CITROEN C6 2005 Manual PDF

C6 2005

CITROEN

CITROEN

https://www.carmanualsonline.info/img/9/57744/w960_57744-0.png

CITROEN C6 2005 Manual PDF

Trending: reset, check oil, oil level, brake, light, brake sensor, alternator

Page 71 of 223

Downloaded from www.Manualslib.com manuals search engine 65

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Reposition the timimg belt, strip «j»well tensioned, in the following order:

- Guide roller (19).

- Camshaft pulley (18).

- Guide roller (16).

- Camshaft pulley (23).

- Tensioner roller (20).

NOTE:If necessary, turn the pulleys (23)and (18)slightly anti-clockwise (the offset must not be

more than one tooth).

Remove the tool [4].

Using a hexagonal spanner, rotate the tensioner roller (20)anti-clockwise.

Position the index "l"facing the notch "k".

Tighten the screw (21) : 2,5 ± 0,2.

Remove the screws (15)and (17)from the pulleys (23)and (18)in order to check that the screws

(15)and (17)are not at the end of slots.

IMPERATIVE: If the screws (15) and (17) are at the end of slots, restart the operations to refit

the timing belt.

B1EP1JHDB1EP1JJC

Angl-C6-page022-82-2005 4/02/05 17:19 Page 65

Page 72 of 223

Downloaded from www.Manualslib.com manuals search engine 66

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Tighten the screws (15)and (17) : 2,2 ± 0,2.

Remove tools [2]and [3].

Rotate the crankshaft 8 times

in the normal direction of rotation.

Fit the tool [2].

Peg the camshafts using tools [3], at "h"and "g".

NOTE:If it is not possible to refit the tools [3], slacken the screws (15)and/or (17)of the camshafts

and drive the camshafts by means of their central screws (25)and/or (26).

Peg the camshafts using tools [3], at "h"and "g".

Tighten the screws (15)and (17) : 2,2 ± 0,2.

Remove tools [2]and [3].

Rotate the crankshaft 8 timesin the normal direction of rotation.

Fit the tool [2].

Fit the tools [3], at "h"and "g".

Check that the index "l"of the tensioner roller (20)is facing the notch "k".

B1EP1JHDB1EP1JJC

Angl-C6-page022-82-2005 4/02/05 17:19 Page 66

Page 73 of 223

Downloaded from www.Manualslib.com manuals search engine 67

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Remove tools [2]and [3].

Refit: The lower timing cover (10), the upper timing covers (11), the crankshaft pulley (9), the engine

support (12), the coolant pump pulley (13), the accessories drive belt (8)(see corresponding operation),

the engine support (4)on the chassis member, the upper RH engine support (5) and the upper RH

engine support tie bar.

Take away the workshop hoist.

Remove the tool [6].

Refit the "Swirl"electrovalve (7)with its support, the header tank (1), the electrical harness.

Remove the tool [1].

Reposition and couple the pipes (3)and (2).

Complete the refitting.

B1EP1JHDB1EP1JJC

Angl-C6-page022-82-2005 4/02/05 17:19 Page 67

Page 74 of 223

Downloaded from www.Manualslib.com manuals search engine 68

ENGINE

EXHAUST SPECIFICATIONS1Upstream oxygen sensor (rear)

2Downstream oxygen sensor (rear)

3Downstream oxygen (front)4,7 ± 0,54Upstream oxygen sensor (front)

5Precatalyser (rear)3,5 ± 0,56Precatalyser (front)7Resonator8Catalytic converter9Rear silencer10Clips2,6 ± 0,3 Engine: ES9A

B1JP08AD

Angl-C6-page022-82-2005 4/02/05 17:19 Page 68

Page 75 of 223

Downloaded from www.Manualslib.com manuals search engine 69

ENGINE

EXHAUST SPECIFICATIONS

Engine: ES9A

Repair.

Respect the precautions to be taken prior to any operation:

- The front flexible pipe must be protected against any external mechanical damage.

- The front flexible pipe must not come into contact with corrosive products.

- Do not deform the front flexible pipe more than 20°angular (X), 20 mm axial, 25 mm shearing

(Y)(front flexible pipe removed).

- Do not deform the front flexible pipe more than 3°angular (X), 0 mm axial, 3 mm shearing (Y)

(front flexible pipe in place).

WARNING: Non-respect of these precautions will shorten the life of the flexible pipe.

It is therefore imperative to disconnect or remove the exhaust line for any operations

necessitating lifting of the engine-gearbox.

