light CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3977 of 4284

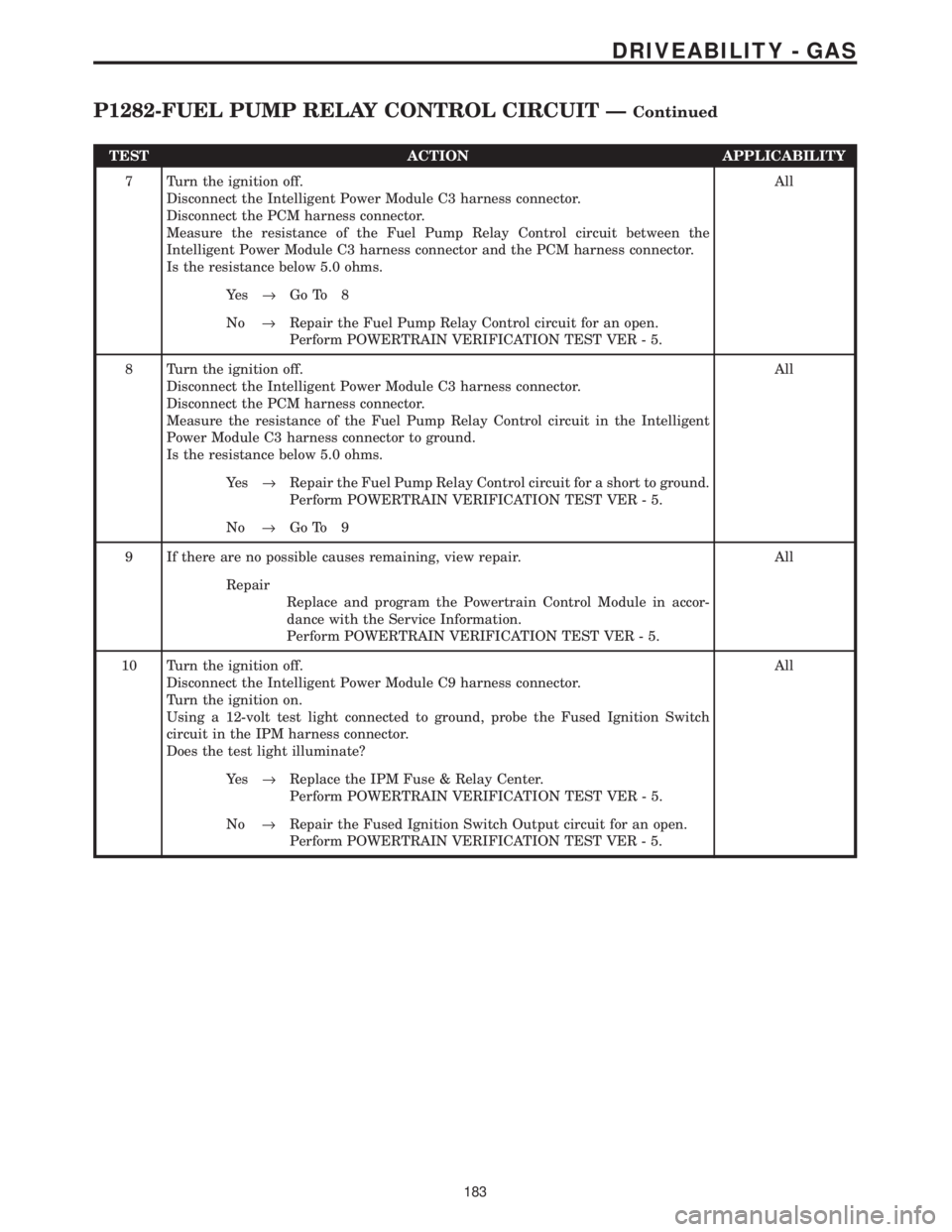

TEST ACTION APPLICABILITY

7 Turn the ignition off.

Disconnect the Intelligent Power Module C3 harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Fuel Pump Relay Control circuit between the

Intelligent Power Module C3 harness connector and the PCM harness connector.

Is the resistance below 5.0 ohms.All

Ye s®Go To 8

No®Repair the Fuel Pump Relay Control circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

8 Turn the ignition off.

Disconnect the Intelligent Power Module C3 harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Fuel Pump Relay Control circuit in the Intelligent

Power Module C3 harness connector to ground.

Is the resistance below 5.0 ohms.All

Ye s®Repair the Fuel Pump Relay Control circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 9

9 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

10 Turn the ignition off.

Disconnect the Intelligent Power Module C9 harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Fused Ignition Switch

circuit in the IPM harness connector.

Does the test light illuminate?All

Ye s®Replace the IPM Fuse & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Repair the Fused Ignition Switch Output circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

