clock CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 979 of 2339

ATC REMOTE SENSOR (ATC)-4WAY

CAV CIRCUIT FUNCTION

1 F600 20LB/PK PROTECTED IGNITION

2 D40 20WT/LB KDB NO. 2 CLOCK

3 C905 20BR/LB SENSOR RETURN

4 D18 20WT/YL KDB NO. 2 DATA

AUTO TEMP CONTROL C1 - NATURAL 13 WAY

CAV CIRCUIT FUNCTION

1 C161 22LB/WT DRIVER BLEND DOOR DRIVER (B)

2 C61 22DB/LG DRIVER BLEND DOOR DRIVER (A)

3 C133 22DB/WT PASSENGER BLEND DOOR DRIVER (B)

4 C33 22LB/BR PASSENGER BLEND DOOR DRIVER (A)

5 C132 22DB/YL RECIRCULATION DOOR DRIVER (B)

6 C32 22DB/TN RECIRCULATION DOOR DRIVER (A)

7 C135 22DB/GY MODE DOOR DRIVER (B)

8 C35 22LB/LG MODE DOOR DRIVER (A)

9 C53 22LB REAR MODE DOOR DRIVER (A)

10 C154 22LB/OR REAR MODE DOOR DRIVER (B)

11 C54 22LB/YL REAR BLEND DOOR DRIVER (A)

12 C169 22DB/OR REAR BLEND DOOR DRIVER (B)

13 - -

AUTO TEMP CONTROL C2 - BLACK 13 WAY

CAV CIRCUIT FUNCTION

1 C21 22LB EVAPORATOR TEMPERATURE SENSOR SIGNAL

2 C121 20DB/DG (LHD) SENSOR GROUND

2 C121 22DB/DG (RHD) SENSOR GROUND

3 E12 20OR/GY PANEL LAMPS DRIVER

4 A114 18GY/RD FUSED B(+) (I.O.D.)

5 F504 20GY/PK FUSED IGNITION SWITCH OUTPUT (RUN)

6 D25 20WT/VT PCI BUS

7 C56 22DB/VT (LHD) BLOWER MOTOR CONTROL

7 C56 22DB/LB (RHD) BLOWER MOTOR CONTROL

8 C59 22DB/LB REAR BLOWER MOTOR CONTROL

9 D22 20WT/TN (3 ZONE) KDB CLOCK

10 D17 22WT/DG KDB DATA

11 Z24 18BK/OR GROUND

12 - -

13 - -

8W - 80 - 10 8W-80 CONNECTOR PIN-OUTSRS

Page 980 of 2339

AUTO TEMP CONTROL C3-4WAY

CAV CIRCUIT FUNCTION

1 F600 20LB/PK PROTECTED IGNITION

2 D40 20WT/LB KDB NO. 2 CLOCK

3 C905 20BR/LB SENSOR RETURN

4 D18 20WT/YL KDB NO. 2 DATA

BACK-UP LAMP SWITCH (MTX) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 T2 18DG/WT TRS REVERSE SENSE

2 Z252 18BK/WT GROUND

BATTERY TEMPERATURE SENSOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 K25 20BR/TN (DIESEL) BATTERY TEMPERATURE SENSOR SIGNAL

1 K91 18DB/YL (GAS) BATTERY TEMP SIGNAL

2 K900 20DB/DG (DIESEL) SENSOR GROUND

2 K900 18DB/DG (GAS) SENSOR GROUND

BELT TENSION SENSOR (OCCUPANT SENSING) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 R86 20LG/LB BELT TENSION SENSOR FEED