B1JP02JC

Angl-C6-page022-82-2005 4/02/05 17:19 Page 69

Page 76 of 223

Downloaded from www.Manualslib.com manuals search engine 70

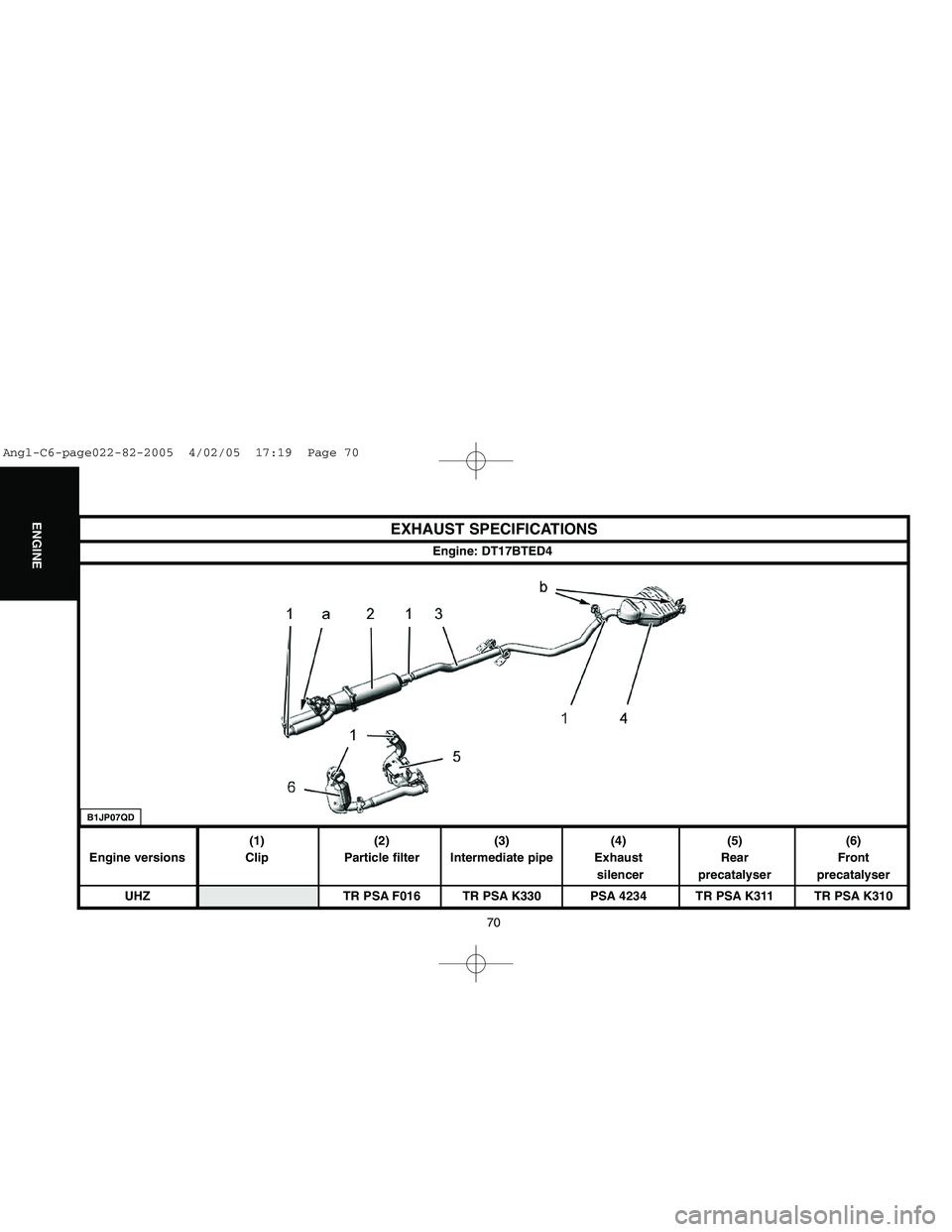

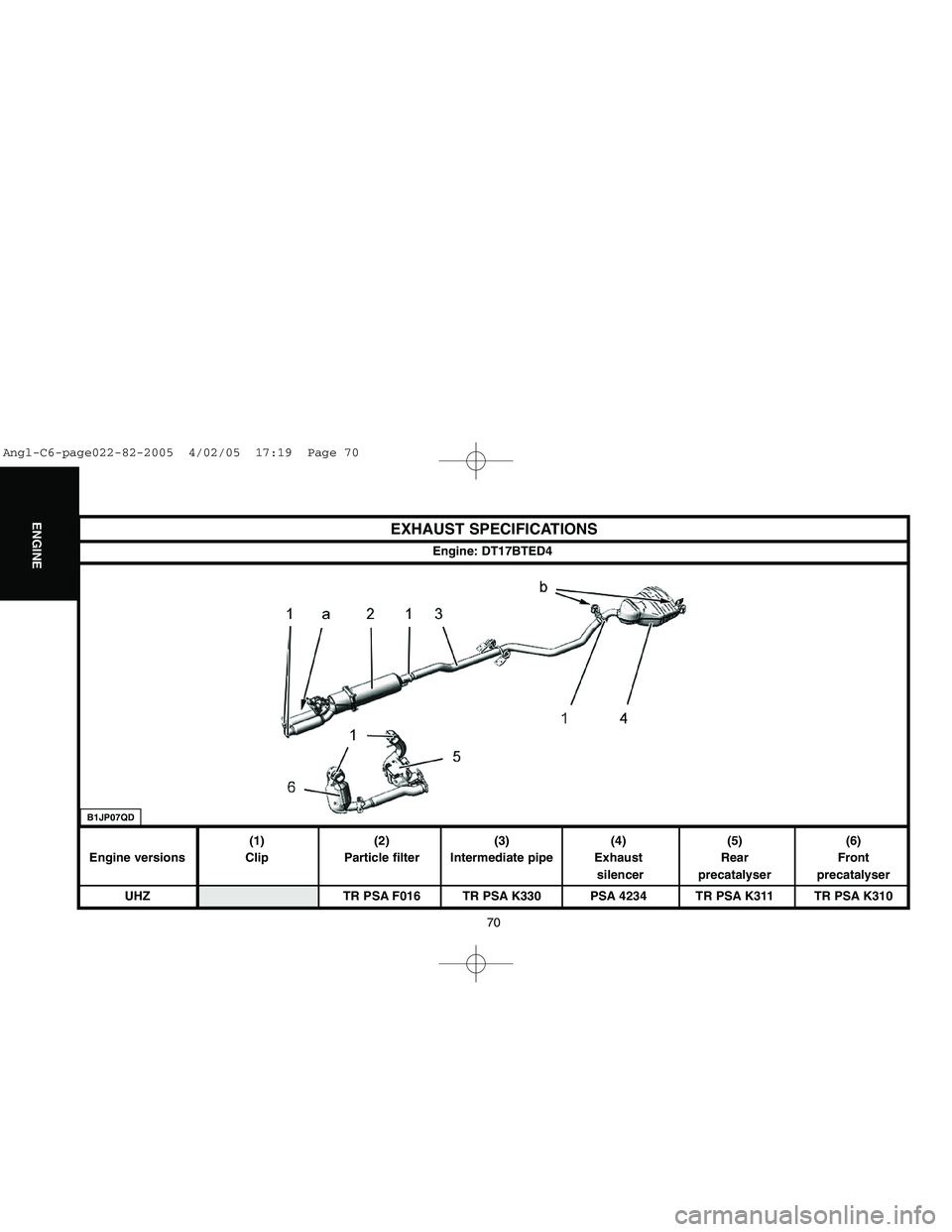

ENGINE

EXHAUST SPECIFICATIONS

(1) (2) (3) (4) (5) (6)

Engine versions Clip Particle filter Intermediate pipe Exhaust Rear Front

silencer precatalyser precatalyser

UHZ TR PSA F016 TR PSA K330 PSA 4234 TR PSA K311 TR PSA K310Engine: DT17BTED4

B1JP07QD

Angl-C6-page022-82-2005 4/02/05 17:19 Page 70

Page 77 of 223

Downloaded from www.Manualslib.com manuals search engine 71

ENGINE

71

EXHAUST SPECIFICATIONS

Engine: DT17BTED4

Repair.

Respect the precautions to be taken prior to any operation:

- The front flexible pipe must be protected against any external mechanical damage.

- The front flexible pipe must not come into contact with corrosive products.

- Do not deform the front flexible pipe more than 20°angular (X), 20 mm axial, 25 mm shearing

(Y) (front flexible pipe removed).

- Do not deform the front flexible pipe more than 3°angular (X), 0 mm axial, 3 mm shearing (Y)

(front flexible pipe in place).

WARNING: Non-respect of these precautions will shorten the life of the flexible pipe.