183

DRIVEABILITY - GAS

P1282-FUEL PUMP RELAY CONTROL CIRCUIT ÐContinued

Page 3979 of 4284

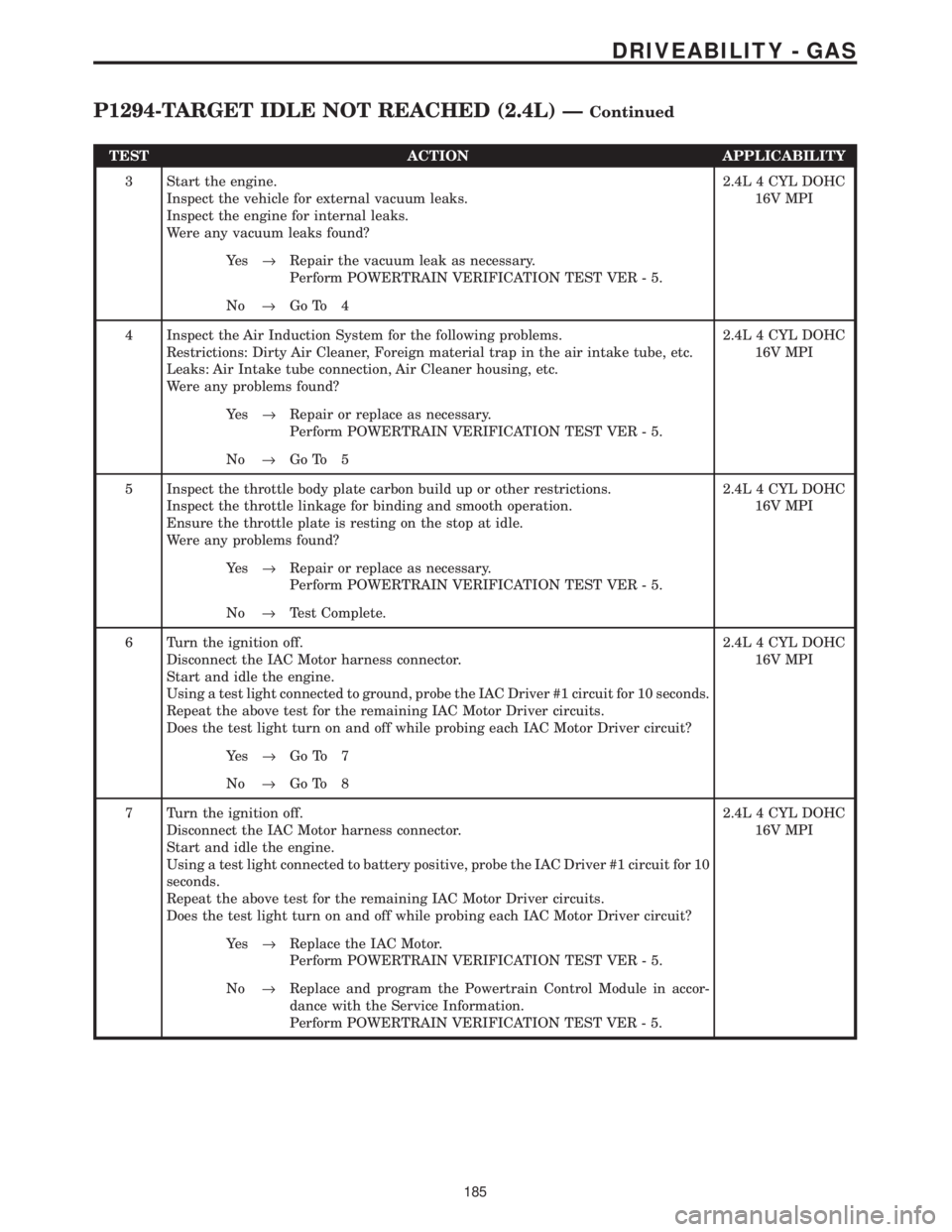

TEST ACTION APPLICABILITY

3 Start the engine.

Inspect the vehicle for external vacuum leaks.

Inspect the engine for internal leaks.

Were any vacuum leaks found?2.4L 4 CYL DOHC

16V MPI

Ye s®Repair the vacuum leak as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Inspect the Air Induction System for the following problems.

Restrictions: Dirty Air Cleaner, Foreign material trap in the air intake tube, etc.

Leaks: Air Intake tube connection, Air Cleaner housing, etc.

Were any problems found?2.4L 4 CYL DOHC

16V MPI

Ye s®Repair or replace as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 Inspect the throttle body plate carbon build up or other restrictions.

Inspect the throttle linkage for binding and smooth operation.

Ensure the throttle plate is resting on the stop at idle.

Were any problems found?2.4L 4 CYL DOHC

16V MPI

Ye s®Repair or replace as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

6 Turn the ignition off.

Disconnect the IAC Motor harness connector.

Start and idle the engine.

Using a test light connected to ground, probe the IAC Driver #1 circuit for 10 seconds.

Repeat the above test for the remaining IAC Motor Driver circuits.

Does the test light turn on and off while probing each IAC Motor Driver circuit?2.4L 4 CYL DOHC

16V MPI

Ye s®Go To 7

No®Go To 8

7 Turn the ignition off.

Disconnect the IAC Motor harness connector.

Start and idle the engine.

Using a test light connected to battery positive, probe the IAC Driver #1 circuit for 10

seconds.

Repeat the above test for the remaining IAC Motor Driver circuits.

Does the test light turn on and off while probing each IAC Motor Driver circuit?2.4L 4 CYL DOHC

