CITROEN C-ELYSÉE 2017 Owners Manual

Manufacturer: CITROEN, Model Year: 2017, Model line: C-ELYSÉE, Model: CITROEN C-ELYSÉE 2017Pages: 260, PDF Size: 7.11 MB

Page 141 of 260

139

C-elysee_en_Chap09_info-pratiques_ed01-2016

F Obtain a bottle of AdBlue®. After first c

hecking

the

use-by

date,

read carefully

t

he instructions on use on the label before

pouring

the

contents

of

the bottle into your

v

ehicle's

Ad

Blue

® tank. F

A

fter emptying the bottle, wipe away any

s

pillage around the tank filler using a damp

c

loth.

F

R

efit the blue cap to the tank and turn it a

6th of a turn clockwise, to its stop.

F

R

efit the plastic blanking plug, clipping it in

t

he orifice.

F

R

eturn the storage box containing the tools

t

o

its location.

F

R

efit the boot floor and close the boot.

Important:

if

your

vehicle's

AdBlue

® tank i

s

completely

empty

-

which

is

c

onfirmed

by

the

alert

displays

and

the

i

mpossibility

of

starting

the

engine

-

you

must

add

at

least

3.8

litres

(so

two

1.89

litre

bottles). If

any additive is split or splashed, wash

i

mmediately

w

ith

c

old

w

ater

o

r

w

ipe

w

ith

a

damp cloth.

If the additive has crystallised, clean it

o

ff using a sponge and hot water.Important:

i

n the event of a top-up after

a breakdown because of a lack of

additive , you must wait around 5 minutes

b

efore switching on the ignition, without

opening the driver's door, locking the

vehicle or introducing the key into the

ignition switch .

Switch on the ignition, then, after

1

0 seconds, start the engine.

Never dispose of AdBlue

® additive b

ottles

in

the

household

waste. Place

t

hem

in

a

special

container provided

t

his

p

urpose

o

r

t

ake

t

hem

t

o

y

our

d

ealer.

9

Practical information

Page 142 of 260

140

C-elysee_en_Chap09_info-pratiques_ed01-2016

1. 12 V compressor, with integral pressure ga

uge.

2.

S

ealant cartridge, with integral hose.

3.

S

peed limit sticker.

Composition of the kit

The speed limit sticker must be secured to the interior of the vehicle in the

driver's

field of vision, to remind you

t

hat a wheel is in temporary use.

This

k

it

i

s

i

nstalled

i

n

t

he

s

torage

b

ox,

u

nder

t

he

b

oot

floor.

Comprising

a

compressor

and

a

sealant

c

artridge,

it

allows

the

temporary repair

of

a

tyre

so

that

you

can

drive

to

the

nearest

g

arage.

It

is

designed

to

repair

most

punctures

which

c

ould

affect

the

tyre,

located

on

the

tyre

tread

o

r

shoulder.

Temporary pu

ncture r epair k it

Access to the kit

The vehicle's electric system allows the c

onnection of the compressor for long

e

nough to inflate a tyre after a puncture

r

epair.

Do

not exceed a speed of 50 mph

(

80 km/h) when driving with a tyre

r

epaired using this type of kit.

Practical information

Page 143 of 260

141

C-elysee_en_Chap09_info-pratiques_ed01-2016

Repair procedure

F Switch off the ignition.

F S ecure the speed limit sticker inside the

v

ehicle. F

U ncoil the pipe stowed under the c

ompressor.

F

C

onnect the pipe from the compressor to

t

he sealant cartridge.

F

T

urn the the sealant cartridge and secure it

i

n the cut-out provided on the compressor.

Avoid

removing any foreign bodies

w

hich have penetrated into the tyre. F

R emove the valve cap from the tyre to be r

epaired, and place it in a clean area.

F

C

onnect the hose from the sealant

c

artridge to the valve of the tyre to be

r

epaired and tighten firmly.