2 R986 20LG/BR BELT TENSION SENSOR GROUND

3 D105 20WT/OR BELT TENSION SENSOR SIGNAL

RS8W-80 CONNECTOR PIN-OUTS8W-80-11

Page 1023 of 2339

CAMSHAFT POSITION SENSOR (GAS) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 F855 20PK/YL (2.4L) 5 VOLT SUPPLY

1 F855 18PK/YL (3.3L/3.8L) 5 VOLT SUPPLY

2 K900 20DB/DG SENSOR GROUND

3 K44 18DB/GY CMP SIGNAL

CD CHANGER-8WAY

CAV CIRCUIT FUNCTION

1 X40 22GY/WT (EXCEPT EXPORT) AUDIO OUT RIGHT

1 X40 20GY/WT (EXPORT) AUDIO OUT RIGHT

2 E14 22OR/TN (EXCEPT EXPORT) PANEL LAMPS DRIVER

2 E14 18OR/TN (EXPORT) PANEL LAMPS DRIVER

3 D25 20WT/VT (EXCEPT EXPORT) PCI BUS

3 D25 20VT/YL (EXPORT) PCI BUS

4 X112 20DG/GY (EXCEPT EXPORT) IGNITION SWITCH SIGNAL

4 X112 20RD (EXPORT) IGNITION SWITCH SIGNAL

5 X41 22DG/WT (EXCEPT EXPORT) AUDIO OUT LEFT

5 X41 20DG/WT (EXPORT) AUDIO OUT LEFT

6 X140 22GY/OR (EXCEPT EXPORT) COMMON AUDIO

6 Z140 18BK/OR (EXPORT) GROUND

7 Z141 20BK/TN (EXCEPT EXPORT) GROUND

7 Z141 18BK/TN (EXPORT) GROUND

8 X160 20GY/YL FUSED B(+)

CENTER HIGH MOUNTED STOP LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z350 20BK/TN GROUND

2 L50 18WT/TN (DIESEL) PRIMARY BRAKE SWITCH SIGNAL

2 L50 18WT/TN (GAS) BRAKE LAMP SWITCH OUTPUT

CLOCKSPRING C1 - WHITE 6 WAY

CAV CIRCUIT FUNCTION

1 X920 22GY/OR (REMOTE AUDIO) RADIO CONTROL MUX RETURN

2 X20 22GY/WT (REMOTE AUDIO) RADIO CONTROL MUX

3 X3 22DG/VT HORN SWITCH SENSE

4 V37 22VT SPEED CONTROL SWITCH SIGNAL

5 K900 20DB/DG SENSOR GROUND

6- -

8W - 80 - 54 8W-80 CONNECTOR PIN-OUTSRS

Page 1024 of 2339

CLOCKSPRING C2 - YELLOW 4 WAY

CAV CIRCUIT FUNCTION

1 R61 20LG/VT (EXCEPT EXPORT) DRIVER SQUIB 2 LINE 2

1 R61 20LB/VT (EXPORT) DRIVER SQUIB 2 LINE 2

2 R63 20LG/WT DRIVER SQUIB 2 LINE 1

3 R43 20LG/BR DRIVER SQUIB 1 LINE 2

4 R45 20LG/OR DRIVER SQUIB 1 LINE 1

CLOCKSPRING C3 - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1- -

2 Z23 20BK/VT LEFT SPEED CONTROL SWITCH GROUND

2 Z23 20BK/VT RIGHT SPEED CONTROL SWITCH GROUND

3 V37 20VT (DIESEL) SPEED CONTROL SWITCH SIGNAL

3 V37 20VT (DIESEL) SPEED CONTROL SWITCH SIGNAL

3 V37 20VT (GAS) S/C SWITCH NO. 1 SIGNAL

3 V37 20VT (GAS) S/C SWITCH NO. 1 SIGNAL

4 X3 20DG/VT HORN SWITCH SENSE

CLOCKSPRING C4 (REMOTE AUDIO)-2WAY

CAV CIRCUIT FUNCTION

1 X10 20RD/DB RADIO CONTROL MUX

2 X20 20RD/BK RADIO CONTROL MUX RETURN

CLUTCH PEDAL INTERLOCK SWITCH (MTX) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 T141 20YL/OR FUSED IGNITION SWITCH OUTPUT (START)