16V MPI

Ye s®Replace the IAC Motor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

185

DRIVEABILITY - GAS

P1294-TARGET IDLE NOT REACHED (2.4L) ÐContinued

Page 3980 of 4284

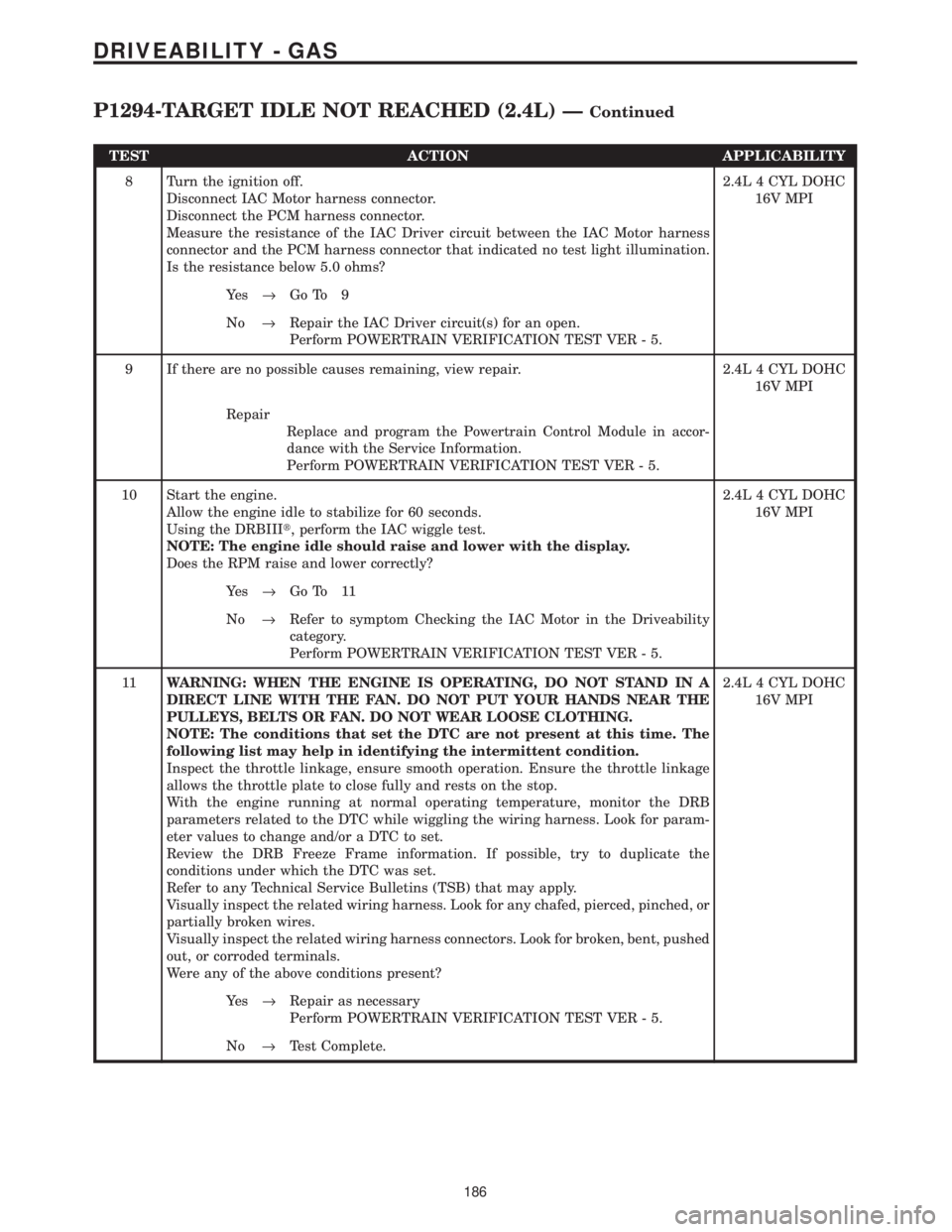

TEST ACTION APPLICABILITY

8 Turn the ignition off.

Disconnect IAC Motor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the IAC Driver circuit between the IAC Motor harness

connector and the PCM harness connector that indicated no test light illumination.

Is the resistance below 5.0 ohms?2.4L 4 CYL DOHC

16V MPI

Ye s®Go To 9

No®Repair the IAC Driver circuit(s) for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

9 If there are no possible causes remaining, view repair. 2.4L 4 CYL DOHC

16V MPI

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

10 Start the engine.

Allow the engine idle to stabilize for 60 seconds.

Using the DRBIIIt, perform the IAC wiggle test.

NOTE: The engine idle should raise and lower with the display.

Does the RPM raise and lower correctly?2.4L 4 CYL DOHC

16V MPI

Ye s®Go To 11

No®Refer to symptom Checking the IAC Motor in the Driveability

category.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

11WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

Inspect the throttle linkage, ensure smooth operation. Ensure the throttle linkage

allows the throttle plate to close fully and rests on the stop.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?2.4L 4 CYL DOHC

