automatic transmission CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1999 of 2585

should be detected by the PCM/TCM during this test.

It no spike is detected, the circuit is tested again to

verify the failure. In addition to the periodic testing,

the solenoid circuits are tested if a speed ratio or

pressure switch error occurs.

PRESSURE SWITCHES

The PCM/TCM relies on three pressure switches to

monitor fluid pressure in the L/R, 2/4, and OD

hydraulic circuits. The primary purpose of these

switches is to help the PCM/TCM detect when clutch

circuit hydraulic failures occur. The range for the

pressure switch closing and opening points is 11-23

psi. Typically the switch opening point will be

approximately one psi lower than the closing point.

For example, a switch may close at 18 psi and open

at 17 psi. The switches are continuously monitored

by the PCM/TCM for the correct states (open or

closed) in each gear as shown in the following chart:

PRESSURE SWITCH STATES

GEAR L/R 2/4 OD

ROPOPOP

P/N CL OP OP 1st CL OP OP

2nd OP CL OP DOPOPCL

OD OP CL CL OP = OPEN

CL = CLOSED

A Diagnostic Trouble Code (DTC) will set if the

PCM/TCM senses any switch open or closed at the

wrong time in a given gear. The PCM/TCM also tests the 2/4 and OD pressure

switches when they are normally off (OD and 2/4 are

tested in 1st gear, OD in 2nd gear, and 2/4 in 3rd

gear). The test simply verifies that they are opera-

tional, by looking for a closed state when the corre-

sponding element is applied. Immediately after a

shift into 1st, 2nd, or 3rd gear with the engine speed

above 1000 rpm, the PCM/TCM momentarily turns

on element pressure to the 2/4 and/or OD clutch cir-

cuits to identify that the appropriate switch has

closed. If it doesn't close, it is tested again. If the

switch fails to close the second time, the appropriate

Diagnostic Trouble Code (DTC) will set.

REMOVAL

NOTE: If solenoid/pressure switch assembly is

being replaced, it is necessary to perform the TCM

Quick Learn Procedure. (Refer t o 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly.

