CITROEN DS3 CABRIO 2016 Handbook (in English)

Manufacturer: CITROEN, Model Year: 2016, Model line: DS3 CABRIO, Model: CITROEN DS3 CABRIO 2016Pages: 450, PDF Size: 17.47 MB

Page 201 of 450

199

The speed l imit s ticker m ust b e s ecured t

o the interior of the vehicle in the

driver's

field of vision, to remind you

t

hat a wheel is in temporary use.

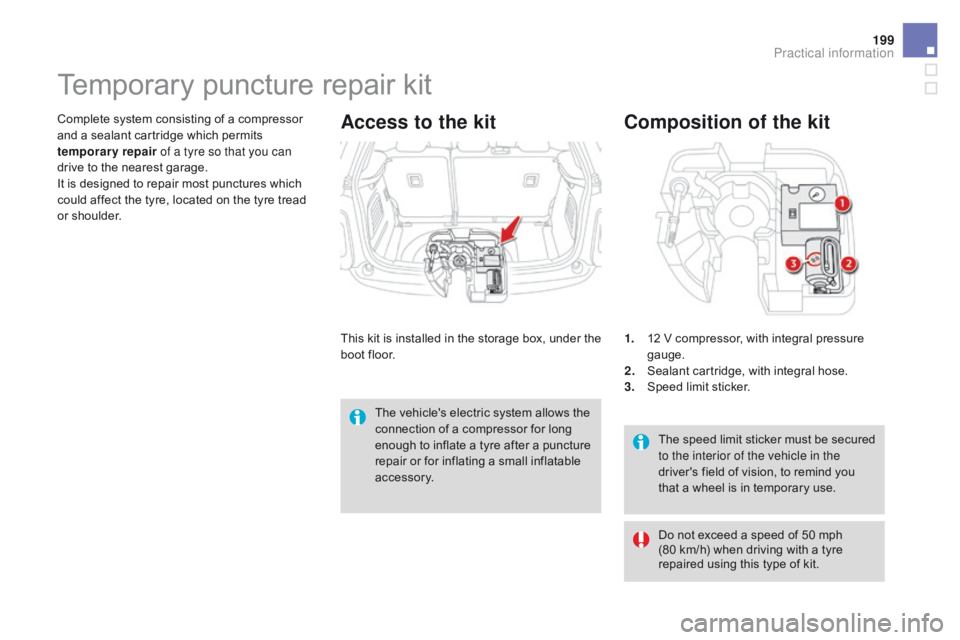

Composition of the kit

1. 12 V compressor, with integral pressure ga

uge.

2.

S

ealant cartridge, with integral hose.

3.

S

peed limit sticker.

Temporary puncture r epair k it

Complete system consisting of a compressor a

nd a sealant cartridge which permits

t

emporary repair of a tyre so that you can

drive

to the nearest garage.

It

is designed to repair most punctures which

c

ould affect the tyre, located on the tyre tread

o

r shoulder.Access to the kit

This kit is installed i n t he s torage b ox, u nder t he b

oot floor.

The

vehicle's electric system allows the

c

onnection of a compressor for long

e

nough to inflate a tyre after a puncture

r

epair or for inflating a small inflatable

a

ccessory. Do

not exceed a speed of 50 mph

(

80 km/h) when driving with a tyre

r

epaired using this type of kit.

Practical information

Page 202 of 450

F Switch off the ignition.

F S ecure the speed limit sticker inside the

v

ehicle.

Repair procedure

Avoid removing any foreign bodies which have penetrated into the tyre.F

U

ncoil the pipe stowed under the

c

ompressor.

F

C

onnect the pipe from the compressor to

t

he sealant cartridge.

F

T

urn the the sealant cartridge and secure it

i

n the cut-out provided on the compressor.F

R

emove the valve cap from the tyre to be

r

epaired, and place it in a clean area.

F

C

onnect the hose from the sealant

c

artridge to the valve of the tyre to be

r

epaired and tighten firmly.

Page 203 of 450

201

If after around 5 to 7 minutes the pressure is not attained, this indicates

t

hat the tyre is not repairable; contact

a

CITROËN dealer or a qualified

w

orkshop for assistance.