16V MPI

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

186

DRIVEABILITY - GAS

P1294-TARGET IDLE NOT REACHED (2.4L) ÐContinued

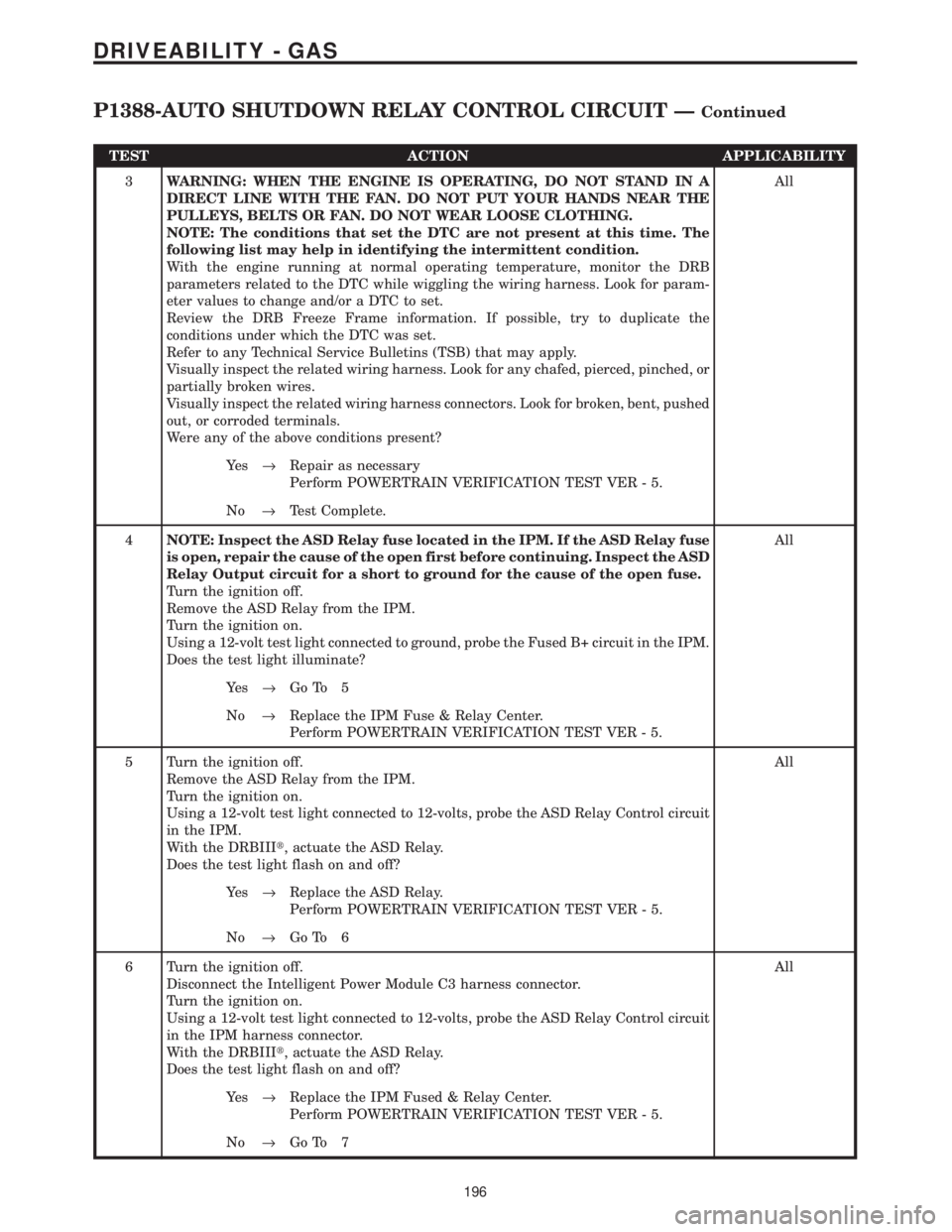

Page 3990 of 4284

TEST ACTION APPLICABILITY

3WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

4NOTE: Inspect the ASD Relay fuse located in the IPM. If the ASD Relay fuse

is open, repair the cause of the open first before continuing. Inspect the ASD

Relay Output circuit for a short to ground for the cause of the open fuse.

Turn the ignition off.

Remove the ASD Relay from the IPM.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Fused B+ circuit in the IPM.

Does the test light illuminate?All

Ye s®Go To 5

No®Replace the IPM Fuse & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

5 Turn the ignition off.

Remove the ASD Relay from the IPM.

Turn the ignition on.

Using a 12-volt test light connected to 12-volts, probe the ASD Relay Control circuit

in the IPM.

With the DRBIIIt, actuate the ASD Relay.

Does the test light flash on and off?All

Ye s®Replace the ASD Relay.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

6 Turn the ignition off.

Disconnect the Intelligent Power Module C3 harness connector.

Turn the ignition on.

Using a 12-volt test light connected to 12-volts, probe the ASD Relay Control circuit

in the IPM harness connector.

With the DRBIIIt, actuate the ASD Relay.

Does the test light flash on and off?All

Ye s®Replace the IPM Fused & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 7