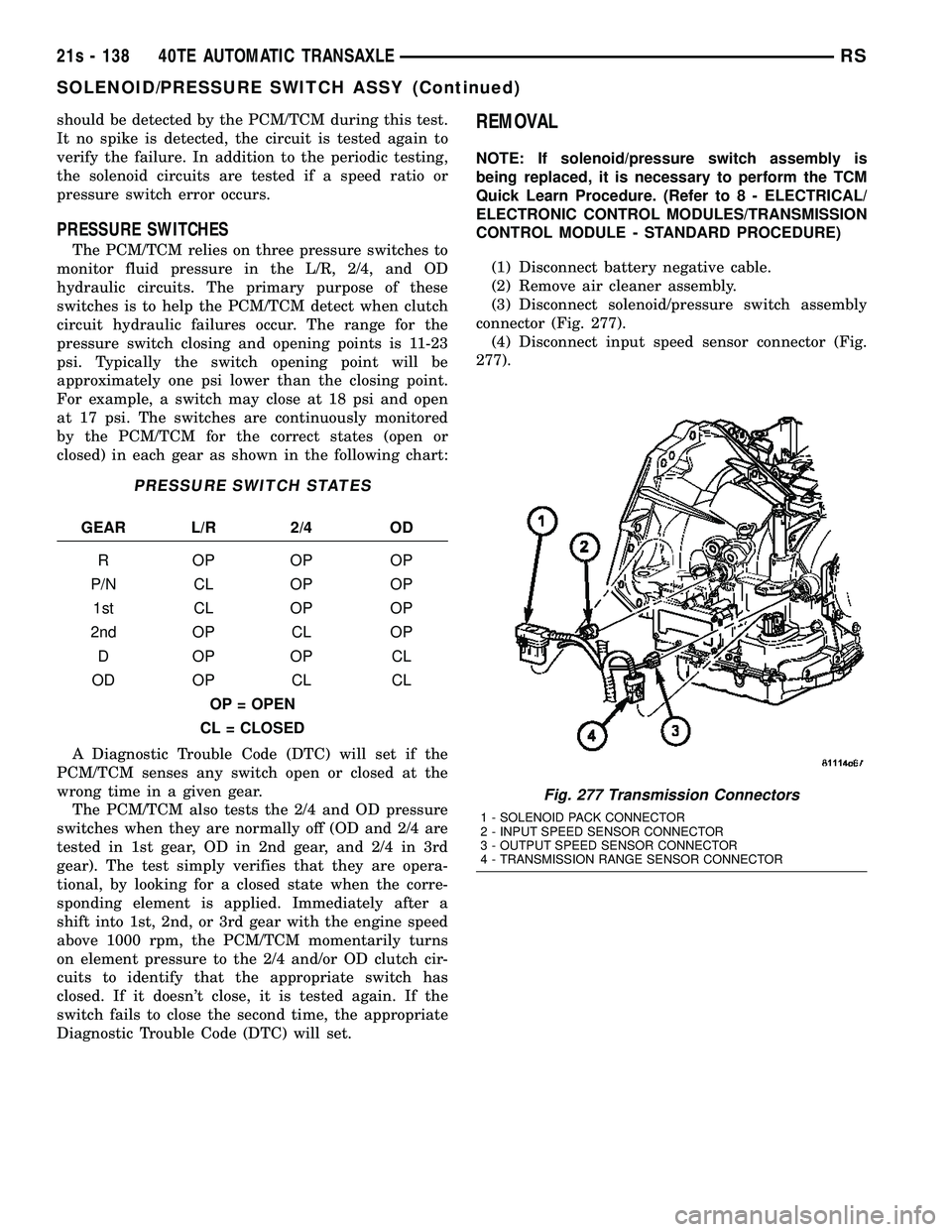

(3) Disconnect solenoid/pressure switch assembly

connector (Fig. 277). (4) Disconnect input speed sensor connector (Fig.

277).

Fig. 277 Transmission Connectors

1 - SOLENOID PACK CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

21s - 138 40TE AUTOMATIC TRANSAXLERS

SOLENOID/PRESSURE SWITCH ASSY (Continued)

Page 2000 of 2585

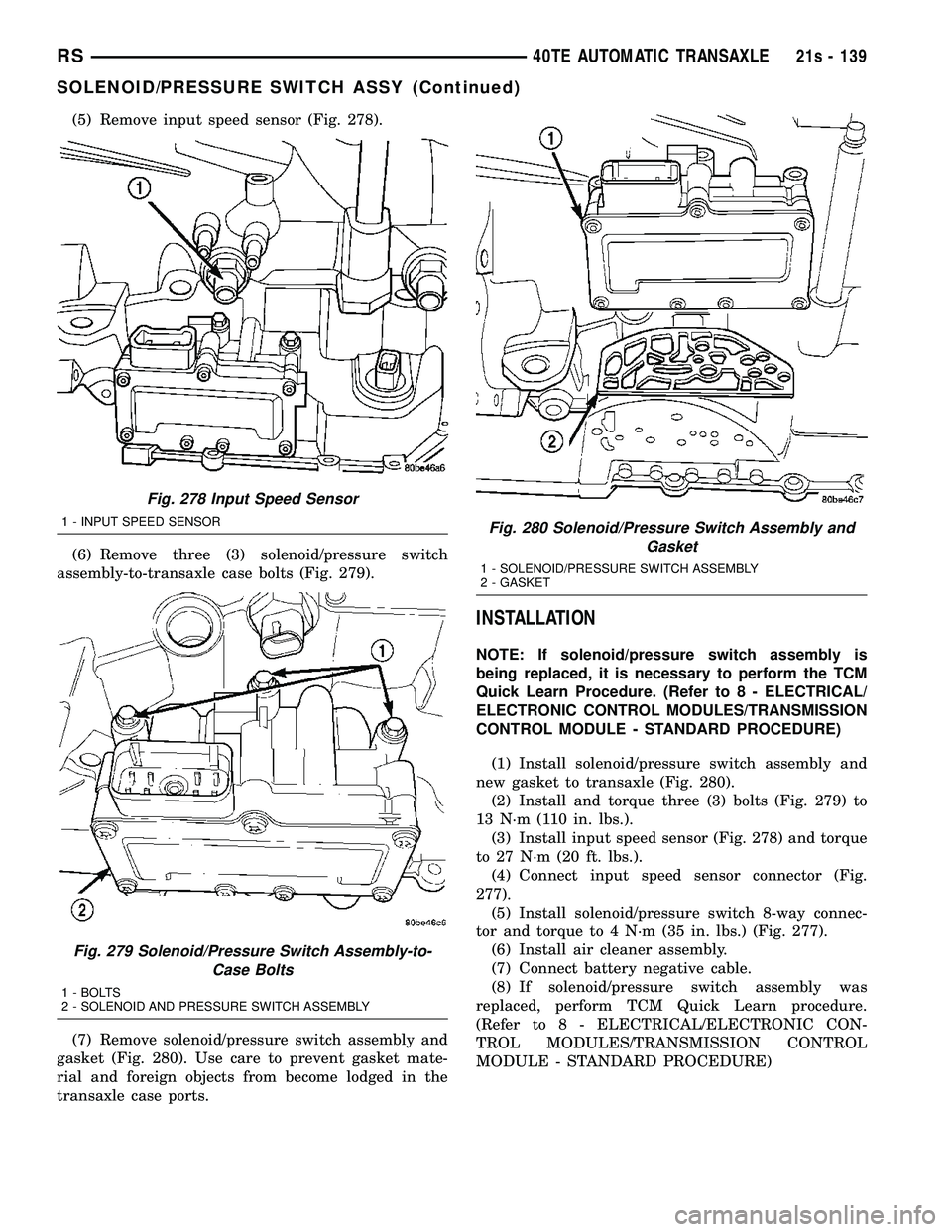

(5) Remove input speed sensor (Fig. 278).

(6) Remove three (3) solenoid/pressure switch

assembly-to-transaxle case bolts (Fig. 279).