9

Pr

Page 144 of 260

142

C-elysee_en_Chap09_info-pratiques_ed01-2016

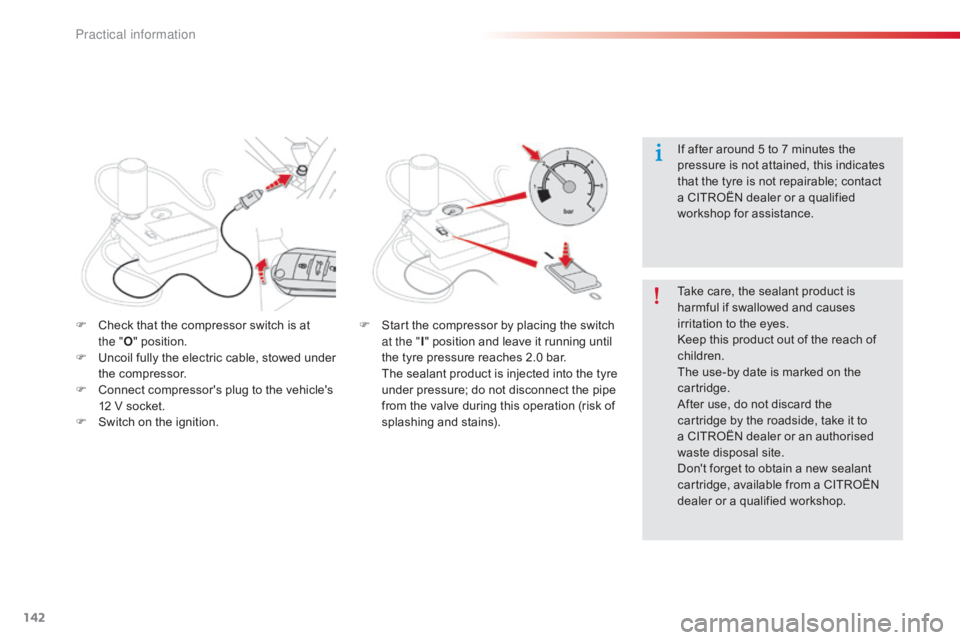

F Check that the compressor switch is at t

he "O "

position.

F

U

ncoil fully the electric cable, stowed under

t

he compressor.

F

C

onnect compressor's plug to the vehicle's

1

2 V socket.

F

S

witch on the ignition. If

after around 5 to 7 minutes the

p

ressure is not attained, this indicates

t

hat the tyre is not repairable; contact

a

CITROËN dealer or a qualified

w

orkshop for assistance.

Take care, the sealant product is

h

armful if swallowed and causes i

rritation to the eyes.

Keep this product out of the reach of

c

hildren.

The

use-by date is marked on the

c

artridge.

After

use, do not discard the

c

artridge by the roadside, take it to

a

CITROËN dealer or an authorised

w

aste disposal site.

Don't

forget to obtain a new sealant

c

artridge, available from a CITROËN

d

ealer or a qualified workshop.

F

S tart the compressor by placing the switch a

t the "I"

position and leave it running until

t

he tyre pressure reaches 2.0 bar.

T

he sealant product is injected into the tyre

u

nder pressure; do not disconnect the pipe

f

rom the valve during this operation (risk of

sp

lashing

an

d

s

tains).

Practical information

Page 145 of 260

143

C-elysee_en_Chap09_info-pratiques_ed01-2016

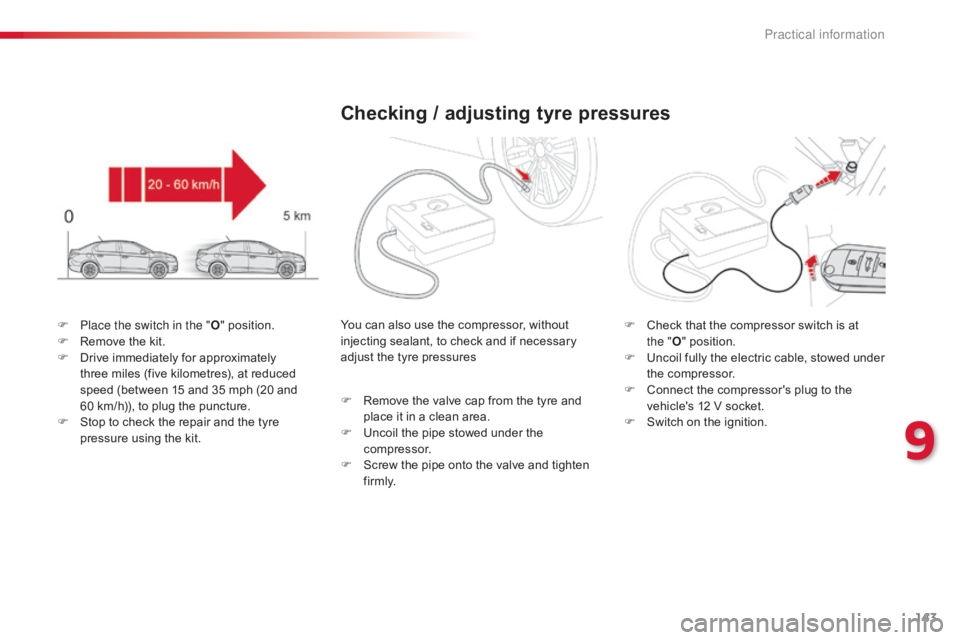

You can also use the compressor, without injecting sealant, to check and if necessary

a

djust the tyre pressures F

C heck that the compressor switch is at

t

he "O "

position.

F

U

ncoil fully the electric cable, stowed under

t

he compressor.

F

C

onnect the compressor's plug to the

v

ehicle's 12 V socket.

F

S

witch on the ignition.

F

P

lace the switch in the " O"

position.

F

R

emove

the

kit.