2 T751 20YL (DIESEL) FUSED IGNITION SWITCH OUTPUT (START)

2 Z429 20BK/OR (GAS) GROUND

RS8W-80 CONNECTOR PIN-OUTS8W-80-55

Page 1093 of 2339

REAR A/C-HEATER UNIT (3 ZONE MTC) - LT. GREEN 10 WAY

CAV CIRCUIT FUNCTION

1 C53 20LB REAR MODE DOOR DRIVER

2 C154 20LB/OR REAR COMMON DOOR DRIVER

3 C51 12LB/BR FUSED REAR BLOWER MOTOR RELAY OUTPUT

4 C152 16LB/LG REAR BLOWER MOTOR MED

5 C151 18LB/DG REAR BLOWER MOTOR LOW

6 C153 12DB/BR REAR BLOWER MOTOR HIGH

7 C54 20LB/YL REAR BLEND DOOR DRIVER

8 C154 20LB/OR REAR COMMON DOOR DRIVER

9- -

10 - -

REAR AUTO TEMP CONTROL SWITCH (3 ZONE ATC) - BLACK 13 WAY

CAV CIRCUIT FUNCTION

1 F504 20GY/PK FUSED IGNITION SWITCH OUTPUT (RUN)

2 Z27 18BK/DG GROUND

3 D22 22WT/TN KDB CLOCK

4 D17 22WT/DG KDB DATA

5 E10 20OR/DG PANEL LAMPS DRIVER

6- -

7- -

8- -

9- -

10 - -

11 - -

12 - -

13 - -

REAR BLOWER FRONT CONTROL SWITCH (3 ZONE MTC) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1- -

2 Z440 12BK/DG GROUND

3- -

4 C153 12DB/BR REAR BLOWER MOTOR HIGH

5- -

6 C152 16LB/LG REAR BLOWER MOTOR MED

7 C151 18LB/DG REAR BLOWER MOTOR LOW

8 C50 12DB/OR REAR BLOWER FRONT CONTROL FEED

8W - 80 - 124 8W-80 CONNECTOR PIN-OUTSRS

Page 1116 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

C317 (Power Sliding Door) BK Right Sliding Door 32, 45

C318 (Trailer Tow) BK Left Quarter N/S

C319 (Trailer Tow)

C320 DKGY Driver Power Seat on Seat Harness N/S

C321 DKGY Under Passenger Seat N/S

C322 (Memory) BK On Seat Harness to Body 32

C324 (Manual Sliding Door) BK Left Sliding Door N/S

C325 (Manual Sliding Door) BK Right Sliding Door 32

C328 (Sunroof) Left Quarter Panel 47

C329 (Diesel) BK Near Fuel Tank N/S

C330 (Diesel) LTGY Near Throttle Body 15, 16

C331 (Diesel) BK Left Rear Engine Compartment N/S

C332 (3 Zone ATC) BK/LTGN Near T/O for Right Rear Lamp

Assembly48

C333 (Except Export DKGY Left Side Instrument Panel 21

C334 BK Right Quarter Panel 48

C335 LTGY Near Fuel Tank 34

Cabin Heater Assist C1 (Diesel) BK Top of Engine N/S

Cabin Heater Assist C2 (Diesel) BK Top of Engine N/S

Camshaft Position Sensor (Gas) BK Rear of Cylinder Head

Right Side of Engine11 , 1 7

Camshaft Position Sensor

(Diesel)BK Rear of Cylinder Head 15, 16

CD Changer Behind CD Changer N/S

Center High Mounted Stop Lamp BK At Lamp 49

Clockspring - C1 WT Steering Column 20, 21, 22, 23, 31

Clockspring - C2 YL Steering Column 20, 21, 22, 23, 31

Clockspring - C3 BK Steering Column N/S

Clockspring - C4 Steering Column N/S

Clutch Pedal Interlock Switch

(MTX)BK At Switch/Driver Side 42

Clutch Pedal Upstop Switch

(Diesel)RD At Switch/Driver Side 42

Controller Anti-Lock Brake BK Right Side of Engine Compartment 11, 16, 17, 18

Crank Case Ventilation Heater

(Diesel)BK Top of Cylinder Head 15

Crankshaft Position Sensor

(Diesel)BK Rear of Engine 16

Crankshaft Position Sensor (Gas) BK Rear of Engine 13, 17

Data Link Connector BK Lower Instrument Panel Near

Steering Column41, 42

Dosing Pump (Diesel) BK Top of Engine N/S

Driver Airbag Squib1 BN/YL Steering Column N/S

Driver Airbag Squib2 BK/YL Steering Column N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1175 of 2339

The IPM provides the primary means of voltage dis-

tribution and protection for the entire vehicle.