(7) Remove solenoid/pressure switch assembly and

gasket (Fig. 280). Use care to prevent gasket mate-

rial and foreign objects from become lodged in the

transaxle case ports.

INSTALLATION

NOTE: If solenoid/pressure switch assembly is

being replaced, it is necessary to perform the TCM

Quick Learn Procedure. (Refer t o 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(1) Install solenoid/pressure switch assembly and

new gasket to transaxle (Fig. 280). (2) Install and torque three (3) bolts (Fig. 279) to

13 N´m (110 in. lbs.). (3) Install input speed sensor (Fig. 278) and torque

to 27 N´m (20 ft. lbs.). (4) Connect input speed sensor connector (Fig.

277). (5) Install solenoid/pressure switch 8-way connec-

tor and torque to 4 N´m (35 in. lbs.) (Fig. 277). (6) Install air cleaner assembly.

(7) Connect battery negative cable.

(8) If solenoid/pressure switch assembly was

replaced, perform TCM Quick Learn procedure.

(Refer t o 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

Fig. 278 Input Speed Sensor

1 - INPUT SPEED SENSOR

Fig. 279 Solenoid/Pressure Switch Assembly-to- Case Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 280 Solenoid/Pressure Switch Assembly and Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

RS 40TE AUTOMATIC TRANSAXLE21s - 139

SOLENOID/PRESSURE SWITCH ASSY (Continued)

Page 2001 of 2585

SPEED SENSOR - INPUT

DESCRIPTION

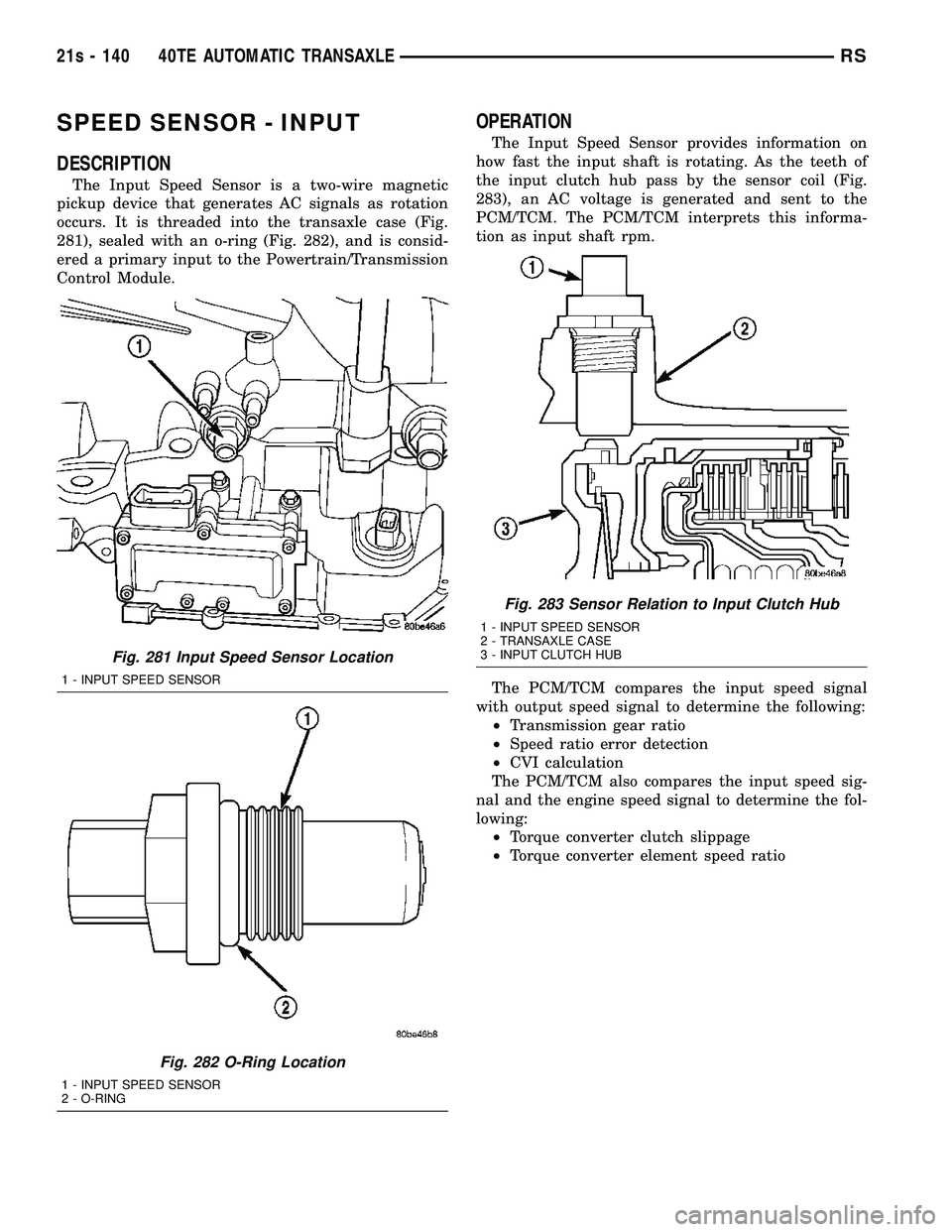

The Input Speed Sensor is a two-wire magnetic

pickup device that generates AC signals as rotation

occurs. It is threaded into the transaxle case (Fig.

