LUG NUT CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1837 of 2339

INSTALLATION

(1) Place front riser into position on luggage rack

side rail.

(2) Install two fasteners into the riser.

(3) Repeat for the opposite side, if necessary.

LUGGAGE RACK CROSSBAR

REMOVAL

(1) Remove luggage rack front risers.

(2) Depress stanchion levers down until they click

into the unlock position. (Fig. 20). Work from side to

side sliding the crossbar assembly forward moving a

little at a time to ensure it remains perpendicular to

the side rails.

(3) Remove crossbar from vehicle.

Fig. 19 LUGGAGE RACK, CROSSBARS AND RISER COVER

1 - LUGGAGE RACK SIDE RAILS

2 - SCREWS

3 - CROSSBARS4 - FRONT RISER COVER

5 - RIV-NUTS

Fig. 20 LUGGAGE RACK CROSSBAR

1 - LUGGAGE RACK

2 - CROSSBAR

3 - SLIDE LOCK

4 - FRONT RISER COVER

5 - FRONT RISER

23 - 58 EXTERIORRS

LUGGAGE RACK RISER (Continued)

Page 1859 of 2339

(1) Slide lower seat belt cover rearward to expose

anchor fastener.

(2) Remove bolt/nut attaching lower seat belt

anchor to floor.

(3) Remove upper B-pillar trim cover.

(4) Remove access panel from B-pillar trim (Fig.

3).

(5) Disengage hidden clips attaching lower trim

cover to B-pillar.

(6) Remove lower B-pillar trim cover from vehicle.

INSTALLATION

NOTE: The driver's side a double ended stud is

used. A nut has to be removed for the seat belt

anchor removal and the stud for the retractor

removal.

NOTE: On the passenger side there is a belt tension

sensor.

(1) On the passenger side secure grommet to seat

belt sensor connector into bottom of B-pillar lower

trim prior to install B-pillar lower trim cover.(2) Place lower B-pillar trim cover in position on

vehicle (Fig. 3).

(3) Insert seat belt through hole in lower B-pillar

trim.

(4) Engage hidden clips attaching lower trim cover

to B-pillar.

(5) Install access cover.

(6) Install upper B-pillar trim cover.

(7) Place seat belt anchor in position on floor so

webbing is pointed rearward and slightly outboard.

(8) Install bolt/nut attaching lower seat belt

anchor to floor. Tighten seat belt anchor bolt/nut to

39 N´m (29 ft. lbs.) torque.

(9) Verify that seat belt anchor does not interfere

with seat track travel.

B-PILLAR UPPER TRIM

REMOVAL

(1) Remove bolt attaching lower seat belt anchor to

floor.

(2) Lower shoulder belt height adjuster to the bot-

tom of travel.

(3) Remove shoulder belt turning loop from height

adjuster.

(4) Use a Snap-ontTrim Pad Remover tool

(A179A), or equivalent, and remove shoulder belt

height adjuster knob.

(5) Remove shoulder belt bezel from trim cover

(Fig. 3).

(6) Remove screw attaching trim cover to B-pillar

from inside bezel cavity.

(7) Disengage hidden clips attaching trim cover to

B-pillar.

(8) Remove B-pillar trim cover from vehicle.

INSTALLATION

(1) Insert seat belt through B-pillar trim and web

guide (Fig. 3).

(2) Place B-pillar trim cover in position on vehicle.

(3) Engage hidden clips attaching trim cover to

B-pillar.

(4) Install shoulder belt bezel into trim cover.

(5) Install height adjuster knob.

(6) Install shoulder belt turning loop onto height

adjuster. Tighten bolt to 39 N´m (29 ft. lbs.) torque.

(7) Place seat anchor in position on floor so web-

bing is pointed rearward and slightly outboard or self

aligning tab on passenger side.

(8) Install bolt attaching lower seat belt anchor to

floor. Tighten seat belt bolt to 39 N´m (29 ft. lbs.)

torque.

Fig. 3 LOWER B-PILLAR TRIM COVER

1 - B-PILLAR UPPER TRIM

2 - B-PILLAR UPPER PLUG

3 - POWER SLIDING DOOR SWITCH AND BEZEL

4 - BELT ASSEMBLY

5 - B-PILLAR LOWER TRIM

23 - 80 INTERIORRS

B-PILLAR LOWER TRIM (Continued)

Page 1861 of 2339

CARPETS - FOLD-IN-FLOOR

REMOVAL

(1) Remove floor mats.