OPERATION

All of the current from the battery and the gener-

ator output enters the Integrated Power Module

(IPM) through a four- pin connector on the bottom of

the module. Internal connections of all of the power

distribution center circuits is accomplished by a com-

bination of bus bars and a printed circuit board.

REMOVAL

(1) Disconnect the negative and positive battery

cables.

(2) Remove the battery thermal guard.

(3) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(4) Using a flat-bladed screwdriver, twist the Inte-

grated Power Module (IPM) bracket retaining latch

outward to free the IPM from its mounting bracket

(Fig. 2).

(5) Rotate the IPM counter-clockwise to access and

disconnect the electrical connectors (Fig. 3).

(6) Remove the IPM bracket clips from the hinge.

INSTALLATION

(1) Snap the left side of the Integrated Power Mod-

ule (IPM) housing in its mounting bracket and con-

nect the various electrical connectors.NOTE: Ensure that the Connector Positive Assur-

ance (CPA) on the five-pin B+ connector is posi-

tively engaged to prevent generating a Diagnostic

Trouble Code (DTC).

(2) Rotate the IPM clock-wise until secured in

mounting bracket. An audible click may be heard.

(3) Install the battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - INSTALLATION).

(4) Install the battery thermal guard.

Fig. 1 INTEGRATED POWER MODULE

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

Fig. 2 INTEGRATED POWER MODULE

Fig. 3 DISCONNECTING IPM

1 - INTEGRATED POWER MODULE

8W - 97 - 2 8W-97 POWER DISTRIBUTION SYSTEMRS

INTEGRATED POWER MODULE (Continued)

Page 1176 of 2339

(5) Connect the negative and positive battery

cables.

(6) Using a scan tool, check for any stored diagnos-

tic trouble codes. Ensure that all vehicle options are

operational.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed from its normal

cavity in the Integrated Power Module (IPM) when

the vehicle is shipped from the factory. Dealer per-

sonnel are to remove the IOD fuse from the storage

location and install it into the IPM fuse cavity

marked IOD as part of the preparation procedures

performed just prior to new vehicle delivery.

The IOD fuse is a 20 ampere blade-type mini fuse

and, when removed, it is stored in a fuse cavity adja-

cent to the washer fuse within the IPM.

OPERATION

The term ignition-off draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position.

The IOD fuse feeds the memory and sleep mode func-

tions for some of the electronic modules in the vehicle

as well as various other accessories that require bat-

tery current when the ignition switch is in the Off

position, including the clock. The only reason the

IOD fuse is removed is to reduce the normal IOD of

the vehicle electrical system during new vehicle

transportation and pre-delivery storage to reduce

battery depletion, while still allowing vehicle opera-

tion so that the vehicle can be loaded, unloaded and

moved as needed by both vehicle transportation com-

pany and dealer personnel.

The IOD fuse is removed from the Integrated

Power Module (IPM) fuse cavity when the vehicle is

shipped from the assembly plant. Dealer personnel

must install the IOD fuse when the vehicle is being

prepared for delivery in order to restore full electrical

system operation. Once the vehicle is prepared for

delivery, the IOD function of this fuse becomes trans-

parent and the fuse that has been assigned the IOD

designation becomes only another Fused B(+) circuit

fuse. The IOD fuse serves no useful purpose to the

dealer technician in the service or diagnosis of any

vehicle system or condition, other than the same pur-

pose as that of any other standard circuit protection

device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed approximately thirty days. However, it mustbe remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than thirty days,

the battery negative cable should be disconnected to

eliminate normal IOD; and, the battery should be

tested and recharged at regular intervals during the

vehicle storage period to prevent the battery from

becoming discharged or damaged.