281), sealed with an o-ring (Fig. 282), and is consid-

ered a primary input to the Powertrain/Transmission

Control Module.

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil (Fig.

283), an AC voltage is generated and sent to the

PCM/TCM. The PCM/TCM interprets this informa-

tion as input shaft rpm.

The PCM/TCM compares the input speed signal

with output speed signal to determine the following: ² Transmission gear ratio

² Speed ratio error detection

² CVI calculation

The PCM/TCM also compares the input speed sig-

nal and the engine speed signal to determine the fol-

lowing: ² Torque converter clutch slippage

² Torque converter element speed ratio

Fig. 281 Input Speed Sensor Location

1 - INPUT SPEED SENSOR

Fig. 282 O-Ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

Fig. 283 Sensor Relation to Input Clutch Hub

1 - INPUT SPEED SENSOR

2 - TRANSAXLE CASE

3 - INPUT CLUTCH HUB

21s - 140 40TE AUTOMATIC TRANSAXLERS

Page 2002 of 2585

REMOVAL

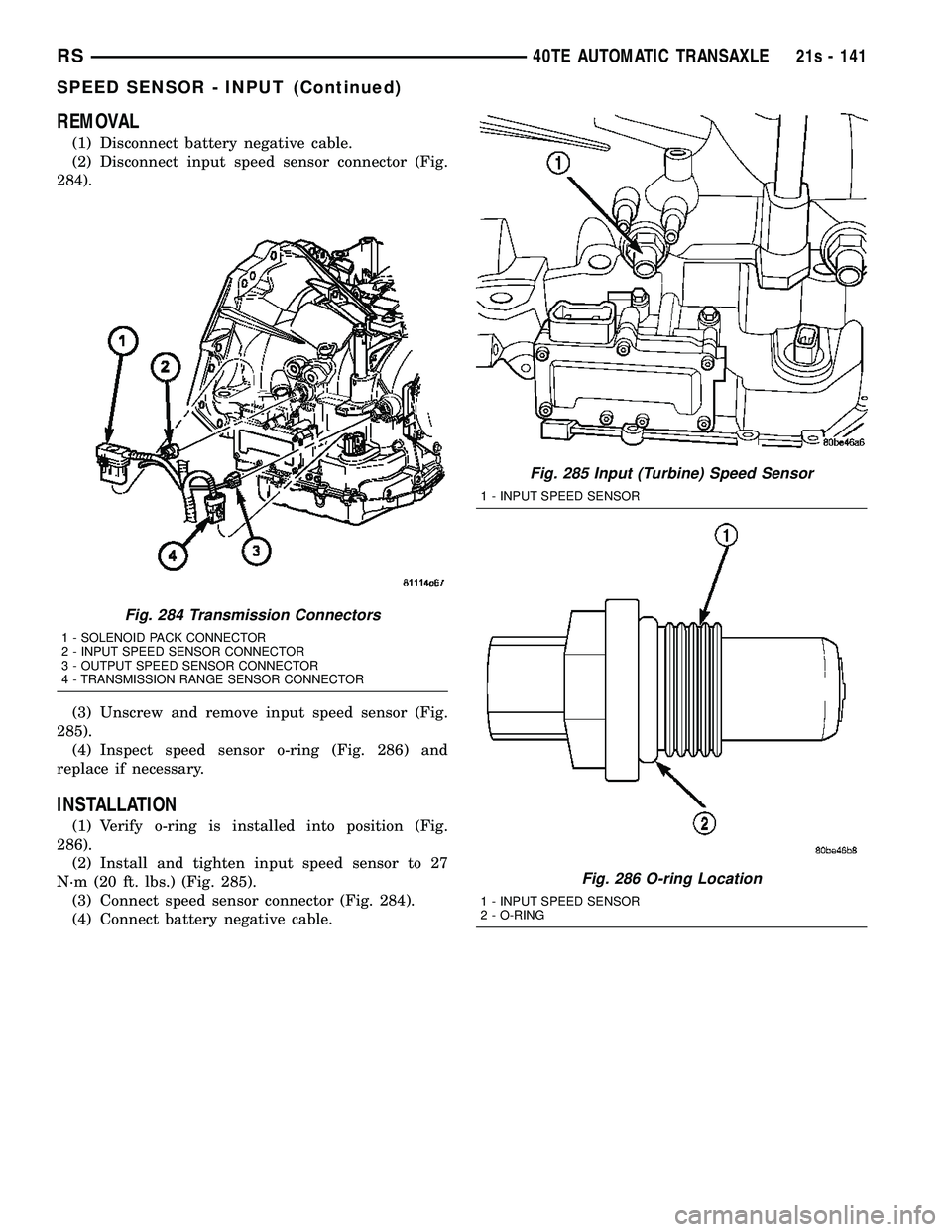

(1) Disconnect battery negative cable.