It is therefore imperative to disconnect or remove the exhaust line for any operations

necessitating lifting of the engine-gearbox.

B1JP02JC

Angl-C6-page022-82-2005 4/02/05 17:19 Page 71

Page 78 of 223

Downloaded from www.Manualslib.com manuals search engine 72

ENGINE

TIGHTENING TORQUES - EXHAUST LINE

1Clip2,6 ± 0,4

2Particle filter hangers

3Intermediate pipe hangers0,8 ± 0,14Silencer hangers5Rear precatalyser screw2 ± 0,36Front precatalyser screw2 ± 0,3 Engine: DT17BTED4

B1JP07ZD

Angl-C6-page022-82-2005 4/02/05 17:19 Page 72

Page 79 of 223

Downloaded from www.Manualslib.com manuals search engine 73

ENGINE

73

COOLING SYSTEM SPECIFICATIONS

Engine type

Capacity

Radiator surface

Pressurisation

Opening of thermostatic regulator

Cooling fan

1st speed

2nd speed

3rd speed

Air con cut-off

Alert

Post cooling

Marking

Information

Sensor

Colour of connector

Tightening (m.daN)

Engines: ES9A - DTE17BTED4

3.0i 24S 2,7 24V

XFV UHZ

11,3 13,2

27 dm

2

1,4 bar

78°C 83°C

1 x 600 W 2 x 150W

FRIC function 97°C or aircon in operation

105°C 101°C or 17 bars in the aircon circuit

105° or 30 bars in the aircon circuit

115°C or 30 bars in the aircon circuit

118°C

6 minutes

11 6

Level of coolant Temperature of coolant Temperature, diesel injection, alert, aircon

Resistance Thermostat Thermostat

Black Blue Grey

1,7 ± 0,4

Angl-C6-page022-82-2005 4/02/05 17:19 Page 73

Page 80 of 223

Downloaded from www.Manualslib.com manuals search engine 74

ENGINE

COOLING SYSTEM SPECIFICATIONS

Engine: ES9A

(1)Heater matrix

(2)Bleed screw

(3)Coolant outlet housing

(4)Coolant inlet housing

(5)Thermostat

(6)Coolant temperature sensor

(7) Coolant/oil heat exchanger (engine)

(8)Cooling radiator drain plug

(9)Coolant/oil heat exchanger (automatic gearbox)

(10)Engine cooling radiator

(11)Coolant level sensor

(12)Header tank

(13) Venting chamber

B1GP0CXP

Angl-C6-page022-82-2005 4/02/05 17:19 Page 74

Trending: load capacity, language, diagnostic menu, wheel bolt torque, check engine light, sport mode, wheel torque

![CITROEN C6 2005 Manual PDF Downloaded from www.Manualslib.com manuals search engine 66

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Tighten the screws (15)and (17) : 2,2 ± 0,2.

Remove tools [2]and [3].

Rotate CITROEN C6 2005 Manual PDF Downloaded from www.Manualslib.com manuals search engine 66

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Tighten the screws (15)and (17) : 2,2 ± 0,2.

Remove tools [2]and [3].

Rotate](/img/9/57744/w960_57744-71.png)

![CITROEN C6 2005 Manual PDF Downloaded from www.Manualslib.com manuals search engine 67

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Remove tools [2]and [3].

Refit: The lower timing cover (10), the upper timing CITROEN C6 2005 Manual PDF Downloaded from www.Manualslib.com manuals search engine 67

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Remove tools [2]and [3].

Refit: The lower timing cover (10), the upper timing](/img/9/57744/w960_57744-72.png)

![CITROEN C6 2005 Manual PDF Downloaded from www.Manualslib.com manuals search engine 66

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Tighten the screws (15)and (17) : 2,2 ± 0,2.

Remove tools [2]and [3].

Rotate CITROEN C6 2005 Manual PDF Downloaded from www.Manualslib.com manuals search engine 66

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Tighten the screws (15)and (17) : 2,2 ± 0,2.

Remove tools [2]and [3].

Rotate](/img/9/57744/w960_57744-71.png)

![CITROEN C6 2005 Manual PDF Downloaded from www.Manualslib.com manuals search engine 67

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Remove tools [2]and [3].

Refit: The lower timing cover (10), the upper timing CITROEN C6 2005 Manual PDF Downloaded from www.Manualslib.com manuals search engine 67

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: DT17BTED4

Remove tools [2]and [3].

Refit: The lower timing cover (10), the upper timing](/img/9/57744/w960_57744-72.png)