POWER OUTLET

DESCRIPTION

Two power outlets are installed in the instrument

panel center lower bezel. Two additional power out-

lets are incorporated into the left rear C-pillar and

the center console (if equipped). The power outlets

bases are secured by a snap fit. A hinged plug flips

closed to conceal and protect the power outlet base

when not in use.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the ON position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-3

INTEGRATED POWER MODULE (Continued)

Page 1177 of 2339

(2) Check for battery voltage at the fused B(+) fuse

in the IPM. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the IPM fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

outlet receptacle and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, go to Step

5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the appropriate bezel. Check for conti-

nuity between the ground circuit cavity of the power

outlet wire harness connector and a good ground.

There should be continuity. If OK, go to Step 6. If not

OK, repair the open ground circuit to ground as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the IPM fuse as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Note position of the retaining bosses (Fig. 4).

(3) Using external snap ring pliers with 90 degree

tips. Insert pliers with tips against bosses and

squeeze forcing bosses out of base.

(4) Pull out the base through mounting ring by

gently rocking pliers.

(5) Disconnect the base wires.

(6) Remove light ring and disconnect wire.

INSTALLATION

(1) Position the mounting ring on the instrument

panel and feed the wires through the ring. Index thecap and the mounting ring with the index tab at the

9 o'clock position to the key in the instrument panel.

Install the ring.

(2) Connect the wires to the base. Orientate the

base alignment rib at the 11 o'clock position to mate

the groove in the mounting ring to the base.

(3) Push the base into the bezel until it locks in

place.

(4) Check operation of outlet or element and

install the outlet cap.

Fig. 4 POWER OUTLET

1 - RETAINING BOSSES-ENGAGE PLIERS HERE

2 - PARTIALLY REMOVED

3 - EXTERNAL SNAP-RING PLIERS

4 - PULL BASE OUT-THROUGH MOUNTING RING

8W - 97 - 4 8W-97 POWER DISTRIBUTION SYSTEMRS

POWER OUTLET (Continued)

Page 1231 of 2339

(6) Install oil pressure switch and connector. (Refer

to 9 - ENGINE/LUBRICATION/OIL PRESSURE

SENSOR/SWITCH - INSTALLATION)