(2) Disconnect input speed sensor connector (Fig.

284).

(3) Unscrew and remove input speed sensor (Fig.

285). (4) Inspect speed sensor o-ring (Fig. 286) and

replace if necessary.

INSTALLATION

(1) Verify o-ring is installed into position (Fig.

286). (2) Install and tighten input speed sensor to 27

N´m (20 ft. lbs.) (Fig. 285). (3) Connect speed sensor connector (Fig. 284).

(4) Connect battery negative cable.

Fig. 284 Transmission Connectors

1 - SOLENOID PACK CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 285 Input (Turbine) Speed Sensor

1 - INPUT SPEED SENSOR

Fig. 286 O-ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

RS 40TE AUTOMATIC TRANSAXLE21s - 141

SPEED SENSOR - INPUT (Continued)

Page 2003 of 2585

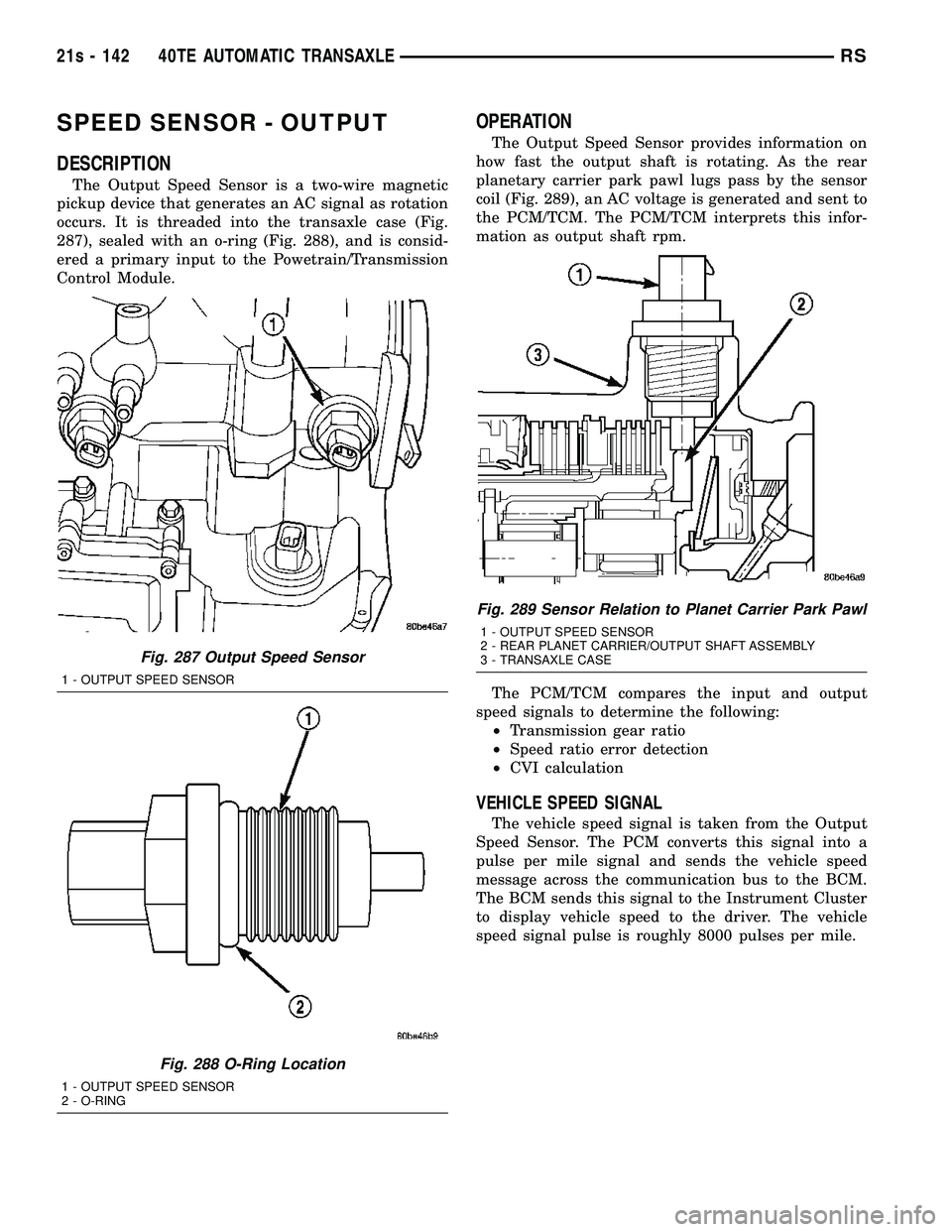

SPEED SENSOR - OUTPUT

DESCRIPTION

The Output Speed Sensor is a two-wire magnetic

pickup device that generates an AC signal as rotation

occurs. It is threaded into the transaxle case (Fig.

287), sealed with an o-ring (Fig. 288), and is consid-

ered a primary input to the Powetrain/Transmission

Control Module.

