Citroen C4 RHD 2015 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2015, Model line: C4 RHD, Model: Citroen C4 RHD 2015 2.GPages: 328, PDF Size: 12.72 MB

Page 191 of 328

1111

189

CHANGING A WHEEL

Procedure for changing a faulty wheel for

the spare wheel using the tools pro -

vided

with the vehicle.

Access to the tools

The tools are installed in the boot under the

floor.

To

gain access to them:

F

open the boot,

F

raise

the floor,

F

secure

it

by

hooking

its

cord

on

the

hook

on the rear shelf support,

F

with

a

standard

size

spare

wheel,

unclip

and

remove

the

box

in

the

middle

of

the

wheel

containing

the

tools,

or

F

with

a

"space-saver"

spare

wheel;

lift

the

wheel

at

the

rear

towards

you

for

access

to

the

storage

box

con

-

taining

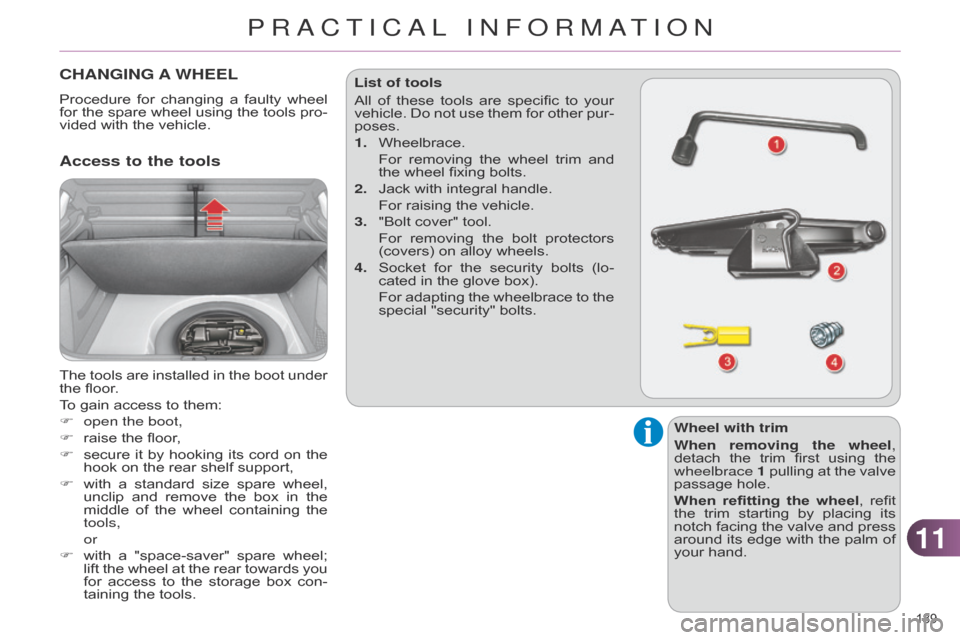

the tools. List of tools

All

of

these

tools

are

specific

to

your

vehicle.

Do

not

use

them

for

other

pur

-

poses.

1.

Wheelbrace.

For

removing

the

wheel

trim

and

the

wheel fixing bolts.

2.

Jack

with integral handle.

For

raising the vehicle.

3.

"Bolt

cover" tool.

For

removing

the

bolt

protectors

(covers)

on alloy wheels.

4.

Socket

for

the

security

bolts

(lo

-

cated in the glove box).

For

adapting

the

wheelbrace

to

the

special

"security" bolts.

Wheel with trim

When removing the wheel,

detach

the

trim

first

using

the

wheelbrace 1

pullin

g

at

the

valve

passage

hole.

When refitting the wheel,

refit

the

trim

starting

by

placing

its

notch

facing

the

valve

and

press

around

its

edge

with

the

palm

of

your

hand.