(2) Remove front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL)

(3) Remove instrument panel lower console. (Refer

to 23 - BODY/INSTRUMENT PANEL/STORAGE

BIN - REMOVAL).

(4) Remove the floor console base tray and discon-

nect wire connector from the base tray.(Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE BASE TRAY -

REMOVAL)

(5) Remove heel blocker (plastic block below accel-

erator pedal).

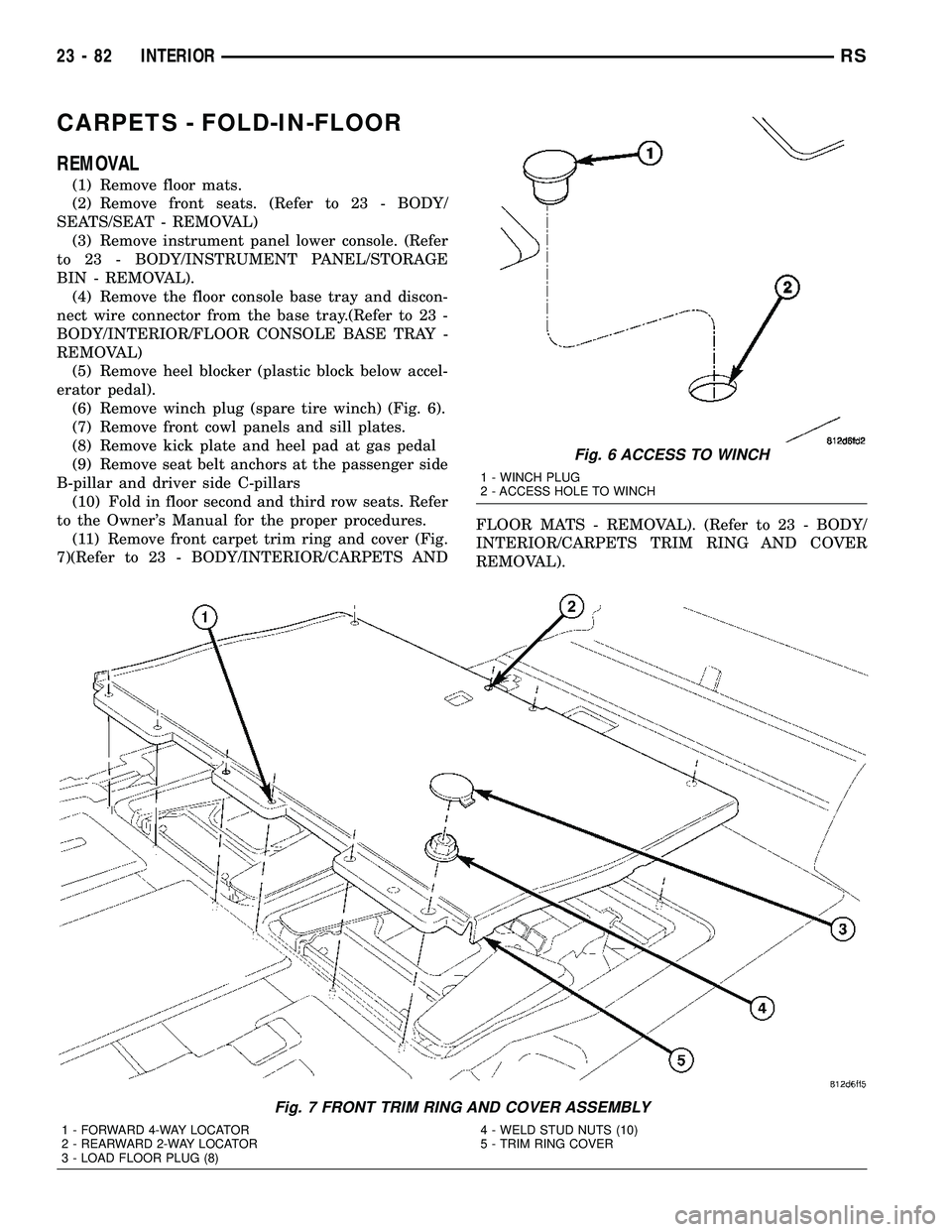

(6) Remove winch plug (spare tire winch) (Fig. 6).

(7) Remove front cowl panels and sill plates.