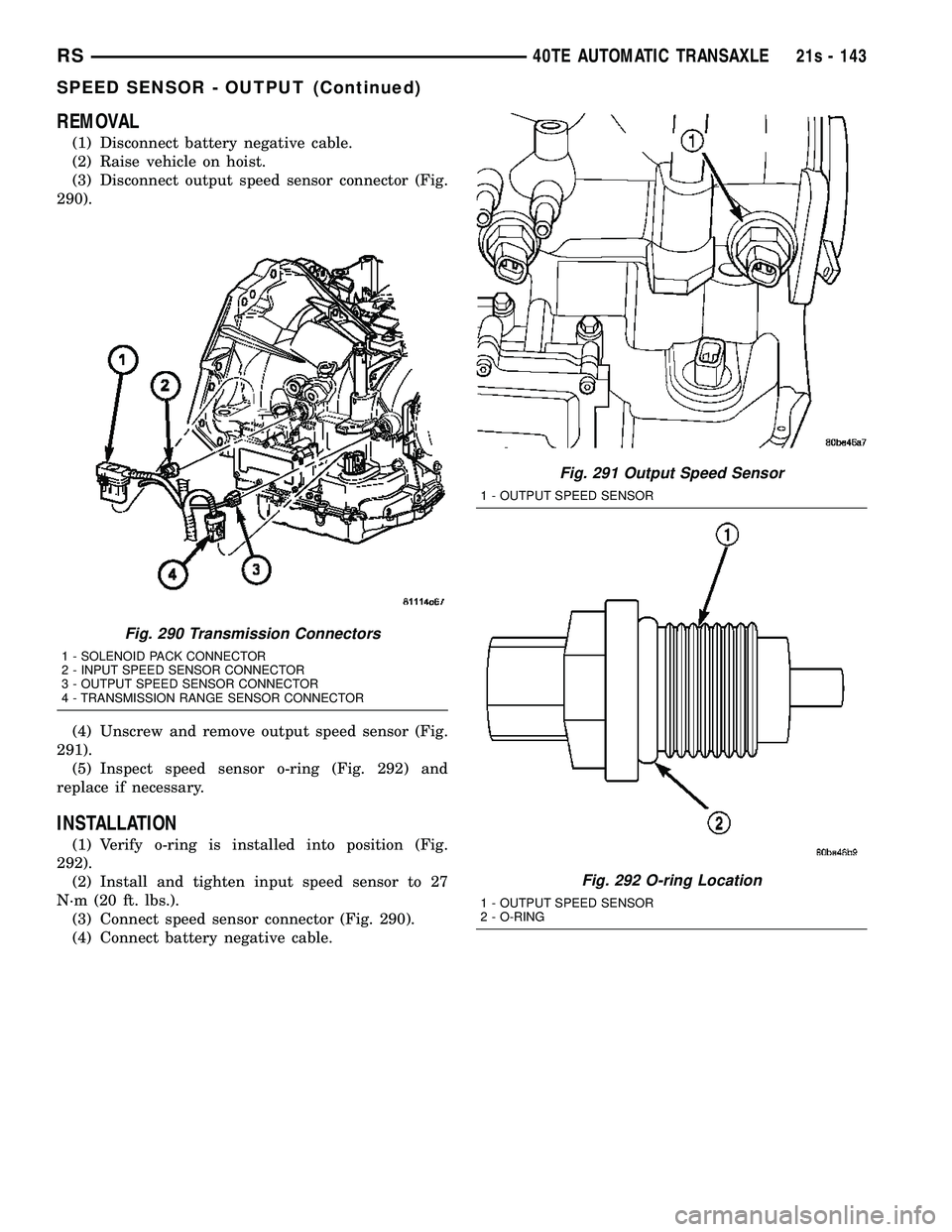

OPERATION

The Output Speed Sensor provides information on

how fast the output shaft is rotating. As the rear

planetary carrier park pawl lugs pass by the sensor

coil (Fig. 289), an AC voltage is generated and sent to

the PCM/TCM. The PCM/TCM interprets this infor-

mation as output shaft rpm.

The PCM/TCM compares the input and output

speed signals to determine the following: ² Transmission gear ratio

² Speed ratio error detection

² CVI calculation

VEHICLE SPEED SIGNAL

The vehicle speed signal is taken from the Output

Speed Sensor. The PCM converts this signal into a

pulse per mile signal and sends the vehicle speed

message across the communication bus to the BCM.

The BCM sends this signal to the Instrument Cluster

to display vehicle speed to the driver. The vehicle

speed signal pulse is roughly 8000 pulses per mile.

Fig. 287 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

Fig. 288 O-Ring Location

1 - OUTPUT SPEED SENSOR

2 - O-RING

Fig. 289 Sensor Relation to Planet Carrier Park Pawl

1 - OUTPUT SPEED SENSOR

2 - REAR PLANET CARRIER/OUTPUT SHAFT ASSEMBLY

3 - TRANSAXLE CASE

21s - 142 40TE AUTOMATIC TRANSAXLERS

Page 2004 of 2585

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3) Disconnect output speed sensor connector (Fig.

290).