PRACTICAL INFORMATION

Page 192 of 328

1111

190

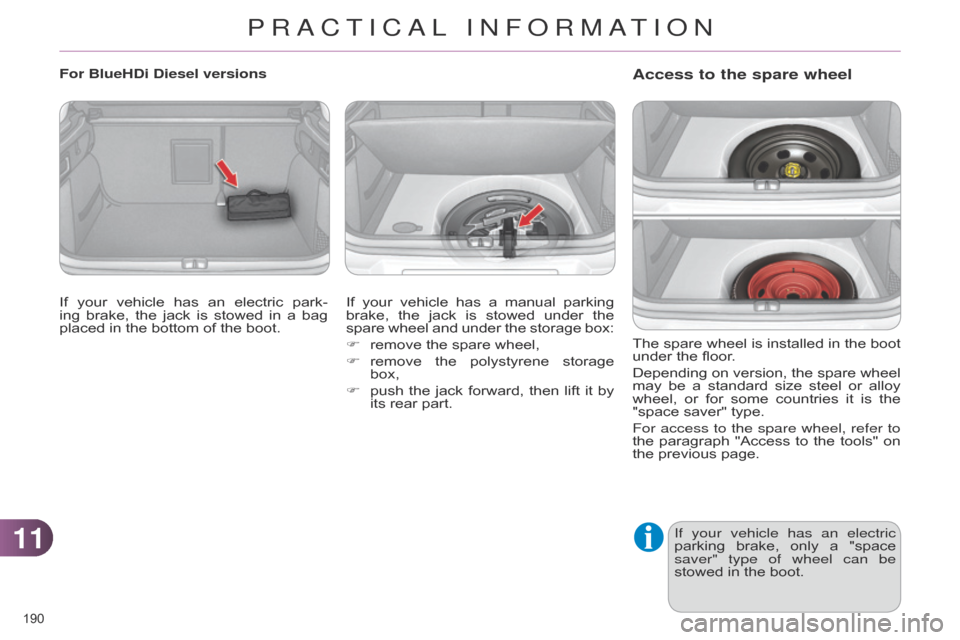

Access to the spare wheel

The spare wheel is installed in the boot under

the floor.

Depending

on

version,

the

spare

wheel

may

be

a

standard

size

steel

or

alloy

wheel,

or

for

some

countries

it

is

the

"space

saver" type.

For access to the spare wheel, refer to

the

paragraph

"Access

to

the

tools"

on

the

previous page.

If your vehicle has an electric

parking

brake,

only

a

"space

saver" type of wheel can be

stowed

in the boot.

For BlueHDi Diesel versions

If

your

vehicle

has

an

electric

park

-

ing

brake,

the

jack

is

stowed

in

a

bag

placed

in

the

bottom

of

the

boot. If

your

vehicle

has

a

manual

parking

brake,

the

jack

is

stowed

under

the

spare

wheel

and

under

the

storage

box:

F

remove

the

spare

wheel,

F

remove

the

polystyrene

storage

box,

F

push

the

jack

forward,

then

lift

it

by

its

rear

part.

PRACTICAL INFORMATION

Page 193 of 328

1111

191

Putting the standard wheel back in

placeTyre under-inflation detection

The

spare

wheel

is

not

fitted

with

a

sensor

.

The

punctured

wheel

must

be

repaired

by

a

CITROËN

dealer

or aqualified workshop.

Taking out the standard wheel

F

Put

the wheel back in its housing.

F

Unscrew

the

yellow

central

bolt

by

a

few turns then put it in place in the

centre

of the wheel.

F

T

ighten

fully

until

the

central

bolt

clicks

to retain the wheel correctly.

F

Unscrew

the

yellow

central

bolt.

F

Raise

the

spare

wheel

towards

you

from

the

rear.

F

T

ake

the

wheel

out

of

the

boot. F

Put

the

box

back

in

place

in

the

cen

-

tre

of the wheel and clip it.

PRACTICAL INFORMATION

Page 194 of 328

1111

192

Ensure that the jack is stable. If the

ground is slippery or loose,

the

jack

may

slip

or

drop

-

Risk

of

injury!

Removing a wheel

Parking the vehicle

Immobilise

the

vehicle

where

it

does

not

block

traffic:

the

ground

must

be

level,

stable

and

non-

slippery

ground.

Apply

the

parking

brake

unless

it has

been

programmed

to

auto

-

matic

mode,

switch

of

f

the

ignition and

engage

first

gear*

to

lock

the wheels.

Check

that

the

braking

warning

lamps

in

the

instrument

panel

are

on (not flashing).

The

occupants

must

get

out

of

the

vehicle

and

wait

where

they

are

safe.

If

necessary

,

place

a

chock

un

-

der

the

wheel

diagonally

oppo

-

site

the wheel to be changed.

Never

go

underneath

a

vehicle

raised

using

a

jack;

use

an

axle

stand. *

position R

for

an

electronic

gearbox;

P

for an automatic gearbox.