(8) Remove kick plate and heel pad at gas pedal

(9) Remove seat belt anchors at the passenger side

B-pillar and driver side C-pillars

(10) Fold in floor second and third row seats. Refer

to the Owner's Manual for the proper procedures.

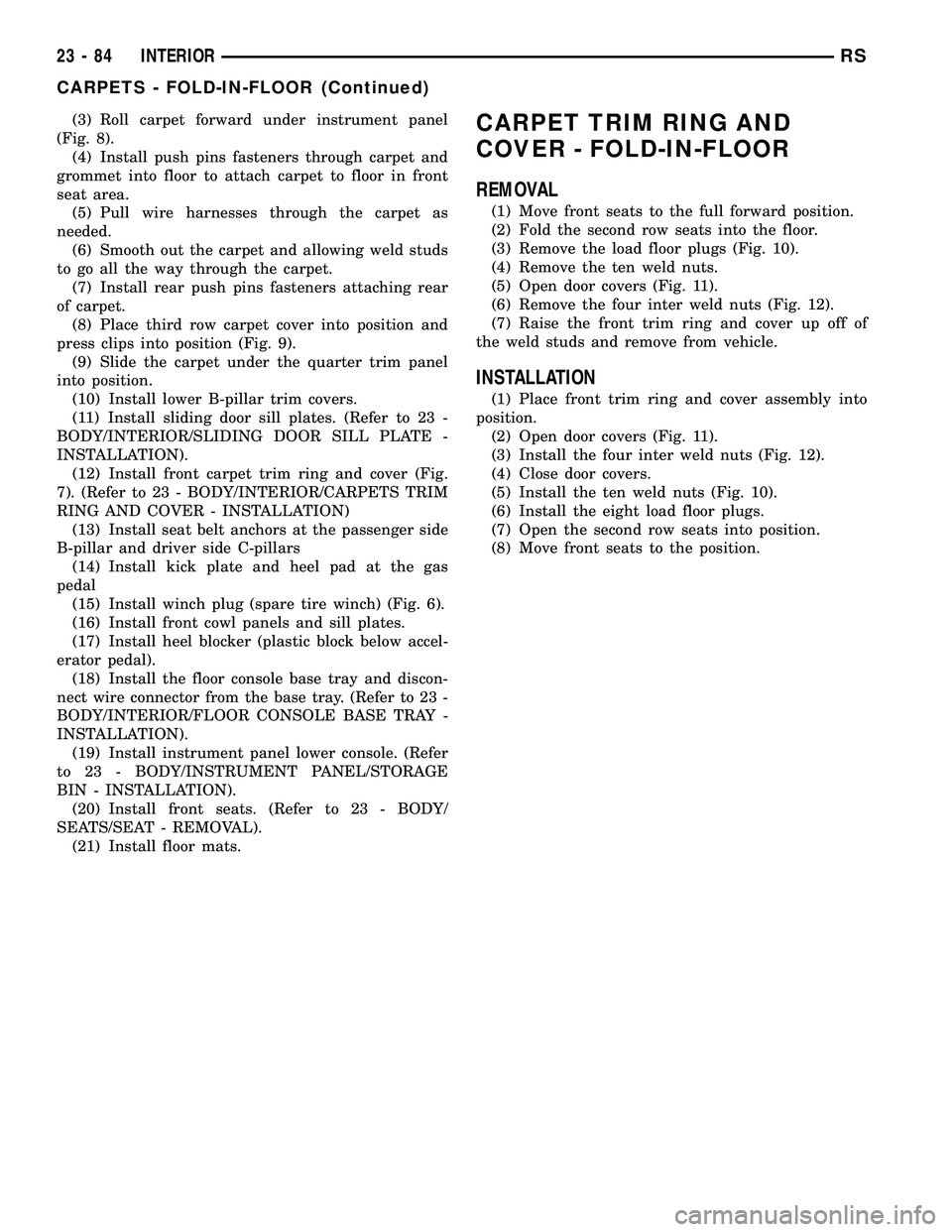

(11) Remove front carpet trim ring and cover (Fig.

7)(Refer to 23 - BODY/INTERIOR/CARPETS ANDFLOOR MATS - REMOVAL). (Refer to 23 - BODY/

INTERIOR/CARPETS TRIM RING AND COVER

REMOVAL).