(4) Unscrew and remove output speed sensor (Fig.

291). (5) Inspect speed sensor o-ring (Fig. 292) and

replace if necessary.

INSTALLATION

(1) Verify o-ring is installed into position (Fig.

292). (2) Install and tighten input speed sensor to 27

N´m (20 ft. lbs.). (3) Connect speed sensor connector (Fig. 290).

(4) Connect battery negative cable.

Fig. 290 Transmission Connectors

1 - SOLENOID PACK CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 291 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

Fig. 292 O-ring Location

1 - OUTPUT SPEED SENSOR

2 - O-RING

RS 40TE AUTOMATIC TRANSAXLE21s - 143

SPEED SENSOR - OUTPUT (Continued)

Page 2005 of 2585

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 293) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump. The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

Fig. 293 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

21s - 144 40TE AUTOMATIC TRANSAXLERS

Page 2006 of 2585

IMPELLER

The impeller (Fig. 294) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving member of the system.

Fig. 294 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION 5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

RS 40TE AUTOMATIC TRANSAXLE21s - 145

TORQUE CONVERTER (Continued)

Page 2009 of 2585

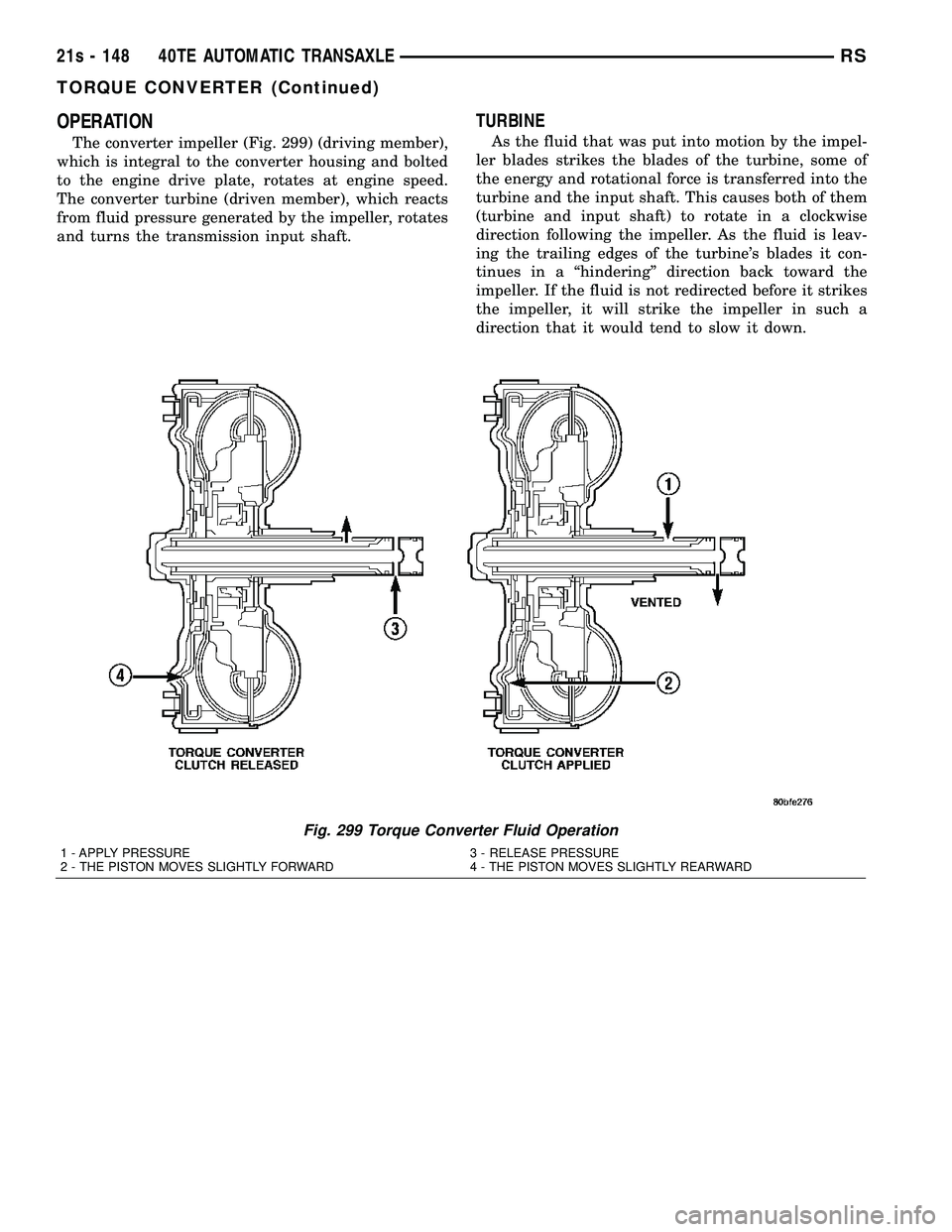

OPERATION

The converter impeller (Fig. 299) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

Fig. 299 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

21s - 148 40TE AUTOMATIC TRANSAXLERS

TORQUE CONVERTER (Continued)