List of operations

F

Extend

the

jack

2

until

its

head

comes

into

contact

with

the

jacking

point A

or B

used;

the

contact

sur

-

face A or B

on

the

vehicle

must

be

engaged

with

the

central

part

of

the

head

of the jack.

F

Raise

the

vehicle

until

there

is

suffi

-

cient

space

between

the

wheel

and

the

ground

to

admit

the

spare

(not

punctured)

wheel easily.

F

Remove the chromed bolt cover from

each of the bolts using the

tool

3 (according to equipment).

F

Fit

the

security

socket

4 on the wheel

-

brace 1

to slacken the security bolt.

F

Slacken

the

other

bolts

using

the

wheelbrace

1 only.

F

Place

the

foot

of

the

jack

2

on the

ground

and

ensure

that

it

is

directly

below the front

A or rear B

jacking

point

provided

on

the

underbody

,

whichever is closest to the wheel to

be

changed.

PRACTICAL INFORMATION

Page 195 of 328

1111

193

Fitting a steel or "space-

saver" spare wheel

If

your

vehicle

is

fitted

with

al

-

loy

wheels,

when

tightening

the

bolts

on

fitting

it

is

normal

to

notice

that

the

washers

do

not

come

into

contact

with

the

steel

or

"space-saver"

spare

wheel.

The

wheel

is

secured

by

the

conical

contact of each bolt.List of operations

F

Remove

the

bolts

and

store

them

in

a

clean

place.

F

Remove

the

wheel. F

Put the wheel in place on the hub.

F Screw in the bolts by hand to the

stop.

F

Pre-tighten

the

security

bolt

using

the wheelbrace

1

fitted

with

the

se

-

curity

socket 4.

F

Pre-tighten

the

other

bolts

using

the

wheelbrace

1 only.

Fitting a wheel

Take care to position the jack only at

one of the jacking points A

or B

under

the

vehicle,

ensuring

that the

head

of

the

jack

is

centred under

the

contact

surface

of

the vehicle.

Otherwise,

there

is

a

risk of

damage

to

the

vehicle

and/or the

jack dropping - Risk of injury!

PRACTICAL INFORMATION

Page 196 of 328

1111

194

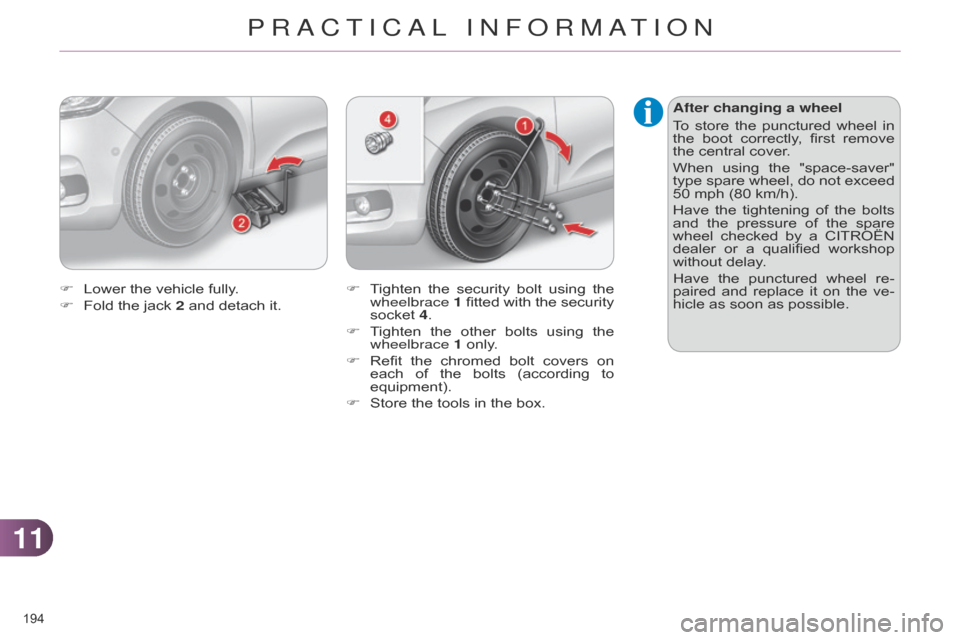

After changing a wheel

To

store

the

punctured

wheel

in

the

boot

correctly

,

first

remove

the

central cover.

When

using

the

"space-saver"

type

spare

wheel,

do

not

exceed

50

mph (80 km/h).