196

DRIVEABILITY - GAS

P1388-AUTO SHUTDOWN RELAY CONTROL CIRCUIT ÐContinued

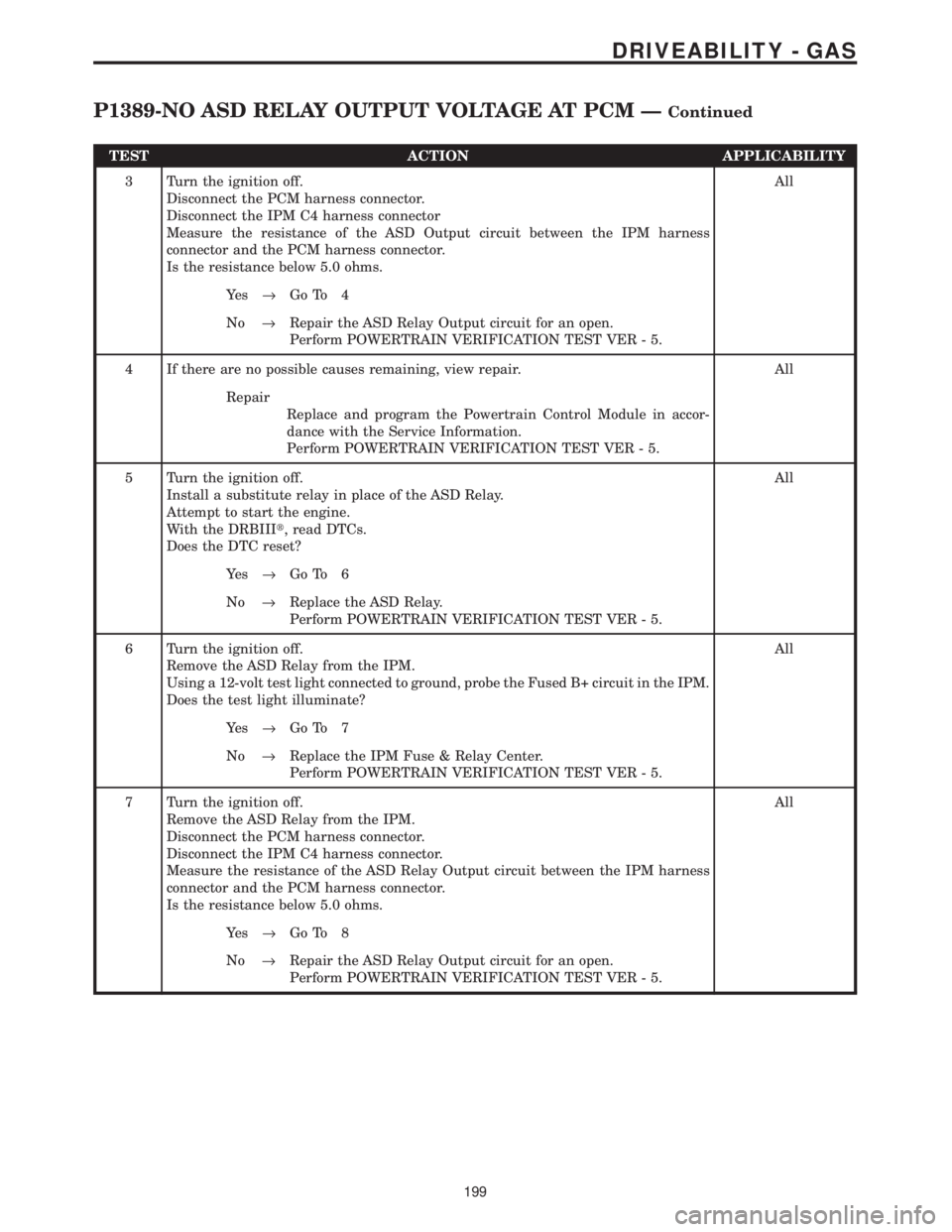

Page 3993 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the IPM C4 harness connector

Measure the resistance of the ASD Output circuit between the IPM harness

connector and the PCM harness connector.

Is the resistance below 5.0 ohms.All

Ye s®Go To 4

No®Repair the ASD Relay Output circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

4 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

5 Turn the ignition off.

Install a substitute relay in place of the ASD Relay.

Attempt to start the engine.

With the DRBIIIt, read DTCs.

Does the DTC reset?All

Ye s®Go To 6

No®Replace the ASD Relay.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

6 Turn the ignition off.

Remove the ASD Relay from the IPM.

Using a 12-volt test light connected to ground, probe the Fused B+ circuit in the IPM.

Does the test light illuminate?All

Ye s®Go To 7

No®Replace the IPM Fuse & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

7 Turn the ignition off.

Remove the ASD Relay from the IPM.

Disconnect the PCM harness connector.

Disconnect the IPM C4 harness connector.

Measure the resistance of the ASD Relay Output circuit between the IPM harness

connector and the PCM harness connector.

Is the resistance below 5.0 ohms.All

Ye s®Go To 8

No®Repair the ASD Relay Output circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