Fig. 6 ACCESS TO WINCH

1 - WINCH PLUG

2 - ACCESS HOLE TO WINCH

Fig. 7 FRONT TRIM RING AND COVER ASSEMBLY

1 - FORWARD 4-WAY LOCATOR

2 - REARWARD 2-WAY LOCATOR

3 - LOAD FLOOR PLUG (8)4 - WELD STUD NUTS (10)

5 - TRIM RING COVER

23 - 82 INTERIORRS

Page 1863 of 2339

(3) Roll carpet forward under instrument panel

(Fig. 8).

(4) Install push pins fasteners through carpet and

grommet into floor to attach carpet to floor in front

seat area.

(5) Pull wire harnesses through the carpet as

needed.

(6) Smooth out the carpet and allowing weld studs

to go all the way through the carpet.

(7) Install rear push pins fasteners attaching rear

of carpet.

(8) Place third row carpet cover into position and

press clips into position (Fig. 9).

(9) Slide the carpet under the quarter trim panel

into position.

(10) Install lower B-pillar trim covers.

(11) Install sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION).

(12) Install front carpet trim ring and cover (Fig.

7). (Refer to 23 - BODY/INTERIOR/CARPETS TRIM

RING AND COVER - INSTALLATION)

(13) Install seat belt anchors at the passenger side

B-pillar and driver side C-pillars

(14) Install kick plate and heel pad at the gas

pedal

(15) Install winch plug (spare tire winch) (Fig. 6).

(16) Install front cowl panels and sill plates.

(17) Install heel blocker (plastic block below accel-

erator pedal).

(18) Install the floor console base tray and discon-

nect wire connector from the base tray. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE BASE TRAY -

INSTALLATION).

(19) Install instrument panel lower console. (Refer

to 23 - BODY/INSTRUMENT PANEL/STORAGE

BIN - INSTALLATION).

(20) Install front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL).

(21) Install floor mats.CARPET TRIM RING AND

COVER - FOLD-IN-FLOOR

REMOVAL

(1) Move front seats to the full forward position.

(2) Fold the second row seats into the floor.

(3) Remove the load floor plugs (Fig. 10).

(4) Remove the ten weld nuts.

(5) Open door covers (Fig. 11).

(6) Remove the four inter weld nuts (Fig. 12).

(7) Raise the front trim ring and cover up off of

the weld studs and remove from vehicle.

INSTALLATION

(1) Place front trim ring and cover assembly into

position.

(2) Open door covers (Fig. 11).

(3) Install the four inter weld nuts (Fig. 12).

(4) Close door covers.

(5) Install the ten weld nuts (Fig. 10).

(6) Install the eight load floor plugs.

(7) Open the second row seats into position.

(8) Move front seats to the position.

23 - 84 INTERIORRS

CARPETS - FOLD-IN-FLOOR (Continued)

Page 1864 of 2339

Fig. 10 FRONT TRIM RING AND COVER ASSEMBLY

1 - FORWARD 4-WAY LOCATOR

2 - REARWARD 2-WAY LOCATOR

3 - LOAD FLOOR PLUG (8)4 - WELD STUD NUTS (10)

5 - TRIM RING COVER

RSINTERIOR23-85

CARPET TRIM RING AND COVER - FOLD-IN-FLOOR (Continued)

Page 1888 of 2339

If any of the remaining OCS components of the

passenger side front seat cushion require replace-

ment, they are serviced only as a factory-calibrated,

assembled, and tamper-evident service replacement

package. This package includes the assembled frame,

springs, pad, bladder, sensor, foam, wiring and a cal-

ibrated OCM. When installing this package, always

replace all of the existing components with the new

components as a unit. Do not attempt to separate or

disconnect any of the new OCS components con-

tained in the service replacement package from each

other, and do not attempt to reuse any of the

replaced components in this or any other vehicle.

Once any of the original factory-installed compo-

nents except the OCM have been replaced with the

service replacement package components, the OCM

can only be serviced by replacing the entire passen-

ger side front seat cushion unit with another com-

plete service replacement package. (Refer to 23 -

BODY/SEATS/SEAT CUSHION - FRONT -

REMOVAL).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECTANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) Remove access winch cover (spare tire) plug

(Fig. 14).

(2) Lower spare tire approximately 18 inches

before raising vehicle to access the nuts.

(3) From under vehicle, remove nuts attaching

front seat risers to the floor.

(4) Lower vehicle.

(5) Remove seat and riser from floor (Fig. 15).

(6) Tip seat rearward and disconnect wire connec-

tors from body harness, if equipped.