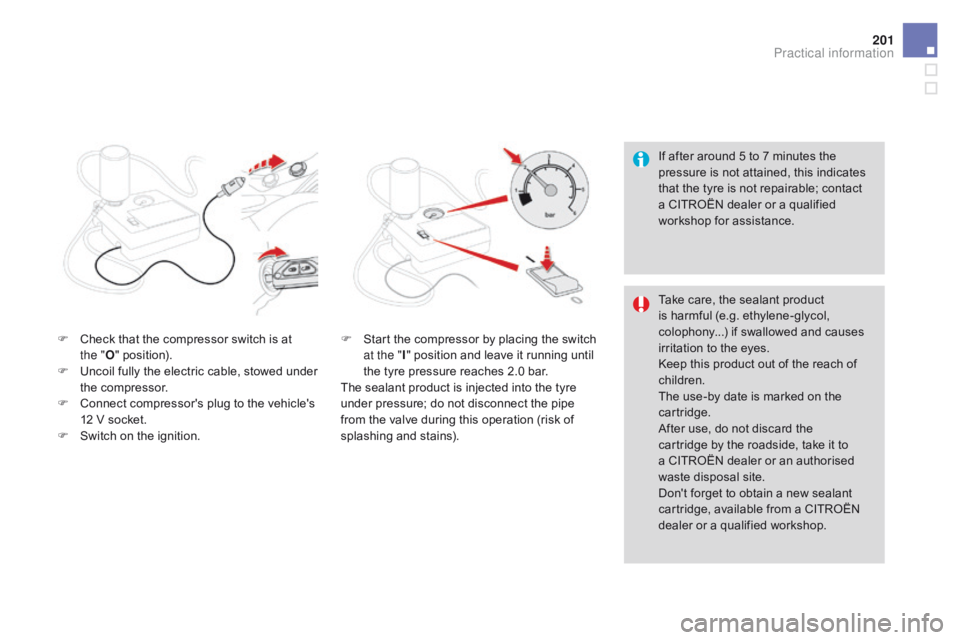

F

C

heck

that

the

compressor

switch

is

at

t

he

" O "

position).

F

U

ncoil

fully

the

electric

cable,

stowed

under

t

he

compressor.

F

C

onnect

compressor's

plug

to

the

vehicle's

1

2

V

socket.

F

S

witch

on

the

ignition. F

S

tart

the

compressor

by

placing

the

switch

a

t the " I"

position

and

leave

it

running

until

t

he

tyre

pressure

reaches

2.0

bar.

The

sealant

product

is

injected

into

the

tyre

u

nder

pressure;

do

not

disconnect

the

pipe

f

rom

the

valve

during

this

operation

(risk

of

sp

lashing

an

d

s

tains). Take

care, the sealant product

i

s harmful (e.g. ethylene-glycol,

c

olophony...) if swallowed and causes

i

rritation to the eyes.

Keep

this product out of the reach of

c

hildren.

The

use-by date is marked on the

c

artridge.

After

use, do not discard the

c

artridge by the roadside, take it to

a

CITROËN dealer or an authorised

w

aste disposal site.

Don't

forget to obtain a new sealant

c

artridge, available from a CITROËN

d

ealer or a qualified workshop.

Practical information

Page 204 of 450

F Place the switch in the "O" position.

F R emove the kit.

F

D

rive immediately for approximately

t

hree miles (five kilometres), at reduced

s

peed (between 15 and 35 mph (20 and

6

0 km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

p

ressure using the kit.

Checking / adjusting tyre pressures

You can also use the compressor, without injecting sealant, to check and if necessary

a

djust the tyre pressures.

F

R

emove the valve cap from the tyre and

p

lace it in a clean area.

F

U

ncoil the pipe stowed under the

c

ompressor.

F

S

crew the pipe onto the valve and tighten

f

i r m l y. F

C heck that the compressor switch is at

t

he "O "

position.

F

U

ncoil fully the electric cable, stowed under

t

he compressor.

F

C

onnect the compressor's plug to the

v

ehicle's 12 V socket.

F

S

witch on the ignition.

Page 205 of 450

203

F Start the compressor by placing the switch a

t the " I"

position and adjust the pressure

t

o the value shown on the vehicle's tyre

p

ressure label.

T

o deflate: press the black button on the

c

ompressor pipe, at the valve connector.

F

O

nce the correct pressure is reached, put

t

he switch to the " O"

position.

F

R

emove the kit then stow it.

Tyre under-inflation

detection

After repair of the tyre, the warning lamp will remain on until the system is

r

einitialised.

For

more information, refer to the

"

Under-inflation

d

etection"

s

ection.

Should

the pressure of one or more

t

yres be adjusted, it is necessary to

r

einitialise the under-inflation detection

s

ystem.

Refer

to the "Under-inflation detection"

s

ection.

Practical information

Page 206 of 450

Changing a wheelProcedure for changing a faulty wheel for the spare wheel using the tools provided with the vehicle.

T he tools are installed in the boot under the

f

l o o r.

To

gain access to them:

F

o

pen the boot,

F

l

ift the boot carpet by pulling the strap

up

wards,

F

r

emove the polystyrene storage box,

F

u

nclip and remove the box containing the

to

ols.

Access to the tools

List of tools Wheel with trim

When removing the wheel

, first

detach the trim using the wheelbrace 1

pulling

at the valve passage hole.