199

DRIVEABILITY - GAS

P1389-NO ASD RELAY OUTPUT VOLTAGE AT PCM ÐContinued

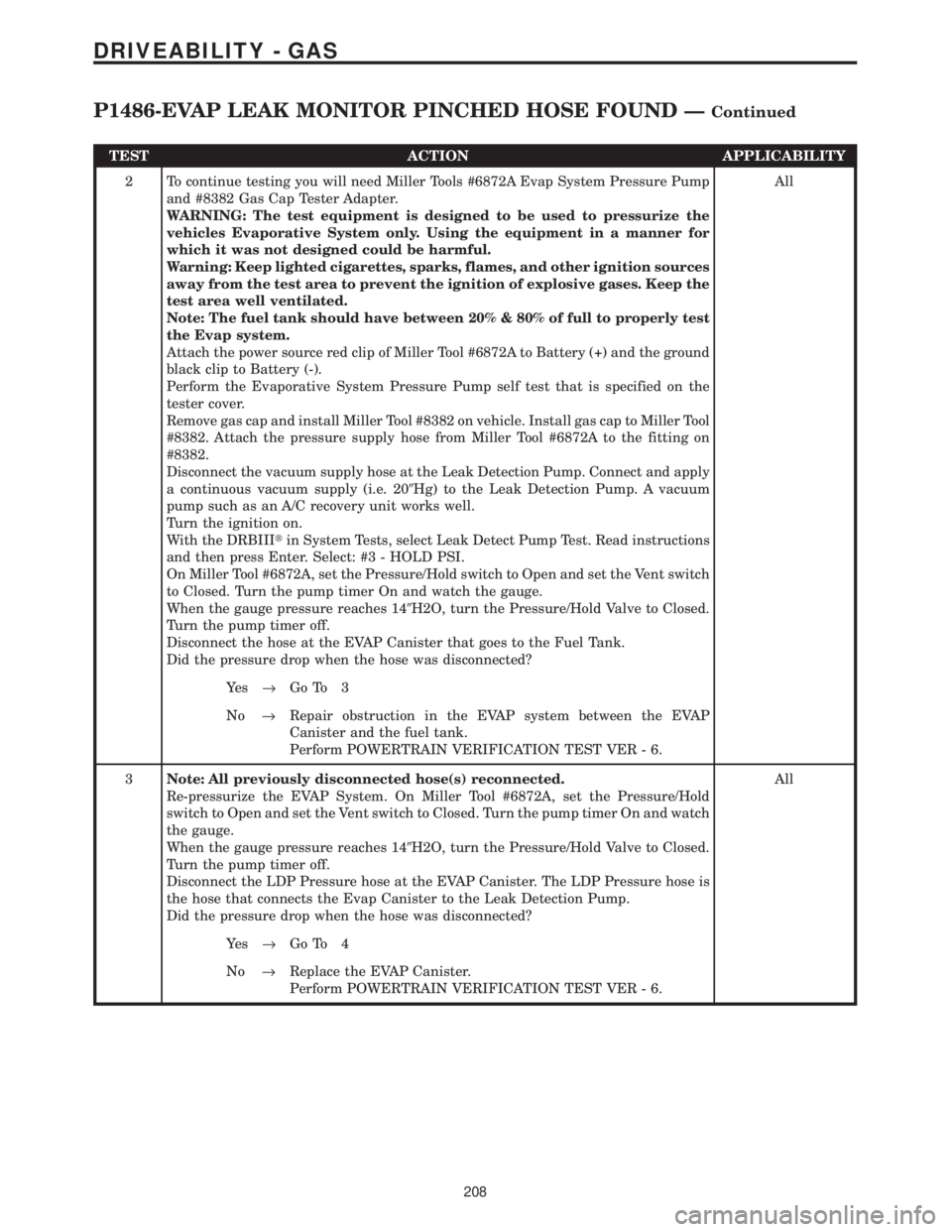

Page 4002 of 4284

TEST ACTION APPLICABILITY

2 To continue testing you will need Miller Tools #6872A Evap System Pressure Pump

and #8382 Gas Cap Tester Adapter.

WARNING: The test equipment is designed to be used to pressurize the

vehicles Evaporative System only. Using the equipment in a manner for

which it was not designed could be harmful.

Warning: Keep lighted cigarettes, sparks, flames, and other ignition sources

away from the test area to prevent the ignition of explosive gases. Keep the

test area well ventilated.

Note: The fuel tank should have between 20% & 80% of full to properly test

the Evap system.

Attach the power source red clip of Miller Tool #6872A to Battery (+) and the ground

black clip to Battery (-).

Perform the Evaporative System Pressure Pump self test that is specified on the

tester cover.

Remove gas cap and install Miller Tool #8382 on vehicle. Install gas cap to Miller Tool

#8382. Attach the pressure supply hose from Miller Tool #6872A to the fitting on

#8382.

Disconnect the vacuum supply hose at the Leak Detection Pump. Connect and apply

a continuous vacuum supply (i.e. 209Hg) to the Leak Detection Pump. A vacuum

pump such as an A/C recovery unit works well.

Turn the ignition on.

With the DRBIIItin System Tests, select Leak Detect Pump Test. Read instructions

and then press Enter. Select: #3 - HOLD PSI.

On Miller Tool #6872A, set the Pressure/Hold switch to Open and set the Vent switch

to Closed. Turn the pump timer On and watch the gauge.

When the gauge pressure reaches 149H2O, turn the Pressure/Hold Valve to Closed.

Turn the pump timer off.

Disconnect the hose at the EVAP Canister that goes to the Fuel Tank.

Did the pressure drop when the hose was disconnected?All

Ye s®Go To 3

No®Repair obstruction in the EVAP system between the EVAP

Canister and the fuel tank.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

3Note: All previously disconnected hose(s) reconnected.

Re-pressurize the EVAP System. On Miller Tool #6872A, set the Pressure/Hold

switch to Open and set the Vent switch to Closed. Turn the pump timer On and watch

the gauge.

When the gauge pressure reaches 149H2O, turn the Pressure/Hold Valve to Closed.

Turn the pump timer off.

Disconnect the LDP Pressure hose at the EVAP Canister. The LDP Pressure hose is

the hose that connects the Evap Canister to the Leak Detection Pump.

Did the pressure drop when the hose was disconnected?All

Ye s®Go To 4

No®Replace the EVAP Canister.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

208

DRIVEABILITY - GAS

P1486-EVAP LEAK MONITOR PINCHED HOSE FOUND ÐContinued

Page 4005 of 4284

TEST ACTION APPLICABILITY

3WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

4 Turn the ignition off.

Disconnect the Radiator Fan Relay harness connector.

Using a 12-volt test light connected to 12-volts, probe the Ground circuit in the

Radiator Fan Relay harness connector.

Does the test light illuminate?All

Ye s®Go To 5

No®Repair the Ground circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

5NOTE: Inspect the Radiator Fan fuse located in the IPM.

Turn the ignition off.

Disconnect the Radiator Fan Relay harness connector.

Measure the voltage of the Fused B+ Output circuit in the Radiator Fan Relay

harness connector.

Is the voltage above 11.0 volts?All

Ye s®Go To 6

No®Repair the Fused B+ circuit. Check and replace any open fuses.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

6NOTE: Ensure the Radiator Fan Relay harness connector is connected.

Turn the ignition off.

Disconnect the PCM harness connector.

Turn the ignition on.

Using a jumper wire, momentarily jumper the Radiator Fan Relay Control circuit to

ground.

Did the Radiator Fans operate?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 7