(7) Remove seat from vehicle.

Fig. 14 ACCESS TO WINCH

1 - WINCH PLUG

2 - ACCESS HOLE TO WINCH

RSSEATS23 - 109

FRONT SEAT (Continued)

Page 1889 of 2339

INSTALLATION

A non-calibrated Occupant Classification Module

(OCM) is the only component of the Occupant Clas-

sification System (OCS) that is available for separate

service replacement, as outlined in the procedures

that follow. The OCS components of the passenger

side front seat cushion including the cushion frame,

springs, pad, occupant detection bladder, pressure

sensor, seat cushion foam and the OCM are a factory-

calibrated and assembled unit. Once this unit is con-

nected to a vehicle electrically, the calibration

settings are uploaded from the OCM and stored in

the memory of the Airbag Control Module (ACM). If

only the OCM is subsequently replaced, the new,

non-calibrated OCM learns the proper calibration

settings from the ACM after it is connected to the

vehicle electrically.

If any of the remaining OCS components of the

passenger side front seat cushion require replace-

ment, they are serviced only as a factory-calibrated,

assembled, and tamper-evident service replacement

package. This package includes the assembled frame,

springs, pad, bladder, sensor, foam, wiring and a cal-

ibrated OCM. When installing this package, always

replace all of the existing components with the new

components as a unit. Do not attempt to separate or

disconnect any of the new OCS components con-

tained in the service replacement package from each

other, and do not attempt to reuse any of the

replaced components in this or any other vehicle.

Once any of the original factory-installed compo-

nents except the OCM have been replaced with the

service replacement package components, the OCM

can only be serviced by replacing the entire passen-

ger side front seat cushion unit with another com-plete service replacement package. (Refer to 23 -

BODY/SEATS/SEAT CUSHION - FRONT -

REMOVAL).

WARNING: TO AVOID PERSONAL INJURY OR DEATH,

ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE

THE SUPPLEMENTAL RESTRAINT SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, AIRBAG, OCCUPANT CLASSIFICATION

SYSTEM, SEAT BELT TENSIONER, IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER DIAG-

NOSIS OR SERVICE. THIS IS THE ONLY SURE WAY

TO DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM. FAILURE TO TAKE THE PROPER PRECAU-

TIONS COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) Place seat into position (Fig. 15).

(2) Tip seat rearward and connect wire connectors

to body harness, if equipped.

(3) Place seat riser studs into openings in the floor.

(4) From under vehicle, install nuts attaching

front seat risers to the floor. Tighten nuts to 88 N´m

(65 ft. lbs.) torque.

(5) Crank winch to raise spare tire into position,

and install winch plug (Fig. 14).

Fig. 15 FRONT SEAT

1 - FRONT SEAT

2 - CONNECTORS

3 - B-PILLAR

23 - 110 SEATSRS

FRONT SEAT (Continued)

Page 1891 of 2339

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) Place seat back into position.

(2) Install both pivot bolts attaching seat back

frame to seat track (Fig. 16). Tighten bolts to 48 N´m

(35 ft. lbs.) torque.

(3) Install nut attaching the recliner to the seat

back frame. Tighten nut to 12 N´m (105 in. lbs.)

torque.

(4) Install both seat cushion side covers. (Refer to

23 - BODY/SEATS/FRONT SEAT CUSHION SIDE

COVER - INSTALLATION).

(5) Install the lumbar adjustment lever.

(6) Install the seat back recliner lever.

(7) Install the armrest. (Refer to 23 - BODY/

SEATS/ARMREST - INSTALLATION).

(8) Install headrest sleeves. (Refer to 23 - BODY/

SEATS/HEADREST SLEEVE - INSTALLATION).

FRONT SEAT BACK ASSIST

STRAP

REMOVAL

(1) Using a small screw driver, pry screw plugs

from ends of assist strap (Fig. 17).

(2) Remove screws attaching assist strap to seat

back.

(3) Remove assist strap from vehicle.

INSTALLATION

(1) Place assist strap in position on vehicle.(2) Install screws attaching assist strap to seat

back. Tighten screws to 7.0 N´m (60 in. lbs.).

(3) Insert screw plugs into ends of assist strap

(Fig. 17).

FRONT SEAT BACK PANEL

REMOVAL

(1) Remove the screws (Fig. 18).

(2) Tip the top of the panel away from the seat

back and lift off the hooks at the bottom to remove.