When refitting the wheel , refit the

trim

starting by placing its cut-out at the

v

alve and press around its edge with

t

he palm of your hand.

1.

W

heelbrace.

F

or

removing

the

wheel

trim

and

removing

t

he

wheel

fixing

bolts.

2.

J

ack

with

integral

handle.

F

or

raising

the

vehicle.

3.

"

Bolt

cover"

tool.

F

or

removing

the

bolt

protectors

(covers)

o

n

alloy

wheels.

4.

S

ocket

for

the

security

wheel

bolts

(located

i

n

the

glove

box).

F

or

adapting

the

wheelbrace

to

the

special

s

ecurity

wheel

bolts

(if

your

vehicle

is

fitted

w

ith

them). All of these tools are specific to your

vehicle.

Do not use them for other

p

urposes.

Never

use a jack other than the

o

ne listed for the vehicle by the

m

anufacturer. If the vehicle does not

h

ave one, contact a CITROËN dealer

o

r a qualified workshop to obtain a jack

s

pecified by the manufacturer.

Page 207 of 450

205

The spare wheel is installed in the boot under the floor.

According

to country, you will have either a

"

space saver" spare wheel or a temporary

p

uncture repair kit.

For access to it, refer to the "Access to the

tools"

s

ection.

Access to the spare wheel

Fitting the "space-saver"

type spare wheel

If your vehicle is fitted with alloy wheels, it is normal to notice, when

t

ightening the bolts on fitting, that the

w

ashers do not come into contact with

t

he "space-saver" type spare wheel.

T

he wheel is secured by the conical

c

ontact sur face of each bolt.

Taking out the wheel

F Unscrew the yellow central bolt.

F R aise the spare wheel towards you from

t

he rear.

F

T

ake the wheel out of the boot.

Practical information

Page 208 of 450

Putting the wheel back in place

F Put the box back in place in the centre of t

he wheel and clip it.

F

P

ut the polystyrene storage box back in

p

lace.

F

R

efit the boot floor carpet by lightly folding

i

t in the middle (refer to the "Boot fittings"

s

ection).

F

P

ut

the

wheel

back

in

its

housing.

F

U

nscrew the yellow central bolt by a few

turns then place it in the centre of the

wheel.

F

T

ighten

fully

until

the

central

bolt

clicks

to

r

etain

the

wheel

correctly. On

vehicles equipped with a "space-

saver"

type spare wheel, the punctured

w

heel can be stowed in place of the

"

space-saver" wheel; however the boot

f

loor will not then be flat.

Page 209 of 450

207

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not block traffic: the ground must be

l

evel, stable and not slippery.

Apply

the parking brake, switch off the

i

gnition and engage first gear* to lock

t

he wheels.

If

necessary, place a chock under the

w

heel diagonally opposite the wheel to

be c

hanged.

It

is imperative that you ensure that the

o

ccupants get out of the vehicle and

w

ait where they are safe.

Never

go underneath a vehicle raised

u

sing a jack; use an axle stand.

List of operations

F Remove the chromed bolt cover from each o

f the bolts using the tool 3 (alloy wheels

o

nly).

F

F

it the socket 4 on the wheelbrace 1 to

slacken

the security bolt (if your vehicle is

f

itted with them).

F

S

lacken the other bolts using the

w

heelbrace 1

o

n l y.

*

position R

for

an

electronic

gearbox,

P for an

automatic

gearbox.

Ensure

that

the

jack

is

stable.

If

the

g

round

is

slippery

or

loose,

the

jack

c

ould

slip

or

drop

-

Risk

of

injury!

Take

care

to

position

the

jack

only

at

o

ne

of

the

jacking

points

A or B under

t

he

vehicle,

ensuring

that

the

vehicle's

c

ontact

area

is

well

centred

on

the

h

ead

of

the

jack.

Other wise,

there

is

a

r

isk

of

damage

to

the

vehicle

and/or

the

j

ack

might

drop

-

Risk

of

injury!

Practical information

Page 210 of 450

F Position the foot of the jack 2 on the ground a

nd ensure that it is directly below the

f

ront A or rear B jacking point provided on

t

he underbody, whichever is closest to the

w

heel to be changed.

O

n vehicles fitted with sill finishers, the

j

acking location is indicated by a marking

o

n the finisher. The jack must be placed

c

entrally in line with this marking, at the

j

acking point located behind the finisher

a

nd not on the plastic finisher itself. F

R emove the bolts and store them in a clean p

lace.

F

R

emove the wheel.

F

E xtend the jack 2 until its head comes into c

ontact with the jacking point A or B used.

T

he contact area A or B on the vehicle

must

be engaged with the central part of

t

he head of the jack.

F

Ra

ise the vehicle until there is sufficient

space

between the wheel and the ground

s

o that the spare (not punctured) wheel can

t

hen be fitted without difficulty.