Have

the

tightening

of

the

bolts

and

the

pressure

of

the

spare

wheel

checked

by

a

CITROËN

dealer

or

a

qualified

workshop

without

delay.

Have

the

punctured

wheel

re

-

paired

and

replace

it

on

the

ve

-

hicle

as soon as possible.

F

T

ighten

the

security

bolt

using

the

wheelbrace 1

fitted

with

the

security

socket

4.

F

T

ighten

the

other

bolts

using

the

wheelbrace

1

only.

F

Refit

the

chromed

bolt

covers

on

each

of

the

bolts

(according

to

equipment).

F

Store

the

tools

in

the

box.

F

Lower

the

vehicle

fully.

F

Fold

the

jack

2

and

detach

it.

PRACTICAL INFORMATION

Page 197 of 328

1111

195

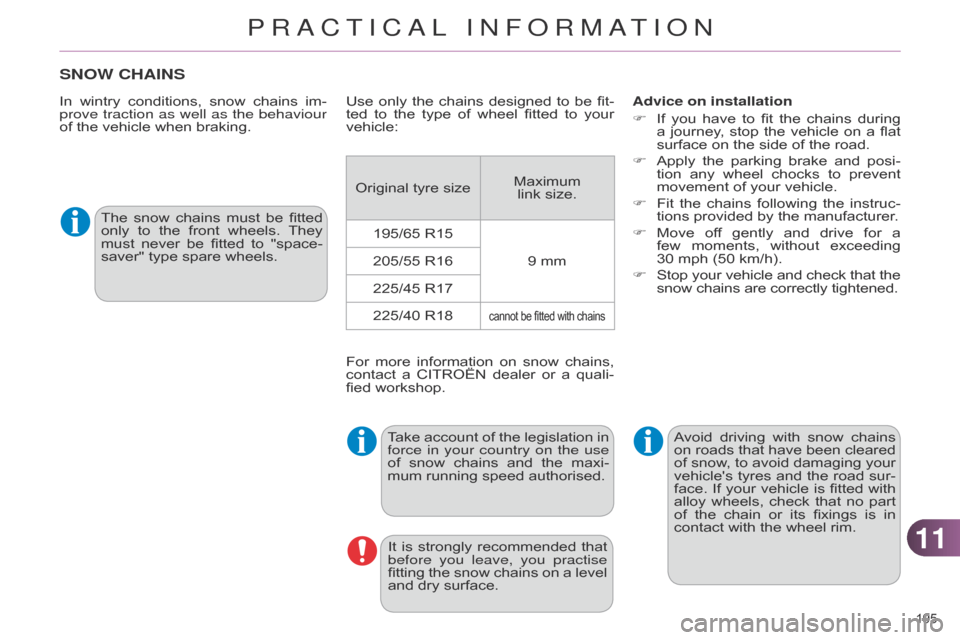

SNOW CHAINS

In wintry conditions, snow chains im -

prove traction as well as the behaviour

of

the vehicle when braking. Advice on installation

F

If

you

have

to

fit

the

chains

during

a

journey

,

stop

the

vehicle

on

a

flat

surface

on the side of the road.

F

Apply

the

parking

brake

and

posi

-

tion

any

wheel

chocks

to

prevent

movement

of your vehicle.

F

Fit

the

chains

following

the

instruc

-

tions

provided by the manufacturer.

F

Move

of

f

gently

and

drive

for

a

few

moments,

without

exceeding

30 mph

(50 km/h).

F

Stop

your

vehicle

and

check

that

the snow

chains are correctly tightened.

The

snow

chains

must

be

fitted

only

to

the

front

wheels.

They

must

never

be

fitted

to

"space-

saver"

type spare wheels.

Take

account

of

the

legislation

in

force in your country on the use

of

snow

chains

and

the

maxi

-

mum

running speed authorised.Avoid

driving

with

snow

chains

on

roads

that

have

been

cleared

of

snow

,

to

avoid

damaging

your

vehicle's

tyres

and

the

road

sur

-

face.

If

your

vehicle

is

fitted

with

alloy

wheels,

check

that

no

part

of

the

chain

or

its

fixings

is

in

contact

with the wheel rim.

Use

only the chains designed to be fit -

ted to the type of wheel fitted to your

vehicle:

Original

tyre sizeMaximum

link

size.

195/65

R159

mm

205/55

R16

225/45

R17

225/40

R18

cannot be fitted with chains

For more information on snow chains, contact

a CITROËN dealer or a quali -

fied

workshop.