OIL

STANDARD PROCEDURE

ENGINE OIL LEVEL CHECK

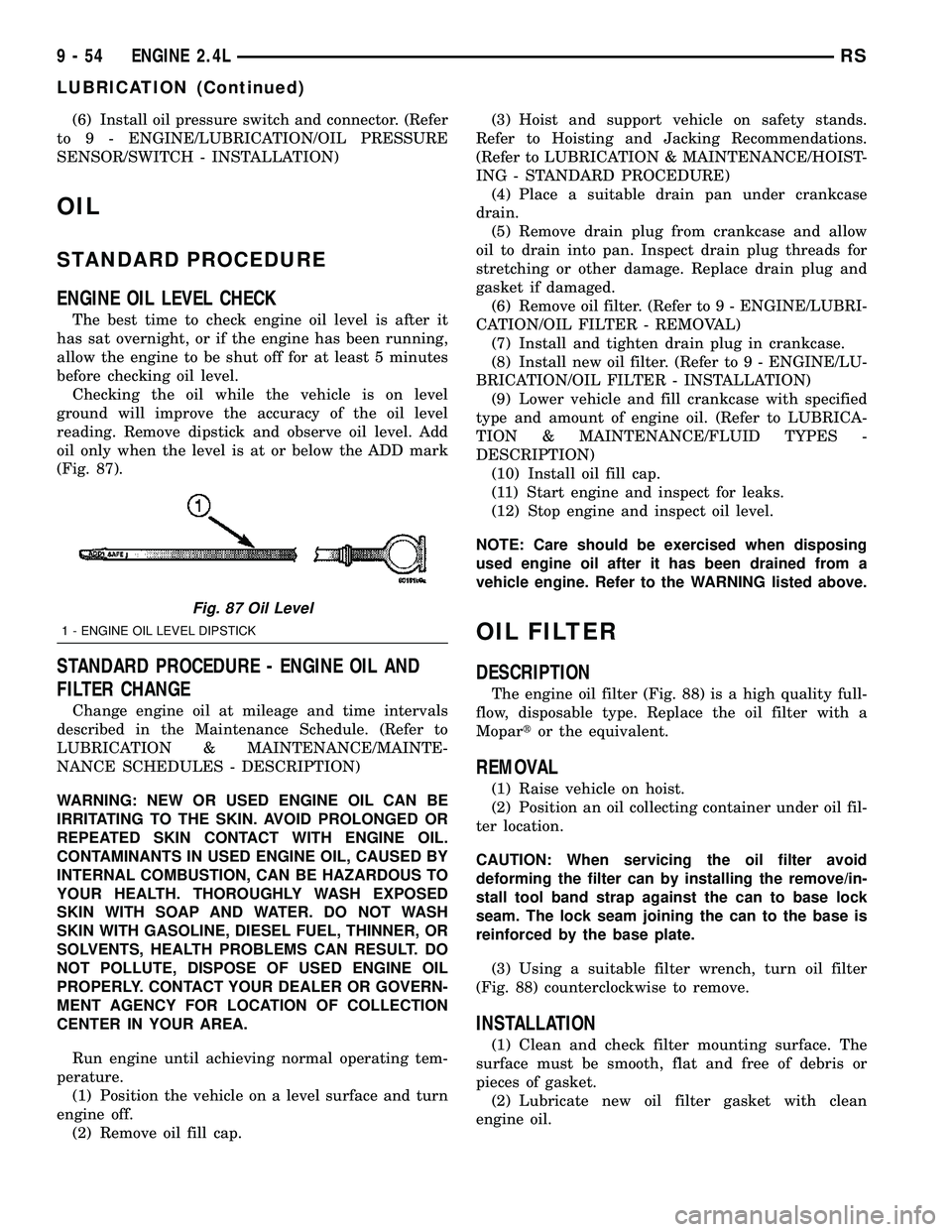

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,

allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Remove dipstick and observe oil level. Add

oil only when the level is at or below the ADD mark

(Fig. 87).

STANDARD PROCEDURE - ENGINE OIL AND

FILTER CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. (Refer to

LUBRICATION & MAINTENANCE/MAINTE-

NANCE SCHEDULES - DESCRIPTION)

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Remove oil fill cap.(3) Hoist and support vehicle on safety stands.

Refer to Hoisting and Jacking Recommendations.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE)

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Remove oil filter. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL)

(7) Install and tighten drain plug in crankcase.

(8) Install new oil filter. (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION)

(9) Lower vehicle and fill crankcase with specified

type and amount of engine oil. (Refer to LUBRICA-

TION & MAINTENANCE/FLUID TYPES -

DESCRIPTION)

(10) Install oil fill cap.

(11) Start engine and inspect for leaks.

(12) Stop engine and inspect oil level.

NOTE: Care should be exercised when disposing

used engine oil after it has been drained from a

vehicle engine. Refer to the WARNING listed above.

OIL FILTER

DESCRIPTION

The engine oil filter (Fig. 88) is a high quality full-

flow, disposable type. Replace the oil filter with a

Mopartor the equivalent.

REMOVAL

(1) Raise vehicle on hoist.

(2) Position an oil collecting container under oil fil-

ter location.

CAUTION: When servicing the oil filter avoid

deforming the filter can by installing the remove/in-

stall tool band strap against the can to base lock

seam. The lock seam joining the can to the base is

reinforced by the base plate.

(3) Using a suitable filter wrench, turn oil filter

(Fig. 88) counterclockwise to remove.

INSTALLATION

(1) Clean and check filter mounting surface. The

surface must be smooth, flat and free of debris or

pieces of gasket.

(2) Lubricate new oil filter gasket with clean

engine oil.

Fig. 87 Oil Level

1 - ENGINE OIL LEVEL DIPSTICK

9 - 54 ENGINE 2.4LRS

LUBRICATION (Continued)