Fig. 17 FRONT SEAT BACK ASSIST STRAP

1 - ASSIST STRAP

2 - SCREW PLUG

3 - SEAT BACK

Fig. 18 FRONT SEAT BACK PANEL - TYPICAL

1 - SCREWS

2 - SEAT BACK PANEL

3 - SEAT BACK

23 - 112 SEATSRS

FRONT SEAT BACK (Continued)

Page 2161 of 2339

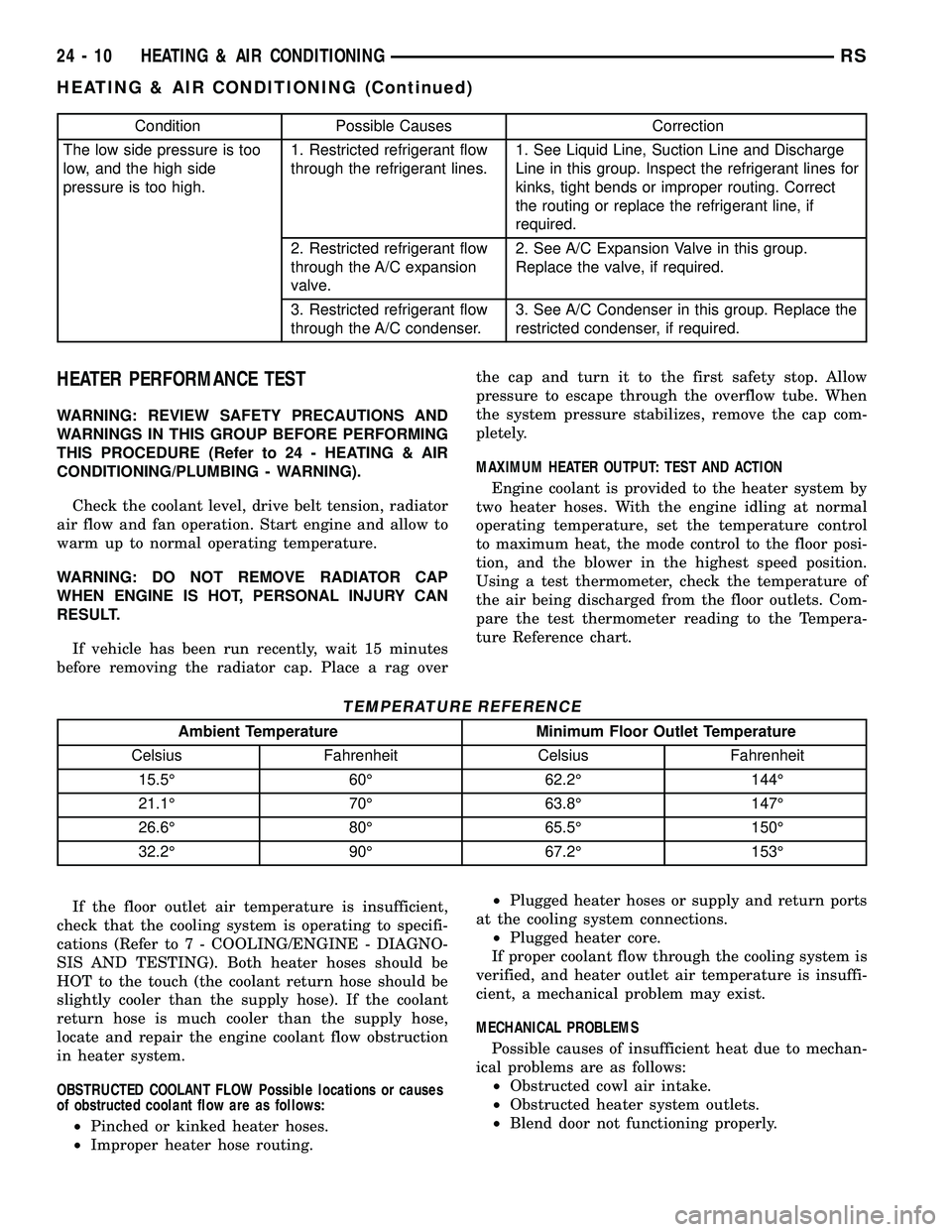

Condition Possible Causes Correction

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid Line, Suction Line and Discharge

Line in this group. Inspect the refrigerant lines for

kinks, tight bends or improper routing. Correct

the routing or replace the refrigerant line, if

required.