211

DRIVEABILITY - GAS

P1491-RAD FAN CONTROL RELAY CIRCUIT ÐContinued

Page 4010 of 4284

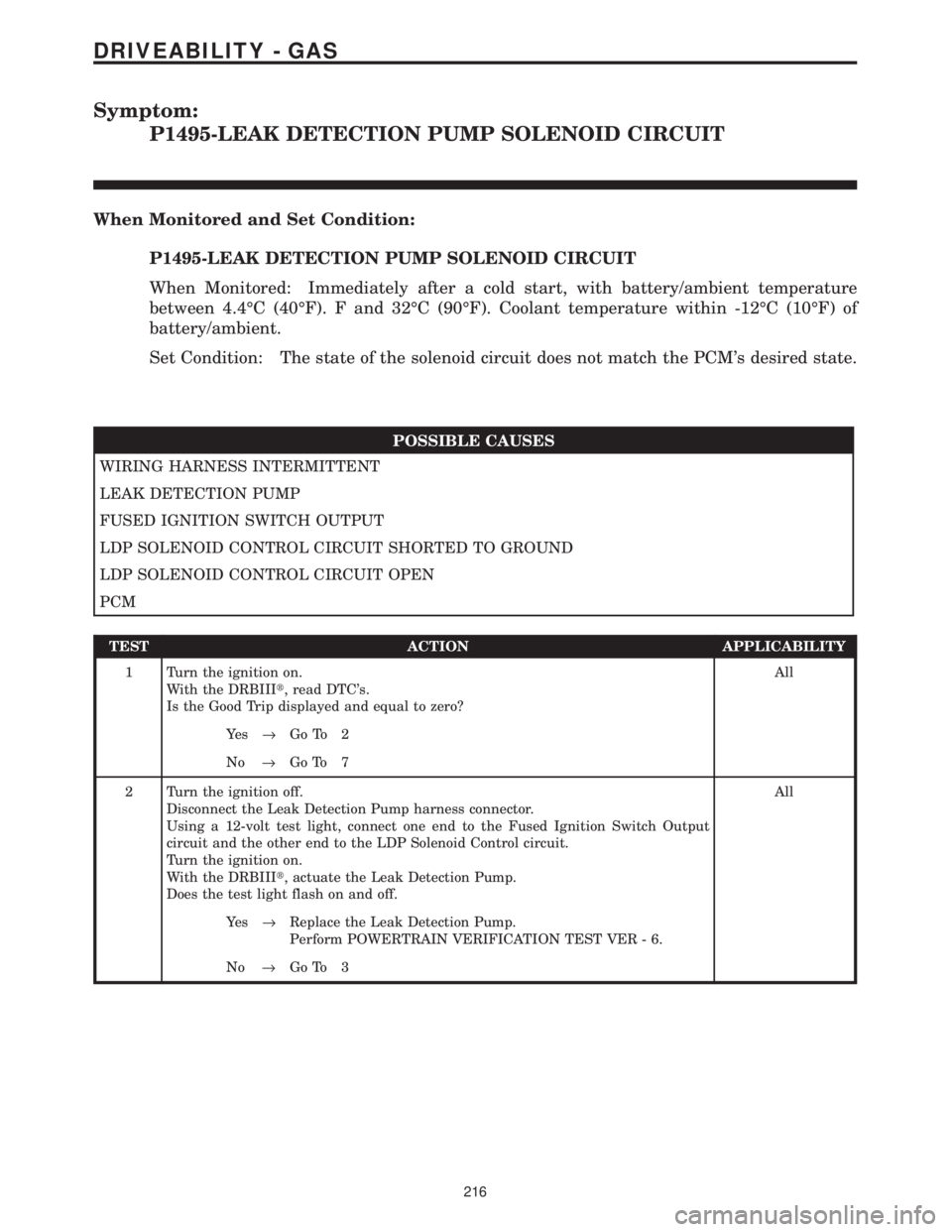

Symptom:

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT

When Monitored and Set Condition:

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT

When Monitored: Immediately after a cold start, with battery/ambient temperature

between 4.4ÉC (40ÉF). F and 32ÉC (90ÉF). Coolant temperature within -12ÉC (10ÉF) of

battery/ambient.

Set Condition: The state of the solenoid circuit does not match the PCM's desired state.

POSSIBLE CAUSES

WIRING HARNESS INTERMITTENT

LEAK DETECTION PUMP

FUSED IGNITION SWITCH OUTPUT

LDP SOLENOID CONTROL CIRCUIT SHORTED TO GROUND

LDP SOLENOID CONTROL CIRCUIT OPEN

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition off.

Disconnect the Leak Detection Pump harness connector.

Using a 12-volt test light, connect one end to the Fused Ignition Switch Output

circuit and the other end to the LDP Solenoid Control circuit.

Turn the ignition on.

With the DRBIIIt, actuate the Leak Detection Pump.

Does the test light flash on and off.All

Ye s®Replace the Leak Detection Pump.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

No®Go To 3

216

DRIVEABILITY - GAS

Page 4011 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the Leak Detection Pump harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Ignition Switch Output

circuit in the LDP harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Repair the Fused Ignition Switch Output circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

4 Turn the ignition off.

Disconnect the Leak Detection Pump harness connector.

Disconnect the Powertrain Control Module harness connector.

Measure the resistance of the LDP Solenoid Control circuit in the LDP harness

connector to ground.

Is the resistance below 5.0 Ohms?All

Ye s®Repair the LDP Solenoid Control circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

No®Go To 5

5 Turn the ignition off.

Disconnect the Leak Detection Pump harness connector.

Disconnect the Powertrain Control Module harness connector.

Measure the resistance of the LDP Solenoid Control circuit between the LDP

Solenoid harness connector and the PCM harness connector.

Is the resistance below 5.0 Ohms?All

Ye s®Go To 6

No®Repair the LDP Solenoid Control circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

7 At this time, the conditions required to set the DTC are not present.

Note: Use the Freeze Frame Data to help you duplicate the conditions that

set the DTC. Pay particular attention to the DTC set conditions, such as,

VSS, MAP, ECT, and Load.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

Note: Visually inspect the related wire harness connectors. Look for broken,

bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB's) that may apply.

Perform a wiggle test of the LDP wiring while the circuit is actuated with the DRB.

Listen for the LDP to quit actuating. Also watch for the Good Trip Counter to change

to 0.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

No®Test Complete.