It

is

strongly

recommended

that

before you leave, you practise

fitting

the

snow

chains

on

a

level

and

dry surface.

PRACTICAL INFORMATION

Page 198 of 328

1111

196

CHANGING A BULB

The headlamps are fitted with polycarbonate

glass with a pro -

tective

coating:

F

do not clean them using a

dry or abrasive cloth,

nor

with a detergent or solvent

product,

F

use

a

sponge

and

soapy

wa

-

ter

or a pH neutral product,

F

when

using

a

high

pressure

washer

on

persistent

marks,

do

not

keep

the

lance

direct

-

ed

towards

the

lamps

or

their

edges

for

too

long,

so

as

not

to

damage

their

protective

coating

and seals.

Changing

a

bulb

should

only

be

done

after

the

headlamp

has

been

switched

of

f

for

several

minutes

(risk of serious burns).

F

Do

not

touch

the

bulb

directly

with

your

fingers,

use

a

lint-

free

cloth.

It

is

imperative

to

use

only

anti-

ultraviolet

(UV)

type

bulbs

to

avoid

damaging the headlamp.

Always

replace

a

failed

bulb

with

a

new

bulb

with

the

same

type

and

specification. Risk of electrocution

Xenon

bulbs

(D1S-35W)

must

be replaced

by

a

CITROËN

dealer or

a qualified workshop.

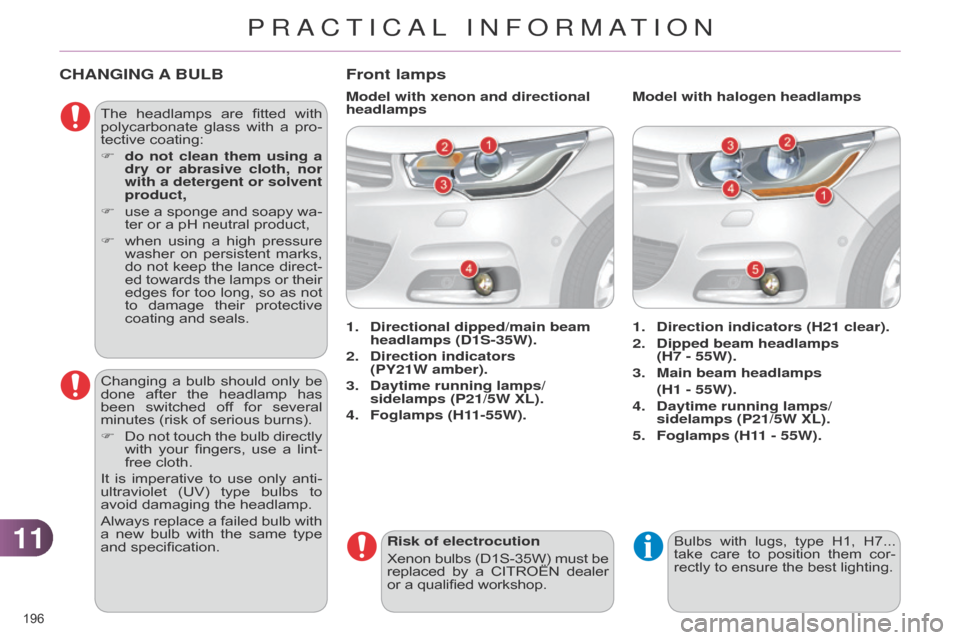

Front lamps

1. Direction indicators (H21 clear).

2.

Dipped beam headlamps

(H7 - 55W).

3.

Main beam headlamps

(H1 - 55W).

4.

Daytime running lamps/

sidelamps (P21/5W XL).

5.

Foglamps (H1

1 - 55W).

1.

Directional dipped/main beam

headlamps (D1S-35W).

2.

Direction indicators

(PY21W

amber).

3.

Daytime running lamps/

sidelamps (P21/5W XL).

4.

Foglamps (H1

1-55W). Model with halogen headlamps

Model with xenon and directional

headlamps

Bulbs with lugs, type H1, H7... take

care to position them cor -

rectly

to ensure the best lighting.

PRACTICAL INFORMATION

Page 199 of 328

1111

197

Amber coloured bulbs, such as the

direction indicators, must be

replaced

with

bulbs

of

identical

specifications

and colour.

When

refitting,

close

the

protec

-

tive cover carefully to preserve

the

sealing of the headlamp.