F

D

rive

immediately

for

approximately

t

hree

miles

(five

kilometres),

at

reduced

s

peed

(between

15

and

35

mph

(20

and

6

0 km/h)),

to

plug

the

puncture.

F

S

top

to

check

the

repair

and

the

tyre

p

ressure

using

the

kit.

Checking / adjusting tyre pressures

F Remove the valve cap from the tyre and p

lace it in a clean area.

F

U

ncoil the pipe stowed under the

c

ompressor.

F

S

crew the pipe onto the valve and tighten

f

i r m l y.

9

Practical information

Page 146 of 260

144

C-elysee_en_Chap09_info-pratiques_ed01-2016

F Start the compressor by placing the switch a

t the " I"

position and adjust the pressure

t

o the value shown on the vehicle's tyre

p

ressure label.

T

o deflate: press the black button on the

c

ompressor pipe, at the valve connector.

F

O

nce the correct pressure is reached, put

t

he switch to the " O"

position.

F

R

emove the kit then stow it.Should

the pressure of one or more

t

yres be adjusted, it is necessary to

r

einitialise the under-inflation detection

s

ystem.

For

more information on under-inflation

d

etection, refer to the corresponding

s

ection.

Tyre under-inflation

detection

After repair of the tyre, the warning lamp will remain on until the system is

r

einitialised.

For

more information on under-inflation

d

etection, refer to the corresponding

s

ection.

Practical information

Page 147 of 260

145

C-elysee_en_Chap09_info-pratiques_ed01-2016

Spare wheel

The tools are installed in the boot under the fl o o r.

To

gain access to them:

F

o

pen the boot,

F

l

ift the floor and remove it.

F

r

emove the storage box containing the

to

ols.

Access to the tools

List of tools

Procedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

T hese tools are specific to your vehicle and

c

an vary according to the level of equipment.

D

o not use them for any purpose other than

d

etailed

belo

w.

1.

W

heelbrace.

F

or removing the wheel trim and removing

t

he wheel bolts.

2.

J

ack with integral handle.

F

or raising the vehicle.

3.

W

heel bolt cover removal tool.

F

or removing the wheel bolt cover on alloy

w

heels.

4.

T

owing eye.

For

more information on towing, refer to the

c

orresponding

s

ection.

The

jack must only be used to change a

w

heel with a damaged tyre.

The

jack does not require any

m

aintenance.

The

jack conforms to European

l

egislation, such as defined in the

M

achinery Directive 2006/42/CE.

9

Practical information

Page 148 of 260

146

C-elysee_en_Chap09_info-pratiques_ed01-2016

The spare wheel is installed in the boot under the floor.

Depending

on engine, the spare wheel is

a

standard wheel or the space-saver type

(

BlueHDi 100).

Access to the spare wheel

Taking out the wheel

F Unclip the tool storage box (standard spare w

heel).

F

U

nscrew the central nut.

F

R

emove the fixing parts (nut and bolt).

F

R

aise the spare wheel towards you from

t

he rear.

F

T

ake the wheel out of the boot.

Pr

Page 149 of 260

147

C-elysee_en_Chap09_info-pratiques_ed01-2016

Putting the wheel back in place

F Put the wheel back in its housing.

F U nscrew the nut a few turns on the bolt.

F

P

osition the fixing parts (nut and bolt) in the

m

iddle of the wheel.

F

T

ighten the central nut until it clicks to

r

etain the wheel correctly. If

there is no wheel in the well, the fixing

p

arts (nut and bolt) cannot be refitted.

F

C lip the tool storage box back into place

(

standard

spar

e

w

heel).

9

Pr

Page 150 of 260

148

C-elysee_en_Chap09_info-pratiques_ed01-2016

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not block traffic: the ground must be level,

s

table and not slippery.

Apply

the parking brake, switch off the

i

gnition and engage first gear* to block

t

he wheels.

Check

that the parking brake warning

l

amp in the instrument panel comes on.

The

occupants must get out of the

v

ehicle and wait where they are safe.

Ensure

that the jack is correctly

p

ositioned at one of the vehicle's

j

acking points.

Incorrect

use of the jack could cause

t

he vehicle to drop.

Never

go underneath a vehicle raised

u

sing a jack; use an axle stand.

List of operations

Do not use a jack other than the one supplied by the manufacturer.

*

P

osition

R

for

an

electronic

gearbox;

P for an

automatic

gearbox.

Wheel with wheel trim

When removing the wheel , first

remove the wheel trim using the

w

heelbrace 1 by pulling at the valve

a

perture.

When refitting the wheel , refit the

wheel

trim, starting by placing its cutout

i

n line with the valve and then pressing

r

ound its edge with the palm of your

han

d. F

R

emove the wheel bolt cover using the

t

ool 3 (alloy wheels).

F

S

lacken the bolts using the wheelbrace 1

o n l y.

Practical information