Page 2010 of 2585

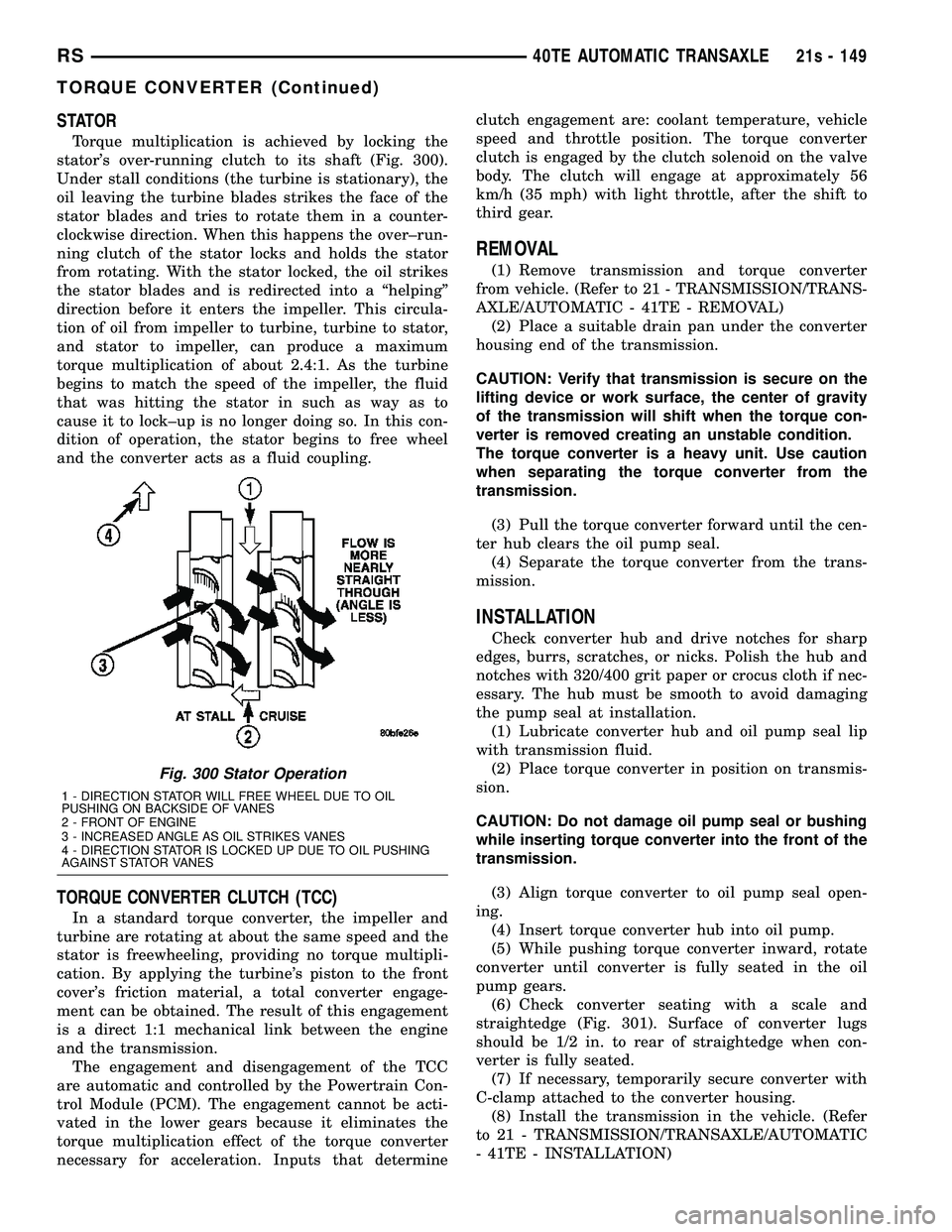

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 300).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the over±run-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock±up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and

turbine are rotating at about the same speed and the

stator is freewheeling, providing no torque multipli-

cation. By applying the turbine's piston to the front

cover's friction material, a total converter engage-

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission. The engagement and disengagement of the TCC

are automatic and controlled by the Powertrain Con-

trol Module (PCM). The engagement cannot be acti-

vated in the lower gears because it eliminates the

torque multiplication effect of the torque converter

necessary for acceleration. Inputs that determine clutch engagement are: coolant temperature, vehicle

speed and throttle position. The torque converter

clutch is engaged by the clutch solenoid on the valve

body. The clutch will engage at approximately 56

km/h (35 mph) with light throttle, after the shift to

third gear.

REMOVAL

(1) Remove transmission and torque converter

from vehicle. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE - REMOVAL) (2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal. (4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation. (1) Lubricate converter hub and oil pump seal lip

with transmission fluid. (2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3) Align torque converter to oil pump seal open-

ing. (4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears. (6) Check converter seating with a scale and

straightedge (Fig. 301). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated. (7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing. (8) Install the transmission in the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE - INSTALLATION)

Fig. 300 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

RS 40TE AUTOMATIC TRANSAXLE21s - 149

TORQUE CONVERTER (Continued)