217

DRIVEABILITY - GAS

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT ÐContinued

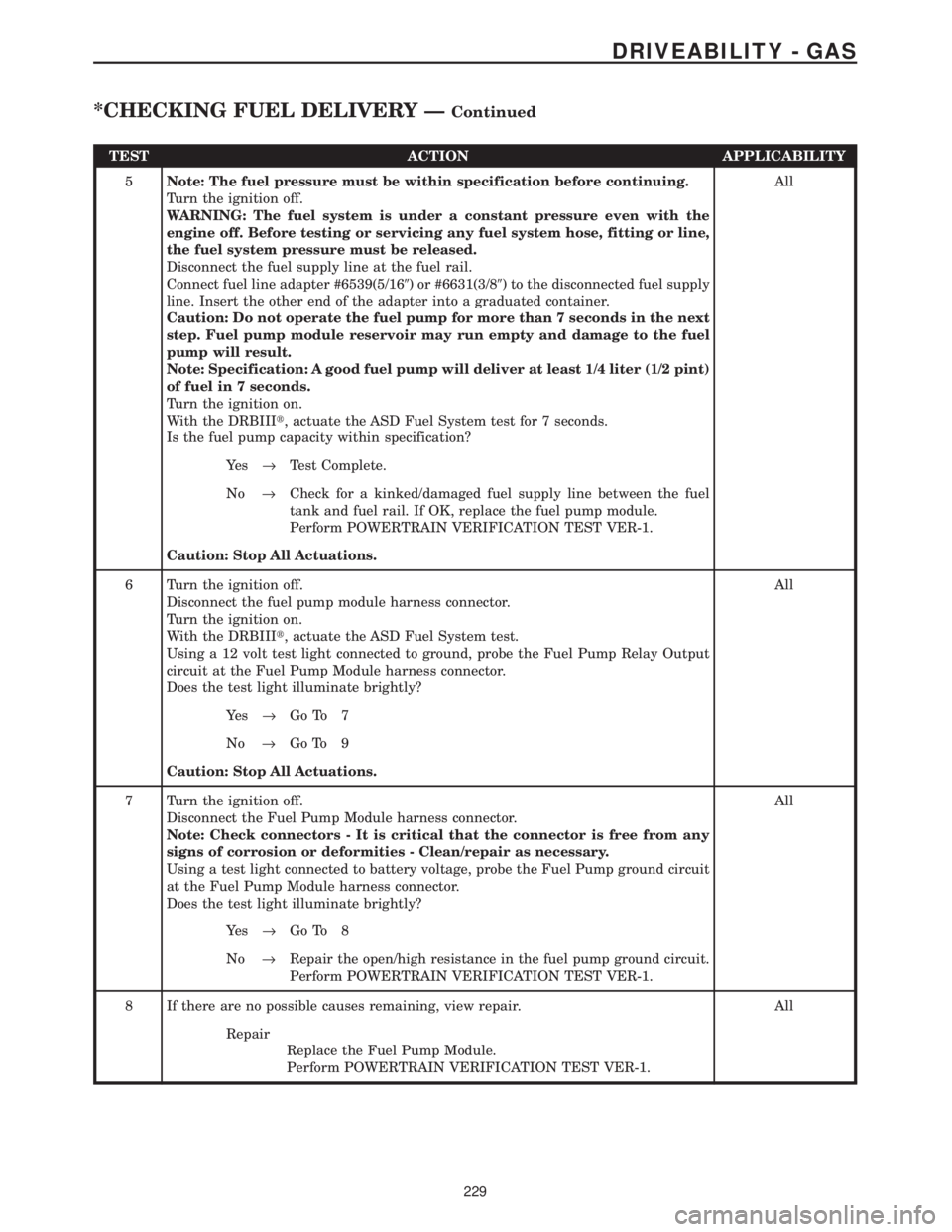

Page 4023 of 4284

TEST ACTION APPLICABILITY

5Note: The fuel pressure must be within specification before continuing.

Turn the ignition off.

WARNING: The fuel system is under a constant pressure even with the

engine off. Before testing or servicing any fuel system hose, fitting or line,

the fuel system pressure must be released.

Disconnect the fuel supply line at the fuel rail.

Connect fuel line adapter #6539(5/169) or #6631(3/89) to the disconnected fuel supply

line. Insert the other end of the adapter into a graduated container.

Caution: Do not operate the fuel pump for more than 7 seconds in the next

step. Fuel pump module reservoir may run empty and damage to the fuel

pump will result.

Note: Specification: A good fuel pump will deliver at least 1/4 liter (1/2 pint)

of fuel in 7 seconds.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test for 7 seconds.

Is the fuel pump capacity within specification?All

Ye s®Test Complete.

No®Check for a kinked/damaged fuel supply line between the fuel

tank and fuel rail. If OK, replace the fuel pump module.

Perform POWERTRAIN VERIFICATION TEST VER-1.

Caution: Stop All Actuations.

6 Turn the ignition off.

Disconnect the fuel pump module harness connector.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test.

Using a 12 volt test light connected to ground, probe the Fuel Pump Relay Output

circuit at the Fuel Pump Module harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 7

No®Go To 9

Caution: Stop All Actuations.

7 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Note: Check connectors - It is critical that the connector is free from any

signs of corrosion or deformities - Clean/repair as necessary.

Using a test light connected to battery voltage, probe the Fuel Pump ground circuit

at the Fuel Pump Module harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 8

No®Repair the open/high resistance in the fuel pump ground circuit.

Perform POWERTRAIN VERIFICATION TEST VER-1.

8 If there are no possible causes remaining, view repair. All

Repair

Replace the Fuel Pump Module.

Perform POWERTRAIN VERIFICATION TEST VER-1.

229

DRIVEABILITY - GAS

*CHECKING FUEL DELIVERY ÐContinued