Changing direction indicator bulbs

Model with halogen headlamps

Rapid

flashing

of

the

direction

indicator

warning

lamp

(right

or

left)

indicates

the

failure

of

a

bulb

on

that

side.

Access to bulbs

F

Remove

the

air

deflector

by

unclip

-

ping

each

of

its

three

attachment

points.

F

Unclip

the

bonnet

release

cable

at

its

two

fixings.

F

Move

the

cable

down.

After

changing

the

failed

bulb,

remember to

put

everything

back

in

place

(cable

and air

deflector).

Depending

on

the

engine

and

only

on

the

left

hand

side,

you

must

first

carry

out

the

following

operations

for

access

to

the

protective

covers

on

the

bulbs.

F

T

urn

the

bulb

holder

a

quarter

of

a

turn

and

extract

it.

F

Pull

out

the

bulb

and

change

it.

To

reassemble,

carry

out

these

opera

-

tions

in

reverse

order. Model with Xenon headlamps

F

Remove

the

protective

cover

by

pullin

g on its tongue.

F

Disconnect

the electrical connector.

F

Separate

the

springs

to

release

the

bulb.

F

Pull

the bulb out and replace it.

To

reassemble,

carry

out

these

opera

-

tions

in reverse order.

PRACTICAL INFORMATION

Page 200 of 328

1111

198

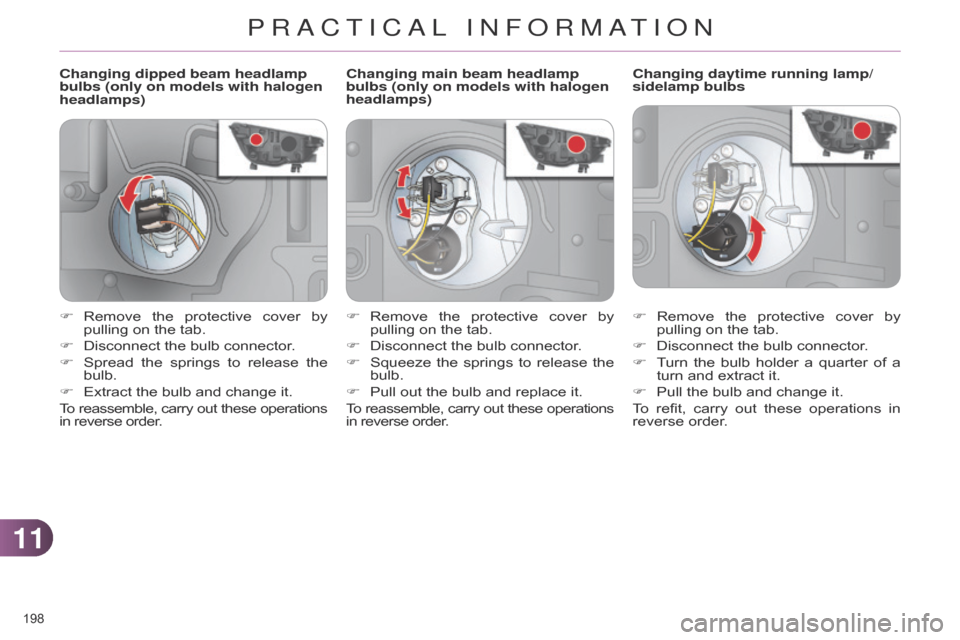

Changing dipped beam headlamp

bulbs (only on models with halogen

headlamps)Changing daytime running lamp/

sidelamp bulbs

F

Remove

the

protective

cover

by

pullin

g on the tab.

F

Disconnect

the bulb connector.

F

T

urn

the

bulb

holder

a

quarter

of

a

turn

and extract it.

F

Pull

the bulb and change it.

To

refit,

carry

out

these

operations

in

reverse

order.

F

Remove

the

protective

cover

by

pullin

g on the tab.

F

Disconnect

the bulb connector.

F

Spread

the

springs

to

release

the

bulb.

F

Extract

the bulb and change it.

To

reassemble,

carry

out

these

operations in

reverse order. Changing main beam headlamp

bulbs (only on models with halogen

headlamps)

F

Remove

the

protective

cover

by

pullin

g on the tab.

F

Disconnect

the bulb connector.

F

Squeeze

the

springs

to

release

the

bulb.

F

Pull

out the bulb and replace it.

To

reassemble,

carry

out

these

operations in

reverse order.

PRACTICAL INFORMATION