2. Restricted refrigerant flow

through the A/C expansion

valve.2. See A/C Expansion Valve in this group.

Replace the valve, if required.

3. Restricted refrigerant flow

through the A/C condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

HEATER PERFORMANCE TEST

WARNING: REVIEW SAFETY PRECAUTIONS AND

WARNINGS IN THIS GROUP BEFORE PERFORMING

THIS PROCEDURE (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING).

Check the coolant level, drive belt tension, radiator

air flow and fan operation. Start engine and allow to

warm up to normal operating temperature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing the radiator cap. Place a rag overthe cap and turn it to the first safety stop. Allow

pressure to escape through the overflow tube. When

the system pressure stabilizes, remove the cap com-

pletely.

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two heater hoses. With the engine idling at normal

operating temperature, set the temperature control

to maximum heat, the mode control to the floor posi-

tion, and the blower in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged from the floor outlets. Com-

pare the test thermometer reading to the Tempera-

ture Reference chart.

TEMPERATURE REFERENCE

Ambient Temperature Minimum Floor Outlet Temperature

Celsius Fahrenheit Celsius Fahrenheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

If the floor outlet air temperature is insufficient,

check that the cooling system is operating to specifi-

cations (Refer to 7 - COOLING/ENGINE - DIAGNO-

SIS AND TESTING). Both heater hoses should be

HOT to the touch (the coolant return hose should be

slightly cooler than the supply hose). If the coolant

return hose is much cooler than the supply hose,

locate and repair the engine coolant flow obstruction

in heater system.

OBSTRUCTED COOLANT FLOW Possible locations or causes

of obstructed coolant flow are as follows:

²Pinched or kinked heater hoses.

²Improper heater hose routing.²Plugged heater hoses or supply and return ports

at the cooling system connections.

²Plugged heater core.

If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is insuffi-

cient, a mechanical problem may exist.

MECHANICAL PROBLEMS

Possible causes of insufficient heat due to mechan-

ical problems are as follows:

²Obstructed cowl air intake.

²Obstructed heater system outlets.

²Blend door not functioning properly.

24 - 10 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

Page 2211 of 2339

(3) Remove the three screws that secure the rear

blower motor to the outboard side of the rear HVAC

housing (Fig. 4).

(4) Remove the rear blower motor from the rear

HVAC housing.

INSTALLATION

(1) Position the rear blower motor into the rear

HVAC housing.

(2) Install the three screws that secure the blower

motor to the rear HVAC housing. Tighten the screws

to 2 N´m (17 in. lbs.).

(3) Reconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control system

, the blower pigtail wire is connected to a take out

and connector of the rear HVAC wire harness. With

the Automatic Temperature Control system, the

blower pigtail wire is connected to a receptacle on

the blower motor power module.(4) Install the rear HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - INSTALLATION).

HVAC HOUSING

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(3) Disconnect and isolate the negative battery

cable.

(4) Raise and support the vehicle.

(5) Remove the nut that secures the underbody

refrigerant line sealing plate to the rear evaporator

extension line tapping plate that extends through the

rear floor panel behind the right rear wheel housing

(Fig. 5) and (Fig. 6).

(6) Disconnect the underbody refrigerant lines

from the rear evaporator extension line tapping plate

and remove and discard the O-ring seals.

(7) Install plugs in, or tape over the opened under-

body refrigerant line fittings and the evaporator

extension line sealing plate ports.

(8) Remove the nuts from the mounting studs that

secure the rear HVAC housing to the rear floor panel

behind the right rear wheel housing (Fig. 7).

(9) Lower the vehicle.

(10) Remove the right quarter trim panel and

right D-pillar trim panel from the quarter inner

panel (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - REMOVAL).

(11) Remove the rear distribution duct from the

rear HVAC housing and the rear roof duct (Refer to

24 - HEATING & AIR CONDITIONING/DISTRIBU-

TION/AIR OUTLETS - REMOVAL).

(12) Disconnect the body wire harness connector

for the rear HVAC housing from the rear HVAC wire

harness connector located near the expansion valve

at the back of the housing.

Fig. 4 Rear Blower Motor

1 - REAR HVAC HOUSING

2 - REAR BLOWER MOTOR

3 - SCREW (3)

4 - BLOWER MOTOR PIGTAIL WIRE

24 - 60 DISTRIBUTION - REARRS

BLOWER MOTOR (Continued)