO

TABLE OF CONTENTS

page page

QUARTER GLASS INTEGRAL ANTENNA

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................1

QUARTER GLASS INTEGRAL ANTENNA......1

ANTENNA MODULE

DESCRIPTION............................2OPERATION.............................2

DIAGNOSIS AND TESTING..................2

ANTENNA MODULE......................2

REMOVAL...............................2

INSTALLATION............................2

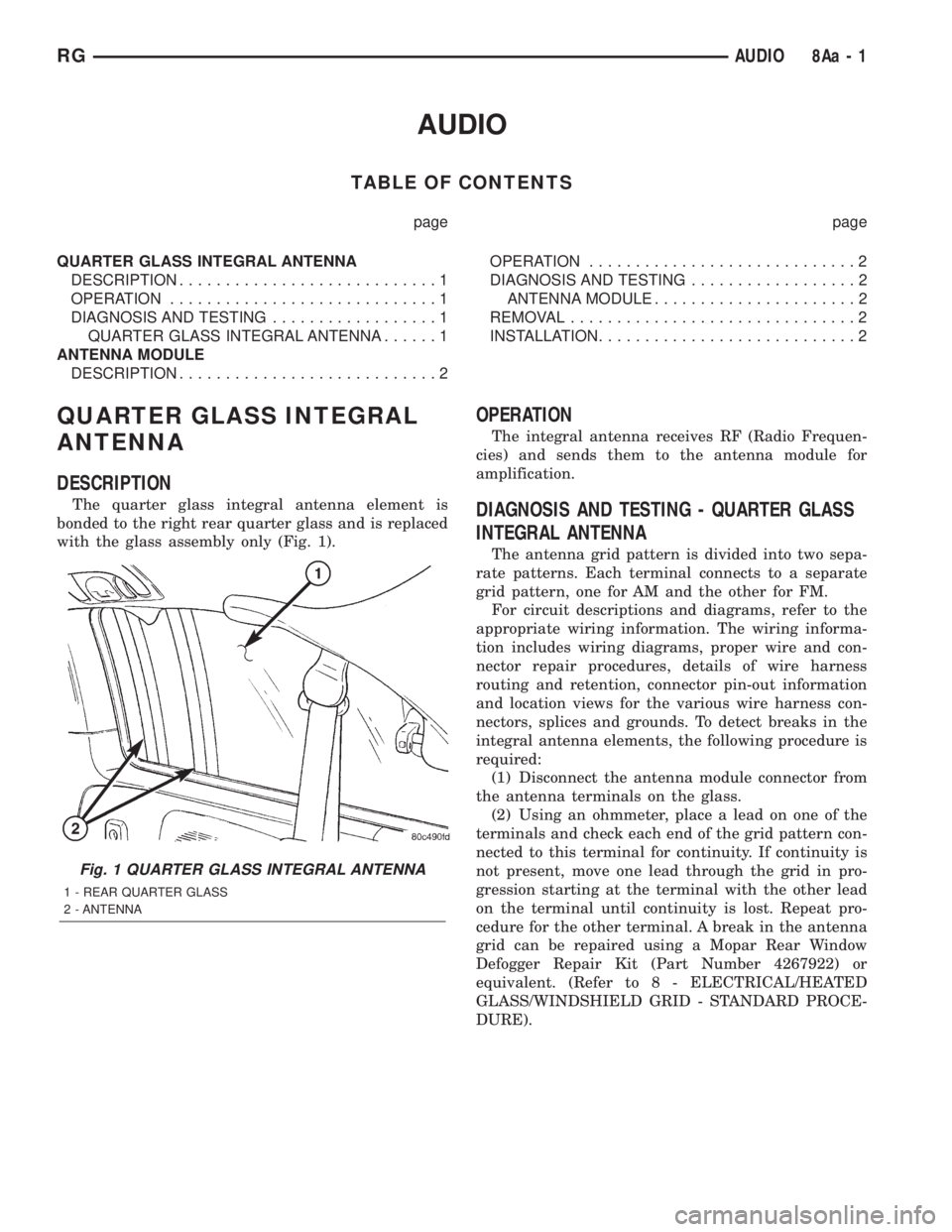

QUARTER GLASS INTEGRAL

ANTENNA

DESCRIPTION

The quarter glass integral antenna element is

bonded to the right rear quarter glass and is replaced

with the glass assembly only (Fig. 1).

OPERATION

The integral antenna receives RF (Radio Frequen-

cies) and sends them to the antenna module for

amplification.

DIAGNOSIS AND TESTING - QUARTER GLASS

INTEGRAL ANTENNA

The antenna grid pattern is divided into two sepa-

rate patterns. Each terminal connects to a separate

grid pattern, one for AM and the other for FM.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds. To detect breaks in the

integral antenna elements, the following procedure is

required:

(1) Disconnect the antenna module connector from

the antenna terminals on the glass.

(2) Using an ohmmeter, place a lead on one of the

terminals and check each end of the grid pattern con-

nected to this terminal for continuity. If continuity is

not present, move one lead through the grid in pro-

gression starting at the terminal with the other lead

on the terminal until continuity is lost. Repeat pro-

cedure for the other terminal. A break in the antenna

grid can be repaired using a Mopar Rear Window

Defogger Repair Kit (Part Number 4267922) or

equivalent. (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

Fig. 1 QUARTER GLASS INTEGRAL ANTENNA

1 - REAR QUARTER GLASS

2 - ANTENNA

RGAUDIO8Aa-1